Extraordinary Magnetoresistance in Semiconductor/Metal Hybrids: A Review

Abstract

:1. Introduction

2. Background

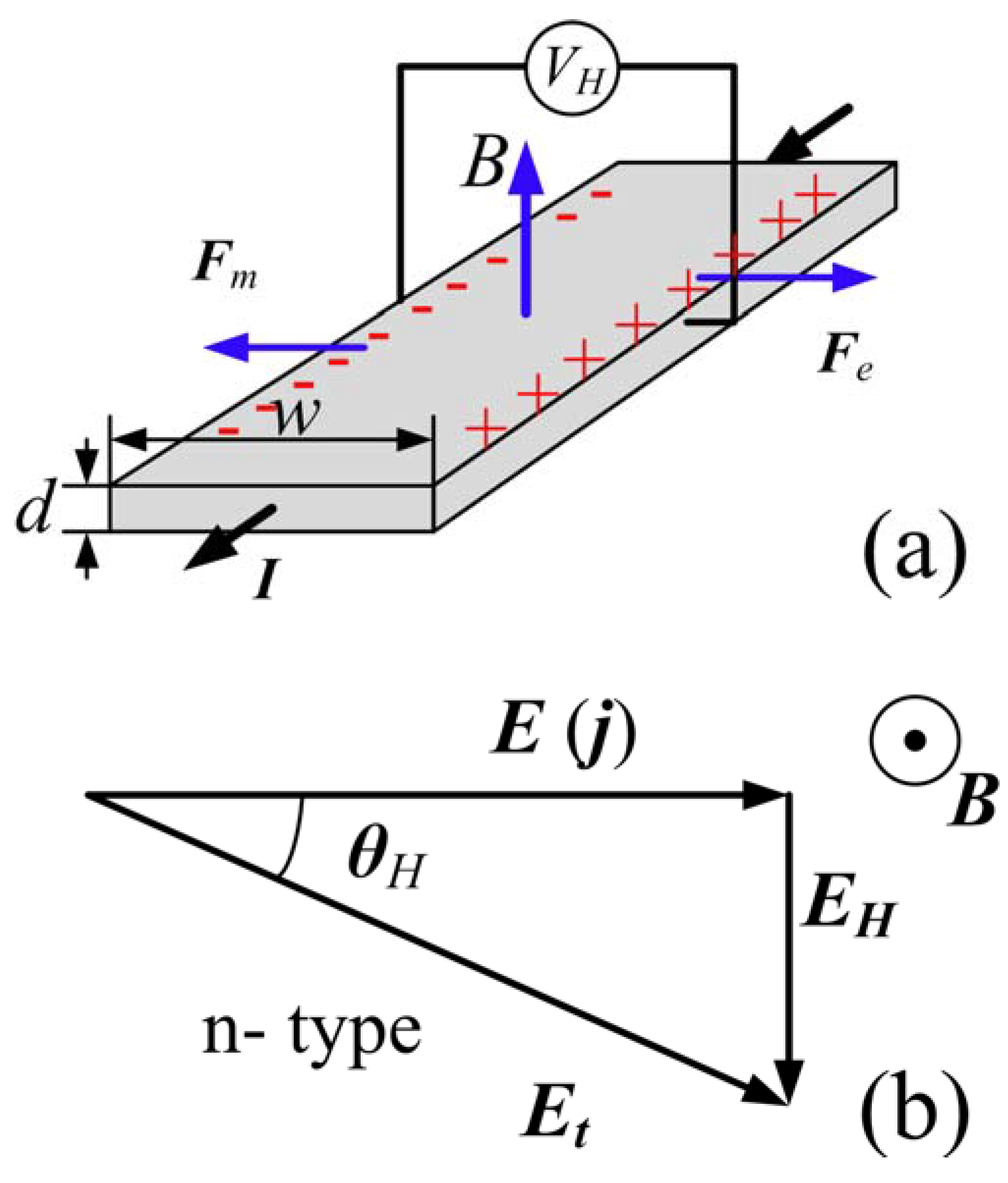

2.1. Basic Principle

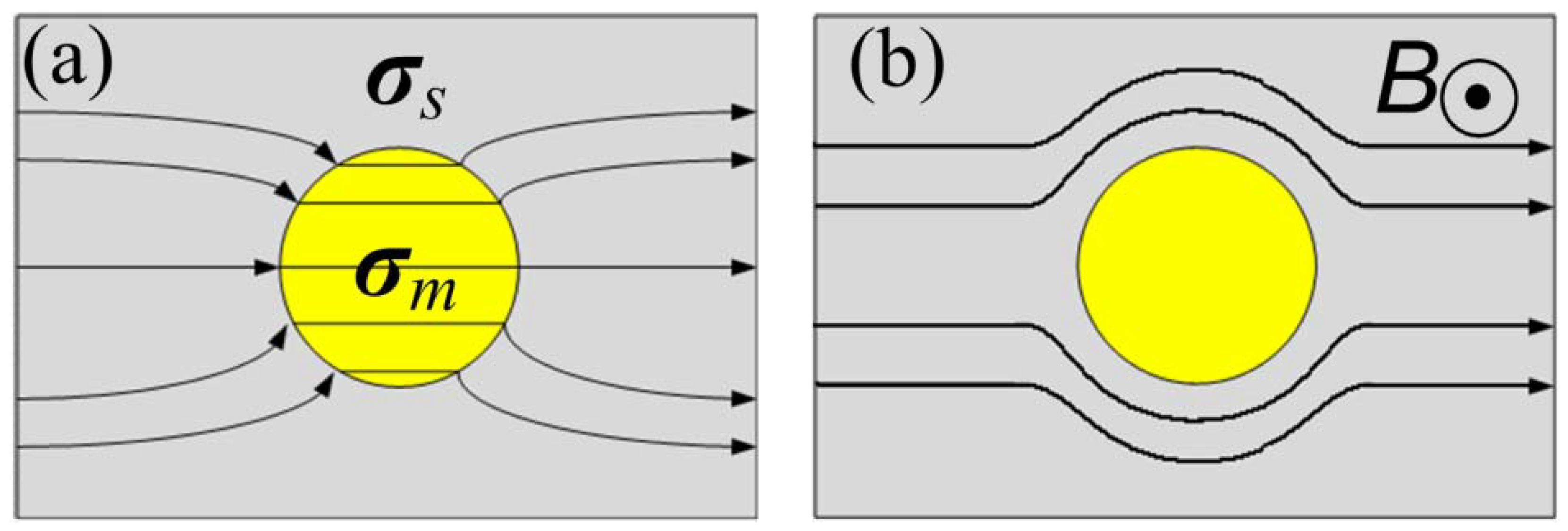

2.2. Diffusive Transport in Hybrid Structures

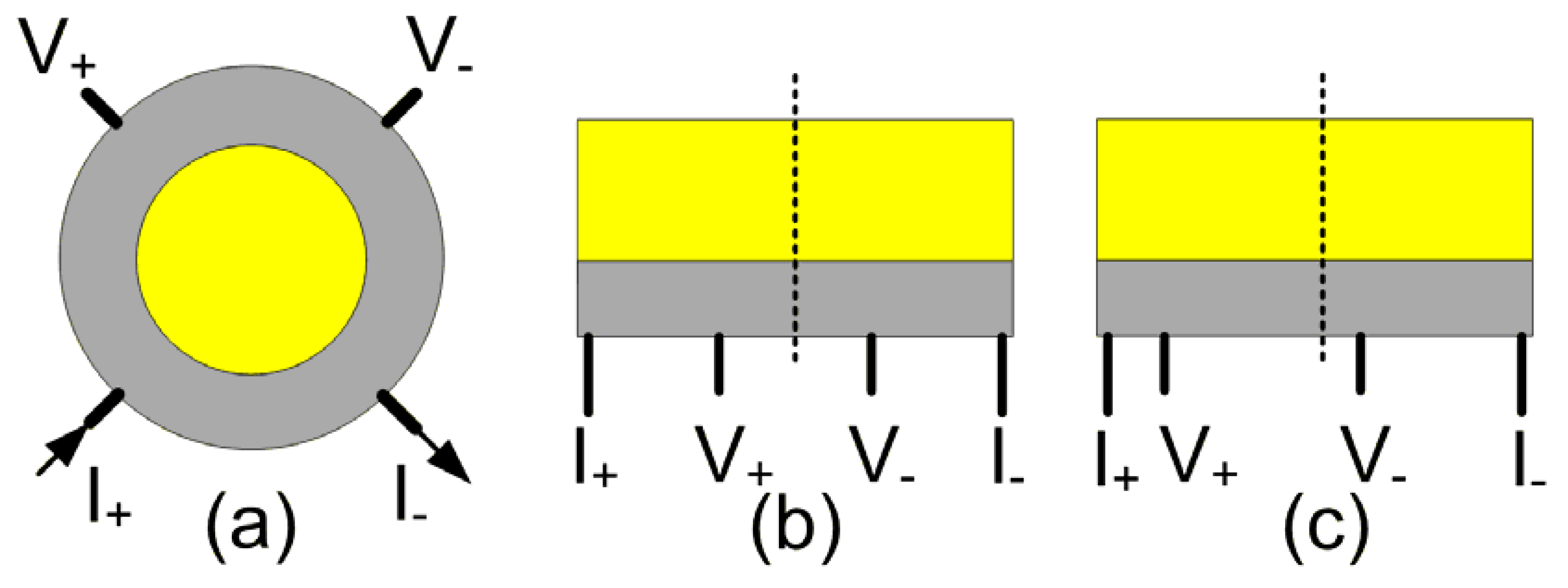

2.3. Device Characterization

3. EMR Effect in Different Device Geometries

3.1. van der Pauw Disk with Inner Inhomogeneity

