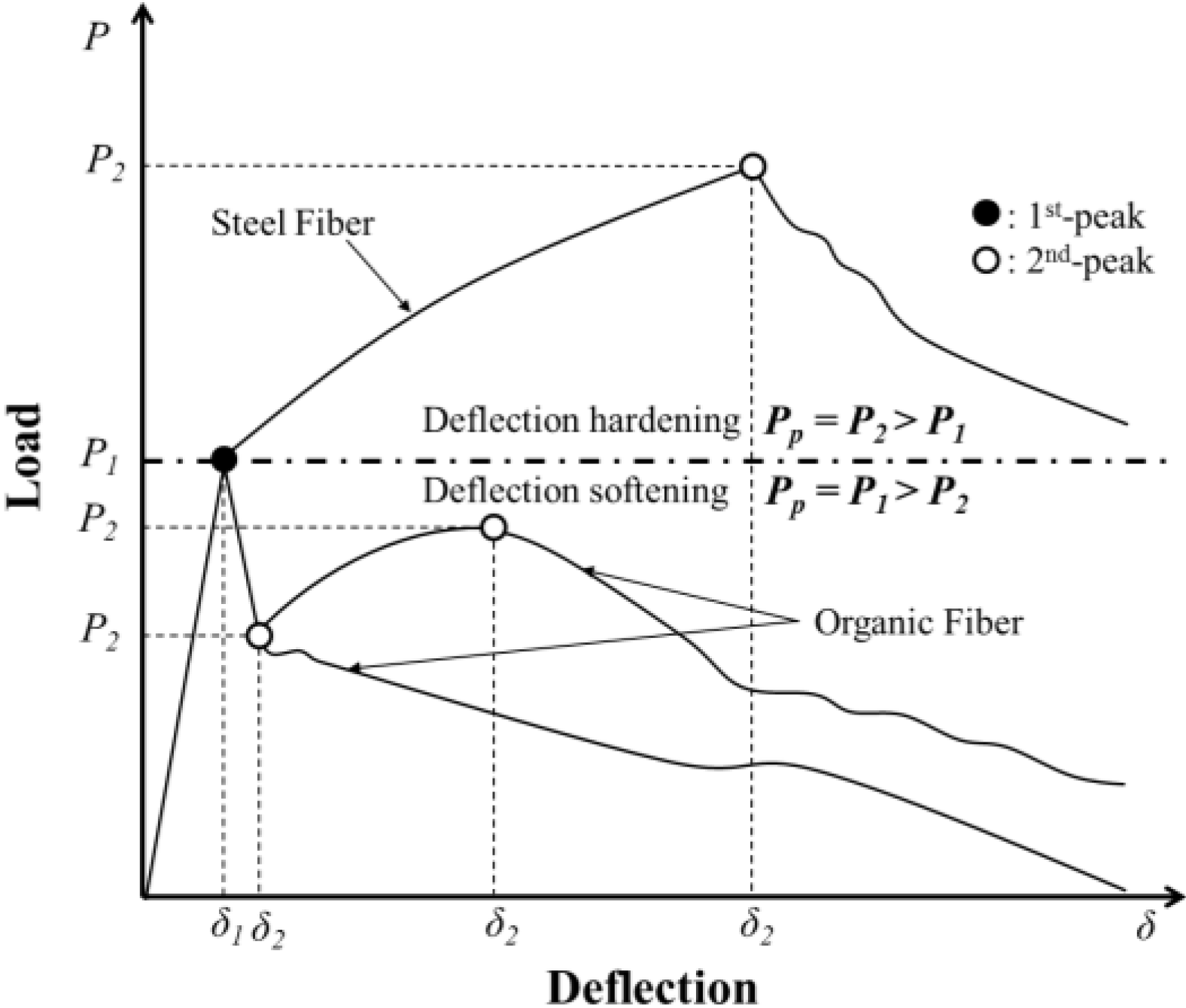

2.1. Macro PA Fiber Development and Processing

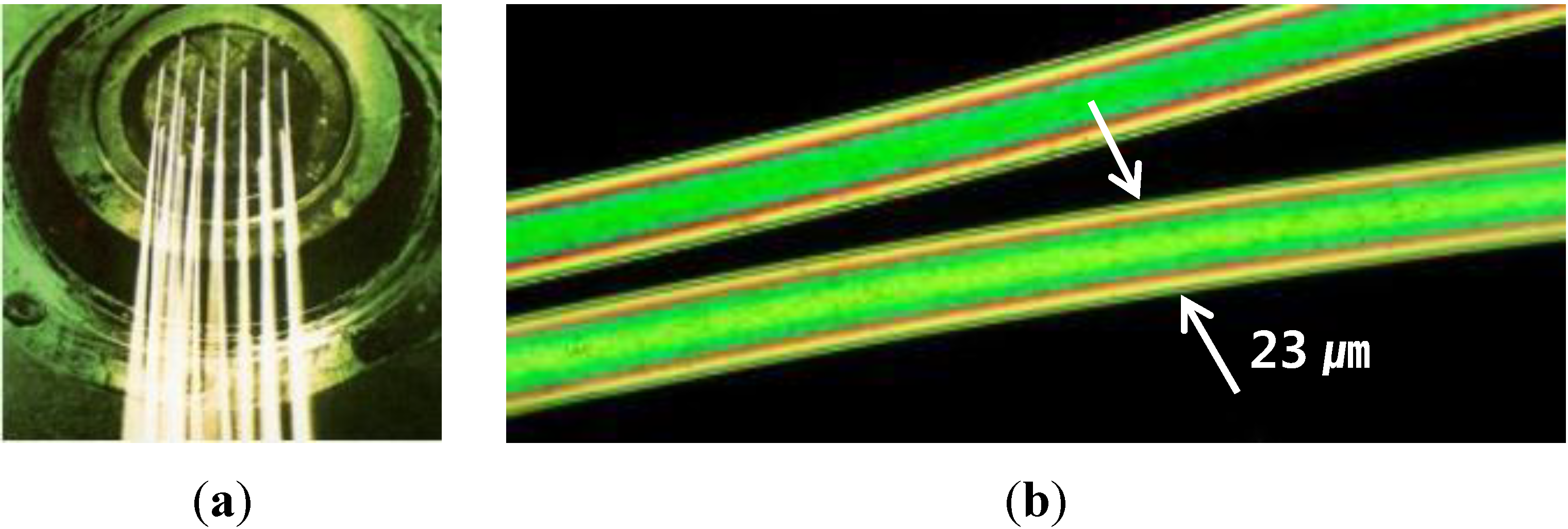

Polyamide (PA) fiber is one of the synthetic fibers commonly used in textiles. A micro-size polyamide fiber is presented in

