Self-Healing of Microcracks in Engineered Cementitious Composites (ECC) Under a Natural Environment

Abstract

:1. Introduction

2. Experimental Investigation

2.1. Mix Proportion and Raw Materials

| Component | Cement | Fly Ash | Sand | Water | HRWRA a | Fiber |

|---|---|---|---|---|---|---|

| Weight Fraction | 1 | 2.2 | 1.16 | 0.85 | 0.01 | 0.067 |

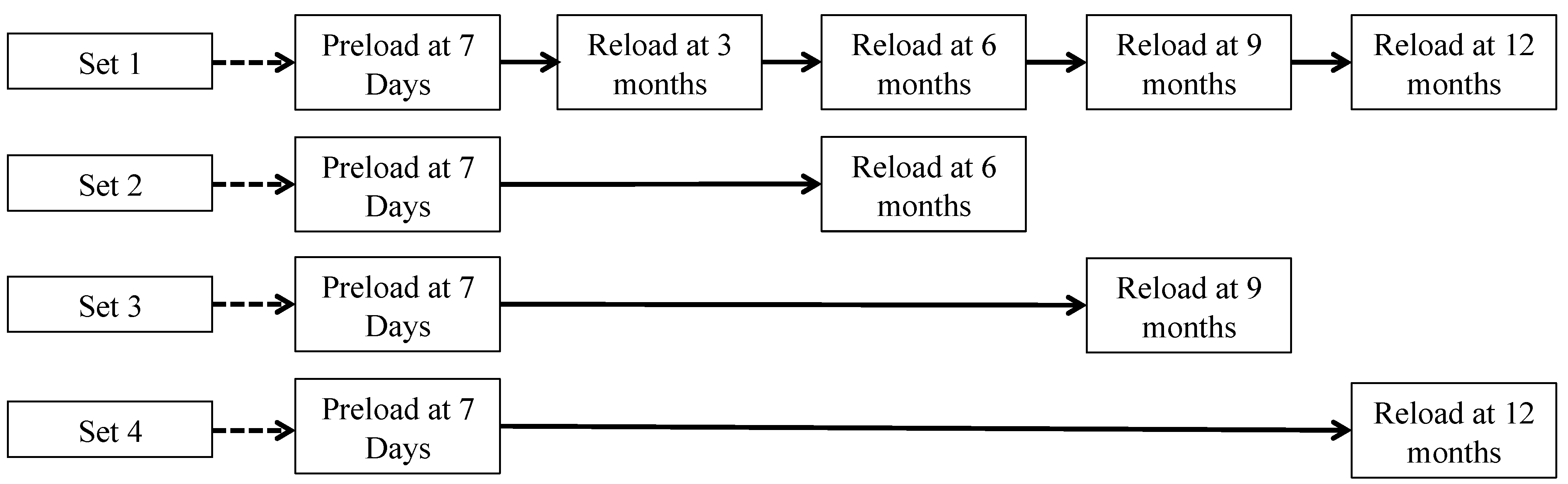

2.2. Specimen Preparation and Preloading

2.3. Natural Environment Exposure

