Preparation and Characterization of Lignocellulosic Oil Sorbent by Hydrothermal Treatment of Populus Fiber

Abstract

:1. Introduction

2. Results and Discussion

2.1. Effects of Reaction Conditions on Sorption Capacity

| Hydrothermal Treatment Condition | Acetylation Condition | Modified Fiber | |||

|---|---|---|---|---|---|

| Temperature (°C) | Reaction Time (h) | Temperature (°C) | Reaction Time (h) | Sample No. | OSC (g oil/g fiber) |

| – a | – | – | – | 1 | 3.94 |

| – | – | 100 | 2 | 2 | 17.40 |

| – | – | 120 | 2 | 3 | 21.57 |

| – | – | 140 | 2 | 4 | 19.79 |

| – | – | 120 | 1 | 5 | 13.54 |

| – | – | 120 | 3 | 6 | 17.74 |

| 170 | 0.5 | – | – | 7 | 16.02 |

| 170 | 1 | – | – | 8 | 16.78 |

| 180 | 1 | – | – | 9 | 16.39 |

| 200 | 1 | – | – | 10 | 12.65 |

| 220 | 1 | – | – | 11 | 7.66 |

| 170 | 0.5 | 120 | 2 | 12 | 17.98 |

| 170 | 1 | 120 | 2 | 13 | 20.30 |