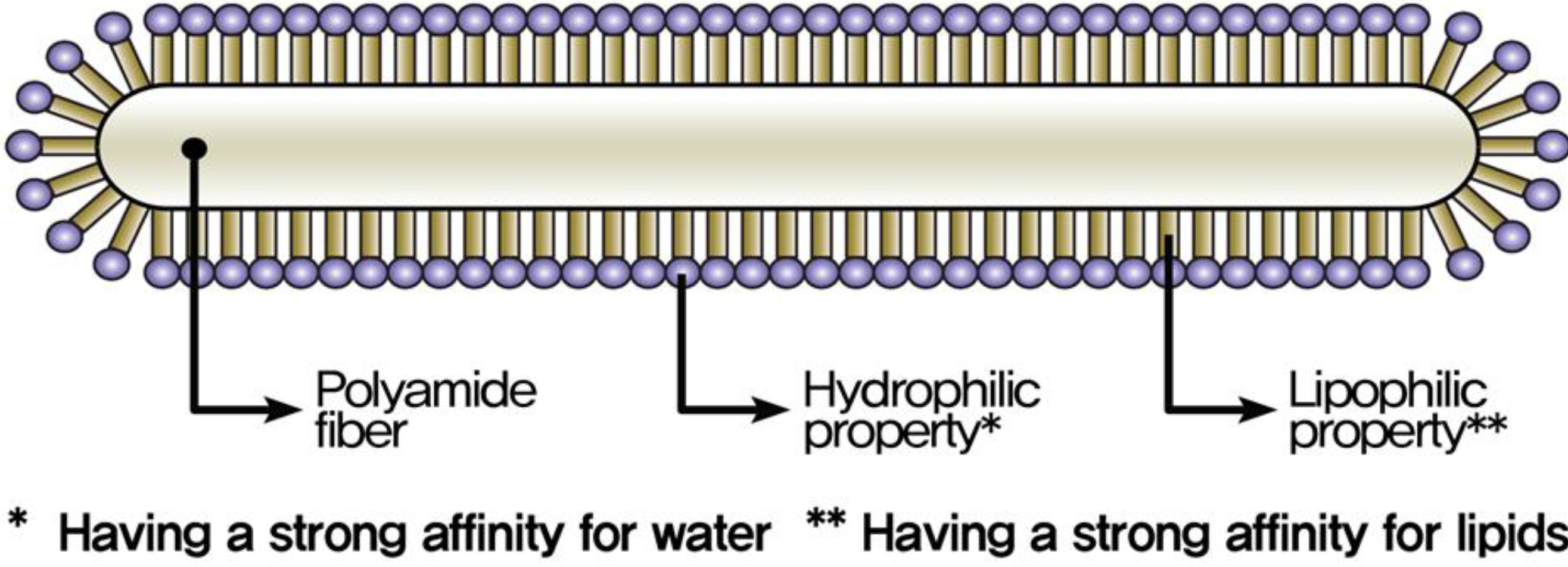

Figure 1. Polyamide fibers are produced through a shaped nozzle, and the thickness of the fiber is constant throughout its length. A dispersant is used during the production of PA filaments to prevent the fibers tangling, as shown in

Figure 2. The dispersant is composed of hydrophilic and lipophilic groups made of 40% to 50% polyalcohol ester lubricant, 30% to 40% nonionic surfactant solution and 10% to 30% anti-static agent. In concrete, the hydrophilic group, having a negative charge, causes repulsion between fibers, prevents the fibers tangling, and improves fiber dispersion. The hydrophilic group induces hydrogen bonding and leads to improved adhesion between the fibers and cement paste. Also, the dispersant coating during the filament production decreases fiber elongation and increases fiber strength.

Figure 1.

Picture of micro polyamide fibers. (a) Single polyamide fiber production; (b) magnification of single polyamide fiber.

Figure 1.

Picture of micro polyamide fibers. (a) Single polyamide fiber production; (b) magnification of single polyamide fiber.

Figure 2.

PA fiber (Diameter: 23 μm) with dispersant coating.

Figure 2.

PA fiber (Diameter: 23 μm) with dispersant coating.

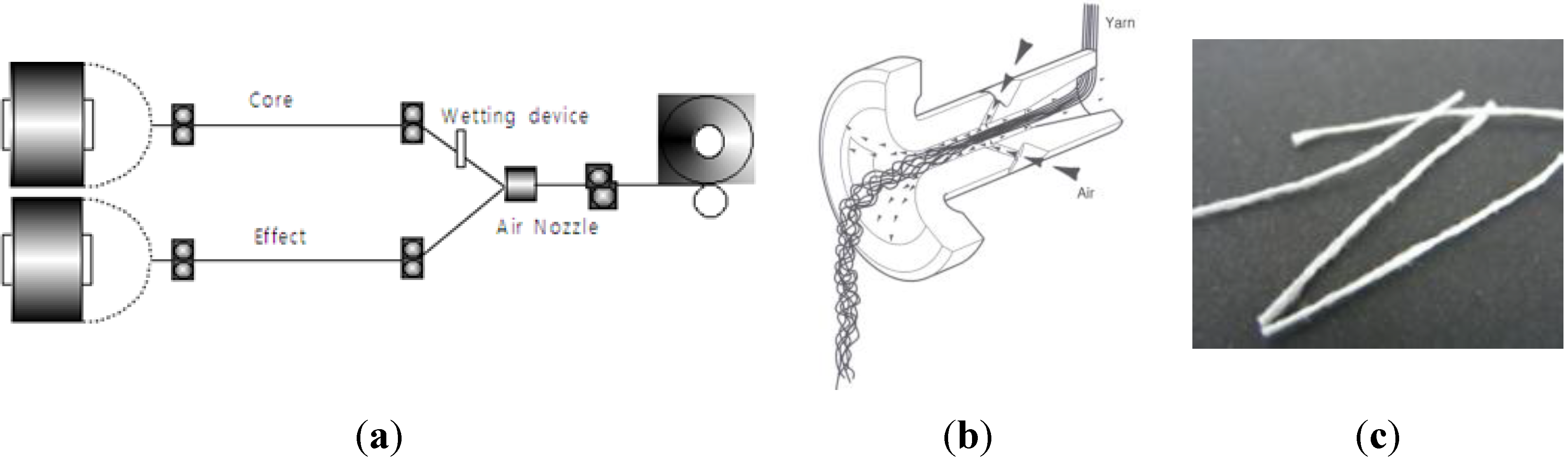

This study used a fiber fabrication method of air-textured yarn to develop bundled PA fibers in a macro size. In the production process two-polyamide filaments, one for the core yarn and one for the effect yarn (see

