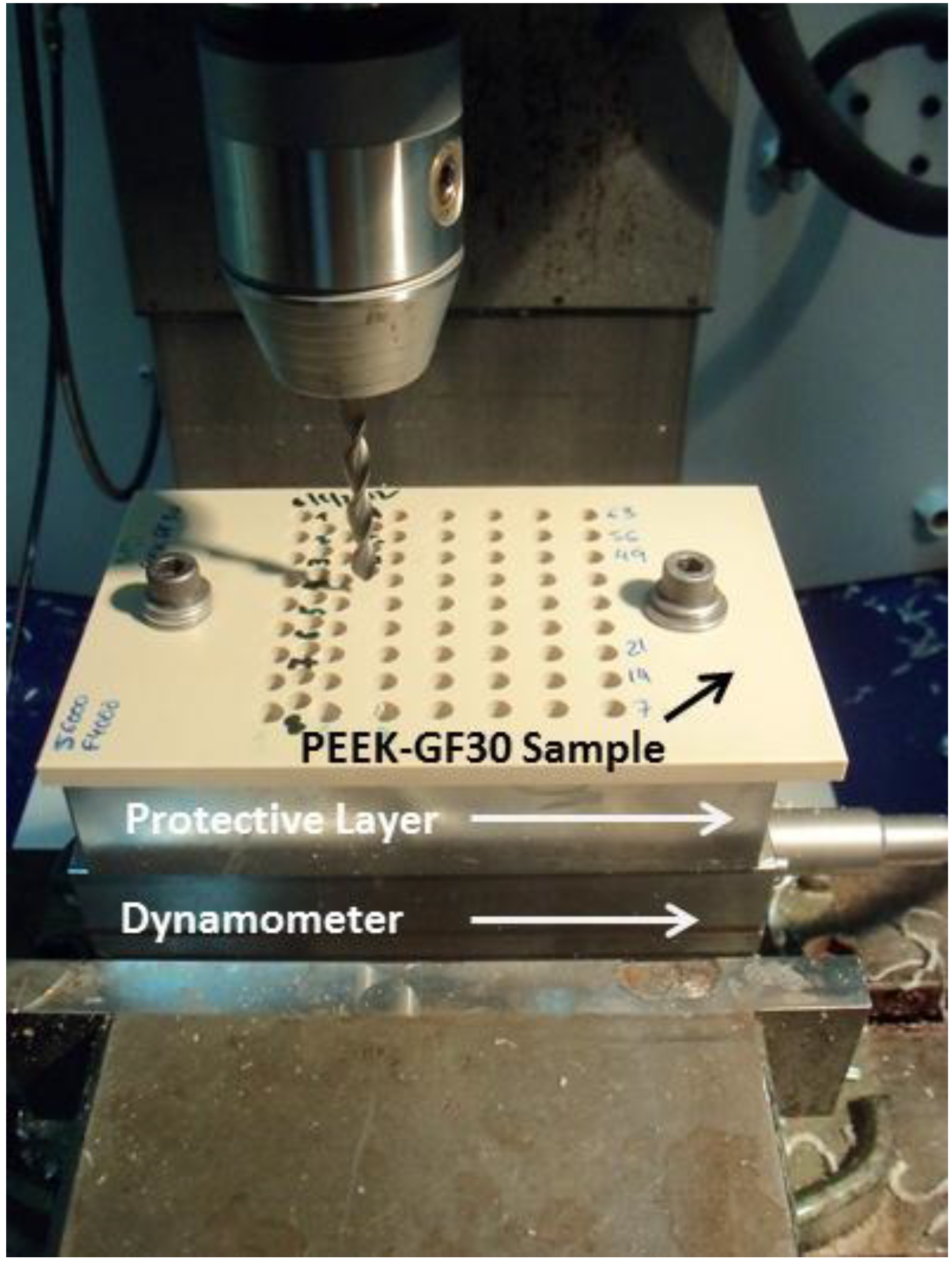

As was previously indicated, the experiments were performed three times for each drill bit type and cutting condition to guarantee the precision of the measurements.

