Photonic Bandgap Propagation in All-Solid Chalcogenide Microstructured Optical Fibers

Abstract

:1. Introduction

2. Fabrication of the Fibers

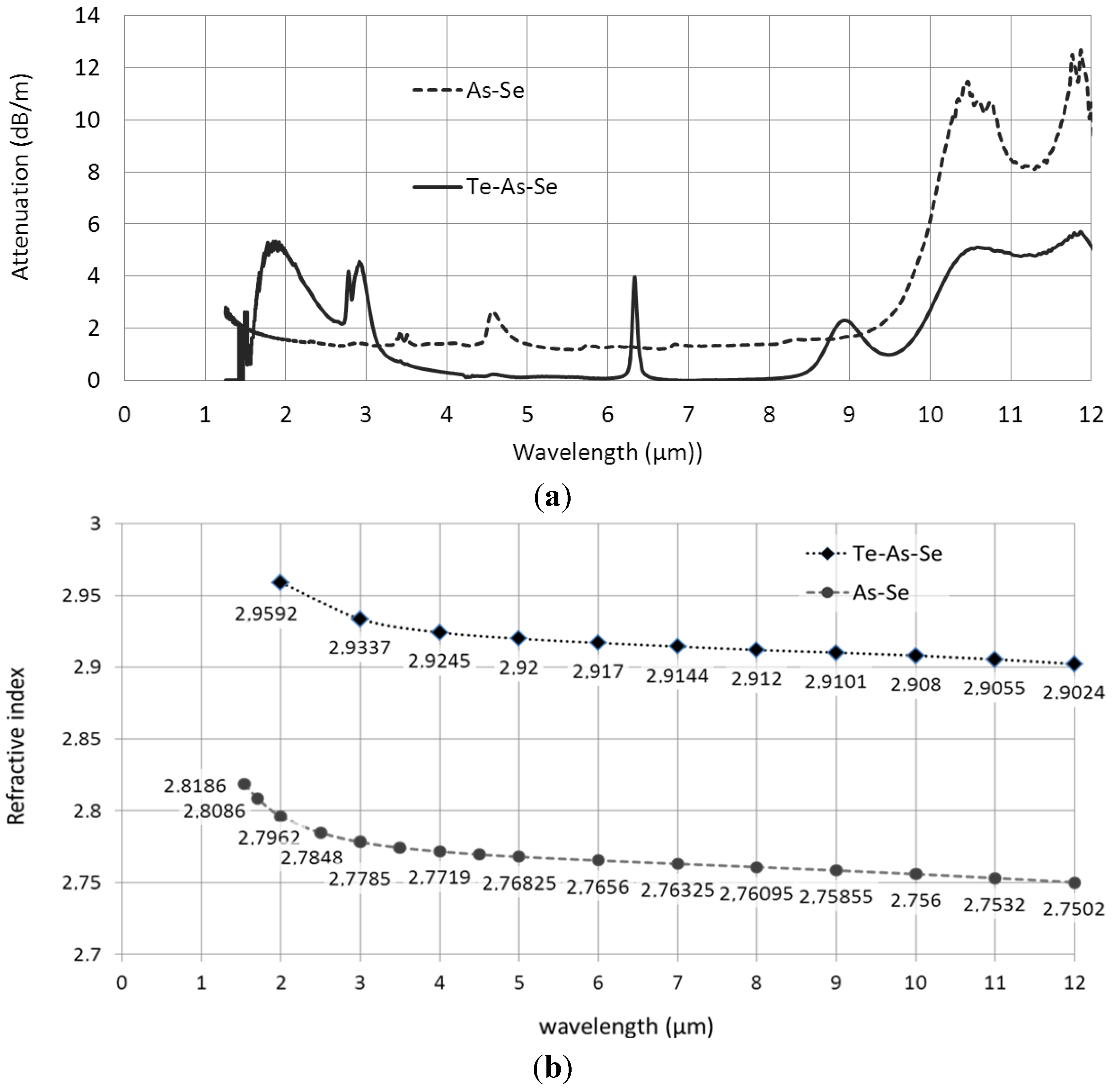

2.1. Glass Synthesis and Characteristics

2.2. Microstructured Fiber Fabrication

| Fiber | Outer diameter | d (µm) ± 0.1 µm | Λ (µm) ± 0.1 µm | d/Λ ± 0.01 | Core diameter |

