Suppression of 3C-Inclusion Formation during Growth of 4H-SiC Si-Face Homoepitaxial Layers with a 1° Off-Angle

Abstract

:1. Introduction

2. Results and Discussion

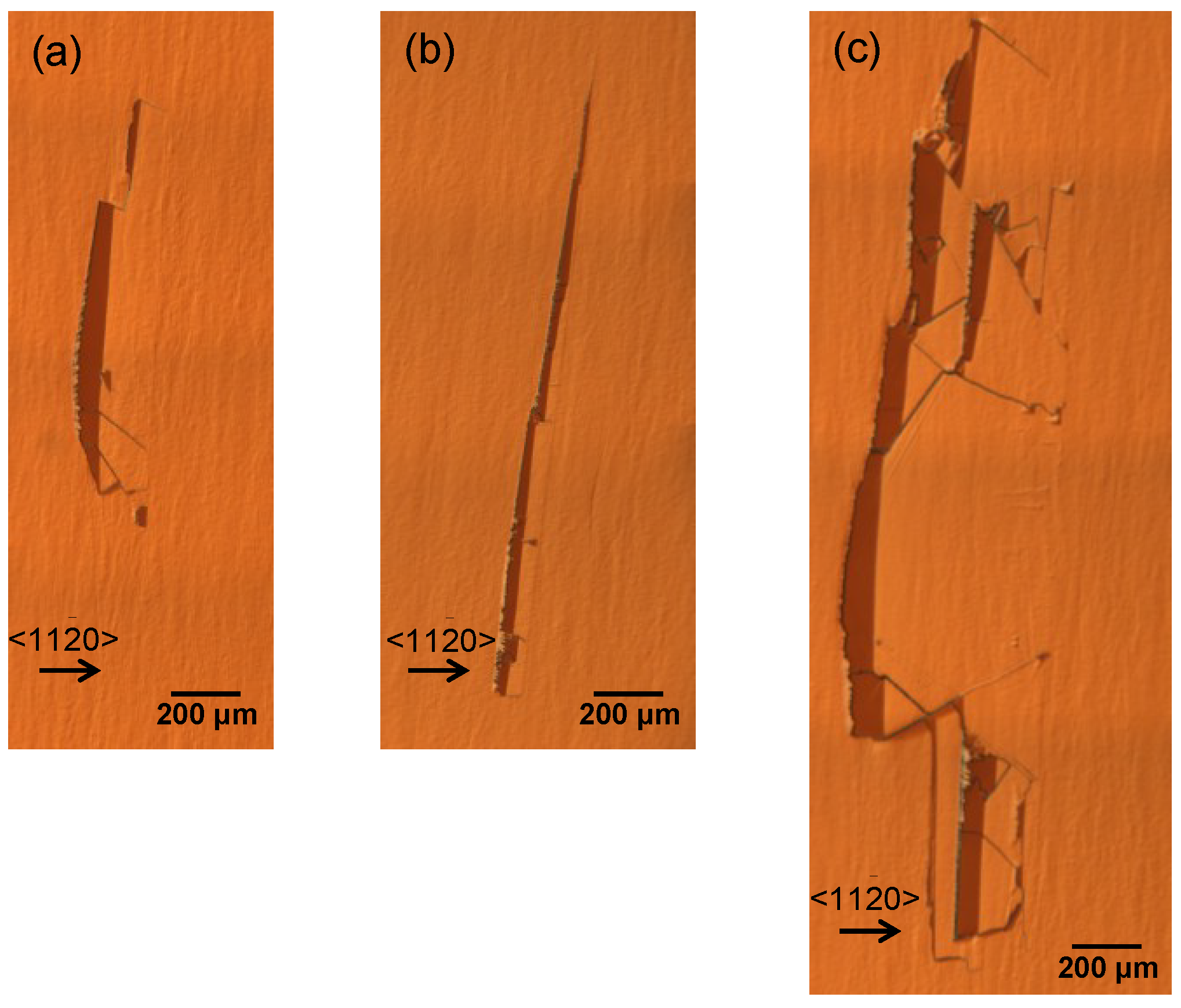

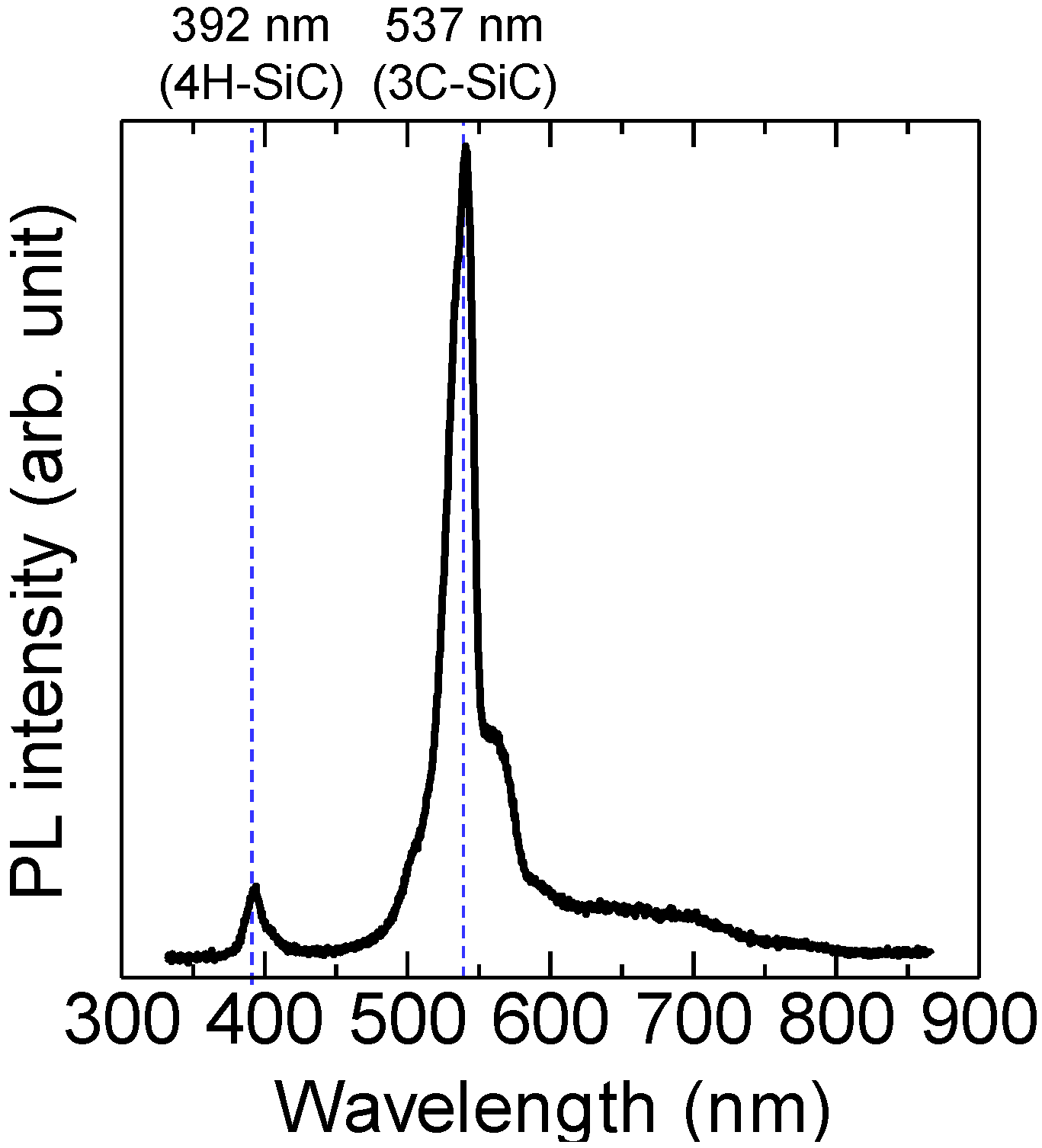

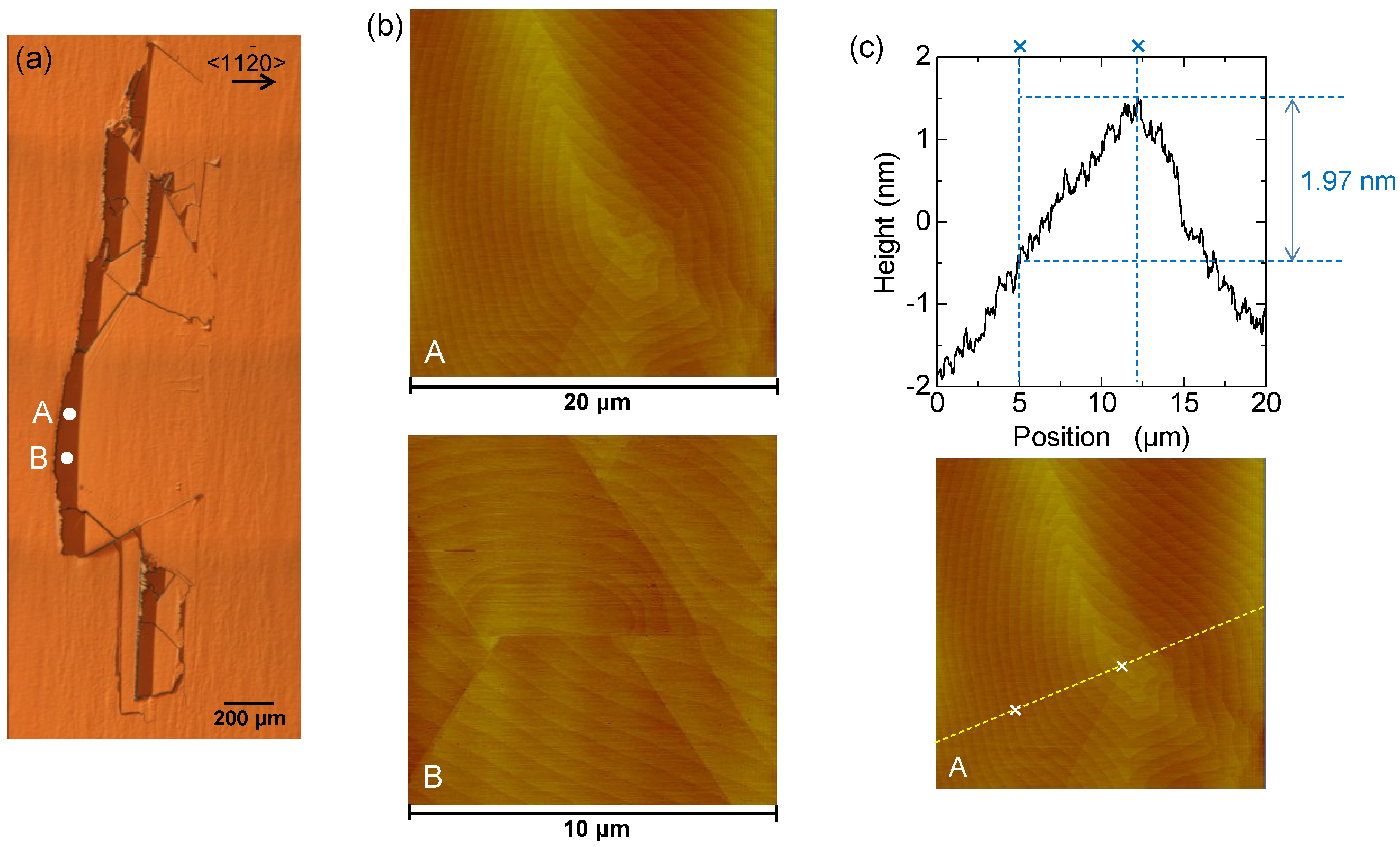

2.1. Defects Generated in 4H-SiC Si-Face Epitaxial Layers with a 1° Off-Angle

