Global Warming Implications of the Use of By-Products and Recycled Materials in Western Australia’s Housing Sector

Abstract

:1. Introduction

1.1. Sustainable Built Environment

1.2. Life Cycle Management Framework

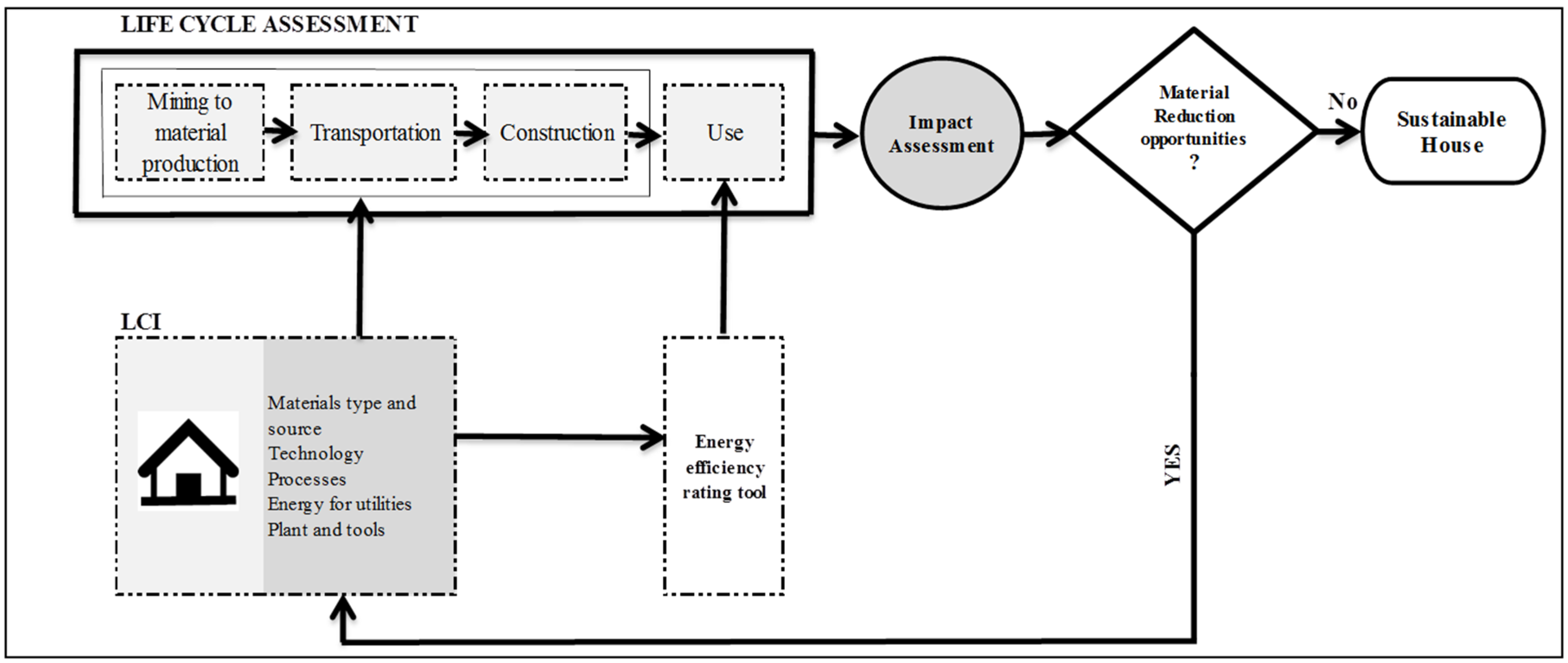

1.2.1. Streamlined Life Cycle Assessment

Goal and Scope

Life Cycle Inventory

| Sr. No. | Material | Location | Amount | Unit | Average Distance (km) | tkm |

|---|---|---|---|---|---|---|

| 1 | Virgin sand | Neerabup/The Lakes | 21.15 | m3 | 50 | 1797.75 |

| 2 | Polythene sheet | Canning Vale | 0.07 | m3 | 30 | 1.31 |

| 3 | Mesh & bar reinforcement | Bibra Lake | 253.69 | m2 | 30 | 19.03 |

| 4 | Ready mix concrete | Canning Vale/Belmont | 32.65 | m3 | 30 | 2350.62 |

| 5 | Clay bricks | Middle Swan/Hazelmere | 48.52 | m3 | 30 | 2838.42 |

| 6 | Brickie sand | Neerabup/The Lakes | 5.69 | m3 | 50 | 484.05 |

| 7 | Cement | Munster | 2.63 | tonne | 30 | 78.75 |

| 8 | Lime | Kwinana/Munster | 0.91 | tonne | 30 | 27.20 |

| 9 | Metal lintels | Malaga/Wangara | 0.58 | tonne | 30 | 17.41 |

| 10 | Aluminium windows | Belmont/Maddington | 1.43 | tonne | 30 | 43.04 |

| 11 | Metal door frames | Maddington | 0.18 | tonne | 30 | 5.40 |

| 12 | Roof Timber | Rockingham | 7.50 | m3 | 30 | 123.75 |

| 13 | Roof Tiles | Middle Swan/Hazelmere | 290.40 | m2 | 30 | 435.60 |

| 14 | Bat Insulation for Roof | Canning Vale | 264.00 | m2 | 30 | 14.26 |

| 15 | Gyprock boards & cornices | Canning Vale | 264.00 | m2 | 30 | 59.40 |

| 16 | Plaster sand | Neerabup/The Lakes | 5.19 | m3 | 50 | 440.76 |

| 17 | Door shutters | Armadale/Bibra Lake | 0.74 | m3 | 30 | 11.14 |

| 18 | Ceramic floor and wall tiles | Osborne Park/Fremantle | 2.09 | m3 | 30 | 184.58 |

| Main Activities | Sub-Activities | Energy | Unit |

|---|---|---|---|

| Excavation and compaction | Bobcat and roller compactor operation | 9 | Hrs. |

| Loading of excavated soil into trucks | Front end loader operation | 3 | Hrs. |

| Mortar Mixing for brick work and rendering | Electricity consumption by Mortar Mixer | 60 | kWh |

