Characterization and Curing Kinetics of Epoxy/Silica Nano-Hybrids

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials and Methods

2.2. Characterization of Epoxy/Silica Nano-Hybrids

3. Results and Discussion

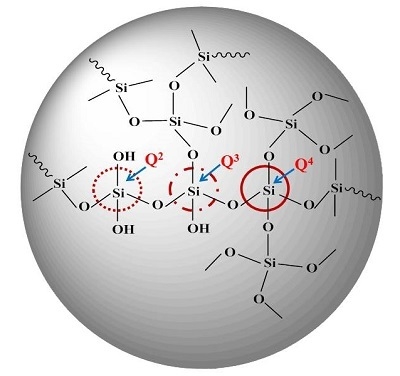

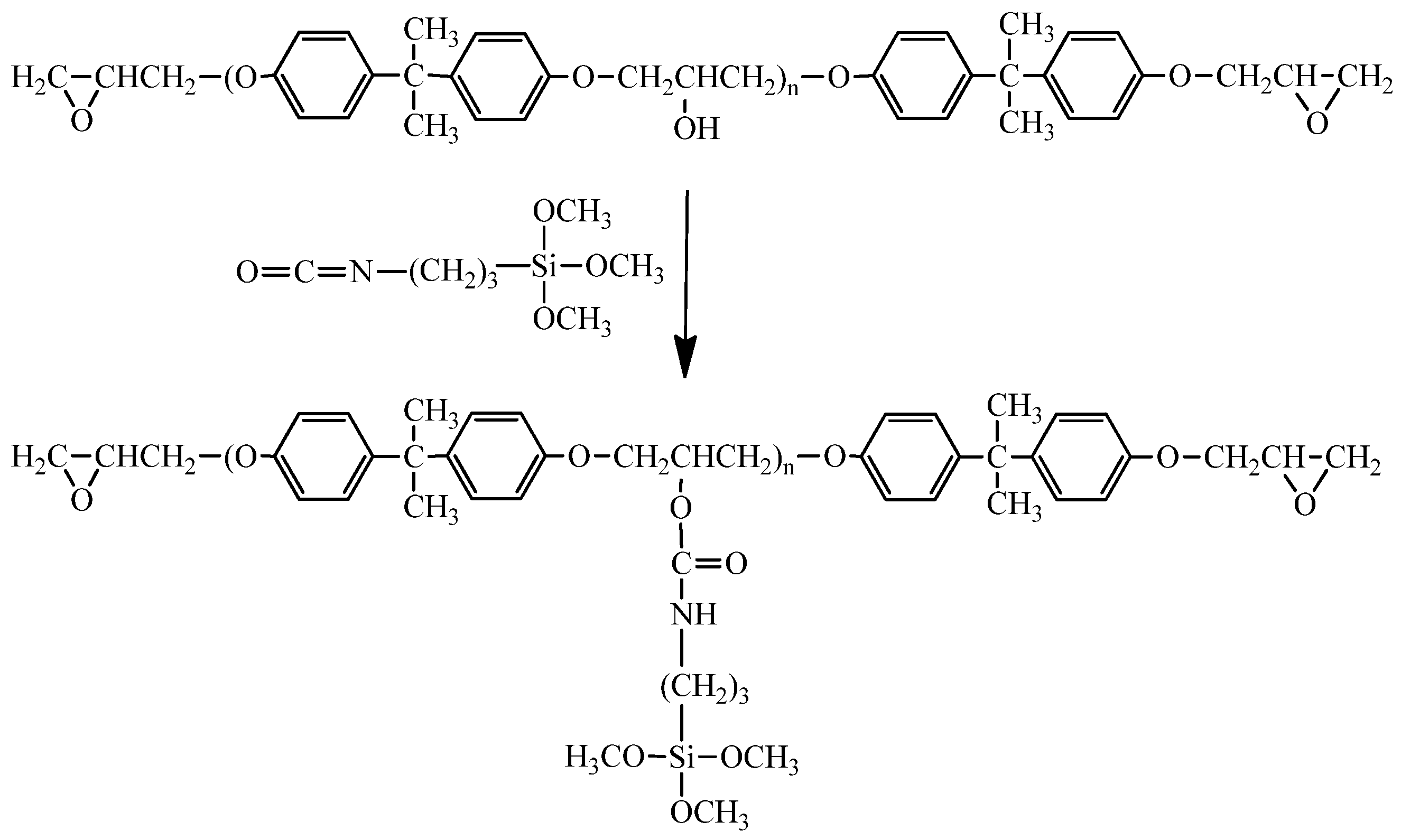