Table 3 shows the resulting mean for each variable and cutting condition; the data were collected randomly, as can be observed in

Table 3, to guarantee the independence of the results. These data were subjected to an ANOVA multifactor analysis. This analysis shows whether the factors

N,

F, and

B and their interactions

N-

F,

N-

B, and

F-

B significantly impact the values of the variables

Rmax,

Ra,

Fd,

Fzmax,

Mzmax, and

E. In addition, the error values (other sources of residual variation) and the corrected total (i.e., considering the error in the analysis) are shown.

Table 4,

Table 5,

Table 6,

Table 7 and

Table 8 show the values of the sum of squares (

SS), the degrees of freedom (

DF), the root mean square (

RMS), the

F-ratio, the

P-value, and the contribution, in percentages, of each factor and interaction to the results.

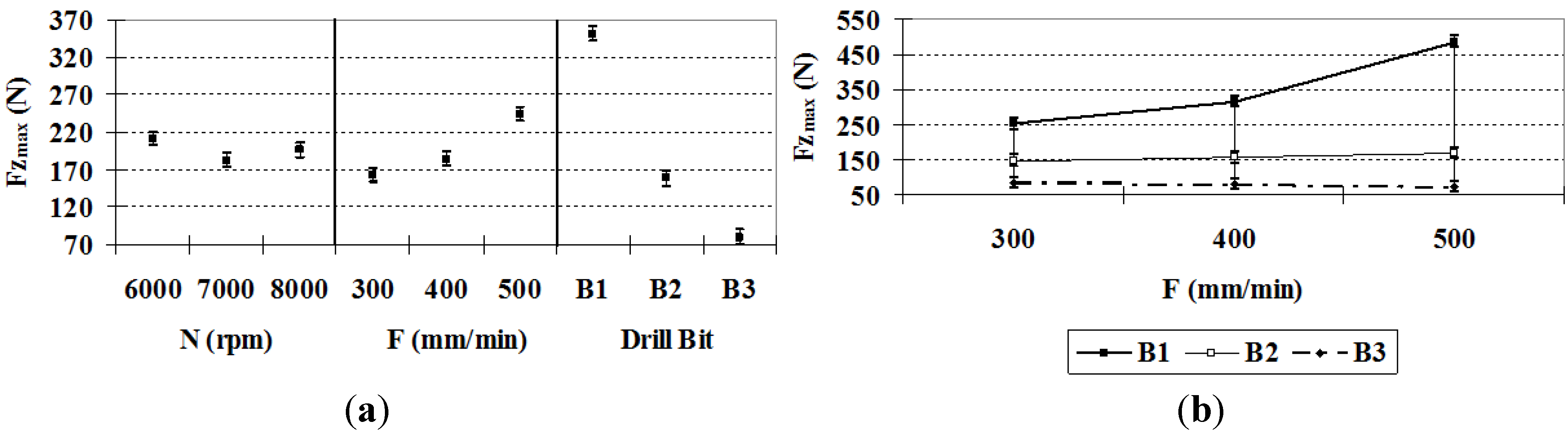

3.1. Thrust Force

The ANOVA analysis (

Table 4) shows that all of the factors and their interactions are significant in the determination of

Fzmax. However, the degree of influence is quite diverse, being much higher for the drill bit type, followed by the

F–

B interaction, which together accounted for 87%. The interaction

N–

F has a low contribution respect to

F because the thrust force is strongly dependent on the feed rate. Thus, the thrust force is little influenced by levels of N.

It can be observed in

Figure 3a that

Fzmax is lower for drill bit

B2 and lowest for drill bit

B3. This result implies that the specific design of drill bit

B3 achieves a good incidence in this type of material without notable differences in the cutting conditions. It is noteworthy that the

B3 drill bit has a point angle of 90°, and it is made of a harder material than

B2, which is harder than

B1, implying that

B3 undergoes less deformation during the drilling process. Regarding the next decisive factor, the

F–

B interaction, the behavior of the variable depends on the variation of

F with respect to the drill bit type (see

Figure 3b). With drill bit

B3, the forces remain approximately constant as

F increases; thus, the use of higher values, which reduces the manufacturing time, is recommended.

