Buckling of Carbon Nanotubes: A State of the Art Review

Abstract

:1. Introduction: Appeal of Nanocarbon Materials

2. Background of Nanotube Buckling Research

3. Resilience and Sensitivity to Buckling

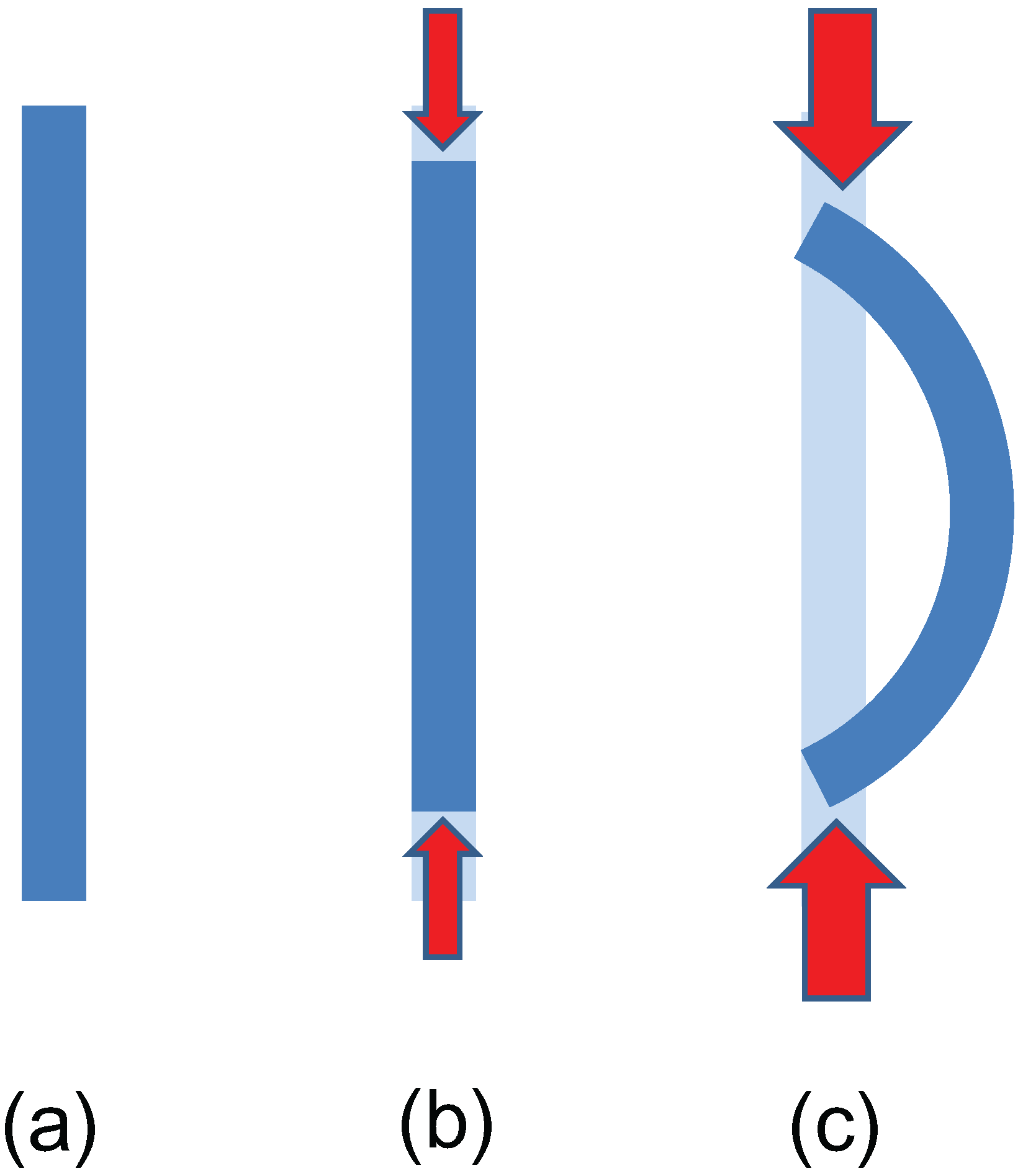

4. Axial Compression Buckling

4.1. Shell Buckling or Column Buckling?

4.2. Force–Displacement Curve

5. Radial Compression Buckling

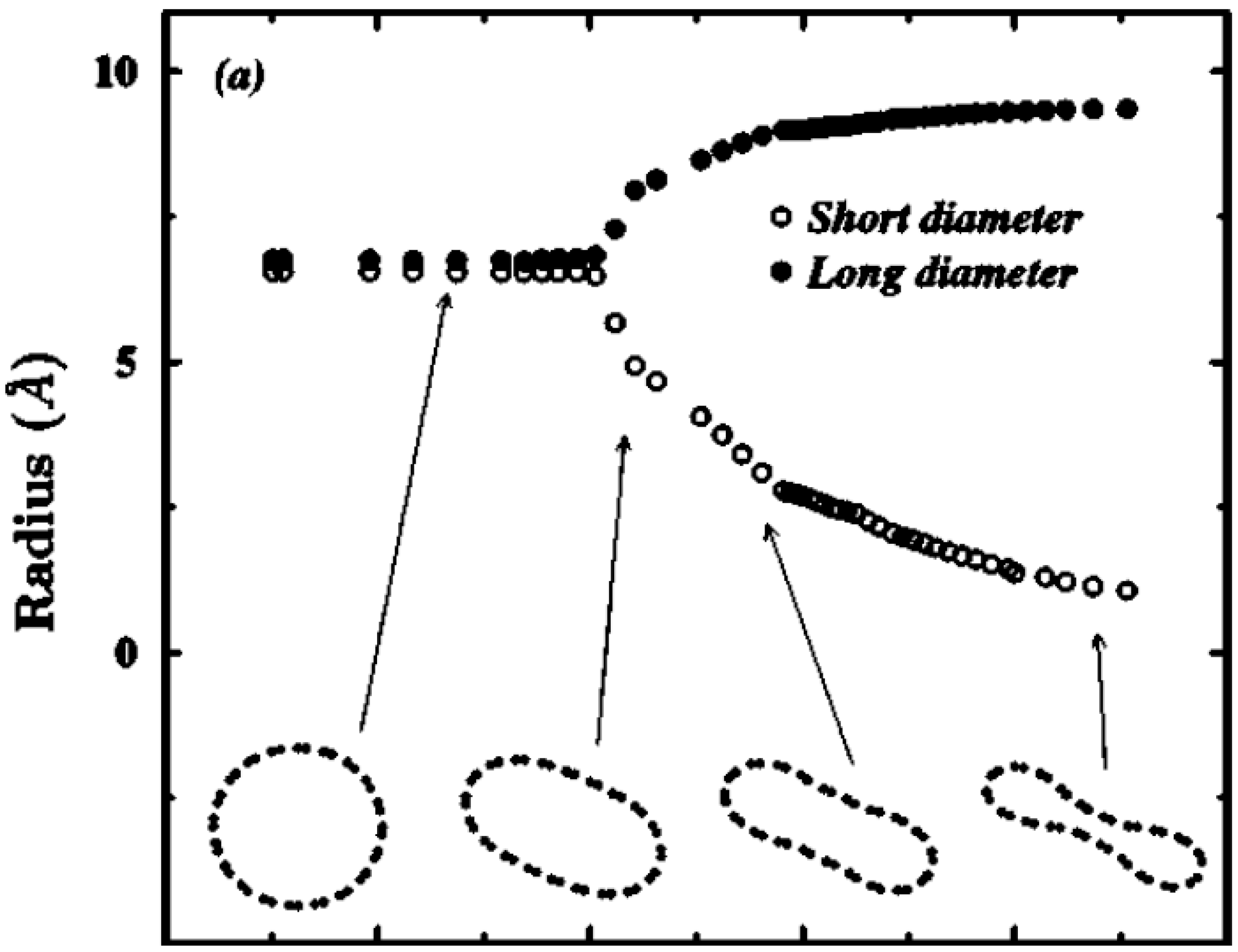

5.1. Uniaxial Collapse of SWNTs

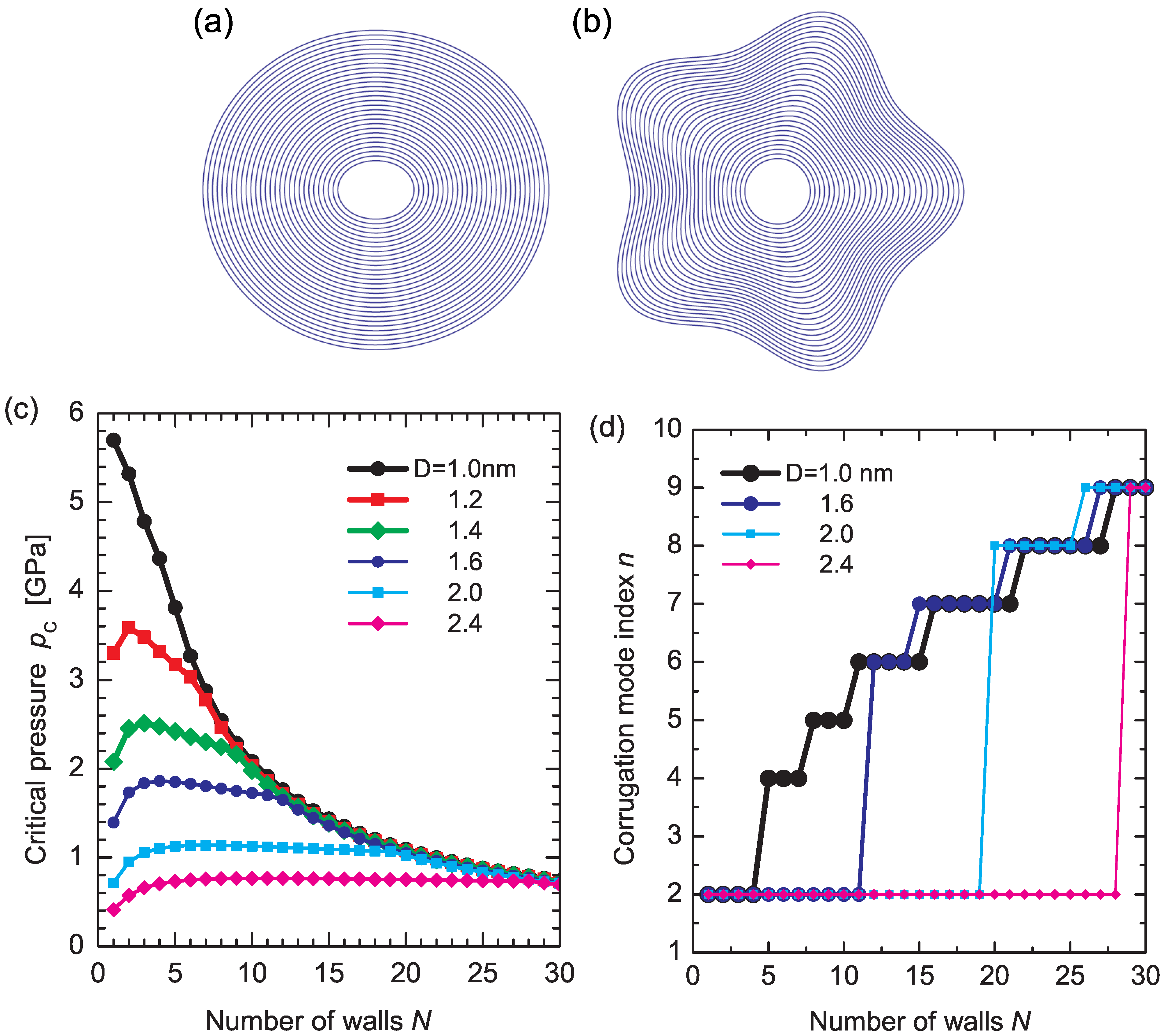

5.2. Radial Corrugation of MWNTs

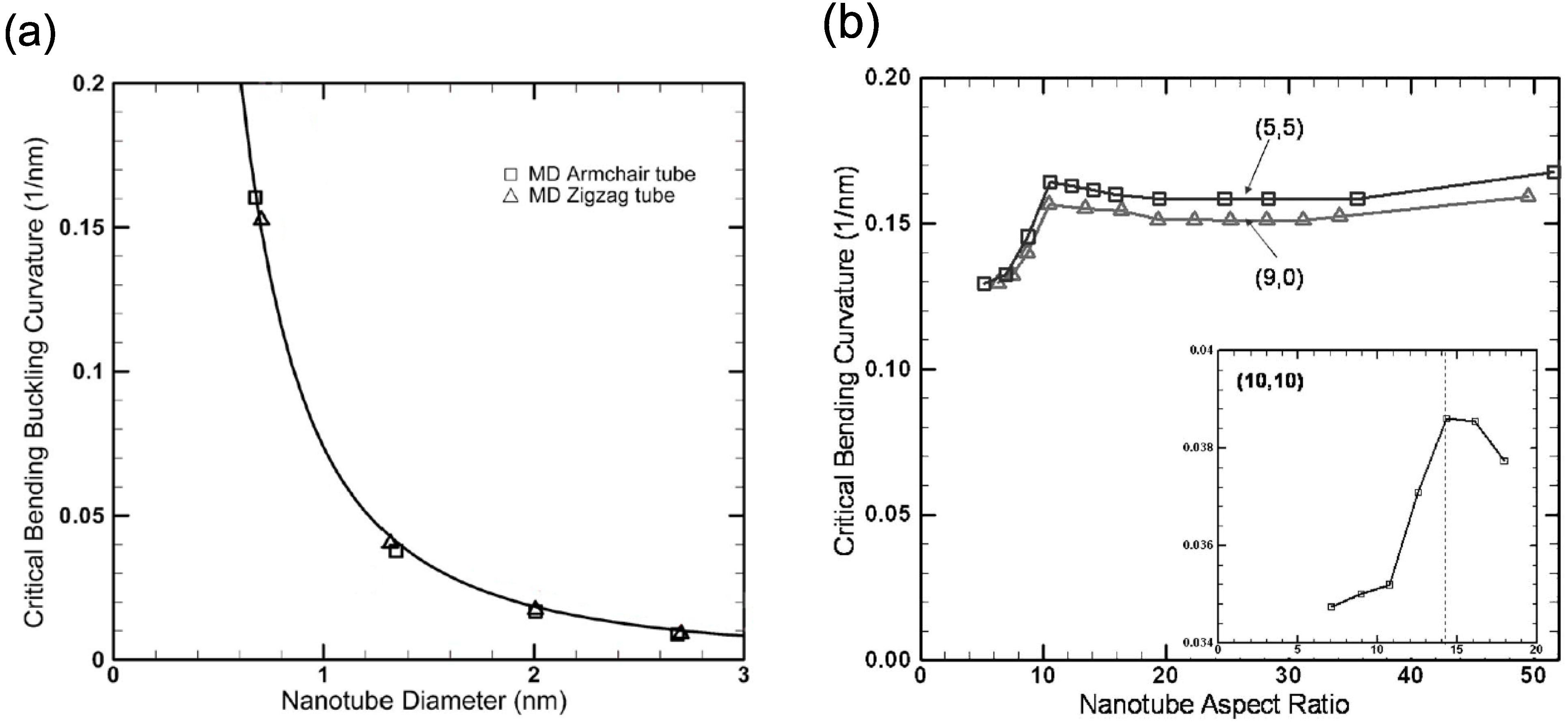

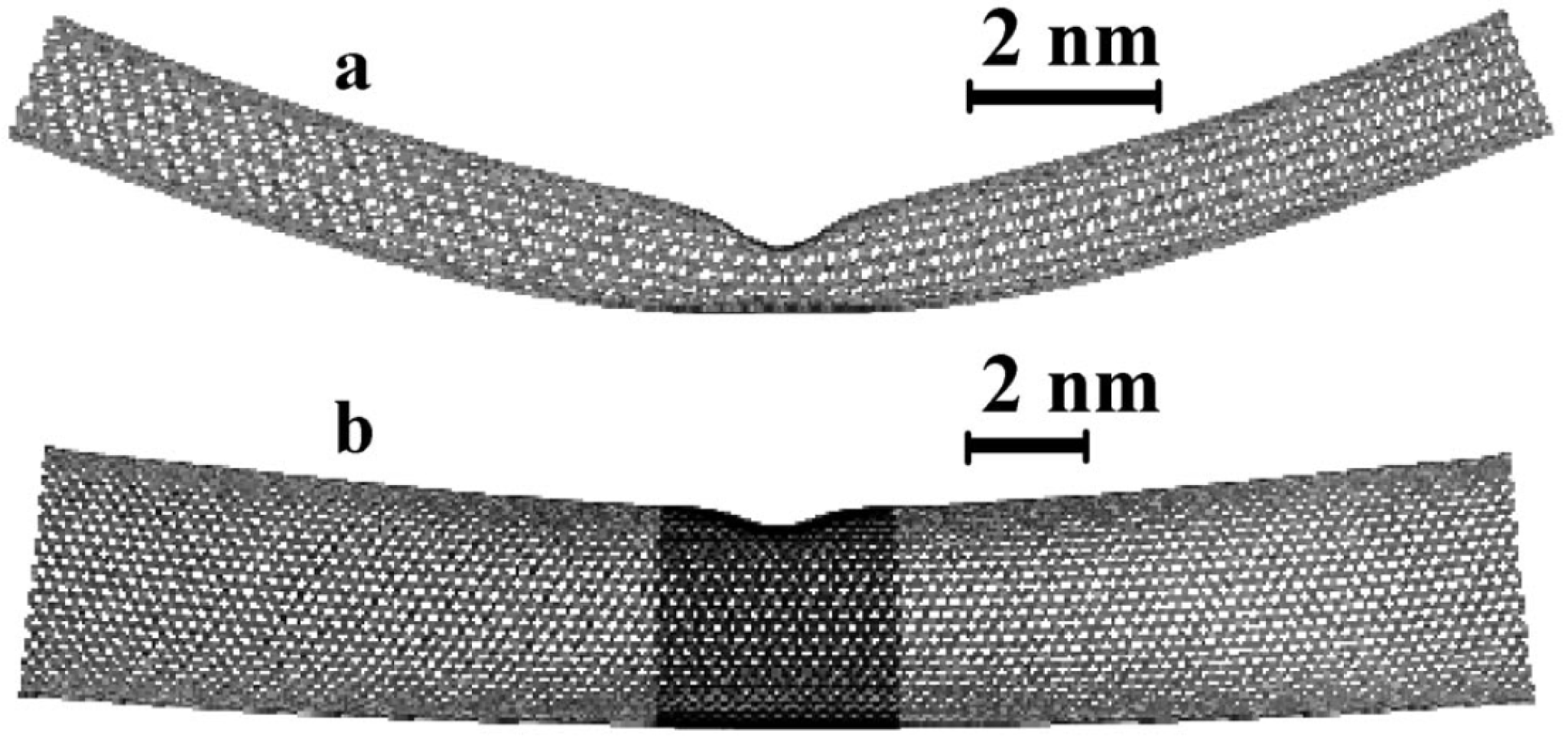

6. Bend Buckling of SWNTs

6.1. Kink Formation

6.2. Diameter Dependence

6.3. Transient Bending

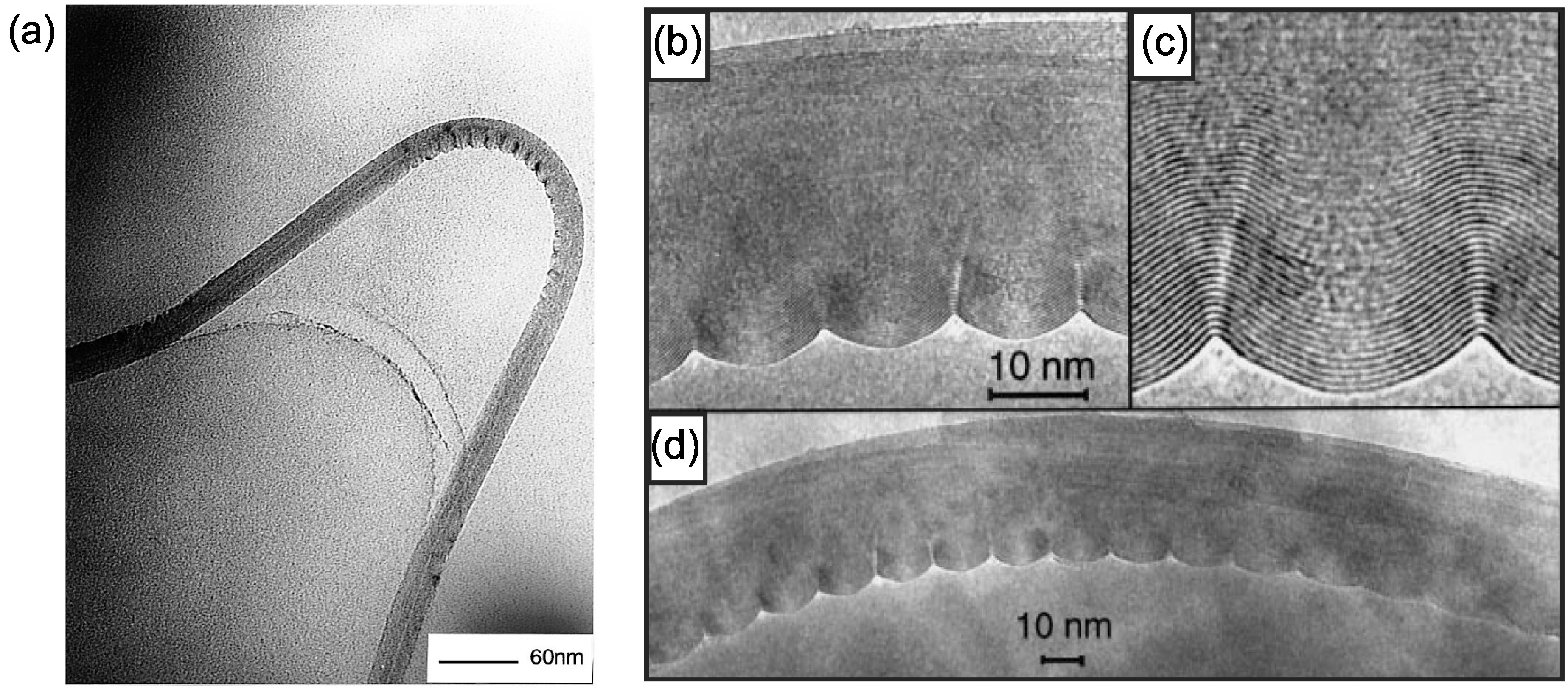

7. Bend Buckling of MWNTs

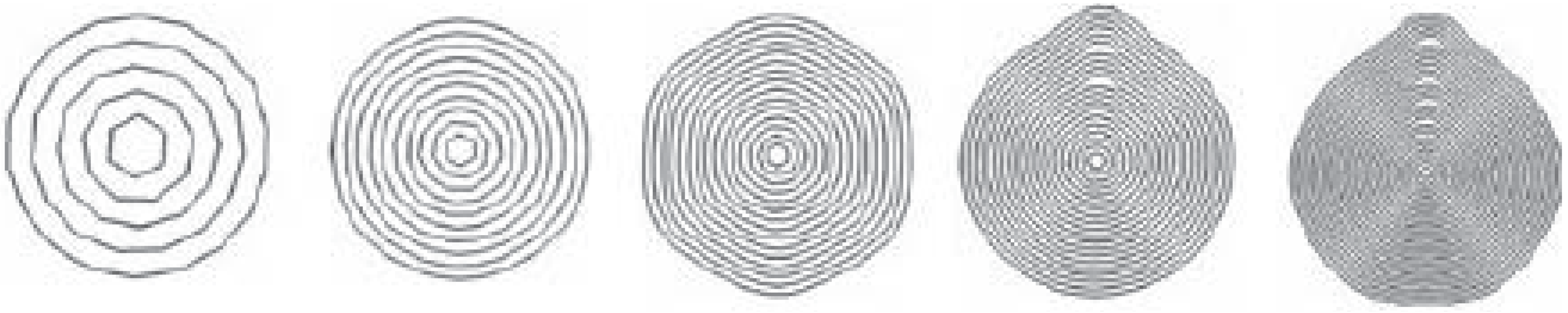

7.1. Emergence of Ripples

7.2. Yoshimura Pattern

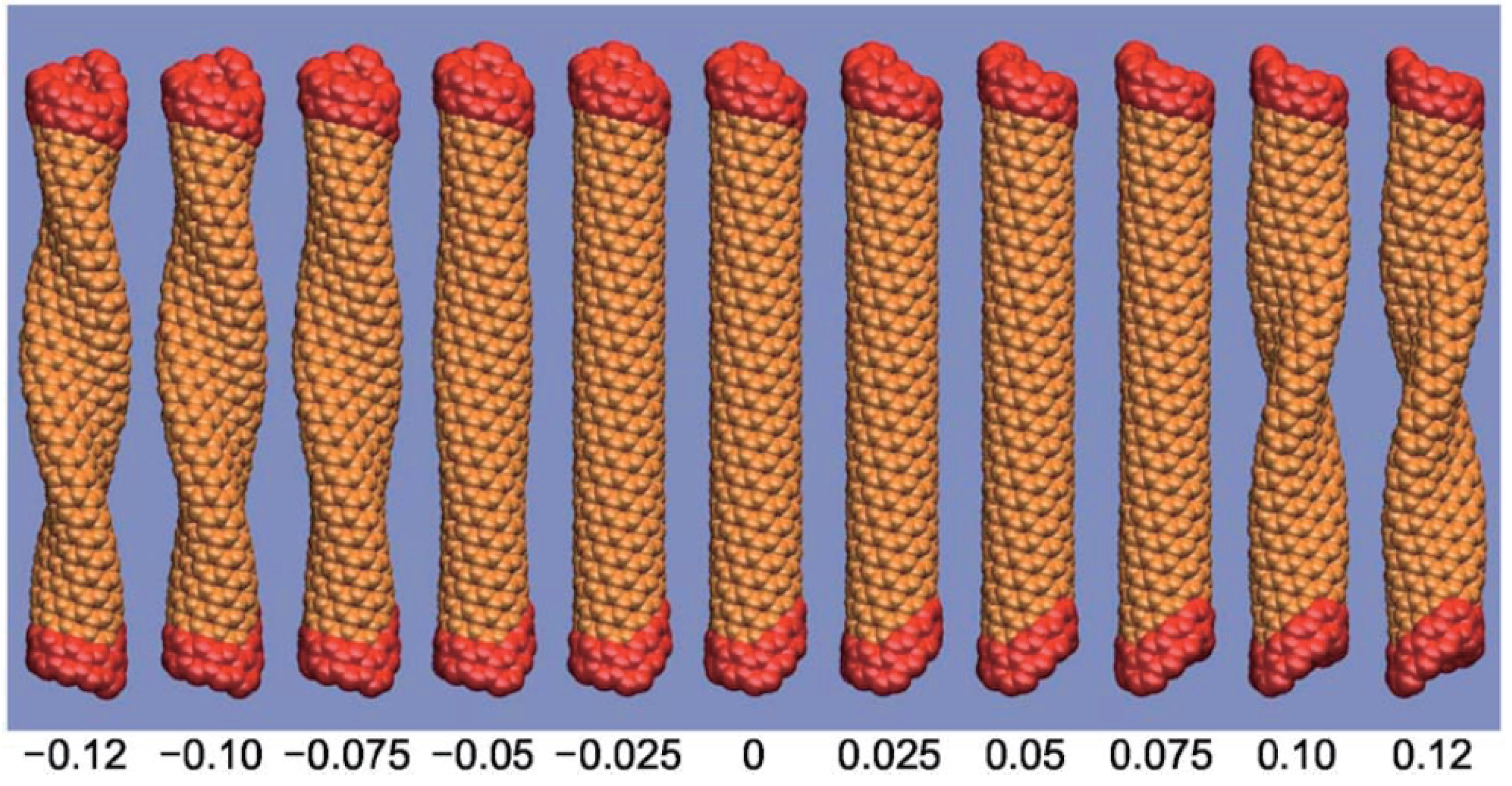

8. Twist Buckling

8.1. Asymmetric Response of SWNTs

8.2. Nontrivial Response of MWNTs

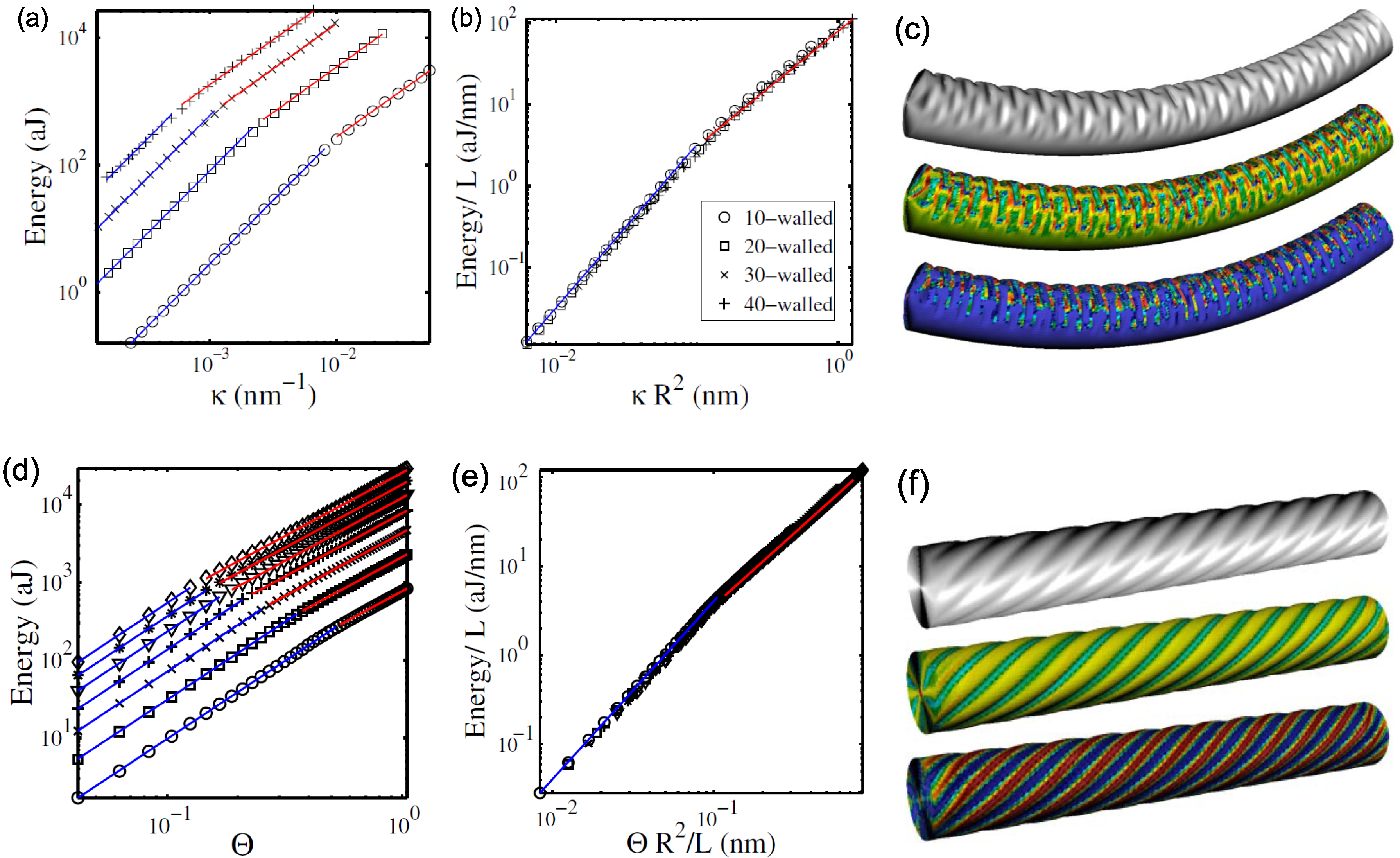

9. Universal Scaling Laws Under Bending and Torsion

10. Challenge and Future Directions

10.1. Buckling Effects on Heat Transport

10.2. Role of Defects and Imperfections

10.3. Relevance to Chemical Reaction

Acknowledgments

Appendix. Who Discovered Carbon Nanotubes First?

A1. Iijima’s Nanotube in 1991

A2. Carbon Nanotubes Prior to 1991

A3. Closing Remarks

References and Notes

- Osawa, E. Superaromaticity. Kagaku 1970, 25, 854–863, in Japanese. [Google Scholar]

- Kroto, H.W.; Heath, J.R.; O’Brien, S.C.; Curl, R.F.; Smalley, R.E. C60: Buckminsterfullerene. Nature 1985, 318, 162–163. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- See Appendix 10.3 for the delicate issue about who should be credited as the first person to discover carbon nanotubes.