| 180 | 1 | 120 | 2 | 14 | 19.04 |

| 200 | 1 | 120 | 2 | 15 | 8.49 |

| 220 | 1 | 120 | 2 | 16 | 8.33 |

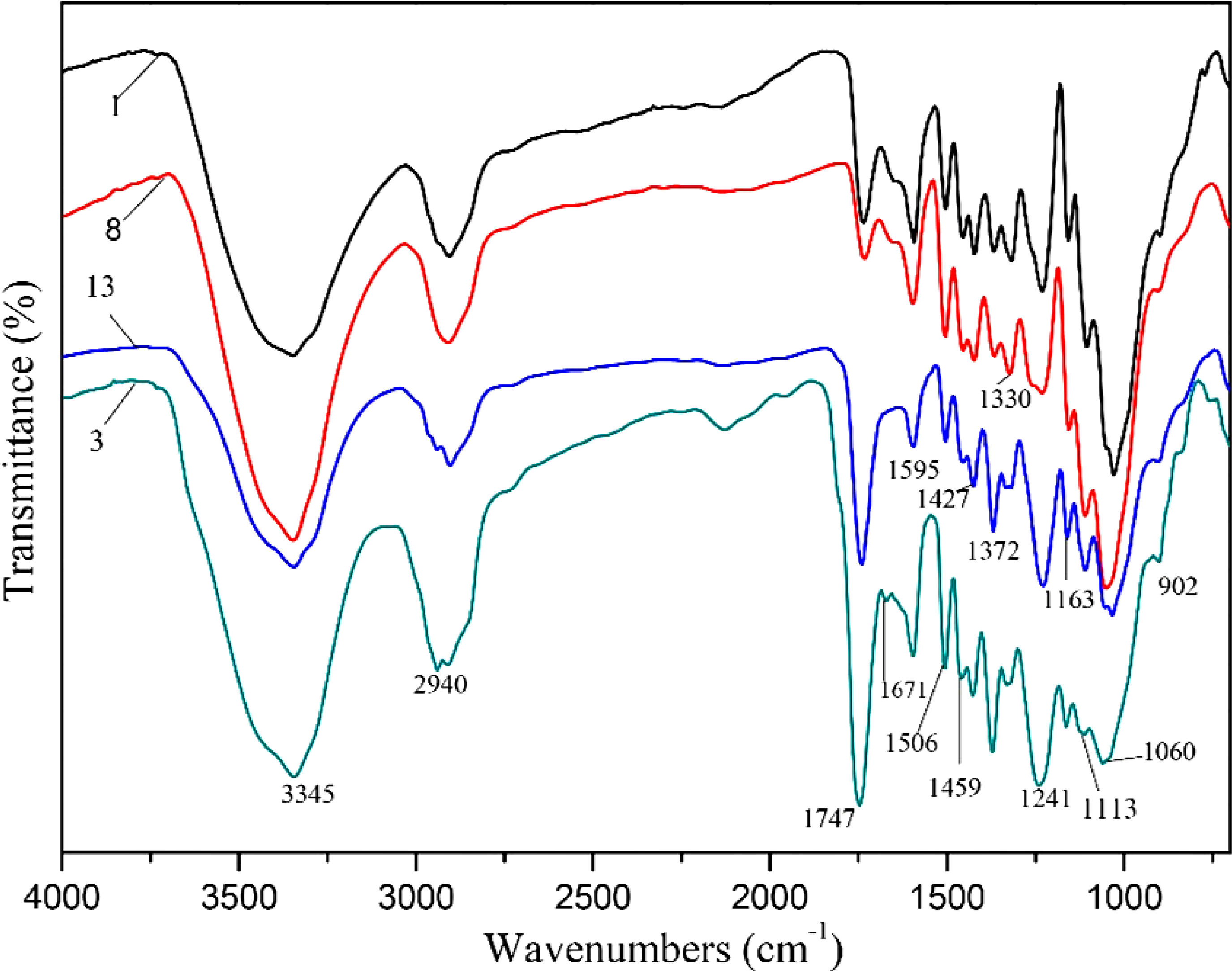

2.2. FT-IR Spectra

| Band Number | Wavenumber (cm−1) | Assignments |

|---|---|---|

| 1 | 3345 | O–H stretching |

| 2 | 2940 | C–H stretching of –CH2– and –CH3 |

| 3 | 1747 | C=O stretching in ester |

| 4 | 1595 | Aromatic skeletal vibrations plus C=O stretching |

| 5 | 1506 | Aromatic C–C stretching from aromatic ring of lignin |

| 6 | 1459 | Aromatic C–H deformation; asymmetric in –CH3 and –CH2– |

| 7 | 1427 | Aromatic skeletal vibration combined with C–H in plane deformation |

| 8 | 1372 | C–H bending vibration in –C–CH3 |

| 9 | 1330 | Phenolic O–H |

| 10 | 1241 | C–O stretching vibration |

| 11 | 1163 | C–O–C vibrations at β-glucosidic linkages in cellulose and hemicelluloses |