Figure 3a), are injected into the nozzle with oblique high-pressure air-flow (see

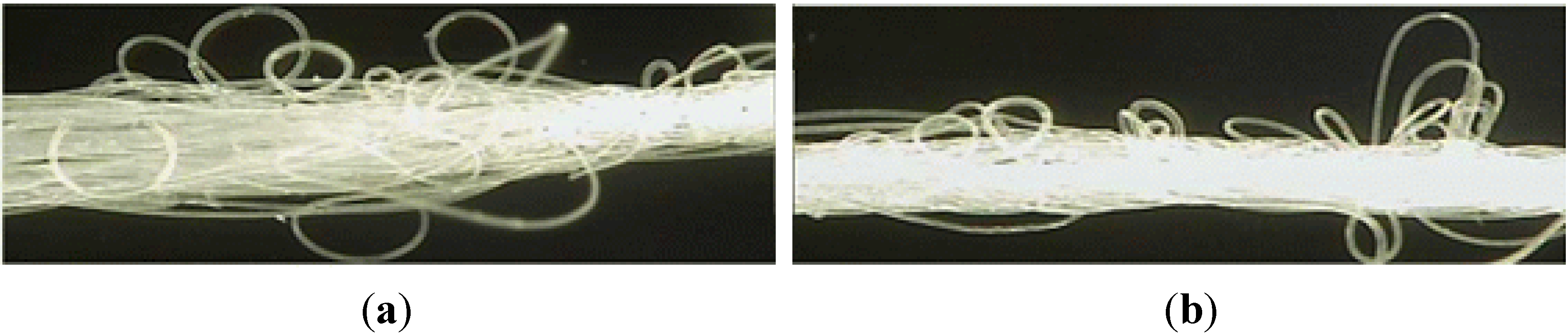

Figure 3b). The injection speed of the effect yarn is slower than the core yarn and a number of loops are subsequently formed due to the difference in injection air-flow speed. After passing the air nozzle, the effect yarn length is longer than the core yarn, and the fiber is then stabilized with a proper temperature treatment, preventing separation of the yarn. Polyamide fiber produced by the air textured yarn method is shown in

Figure 4. The loops and bulking of the textured yarn allows cement paste to pass through the yarn, and produces an increased surface area for contact between the cement paste and yarns, resulting in better adhesion. It is expected that this improved adhesion property will produce higher flexural responses compared to polypropylene (PP) fibers, which are mono-filaments.

Figure 3.

Production process of bundled PA fiber using air textured yarn. (a) Air texturing process; (b) air nozzle; (c) PA fiber (30 mm × 0.47 mm).

Figure 3.

Production process of bundled PA fiber using air textured yarn. (a) Air texturing process; (b) air nozzle; (c) PA fiber (30 mm × 0.47 mm).

Figure 4.

PA fiber processed by air textured yarn (Optical microscope ×8). (a) PA fiber before temperature treatment; (b) PA fiber after temperature treatment.

Figure 4.

PA fiber processed by air textured yarn (Optical microscope ×8). (a) PA fiber before temperature treatment; (b) PA fiber after temperature treatment.

The bundled PA fibers developed by this study have a larger fiber size and greater number of filaments compared to PP fibers and other organic fibers. To determine the number of PA filaments needed to fit the desired mechanical properties, this study tested and optimized the number of PA filaments at 1,800 Denier and 384 filaments of PA fiber. The mechanical properties of the PA fiber are tabulated in

Table 1 and compared to polypropylene (PP) fibers. For PP fibers, BarChip Macro produced by Elasto Plastic Concrete [

21], which is a synthetic fiber frequently used in Europe [

18], was selected.

Table 1.

Material properties of PA and PP fibers.

Table 1.