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Together with the three famous nanocarbons, “nanodiamond” deserves attention as the fourth member of nanocarbon materials, being classic yet novel. Nanodiamond was initially synthesized by Volkov [7] in 1963, and recently, a wide variety of applications has been proposed; see References [8,9] for instance.

- Danilenko, V.V. On the history of the discovery of nanodiamond synthesis. Phys. Solid State 2004, 46, 595–599. [Google Scholar] [CrossRef]

- Osawa, E. Monodisperse single nanodiamond particulates. Pure Appl. Chem. 2008, 80, 1365–1379. [Google Scholar] [CrossRef]

- Ho, D. Nanodiamonds: Applicationsin Biology and Nanoscale Medicine; Springer-Verlag: Berlin, Heidelberg, Germany, 2010. [Google Scholar]

- A forthcoming monograph [11], which covers broad topics of carbon nanotube deformation, including buckling, will be of great help to readers who are interested in the subject.

- Shima, H.; Sato, M. Elastic and Plastic Deformation of Carbon Nanotubes; Pan Stanford Publishing: Singapore, 2012; in press. [Google Scholar]

- Waters, J.F.; Gudurua, P.R.; Xu, J.M. Nanotube mechanics—Recent progress in shell buckling mechanics and quantum electromechanical coupling. Compos. Sci. Technol. 2006, 66, 1141–1150. [Google Scholar] [CrossRef]

- Wang, C.Y.; Zhang, Y.Y.; Wang, C.M.; Tan, V.B.C. Buckling of carbon nanotubes: A literature survey. J. Nanosci. Nanotechnol. 2007, 7, 4221–4247. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.M.; Zhang, Y.Y.; Xiang, Y.; Reddy, J.N. Recent studies on buckling of carbon nanotubes. Appl. Mech. Rev. 2010, 63, 030804. [Google Scholar] [CrossRef]