| 12 | 1113 | C–O, C–C stretching in cellulose and hemicelluloses |

| 13 | 1060 | C–O stretching in C–O–C linkages |

| 14 | 902 | C–O–C stretching at β-glucosidic linkages |

2.3. CP-MAS 13C-NMR Spectra

2.4. Morphology Analyses

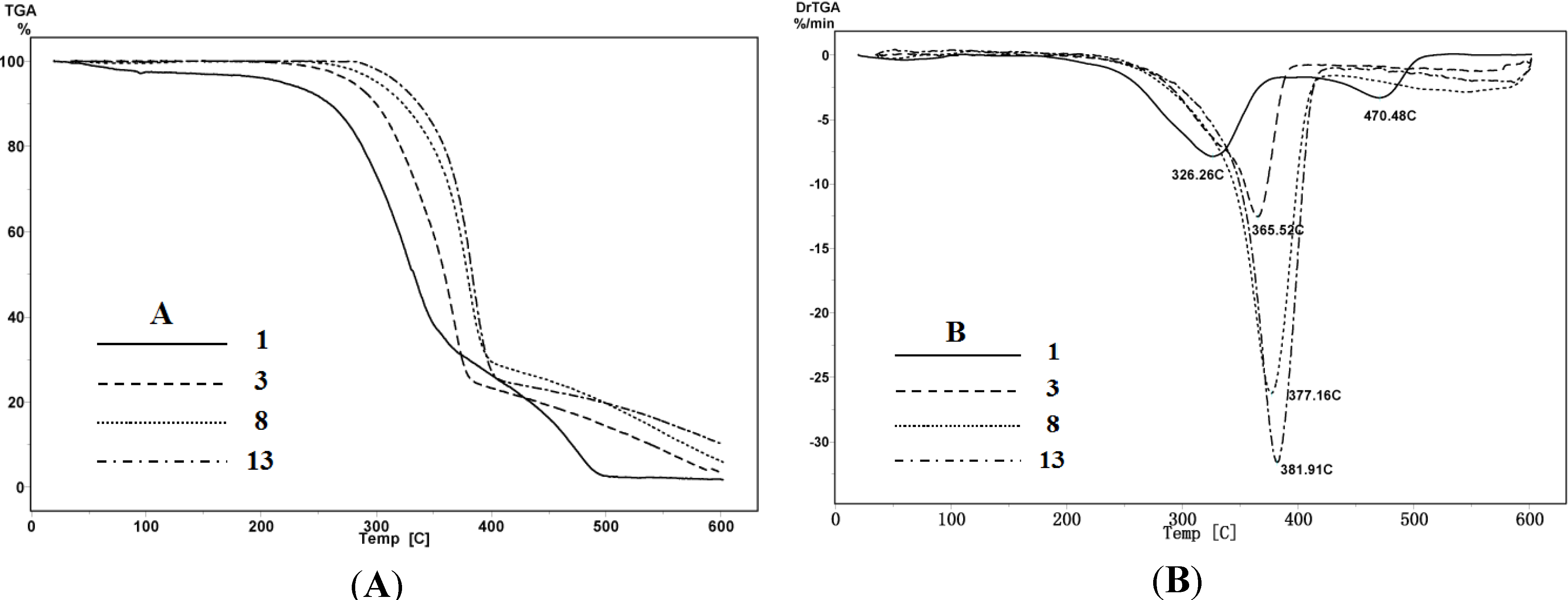

2.5. Thermal Analysis

3. Experimental Section

3.1. Materials

3.2. Sample Preparation

3.2.1. Acetylation of Populus Fiber (APF)

3.2.2. Preparation of Hydrothermal Treatment Populus Fiber (HPF)

3.2.3. Acetylation of the Fiber after Hydrothermal Pretreatment (AHPF)

3.3. Characterization of the Modified Fiber

3.4. Measurements of Oil Sorption Capacity

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hussein, M.; Amer, A.A.; Sawsan, I.I. Oil spill sorption using carbonized pith bagasse: Trial for practical application. Int. J. Environ. Sci. Technol. 2008, 5, 233–242. [Google Scholar]

- Rengasamy, R.S.; Das, D.; Karan, C.P. Study of oil sorption behavior of filled and structured fiber assemblies made from polypropylene, kapok and milkweed fibers. J. Hazard. Mater. 2011, 186, 526–532. [Google Scholar]

- Abdullah, M.A.; Rahmah, A.U.; Man, Z. Physicochemical and sorption characteristics of Malaysian Ceibapentandra (L.) Gaertn. as a natural oil sorbent. J. Hazard. Mater. 2010, 177, 683–691. [Google Scholar]

- Banerjee, S.S.; Joshi, M.V.; Jayaram, R.V. Treatment of oil spill by sorption technique using fatty acid grafted sawdust. Chemosphere 2006, 64, 1026–1031. [Google Scholar]

- Peng, D.; Lan, Z.L.; Guo, C.L.; Yang, C.; Dang, Z. Application of cellulase for the modification of corn stalk: Leading to oil sorption. Bioresource Technol. 2013, 137, 414–418. [Google Scholar]

- Wang, J.T.; Zheng, Y.; Wang, A.Q. Investigation of acetylated kapok fibers on the sorption of oil in water. J. Environ. Sci. 2013, 25, 246–253. [Google Scholar]

- Singh, V.; Jinka, S.; Hake, K.; Parameswaran, S.; Kendall, R.J.; Ramkumar, S. Noval natural sorbent for oil spill cleanup. Ind. Eng. Chem. Res. 2014, 53, 11954–11961. [Google Scholar]

