Controlling Morphological Parameters of Anodized Titania Nanotubes for Optimized Solar Energy Applications

Abstract

:1. Introduction

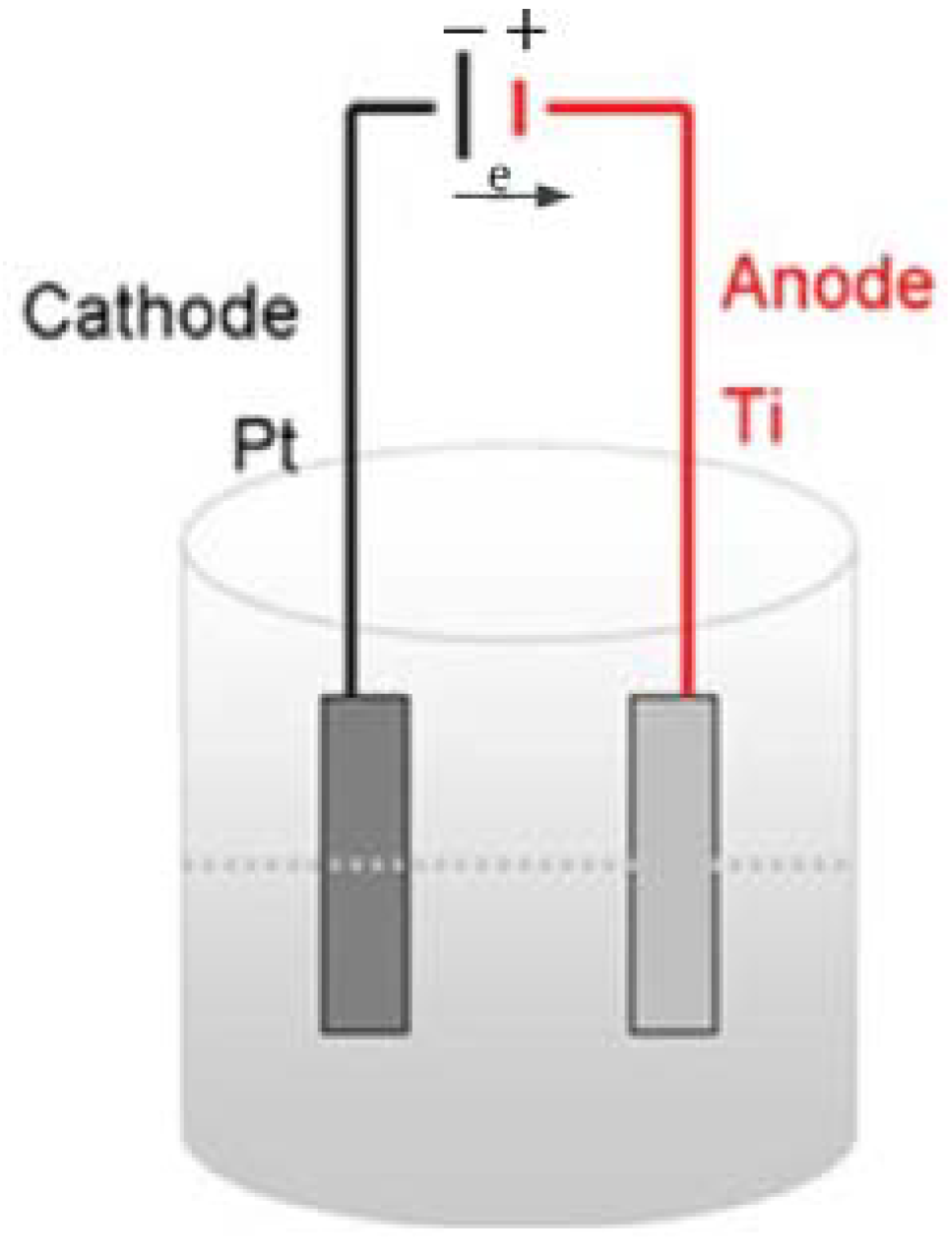

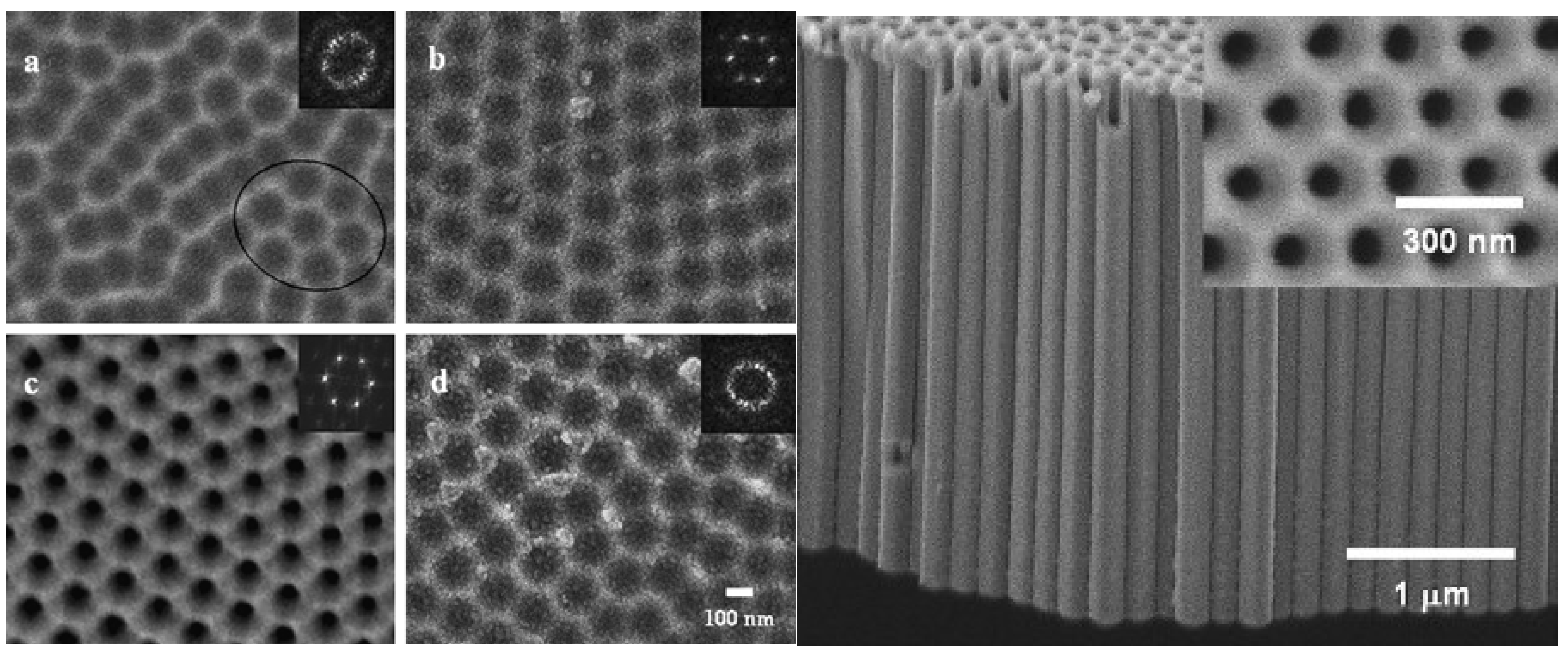

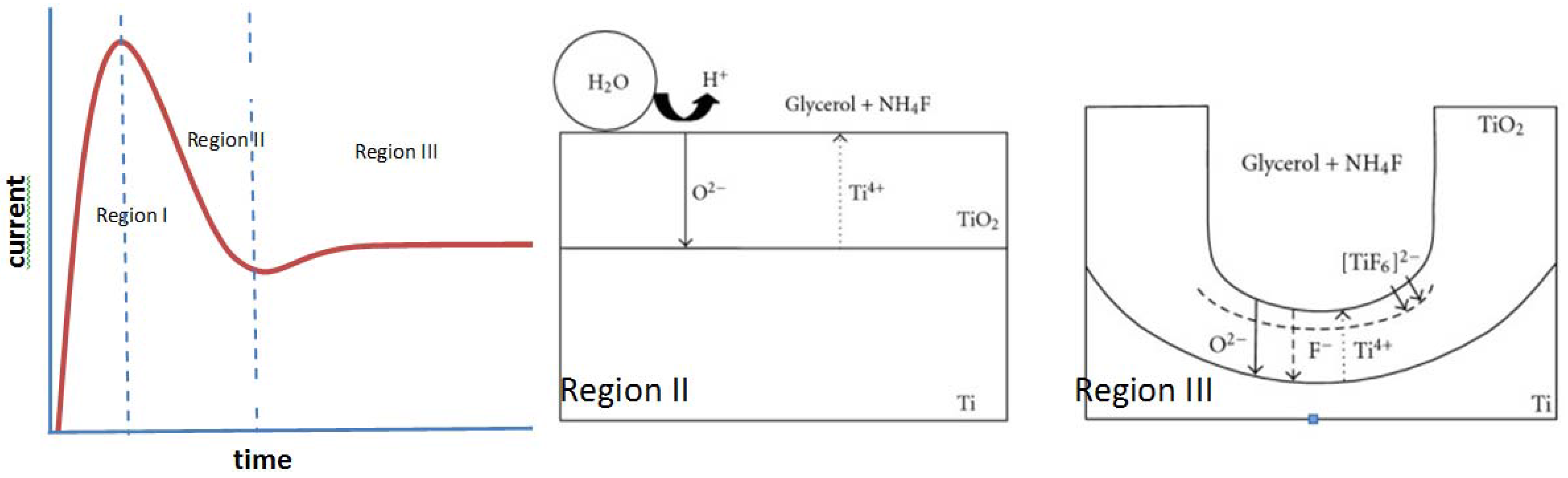

2. Anodized Titania Nanotube Formation

2.1. Control of Morphology

| Voltage | 10–240V [32,33] | Electrolyte Solvent | water, ethylene glycol, diethylene glycol, DMSO, DMF, formamide, acetic acid [34,35] |