- Brush, D.O.; Almroth, B.O. Buckling of Bars, Plates, and Shells; McGraw-Hill: New York, NY, USA, 1975. [Google Scholar]

- Sato, M.; Patel, M.H. Exact and simplified estimations for elastic buckling pressures of structural pipe-in-pipe cross sections under external hydrostatic pressure. J. Mar. Sci. Technol. 2007, 12, 251–262. [Google Scholar] [CrossRef]

- Sato, M.; Patel, M.H.; Trarieux, F. Static displacement and elastic buckling characteristics of structural pipe-in-pipe cross-sections. Struct. Eng. Mech. 2008, 30, 263–278. [Google Scholar] [CrossRef]

- Yakobson, B.I.; Brabec, C.J.; Bernholc, J. Nanomechanics of carbon tubes: Instabilities beyond linear response. Phys. Rev. Lett. 1996, 76, 2511–2514. [Google Scholar] [CrossRef] [PubMed]

- Ru, C.Q. Effect of Van der Waals forces on axial buckling of a doublewalled carbon nanotube. J. Appl. Phys. 2000, 87, 7227–7231. [Google Scholar] [CrossRef]

- Ru, C.Q. Axially compressed buckling of a doublewalled carbon nanotube embedded in an elastic medium. J. Mech. Phys. Solids 2001, 49, 1265–1279. [Google Scholar] [CrossRef]

- Ru, C.Q. Degraded axial buckling strain of multiwalled carbon nanotubes due to interlayer slips. J. Appl. Phys. 2001, 89, 3426–3433. [Google Scholar] [CrossRef]

- Ni, B.; Sinnott, S.B.; Mikulski, P.T.; Harrison, J.A. Compression of carbon nanotubes filled with C60, CH4, or Ne: Predictions from molecular dynamics simulations. Phys. Rev. Lett. 2002, 88, 205505. [Google Scholar] [CrossRef] [PubMed]