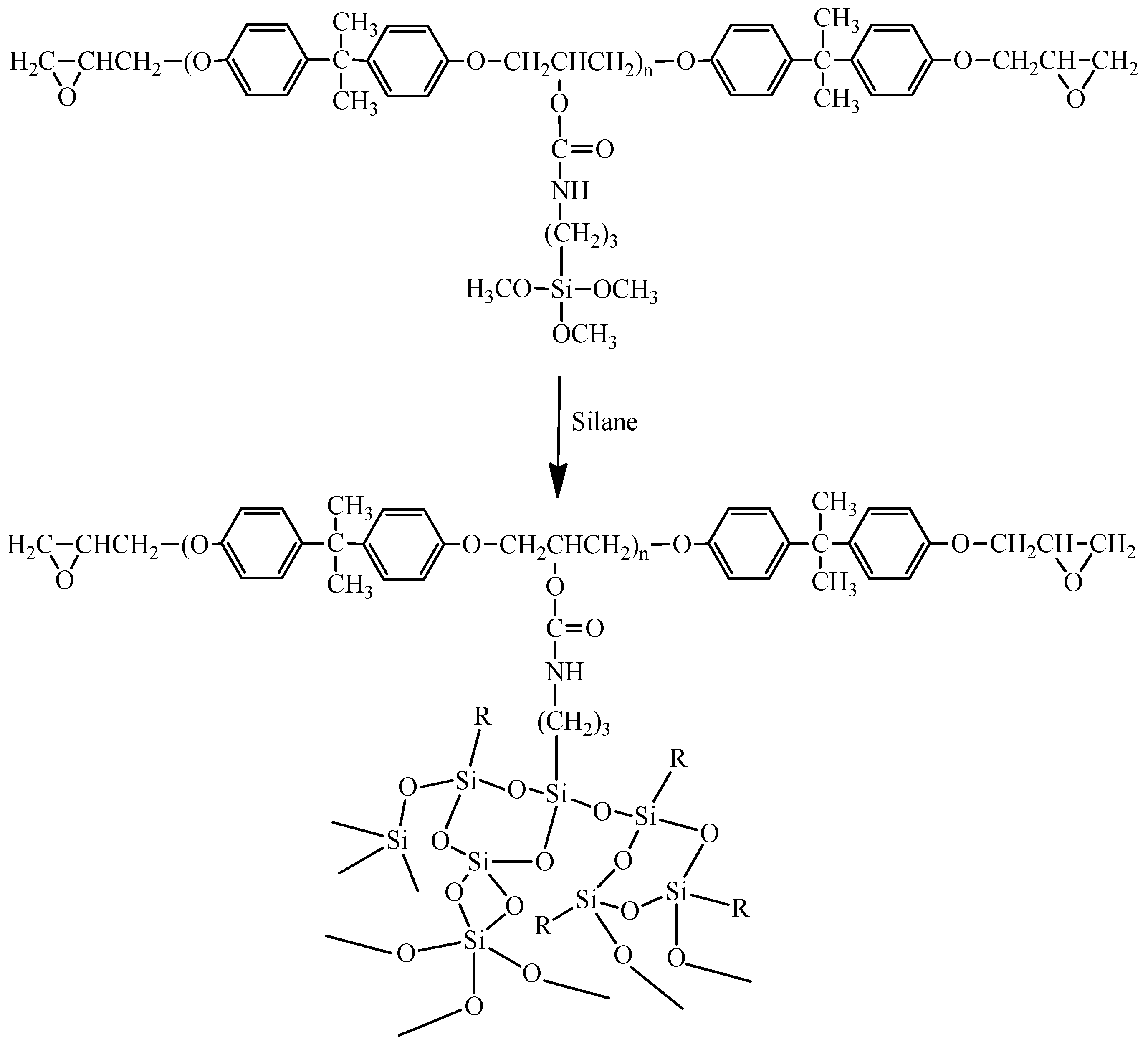

3.1. Characterization of Epoxy/Silica Nano-Hybrids

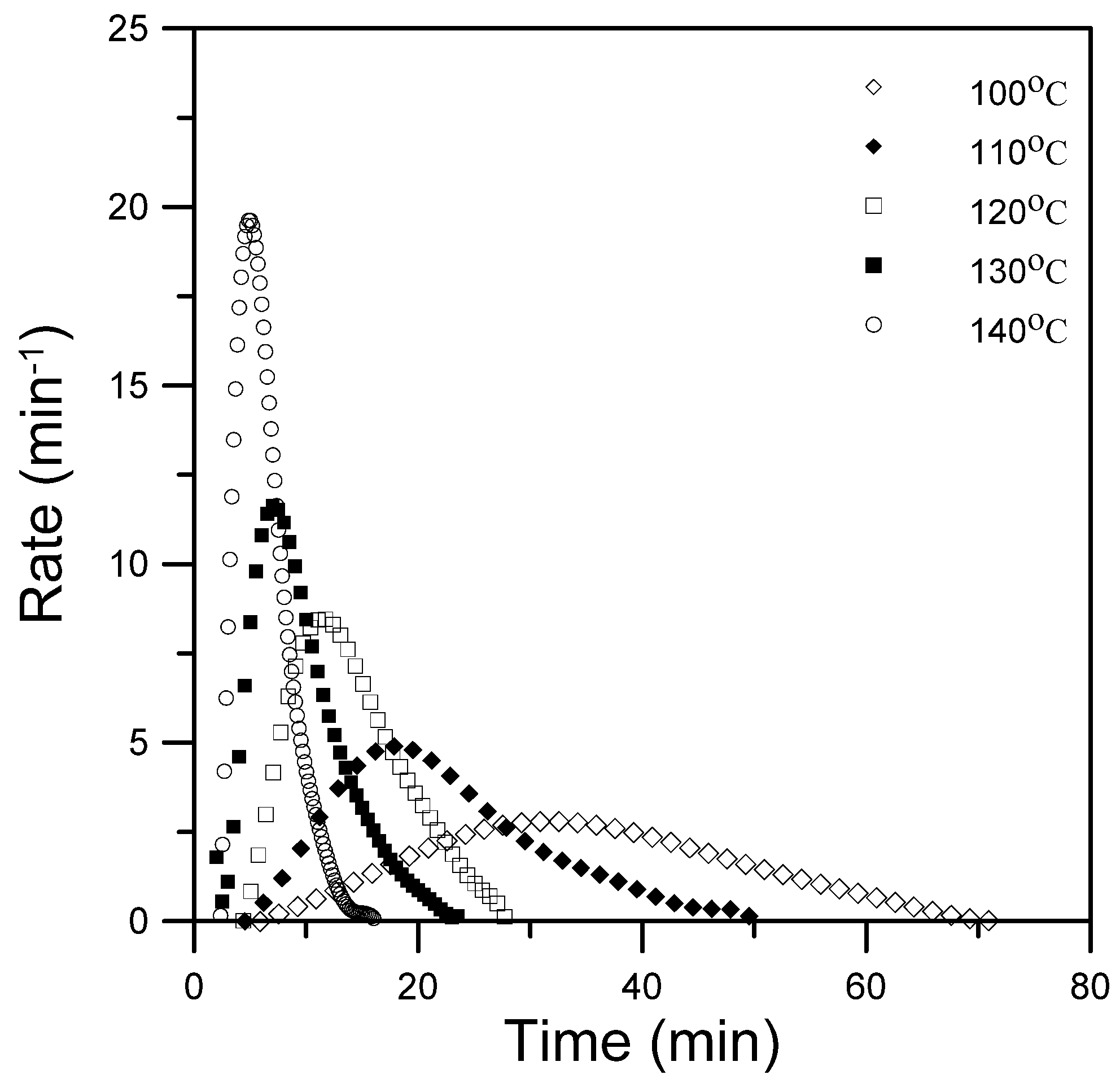

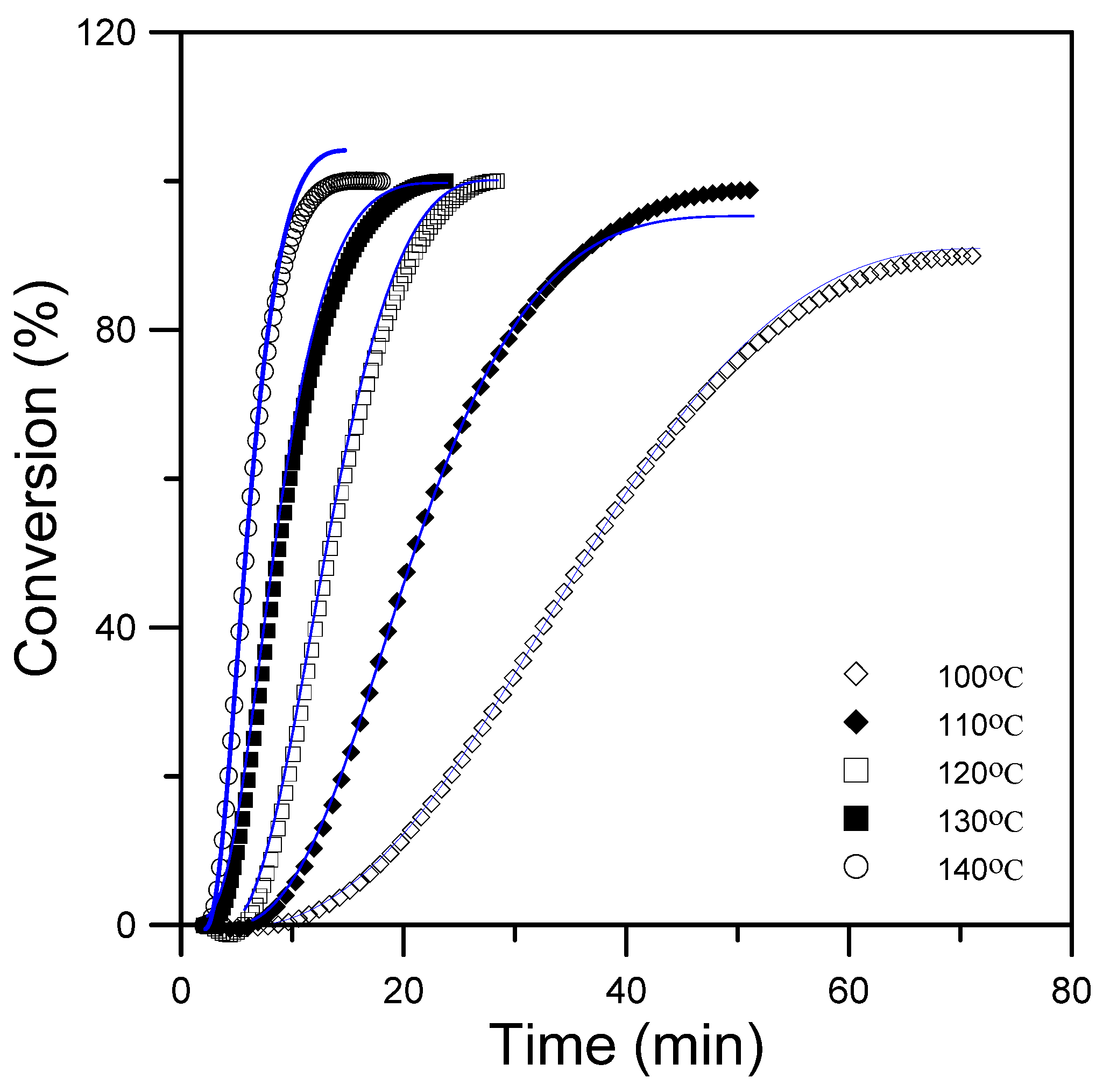

3.2. Cure Kinetics of Epoxy/Silica Nano-Hybrids

| T (°C) | m | n | k1 (min−1) | k2 (min−1) | Ea1 (kJmol−1) | Ea2 (kJmol−1) | A1 | A2 |