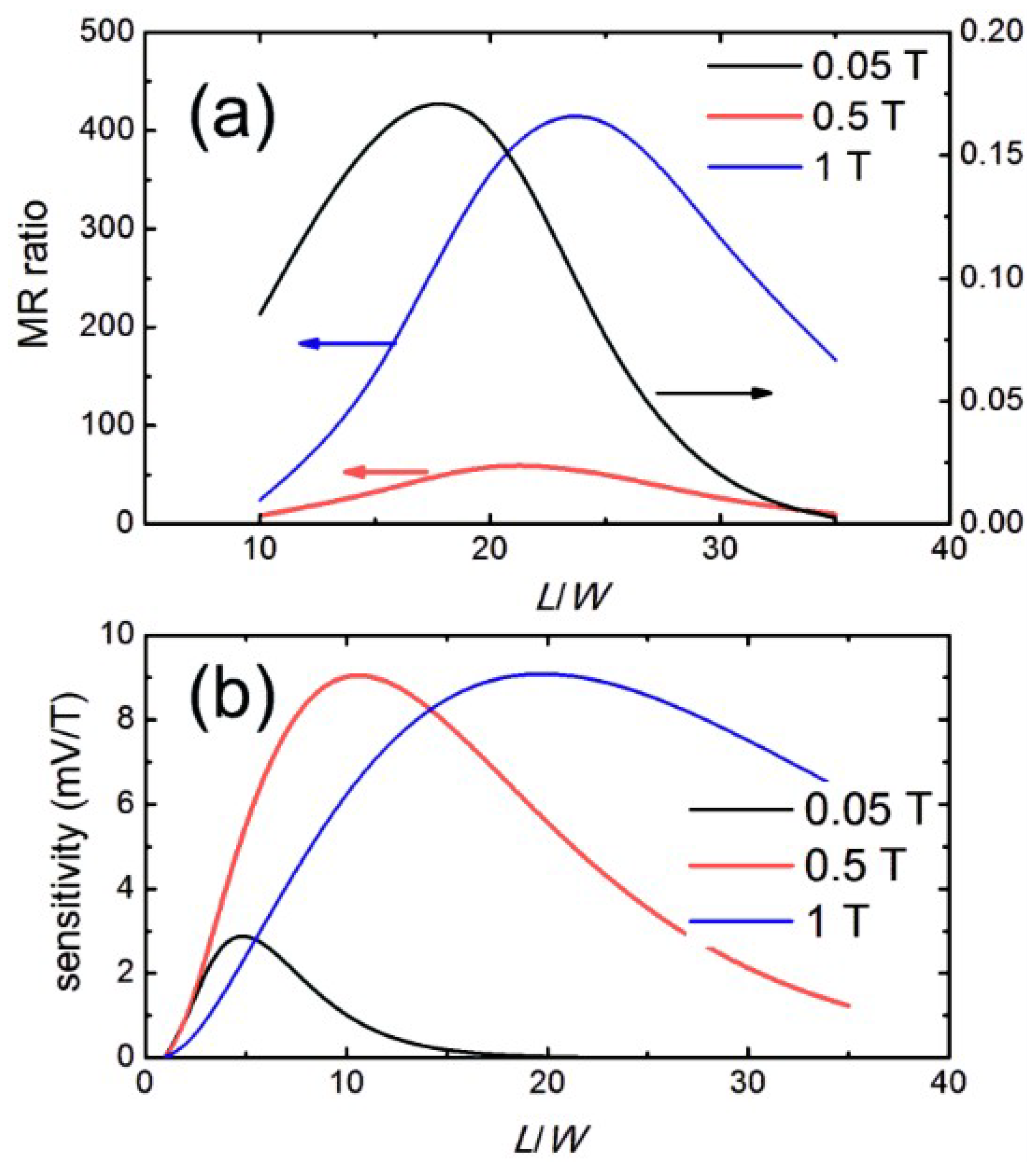

3.2. Externally Shunted Bar-Type Structure

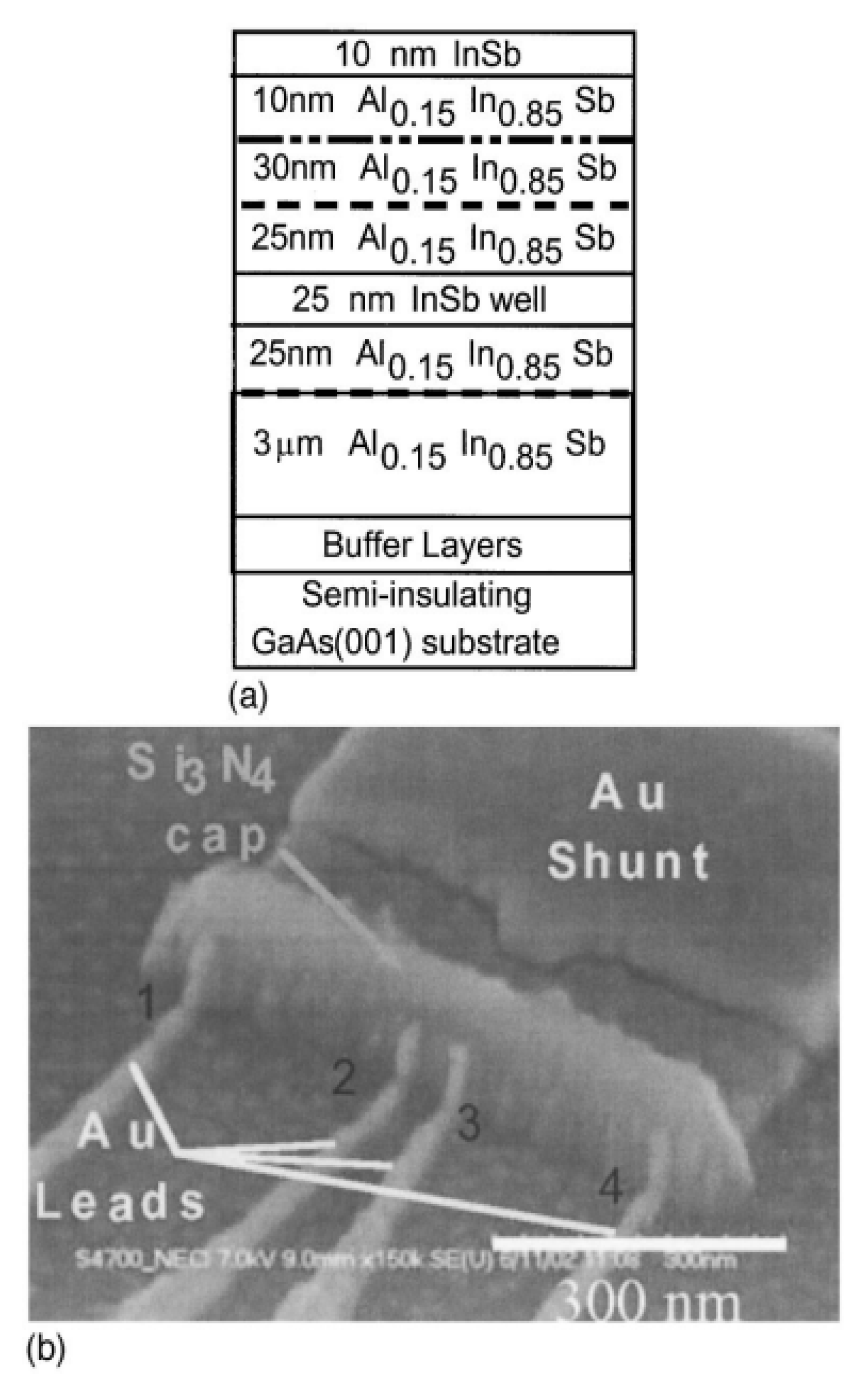

4. Materials Selections

5. Conclusions

References

- Brug, J.A.; Anthony, T.C.; Nickel, J.H. Magnetic recording head materials. MRS Bull. 1996, 21, 23–27. [Google Scholar]

- Daughton, J.M.; Chen, Y.J. Gmr materials for low field applications. IEEE Trans. Magn. 1993, 29, 2705–2710. [Google Scholar] [CrossRef]