- Buehler, M.J.; Kong, J.; Gao, H.J. Deformation mechanism of very long single-wall carbon nanotubes subject to compressive loading. J. Eng. Mater. Technol. 2004, 126, 245–249. [Google Scholar] [CrossRef]

- Waters, J.F.; Riester, L.; Jouzi, M.; Guduru, P.R.; Xu, J.M. Buckling instabilities in multiwalled carbon nanotubes under uniaxial compression. Appl. Phys. Lett. 2004, 85, 1787–1789. [Google Scholar] [CrossRef]

- Pantano, A.; Boyce, M.C.; Parks, D.M. Mechanics of axial compression of single-and multi-wall carbon nanotubes. J. Eng. Mater. Technol. 2004, 126, 279–284. [Google Scholar] [CrossRef]

- Waters, J.F.; Guduru, P.R.; Jouzi, M.; Xu, J.M.; Hanlon, T.; Suresh, S. Shell buckling of individual multi-walled carbon nanotubes using nanoindentation. Appl. Phys. Lett. 2005, 87, 103109. [Google Scholar] [CrossRef]

- Sears, A.; Batra, R.C. Buckling of multiwalled carbon nanotubes under axial compression. Phys. Rev. B 2006, 73, 085410. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Wang, M.; Tan, V.B.C. Examining the effects of wall numbers on buckling behavior and mechanical properties of multiwalled carbon nanotubes via molecular dynamics simulations. J. Appl. Phys. 2008, 103, 053505. [Google Scholar] [CrossRef]

- Venkateswaran, U.D.; Rao, A.M.; Richter, E.; Menon, M.; Rinzler, A.; Smalley, R.E.; Eklund, P.C. Probing the single-wall carbon nanotube bundle: Raman scattering under high pressure. Phys. Rev. B 1999, 59, 10928–10934. [Google Scholar] [CrossRef]

- Tang, J.; Qin, J.C.; Sasaki, T.; Yudasaka, M.; Matsushita, A.; Iijima, S. Compressibility and polygonization of single-walled carbon nanotubes under hydrostatic pressure. Phys. Rev. Lett. 2000, 85, 1887–1889. [Google Scholar] [CrossRef] [PubMed]