Finally, it should be noted that the cutting speed has a negligible influence on

Fzmax [

12].

Theses results are in agreement with what Abrão

et al. have found when drilling glass fiber reinforced plastic composite [

25].

Figure 3.

(a) Fzmax (95% confidence interval); (b) Fzmax F–B interactions (95% confidence interval).

Figure 3.

(a) Fzmax (95% confidence interval); (b) Fzmax F–B interactions (95% confidence interval).

3.2. Momentum

In the analysis of momentum (see

Table 5), it was found that all of the factors and interactions are significant at a 95.0% level of confidence, except for the

F–

B interaction. It was also observed that nearly 70% of the variance is attributable to

B and the interactions

N–

B and

N–

F.

The momentum does not present a regular pattern, but it can be observed that the

B1 drill bit gives higher values, and the

B3 drill bit gives lower values (

Figure 4a), which can be explained by the same causes as the feed force results.

Figure 4.

(a) Mzmax (95% confidence interval); (b) Mzmax N–F and F–B interactions (95% confidence interval).

Figure 4.

(a) Mzmax (95% confidence interval); (b) Mzmax N–F and F–B interactions (95% confidence interval).

Regarding the interaction (

Figure 4b)

N–

B, when the rotation speed increases for drill bit

B3, the momentum decreases, whereas in relation to

N–

F, the lower feed rate results in a greater reduction in the momentum at high speeds, as expected because of the concept of the feed rate.

In the case of Mzmax, it is observed that the rotation speed of the drill bit is more relevant (except for the significant effect of the drill bit type), unlike Fzmax, in which the feed rate is predominant.

3.3. Energy

The analysis of the energy consumed in drilling requires knowledge of the thrust force and the momentum because both variables contribute to the energy.

Table 6 shows that only,

B,

F and the

N–

B interaction are significant because, for the others, the

P-value is greater than 0.05. Of the three, the variable that has the greatest influence is the drill bit type, followed by the

N-B interaction and the feed rate, which together account for nearly 63% of the variance. It can be observed that the first two variables are the same variables that have the most influence on the momentum, which is expected because the momentum is usually responsible for more than 98% of the energy required [

20].

Consistent with the results for the thrust force and the momentum, the drill bit type that results in the lowest energy consumption is

B3 (see

Figure 5b). As the feed increases, the energy consumption decreases (

Figure 5a). The influence of N depends on the drill bit type: for

B1 and

B3, the energy decreases with increasing

N, but in the case of

B2 the energy does not follow the same pattern and the behavior is irregular (

Figure 5b). The interaction

N–

F is not significant, so the influence of

N on the level of

F is negligible, mainly respect to the influence of the drill.

Figure 5.

(a) E (95% confidence interval); (b) E N–B interaction (95% confidence interval).

Figure 5.

(a) E (95% confidence interval); (b) E N–B interaction (95% confidence interval).

It will be shown in the following that similar behavior was observed in the mean and maximum roughness as in the momentum and the energy. It was observed that a larger amount of energy was consumed for the highest rotational speed of the drill bit (8000 rpm), with results very similar to those obtained for drill bits B2 and B3.