|---|---|---|---|---|---|

| 1 | 230 µm | 5.5 | 14.7 | 0.374 | 23.9 |

| 2 | 200 µm | 4.9 | 13.0 | 0.377 | 22.3 |

| 3 | 165 µm | 4.3 | 11.8 | 0.364 | 19.4 |

3. Results

3.1. Experimental Transmission of the Fibers

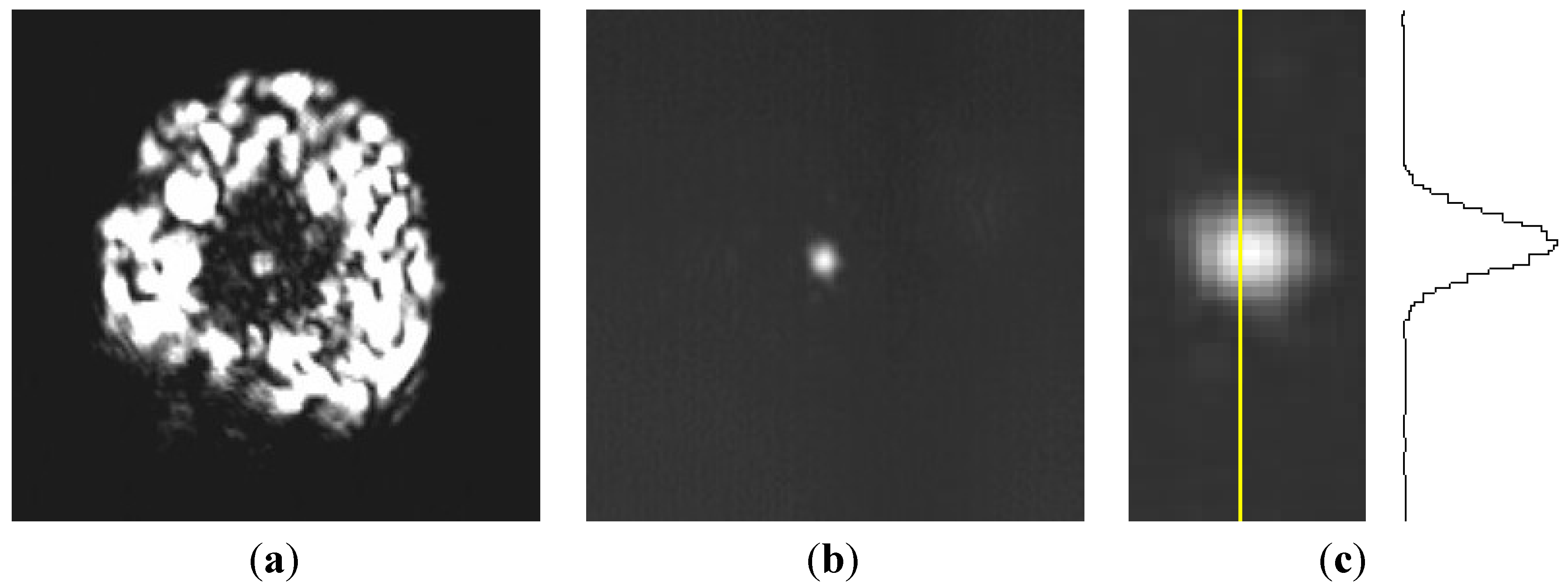

3.2. Near-Field Measurements

3.3. Modeling

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zolla, F.; Renversez, G.; Nicolet, A.; Kuhlmey, B.; Guenneau, S.; Felbacq, D.; Argyros, A.; Leon-Saval, S. Foundations of Photonic Crystal Fibres, 2nd ed.; Imperial College Press: London, UK, 2012. [Google Scholar]