| Lifting of bricks/lintels/roof beams | Fork Lift operation | 20 | Hrs. |

| Cutting of bricks, timber, steel and tiles, drilling, nailing, grinding & sanding | Electricity consumption by Hand tools | 60 | kWh |

| Cart away of excavated soil and construction waste | Transport operation | 3409 | tkm |

Impact Assessment

1.2.2. Application of Cleaner Production Strategies

1.2.3. Product Modification Cleaner Production Strategy

1.2.4. Recycling Strategy

Substitution of Concrete Constituents with By-Products and Recyclates

Structural and Environmental Implications of By-Products and Recyclates in Concrete

| Concrete Grade | Cement Substitution | Aggregate Substitution | Sand Substitution | References | |

|---|---|---|---|---|---|

| FA | GGBFS | RCA | MS | ||

| 40 MPa | 25%–50% | 25%–70% | Berndt, 2009 [52] | ||

| 40 MPa | 30% | 50%–80% | Elchalakani et al., 2014 [54] | ||

| 35 MPa | 20%–40% | Arivalagam, 2014 [55] | |||

| 50 MPa | 30%–40% | Nath and Sarker, 2011 [50] | |||

| 62–68 MPa | 30%–40% | Sarker and Mckenzie, 2009 [51] | |||

| 25–32 MPa | 25% | 40% | Flower and Sanjayan, 2007 [56] | ||

| 32 MPa | 70% | Crossin, 2015 [57] | |||

| 30 MPa | 65% | Marinkovic et al., 2010 [58] | |||

| 40 MPa | 40% | 25%–100% | Ahmed, 2012 [59] | ||

| 30–35 MPa | 30% | 70%–85% | Corinaldesi and Moriconi, 2009 [60] | ||

| 30–60 MPa | 100% | Chow et al., 2013 [61] | |||

| 30 MPa | 20%–80% | Naveenth and Satheeshkumar, 2015 [62] | |||

| 20 MPa | 20%–100% | Jadhav and Kulkarni, 2012 [63] | |||

| 50 MPa | 30%–100% | Sheng-Dong et al., 2015 [64] | |||

| 60 MPa | 35% | 55% | 50%–100% | Kou et al., 2011 [65] | |

| 25 MPa | 25%–100% | 35%–45% | Etxeberria et al., 2010 [66] | ||

| 20 MPa, 45 MPa, 65 MPa | 100% | D Pedro et al., 2014 [67] | |||

- Up to 30% of cementitious material and 40% of natural aggregate (NA) and 40% of natural sand (NS) could be substituted with FA, GGBFS, RCA and MS with minor adjustments in concrete mix design for various combinations with acceptable structural performance.