- Peters, M.J.; McNeil, L.E.; Lu, J.P.; Kahn, D. Structural phase transition in carbon nanotube bundles under pressure. Phys. Rev. B 2000, 61, 5939–5944. [Google Scholar] [CrossRef]

- Sharma, S.M.; Karmakar, S.; Sikka, S.K.; Teredesai, P.V.; Sood, A.K.; Govindaraj, A.; Rao, C.N.R. Pressure-induced phase transformation and structural resilience of single-wall carbon nanotube bundles. Phys. Rev. B 2001, 63, 205417. [Google Scholar] [CrossRef]

- Rols, S.; Gontcharenko, I.N.; Almairac, R.; Sauvajol, J.L.; Mirebeau, I. Polygonization of single-wall carbon nanotube bundles under high pressure. Phys. Rev. B 2001, 64, 153401. [Google Scholar] [CrossRef]

- Reich, S.; Thomsen, C.; Ordejón, P. Elastic properties of carbon nanotubes under hydrostatic pressure. Phys. Rev. B 2003, 65, 153407. [Google Scholar] [CrossRef]

- Wang, C.Y.; Ru, C.Q.; Mioduchowski, A. Elastic buckling of multiwall carbon nanotubes under high pressure. J. Nanosci. Nanotechnol. 2003, 3, 199–208. [Google Scholar] [CrossRef] [PubMed]

- Pantano, A.; Parks, D.M.; Boyce, M.C. Mechanics of deformation of single- and multi-wall carbon nanotubes. J. Mech. Phys. Solids 2004, 52, 789–821. [Google Scholar] [CrossRef]

- Elliott, J.A.; Sandler, L.K.W.; Windle, A.H.; Young, R.J.; Shaffer, M.S.P. Collapse of single-wall carbon nanotubes is diameter dependent. Phys. Rev. Lett. 2004, 92, 095501. [Google Scholar] [CrossRef] [PubMed]

- Sun, D.Y.; Shu, D.J.; Ji, M.; Liu, F.; Wang, M.; Gong, X.G. Pressure-induced hard-to-soft transition of a single carbon nanotube. Phys. Rev. B 2004, 70, 165417. [Google Scholar] [CrossRef]

- Tangney, P.; Capaz, R.B.; Spataru, C.D.; Cohen, M.L.; Louie, S.G. Structural transformations of carbon nanotubes under hydrostatic pressure. Nano Lett. 2005, 5, 2268–2273. [Google Scholar] [CrossRef] [PubMed]

- Gadagkar, V.; Maiti, P.K.; Lansac, Y.; Jagota, A.; Sood, A.K. Collapse of double-walled carbon nanotube bundles under hydrostatic pressure. Phys. Rev. B 2006, 73, 085402. [Google Scholar] [CrossRef]

- Wang, X.; Yang, H.K. Bending stability of multiwalled carbon nanotubes. Phys. Rev. B 2006, 73, 085409. [Google Scholar] [CrossRef]

- Zhang, S.; Khare, R.; Belytschko, T.; Hsia, K.J.; Mielke, S.L.; Schatz, G.C. Transition states and minimum energy pathways for the collapse of carbon nanotubes. Phys. Rev. B 2006, 73, 075423. [Google Scholar] [CrossRef]

- Hasegawa, M.; Nishidate, K. Radial deformation and stability of single-wall carbon nanotubes under hydrostatic pressure. Phys. Rev. B 2006, 74, 115401. [Google Scholar] [CrossRef]

- Huang, Y.; Wu, J.; Hwang, K. Thickness of graphene and single-wall carbon nanotubes. Phys. Rev. B 2006, 74, 245413. [Google Scholar] [CrossRef]

- Yang, X.; Wu, G.; Dong, J. Structural transformations of double-walled carbon nanotube bundle under hydrostatic pressure. Appl. Phys. Lett. 2006, 89, 113101. [Google Scholar] [CrossRef]

- Wang, H.Y.; Zhao, M.; Mao, S.X. Radial moduli of individual single-walled carbon nanotubes with and without electric current flow. Appl. Phys. Lett. 2006, 89, 211906. [Google Scholar] [CrossRef]

- Christofilos, D.; Arvanitidis, J.; Kourouklis, G.A.; Ves, S.; Takenobu, T.; Iwasa, Y.; Kataura, H. Identification of inner and outer shells of double-wall carbon nanotubes using high-pressure Raman spectroscopy. Phys. Rev. B 2007, 76, 113402. [Google Scholar] [CrossRef]

- Imtani, A.N.; Jindal, V.K. Structure of armchair single-wall carbon nanotubes under hydrostatic pressure. Phys. Rev. B 2007, 76, 195447. [Google Scholar] [CrossRef]

- Peng, J.; Wu, J.; Hwang, K.C.; Song, J.; Huang, Y. Can a single-wall carbon nanotube be modeled as a thin shell? J. Mech. Phys. Solids 2008, 56, 2213–2224. [Google Scholar] [CrossRef]

- Giusca, C.E.; Tison, Y.; Silva, S.R.P. Evidence for metal-semiconductor transitions in twisted and collapsed double-walled carbon nanotubes by scanning tunneling microscopy. Nano Lett. 2008, 8, 3350–3356. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Huang, M.; Wang, F.; Huang, X.M.H.; Rosenblatt, S.; Huang, L.; Yan, H.; O’Brien, S.P.; Hone, J.; Heinz, T.F. Determination of the Young’s modulus of structurally defined carbon nanotubes. Nano Lett. 2008, 8, 4158–4161. [Google Scholar] [CrossRef] [PubMed]

- Jeong, B.W.; Lim, J.K.; Sinnott, S.B. Tuning the torsional properties of carbon nanotube systems with axial prestress. Appl. Phys. Lett. 2008, 92, 253114. [Google Scholar] [CrossRef]

- Shima, H.; Sato, M. Multiple radial corrugations in multiwall carbon nanotubes under pressure. Nanotechnology 2008, 19, 495705. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Wang, L.; Zheng, Q. Enhanced mechanical properties of prestressed multi-walled carbon nanotubes. Small 2008, 4, 733–737. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.H.; Feng, L.L.; Feng, F. Torsional behaviour of carbon nanotubes with abnormal interlayer distances. J. Phys. D Appl. Phys. 2009, 42, 055414. [Google Scholar] [CrossRef]

- Kuang, Y.D.; He, X.Q.; Chen, C.Y.; Li, G.Q. Buckling of functionalized single- walled nanotubes under axial compression. Carbon 2009, 47, 279–285. [Google Scholar] [CrossRef]

- Lu, W.B.; Liu, B.; Wu, J.; Xiao, J.; Hwang, K.C.; Fu, S.Y.; Huang, Y. Continuum modeling of van der Waals interactions between carbon nanotube walls. Appl. Phys. Lett. 2009, 94, 101917. [Google Scholar] [CrossRef]

- Shima, H.; Sato, M. Pressure-induced structural transitions in multi-walled carbon nanotubes. Phys. Status Solidi A 2009, 206, 2228–2233. [Google Scholar] [CrossRef]

- Barboza, A.P.M.; Chacham, H.; Neves, B.R.A. Universal response of single-wall carbon nanotubes to radial compression. Phys. Rev. Lett. 2009, 102, 025501. [Google Scholar] [CrossRef] [PubMed]

- Shima, H.; Sato, M.; Iiboshi, K.; Ghosh, S.; Arroyo, M. Diverse corrugation pattern in radially shrinking carbon nanotubes. Phys. Rev. B 2010, 82, 085401. [Google Scholar] [CrossRef]

- Shima, H.; Ghosh, S.; Arroyo, M.; Iiboshi, K.; Sato, M. Thin-shell theory based analysis of radially pressurized multiwall carbon nanotubes. Comput. Mater. Sci. 2012, 52, 90–94. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.H.; Li, W.Z. Radial elasticity of single-walled carbon nanotube measured by atomic force microscopy. Appl. Phys. Lett. 2011, 98, 041901. [Google Scholar] [CrossRef]

- Huang, X.; Liang, W.; Zhang, S. Radial corrugations of multi-walled carbon nanotubes driven by inter-wall nonbonding interactions. Nanoscale Res. Lett. 2011, 6, 53. [Google Scholar] [CrossRef]

- Iijima, S.; Brabec, C.; Maiti, A.; Bernholc, J. Structural flexibility of carbon nanotubes. J. Chem. Phys. 1996, 104, 2089–2092. [Google Scholar] [CrossRef]

- Falvo, M.R.; Clary, G.J.; Taylor, R.M., II; Chi, V.; Brooks, F.P., Jr.; Washburn, S.; Superfine, R. Bending and buckling of carbon nanotubes under large strain. Nature 1997, 389, 582–584. [Google Scholar] [PubMed]

- Poncharal, P.; Wang, Z.L.; Ugarte, D.; de Heer, W.A. Electrostatic deflections and electromechanical resonances of carbon nanotubes. Science 1999, 283, 1513–1516. [Google Scholar] [CrossRef] [PubMed]

- Shibutani, Y.; Ogata, S. Mechanical integrity of carbon nanotubes for bending and torsion. Model. Simul. Mater. Sci. Eng. 2004, 12, 599–610. [Google Scholar] [CrossRef]

- Kutana, A.; Giapis, K.P. Transient deformation regime in bending of single-walled carbon nanotubes. Phys. Rev. Lett. 2006, 97, 245501. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.K.; Wang, X. Bending stability of multi-wall carbon nanotubes embedded in an elastic medium. Model. Simul. Mater. Sci. Eng. 2006, 14, 99–116. [Google Scholar] [CrossRef]