- Deschamps, G.; Caruel, H.; Borredon, M.E.; Bonnin, C.; Vignoles, C. Oil removal from water by selective sorption on hydrophobic cotton fibers. 1. Study of sorption properties and comparison with other cotton fiber-based sorbents. Environ. Sci. Technol. 2003, 37, 1013–1015. [Google Scholar]

- Wang, J.T.; Zheng, Y.; Wang, A.Q. Superhydrophobic kapok fiber oil-absorbent: Preparation and high oil absorbency. Chem. Eng. J. 2012, 213, 1–7. [Google Scholar]

- Ali, N.; El-Harbawi, M.; Jabal, A.A.; Yin, C.Y. Characteristics and oil sorption effectiveness of kapok fibre, sugarcane bagasse and rice husks: Oil removal suitability matrix. Environ. Technol. 2012, 33, 481–486. [Google Scholar]

- Pham, V.H.; Dickerson, J.H. Superhydrophobic silanized melamine sponges as high efficiency oil absorbent materials. ACS Appl. Mater. Interfaces 2014, 6, 14181–14188. [Google Scholar]

- Pan, Y.; Shi, K.; Peng, C.; Wang, W.; Liu, Z.; Ji, X. Evaluation of hydrophobic polyvinyl-alcohol formaldehyde sponges as absorbents for oil spill. ACS Appl. Mater. Interfaces 2014, 6, 8654–8659. [Google Scholar]

- Wang, J.T.; Zheng, Y.; Kang, Y.R.; Wang, A.Q. Investigation of oil sorption capability of PBMA/SiO2 coated kapok fiber. Chem. Eng. J. 2013, 223, 632–637. [Google Scholar]

- Sun, R.C.; Sun, X.F.; Sun, J.X.; Zhu, Q.K. Effect of tertiary amine catalysts on the acetylation of wheat straw for the production of oil sorption-active materials. C. R. Chim. 2004, 7, 125–134. [Google Scholar]

- Rajakovic, V.; Aleksic, G.; Radetic, M.; Rajakovic, L.J. Efficiency of oil removal from real wastewater with different sorbent materials. J. Hazard. Mater. 2007, 143, 494–499. [Google Scholar]

- Chol, H.M.; Cloud, R.M. Natural sorbents in oil spill cleanup. Environ. Sci. Technol. 1992, 26, 772–776. [Google Scholar]

- Khan, E.; Virojnagud, W.; Ratpukdi, T. Use of biomass sorbents for oil removal from gas station runoff. Chemosphere 2004, 57, 681–689. [Google Scholar]

- Liu, Y.; Ma, J.K.; Wu, T.; Wang, X.R.; Huang, G.B.; Liu, Y.; Qiu, H.X.; Li, Y.; Wang, W.; Gao, J.P. Cost-effective reduced graphene oxide-coated polyurethane sponge as a highly efficient and reusable oil-absorbent. ACS Appl. Mater. Interfaces 2013, 5, 10018–10026. [Google Scholar]

- Thompson, N.E.; Emmanue, G.C.; Adagadzu, K.J.; Yusuf, N.B. Sorption studies of crude oil on acetylated rice husks. Arch. Appl. Sci. Res. 2010, 2, 142–151. [Google Scholar]

- Hussein, M.; Amer, A.A.; Sawsan, I.I. Oil spill sorption using carbonized pith bagasse. 1. Preparation and characterization of carbonized pith bagasse. J. Anal. Appl. Pyrolysis 2008, 82, 202–211. [Google Scholar]

- Rattanawong, O.; Kaewsichan, L.; Grisdanurak, N.; Yuasa, A. Sorption of oil emulsified in water on oil palm fibers. Korean J. Chem. Eng. 2007, 24, 67–71. [Google Scholar]

- Sun, X.F.; Sun, R.C.; Sun, J.X. A convenient acetylation of sugarcane bagasse using NBS as a catalyst for the preparation of oil sorption-active materials. J. Mater. Sci. 2003, 38, 3915–3923. [Google Scholar]