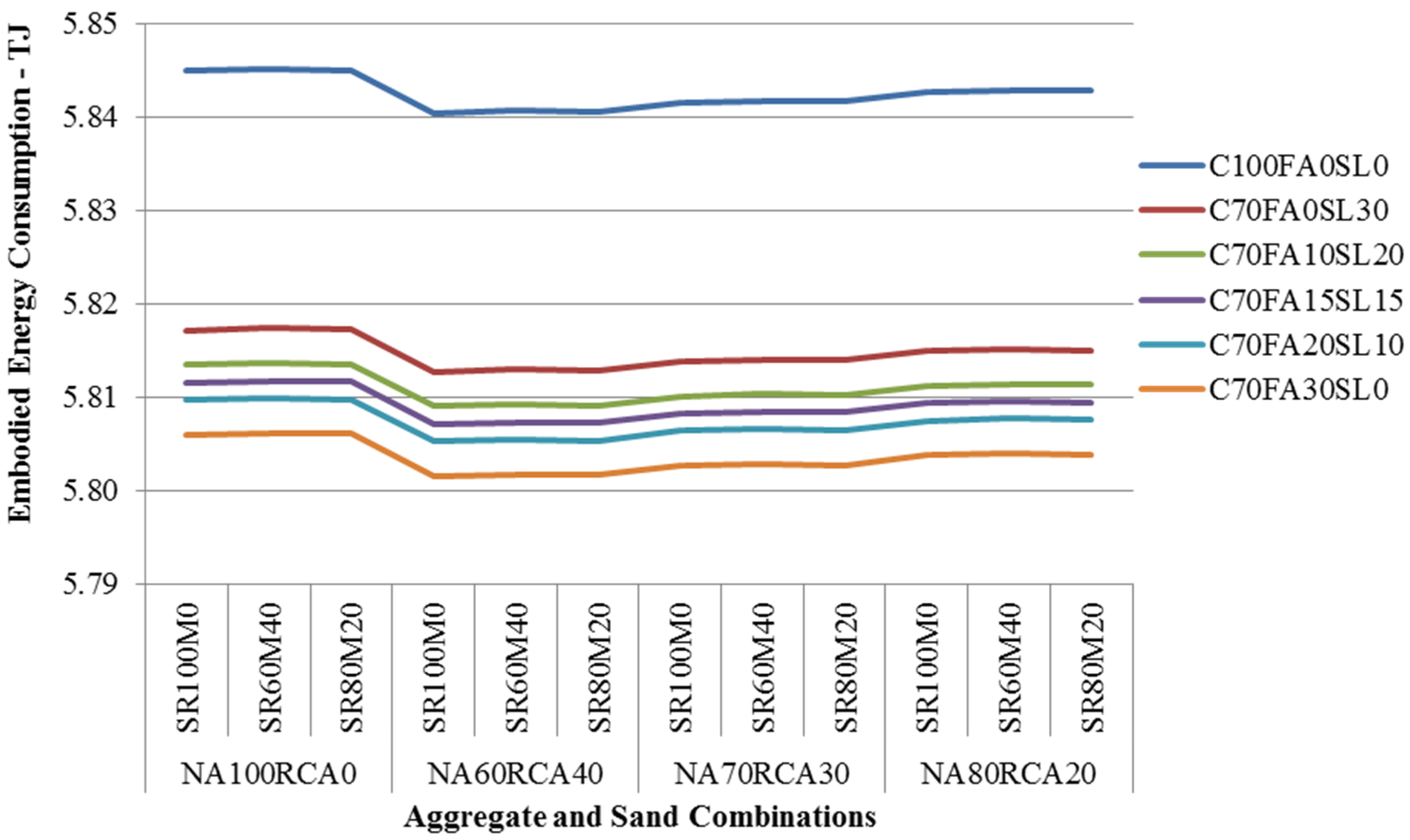

- The changes in market and products may affect the constant supply of by-products and therefore it is important to consider a number of structurally sound compositions to suit to any situation during the time of resource scarcity. As a result, seventy two possible compositions (one current/conventional + seventy one alternatives) of concrete have been considered for determination of possible GHG emissions saving implications of this research.

- The cementitious material is divided in to six groups as 100% OPC, 70% OPC + 30% FA, 70% OPC + 20% FA + 10% GGBFS, 70% OPC + 15% FA + 15% GGBFS, 70% OPC + 10% FA + 20% GGBFS, and 70% OPC + 30% GGBFS. Each of these cementitious composition has been used for four aggregate compositions including 100% NA, 60% NA + 40% RCA, 70% NA + 30% RCA, and 80% NA + 20% RCA, where each of these aggregate compositions are further sub-divided in to three sand categories each as 100% NS, 60% NS + 40% MS, and 80% NS + 20% MS each respectively. Therefore, the total number of compositions of concrete considered in this study is (6 × 4 × 3) or 72 as shown in Figure 2.