2.4. Self-Healing Evaluation Methods

2.4.1. Resonant Frequency (RF)

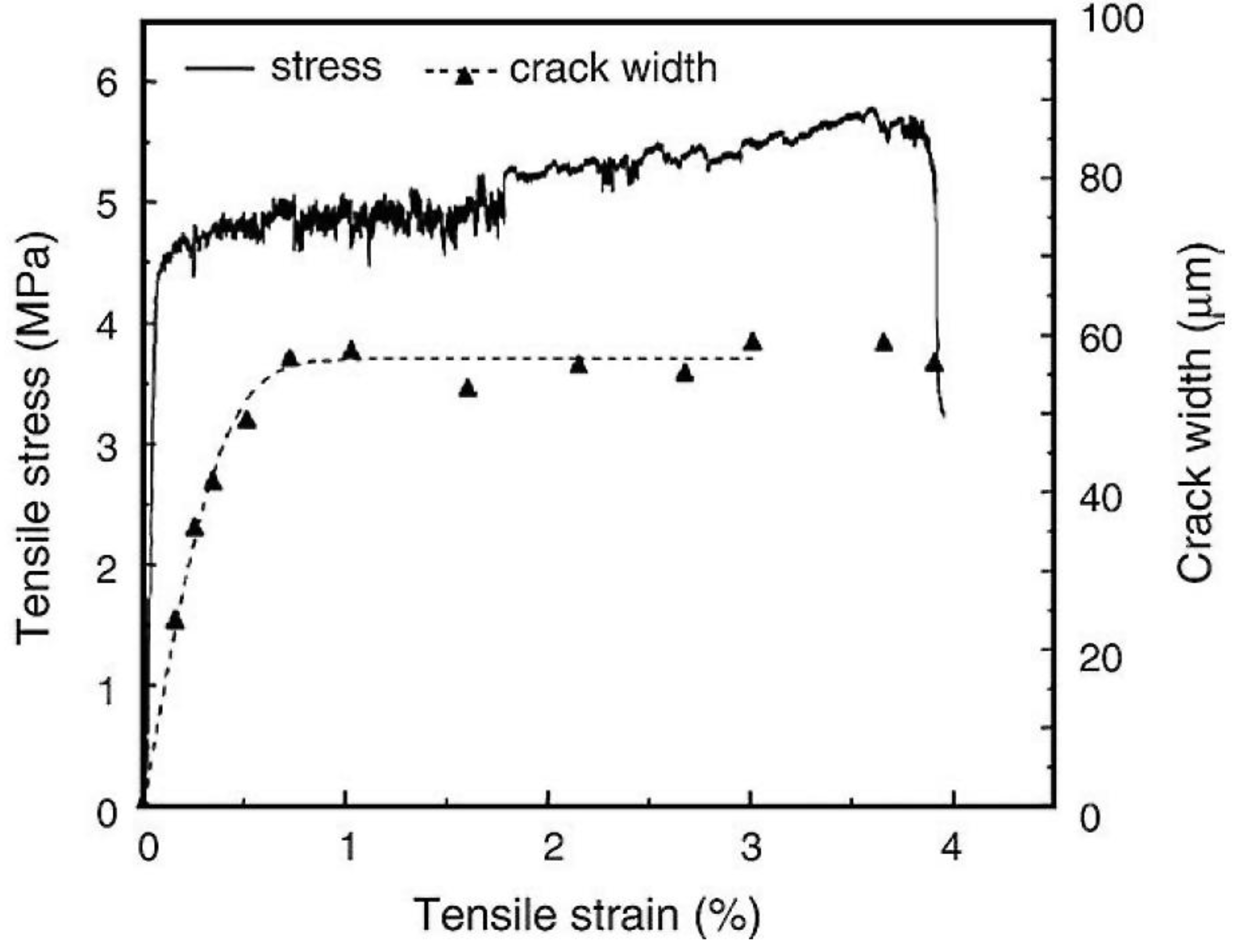

2.4.2. Uniaxial Tensile Test (Reloading)

3. Experimental Results and Discussion

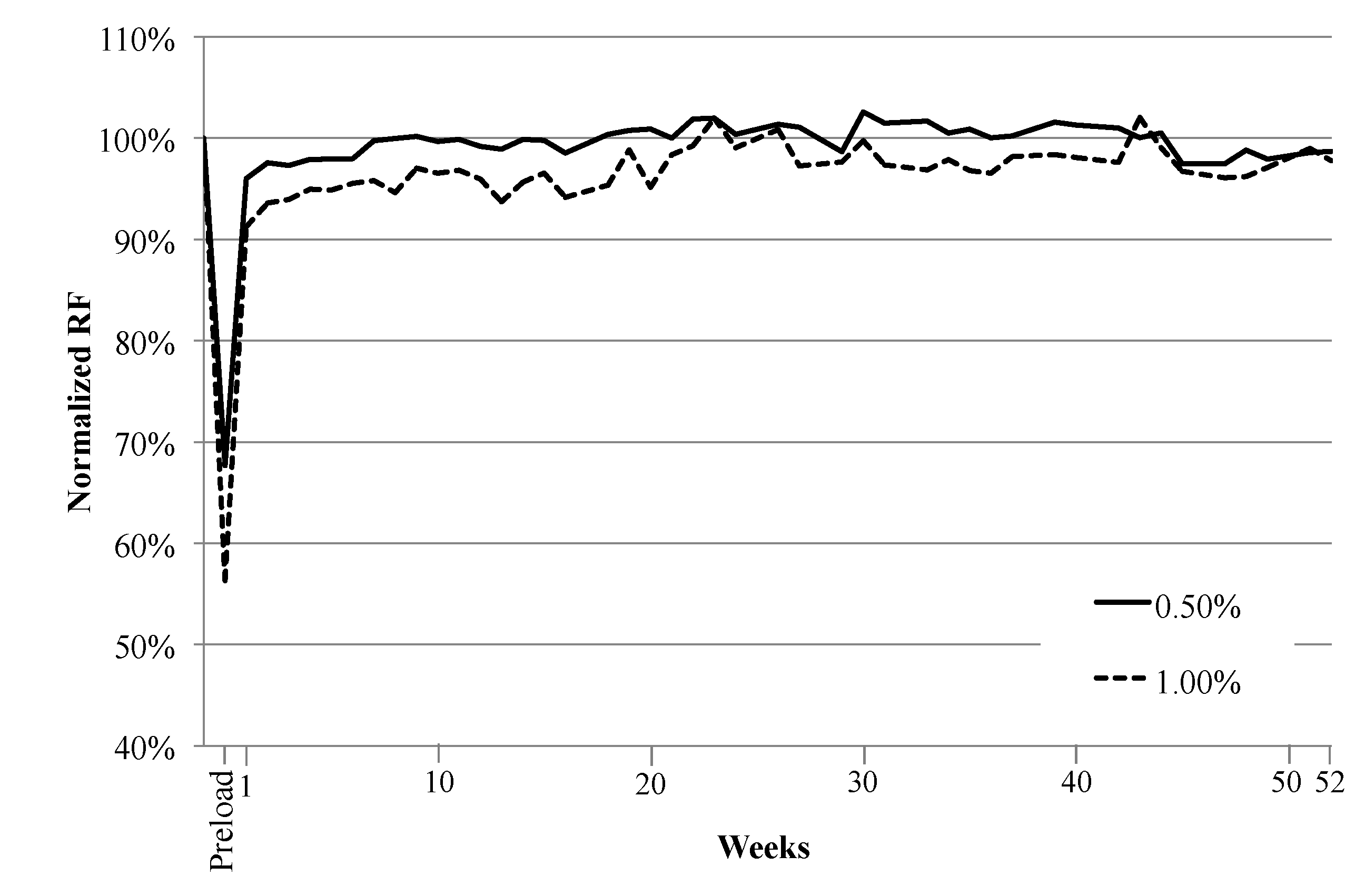

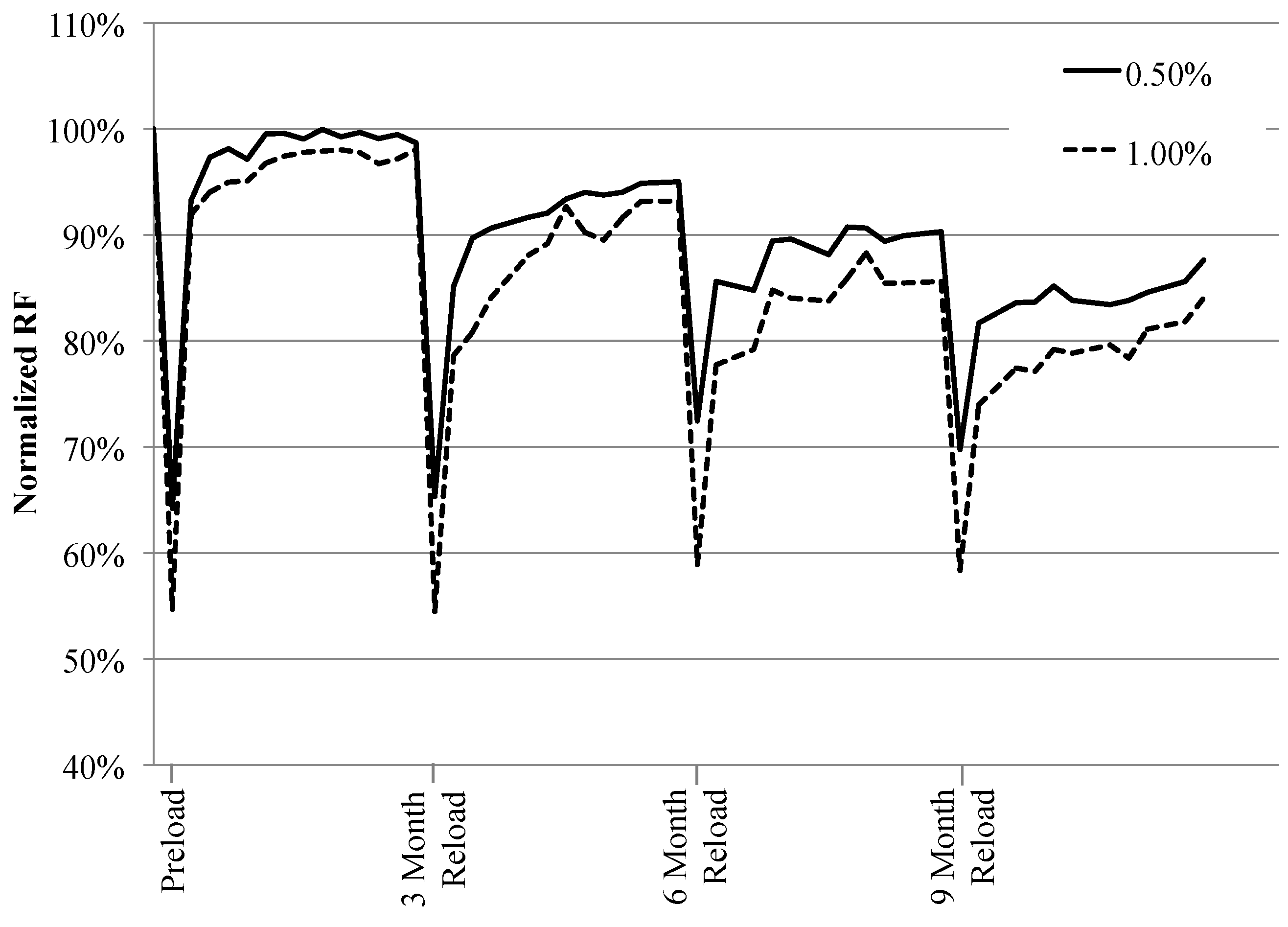