Material properties of PA and PP fibers.

| Fiber Type | Density (g/cm3) | Length (mm) | Diameter (mm) | Elastic Modulus (GPa) | Tensile Strength (MPa) |

|---|

| PA | 1.14 | 30 | 0.47 | Min. 3 | 650 |

| *PP | 0.9–0.92 | 42 | **Rec. | 8.2 | 550 |

2.2. Experimental Program for Pull-Out Test

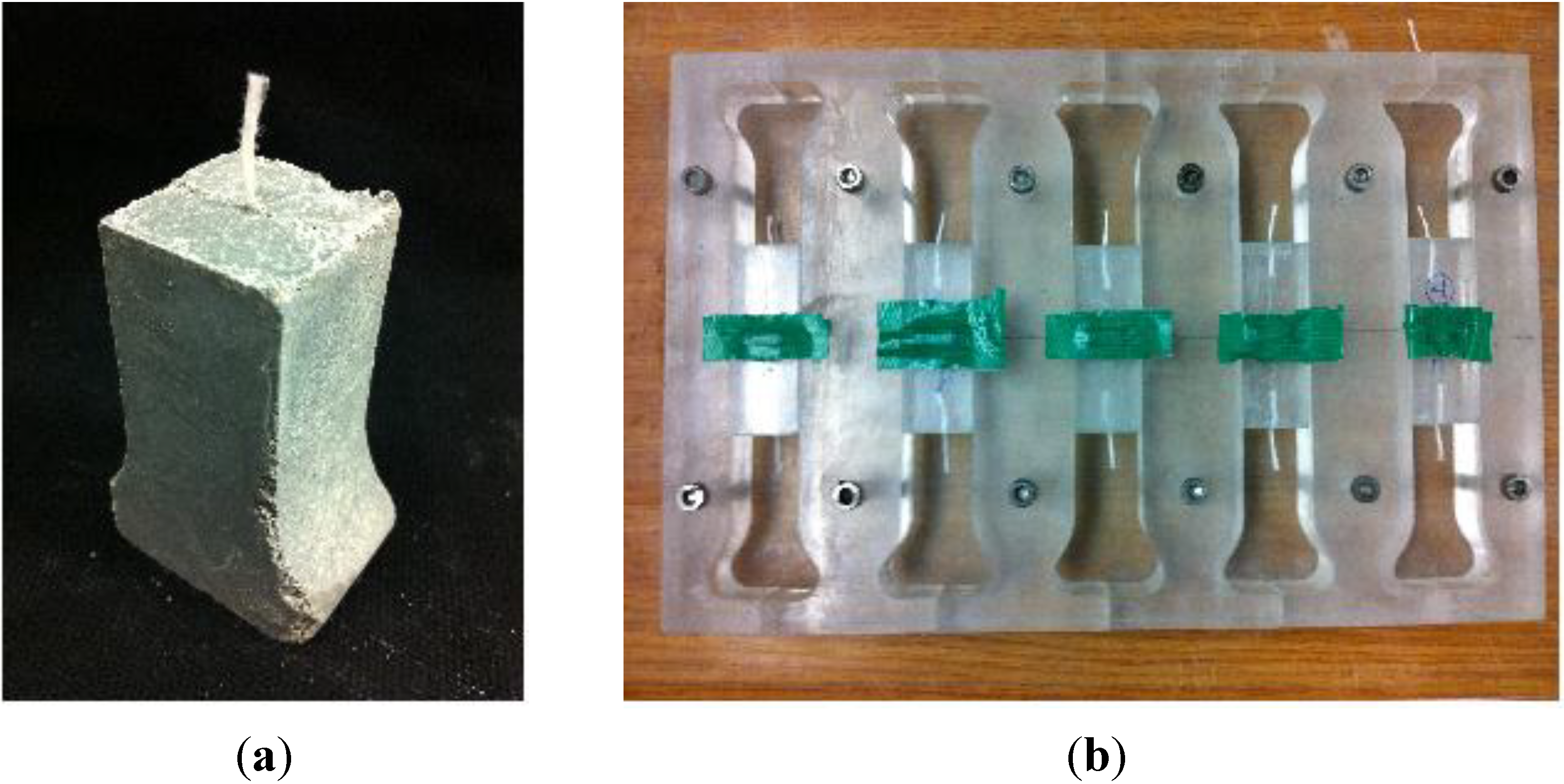

A pull-out test of a macro-size PA fiber was conducted to determine the fiber-to-matrix bond behavior, as shown in