2. Results and Discussion

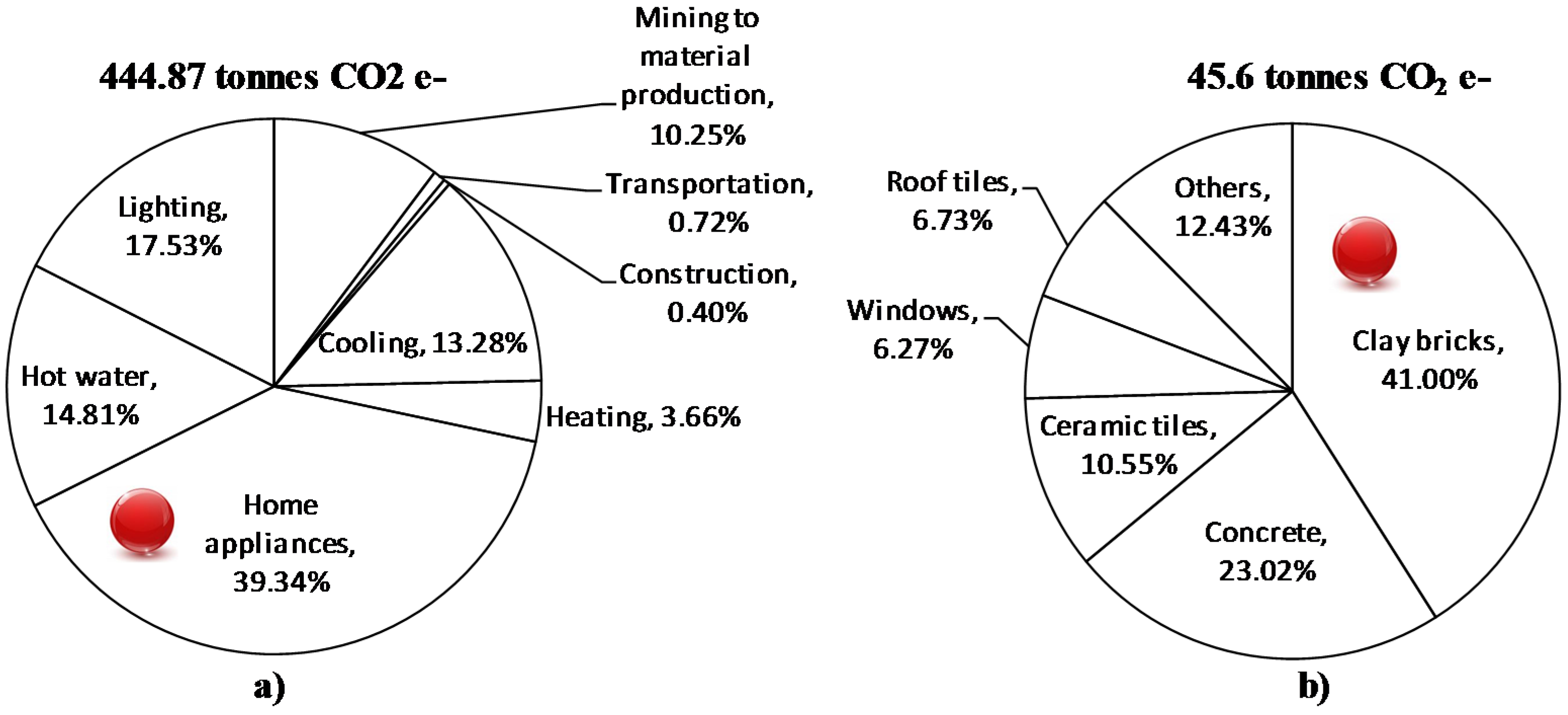

2.1. GHG Emission and Embodied Energy Consumption Assessment of WA’s Current Building Practice

2.2. GHG Emissions and Embodied Energy Consumption Implications of the Use of Cast In-Situ Sandwich Wall Systems

| Stage | GHG Emissions (tonnes CO2 e-) | Embodied Energy (TJ) | ||||

|---|---|---|---|---|---|---|

| CBWH | CCSWH | % Saving | CBWH | CCSWH | % Saving | |

| Mining to material production | 45.60 | 39.06 | 14.35% | 0.75 | 0.63 | 15.98% |

| Transportation | 3.21 | 2.56 | 20.25% | 0.05 | 0.04 | 20.08% |

| Construction | 1.76 | 1.12 | 36.36% | 0.03 | 0.02 | 36.74% |

| Cooling | 59.10 | 46.20 | 21.83% | 0.76 | 0.60 | 21.86% |

| Heating | 16.30 | 7.97 | 51.10% | 0.29 | 0.14 | 50.88% |

| Home appliances | 175.00 | 175.00 | 0.00% | 2.26 | 2.26 | 0.00% |

| Hot water | 65.90 | 65.90 | 0.00% | 1.15 | 1.15 | 0.00% |

| Lighting | 78.00 | 78.00 | 0.00% | 1.01 | 1.01 | 0.00% |

| Total | 444.87 | 415.81 | 6.53% | 6.30 | 5.84 | 7.17% |

2.3. GHG Emissions and Embodied Energy Consumption Implications of the Use of by-Products and Recyclates

| Concrete Mix Compositions with All Aggregate Groups and Sand sub-Groups | % Mitigation Potential | |

