Half-Heusler (TiZrHf)NiSn Unileg Module with High Powder Density

Abstract

:1. Introduction

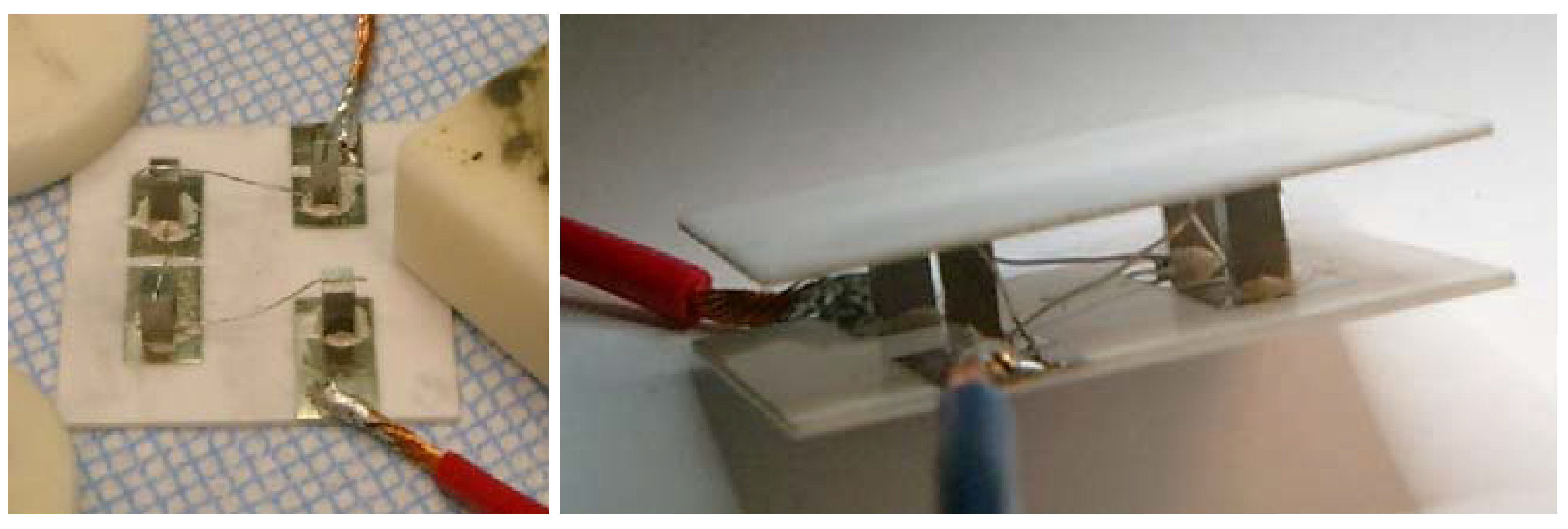

2. Experimental

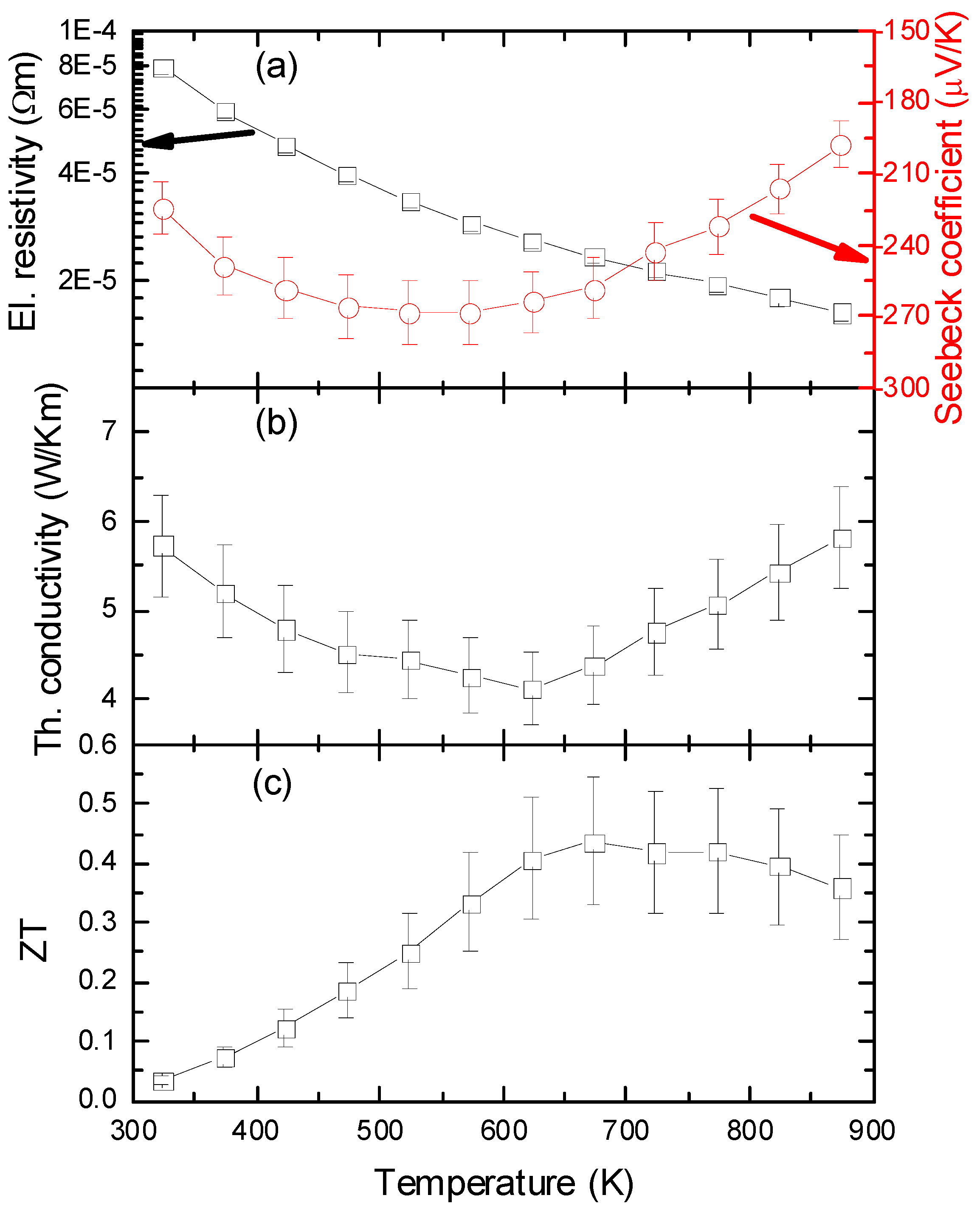

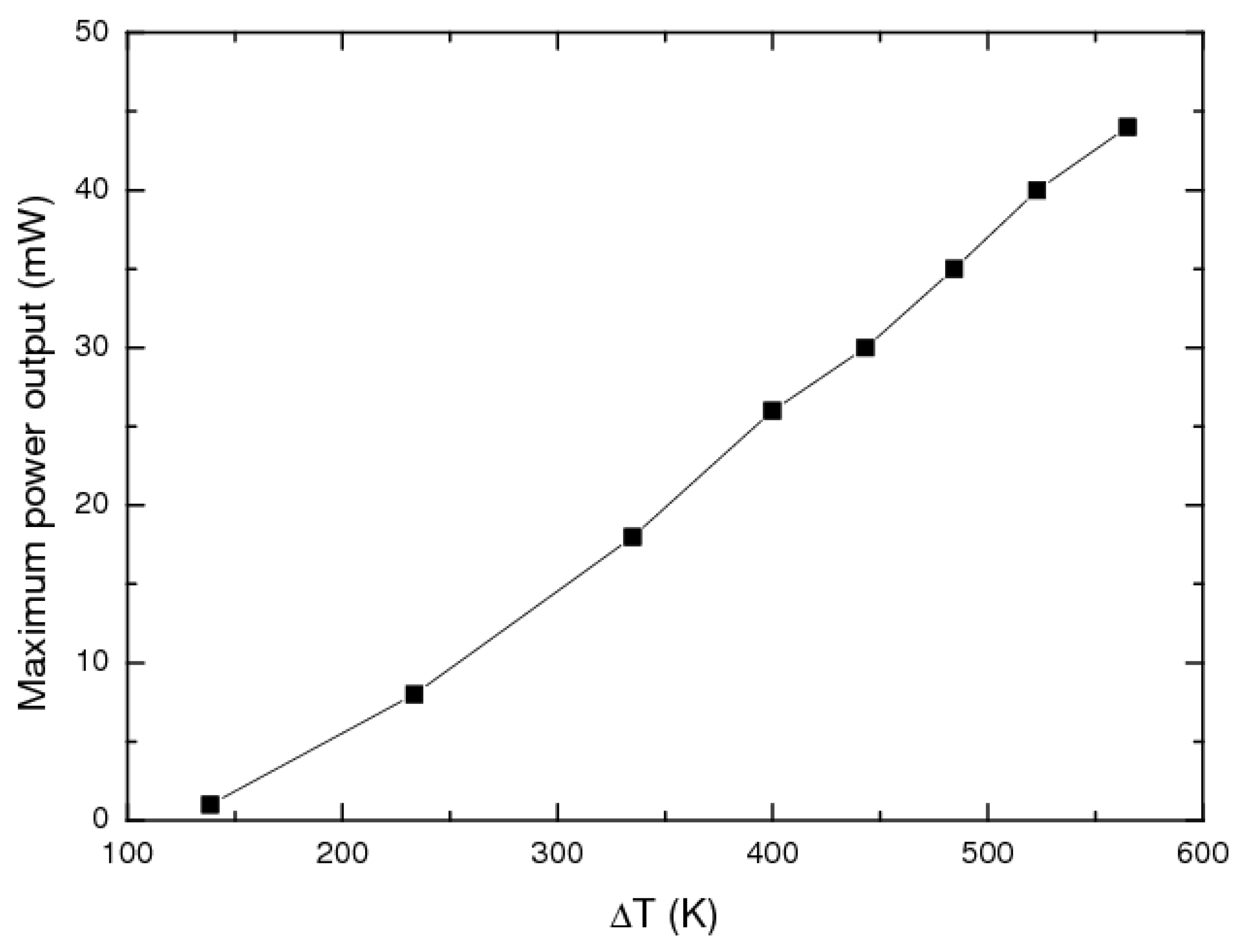

3. Results

| Module | Material | ΔT (K) | Pout, Max (mW) | Leg dimensions (mm) | Power density | |

|---|---|---|---|---|---|---|

| (mW/cm2) | (mW/cm3) | |||||

| HH-Empa (this work) | Ti0.33Zr0.33Hf0.33NiSn unileg | 565 | 44 | 4-times 2 × 2 × 4 | 275 | 700 |

| Heusler1 Mikami [16] | Fe2VAl0.9Si0.1/Fe2V0.9Ti0.1Al | 280 | 940 | 36-times diameter 5 × 5 | 133 | 266 |

| Heusler2 Mikami [17] | Fe2V0.84Ti0.16Al0.97Sb0.03/Fe2VAl0.9Si0.07Sb0.03 | 280 | 2500 | 36-times 4.5 × 4.5 × 4.2 | 342 | 816 |

| HH Poon [15] | Hf0.3Zr0.7CoSn0.3Sb0.7/Hf0.6Zr0.4NiSn0.995Sb0.005 | 704 | 423 | 2 legs | – | – |

| Funahashi [19] | Ca2.7Bi0.3Co4O9/La0.9Bi0.1NiO3 | 500 | 94 | 2-times 3.7 × 4.5 | 105 (282) | 246 (660) |