- Mao, S.; Nowak, J.; Song, D.; Kolbo, P.; Wang, L.; Linville, E.; Saunders, D.; Murdock, E.; Ryan, P. Spin tunneling heads above 20 Gb/In(2). IEEE Trans. Magn. 2002, 38, 78–83. [Google Scholar] [CrossRef]

- Li, G.X.; Joshi, V.; White, R.L.; Wang, S.X.; Kemp, J.T.; Webb, C.; Davis, R.W.; Sun, S.H. Detection of single micron-sized magnetic bead and magnetic nanoparticles using spin valve sensors for biological applications. J. Appl. Phys. 2003, 93, 7557–7560. [Google Scholar] [CrossRef]

- Graham, D.L.; Ferreira, H.A.; Freitas, P.P. Magnetoresistive-based biosensors and biochips. Trends Biotechnol. 2004, 22, 455–462. [Google Scholar] [CrossRef] [PubMed]

- Diaz-Michelena, M. Small magnetic sensors for space applications. Sensors 2009, 9, 2271–2288. [Google Scholar] [CrossRef] [PubMed]

- Lenz, J.; Edelstein, A.S. Magnetic sensors and their applications. IEEE Sens. J. 2006, 6, 631–649. [Google Scholar] [CrossRef]

- Wolf, S.; Awschalom, D.; Buhrman, R.; Daughton, J.; von Molnar, S.; Roukes, M.; Chtchelkanova, A.Y.; Treger, D. Spintronics: A spin-based electronics vision for the future. Science 2001, 294, 1488–1495. [Google Scholar] [CrossRef] [PubMed]

- Becker, W.; Ramdas, A.; Fan, H. Energy band structure of gallium antimonide. J. Appl. Phys. 1961, 32, 2094–2102. [Google Scholar] [CrossRef]