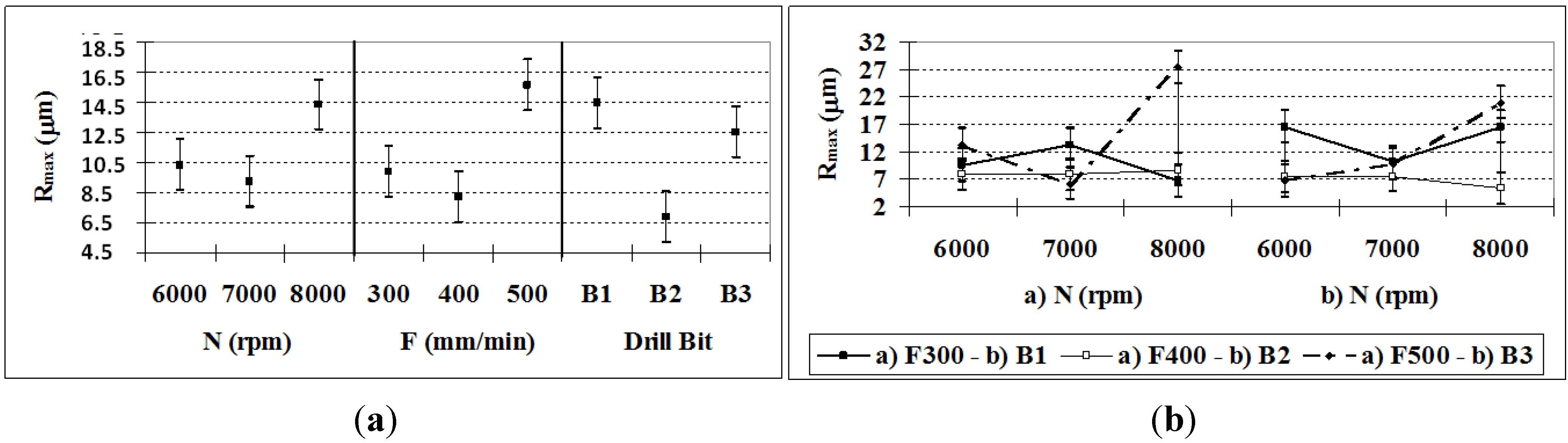

3.4. Surface Quality: Maximum and Mean Roughness

The surface quality was determined through the maximum and mean roughness, which were measured on the walls of the drilled holes and in the feed direction.

According to the ANOVA (

Table 7), all of the factors and their interactions have a significant effect on

Rmax. Among them, the

N–

F and

N–

B interactions and

B and

F account for nearly 70% of the influence in the determination of

Rmax. In

Figure 6a, it can be observed that drill bit

B2 and the feed rate

F = 400 mm/min give the lowest

Rmax values. There is a direct relationship between the combinations of the factors

N–

F and

N–

B and

Rmax;

Rmax decreases as the feed rate and the rotation speed decrease. This follows the concept of

F, where

N is already considered. Moreover, the drill bit type has a smaller influence for this variable (

Figure 6b).

Figure 6.

(a) Rmax means and confidence intervals at 95.0%; (b) Rmax: N–F and N–B Interactions, and confidence intervals at 95.0% of Rmax.

Figure 6.

(a) Rmax means and confidence intervals at 95.0%; (b) Rmax: N–F and N–B Interactions, and confidence intervals at 95.0% of Rmax.

The Rmax value is lower for the holes drilled with bit B2, which generally produces lower values for all of the cutting conditions, although B2 is better for lower feed rates. In this sense, the TiAlN coating is recommended for this material, especially when high cutting speeds are required, in mass production, and where a lower tool cost is desired.