| Duration | seconds–9 days [36,37] | Water Content | 0%–100% [38] |

| Etching species | HF, NH4F, Bu4NF [34] | Electrolyte Additives | Na2EDTA, H2O2 lactic acid [31,36,39] |

| Fluoride Conc. | 0.05–0.5M NH4F [3,31] | Electrolyte Age | unused-120 h [40] |

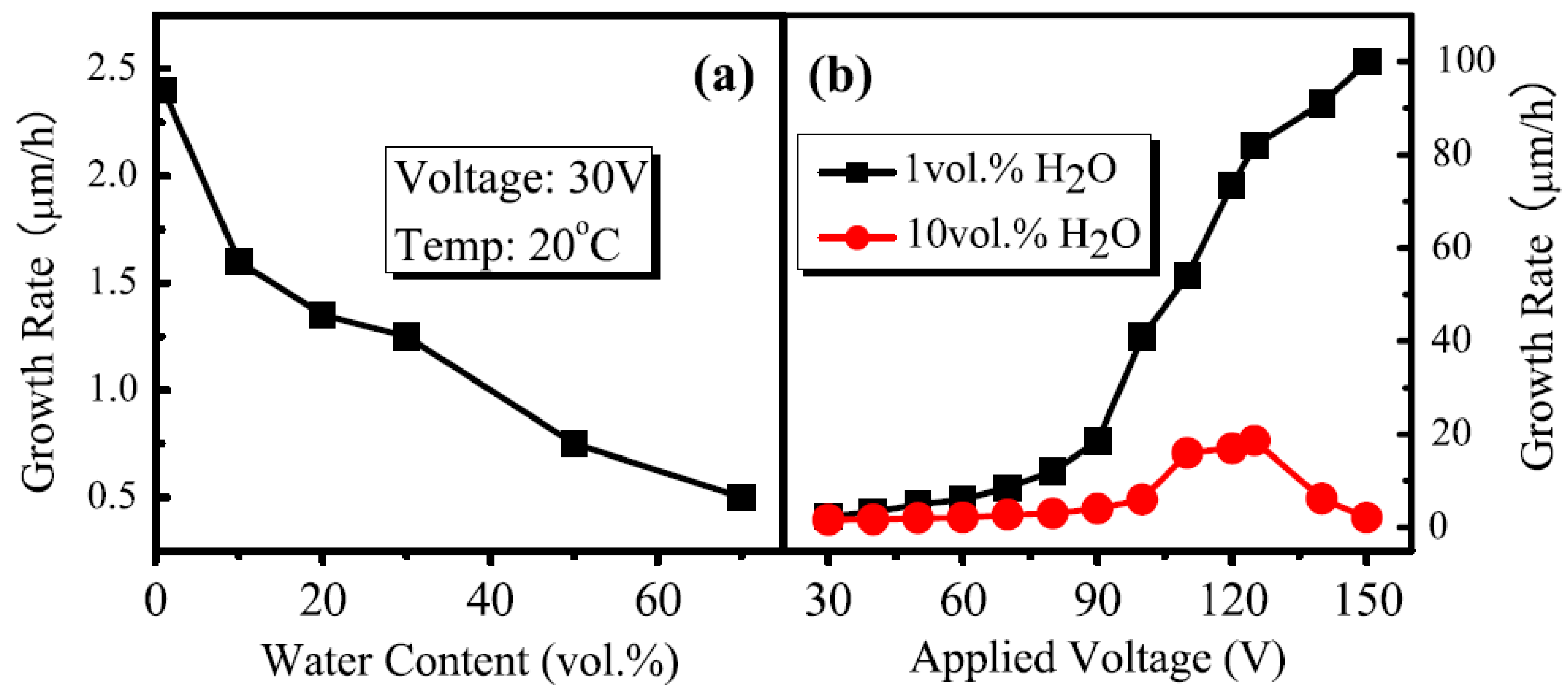

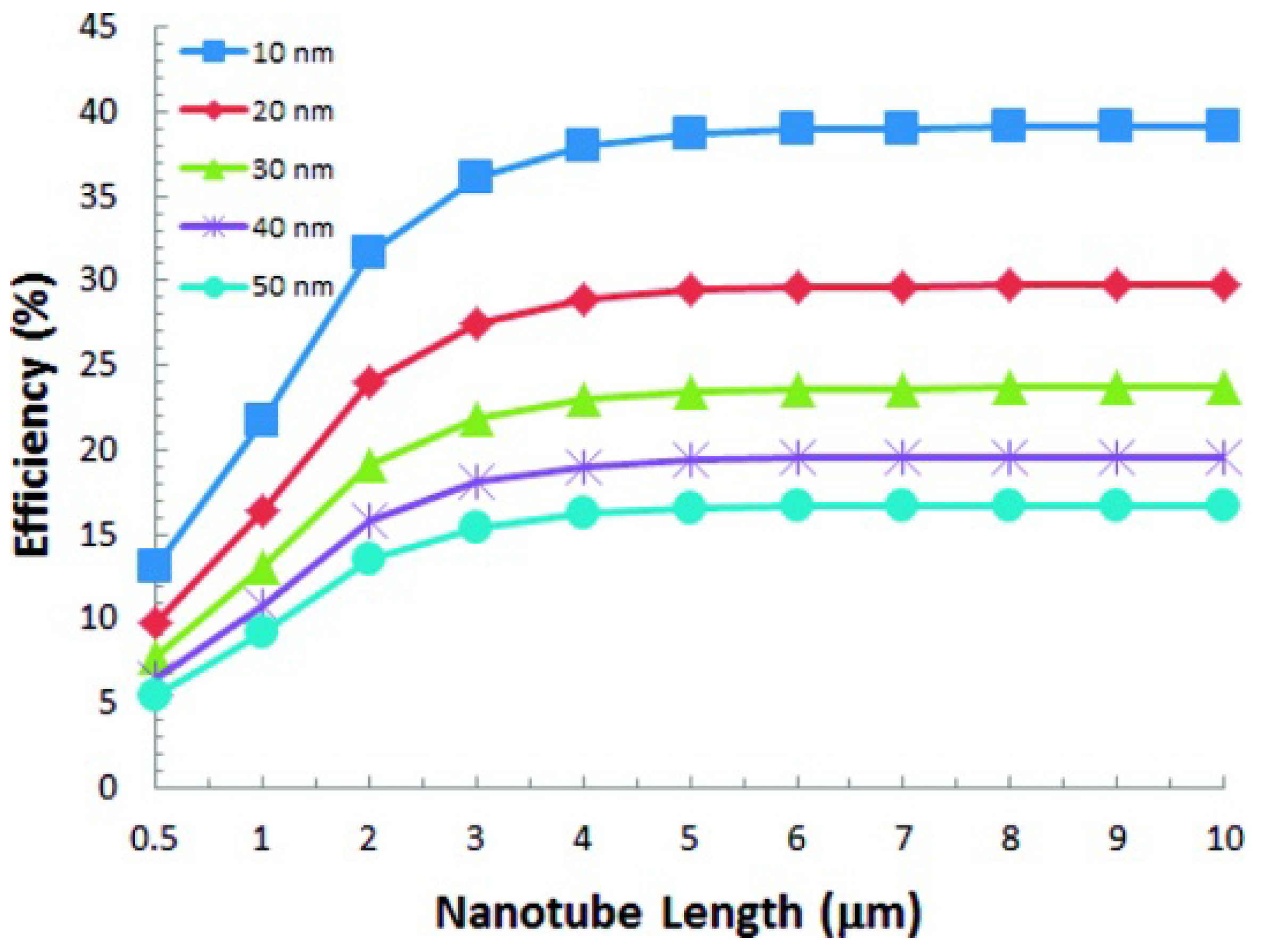

2.1.1. Nanotube Length

| Length (µm) | Duration | Electrolyte | Voltage (V) | Reference |

|---|---|---|---|---|

| 20 | 2 h | 0.09 M NH4F ethylene glycol | 60 | [48] (SI) |

| 20 | 0.5 h | 0.5 M NH4F, 0.25 M Na2EDTA, 5% water, ethylene glycol | 80 | [31] |

| 18 | 1 min | 0.1 M NH4F, 1.5 M lactic acid, 5% water, ethylene glycol (60 °C) | 150 | [36] |