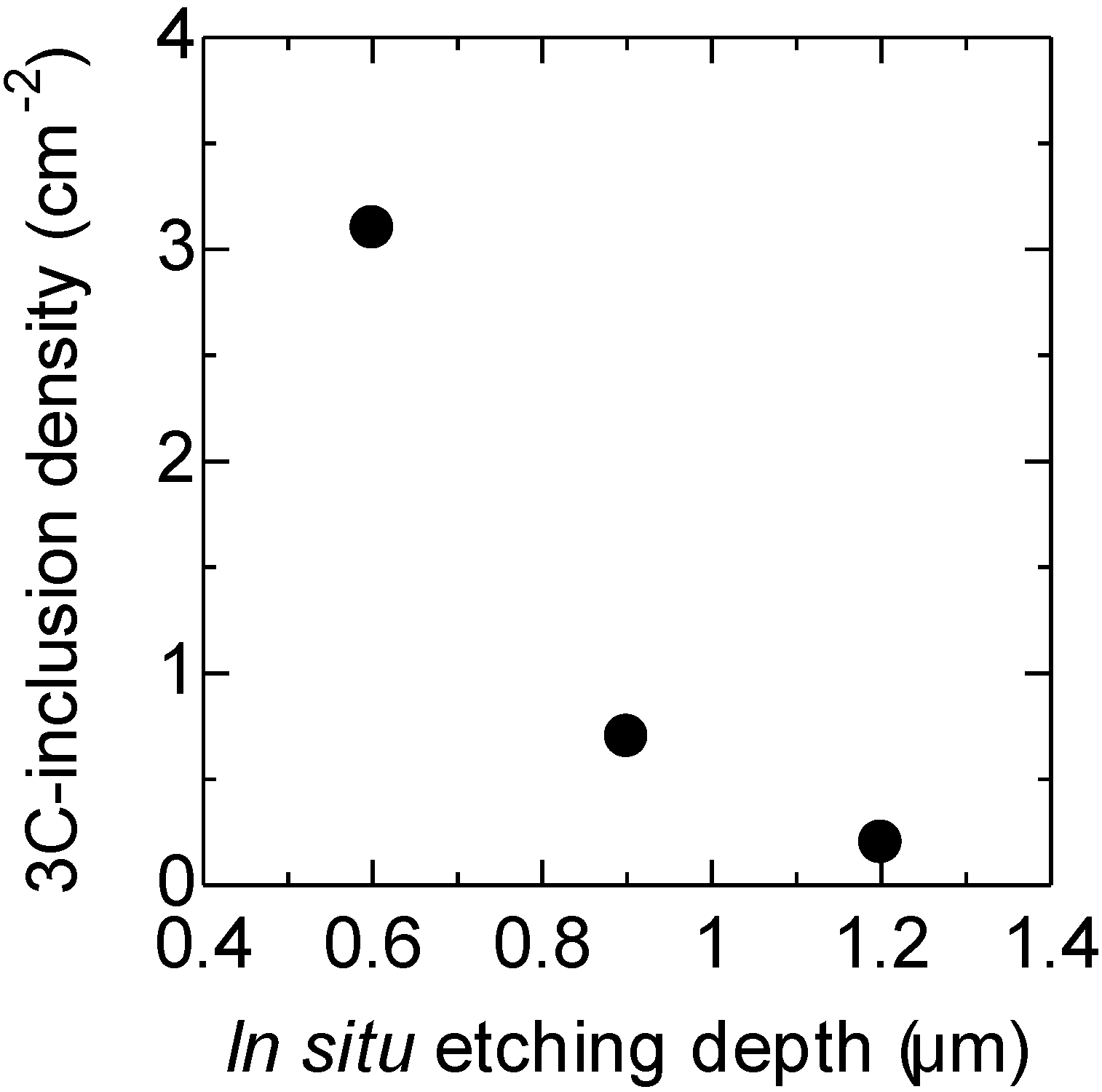

2.2. Suppression of 3C Inclusions

2.3. Post-Processing for 4H-SiC Si-Face Epitaxial Layers with a 1° Off-Angle

3. Experimental Section

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Feng, G.; Suda, J.; Kimoto, T. Characterization of major in-grown stacking faults in 4H-SiC epilayers. Physica B 2009, 404, 4745–4748. [Google Scholar] [CrossRef]

- Kimoto, T.; Matsunami, H. Surface kinetics of adatoms in vapor phase epitaxial growth of SiC on 6H SiC{0001} vicinal surfaces. J. Appl. Phys. 1994, 75, 850–859. [Google Scholar] [CrossRef]

- Kimoto, T.; Itoh, A.; Matsunami, H. Step-Controlled epitaxial growth of high-quality SiC layers. Phys. Stat. Sol. B 1997, 202, 247–261. [Google Scholar] [CrossRef]

- Tamura, K.; Kudou, C.; Masumoto, K.; Nishio, J.; Kojima, K. Homo-epitaxial growth on 2° off-cut 4H-SiC(0001) Si-face substrates using H2-SiH4-C3H8 CVD system. Mater. Sci. Forum 2014, 778–780, 214–217. [Google Scholar] [CrossRef]