|---|---|---|

| GHG | Embodied Energy | |

| Conventional concrete mix with 100% OPC | - | - |

| Concrete mix with 70% OPC and 30% GGBFS | 17.47% | 15.19% |

| Concrete mix with 70% OPC, 10% FA and 20% GGBFS | 19.92% | 17.23% |

| Concrete mix with 70% OPC, 15% FA and 15% GGBFS | 21.15% | 18.26% |

| Concrete mix with 70% OPC, 20% FA and 10% GGBFS | 22.37% | 19.28% |

| Concrete mix with 70% OPC, 30% FA | 24.82% | 21.32% |

| Stage | GHG Emissions (Tonnes CO2 e-) | Embodied Energy (TJ) | ||||

|---|---|---|---|---|---|---|

| CCSWH | CCSWH–PET | % Saving | CCSWH | CCSWH–PET | % Saving | |

| Mining to material production | 39.06 | 38.70 | 0.91% | 0.63 | 0.60 | 5.67% |

| Transportation | 2.56 | 2.58 | -0.78% | 0.04 | 0.04 | -0.51% |

| Construction | 1.12 | 1.12 | 0.00% | 0.02 | 0.02 | 0.00% |

| Cooling | 46.20 | 45.30 | 1.95% | 0.60 | 0.59 | 1.84% |

| Heating | 7.97 | 7.35 | 7.78% | 0.14 | 0.13 | 7.86% |

| Home appliances | 175.00 | 175.00 | 0.00% | 2.26 | 2.26 | 0.00% |

| Hot water | 65.90 | 65.90 | 0.00% | 1.15 | 1.15 | 0.00% |

| Lighting | 78.00 | 78.00 | 0.00% | 1.01 | 1.01 | 0.00% |

| Total | 415.81 | 413.95 | 0.45% | 5.84 | 5.79 | 0.99% |

3. Summary of GHG and Embodied Energy Savings Due to Use of CPS

| Impact | Original | Mitigation Potential Using CPS | Revised | ||

|---|---|---|---|---|---|

| Product Modification | Input Substitution | Re-Use and Recycle | |||

| GHG emissions–tonnes CO2 e- | 444.87 | 29.06 | 5.11 | 1.86 | 408.84 |

| Embodied Energy–TJ | 6.30 | 0.46 | 0.04 | 0.06 | 5.74 |

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Department of the Environment. Australian National Greenhouse Accounts—Quarterly Update of Australia’s National Greenhouse Gas Inventory—March 2015; Department of the Environment: Parkes, Australia, 2015.

- World Wide Fund for Nature. Living Planet Report 2014; World Wide Fund for Nature (WWF): Gland, Switzerland, 2014. [Google Scholar]

- Australian Bureau of Statistics. Population Projections, Australia, 2012 (Base) to 2101; Australian Bureau of Statistics: Canberra, Australia, 2013.

- Joseph, P.; Tretsiakova-McNally, S. Sustainable non-metallic building materials. Sustainability 2010, 2, 400–427. [Google Scholar] [CrossRef]

- Kibert, C.J.; Sendzimir, J.; Guy, B. Construction ecology and metabolism: Natural system analogues for a sustainable built environment. Constr. Manag. Econ. 2000, 18, 903–916. [Google Scholar] [CrossRef]

- Chwieduk, D. Towards sustainable-energy buildings. Appl. Energy 2003, 76, 211–217. [Google Scholar] [CrossRef]

- Williams, J. The role of planning in delivering low-carbon urban infrastructure. Environ. Plan. B Plan. Des. 2013, 40, 683–706. [Google Scholar] [CrossRef]

- Australian Sustainable Built Environment Council. Capitalising on the Building Sector's Potential to Lessen the Costs of a Broad Based GHG Emissions Cut; Centre for International Economics: Canberra, Australia, 2007. [Google Scholar]

- Australian Building Codes Board. Ncc volume two—Energy efficiency provisions—Second edition. In Handbook—Non Mandatory Document; Australian Building Codes Board (ABCB): Canberra, Australia, 2015. [Google Scholar]

- Biswas, W.K. Carbon footprint and embodied energy consumption assessment of building construction works in western Australia. Int. J. Sustain. Built Environment 2014, 3, 179–186. [Google Scholar] [CrossRef]

- Ding, G.K.C. Sustainable construction—The role of environmental assessment tools. J. Environ. Manag. 2008, 86, 451–464. [Google Scholar] [CrossRef] [PubMed]

- Horne, R.; Grant, T.; Verghese, K. Life Cycle Assessment: Principles, Practice, and Prospects; Csiro Publishing: Victoria, Australia, 2009. [Google Scholar]

- Monahan, J.; Powell, J. An embodied carbon and energy analysis of modern methods of construction in housing: A case study using a lifecycle assessment framework. Energy Build. 2011, 43, 179–188. [Google Scholar] [CrossRef]

- Milne, G.; Reardon, C. Materials, Embodied Energy—Your Home Australia’s Guide to Environmentally Sustainable Homes, 5th ed.; Commonwealth of Australia (Department of Industry): Canberra, Australia, 2013. [Google Scholar]

- State of Environment Report, 2011; Department of Environment, Australian Government: Canberra, Australia, 2011.

- National Housing Supply Council. The Key Findings of 2011, the State of Supply Report, the Australian Government; National Housing Supply Council: Canberra, Australia, 2011.

- Department of Environment. National Waste Reporting 2013; Department of Environment, Australian Government: Parkes, Australia, 2013.