| Tomes [20] | La1.98Sr0.02CuO4/CaMn0.98Nb0.02O3 | 622 | 88 | 4-times 4.5 × 4.5 | 108 | 216 |

4. Summary and Conclusion

Acknowledgement

References

- Terasaki, I.; Sasago, Y.; Uchinokura, K. Large thermoelectric power in NaCo2O4 single crystals. Phys. Rev. B 1997, 56, R12685–R12687. [Google Scholar]

- Wang, Y.; Rogado, N.S.; Cava, R.J.; Ong, N.P. Spin entropy as the likely source of enhanced thermopower in Na(x)Co2O4. Nature 2003, 423, 425–428. [Google Scholar]

- Populoh, S.; Auban-Senzier, P.; Wzietek, P.; Pasquier, C.R. The power factor of Cr-doped V2O3 near the Mott transition. Appl. Phys. Lett. 2011, 99, 171902–171904. [Google Scholar] [CrossRef]

- Graf, T.; Felser, C.; Parkin, S.S.P. Simple rules for the understanding of Heusler compounds. Prog. Solid State Chem. 2011, 39, 1–50. [Google Scholar] [CrossRef]

- Aliev, F.G.; Kozyrkov, V.V.; Moshchalkov, V.V.; Skolozdra, R.V.; Durczewski, K. Narrow band in the intermetallic compounds MNiSn (M = Ti, Zr, Hf). Z. Phys. B Condens. Matter 1990, 80, 353–357. [Google Scholar] [CrossRef]

- Hohl, H.; Ramirez, A.; Kaefer, W.; Fess, K.; Thurner, C.; Kloc, C.; Bucher, E. A new class of materials with promising thermoelectric properties: MNiSn (M = Ti, Zr, Hf). Mater. Res. Soc. Symp. Proc. 1997, 478, 109–114. [Google Scholar] [CrossRef]

- Uher, C.; Yang, J.; Hu, S.; Morelli, D.T.; Meisner, G.P. Transport properties of pure and doped MNiSn (M = Zr, Hf). Phys. Rev. B 1999, 59, 8615–8621. [Google Scholar] [CrossRef]

- Sakurada, S.; Shutoh, N. Effect of Ti substitution on the thermoelectric properties of (Zr,Hf)NiSn half-Heusler compounds. Appl. Phys. Lett. 2005, 86, 082105:1–082105:3. [Google Scholar] [CrossRef]

- Culp, S.R.; Poon, S.J.; Hickman, N.; Tritt, T.M.; Blumm, J. Effect of substitutions on the thermoelectric figure of merit of half-Heusler phases at 800 °C. Appl. Phys. Lett. 2006, 88, 042106:1–042106:3. [Google Scholar] [CrossRef]