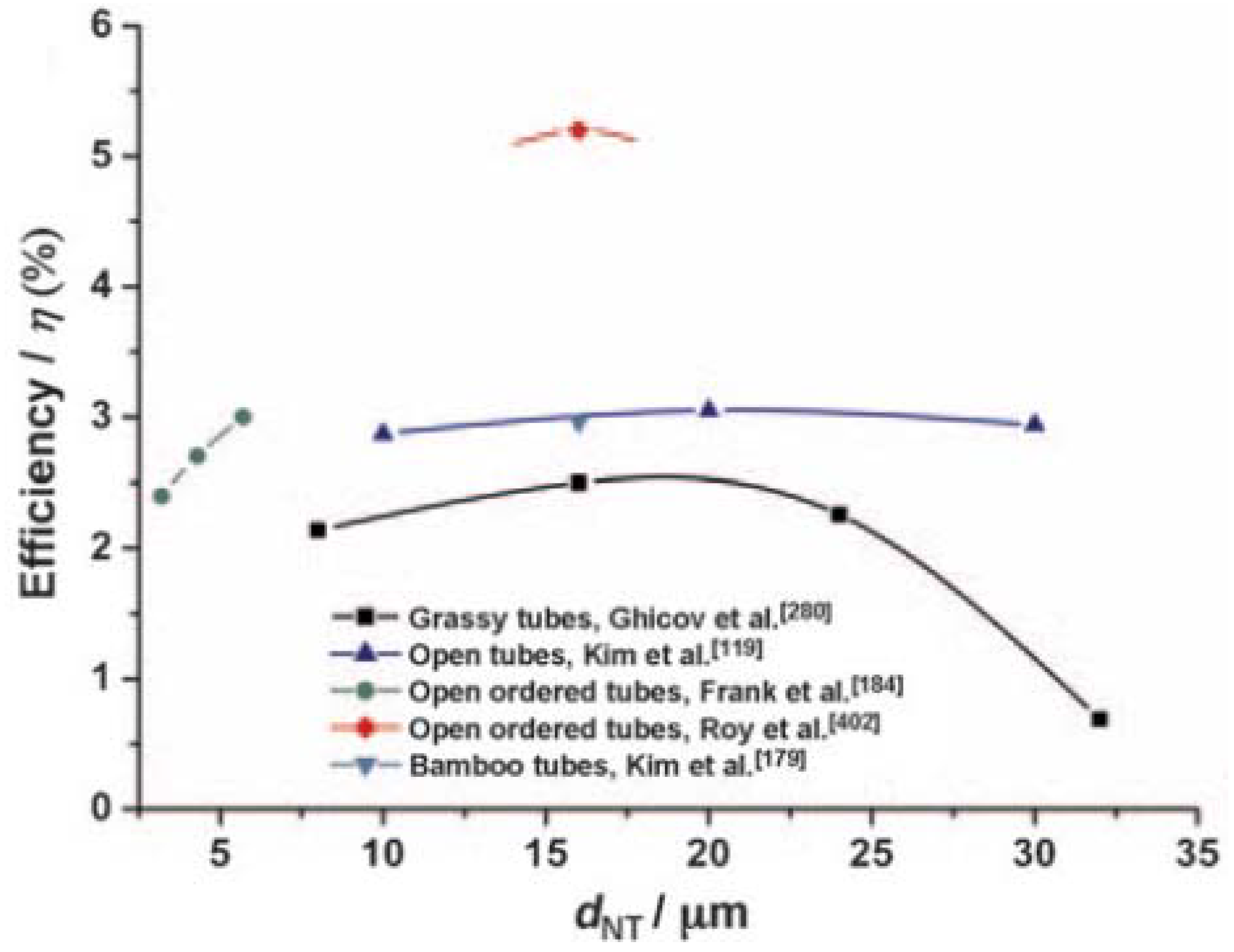

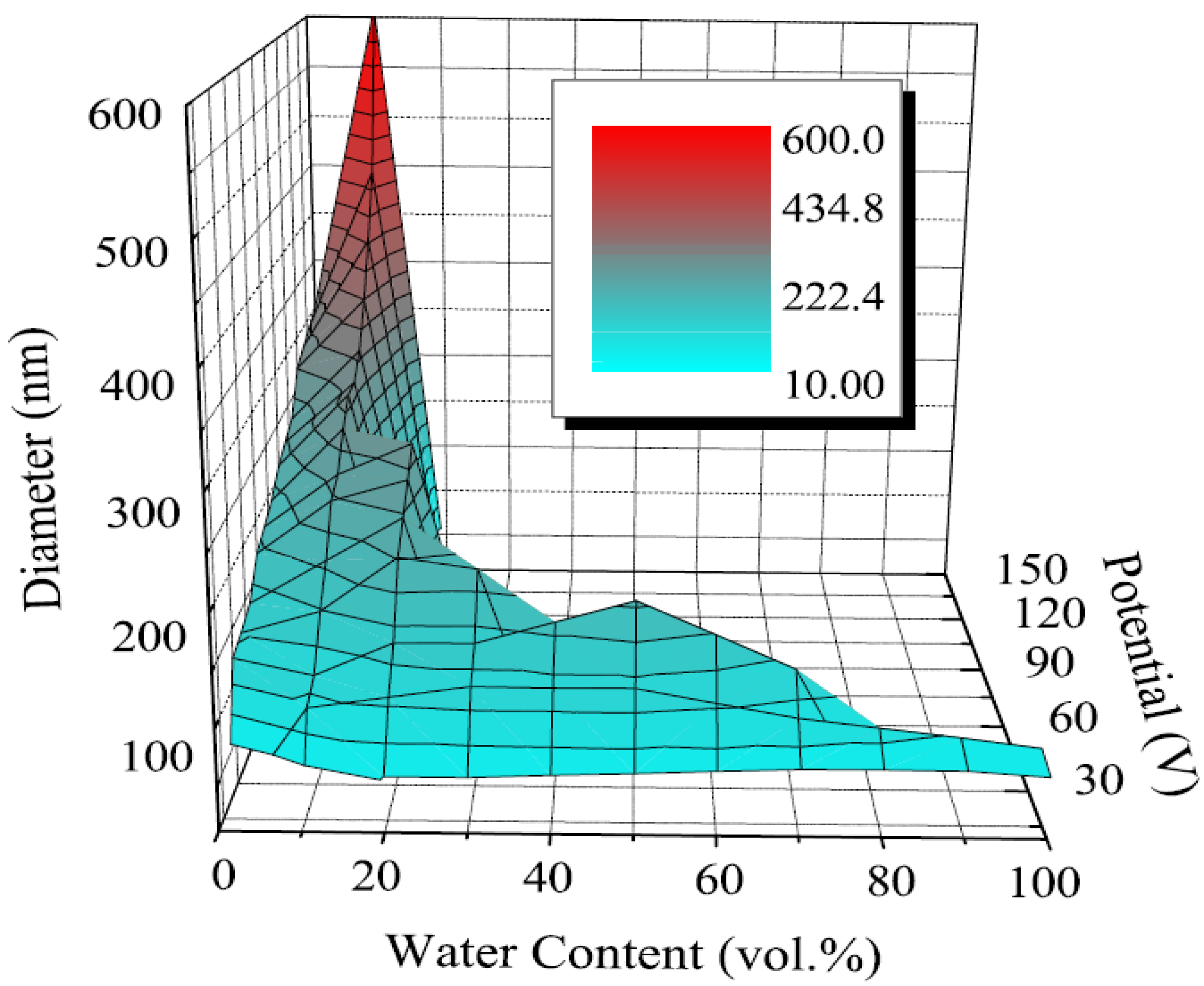

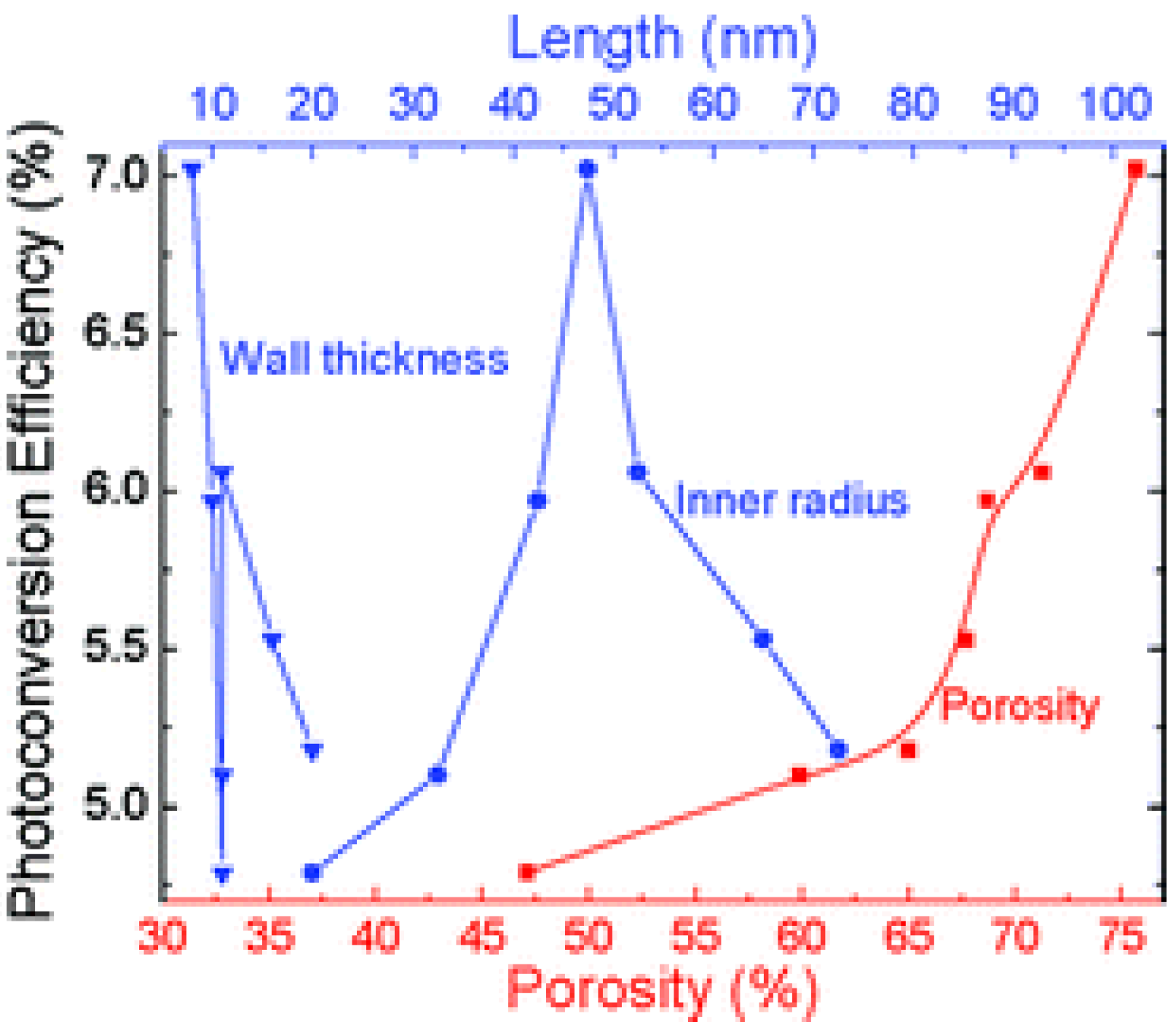

2.1.2. Diameter and Wall Thickness

| Inner Diameter | Duration | Electrolyte | Voltage | Reference |

|---|---|---|---|---|

| 15 nm | 24 h | 0.2 M HF, 3.6% water, ethylene glycol | 10 V | [32] |

| 709 nm | 47 h | 0.25% HF, 1% water, diethylene glycol | 120 V | [62] |

| 80 nm | 1.5 h | 0.15 M NH4F, 3% water, glycerol | 80 V | [29] |