3.1. Resonant Frequency Recovery

3.1.1. Effect of Natural Environment Exposure Time on RF

3.1.2. Effect of Multiple Damage (Reloading) Events on RF

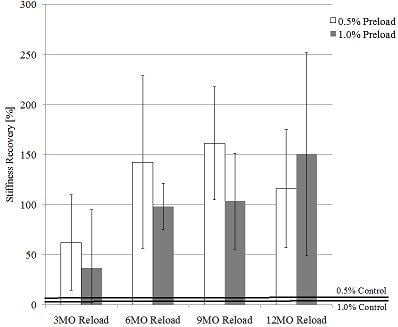

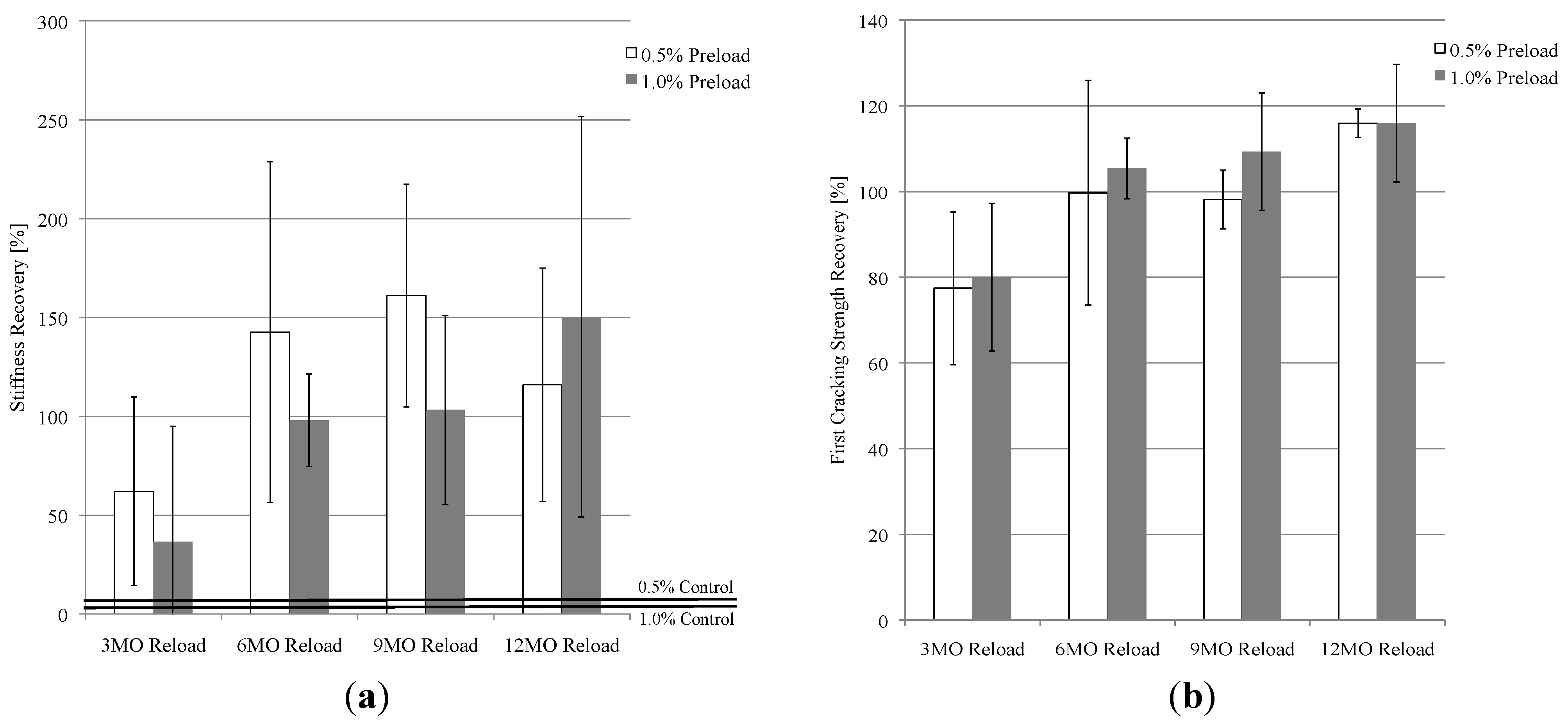