- Hill, C.A.S.; Khalil, H.P.S.; Hale, M.D. A study of the potential of acetylation to improve the properties of plant fibres. Ind. Crop. Prod. 1998, 8, 53–63. [Google Scholar]

- Cybulska, I.; Brudecki, G.; Lei, H. Hydrothermal Pretreatment of Lignocellulosic Biomass. In Green Biomass Pretreatment for Biofuels Production; Gu, T., Ed.; Springer Netherlands: Dordrecht, The Netherlands, 2013; pp. 87–106. [Google Scholar]

- Wan, C.; Zhou, Y.; Li, Y. Liquid hot water and alkaline pretreatment of soybean straw for improving cellulose digestibility. Bioresource Technol. 2011, 102, 6254–6259. [Google Scholar]

- Toor, S.S.; Rosendahl, L.; Rudolf, A. Hydrothermal liquefaction of biomass: A review of subcritical water technologies. Energy 2011, 36, 2328–2342. [Google Scholar]

- Pérez, J.A.; González, A.; Oliva, J.M.; Ballesteros, I.; Manzanares, P. Effect of process variables on liquid hot water pretreatment of wheat straw for bioconversion to fuel-ethanol in a batch reactor. J. Chem. Technol. Biotechnol. 2007, 82, 929–938. [Google Scholar]

- Mosier, N.; Wyman, C.; Dale, B.; Elander, R.; Lee, Y.Y.; Holtzapple, M.; Ladisch, M. Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresource Technol. 2005, 96, 673–686. [Google Scholar]

- Li, H.; Pu, Y.; Kumar, R.; Ragauskas, A.J.; Wyman, C.E. Investigation of lignin deposition on cellulose during hydrothermal pretreatment, its effect on cellulose hydrolysis, and underlying mechanisms. Biotechnol. Bioeng. 2014, 111, 485–492. [Google Scholar]

- Selig, M.J.; Viamajala, S.; Decker, S.R.; Tucker, M.P.; Himmel, M.E.; Vinzant, T.B. Deposition of lignin droplets produced during dilute acid pretreatment of maize stems retards enzymatic hydrolysis of cellulose. Biotechnol. Prog. 2007, 23, 1333–1339. [Google Scholar]

- Khalil, M.I.; Hashem, A.; Hebeish, A. Preparation and characterization of starch acetate. Starch Stärke 1995, 47, 394–398. [Google Scholar]

- Hill, C.A.S.; Jones, D.; Strickland, G.; Cetin, N.S. Kinetic and mechanistic aspects of the acetylation of wood with acetic anhydride. Holzforschung 1998, 52, 623–629. [Google Scholar]

- Sun, X.F.; Sun, R.C.; Sun, J.X. Acetylation of sugarcane bagasse using NBS as a catalyst under mild reaction conditions for the production of oil sorption-active materials. Bioresource Technol. 2004, 95, 343–350. [Google Scholar]

- Rowell, R.M.; Simonsen, R.; Tillman, A.M. Acetylation balance for the acetylation of wood particles by a simplified procedure. Holzforschung 1990, 44, 263–269. [Google Scholar]

- Mosier, N.S.; Hendrickson, R.; Brewer, M.; Ho, N.; Sedlak, M.; Dreshel, R.; Welch, G.; Dien, B.S.; Aden, A.; Ladisch, M.R. Industrial scale-up of pH-controlled liquid hot water pretreatment of corn fiber for fuel ethanol production. Appl. Biochem. Biotechnol. 2005, 125, 77–97. [Google Scholar]

- Liu, S.J. Woody biomass: Niche position as a source of sustainable renewable chemicals and energy and kinetics of hot-water extraction/hydrolysis. Biotechnol. Adv. 2010, 28, 563–582. [Google Scholar]

- Liu, H.M.; Li, M.F.; Yang, S.; Sun, R.C. Understanding the mechanism of cypress liquefaction in hot-compressed water through characterization of solid residues. Energies 2013, 6, 1590–1603. [Google Scholar]