- Kojima, K.; Masumoto, K.; Ito, S.; Nagata, A.; Okumura, H. 4H-SiC homoepitaxial growth on substrate with vicinal off-angle lower than 1°. ECS J. Sol. State Sci. Tech. 2013, 2, N3012–N3017. [Google Scholar] [CrossRef]

- Masumoto, K.; Kojima, K.; Okumura, H. The growth of 3-inch 4H-SiC Si-face epitaxial wafer with vicinal off-angle. Mater. Sci. Forum 2013, 740–742, 193–196. [Google Scholar] [CrossRef]

- Harada, S.; Ito, S.; Kato, M.; Takatsuka, A.; Kojima, K.; Fukuda, K.; Okumura, H. Isotropic channel mobility in UMOSFETs on 4H-SiC C-face with vicinal off-angle. Mater. Sci. Forum 2010, 645–648, 999–1004. [Google Scholar] [CrossRef]

- Masumoto, K.; Ito, S.; Goto, H.; Yamaguchi, H.; Tamura, K.; Kudou, C.; Nishio, J.; Kojima, K.; Ohno, T.; Okumura, H. Conversion of basal plane dislocations to threading edge dislocations in growth of epitaxial layers on 4H-SiC substrates with a vicinal off-angle. Mater. Sci. Forum 2014, 778–780, 99–102. [Google Scholar] [CrossRef]

- Kosciewicz, K.; Strupinski, W.; Teklinska, D.; Mazur, K.; Tokarczyk, M.; Kowalski, G.; Olszyna, A. Epitaxial growth on 4H-SiC on axis, 0.5°, 1.25°, 2°, 4°, 8° off-axis substrates-defects analysis and reduction. Mater. Sci. Forum 2011, 679–680, 95–98. [Google Scholar] [CrossRef]

- Skowronski, M.; Ha, S. Degradation of hexagonal silicon-carbide-based bipolar devices. J. Appl. Phys. 2006, 99, 011101:1–011101:24. [Google Scholar] [CrossRef]

- Ohno, T.; Yamaguchi, H.; Kuroda, S.; Kojima, K.; Suzuki, T.; Arai, K. Influence of growth conditions on basal plane dislocation in 4H-SiC epitaxial layer. J. Cryst. Growth 2004, 271, 1–7. [Google Scholar] [CrossRef]

- Burk, A.A.; Tsvetkov, D.; Barnhardt, D.; O’Loughlin, M.J.; Garrett, L.; Towner, P.; Seaman, J.; Deyneka, E.; Khlebnikov, Y.; Palmour, J.W. SiC epitaxial layer growth in a 6 × 150 mm warm-wall planetary reactor. Mater. Sci. Forum 2012, 717–720, 75–80. [Google Scholar] [CrossRef]

- Miyasaka, A.; Norimatsu, J.; Fukada, K.; Tajima, Y.; Muto, D.; Kimura, Y.; Odawara, M.; Okano, T.; Momose, K.; Osawa, Y.; et al. Step-bunching free and 30 μm-thick SiC epitaxial layer growth on 150 mm SiC substrate. Mater. Sci. Forum 2013, 740–742, 197–200. [Google Scholar] [CrossRef]

- Masumoto, K.; Kudou, C.; Tamura, K.; Nishio, J.; Ito, S.; Kojima, K.; Ohno, T.; Okumura, H. Growth of silicon carbide epitaxial layers on 150-mm-diameter wafers using a hot-wall chemical vapor deposition. J. Cryst. Growth 2013, 381, 139–143. [Google Scholar] [CrossRef]

- Larkin, D.J. SiC dopant incorporation control using site-competition CVD. Phys. Stat. Sol. B 1997, 202, 305–320. [Google Scholar] [CrossRef]

- Mahadik, N.A.; Stahlbush, R.E.; Qadri, S.B.; Glembocki, O.J.; Alexson, D.A.; Hobart, K.D.; Caldwell, J.D.; Myers-Ward, R.L.; Tedesco, J.L.; Eddy, C.R., Jr.; et al. Structure and morphology of inclusions in 4° offcut 4H-SiC epitaxial layers. J. Electron. Mater. 2011, 40, 413–418. [Google Scholar] [CrossRef]

- Hassan, J.; Bergman, J.P.; Palisaitis, J.; Henry, A.; McNally, P.J.; Anderson, S.; Janzen, E. Growth and properties of SiC on-axis homoepitaxial layers. Mater. Sci. Forum 2010, 645–648, 83–88. [Google Scholar] [CrossRef]