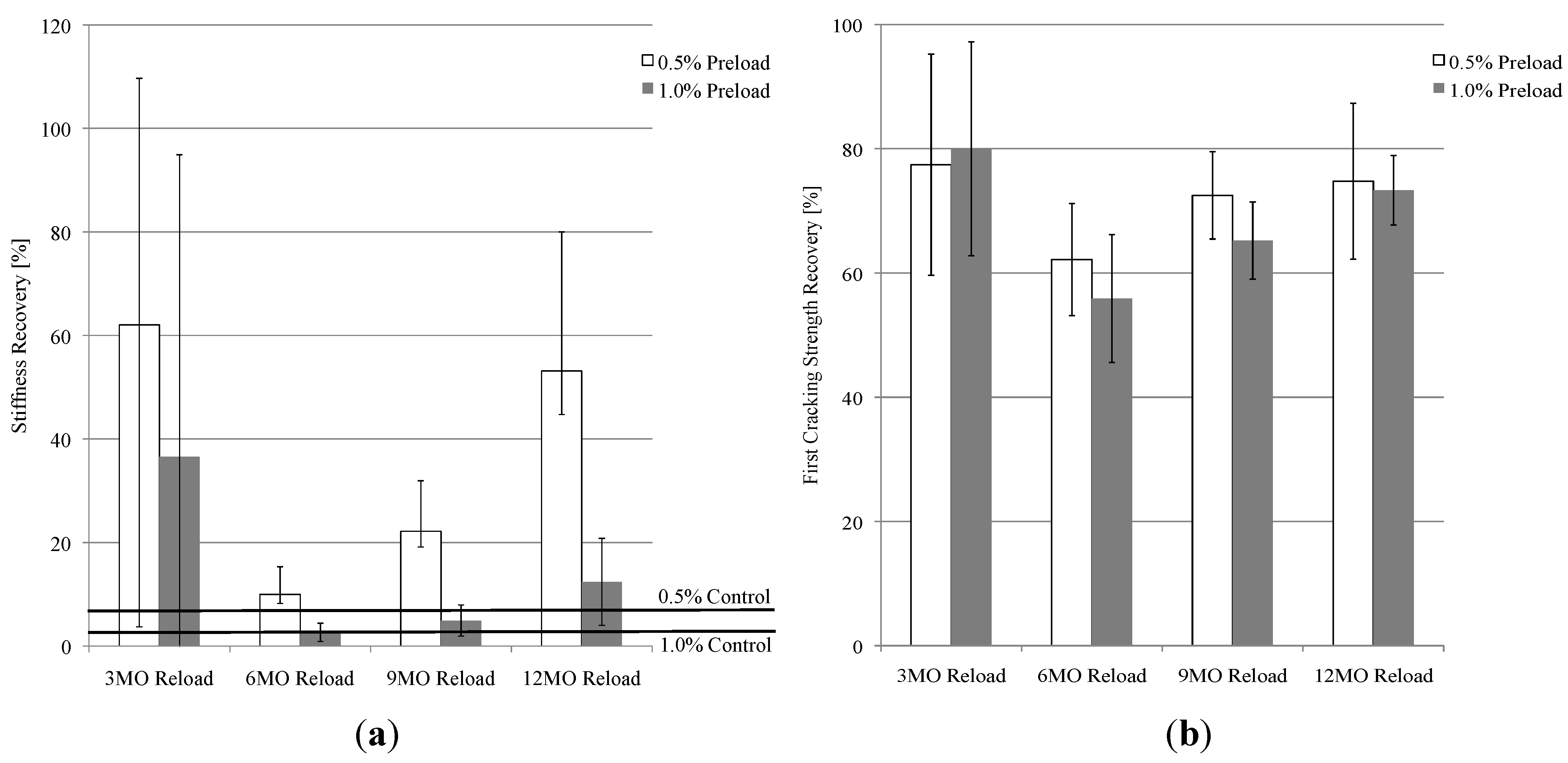

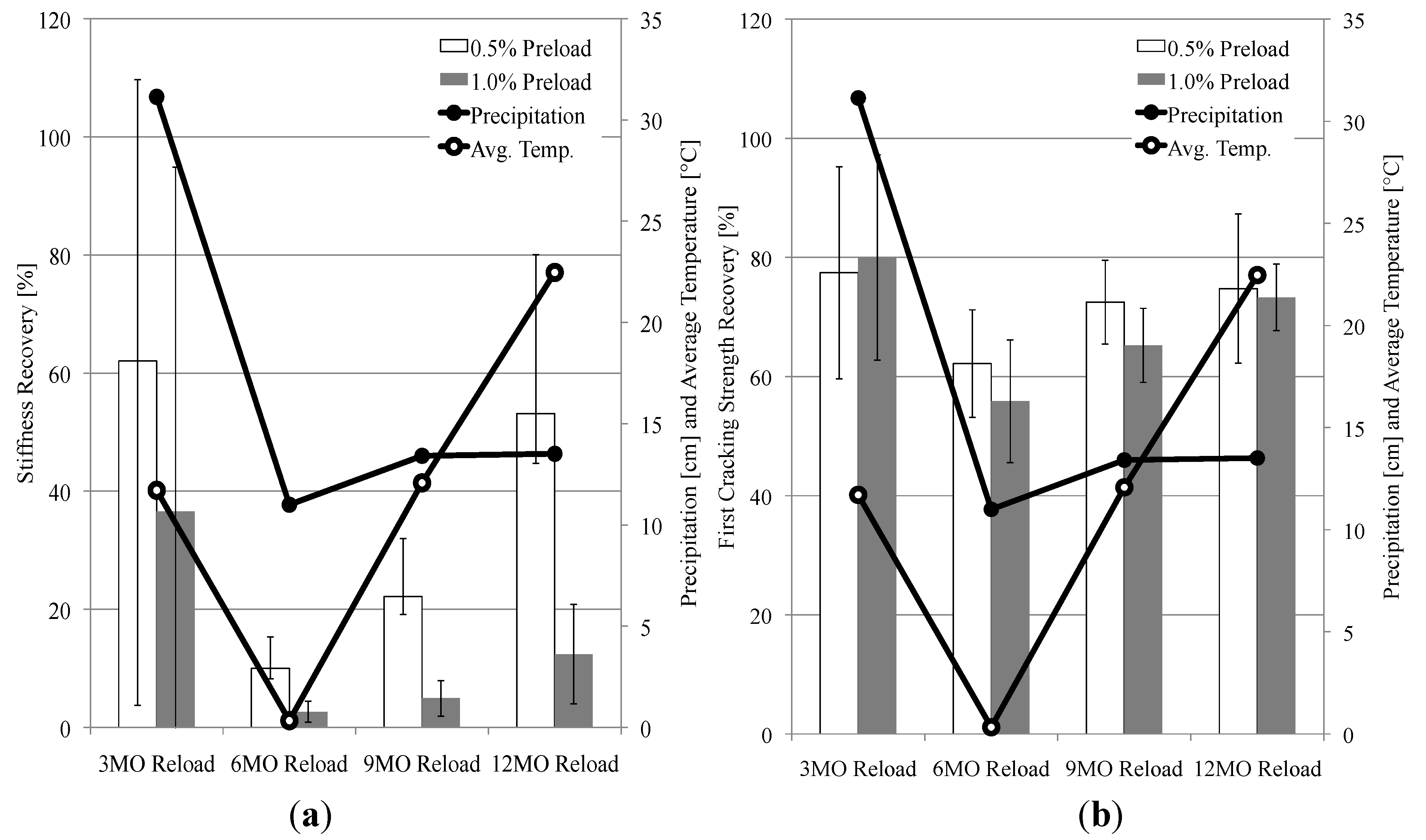

3.2. Stiffness and First Cracking Strength Recovery

3.2.1. Effect of Natural Environment Exposure Time on Mechanical Properties

3.2.2. Effect of Multiple Damage (Reloading) Events on Mechanical Properties

4. Conclusions

Acknowledgments

Conflict of Interest

References

- Edvardsen, C. Water Permeability and Autogenous Healing of Cracks in Concrete. ACI Mater. J. 1999, 96, 448–455. [Google Scholar]