- Xiu, S.; Shahbazi, A.; Shirley, V.; Cheng, D. Hydrothermal pyrolysis of swine manure to bio-oil: Effects of operating parameters on products yield and characterization of bio-oil. J. Anal. Appl. Pyrol. 2010, 88, 73–79. [Google Scholar]

- Sun, P.; Heng, M.; Sun, S.H.; Chen, J. Analysis ofliquid and solid products from liquefaction of paulownia in hot-compressed water. Energy Convers. Manag. 2011, 52, 924–933. [Google Scholar]

- Uzunov, I.; Uzunova, S.; Angelova, D.; Gigova, A. Effects of the pyrolysis process on the oil sorption capacity of rice husk. J. Anal. Appl. Pyrol. 2012, 98, 166–176. [Google Scholar]

- Sun, R.C.; Lu, Q.; Sun, X.F. Physico-chemical and thermal characterization of lignins from Caligonum monogoliacum and Tamarix spp. Polym. Degrad. Stabil. 2001, 72, 229–238. [Google Scholar]

- Nuopponen, M.H.; Wikberg, H.I.; Birch, G.M.; Jääskeläinen, A.S.; Maunu, S.L.; Vuorinen, T.; Stewart, D. Characterization of 25 tropical hardwoods with Fourier transform infrared, ultraviolet resonance Raman, and 13C-NMR cross-polarization/magic-angle spinning spectroscopy. J. Appl. Polym. Sci. 2006, 102, 810–819. [Google Scholar]

- Delmotte, L.; Ganne-Chedeville, C.; Leban, J.M.; Pizzi, A.; Pichelin, F. CP-MAS 13C-NMR and FT-IR investigation of the degradation reactions of polymer constituents in wood welding. Polym. Degrad. Stab. 2008, 93, 406–412. [Google Scholar]

- Popescu, C.M.; Larsson, P.T.; Vasile, C. Carbon-13 CP/MAS solid state NMR and X-ray diffraction spectroscopy studies on lime wood decayed by Chaetomium globosum. Carbohydr. Polym. 2011, 83, 808–812. [Google Scholar]

- Wikberg, H.; Maunu, S.L. Characterisation of thermally modified hard- and softwoods by 13C CPMAS NMR. Carbohydr. Polym. 2004, 58, 461–466. [Google Scholar]

- Likon, M.; Remškar, M.; Ducman, V.; Švegl, F. Populus seed fibers as a natural source for production of oil super absorbents. J. Environ. Manage. 2013, 114, 158–167. [Google Scholar]

- Wahi, R.; Chuah, L.A.; Choong, T.S.Y.; Ngaini, Z.; Nourouzi, M.M. Oil removal from aqueous state by natural fibrous sorbent: An overview. Sep. Purif. Technol. 2013, 113, 51–63. [Google Scholar]

- Nadji, H.; Diouf, P.N.; Benaboura, A.; Bedard, Y.; Riedl, B.; Stevanovic, T. Comparative study of lignins isolated from Alfa grass (Stipa tenacissima L.). Bioresour. Technol. 2009, 100, 3585–3592. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Zhang, Y.; Yang, S.; Wu, J.-Q.; Yuan, T.-Q.; Sun, R.-C. Preparation and Characterization of Lignocellulosic Oil Sorbent by Hydrothermal Treatment of Populus Fiber. Materials 2014, 7, 6733-6747. https://doi.org/10.3390/ma7096733

Zhang Y, Yang S, Wu J-Q, Yuan T-Q, Sun R-C. Preparation and Characterization of Lignocellulosic Oil Sorbent by Hydrothermal Treatment of Populus Fiber. Materials. 2014; 7(9):6733-6747. https://doi.org/10.3390/ma7096733

Chicago/Turabian StyleZhang, Yue, Sheng Yang, Jian-Quan Wu, Tong-Qi Yuan, and Run-Cang Sun. 2014. "Preparation and Characterization of Lignocellulosic Oil Sorbent by Hydrothermal Treatment of Populus Fiber" Materials 7, no. 9: 6733-6747. https://doi.org/10.3390/ma7096733