- Culp, S.R.; Simonson, J.W.; Poon, S.J.; Ponnambalam, V.; Edwards, J.; Tritt, T.M. (Zr,Hf)Co(Sb,Sn) half-Heusler phases as high-temperature (>700 °C) p-type thermoelectric materials. Appl. Phys. Lett. 2008, 93, 022105:1–022105:3. [Google Scholar] [CrossRef]

- Xie, W.J.; Jin, Q.; Tang, X. The preparation and thermoelectric properties of Ti0.5Zr0.25Hf0.25Co1−xNixSb half-Heusler compounds. J. Appl. Phys. 2008, 103, 043711:1–043711:5. [Google Scholar]

- Xie, W.J.; He, J.; Zhu, S.; Su, X.L.; Wang, S.Y.; Holgate, T.; Graff, J.W.; Ponnambalam, V.; Poon, S.J.; Tang, X.F.; Zhang, Q.J.; Tritt, T.M. Simultaneously optimizing the independent thermoelectric properties in (Ti,Zr,Hf)(Co,Ni)Sb alloy by in situ forming InSb nanoinclusions. Acta Mater. 2010, 58, 4705–4713. [Google Scholar] [CrossRef]

- Yan, X.; Joshi, G.; Liu, W.; Lan, Y.; Wang, H.; Lee, S.; Simonson, J.W.; Poon, S.J.; Tritt, T.M.; Chen, G.; Ren, Z.F. Enhanced thermoelectric figure of merit of p-type Half-Heuslers. Nano Lett. 2011, 11, 556–560. [Google Scholar] [CrossRef] [PubMed]

- Populoh, S.; Aguirre, M.H.; Brunko, O.C.; Galazka, K.; Lu, Y.; Weidenkaff, A. High figure of merit in (Ti,Zr,Hf)NiSn half-Heusler alloys. Scripta Mater. 2012, 66, 1073–1076. [Google Scholar] [CrossRef]

- Poon, S.J.; Wu, D.; Zhu, S.; Xie, W.J.; Tritt, T.M.; Thomas, P.; Venkatasubramanian, R. Half-Heusler phases and nanocomposites as emerging high-ZT thermoelectric materials. J. Mater. Res. 2011, 26, 2795–2802. [Google Scholar] [CrossRef]

- Mikami, M.; Kobayashi, K.; Kawada, T.; Kubo, K.; Uchiyama, N. Development of a thermoelectric module using the heusler alloy Fe2VAl. J. Electron. Mater. 2009, 38, 1121–1126. [Google Scholar] [CrossRef]

- Mikami, M.; Kobayashi, K.; Tanaka, S. Power generation performance of thermoelectric module consisting of Sb-doped Heusler Fe2VAl sintered alloy. Mater. Trans. 2011, 52, 1546–1548. [Google Scholar] [CrossRef]

- Lemonnier, S.; Goupil, C.; Noudem, J.; Guilmeau, E. Four-leg Ca0.95Sm0.05MnO3 unileg thermoelectric device. J. Appl. Phys. 2008, 104, 014505:1–014505:4. [Google Scholar] [CrossRef]

- Funahashi, R.; Urata, S.; Mizuno, K.; Kouuchi, T.; Mikami, M. Ca2.7Bi0.3Co4O9/La0.9Bi0.1NiO3 thermoelectric devices with high output power density. Appl. Phys. Lett. 2004, 85, 1036–1038. [Google Scholar] [CrossRef]

- Tomeš, P.; Trottmann, M.; Suter, C.; Aguirre, M.H.; Steinfeld, A.; Haueter, P.; Weidenkaff, A. Thermoelectric oxide modules (TOMs) for the direct conversion of simulated solar radiation into electrical energy. Materials 2010, 3, 2801–2814. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Populoh, S.; Brunko, O.C.; Gałązka, K.; Xie, W.; Weidenkaff, A. Half-Heusler (TiZrHf)NiSn Unileg Module with High Powder Density. Materials 2013, 6, 1326-1332. https://doi.org/10.3390/ma6041326

Populoh S, Brunko OC, Gałązka K, Xie W, Weidenkaff A. Half-Heusler (TiZrHf)NiSn Unileg Module with High Powder Density. Materials. 2013; 6(4):1326-1332. https://doi.org/10.3390/ma6041326

Chicago/Turabian StylePopuloh, Sascha, Oliver C. Brunko, Krzysztof Gałązka, Wenjie Xie, and Anke Weidenkaff. 2013. "Half-Heusler (TiZrHf)NiSn Unileg Module with High Powder Density" Materials 6, no. 4: 1326-1332. https://doi.org/10.3390/ma6041326