- Powell, J.A.; Petit, J.B.; Edgar, J.H.; Jenkins, I.G.; Matus, L.G.; Yang, J.W.; Pirouz, P.; Choyke, W.J.; Clemen, L.; Yoganathan, M. Controlled growth of 3CSiC and 6HSiC films on lowtiltangle vicinal (0001) 6HSiC wafers. Appl. Phys. Lett. 1991, 59, 333–335. [Google Scholar] [CrossRef]

- Nakamura, S.; Kimoto, T.; Matsunami, H. Homoepitaxy of 6H-SiC on nearly on-axis (0001) faces by chemical vapor deposition Part I: Effect of C/Si ratio on wide-area homoepitaxy without 3C-SiC inclusions. J. Cryst. Growth 2003, 256, 341–346. [Google Scholar] [CrossRef]

- Ishida, Y.; Takahashi, T.; Okumura, H.; Arai, K.; Yoshida, S. Origin of giant step bunching on 4H-SiC (0001) surfaces. Mater. Sci. Forum 2009, 600–603, 473–476. [Google Scholar] [CrossRef]

- Kimoto, T.; Matsunami, H. Surface diffusion lengths of adatoms on 6HSiC{0001} faces in chemical vapor deposition of SiC. J. Appl. Phys. 1995, 78, 3132–3137. [Google Scholar] [CrossRef]

- Tairov, Y.M.; Tsvetkov, V.F. Progress in controlling the growth of polytypic crystals. Prog. Cryst. Growth Charact. 1983, 7, 111–162. [Google Scholar] [CrossRef]

- Yakimova, R.; Vasiliauskas, R.; Eriksson, J.; Syvajarvi, M. Progress in 3C-SiC growth and novel applications. Mater. Sci. Forum 2012, 711, 3–10. [Google Scholar] [CrossRef]

- Bishop, S.M.; Reynolds, C.L.; Liliental-Weber, Z.; Uprety, Y.; Zhu, J.; Wang, D.; Park, M.; Molstad, J.C.; Barnhardt, D.E.; Shrivastava, A.; et al. Polytype stability and microstructural characterization of silicon carbide epitaxial films grown on - and [0001]-oriented silicon carbide substrates. J. Electron. Mater. 2007, 36, 285–296. [Google Scholar] [CrossRef]

- Bishop, S.M.; Reynolds, C.L., Jr.; Liliental-Weber, Z.; Uprety, Y.; Ebert, C.W.; Stevie, F.A.; Park, J.S.; Davis, R.F. Sublimation growth of an in-situ-deposited layer in SiC chemical vapor deposition on 4H-SiC. J. Cryst. Growth 2008, 311, 72–78. [Google Scholar] [CrossRef]

- Yamada, K.; Ishiyama, O.; Tamura, K.; Yamashita, T.; Shimozato, A.; Kato, T.; Senzaki, J.; Matsuhata, H.; Kitabatake, M. Reliability of gate oxides on 4H-SiC epitaxial surface planarized by CMP treatment. Mater. Sci. Forum 2014, 778–780, 545–548. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masumoto, K.; Asamizu, H.; Tamura, K.; Kudou, C.; Nishio, J.; Kojima, K.; Ohno, T.; Okumura, H. Suppression of 3C-Inclusion Formation during Growth of 4H-SiC Si-Face Homoepitaxial Layers with a 1° Off-Angle. Materials 2014, 7, 7010-7021. https://doi.org/10.3390/ma7107010

Masumoto K, Asamizu H, Tamura K, Kudou C, Nishio J, Kojima K, Ohno T, Okumura H. Suppression of 3C-Inclusion Formation during Growth of 4H-SiC Si-Face Homoepitaxial Layers with a 1° Off-Angle. Materials. 2014; 7(10):7010-7021. https://doi.org/10.3390/ma7107010

Chicago/Turabian StyleMasumoto, Keiko, Hirokuni Asamizu, Kentaro Tamura, Chiaki Kudou, Johji Nishio, Kazutoshi Kojima, Toshiyuki Ohno, and Hajime Okumura. 2014. "Suppression of 3C-Inclusion Formation during Growth of 4H-SiC Si-Face Homoepitaxial Layers with a 1° Off-Angle" Materials 7, no. 10: 7010-7021. https://doi.org/10.3390/ma7107010