- Branford, W.R.; Husmann, A.; Solin, S.A.; Clowes, S.K.; Zhang, T.; Bugoslavsky, Y.V.; Cohen, L.F. Geometric manipulation of the high-field linear magnetoresistance in InSb epilayers on GaAs(001). Appl. Phys. Lett. 2005, 86, 202116:1–202116:3. [Google Scholar] [CrossRef] [Green Version]

- Wan, C.; Zhang, X.; Gao, X.; Wang, J.; Tan, X. Geometrical enhancement of low-field magnetoresistance in silicon. Nature 2011, 477, 304–307. [Google Scholar] [CrossRef] [PubMed]

- Solin, S.A.; Ram-Mohan, L.R. Geometry-driven magnetoresistance. In Handbook of Magnetism and Advanced Magnetic Materials; John Wiley & Sons: Hoboken, NJ, USA, 2007; Volume 5, pp. 1–19. [Google Scholar]

- Baker, D.R.; Heremans, J.P. Linear geometrical magnetoresistance effect: Influence of geometry and material composition. Phys. Rev. B 1999, 59, 13927–13942. [Google Scholar] [CrossRef]

- Baibich, M.N.; Broto, J.M.; Fert, A.; Vandau, F.N.; Petroff, F.; Eitenne, P.; Creuzet, G.; Friederich, A.; Chazelas, J. Giant magnetoresistance of (001)Fe/(001)Cr magnetic superlattices. Phys. Rev. Lett. 1988, 61, 2472–2475. [Google Scholar] [CrossRef] [PubMed]

- Julliere, M. Tunneling between ferromagnetic-films. Phys. Lett. A 1975, 54, 225–226. [Google Scholar] [CrossRef]

- Nagasaka, K. CPP-GMR technology for magnetic read heads of future high-density recording systems. J. Magn. Magn. Mater. 2009, 321, 508–511. [Google Scholar] [CrossRef]

- Solin, S.A.; Thio, T.; Hines, D.R.; Heremans, J.J. Enhanced room-temperature geometric magnetoresistance in inhomogeneous narrow-gap semiconductors. Science 2000, 289, 1530–1532. [Google Scholar] [CrossRef] [PubMed]

- Ozbay, A.; Gokce, A.; Flanagan, T.; Stearrett, R.A.; Nowak, E.R.; Nordman, C. Low frequency magnetoresistive noise in spin-valve structures. Appl. Phys. Lett. 2009, 94, 202506:1–202506:3. [Google Scholar] [CrossRef]

- Smith, N.; Arnett, P. White-noise magnetization fluctuations in magnetoresistive heads. Appl. Phys. Lett. 2001, 78, 1448–1451. [Google Scholar] [CrossRef]

- Kasap, S.O. Principles of Electronic Materials and Devices; McGraw-Hill: Boston, MA, USA, 2006. [Google Scholar]

- Ellmer, K. Hall effect and conductivity measurements in semiconductor crystals and thin films. In Characterization of Materials; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; pp. 1–16. [Google Scholar]

- Rowe, A.; Solin, S. Importance of interface sampling for extraordinary resistance effects in metal semiconductor hybrids. Phys. Rev. B 2005, 71, 235323:1–235323:5. [Google Scholar] [CrossRef]

- Moussa, J.; Ram-Mohan, L.; Sullivan, J.; Zhou, T.; Hines, D.; Solin, S. Finite-element modeling of extraordinary magnetoresistance in thin film semiconductors with metallic inclusions. Phys. Rev. B 2001, 64, 184410:1–184410:8. [Google Scholar] [CrossRef]

- Sun, J.; Kosel, J.; Gooneratne, C.; Soh, Y.-A. Optimization of an extraordinary magnetoresistance sensor in the semiconductor-metal hybrid structure. In Proceeding of 2010 9th IEEE Sensors Conference, Kona, HI, USA, 1–4 November 2010.