|---|---|---|---|---|---|---|---|---|

| 100 | 0.5 | 0.9 | 0.3 | 6.4 | – | – | – | – |

| 110 | 0.6 | 1.0 | 0.6 | 14.0 | – | – | – | – |

| 120 | 0.6 | 1.0 | 1.2 | 18.8 | 5.6 | 5.4 | 287 | 4699 |

| 130 | 0.6 | 1.0 | 1.6 | 30.0 | – | – | – | – |

| 140 | 0.6 | 0.9 | 1.9 | 45.2 | – | – | – | – |

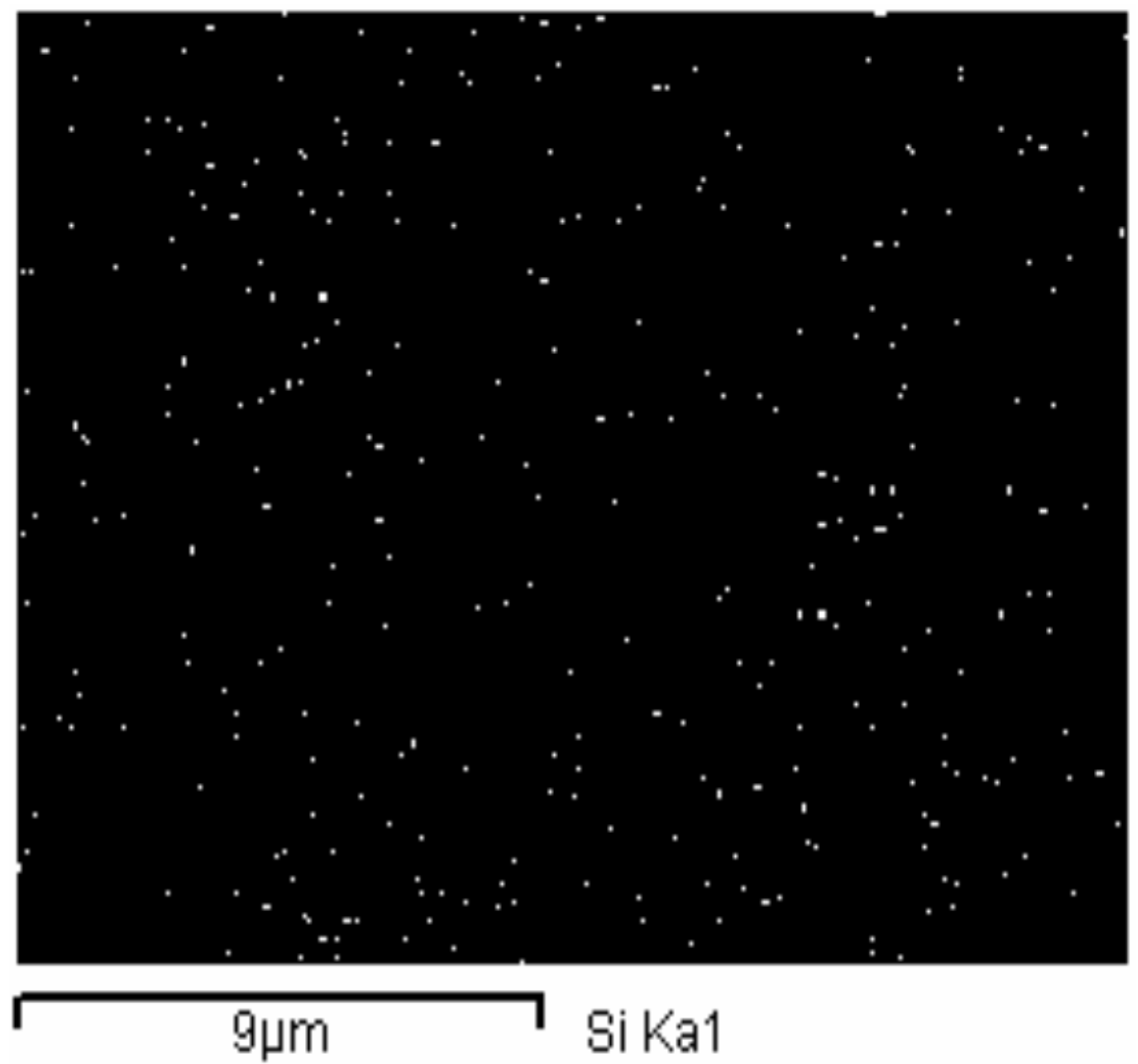

3.3. Morphological Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Su, C.C.; Wei, C.H.; Yang, C.C. Elucidating How Advanced Organophosphine Accelerators Affect Molding Compounds. Ind. Eng. Chem. Res. 2013, 52, 2525–2536. [Google Scholar] [CrossRef]

- Zhang, J.; Li, T.; Wang, H.P.; Liu, Y.; Yu, Y.F. Monitoring extent of curing and thermal-mechanical property study of printed circuit board substrates. Microelectron. Reliab. 2014, 54, 619–628. [Google Scholar] [CrossRef]

- Sa, R.; Wei, Z.; Yan, Y.; Wang, L.; Wang, W.; Zhang, L.; Ning, N.; Tian, M. Catechol and epoxy functionalized ultrahigh molecular weight polyethylene (UHMWPE) fibers with improved surface activity and interfacial adhesion. Compos. Sci. Technol. 2015, 113, 54–62. [Google Scholar] [CrossRef]

- Vakili, H.; Ramezanzadeh, B.; Amini, R. The corrosion performance and adhesion properties of the epoxy coating applied on the steel substrates treated by cerium-based conversion coatings. Corros. Sci. 2015, 94, 466–475. [Google Scholar] [CrossRef]

- Ni, Y.; Chen, L.; Teng, K. Superior mechanical properties of epoxy composites reinforced by 3D interconnected graphene skeleton. ACS Appl. Mater. Interfaces 2015, 7, 11583–11591. [Google Scholar] [CrossRef] [PubMed]