- Reardon, C.; Downton, P.; McGee, C. Materials, Construction Systems—Your Home Australia’s Guide to Environmentally Sustainable Homes, 5th ed.; Commonwealth of Australia (Department of Industry): Canberra, Australia, 2013. [Google Scholar]

- Biswas, W.K.; John, M.; Robson, S. Life Cycle Assessment of Building Construction Wastes in Western Australia; EarthCare: Perth, Australia, 2008. [Google Scholar]

- Sharma, A.; Saxena, A.; Sethi, M.; Shree, V.; Varun. Life cycle assessment of buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 871–875. [Google Scholar] [CrossRef]

- Blengini, G.A. Life cycle of buildings, demolition and recycling potential: A case study in turin, Italy. Build. Environ. 2009, 44, 319–330. [Google Scholar] [CrossRef]

- Todd, J.A.; Curran, M.A.; Weitz, K.; Sharma, A.; Vigon, B.; Price, E.; Norris, G.; Eagan, P.; Owens, W.; Veroutis, A. Streamlined Life-Cycle Assessment: A Final Report from the SETAC North America Streamlined LCA Workgroup; Society of Environmental Toxicology and Chemistry (SETAC): Brussels, Belgium; SETAC Foundation for Environmental Education: Pensacola, FL, USA, 1999. [Google Scholar]

- International Organization for Standardization. ISO 14040:2006—Environmental Management—Life Cycle Assessment—Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Aldawi, F.; Date, A.; Alam, F.; Khan, I.; Alghamdi, M. Energy efficient residential house wall system. Appl. Therm. Eng. 2013, 58, 400–410. [Google Scholar] [CrossRef]

- Commonwealth Scientific and Industrial Research Organization. Accurate Sustainability v2.0.2.13sp1, Hearne.software; Hearne Scientific Software Pty Ltd.: Auckland, New Zealand, 2013.

- Morrissey, J.; Horne, R. Life cycle cost implications of energy efficiency measures in new residential buildings. Energy Build. 2011, 43, 915–924. [Google Scholar] [CrossRef]

- Bala, A.; Raugei, M.; Benveniste, G.; Gazulla, C.; Fullana-i-Palmer, P. Simplified tools for global warming potential evaluation: When ‘good enough’ is best. Int. J. Life Cycle Assess. 2010, 15, 489–498. [Google Scholar] [CrossRef]

- Islam, H.; Jollands, M.; Setunge, S. Life cycle assessment of residential buildings: Sustainable material options in wall assemblies. In Proceedings of the Chemeca 2010: Engineering at the Edge, Hilton Adelaide, Australia, 26–29 September 2010; Engineers Australia: Barton, Australia, 2010; pp. 3443–3452. [Google Scholar]

- Think Brick Australia. LCA of Brick Products, Life Cycle Assessment(LCA) Report; Think Brick Australia: Artarmon, Australia, 2010. [Google Scholar]

- International Organization for Standardization. ISO 14044:2006—Environmental Management—Life Cycle Assessment—Requirements and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- PRé-Consultants. Simapro 8.02 LCA Software, PRé Consultants bv: Amersfoort, The Netherlands, 2013.

- Hans-Jorg, A. Ecoinvent Unit Processes for Simapro; Life cycle assessment and modelling group: Dübendorf, Switzerland, 2010. [Google Scholar]

- United Nations Industrial Development Organization. Manual on the Development of Cleaner Production Policies—Approaches and Instruments; UNIDO CP Programme: Vienna, Austria, 2002. [Google Scholar]

- United Nations Environment Programme. Government Strategies & Policies for Cleaner Production 928071442-2; United Nations Environment Programme: Nairobi, Kenya, 1994. [Google Scholar]

- Van Berkel, R. Cleaner production and eco-efficiency initiatives in western Australia 1996–2004. J. Clean. Prod. 2007, 15, 741–755. [Google Scholar] [CrossRef]

- QUESTECH. Evg-3d—Revolutionary Building System. Available online: http://www.questech.com.au (accessed on 21 March 2014).

- Rezaifar, O.; Gholhaki, M. Nonlinear dynamic behavior of structural frames constructed with 3D wall panels with vertical irregular arrangement. In Proceedings of the 1st International Conference on Seismic Retrofitting, Tabriz, Iran, 20–22 October 2008.

- Carbonari, G.; Cavalaro, S.; Cansario, M.; Aguado, A. Flexural behaviour of light-weight sandwich panels composed by concrete and eps. Constr. Build. Mater. 2012, 35, 792–799. [Google Scholar] [CrossRef]

- Gara, F.; Ragni, L.; Roia, D.; Dezi, L. Experimental tests and numerical modelling of wall sandwich panels. Elsevier Eng. Struct. 2012, 37, 193–204. [Google Scholar] [CrossRef]

- Mashal, M.; Filiatrault, A. Quantification of Seismic Performance Factors for Buildings Incorporating Three-Dimensional Construction System, 15 WCEE—World Conference on Earthquake Engineering, Lisbon, Portugal, 24–28 September 2012.