- Wang, Q.; Liew, K.M.; He, X.Q.; Xiang, Y. Local buckling of carbon nanotubes under bending. Appl. Phys. Lett. 2007, 73, 093128. [Google Scholar] [CrossRef]

- Duan, X.J.; Tang, C.; Zhang, J.; Guo, W.L.; Liu, Z.F. Two distinct buckling modes in carbon nanotube bending. Nano Lett. 2007, 7, 143–148. [Google Scholar] [CrossRef] [PubMed]

- Jeong, B.W.; Lim, J.K.; Sinnott, S.B. Turning stiffness of carbon nanotube systems. Appl. Phys. Lett. 2007, 91, 093102. [Google Scholar] [CrossRef]

- Yang, H.K.; Wang, X. Torsional buckling of multi-wall carbon nanotubes embedded in an elastic medium. Compos. Struct. 2007, 77, 182–192. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Wang, C.M. Torsional responses of double-walled carbon nanotubes via molecular dynamics simulations. J. Phys. Condens. Mat. 2008, 20, 455214. [Google Scholar] [CrossRef]

- Wang, Q. Torsional buckling of double-walled carbon nanotubes. Carbon 2008, 46, 1172–1174. [Google Scholar] [CrossRef]

- Wang, Q. Transportation of hydrogen molecules using carbon nanotube in torsion. Carbon 2009, 47, 1870–1873. [Google Scholar] [CrossRef]

- Jeong, B.W.; Sinnott, S.B. Unique buckling responses of multi-walled carbon nanotubes incorporated as torsion springs. Carbon 2010, 48, 1697–1701. [Google Scholar] [CrossRef]

- Wang, X.; Sun, B.; Yang, H.K. Stability of multi-walled carbon nanotubes under combined bending and axial compression loading. Nanotechnology 2006, 17, 815–823. [Google Scholar] [CrossRef]

- Lu, Y.J.; Wang, X. Combined torsional buckling of multi-walled carbon nanotubes. J. Phys. D 2006, 39, 3380–3387. [Google Scholar] [CrossRef]

- Wang, X.; Lu, G.X.; Lu, Y.J. Buckling of embedded multi-walled carbon nanotubes under combined torsion and axial loading. Int. J. Solids Struct. 2007, 44, 336–351. [Google Scholar] [CrossRef]

- Zhang, C.L.; Shen, H.S. Buckling and postbuckling of single-walled carbon nanotubes under combined axial compression and torsion in thermal environments. Phys. Rev. B 2007, 75, 045408. [Google Scholar] [CrossRef]

- Jeong, B.W.; Lim, J.K.; Sinnott, S.B. Tuning the torsional properties of carbon nanotube systems with axial prestress. Appl. Phys. Lett. 2008, 92, 253114. [Google Scholar] [CrossRef]

- Zhang, R.; Wen, Q.; Qian, W.; Sheng, D.; Zhang, Q.; Wei, F. Superstrong ultralong carbon nanotubes for mechanical energy storage. Adv. Mater. 2011, 23, 3387–3391. [Google Scholar] [CrossRef] [PubMed]

- Weick, G.; Pistolesi, F.; Mariani, E.; von Oppen, F. Discontinuous Euler instability in nanoelectromechanical systems. Phys. Rev. B 2010, 81, 121409. [Google Scholar] [CrossRef]

- Naieni, A.K.; Yaghoobi, P.; Woodsworth, D.J.; Nojeh, A. Structural deformations and current oscillations in armchair-carbon nanotube cross devices: A theoretical study. J. Phys. D Appl. Phys. 2011, 44, 085402. [Google Scholar] [CrossRef]

- Weick, G.; von Oppen, F.; Pistolesi, F. Euler buckling instability and enhanced current blockade in suspended single-electron transistors. Phys. Rev. B 2011, 83, 035420. [Google Scholar] [CrossRef]