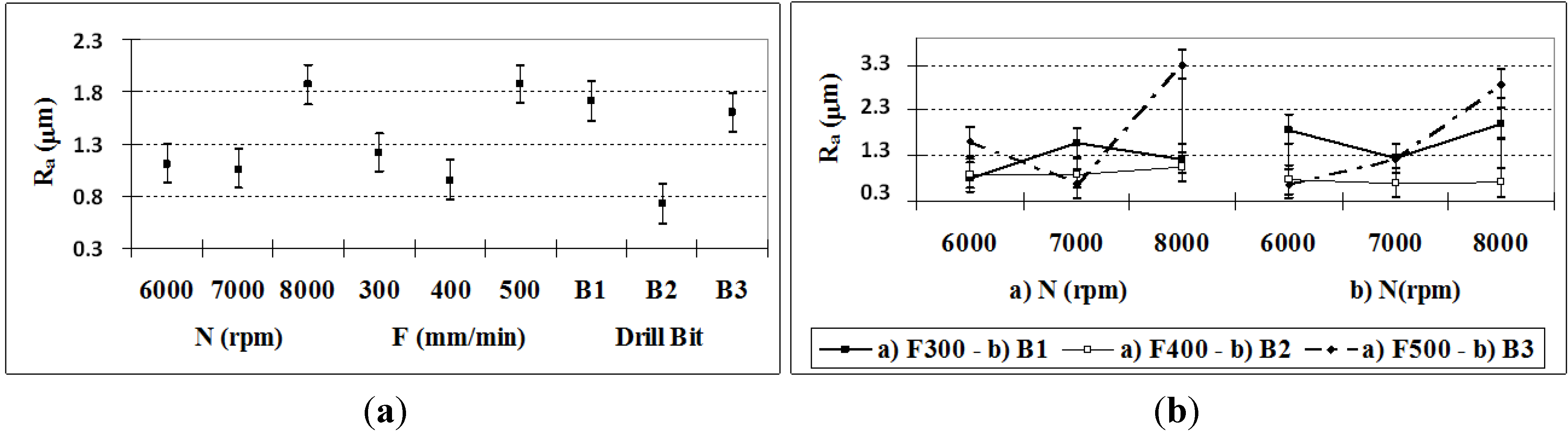

In

Table 7, it can be observed that all of the P-values for the factors and their interactions are lower than 0.05, so they all have significant effects on R

a. However, the most influential factors on

Ra are, in order of relevance,

N–F,

B,

N–B,

F,

N, and

F–B, where the first five account for 80%. In agreement with other studies [

12,

26] when

F and

N are increased, R

a should increase, but there are exceptions for

F = 400 mm/min and

N = 7000 rpm (see

Figure 7a), which motivates the analysis of the interactions. These interactions have an incremental effect on

Ra (

Figure 7b), with the aforementioned exception (particularly for bit

B2).

Figure 7.

(a) Ra (95% confidence interval); (b) Ra N–F and F–B interactions (95% confidence interval).

Figure 7.

(a) Ra (95% confidence interval); (b) Ra N–F and F–B interactions (95% confidence interval).

The maximum and mean roughness values show a close correlation.

Table 7 indicates that the factors that contribute the most to both roughness measures are nearly the same. The factor with the greatest influence is the

N-F interaction, followed by the drill bit type and the

N–B interaction.

The mean roughness values produced by bits

B2 and

B3 were 0.5 and 0.6 μm, respectively, which implies a surface finish grade of N6 according to the ISO 1302 standard [

27]. For bit

B1, the minimum value of

Ra was 0.96 μm, which equates to a grade of N7. In exterior turning operations with this material [

3,

4], higher mean roughness values were observed. Type

B2 drill bits normally produce better surface quality (see

Table 3), so the fact that bit

B2 had the lowest mean roughness in the tests indicates that the conditions were favorable. Another possible explanation is that drilling generates higher temperatures than those of exterior turning operations, which has a favorable impact on the behavior of PEEK GF30 matrix material. The similar variations in

Rmax and

Ra allow the establishment of a relationship between them, so that in future investigations, it will not be necessary to measure both to draw conclusions about the behavior of the tool in drilling operations with PEEK-GF30.