- Su, C.C.; Wei, C.H.; Li, B.C. Thermal and cure kinetics of epoxy molding compounds cured with thermal latency accelerators. Adv. Mater. Sci. Eng. 2013, 391267, 1–10. [Google Scholar] [CrossRef]

- Su, C.C.; Woo, E.M. Cure kinetics and morphology of amine-curerd tetraglycidyl-4,4'-diaminodiphenylmethane epoxy blends with polyetherimide. Polymer 1995, 36, 2883–2894. [Google Scholar] [CrossRef]

- Catauro, M.; Bollino, F.; Papale, F.; Giovanardi, R.; Veronesi, P. Corrosion behavior and mechanical properties of bioactive sol-gel coatings on titanium implants. Mater. Sci. Eng. C 2014, 43, 375–382. [Google Scholar] [CrossRef] [PubMed]

- Cao, D.; Zhang, Y.; Dong, W.; Yang, J.; Bai, W.; Chen, Y.; Wang, G.; Dong, X.; Tang, X. Structure, magnetic and transport properties of La0.7Ca0.3-xSrxMnO3 thin films by sol-gel method. Ceram. Int. 2015, 1, S381–S386. [Google Scholar] [CrossRef]

- Subasri, R.; Madhav, C.S.; Somaraju, K.R.C.; Padmanabham, G. Decorative, hydrophobic sol-gel coatings densified using near-infrared radiation. Surf. Coat. Technol. 2012, 206, 2417–2421. [Google Scholar] [CrossRef]

- Puja, G.; Manju, A. Dielectric relaxation and electro-optic response in nano-ceria dispersed ferroelectric liquid crystal nanocomposites: Effect of structural deformation and lattice straining. RSC Adv. 2015, 5, 29741–29747. [Google Scholar]

- Wen, Z.L.; Xiao, P.; Li, Z.; Hong, W.; Luo, H.; Yu, X.Y.; Li, Y.; Chen, W.B. Microstructure and oxidation behavior of sol-gel mullite coating on SiC-coated carbon/carbon composites. J. Eur. Ceram. Soc. 2015, 35, 3789–3796. [Google Scholar]