Figure 5. The bundled PA fibers have a larger specific surface area, which accommodates attachment to cement, compared to PP fibers and other fiber reinforcements. The PA fibers used in the test had Ф0.47 mm and the length of the fiber embedded in the matrix (25 × 25 mm) was 15 mm (half of the total PA fiber length). A total of four specimens were prepared for the test. Similar to the method used in previous research [

22], the pull-out load was directly measured from the load cell in the cross head, and the displacement or slip of the PA fiber was measured using a linear variable differential transformer (LVDT).

Figure 5.

Pictures of pull-out test specimen and mold. (a) Pull-out test specimen; (b) pull-out test mold.

Figure 5.

Pictures of pull-out test specimen and mold. (a) Pull-out test specimen; (b) pull-out test mold.

The weight ratios of cement matrix used in the pull-out test were 0.628, 1.0, 0.25, 2.3, 0.00089 and 0.0079 for water, ordinary portland cement (OPC), fly ash, sand, air-entraining agents (AEA) and water-reducing admixture (WRA). The compressive strength of the specimen on the 28th day was 58.09 MPa. In the cement matrix, only fine aggregates with AEA were used with OPC. An appropriate amount of WRA was used to meet the target slump of 120 ± 25 mm, which is standard for tunnel shotcrete. The mixture was mixed with PA fibers and placed in a mold for three days. After demolding, the specimens were cured at room temperature. All specimens were tested on the 28th day.