- Granger, S.; Loukili, A.; Pijaudier-Cabot, G.; Chanvillard, G. Experimental Characterization of the Self-Healing of Cracks in an Ultra High Performance Cementitious Material: Mechanical Tests and Acoustic Emission Analysis. Cem. Concr. Res. 2007, 37, 519–527. [Google Scholar] [CrossRef]

- Wang, K.; Jansen, D.; Shah, S.; Karr, A. Permeability Study of Cracked Concrete. Cem. Concr. Res. 1997, 27, 381–393. [Google Scholar] [CrossRef]

- Reinhardt, H.W.; Jooss, M. Permeability and self-healing of cracked concrete as a function of temperature and crack width. Cem. Concr. Res. 2003, 33, 981–985. [Google Scholar] [CrossRef]

- Huang, H.; Ye, G. Application of sodium silicate solution as self-healing agent in cementitious materials. In International RILEM Conference on Advances in Construction Materials through Science and Engineering; Christopher, L., Wan, K.T., Eds.; RILEM Publications SARL: Hong Kong, China, 2011; pp. 530–536. [Google Scholar]

- Jonkers, H.M. Bacteria-based self-healing concrete. Heron 2011, 56, 1–12. [Google Scholar]

- Wiktor, V.; Jonkers, H.M. Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem. Concr. Compos. 2011, 33, 763–770. [Google Scholar] [CrossRef]

- Wang, J.; van Tittelboom, K.; de Belie, N.; Verstraete, W. Use of silica gel or polyurethane immobilized bacteria for self-healing concrete. Constr. Build. Mater. 2012, 26, 532–540. [Google Scholar] [CrossRef]

- Kishi, T.; Ahn, T.; Hosoda, A.; Suzuki, S.; Takaoka, H. Self-healing behaviour by cementitious recrystallization of cracked concrete incorporating expansive agent. In Proceedings of the 1st International Conference on Self-Healing Materials, Noordwijkaan Zee, The Netherlands, 18–20 April 2007.

- Hosoda, A.; Kishi, T.; Arita, H.; Takakuwa, Y. Self healing of crack and water permeability of expansive concrete. In Proceedings of the 1st International Conference on Self-Healing Materials, Noordwijkaan Zee, The Netherlands, 18–20 April 2007.

- Sisomphon, K.; Copuroglu, O. Self healing mortars by using different cementitious materials. In International RILEM Conference on Advances in Construction Materials through Science and Engineering; Christopher, L., Wan, K.T., Eds.; RILEM Publications SARL: Hong Kong, China, 2011; pp. 545–552. [Google Scholar]

- Sisomphon, K.; Copuroglu, O.; Koenders, E.A.B. Surface crack self-healing behaviour of mortars with expansive additives. In Proceedings of the 3rd International Conference on Self-Healing Materials, Bath, UK, 27–29 June 2011.

- Van Tittelboom, K.; Gruyaert, E.; Rahier, H.; de Belie, N. Influence of mix composition on the extent of autogenous crack healing by continued hydration or calcium carbonate formation. Constr. Build. Mater. 2012, 37, 349–359. [Google Scholar] [CrossRef]

- Sahmaran, M; Keskin, S.B.; Ozerkan, G.; Yaman, I.O. Self-healing of mechanically-loaded self consolidating concretes with high volumes of fly ash. Cem. Concr. Compos. 2008, 30, 872–879. [Google Scholar] [CrossRef]

- Li, V.C.; Lim, Y.M.; Chan, Y. Feasibility study of a passive smart self-healing cementitious composite. Compos. Part B Eng. 1998, 29, 819–827. [Google Scholar] [CrossRef]

- Joseph, C.; Jefferson, A.D.; Isaacs, B.; Lark, R.; Gardner, D. Experimental investigation of adhesive-based self-healing of cementitious materials. Mag. Concr. Res. 2010, 62, 831–843. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; de Belie, N.; van Loo, D.; Jacobs, P. Self-healing efficiency of cementitious materials containing tubular capsules filled with healing agent. Cem. Concr. Compos. 2011, 31, 497–505. [Google Scholar] [CrossRef]