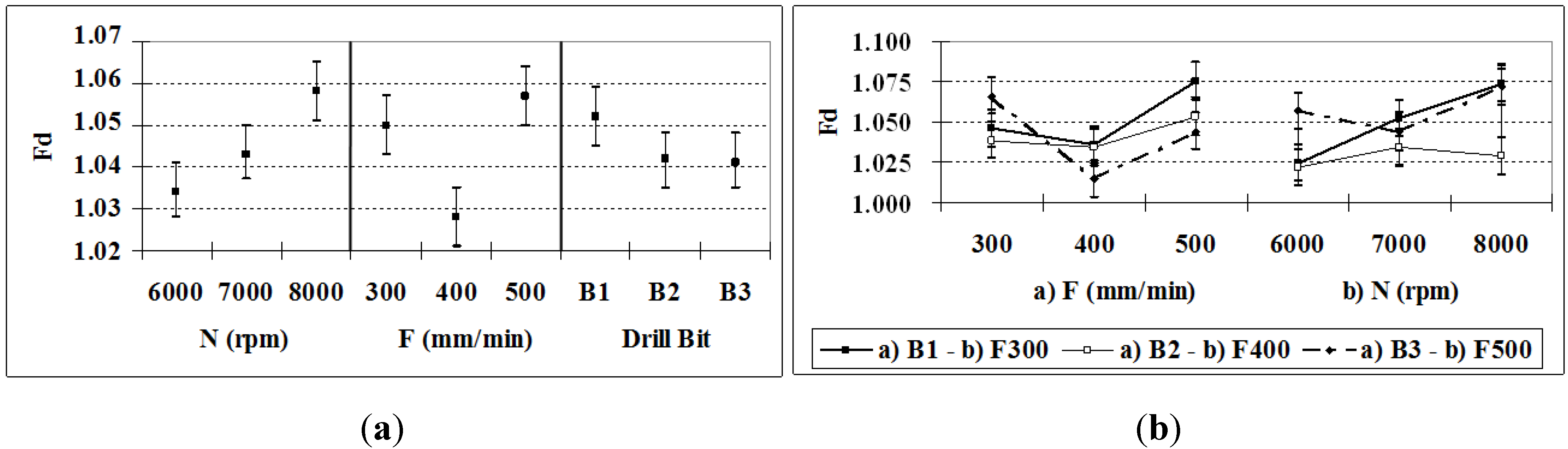

3.5. Delamination Factor

Regarding the delamination factor

Fd, the ANOVA indicates that all of the factors and their interactions are significant and that the most influential factor is

F, followed by

F–B, and then

N and

N-F, which together account for more than 60% (

Table 8). Theses results are in agreement with what other researchers have found when drilling reinforced polyester composites [

7], glass fiber reinforced plastic composite [

25], carbon fiber reinforced thermosets [

28], or carbon fiber-reinforced plastic [

29], and in opposition with what, Rubio

et al. [

8] have found when high speed drilling glass fiber reinforced plastic

The mean values of the delamination factor are shown in

Figure 8a. Although increasing feed rate tends to increase the delamination,

Figure 8b shows that Fd decreases for

F = 400 mm/min, whereas an increase in

N increases the delamination factor. In general, the combination of

F and

B is associated with less delamination up to the value

F = 400 mm/min; bit

B1 had worse behavior for

F = 300 mm/min (

Figure 8). It can be observed that the factors influencing

Fd are very different from those influencing the surface quality.

Figure 8.

(a) Fd (95% confidence interval); (b) Fd N–B and F–B interactions (95% confidence interval).

Figure 8.

(a) Fd (95% confidence interval); (b) Fd N–B and F–B interactions (95% confidence interval).

The results obtained in all of the cases can be considered acceptable because the delamination factor was smaller than what has been observed in drilling similar materials, such as polyester reinforced with glass fibers [

7]. The delamination factor was between 1.011 (

N = 8000 rpm and

F = 400 mm/min with drill bit

B3) and 1.086 (

N = 8000 rpm and

F = 500 mm/min with drill bit

B1). In general terms, higher rotation speeds, lower feed rates (so, low feed per revolutions), and smaller angles in the drill bit head (drill bit

B3) reduce delamination. This result is consistent with those obtained using glass-fiber-reinforced epoxy [

9] and, thus, indicate the best cutting conditions for the drilling of polymeric materials reinforced with glass fibers. Images of the drilled holes and the hole profiles, taken at 20× magnification, are provided in

Table 9.

Table 9.

Real hole and screen shoot from three-dimensional measurement device with a TESA VISIO optical sensor (PEEK G30 material).