2.1.3. Nanotube Roughness and Intertube Spacing

| Electrolyte Solvent | Viscosity (cP) [69] |

| Glycerol | 934 |

| Ethylene Glycol | 16.1 |

| Formamide | 3.34 |

| DMSO | 1.99 |

| Water | 0.89 |

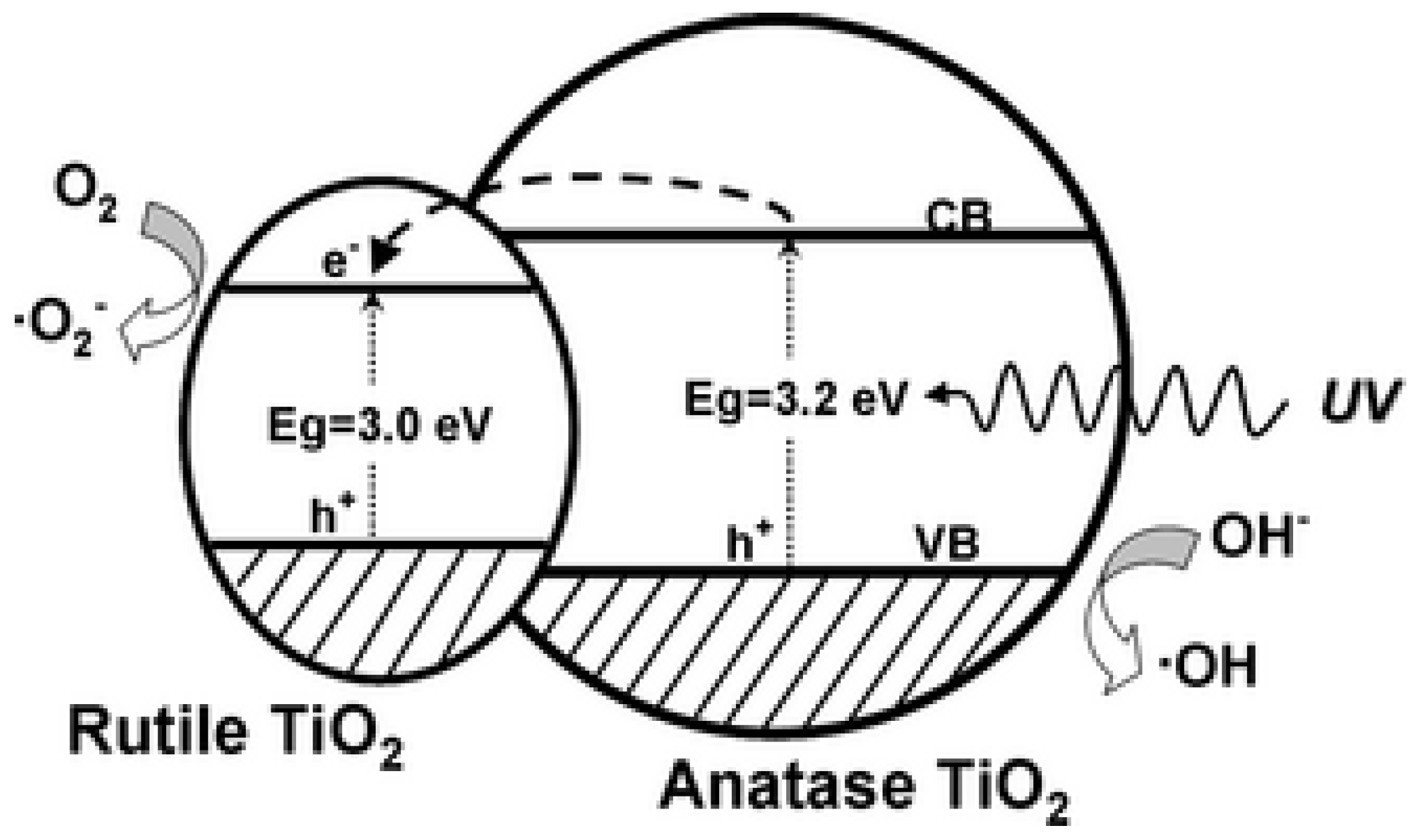

2.2. Control of Crystallinity

| Annealing Temperature (°C) | unannealed | 350 | 450 | 550 | 650 | 750 |

| Anatase/Rutile Mass Fraction | amorphous | 100/0 | 100/0 | 1/1.2 | 1/2.2 | 1/37.2 |