- Smith, C.M.; Venkataraman, N.; Gallagher, M.T.; Muller, D.; West, J.A.; Borrelli, N.F.; Allan, D.C.; Koch, K.W. Low-loss hollow-core silica/air photonic bandgap fibre. Nature 2003, 424, 657–659. [Google Scholar]

- Kuhlmey, B.T.; McPhedran, R.C.; de Sterke, C.M.; Robinson, P.A.; Renversez, G.; Maystre, D. Microstructured optical fibers: Where’s the edge? Opt. Express 2002, 10, 1285–1290. [Google Scholar] [CrossRef]

- Renversez, G.; Bordas, F.; Kuhlmey, B.T. Second mode transition in microstructured optical fibers: Determination of the critical geometrical parameter and study of the matrix refractive index and effects of cladding size. Opt. Lett. 2005, 30, 1264–1266. [Google Scholar]

- Benabid, F. Hollow-core photonic bandgap fibre: New light guidance for new science and technology. Philoso. Trans. R. Soc. A Math. Phys. Eng. Sci. 2006, 364, 3439–3462. [Google Scholar]

- Brilland, L.; Smektala, F.; Renversez, G.; Chartier, T.; Troles, J.; Nguyen, T.N.; Traynor, N.; Monteville, A. Fabrication of complex structures of holey Fibers in chalcogenide glass. Opt. Express 2006, 14, 1280–1285. [Google Scholar]

- Troles, J.; Brilland, L.; Smektala, F.; Houizot, P.; Desevedavy, F.; Coulombier, Q.; Traynor, N.; Chartier, T.; Nguyen, T.N.; Adam, J.L.; et al. Chalcogenide microstructured fibers for infrared systems, elaboration modelization, and characterization. Fiber Integr. Opt. 2009, 28, 11–26. [Google Scholar] [CrossRef]

- Troles, J.; Coulombier, Q.; Canat, G.; Duhant, M.; Renard, W.; Toupin, P.; Calvez, L.; Renversez, G.; Smektala, F.; El Amraoui, M.; et al. Low loss microstructured chalcogenide fibers for large non linear effects at 1995 nm. Opt. Express 2010, 18, 26647–26654. [Google Scholar] [Green Version]

- Desevedavy, F.; Renversez, G.; Troles, J.; Houizot, P.; Brilland, L.; Vasilief, I.; Coulombier, Q.; Traynor, N.; Smektala, F.; Adam, J.-L. Chalcogenide glass hollow core photonic crystal fibers. Opt. Mater. 2010, 32, 1532–1539. [Google Scholar]

- Lian, Z.G.; Li, Q.Q.; Furniss, D.; Benson, T.M.; Seddon, A.B. Solid microstructured chalcogenide glass optical fibers for the near- and mid-infrared spectral regions. IEEE Photonics Technol. Lett. 2009, 21, 1804–1806. [Google Scholar]

- Toupin, P.; Brilland, L.; Renversez, G.; Troles, J. All-solid all-chalcogenide microstructured optical fiber. Opt. Express 2013, 21, 14643–14648. [Google Scholar]

- Liao, M.; Chaudhari, C.; Qin, G.; Yan, X.; Kito, C.; Suzuki, T.; Ohishi, Y.; Matsumoto, M.; Misumi, T. Fabrication and characterization of a chalcogenide-tellurite composite microstructure fiber with high nonlinearity. Opt. Express 2009, 17, 21608–21614. [Google Scholar]