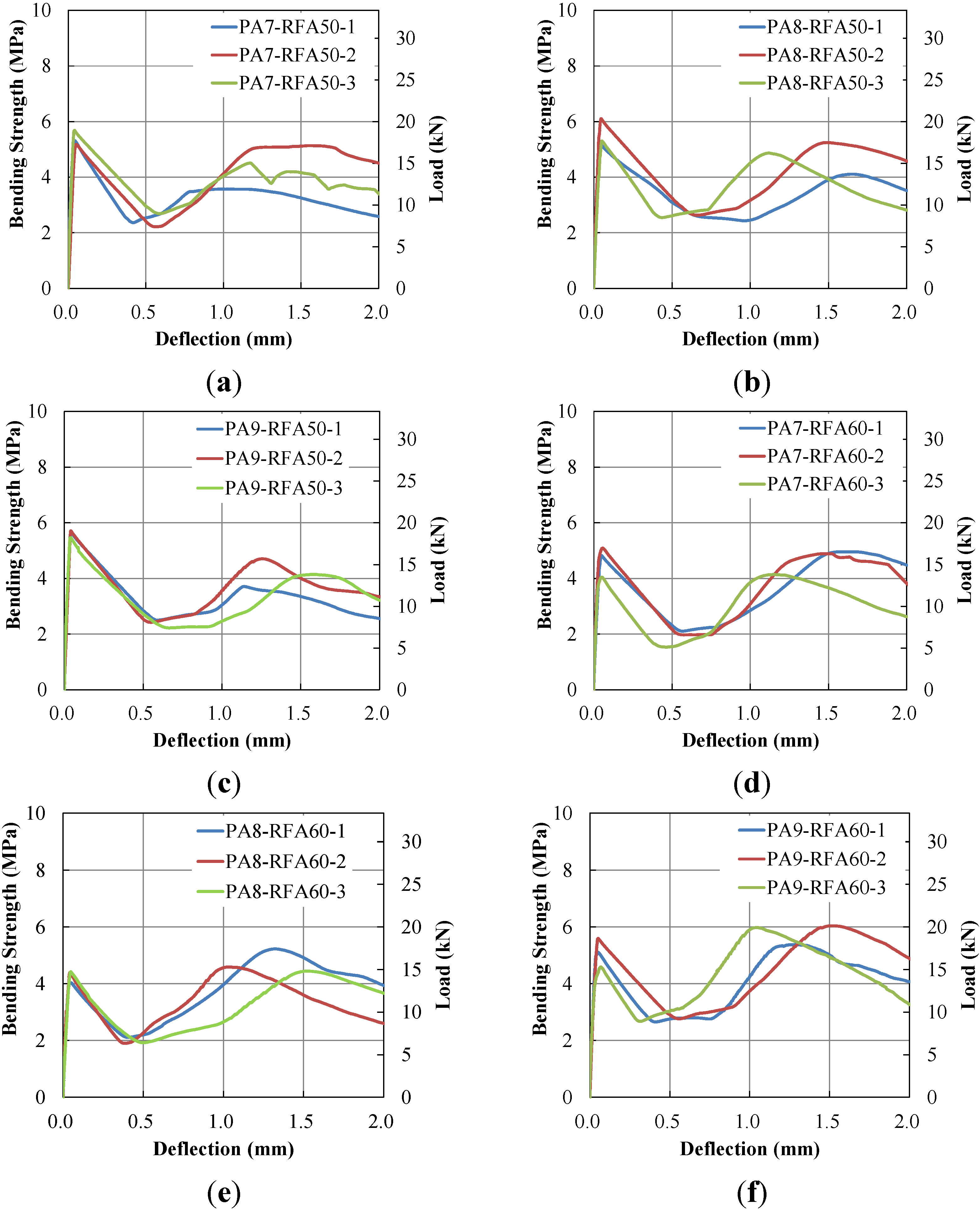

2.3. Experimental Program for Flexural Bending Test

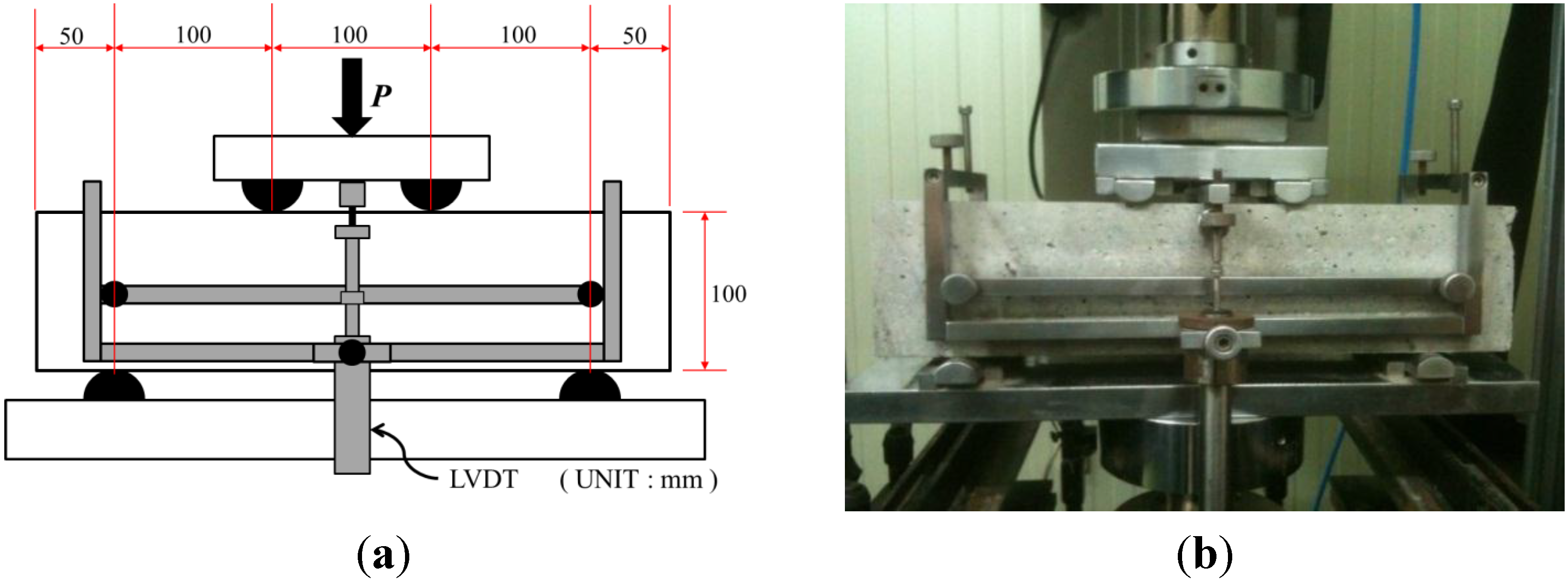

The schematic and picture of the flexural test set-up are presented in

Figure 6. An INSTRON 5582 testing machine (DatapointLabs, Ithaca, NY, USA) was used in a laboratory for this flexural test. The rate of deflection was controlled to 0.1 mm/min after