- Hewett, T.; Kusmartsev, F. Geometrically enhanced extraordinary magnetoresistance in semiconductor-metal hybrids. Phys. Rev. B 2010, 82, 212404:1–212404:4. [Google Scholar] [CrossRef]

- Sun, J.; Kosel, J. Finite element analysis on the influence of contact resistivity in an extraordinary magnetoresistance magnetic field micro sensor. J. Supercond. Nov. Magn. 2012, 25, 2749–2752. [Google Scholar] [CrossRef]

- Sun, J.; Gooneratne, C.P.; Kosel, J. Design study of a bar-type EMR device. IEEE Sens. J. 2012, 12, 1356–1360. [Google Scholar] [CrossRef]

- Holz, M.; Kronenwerth, O.; Grundler, D. Optimization of semiconductor-metal hybrid structures for application in magnetic-field sensors and read heads. Appl. Phys. Lett. 2003, 83, 3344–3346. [Google Scholar] [CrossRef]

- Sun, J.; Kosel, J. The influence of semiconductor/metal interface geometry in an EMR sensor. IEEE Sens. J. 2013, 3, 664–669. [Google Scholar] [CrossRef]

- Sun, J.; Kosel, J. Finite-element modelling and analysis of hall effect and extraordinary magnetoresistance effect. In Finite Element Analysis—New Trends and Developments; Ebrahimi, F., Ed.; InTech: Manhattan, NY, USA, 2012; pp. 201–224. [Google Scholar]

- Lu, J.; Zhang, H.; Shi, W.; Wang, Z.; Zheng, Y.; Zhang, T.; Wang, N.; Tang, Z.; Sheng, P. Graphene magnetoresistance device in van der pauw geometry. Nano Lett. 2011, 11, 2973–2977. [Google Scholar] [CrossRef] [PubMed]

- Suh, J.; Kim, W.; Chang, J.; Han, S.H.; Kim, E. Magnetoresistance of a polycrystalline InSb disk with anembedded Au core. J. Korean Phys. Soc. 2009, 55, 577–580. [Google Scholar] [CrossRef]

- Xu, R.; Husmann, A.; Rosenbaum, T.; Saboungi, M.; Enderby, J.; Littlewood, P. Large magnetoresistance in non-magnetic silver chalcogenides. Nature 1997, 390, 57–59. [Google Scholar] [CrossRef]

- Zhou, T.; Hines, D.; Solin, S. Extraordinary magnetoresistance in externally shunted van der pauw plates. Appl. Phys. Lett. 2001, 78, 667–669. [Google Scholar] [CrossRef]

- Solin, S.; Hines, D.; Rowe, A.; Tsai, J.; Pashkin, Y.A. Nanoscopic magnetic field sensor based on extraordinary magnetoresistance. J. Vac. Sci. Technol. B 2003, 21, 3002–3006. [Google Scholar] [CrossRef]

- Rong, C.; Zhang, H.; Sun, J.; Shen, B. Geometry and material optimization of the extraordinary magnetoresistance in the semiconductor–metal hybrid structure. J. Magn. Magn. Mater. 2006, 301, 407–414. [Google Scholar] [CrossRef]

- Hoener, M.; Kronenwerth, O.; Heyn, C.; Grundler, D.; Holz, M. Geometry-enhanced magnetoresistance of narrow Au/InAs hybrid structures incorporating a two-dimensional electron system. J. Appl. Phys. 2006, 99, 036102:1–036102:3. [Google Scholar] [CrossRef]

- Holz, M.; Kronenwerth, O.; Grundler, D. Semiconductor-metal hybrid structures as local magnetic-field probes: Magnetoresistance and spatial sensitivity profile. Appl. Phys. Lett. 2005, 87, 172501:1–172501:3. [Google Scholar] [CrossRef]

- Sun, J.; Patil, S.B.; Soh, Y.-A.; Kosel, J. Strong temperature dependence of extraordinary magnetoresistance correlated to mobility in a two-contact device. Appl. Phys. Express 2012, 5, 033002:1–033002:3. [Google Scholar]