- Sahmaran, M.; Li, V.C. Durability of mechanically loaded engineered cementitious composites under highly alkaline environments. Cem. Concr. Compos. 2008, 30, 72–81. [Google Scholar] [CrossRef]

- Yang, Y.; Lepech, M.D.; Yang, E.; Li, V.C. Autogenous healing of engineered cementitious composites under wet-dry cycles. Cem. Concr. Res. 2009, 39, 382–390. [Google Scholar]

- Yamamoto, A.; Watanabe, K.; Li, V.C.; Niwa, J. Effect of wet-dry condition on self-healing property of early-age ECC. Jpn. Concr. Inst. 2010, 32, 251–256. [Google Scholar]

- Li, M.; Li, V.C. Cracking and Healing of Engineered Cementitious Composites under Chloride Environment. ACI Mater. J. 2011, 108, 333–340. [Google Scholar]

- Li, V.C.; Herbert, E.N. Robust Self-Healing Concrete for Sustainable Infrastructure. J. Adv. Concr. Technol. 2012, 10, 207–218. [Google Scholar] [CrossRef]

- Kan, L.L.; Shi, H.S.; Sakulich, A.R.; Li, V.C. Self-Healing Characterization of Engineered Cementitious Composites (ECC). ACI Mater. J. 2010, 107, 617–624. [Google Scholar]

- Fukuda, D.; Nara, Y.; Kobayashi, Y.; Maruyama, M.; Koketsu, M.; Hayashi, D.; Ogawa, H.; Kaneko, K. Investigation of self-healing in high-strength and ultra-low-permeability concrete in water using micro-focus X-ray CT. Cem. Concr. Res. 2012, 42, 1494–1500. [Google Scholar] [CrossRef] [Green Version]

- Li, V.C.; Wang, S.; Wu, C. Tensile Strain-Hardening Behavior of PVA-ECC. ACI Mater. J. 2001, 98, 483–492. [Google Scholar]

- Li, V.C. On Engineered Cementitious Composites (ECC): A Review of the Material and Its Applications. J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef]

- Li, V.C. From Micromechanics to Structural Engineering—The Design of Cementitious Composites for Civil Engineering Applications. JSCE J. Struct. Mech. Earthq. Eng. 1993, 10, 37–48. [Google Scholar]

- Herbert, E.N; Li, V.C. Self-healing of Engineered Cementitious Composites in the Natural Environment. High Perform. Fiber Reinf. Cem. Compos. 6 2012, 2, 155–162. [Google Scholar]

- Sahmaran, M.; Li, V.C. Durability properties of micro-cracked ECC containing high volumes fly ash. Cem. Concr. Res. 2009, 39, 1033–1043. [Google Scholar] [CrossRef]

- Li, V.C.; Wu, C.; Wang, S.; Ogawa, A.; Saito, T. Interface Tailoring for Strain-Hardening PVA-ECC. ACI Mater. J. 2002, 99, 463–472. [Google Scholar]

- Li, V.C.; Yang, E.H. Self Healing in Concrete Materials. In Self Healing Materials: An Alternative Approach to 20 Centuries of Materials Science; Zwaag, S.V.D., Ed.; Springer Netherlands: Dordrecht, The Netherlands, 2008; pp. 161–193. [Google Scholar]

- Japan Society of Civil Engineers. Recommendations for Design and Construction of High Performance Fiber Reinforced Cement Composites with Multiple Fine Cracks (HPFRCC); Tokyo, Japan, 2008. [Google Scholar]

- Weather Underground Home Page. Available online: www.wunderground.com (accessed on 1 September 2012).

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Herbert, E.N.; Li, V.C. Self-Healing of Microcracks in Engineered Cementitious Composites (ECC) Under a Natural Environment. Materials 2013, 6, 2831-2845. https://doi.org/10.3390/ma6072831

Herbert EN, Li VC. Self-Healing of Microcracks in Engineered Cementitious Composites (ECC) Under a Natural Environment. Materials. 2013; 6(7):2831-2845. https://doi.org/10.3390/ma6072831

Chicago/Turabian StyleHerbert, Emily N., and Victor C. Li. 2013. "Self-Healing of Microcracks in Engineered Cementitious Composites (ECC) Under a Natural Environment" Materials 6, no. 7: 2831-2845. https://doi.org/10.3390/ma6072831