| Photoconversion Efficiency (%) | 1.4 | 5.86 | 5.93 | 7.25 | 8.56 | 0.4 |

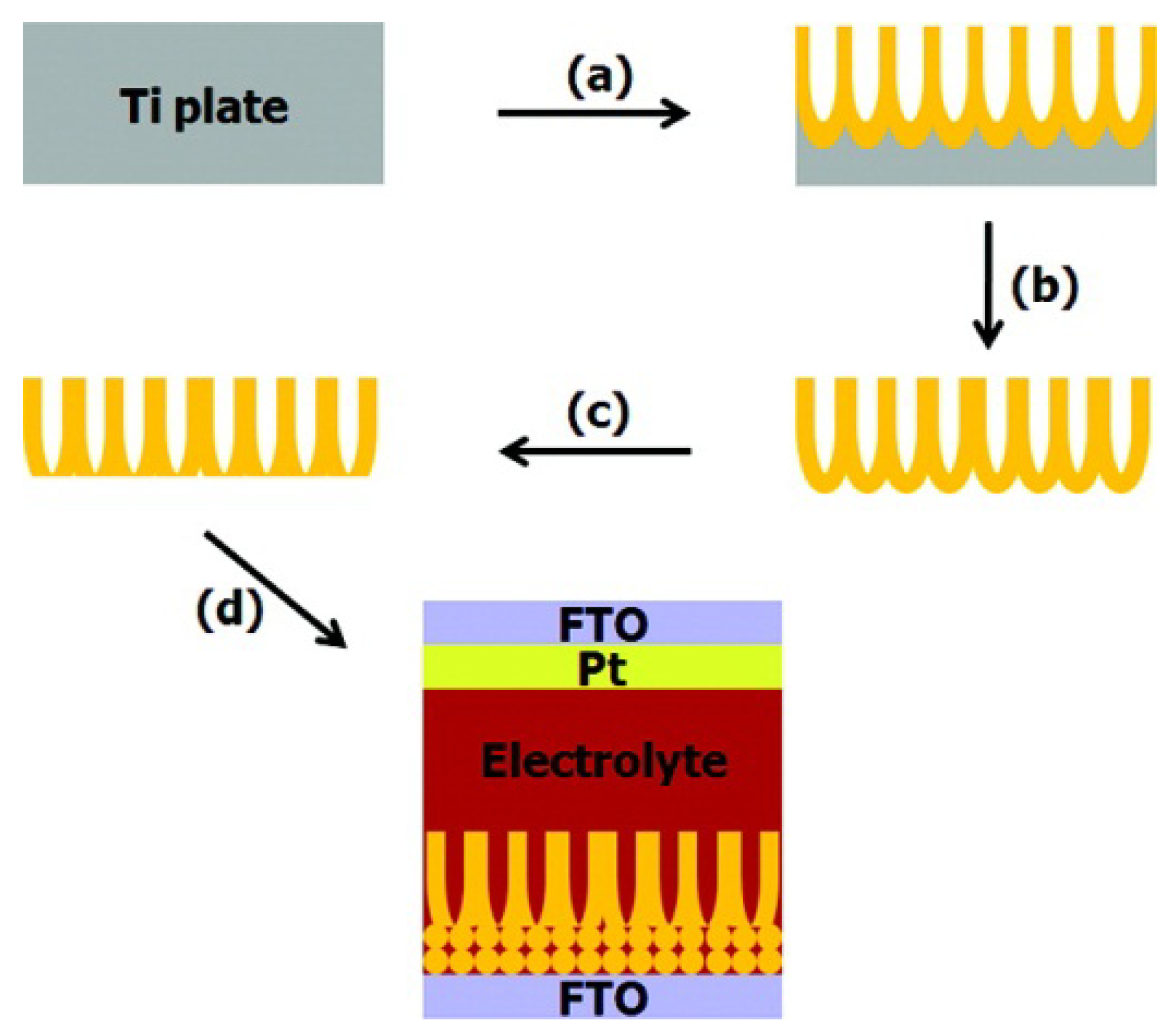

3. Solar Cell Fabrication

3.1. Removing the Array

3.2. Anodizing on Conductive Substrates

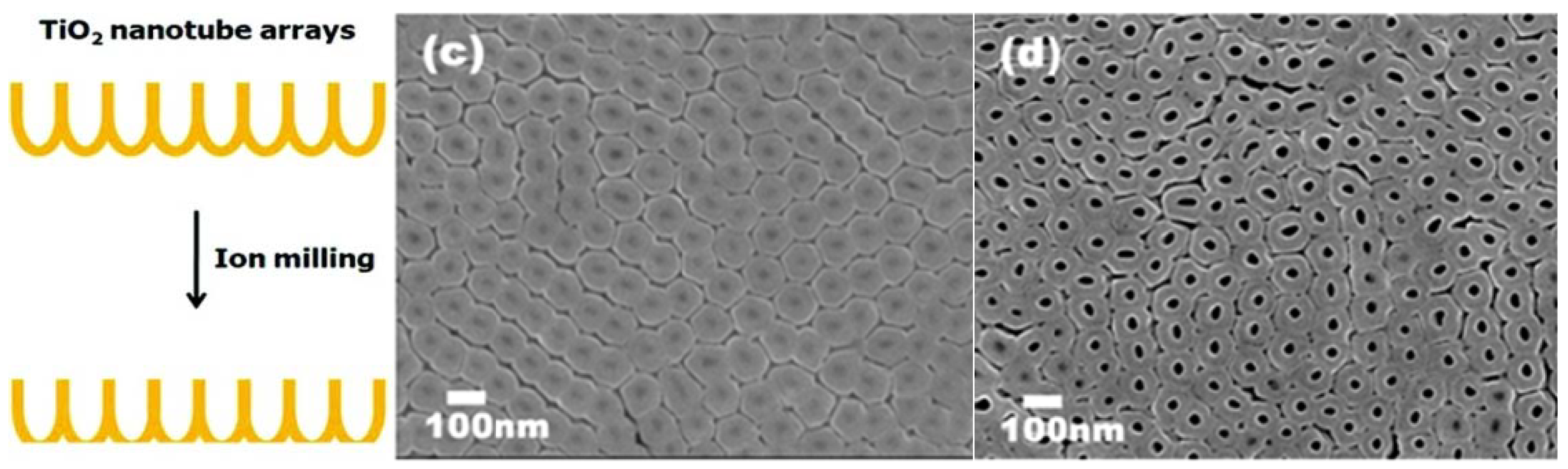

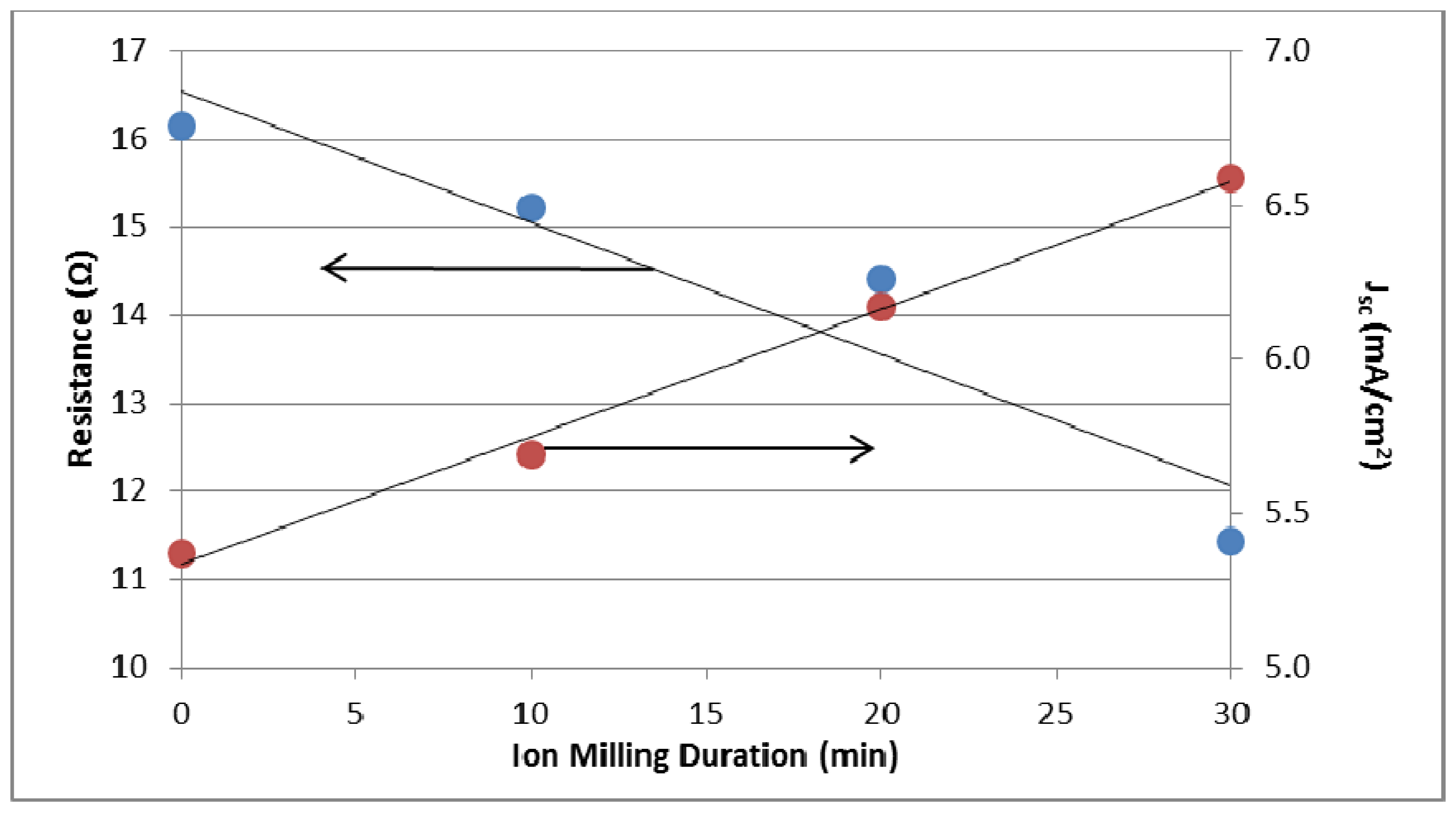

3.3. Removal of Barrier Layer

4. Conclusions

Acknowledgments

References

- Park, J.T.; Patel, R.; Jeon, H.; Kim, D.J.; Shin, J.-S.; Kim, J.H. Facile fabrication of vertically aligned TiO2 nanorods with high density and rutile/anatase phases on transparent conducting glasses: High efficiency dye-sensitized solar cells. J. Mater. Chem. 2012, 22, 6131–6138. [Google Scholar] [CrossRef]

- Chen, R.S.; Chen, C.A.; Tsai, H.Y.; Wang, W.C.; Huang, Y.S. Ultrahigh efficient single-crystalline TiO2 nanorod photoconductors. Appl. Phys. Lett. 2012, 100, 123108:1–123108:4. [Google Scholar]

- Roy, P.; Berger, S.; Schmuki, P. TiO2 nanotubes: Synthesis and applications. Angew. Chem. Int. Ed. 2011, 50, 2904–2939. [Google Scholar] [CrossRef]

- Lockman, Z.; Ismail, S.; Sreekantan, S.; Schmidt-Mende, L.; MacManus-Driscoll, J. The rapid growth of 3 µm long titania nanotubes by anodization of titanium in a neutral electrochemical bath. Nanotechnology 2010, 21, 055601:1–055601:6. [Google Scholar] [CrossRef]