- Mousa, M.A.; Uddin, N. Structural behavior and modeling of full-scale composite structural insulated wall panels. Eng. Struct. 2012, 41, 320–334. [Google Scholar] [CrossRef]

- Bajracharya, R.M.; Lokuge, W.P.; Karunasena, W.; Lau, K.T.; Mosallam, A.S. Structural Evaluation of Concrete Expanded Polystyrene Sandwich Panels for Slab Application. Available online: http://eprints.usq.edu.au/22601/5/Bajracharya_Lokuge_Karnasena_Lau_ACMSM (accessed on 8 April 2014).

- Ricci, I.; Palermo, M.; Gasparini, G.; Silvestri, S.; Trombetti, T. Results of pseudo-static tests with cyclic horizontal load on cast in situ sandwich squat concrete walls. Eng. Struct. 2013, 54, 131–149. [Google Scholar] [CrossRef]

- Australian Building Codes Board. National construction code series 2015 volume two. In Building Code of Australia Class 1 and Class 10 Buildings; Australian Building Codes Board (ABCB): Canberra, Australia, 2015. [Google Scholar]

- Cement Industry Federation Australia. Industry report 2013; Cement Industry Federation Australia: Canberra, Australia, 2014. [Google Scholar]

- Cement Concrete and Agregates Australia. Sustainable Concrete Materials, Briefing 11; Cement Concrete and Agregates Australia: Sydney, Australia, 2012. [Google Scholar]

- Cement Concrete and Agregates Australia. Sustainable Use of Aggregates, Briefing 19; Cement Concrete and Agregates Australia: Sydney, Australia, 2013. [Google Scholar]

- O’Brien, K.; Ménaché, J.; O’Moore, L. Impact of fly ash content and fly ash transportation distance on embodied greenhouse gas emissions and water consumption in concrete. Int. J. Life Cycle Assess. 2009, 14, 621–629. [Google Scholar] [CrossRef] [Green Version]

- Nath, P.; Sarker, P.K. Effect of mixture proportions on the drying shrinkage and permeation properties of high strength concrete containing class f fly ash. KSCE J. Civ. Eng. 2013, 17, 1437–1445. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P. Effect of fly ash on the durability properties of high strength concrete. Procedia Eng. 2011, 14, 1149–1156. [Google Scholar] [CrossRef]

- Sarker, P.; McKenzie, L. Strength and hydration heat of concrete using fly ash as a partial replacement of cement. In Proceedings of the 24th Biennial Conference of the Concrete Institute of Australia, Sydney, Australia, 17 September 2009.

- Berndt, M.L. Properties of sustainable concrete containing fly ash, slag and recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 2606–2613. [Google Scholar] [CrossRef]

- Lima, C.; Caggiano, A.; Faella, C.; Martinelli, E.; Pepe, M.; Realfonzo, R. Physical properties and mechanical behaviour of concrete made with recycled aggregates and fly ash. Constr. Build. Mater. 2013, 47, 547–559. [Google Scholar] [CrossRef]

- Elchalakani, M.; Aly, T.; Abu-Aisheh, E. Sustainable concrete with high volume ggbfs to build masdar city in the UAE. Case Stud. Constr. Mater. 2014, 1, 10–24. [Google Scholar] [CrossRef]

- Arivalagan, S. Sustainable studies on concrete with ggbs as a replacement material in cement. Jordan J. Civ. Eng. 2014, 8, 263–270. [Google Scholar]

- Flower, D.J.; Sanjayan, J.G. Green house gas emissions due to concrete manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Crossin, E. The greenhouse gas implications of using ground granulated blast furnace slag as a cement substitute. J. Clean. Prod. 2015, 95, 101–108. [Google Scholar] [CrossRef]

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, S.F.U. Properties of concrete containing construction and demolition wastes and fly ash. J. Mater. Civ. Eng. 2012, 25, 1864–1870. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Influence of mineral additions on the performance of 100% recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2869–2876. [Google Scholar] [CrossRef]

- Chow, R.K.K.; Yip, S.W.S.; Kwan, A.K.H. Processing crushed rock fine to produce manufactured sand for improving overall performance of concrete. HKIE Trans. 2013, 20, 240–249. [Google Scholar] [CrossRef]

- Naveenth, N.; Satheeshkumar, G. Optimization of partial replacement of natural sand by manufactured sand in concrete. Optimization 2015, 1, 35–38. [Google Scholar]

- Jadhav, P.A.; Kulkarni, D.K. An experimental investigation on the properties of concrete containing manufactured sand. Int. J. Adv. Eng. Technol. 2012, 3, 101–104. [Google Scholar]

- He, S.-D.; Wang, H.; Li, L. Experimental study on compressive strength of manufactured sand concrete. In Proceedings of the International Conference on Material Science and Application (ICMSA 2015), Suzhou, China, 13–14 June 2015.