- Klein, L.C.; Garvey, G.J. Kinetics of the Sol-Gel Transition. J. Non-Cryst. Solids 1980, 38, 45–50. [Google Scholar] [CrossRef]

- Brinker, C.J.; Keefer, K.D.; Schaefer, D.W.; Assink, R.A.; Kay, B.D.; Ashley, C.S. Sol-gel transition in simple silicates. J. Non-Cryst. Solids 1982, 1, 47–64. [Google Scholar] [CrossRef]

- Yang, C.F.; Hsu, W.C.; Wu, S.M.; Su, C.C. Elucidating how surface functionalization of multiwalled carbon nanotube affects nanostructured MWCNT/titania hybrid materials. J. Nanomater. 2015, 952797, 1–8. [Google Scholar] [CrossRef]

- Matijevic, E. Monodispersed colloids: Art and science. Langmuir 1986, 2, 12–20. [Google Scholar] [CrossRef]

- Yoldas, B.E. Monolithic glass formation by chemical polymerization. J. Mater. Sci. 1979, 14, 1843–1949. [Google Scholar] [CrossRef]

- Prochazka, S.; Klug, F.J. Infrared-transparent mullite ceramic. J. Am. Ceram. Soc. 1983, 66, 874–880. [Google Scholar] [CrossRef]

- Ikesue, A.; Kinoshita, T.; Kamata, K.; Yoshida, K. Fabrication and optical properties of high-performance polycrystalline Nd:YAG ceramics for solid-state lasers. J. Am. Ceram. Soc. 1995, 78, 1033–1040. [Google Scholar] [CrossRef]

- Ausman, K.D.; Piner, R.; Lourie, O.; Ruoff, R.S.; Korobov, M. Organic solvent dispersion of single-walled carbon nanotubes. J. Phys. Chem. B 2000, 104, 8911–8915. [Google Scholar] [CrossRef]

- Afzal, A.; Siddiqi, H.M.; Saeed, S.; Ahmad, Z. Exploring resin viscosity effects in solventless processing of nano-SiO2/epoxy polymer hybrids. RSC Adv. 2013, 3, 3885–3892. [Google Scholar] [CrossRef]

- Chen, Y.C.; Zhou, S.X.; Yang, H.H.; Wu, L.M. Structure and mechanical property of polyurethane/silica hybrid coatings. Mol. Mater. Eng. 2005, 290, 1001–1008. [Google Scholar] [CrossRef]

- Afzal, A.; Siddiqi, H.M. A comprehensive study of the bicontinuous epoxy-silica hybrid polymers. Polymer 2011, 52, 1345–1355. [Google Scholar] [CrossRef]

- Chiu, Y.C.; Liu, F.Y.; Maa, C.C.; Chou, I.C.; Riang, L.; Chiang, C.L.; Yang, J.C. Syntheses and characterization of novel P/Si polysilsesquioxanes/epoxy nanocomposites. Thermochim. Acta 2008, 473, 7–13. [Google Scholar] [CrossRef]

- Liu, Y.L.; Su, Y.H.; Lai, J.Y. In situ crosslinking of chitosan and formation of chitosan-silica hybrid membranes with using γ-glycidoxypropyltrimethoxysilane as a crosslinking agent. Polymer 2004, 45, 6831–6837. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.-F.; Wang, L.-F.; Wu, S.-M.; Su, C.-C. Characterization and Curing Kinetics of Epoxy/Silica Nano-Hybrids. Materials 2015, 8, 7032-7040. https://doi.org/10.3390/ma8105357

Yang C-F, Wang L-F, Wu S-M, Su C-C. Characterization and Curing Kinetics of Epoxy/Silica Nano-Hybrids. Materials. 2015; 8(10):7032-7040. https://doi.org/10.3390/ma8105357

Chicago/Turabian StyleYang, Cheng-Fu, Li-Fen Wang, Song-Mao Wu, and Chean-Cheng Su. 2015. "Characterization and Curing Kinetics of Epoxy/Silica Nano-Hybrids" Materials 8, no. 10: 7032-7040. https://doi.org/10.3390/ma8105357