- Paulose, M.; Mor, G.; Varghese, O.; Shankar, K.; Grimes, C. Visible light photoelectrochemical and water-photoelectrolysis properties of titania nanotube arrays. J. Photochem. Photobiol. A 2006, 178, 8–15. [Google Scholar] [CrossRef]

- Li, Y.; Yu, X.; Yang, Q. Fabrication of TiO2 nanotube thin films and their gas sensing properties. J. Sens. 2009, 2009, 402174:1–402174:19. [Google Scholar]

- Lu, X.; Wang, G.; Zhai, T.; Yu, M.; Gan, J.; Tong, Y.; Li, Y. Hydrogenated TiO2 nanotube arrays for supercapacitors. Nano Lett. 2012, 12, 1690–1696. [Google Scholar] [CrossRef] [PubMed]

- Zwilling, V.; Aucoututier, M.; Darque-Ceretti, E. Anodic oxidation of titanium and TA6V alloy in chromic media. An electrochemical approach. Electrochim. Acta 1999, 45, 921–929. [Google Scholar] [CrossRef]

- Gong, D.; Grimes, C.; Varghese, O.; Hu, W.; Singh, R.; Chen, Z. Titanium oxide nanotube arrays prepared by anodic oxidation. J. Mater. Res. 2001, 16, 3331–3334. [Google Scholar] [CrossRef]

- Varghese, O.; Gong, D.; Paulose, M.; Grimes, C.; Dickey, E. Crystallization and high-temperature structural stability of titanium oxide nanotube arrays. J. Mater. Res. 2003, 18, 156–165. [Google Scholar] [CrossRef]

- Ghicov, A.; Tsuchiya, H.; Macak, J.; Schmuki, P. Annealing effects on the photoresponse of TiO2 nanotubes. Phys. Stat. Sol. A 2006, 203, R28–R30. [Google Scholar] [CrossRef]

- Fabregat-Santiago, F.; Barea, E.; Bisquert, J.; Mor, G.; Shankar, K.; Grimes, C.A. High carrier density and capacitance in TiO2 nanotube arrays induced by electrochemical doping. J. Am. Chem. Soc. 2008, 130, 11312–11316. [Google Scholar] [CrossRef] [PubMed]

- Morris, A.; Meyer, G. TiO2 surface functionalization to control the density of states. J. Phys. Chem. C 2008, 112, 18224–18231. [Google Scholar] [CrossRef]

- Sturgeon, M.; Lai, P.; Hu, M. A comparative study of anodized titania nanotube architectures in aqueous and nonaqueous solutions. J. Mater. Res. 2011, 26, 2612–2623. [Google Scholar] [CrossRef]

- Honda, K.; Fujishima, A. Electrochemical photolysis of water at a semiconductor electrode. Nature 1972, 238, 37–38. [Google Scholar] [CrossRef] [PubMed]

- Yun, H.J.; Lee, H.; Joo, J.B.; Kim, N.D.; Yi, J. Effect of TiO2 nanoparticle shape on hydrogen evolution via water splitting. J. Nanosci. Nanotechnol. 2011, 11, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Wolcott, A.; Smith, W.; Kuykendall, T.; Zhao, Y.; Zhang, J. Photoelectrochemical water splitting using dense and aligned TiO2 nanorod arrays. Small 2009, 5, 104–111. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Wang, P. Optimization of photoelectrochemical water splitting performance on hierarchical TiO2 nanotube arrays. Energy Environ. Sci. 2012, 5, 6506–6512. [Google Scholar] [CrossRef]

- Ghicov, A.; Schmuki, P. Self-ordering electrochemistry: A review on growth and functionality of TiO2 nanotubes and other self-aligned MOx structures. Chem. Commun. 2009, 2791–2808. [Google Scholar]

- Yan, J.; Zhou, F. TiO2 nanotubes: Structure optimization for solar cells. J. Mater. Chem. 2011, 21, 9406–9418. [Google Scholar] [CrossRef]

- Tepavcevic, S.; Darling, S.; Dimitrijevic, N.; Rajh, T.; Sibener, S. Improved hybrid solar cells via in situ UV polymerization. Small 2009, 5, 1776–1783. [Google Scholar] [CrossRef] [PubMed]

- Ayzner, A.; Tassone, C.; Tolbert, S.; Schwartz, B. Reappraising the need for bulk heterojunctions in polymer-fullerene photovoltaics: The role of carrier transport in all-solution-processed P3HT/PCBM bilayer solar cells. J. Phys. Chem. C 2009, 113, 20050–20060. [Google Scholar] [CrossRef]

- Yella, A.; Lee, H.-W.; Tsao, H.N.; Yi, C.; Chandiran, A.; Nazeeruddin, M.K.; Diau, E.; Yeh, C.-Y.; Zakeeruddin, S.; Grätzel, M. Porphyrin-sensitized solar cells with cobalt (II/III)-based redox electrolyte exceed 12 percent efficiency. Science 2011, 334, 629–634. [Google Scholar] [CrossRef] [PubMed]

- Kannan, B.; Castelino, K.; Majumdar, A. Design of nanostructured heterojunction polymer photvoltaic devices. Nano Lett. 2003, 3, 1729–1733. [Google Scholar] [CrossRef]

- Roy, P.; Kim, D.; Lee, K.; Spiecker, E.; Schmuki, P. TiO2 nanotubes and their application in dye-sensitized solar cells. Nanoscale 2010, 2, 45–49. [Google Scholar] [CrossRef] [PubMed]

- Boucle, J.; Ackermann, J. Solid-state dye-sensitized and bulk heterojunction solar cells using TiO2 and ZnO nanostructures: Recent progress and new concepts at the borderline. Polym. Int. 2012, 61, 355–373. [Google Scholar] [CrossRef]

- Wang, M.; Liu, Y.; Yang, H. A unified theory for the formation of anodized metal oxide structures. Electrochim. Acta 2012, 62, 424–432. [Google Scholar] [CrossRef]

- Li, S.; Zhang, G.; Guo, D.; Yu, L.; Zhang, W. Anodization fabrication of highly ordered TiO2 nanotubes. J. Phys. Chem. C 2009, 113, 12759–12765. [Google Scholar] [CrossRef]

- Galstyan, V.; Vomiero, A.; Comini, E.; Faglia, G.; Sberveglieri, G. TiO2 nanotubular and nanoporous arrays by electrochemical anodization on different substrates. RSC Adv. 2011, 1, 1038–1044. [Google Scholar] [CrossRef]

- Zhang, G.; Huang, H.; Zhang, Y.; Chan, H.; Zhou, L. Highly ordered nanoporous TiO2 and its photocatalytic properties. Electrochem. Commun. 2007, 9, 2854–2858. [Google Scholar] [CrossRef]

- Banerjee, S.; Misra, M.; Mohapatra, S.K.; Howard, C.; Mohapatra, S.K.; Kamilla, S.K. Formation of chelating agent driven anodized TiO2 nanotubular membrane and its photovoltaic application. Nanotechnology 2010, 21, 145201:1–145201:9. [Google Scholar]

- Liu, N.; Lee, K.; Schmuki, P. Small diameter TiO2 nanotubes vs. nanopores in dye sensitized solar cells. Electrochem. Commun. 2012, 15, 1–4. [Google Scholar] [CrossRef]

- Alivov, Y.; Pandikunta, M.; Nikishin, S.; Fan, Z. The anodization voltage influence on the properties of TiO2 nanotubes grown by electrochemical oxidation. Nanotechnology 2009, 20, 225602:1–225602:6. [Google Scholar]

- Yoriya, S.; Mor, G.; Sharma, S.; Grimes, C. Synthesis of ordered arrays of discrete, partially crystalline titania nanotubes by Ti anodization using diethylene glycol electrolytes. J. Mater. Chem. 2008, 18, 3332–3336. [Google Scholar] [CrossRef]

- Tsuchiya, H.; Macak, J.; Taveira, L.; Balaur, E.; Ghicov, A.; Sirotna, K.; Schmuki, P. Self-organized TiO2 nanotubes prepared in ammonium fluoride containing acetic acid electrolytes. Electrochem. Commun. 2005, 7, 576–580. [Google Scholar] [CrossRef]

- So, S.; Lee, K.; Schmuki, P. Ultrafast growth of highly ordered anodic TiO2 nanotubes in lactic acid electrolytes. J. Am. Chem. Soc. 2012, 134, 11316–11318. [Google Scholar] [CrossRef] [PubMed]

- Paulose, M.; Prakasam, H.; Varghese, O.; Peng, L.; Popat, K.; Mor, G.; Desai, T.; Grimes, C. TiO2 Nanotube Arrays of 1000 µm length by anodization of titanium foil: Phenol red diffusion. J. Phys. Chem. C 2007, 111, 14992–14997. [Google Scholar] [CrossRef]

- Yin, H.; Liu, H.; Shen, W.Z. The large diameter and fast growth of self-organized TiO2 nanotube arrays achieved via electrochemical anodization. Nanotechnology 2010, 21, 035601:1–035601:7. [Google Scholar]

- Sreekantan, S.; Wei, L.; Lockman, Z. Extremely fast growth rate of TiO2 nanotube arrays in electrochemical bath containing H2O2. J. Electrochem. Soc. 2011, 158, C397–C402. [Google Scholar] [CrossRef]