L/900 (=0.333 mm) with the sampling rate of 16 Hz (≥2.5 Hz). The boundary conditions follow ASTM Testing Method C78 [

23], which allows supporting rollers rotating on their axes. The beam specimen size of 100 × 100 × 400 mm with a span length (

L) of 300 mm was determined in accordance with ASTM C1609/C 1609M-05 [

20]. The specimen was built with dimensions of 150 × 150 × 550 mm and then cut into the size 100 × 100 × 400 mm (

L = 300 mm) to prevent the fiber aligning parallel to the direction of the beam length, and to place the fiber randomly. A steel frame was attached at the neutral axis of the beam specimen to measure the net deflection of the beam using two LVDTs at both sides. (Only one LVDT is shown in

Figure 6 and the other one is located at the other side of the beam.) Applied load (P) was measured directly from the load cell in the crosshead.

Figure 6.

Bending specimen geometry and test set-up. (a) Specimen geometry; (b) Test set-up picture.

Figure 6.

Bending specimen geometry and test set-up. (a) Specimen geometry; (b) Test set-up picture.

The specimens were prepared in a laboratory. The concrete mix design used in this study is summarized in

Table 2. The maximum gravel size (

Gmax) was controlled to be 10 mm, the ratio of sand to aggregate (

S/

a) was fixed at 60% for all specimens. Ordinary Portland cement (OPC) was 480 to 482 kg/m

3. An appropriate amount of water-reducing admixture (AD) was used to meet the target slump of 120 ± 25 mm, which was determined for tunnel shotcrete usage. The mixture was then mixed with PA fibers and placed in a mold for three days. After demolding, the specimens were cured at room temperature to represent PAFRC used in tunnel shotcrete. All specimens were tested on the 28th day. The 28-day compressive strength of the PAFRC was measured based on Ф100 × 200 mm cylindrical specimens. The slump and compressive strength of the specimens are presented in

Table 3.

Table 2.

Concrete mix proportions.

Table 2.

Concrete mix proportions.

| Specimen | Gmax (mm) | W/C (%) | S/a (%) | Unit Weight (kg/m3) | WRA (C%) |

|---|

| W | OPC | S | CS | G | Fiber |

|---|

| PA7-RFA50 * | 10 | 43.1 | 60 | 207 | 480 | 480 | 484 | 640 | 7.0 | 0.7 |

| PA8-RFA50 * | 10 | 43.1 | 60 | 207 | 480 | 480 | 484 | 640 | 8.0 | 0.8 |

| PA9-RFA50 * | 10 | 43.1 | 60 | 207 | 480 | 480 | 484 | 640 | 9.0 | 0.9 |

| PA7-RFA60 * | 10 | 43.8 | 60 | 211 | 482 | 381 | 576 | 635 | 7.0 | 0.8 |

| PA8-RFA60 * | 10 | 43.8 | 60 | 211 | 482 | 381 | 576 | 635 | 8.0 | 0.9 |

| PA9-RFA60 * | 10 | 43.8 | 60 | 211 | 482 | 381 | 576 | 635 | 9.0 | 1.0 |

| PA10-RFA60 * | 10 | 43.8 | 60 | 211 | 482 | 381 | 576 | 635 | 10.0 | 1.1 |

Table 3.

PAFRC slump and compressive strength.

Table 3.

PAFRC slump and compressive strength.

| Specimen | Slump (mm) | 28-day Compressive strength (MPa) |

|---|

| SP-1 | SP-2 | SP-3 | Avg. |

|---|

| PA7-RFA50 | 120 | 51.0 | 49.8 | 50.5 | 50.4 |

| PA8-RFA50 | 115 | 51.5 | 50.2 | 51.8 | 51.0 |

| PA9-RFA50 | 120 | 52.8 | 51.5 | 53.1 | 52.5 |

| PA7-RFA60 | 115 | 47.5 | 49.6 | 49.5 | 48.9 |

| PA8-RFA60 | 110 | 50.4 | 51.1 | 48.0 | 49.8 |

| PA9-RFA60 | 120 | 49.7 | 48.9 | 51.4 | 50.0 |

| PA10-RFA60 | 110 | 49.1 | 52.0 | 47.5 | 49.5 |