- Boone, T.D.; Smith, N.; Folks, L.; Katine, J.A.; Marinero, E.E.; Gurney, B.A. Mesoscopic EMR device magnetic sensitivity in I-V-I-V configuration. IEEE Electron Device Lett. 2009, 30, 117–119. [Google Scholar] [CrossRef]

- Holz, M.; Kronenwerth, O.; Grundler, D. Enhanced sensitivity due to current redistribution in the hall effect of semiconductor-metal hybrid structures. Appl. Phys. Lett. 2005, 86, 072513:1–072513:3. [Google Scholar] [CrossRef]

- Sun, J.; Kosel, J. Hall effect enhanced low-field sensitivity in a three-contact extraordinary magnetoresistance sensor. Appl. Phys. Lett. 2012, 100, 232407:1–232407:3. [Google Scholar]

- Rong, C.B.; Zhang, H.W.; Sun, J.R.; Shen, B.G. Enhanced extraordinary magnetoresistance in the semiconductor-metal hybrid structure with three current leads. Appl. Phys. Lett. 2006, 89, 052503:1–052503:3. [Google Scholar] [CrossRef]

- Holz, M.; Kronenwerth, O.; Grundler, D. Magnetoresistance of semiconductor-metal hybrid structures: The effects of material parameters and contact resistance. Phys. Rev. B 2003, 67, 195312:1–195312:10. [Google Scholar] [CrossRef]

- Troup, A.; Hasko, D.; Wunderlich, J.; Williams, D. Magnetoresistance in silicon-based semiconductor-metal hybrid structures. Appl. Phys. Lett. 2006, 89, 022116:1–022116:3. [Google Scholar] [CrossRef]

- Parker, S.; Williams, R.; Droopad, R.; Stradling, R.; Barnham, K.; Holmes, S.; Laverty, J.; Phillips, C.; Skuras, E.; Thomas, R. Observation and control of the amphoteric behaviour of Si-doped InSb grown on gaas by MBE. Semicond. Sci. Technol. 1989, 4, 663–676. [Google Scholar] [CrossRef]

- Kroemer, H. The 6.1 a family (InAs, GaSb, AlSb) and its heterostructures: A selective review. Physica E 2004, 20, 196–203. [Google Scholar] [CrossRef]

- Pisana, S.; Braganca, P.M.; Marinero, E.E.; Gurney, B.A. Graphene magnetic field sensors. IEEE Trans. Magn. 2010, 46, 1910–1913. [Google Scholar] [CrossRef]

- Pisana, S.; Braganca, P.M.; Marinero, E.E.; Gurney, B.A. Tunable nanoscale graphene magnetometers. Nano Lett. 2009, 10, 341–346. [Google Scholar] [CrossRef]

- Friedman, A.L.; Robinson, J.T.; Perkins, F.K.; Campbell, P.M. Extraordinary magnetoresistance in shunted chemical vapor deposition grown graphene devices. Appl. Phys. Lett. 2011, 99, 022108:1–022108:3. [Google Scholar] [CrossRef]

- Boos, J.; Bennett, B.; Kruppa, W.; Park, D.; Mittereder, J.; Bass, R.; Twigg, M. Ohmic contacts in AlSb/InAs high electron mobility transistors for low-voltage operation. J. Vac. Sci. Technol. B 1999, 17, 1022–1027. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Sun, J.; Kosel, J. Extraordinary Magnetoresistance in Semiconductor/Metal Hybrids: A Review. Materials 2013, 6, 500-516. https://doi.org/10.3390/ma6020500

Sun J, Kosel J. Extraordinary Magnetoresistance in Semiconductor/Metal Hybrids: A Review. Materials. 2013; 6(2):500-516. https://doi.org/10.3390/ma6020500

Chicago/Turabian StyleSun, Jian, and Jürgen Kosel. 2013. "Extraordinary Magnetoresistance in Semiconductor/Metal Hybrids: A Review" Materials 6, no. 2: 500-516. https://doi.org/10.3390/ma6020500