- Lee, K.; Kim, J.; Kim, H.; Lee, Y.; Tak, Y.; Kim, D.; Schmuki, P. Effect of electrolyte conductivity on the formation of a nanotubular TiO2 photoanode for a DSSC. J. Korean Phys. Soc. 2009, 54, 1027–1031. [Google Scholar] [CrossRef]

- Portan, D.; Papaefthymiou, K.; Arvanita, E.; Jiga, G.; Papanicolaou, G. A combined statistical and microscopic analysis of TiO2 nanotubes synthesized under different electrochemical anodizing conditions. J. Mater. Res. 2012, 47, 4696–4705. [Google Scholar]

- Chin, L.; Zainal, Z.; Hussein, M.; Tee, T.W. Fabrication of highly ordered TiO2 nanotubes from fluoride containing aqueous electrolyte and their photoelectrochemical response. J. Nanosci. Nanotechnol. 2011, 11, 4900–4909. [Google Scholar] [CrossRef] [PubMed]

- Sreekantan, S.; Saharudin, K.A.; Lockman, Z.; Tzu, T.W. Fast-rate formation of TiO2 nanotube arrays in an organic bath and their applications in photocatalysis. Nanotechnology 2010, 21, 365603:1–365603:8. [Google Scholar] [CrossRef]

- Li, D.; Shiwei, L.; Li, S.; Huang, X.; Cao, X.; Li, J. Effects of geometric and crystal structures on the photoelectrical properties of highly ordered TiO2 nanotube arrays. J. Mater. Res. 2012, 27, 1029–1036. [Google Scholar] [CrossRef]

- Yoriya, S.; Paulose, M.; Varghese, O.; Mor, G.; Grimes, C. Fabrication of vertically oriented TiO2 nanotube arrays using dimethyl sulfoxide electrolytes. J. Phys. Chem. C 2007, 111, 13770–13776. [Google Scholar] [CrossRef]

- Prakasam, H.; Shankar, K.; Paulose, M.; Varghese, O.; Grimes, C. A new benchmark for TiO2 nanotube array growth by anodization. J. Phys. Chem. C 2007, 111, 7235–7241. [Google Scholar] [CrossRef]

- Lai, C.W.; Sreekantan, S. Effect of applied potential on the formation of self-organized TiO2 nanotube arrays and its photoelectrochemical response. J. Nanomater. 2011, 2011, 142463:1–142463:7. [Google Scholar]

- Varghese, O.; Paulose, M.; Grimes, C. Long vertically aligned titania nanotubes on transparent conducting oxide for highly efficient solar cells. Nat. Nanotechnol. 2009, 4, 592–597. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Nakata, K.; Liu, S.; Sakai, M.; Ochiai, T.; Murakami, T.; Takagi, K.; Fujishima, A. Theoretical kinetic analysis of heterogeneous photocatalysis by TiO2 nanotube arrays: The effects of nanotube geometry on photocatalytic activity. J. Phys. Chem. C 2012, 116, 7471–7479. [Google Scholar] [CrossRef]

- Kontos, A.; Katsanaki, A.; Maggos, T.; Likodimos, V.; Ghicov, A.; Kim, D.; Kunze, J.; Vasilakos, C.; Schmuki, P.; Falara, P. Photocatalytic degradation of gas pollutants on self-assembled titania nanotubes. Chem. Phys. Lett. 2010, 490, 58–62. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, X.; Nishimoto, S.; Murakami, T.; Fujishima, A. Efficient photocatalytic degradation of gaseous acetaldehyde by highly ordered TiO2 nanotube arrays. Environ. Sci. Technol. 2008, 42, 8547–8551. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Zhang, X.; Nishimoto, S.; Jin, M.; Tryk, D.; Murakami, T.; Fujishima, A. Highly ordered TiO2 nanotube arrays with controllable length for photoelectrocatalytic degradation of phenol. J. Phys. Chem. C 2008, 112, 253–259. [Google Scholar] [CrossRef]

- Zhuang, H.-F.; Lin, C.-J.; Lai, Y.-K.; Sun, L.; Li, J. Some critical structure factors of titanium oxide nanotube array in its photocatalytic activity. Environ. Sci. Technol. 2007, 41, 4735–4740. [Google Scholar] [CrossRef] [PubMed]

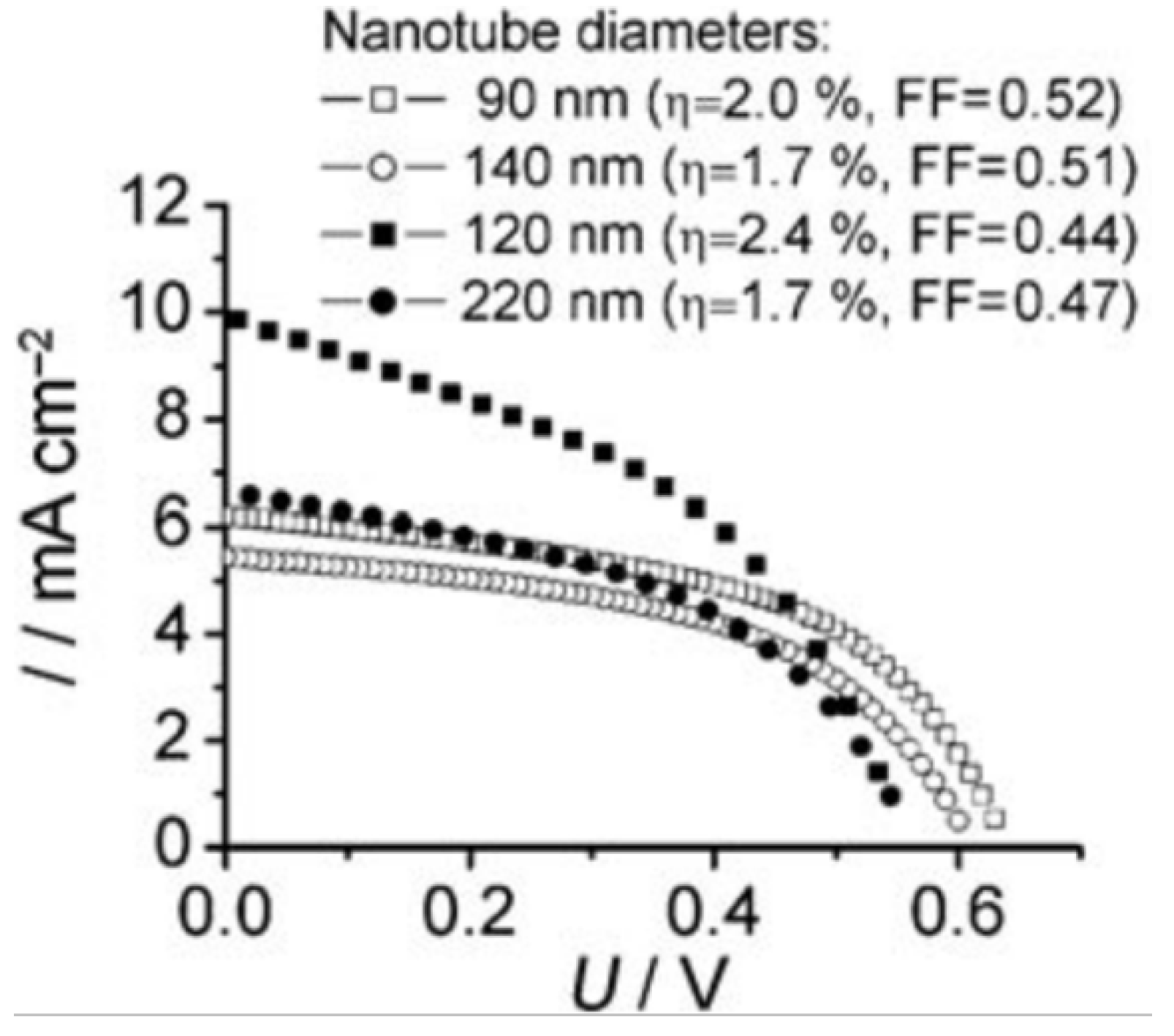

- Ghicov, A.; Albu, S.; Hahn, R.; Kim, D.; Stergiopoulos, T.; Kunze, J.; Schiller, C.-A.; Falaras, P.; Schmuki, P. TiO2 nanotubes in dye-sensitized solar cells: Critical factors for the conversion efficiency. Chem. Asian J. 2009, 4, 520–525. [Google Scholar] [CrossRef] [PubMed]

- Jennings, J.; Ghicov, A.; Peter, L.; Schmuki, P.; Walker, A. Dye-sensitized solar cells based on oriented TiO2 nanotube arrays: Transport, trapping, and transfer of electrons. J. Am. Chem. Soc. 2008, 130, 13364–13372. [Google Scholar] [CrossRef] [PubMed]

- Peter, L. Transport, trapping and interfacial transfer of electrons in dye-sensitized nanocrystalline solar cells. J. Electroanal. Chem. 2007, 599, 233–240. [Google Scholar] [CrossRef]