- Cheng, T.; Kanou, Y.; Deng, D.; Xue, X.; Matsumoto, M.; Misumi, T.; Suzuki, T.; Ohishi, Y. Fabrication and characterization of a hybrid four-hole AsSe2-As2S5 microstructured optical fiber with a large refractive index difference. Opt. Express 2014, 22, 13322–13329. [Google Scholar]

- Duguay, M.A.; Kokubun, Y.; Koch, T.L.; Pfeiffer, L. Antiresonant reflecting optical waveguides in SiO2-Si multilayer structures. Appl. Phys. Lett. 1986, 49, 13–15. [Google Scholar]

- Renversez, G.; Boyer, P.; Sagrini, A. Antiresonant reflecting optical waveguide microstructuredfibers revisited: A new analysis based on leaky mode coupling. Opt. Express 2006, 14, 5682–5687. [Google Scholar]

- Perrin, M.; Quiquempois, Y.; Bouwmans, G.; Douay, M. Coexistence of total internal reflexion and bandgap modes in solid core photonic bandgap fibre with intersticial air holes. Opt. Express 2007, 15, 13783–13795. [Google Scholar]

- Granzow, N.; Uebel, P.; Schmidt, M.A.; Tverjanovich, A.S.; Wondraczek, L.; Russell, P.S.J. Bandgap guidance in hybrid chalcogenide-silica photonic crystal fibers. Opt. Lett. 2011, 36, 2432–2434. [Google Scholar]

- Lezal, D.; Pedlikova, J.; Gurovic, J.; Vogt, R. The preparation of chalcogenide glasses in chlorine reactive atmosphere. Ceramics 1996, 40, 55–59. [Google Scholar]

- Toupin, P.; Brilland, L.; Trolès, J.; Adam, J.-L. Small core Ge-As-Se microstructured optical fiber with single-mode propagation and low optical losses. Opt. Mater. Express 2012, 2, 1359–1366. [Google Scholar]

- Coulombier, Q.; Brilland, L.; Houizot, P.; Chartier, T.; Nguyen, T.N.; Smektala, F.; Renversez, G.; Monteville, A.; Méchin, D.; Pain, T.; et al. Casting method for producing low-loss chalcogenide microstructured optical fibers. Opt. Express 2010, 18, 9107–9112. [Google Scholar]

- Kuhlmey, B.T.; White, T.P.; Renversez, G.; Maystre, D.; Botten, L.C.; Martijn de Sterke, C.; McPhedran, R.C. Multipole method for microstructured optical fibers. II. Implementation and results. J. Opt. Soc. Am. B Opt. Phys. 2002, 19, 2331–2340. [Google Scholar] [CrossRef]

- Brilland, L.; Troles, J.; Houizot, P.; Desevedavy, F.; Coulombier, Q.; Renversez, G.; Chartier, T.; Nguyen, T.N.; Adam, J.L.; Traynor, N. Interfaces impact on the transmission of chalcogenide photonic crystal fibres. J. Ceram. Soc. Jpn. 2008, 116, 1024–1027. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Caillaud, C.; Renversez, G.; Brilland, L.; Mechin, D.; Calvez, L.; Adam, J.-L.; Troles, J. Photonic Bandgap Propagation in All-Solid Chalcogenide Microstructured Optical Fibers. Materials 2014, 7, 6120-6129. https://doi.org/10.3390/ma7096120

Caillaud C, Renversez G, Brilland L, Mechin D, Calvez L, Adam J-L, Troles J. Photonic Bandgap Propagation in All-Solid Chalcogenide Microstructured Optical Fibers. Materials. 2014; 7(9):6120-6129. https://doi.org/10.3390/ma7096120

Chicago/Turabian StyleCaillaud, Celine, Gilles Renversez, Laurent Brilland, David Mechin, Laurent Calvez, Jean-Luc Adam, and Johann Troles. 2014. "Photonic Bandgap Propagation in All-Solid Chalcogenide Microstructured Optical Fibers" Materials 7, no. 9: 6120-6129. https://doi.org/10.3390/ma7096120