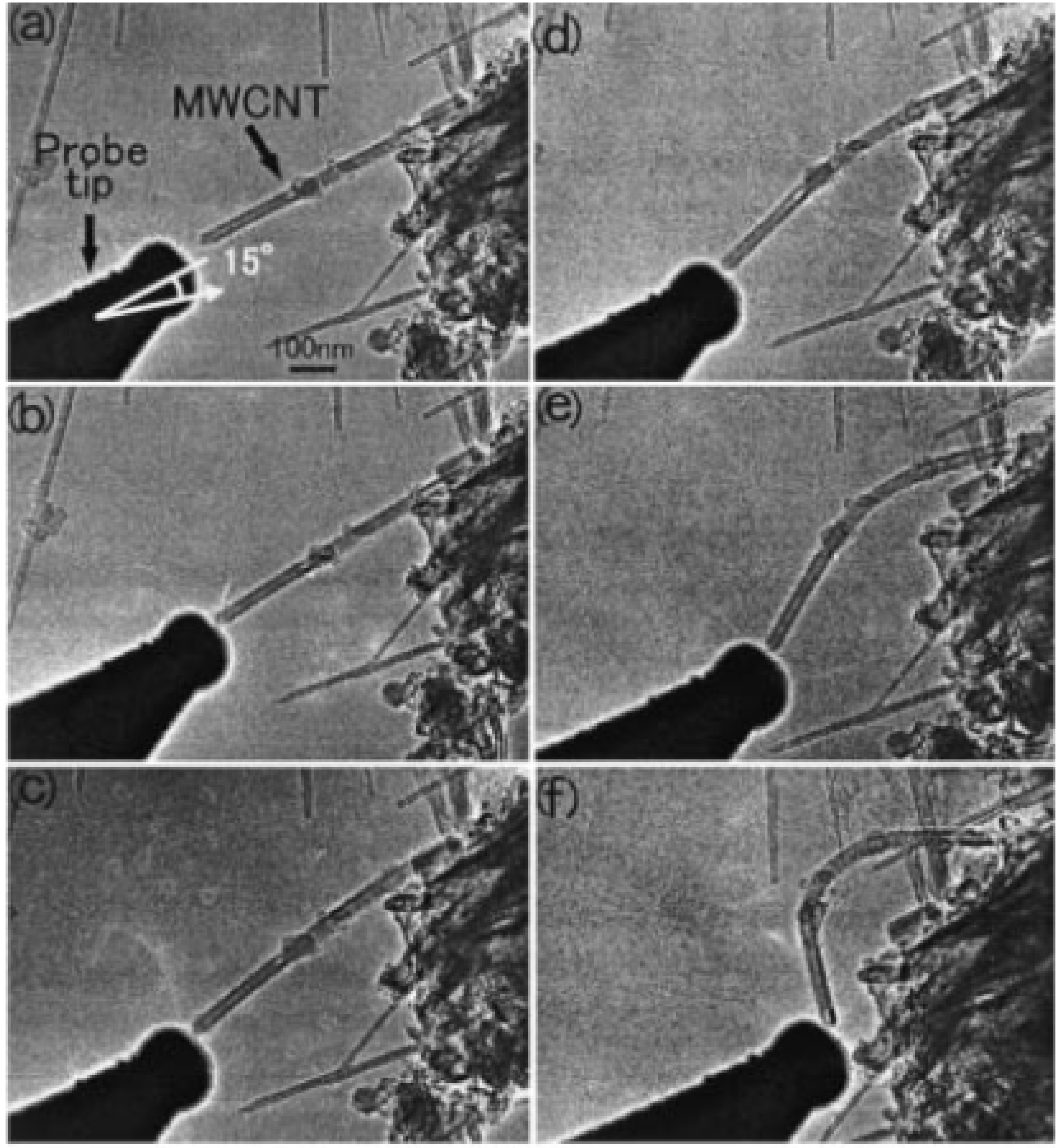

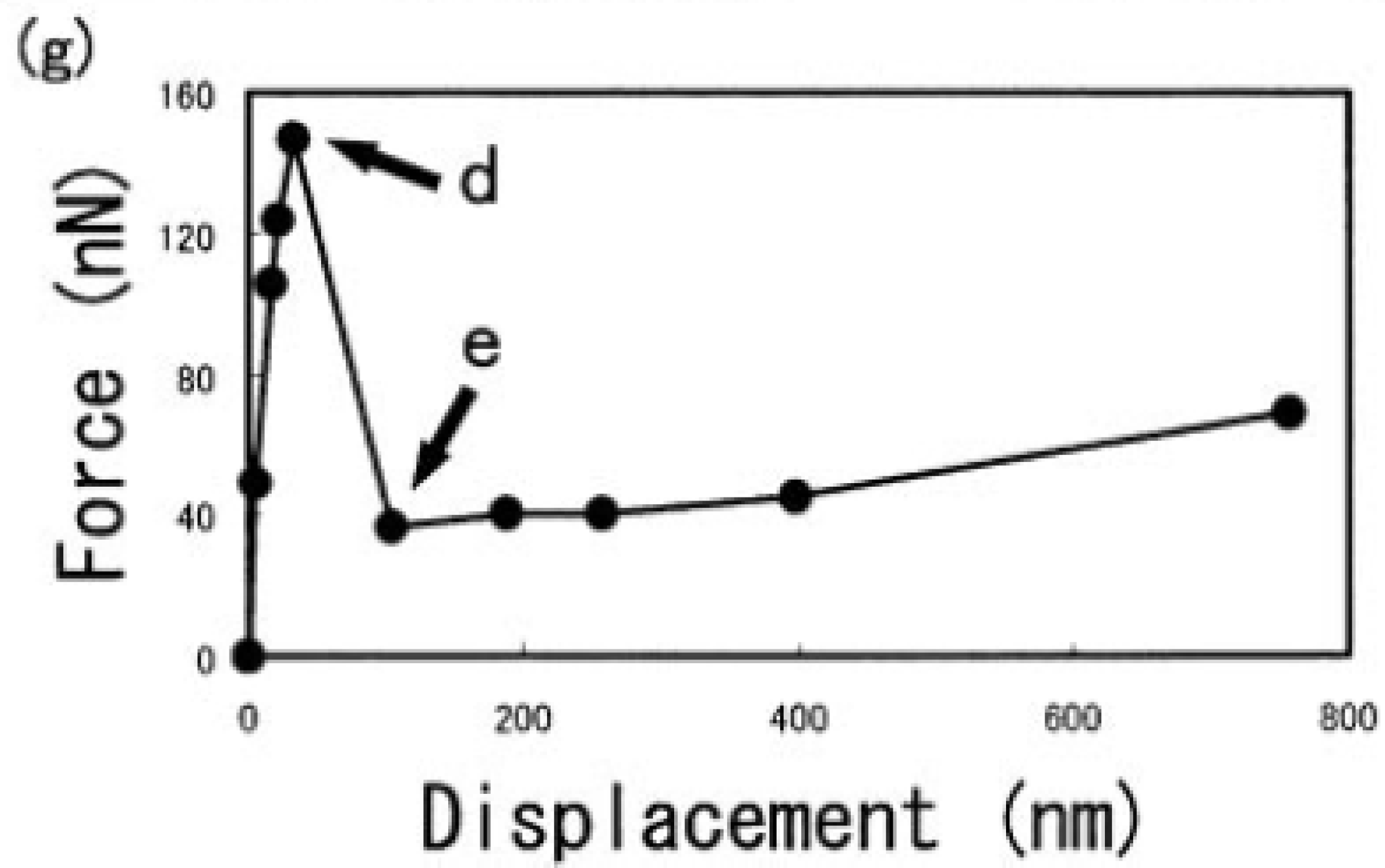

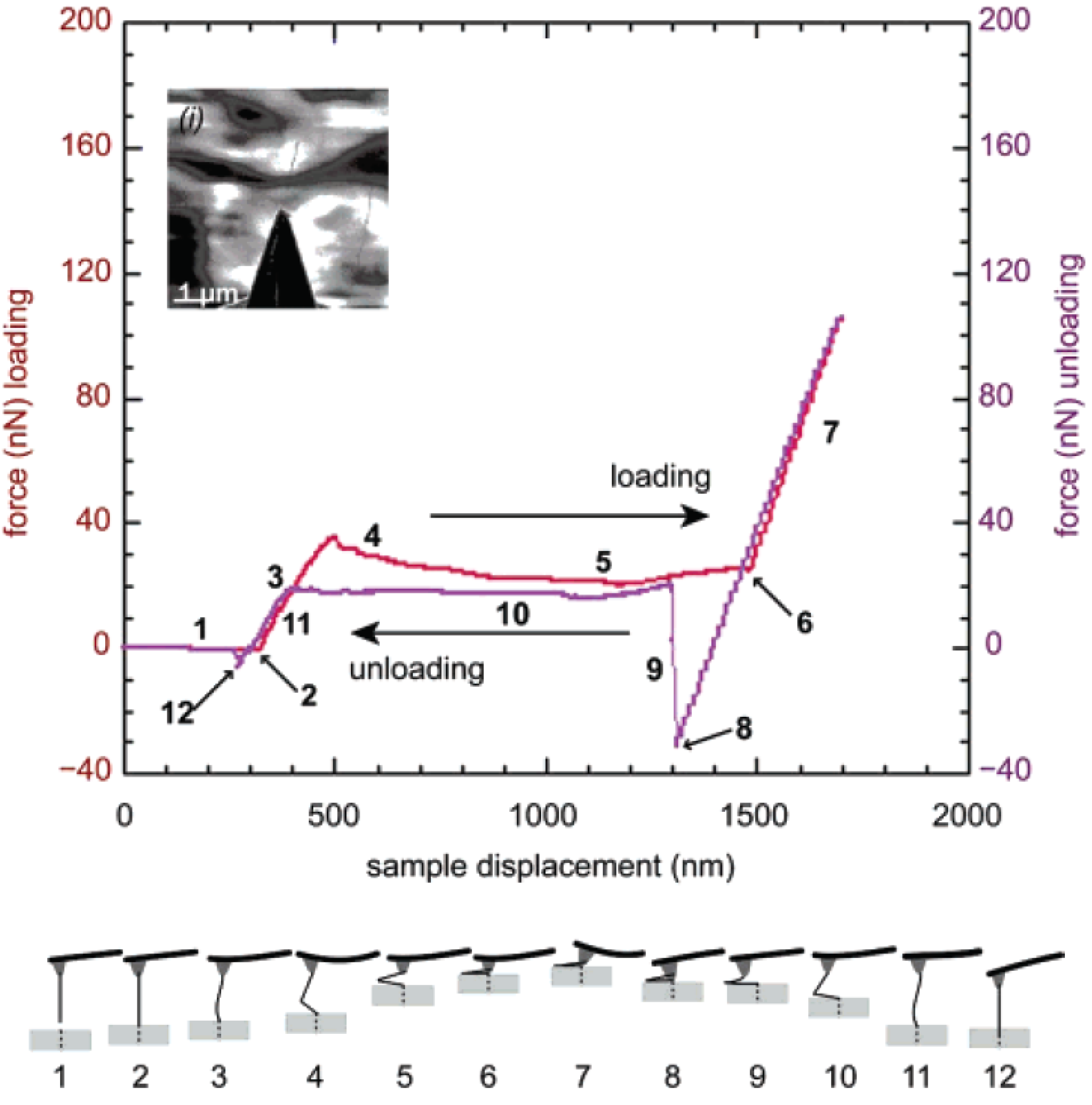

- Yap, H.W.; Lakes, R.S.; Carpick, R.W. Mechanical instabilities of individual multiwalled carbon nanotubes under cyclic axial compression. Nano Lett. 2007, 7, 1149–1154. [Google Scholar] [CrossRef] [PubMed]

- Kuzumaki, T.; Mitsuda, Y. Nanoscale mechanics of carbon nanotube evaluated by nanoprobe manipulation in transmission electron microscope. Jpn. J. Appl. Phys. 2006, 45, 364–368. [Google Scholar] [CrossRef]

- Misra, A.; Tyagi, P.K.; Rai, P.; Mahopatra, D.R.; Ghatak, J.; Satyam, P.V.; Avasthi, D.K.; Misra, D.S. Axial buckling and compressive behavior of nickel-encapsulated multiwalled carbon nanotubes. Phys. Rev. B 2007, 76, 014108. [Google Scholar] [CrossRef]

- Zhao, J.; He, M.R.; Dai, S.; Huang, J.Q.; Wei, F.; Zhu, J. TEM observations of buckling and fracture modes for compressed thick multiwall carbon nanotubes. Carbon 2011, 49, 206–213. [Google Scholar] [CrossRef]

- Ru, C.Q. Column buckling of multiwalled carbon nanotubes with interlayer radial displacements. Phys. Rev. B 2000, 62, 16962–16967. [Google Scholar] [CrossRef]

- Kudin, K.N.; Scuseria, G.E.; Yakobson, B.I. C2F, BN, and C nanoshell elasticity from ab initio computations. Phys. Rev. B 2001, 64, 235406. [Google Scholar] [CrossRef]

- Wang, C.Y.; Ru, C.Q.; Mioduchowski, A. Axially compressed buckling of pressured multiwall carbon nanotubes. Int. J. Solids Struct. 2003, 40, 3893–3911. [Google Scholar] [CrossRef]

- Shen, H.S. Postbuckling prediction of double-walled carbon nanotubes under hydrostatic pressure. Int. J. Solids Struct. 2004, 41, 2643–2657. [Google Scholar] [CrossRef]

- Rafii-Tabar, H. Computational modelling of thermo-mechanical and transport properties of carbon nanotubes. Phys. Rep. 2004, 390, 235–452. [Google Scholar] [CrossRef]

- He, X.Q.; Kitipornchai, S.; Liew, K.M. Buckling analysis of multi-walled carbon nanotubes: A continuum model accounting for van der Waals interaction. J. Mech. Phys. Solids 2005, 53, 303–326. [Google Scholar] [CrossRef]

- Chandraseker, K.; Mukherjee, S. Atomistic-continuum and ab initio estimation of the elastic moduli of single-walled carbon nanotubes. Comput. Mater. Sci. 2007, 40, 147–158. [Google Scholar] [CrossRef]

- Silvestre, N. Length dependence of critical measures in single-walled carbon nanotubes. Int. J. Solids Struct. 2008, 45, 4902–4920. [Google Scholar] [CrossRef]

- Kulathunga, D.D.T.K.; Ang, K.K.; Reddy, J.N. Accurate modeling of buckling of single- and double-walled carbon nanotubes based on shell theories. J. Phys. Condens. Matter 2009, 21, 435301. [Google Scholar] [CrossRef] [PubMed]

- Silvestre, N.; Wang, C.M.; Zhang, Y.Y.; Xiang, Y. Sanders shell model for buckling of single-walled carbon nanotubes with small aspect ratio. Compos. Struct. 2011, 93, 1683–1691. [Google Scholar] [CrossRef]

- Knechtel, W.H.; Dusberg, G.S.; Blau, W.J.; Hernandez, E.; Rubio, A. Reversible bending of carbon nanotubes using a transmission electron microscope. Appl. Phys. Lett. 1998, 73, 1961–1963. [Google Scholar] [CrossRef]

- Lourie, O.; Cox, D.M.; Wagner, H.D. Buckling and collapse of embedded carbon nanotubes. Phys. Rev. Lett. 1998, 81, 1638–1641. [Google Scholar] [CrossRef]

- Bower, C.; Rosen, R.; Jin, L.; Han, J.; Zhou, O. Deformation of carbon nanotubes in nanotube-polymer composites. Appl. Phys. Lett. 1999, 74, 3317–3319. [Google Scholar] [CrossRef]