- Kang, S.H.; Kim, H.S.; Kim, J.; Sung, Y.E. An investigation on electron behavior employing vertically-aligned TiO2 nanotube electrodes for dye-sensitized solar cells. Nanotechnology 2009, 20, 355307:1–355307:6. [Google Scholar]

- Leng, W.; Barnes, P.; Juozapavicius, M.; O’Regan, B.; Durrant, J. Electron diffusion in mesoporous nanocrystalline TiO2 photoelectrodes during water oxidation. J. Phys. Chem. Lett. 2010, 1, 967–972. [Google Scholar] [CrossRef]

- Park, J.; Lee, T-W.; Kang, M. Growth, detachment and transfer of highly-ordered TiO2 nanotube arrays: Use in dye-sensitized solar cells. Chem. Commun. 2008, 2867–2869. [Google Scholar]

- Dubey, M.; Shrestha, M.; Zhong, Y.; Galipeau, D.; He, H. TiO2 nanotube membranes on transparent conducting glass for high efficiency dye-sensitized solar cells. Nanotechnology 2011, 22, 285201:1–285201:9. [Google Scholar] [CrossRef]

- Dale, G.; Hamilton, W.; Dunlop, P.; Lemoine, P.; Byrne, J. Electrochemical growth of titanium oxide nanotubes: Effect of surface roughness and applied potential. J. Nanosci. Nanotechnol. 2009, 9, 4215–4219. [Google Scholar] [CrossRef] [PubMed]

- Mohammadpour, A.; Shankar, K. Anodic TiO2 nanotube arrays with optical wavelength-sized apertures. J. Mater. Chem. 2010, 20, 8474–8477. [Google Scholar] [CrossRef]

- Liang, S.; He, J.; Sun, Z.; Liu, Q.; Jiang, Y.; Cheng, H.; He, B.; Xie, Z.; Wei, S. Improving photoelectrochemical water splitting activity of TiO2 nanotube arrays by tuning geometrical parameters. J. Phys. Chem. C 2012, 116, 9049–9053. [Google Scholar] [CrossRef]

- Haugeneder, A.; Neges, M.; Kallinger, C.; Spirkl, W.; Lemmer, U.; Feldmann, J. Exciton diffusion and dissociation in conjugated polymer/fullerene blends and heterostructures. Phys. Rev. B 1999, 59, 15346–15351. [Google Scholar] [CrossRef]

- Coakley, K.; Liu, Y.; McGehee, M.; Frindell, K.; Stucky, G. Infiltrating semiconducting polymers into self-assembled mesoporous titania films for photovoltaic applications. Adv. Funct. Mater. 2003, 13, 301–306. [Google Scholar] [CrossRef]

- Macak, J.; Tsuchiya, H.; Taveira, L.; Aldabergerova, S.; Schmuki, P. Smooth anodic TiO2 nanotubes. Angew. Chem. Int. Ed. 2005, 44, 7463–7465. [Google Scholar] [CrossRef]

- Macak, J.; Tsuchiya, H.; Schmuki, P. High-aspect-ratio TiO2 nanotubes by anodization of titanium. Angew. Chem. Int. Ed. 2005, 44, 2100–2102. [Google Scholar] [CrossRef]

- Balaur, E.; Macak, J.; Tsuchiya, H.; Schmuki, P. Wetting behavior of layers of TiO2 nanotubes with different diameters. J. Mater. Chem. 2005, 15, 4488–4491. [Google Scholar] [CrossRef]

- Lide, D.R. CRC Handbook of Chemistry and Physics, 85th ed.; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Chen, Y.; Lu, H.; Wang, X.; Lu, S. Large-scale sparse TiO2 nanotube arrays by anodization. J. Mater. Chem. 2012, 22, 5921–5923. [Google Scholar] [CrossRef]

- Zhu, K.; Vinzant, T.; Neale, N.; Frank, A. Removing structural disorder from oriented TiO2 nanotube arrays: Reducing the dimensionality of transport and recombination in dye-sensitized solar cells. Nano Lett. 2007, 7, 3739–3746. [Google Scholar] [CrossRef] [PubMed]

- Allman, N.; Grimes, C. Room temperature one-step polyol synthesis of anatase TiO2 nanotube arrays: Photoelectrochemical properties. Langmuir 2009, 25, 7234–7240. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.; Kim, D.; Roy, P.; Paramasivam, I.; Birajdar, B.I.; Spiecker, E.; Schmuki, P. Anodic formation of thick anatase TiO2 mesosponge layers for high-efficiency photocatalysis. J. Am. Chem. Soc. 2010, 132, 1478–1479. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Khare, A.; Aydil, E. Synthesis of single-crystalline anatase nanorods and nanoflakes on transparent conducting substrates. Chem. Commun. 2012, 48, 8565–8567. [Google Scholar] [CrossRef]

- Fàbrega, C.; Hernández-Ramírez, F.; Prades, J.D.; Jiménez-Díaz, R.; Andreu, T.; Morante, J.R. On the photoconduction properties of low resistivity TiO2 nanotubes. Nanotechnology 2010, 21, 445703:1–445703:6. [Google Scholar] [CrossRef]

- Richter, C.; Schmuttenmaer, C. Exciton-like trap states limit electron mobility in TiO2 nanotubes. Nat. Nanotechnol. 2010, 5, 769–772. [Google Scholar] [CrossRef] [PubMed]

- Liao, Y.; Que, W. Preparation and photocatalytic activity of TiO2 nanotube powders derived by a rapid anodization process. J. Alloy. Compd. 2010, 1, 243–248. [Google Scholar] [CrossRef]

- Li, H.; Zhang, W.; Pan, W. Enhanced photocatalytic activity of electrospun TiO2 nanofibers with optimal anatase/rutile ratio. J. Am. Ceram. Soc. 2011, 94, 3184–3187. [Google Scholar] [CrossRef]

- Berry, R.; Mueller, M. Photocatalytic decomposition of crude oil slicks using TiO2 on a floating substrate. Microchem. J. 1994, 50, 28–32. [Google Scholar] [CrossRef]

- Allam, N.; El-Sayed, M. Photoelectrochemical water oxidation characteristics of anodically fabricated TiO2 nanotube arrays: Structural and optical properties. J. Phys. Chem. C 2010, 114, 12024–12029. [Google Scholar] [CrossRef]

- Park, N.-G.; van de Lagemaat, J.; Frank, A. Comparison of dye-sensitized rutile- and anatase-based TiO2 solar cells. J. Phys. Chem. B 2000, 104, 8989–8994. [Google Scholar] [CrossRef]

- Albu, S.; Ghicov, A.; Macak, J.; Hahn, R.; Schmiki, P. Self-organized, free-standing TiO2 nanotube membrane for flow-through photocatalytic applications. Nano Lett. 2007, 7, 1286–1289. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Lu, K.; Tian, Z. Effects of titania nanotube distance and arrangement during focused ion beam guided anodization. J. Mater. Chem. 2011, 21, 8835–8840. [Google Scholar] [CrossRef]

- Wang, J.; Lin, Z. Freestanding TiO2 nanotube arrays with ultrahigh aspect ratio via electrochemical anodization. Chem. Mater. 2008, 20, 1257–1261. [Google Scholar] [CrossRef]

- Lai, C.W.; Sreekantan, S. Photoelectrochemical performance of smooth TiO2 nanotube arrays: Effect of anodization temperature and cleaning methods. Int. J. Photoenergy 2012, 2012, 356943:1–356943:11. [Google Scholar] [CrossRef]

- Chen, Q.; Xu, D.; Wu, Z.; Liu, Z. Free-standing TiO2 nanotube arrays made by anodic oxidation and ultrasonic splitting. Nanotechnology 2008, 19, 365708:1–365708:5. [Google Scholar]

- Rho, C.; Min, J.; Suh, J.S. Barrier layer effect on the electron transport of the dye-sensitized solar cells based on TiO2 nanotube arrays. J. Phys. Chem. C 2012, 116, 7213–7218. [Google Scholar] [CrossRef]

- Kim, D.; Lee, K.; Roy, P.; Birajdar, B.I.; Spiecker, E.; Schmuki, P. Formation of a non-thickness-limited titanium dioxide mesosponge and its use in dye-sensitized solar cells. Angew. Chem. Int. Ed. 2009, 48, 9326–9329. [Google Scholar] [CrossRef]

- Jung, H.Y.; Jung, S.M.; Gu, G.H.; Suh, J.S. Anodic aluminum oxide membrane bonded on a silicon wafer for carbon nanotube field emitter arrays. Appl. Phys. Lett. 2006, 89, 013121:1–013121:3. [Google Scholar]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Haring, A.; Morris, A.; Hu, M. Controlling Morphological Parameters of Anodized Titania Nanotubes for Optimized Solar Energy Applications. Materials 2012, 5, 1890-1909. https://doi.org/10.3390/ma5101890

Haring A, Morris A, Hu M. Controlling Morphological Parameters of Anodized Titania Nanotubes for Optimized Solar Energy Applications. Materials. 2012; 5(10):1890-1909. https://doi.org/10.3390/ma5101890

Chicago/Turabian StyleHaring, Andrew, Amanda Morris, and Michael Hu. 2012. "Controlling Morphological Parameters of Anodized Titania Nanotubes for Optimized Solar Energy Applications" Materials 5, no. 10: 1890-1909. https://doi.org/10.3390/ma5101890