- Kou, S.-C.; Poon, C.-S.; Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Etxeberria, M.; Pacheco, C.; Meneses, J.; Berridi, I. Properties of concrete using metallurgical industrial by-products as aggregates. Constr. Build. Mater. 2010, 24, 1594–1600. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Influence of the use of recycled concrete aggregates from different sources on structural concrete. Constr. Build. Mater. 2014, 71, 141–151. [Google Scholar] [CrossRef]

- Galvin, B.; Lloyd, N. Fly Ash Based Geopolymer Concrete with Recycled Concrete Aggregate, Proceedings of the 25th Biennial Conference of Concrete Institute of Australia (Concrete 2011), Perth, Australia, 12–14 October 2011; pp. 13–14.

- Kayali, O. Fly ash lightweight aggregates in high performance concrete. Constr. Build. Mater. 2008, 22, 2393–2399. [Google Scholar] [CrossRef]

- Beggas, D.; Zeghiche, J. The use of slag stone concrete to improve the thermal performance of light steel buildings. Sustain. Cities Soc. 2013, 6, 22–26. [Google Scholar] [CrossRef]

- Silva, R.; de Brito, J.; Dhir, R. The influence of the use of recycled aggregates on the compressive strength of concrete: A review. Eur. J. Environ. Civ. Eng. 2014, 19, 825–849. [Google Scholar] [CrossRef]

- Ji, T.; Chen, C.-Y.; Zhuang, Y.-Z.; Chen, J.-F. A mix proportion design method of manufactured sand concrete based on minimum paste theory. Constr. Build. Mater. 2013, 44, 422–426. [Google Scholar] [CrossRef]

- Cement Concrete and Agregates Australia. Guide to the Specification and Use of Manufactured Sand in Concrete; Cement Concrete and Agregates Australia: Sydney, Australia, 2008. [Google Scholar]

- Pofale, A.; Quadri, S.R. Effective utilization of crusher dust in concrete using portland pozzolana cement. Int. J. Sci. Res. Publ. 2013, 3, 1–10. [Google Scholar]

- Ash Development Association of Australia. Annual Membership Survey Results—January–December 2013; Ash Development Association of Australia: Wollongong, Australia, 2014. [Google Scholar]

- Australasian (Iron & Steel) Slag Association. Reference Data Sheet 1—2011 Blast Furnace Slag Aggregate & Cementitious Products; Australasian (Iron & Steel) Slag Association: Wollongong, Australia, 2011. [Google Scholar]

- Sustainable Aggregates South Australia. Recycled Aggregates Bring Carbon Reduction Benefits—Info Sheet; Sustainable Aggregates South Australia: Adelaide, Australia, 2010. [Google Scholar]

- Crossin, E. Comparative Life Cycle Assessment of Concrete Blends; Centre for Design, RMIT University: Melbourne, Australia, 2012. [Google Scholar]

- O’Flynn, M. Manufactured sands from hardrock quarries: Environmental solution or dilemma for southeast Queensland? Aust. J. Earth Sci. 2000, 47, 65–73. [Google Scholar] [CrossRef]

- Foti, D. Preliminary analysis of concrete reinforced with waste bottles pet fibers. Constr. Build. Mater. 2011, 25, 1906–1915. [Google Scholar] [CrossRef]

- Intini, F.; Kühtz, S. Recycling in buildings: An lca case study of a thermal insulation panel made of polyester fiber, recycled from post-consumer pet bottles. Int. J. Life Cycle Assess. 2011, 16, 306–315. [Google Scholar] [CrossRef]

- Saikia, N.; de Brito, J. Use of plastic waste as aggregate in cement mortar and concrete preparation: A review. Constr. Build. Mater. 2012, 34, 385–401. [Google Scholar] [CrossRef]

- Awaja, F.; Pavel, D. Recycling of pet. Eur. Polym. J. 2005, 41, 1453–1477. [Google Scholar] [CrossRef]

- Japon, S.; Leterrier, Y.; Månson, J.A.E. Recycling of poly (ethylene terephthalate) into closed-cell foams. Polym. Eng. Sci. 2000, 40, 1942–1952. [Google Scholar] [CrossRef]

- Australian Packaging Covenant. 2012–13 National Plastics Recycling Survey—Final Report; Australian Packaging Covenant: Sydney, Australia, 2014. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lawania, K.; Sarker, P.; , W.B. Global Warming Implications of the Use of By-Products and Recycled Materials in Western Australia’s Housing Sector. Materials 2015, 8, 6909-6925. https://doi.org/10.3390/ma8105347

Lawania K, Sarker P, WB. Global Warming Implications of the Use of By-Products and Recycled Materials in Western Australia’s Housing Sector. Materials. 2015; 8(10):6909-6925. https://doi.org/10.3390/ma8105347

Chicago/Turabian StyleLawania, Krishna, Prabir Sarker, and Wahidul Biswas . 2015. "Global Warming Implications of the Use of By-Products and Recycled Materials in Western Australia’s Housing Sector" Materials 8, no. 10: 6909-6925. https://doi.org/10.3390/ma8105347