- Tombler, T.W.; Zhou, C.; Alexseyev, L.; Kong, J.; Dai, H.; Liu, L.; Jayanthi, C.S.; Tang, M.; Wu, S.Y. Reversible electromechanical characteristics of carbon nanotubes under local-probe manipulation. Nature 2000, 405, 769–772. [Google Scholar] [PubMed]

- Lee, C.; Wei, X.D.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.Q.; Zhang, H.W.; Zheng, Y.G.; Wang, L.; Wang, J.B. Gas separation by kinked single-walled carbon nanotubes: Molecular dynamics simulations. Phys. Rev. B 2008, 78, 035439. [Google Scholar] [CrossRef]

- Wang, Q. Atomic transportation via carbon nanotubes. Nano Lett. 2009, 9, 245–249. [Google Scholar] [CrossRef] [PubMed]

- Duan, W.H.; Wang, Q. Water transport with a carbon nanotube pump. ACS Nano 2010, 4, 2338–2344. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Buehler, M.J. Strain controlled thermomutability of single-walled carbon nanotubes. Nanotechnology 2009, 20, 185701. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Maute, K.; Dunn, M.L.; Yang, R. Strain effects on the thermal conductivity of nanostructures. Phys. Rev. B 2010, 81, 245318. [Google Scholar] [CrossRef]

- Huang, Z.; Tang, Z.; Yu, J.; Bai, S. Temperature-dependent thermal conductivity of bent carbon nanotubes by molecular dynamics simulation. J. Appl. Phys. 2011, 109, 104316. [Google Scholar] [CrossRef]

- Yang, W.; Wang, R.Z.; Yan, H. Strain-induced Raman-mode shift in single-wall carbon nanotubes: Calculation of force constants from molecular-dynamics simulations. Phys. Rev. B 2008, 77, 195440. [Google Scholar] [CrossRef]

- Tang, C.; Guo, W.; Chen, C. Bending manipulation induced sp2-sp3 bond transition in carbon nanotubes. J. Appl. Phys. 2010, 108, 026108. [Google Scholar] [CrossRef]

- Farajian, A.A.; Yakobson, B.I.; Mizuseki, H.; Kawazoe, Y. Electronic transport through bent carbon nanotubes: Nanoelectromechanical sensors and switches. Phys. Rev. B 2003, 67, 205423. [Google Scholar] [CrossRef]

- Rochefort, A.; Avouris, P.; Lesage, F.; Salahub, D.R. Electrical and mechanical properties of distorted carbon nanotubes. Phys. Rev. B 1999, 60, 13824–13830. [Google Scholar] [CrossRef]

- Bozovic, D.; Bockrath, M.; Hafner, J.H.; Lieber, C.M.; Park, H.; Tinkham, M. Electronic properties of mechanically induced kinks in single-walled carbon nanotubes. Appl. Phys. Lett. 2001, 78, 3693–3695. [Google Scholar] [CrossRef]

- Hall, A.R.; Falvo, M.R.; Superfine, R.; Washburn, S. Electromechanical response of single-walled carbon nanotubes to torsional strain in a self-contained device. Nat. Nanotechnol. 2007, 2, 413–416. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.B.; Dumitricǎ, T. Effective shear-strain driven electromechanical response in helical rippled carbon nanotubes. Phys. Rev. B 2010, 82, 193401. [Google Scholar] [CrossRef]

- Peters, M.J.; McNeil, L.E.; Lu, J.P.; Kahan, D. Structural phase transition in carbon nanotube bundles under pressure. Phys. Rev. B 2000, 61, 5939–5944. [Google Scholar] [CrossRef]

- Hall, A.R.; Falvo, M.R.; Superfine, R.; Washburn, S. A self-sensing nanomechanical resonator built on a single-walled carbon nanotube. Nano Lett. 2008, 8, 3746–3749. [Google Scholar] [CrossRef] [PubMed]

- Feliciano, J.; Chun Tang, C.; Zhang, Y.Y.; Chen, C.F. Aspect ratio dependent buckling mode transition in single-walled carbon nanotubes under compression. J. Appl. Phys. 2011, 109, 084323. [Google Scholar] [CrossRef]

- Recently, shell buckling behavior of short nanotubes with aspect ratior ~1 or less was considered, showing the significant dependence of the buckling strain on the nanotube length [123].

- Korayem, A.H.; Duan, W.H.; Zhao, X.L. Investigation on buckling behavior of short MWCNT. Proc. Eng. 2011, 14, 250–255. [Google Scholar] [CrossRef]

- The critical strain of shell buckling is inversely proportional to the tube diameter [125].

- Zhang, Y.Y.; Wang, C.M.; Duan, W.H.; Xiang, Y.; Zong, Z. Assessment of continuum mechanics models in predicting buckling strains of single-walled carbon nanotubes. Nanotechnology 2009, 20, 395707. [Google Scholar] [CrossRef] [PubMed]

- Similar sequential transitions can be observed when a SWNT is bent [68]. See Section 6.3 for details.

- Arash, B.; Wang, Q. A review on the application of nonlocal elastic models in modeling of carbon nanotubes and graphenes. Comput. Mater. Sci. 2012, 51, 303–313. [Google Scholar] [CrossRef]

- Huang, X.; Yuan, H.Y.; Hsia, K.J.; Zhang, S.L. Coordinated buckling of thick multi-walled carbon nanotubes under uniaxial compression. Nano Res. 2010, 3, 32–42. [Google Scholar] [CrossRef]

- Guduru, P.R.; Xia, Z. Shell buckling of imperfect multiwalled carbon nanotubes—Experiments and analysis. Exp. Mech. 2007, 47, 153–161. [Google Scholar] [CrossRef]

- The actual direction of the applied force deviates from the exact axial one by approximately 15°, as indicated in Figure 2(a).

- The instability at (8) and the sharp rise at (9) during unloading stem from the tip pulled out of contact from the sample, while the nanotube end remains in contact.

- Palaci, I.; Fedrigo, S.; Brune, H.; Klinke, C.; Chen, M.; Riedo, E. Radial elasticity of multiwalled carbon nanotubes. Phys. Rev. Lett. 2005, 94, 175502. [Google Scholar] [CrossRef] [PubMed]

- Majid, M.J.; Yu, M.F. Reversible radial deformation up to the complete flattening of carbon nanotubes in nanoindentation. J. Appl. Phys. 2008, 103, 073516. [Google Scholar]

- Lu, W.; Tsu-Wei Chou, T.W.; Byung-Sun Kim, B.S. Radial deformation and its related energy variations of single-walled carbon nanotubes. Phys. Rev. B 2011, 83, 134113. [Google Scholar] [CrossRef]

- For larger radius SWNTs, the peanut-like deformed structure can be transformed to dumbbell-like configurations by van der Waals (vdW) attractions between the opposite walls of nanotubes. The latter structure is energetically stable even when the applied force is unloaded.

- Barboza, A.P.M.; Gomes, A.P.; Archanjo, B.S.; Araujo, P.T.; Jorio, A.; Ferlauto, A.S.; Mazzoni, M.S.C.; Chacham, H.; Neves, B.R.A. Deformation induced semiconductor-metal transition in singlewall carbon nanotubes probed by electric force microscopy. Phys. Rev. Lett. 2008, 100, 256804. [Google Scholar] [CrossRef] [PubMed]

- Giusca, C.E.; Tison, Y.; Silva, S.R.P. Evidence for metal-semiconductor transitions in twisted and collapsed double-walled carbon nanotubes by scanning tunneling microscopy. Nano Lett. 2008, 8, 3350–3356. [Google Scholar] [CrossRef] [PubMed]

- Thirunavukkuarasu, K.; Hennrich, F.; Kamarás, K.; Kuntscher, C.A. Infrared spectroscopic studies on unoriented single-walled carbon nanotube films under hydrostatic pressure. Phys. Rev. B 2010, 81, 045424. [Google Scholar] [CrossRef]

- Diniz, E.M.; Nunes, R.W.; Chacham, H.; Mazzoni, M.S.C. Bistability, softening, and quenching of magnetic moments in Ni-filled carbon nanotubes. Phys. Rev. B 2010, 81, 153413. [Google Scholar] [CrossRef]

- Fonseca, A.F.; Borders, T.; Baughman, R.H.; Cho, K. Load transfer between cross-linked walls of a carbon nanotube. Phys. Rev. B 2010, 81, 045429. [Google Scholar] [CrossRef]

- Sakurai, M.; Saito, S. Pressure-induced structural phase transition of small-diameter carbon nanotubes. Physica E 2011, 43, 673–676. [Google Scholar] [CrossRef]

- Xia, Z.H.; Guduru, P.R.; Curtin, W.A. Enhancing mechanical properties of multiwall carbon nanotubes via sp3 interwall bridging. Phys. Rev. Lett. 2007, 98, 245501. [Google Scholar] [CrossRef] [PubMed]

- Byrne, E.M.; McCarthy, M.A.; Xia, Z.; Curtin, W.A. Multiwall nanotubes can be stronger than singlewall nanotubes and implications for nanocomposite design. Phys. Rev. Lett. 2009, 103, 045502. [Google Scholar] [CrossRef] [PubMed]

- Filleter, T.; Bernal, R.; Li, S.; Espinosa, H.D. Ultrahigh strength and stiffness in cross-linked hierarchical carbon nanotube bundles. Adv. Mater. 2011, 23, 2855–2860. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.Y.; Wang, C.M.; Xiang, Y. Bending behavior of double-walled carbon nanotubes with sp3 interwall bonds. J. Appl. Phys. 2011, 109, 083516. [Google Scholar] [CrossRef]

- Yang, X.; Wu, G. The study of structural, electronic and optical properties of double-walled carbon nanotube bundles under hydrostatic pressure. EPL 2008, 81, 47003. [Google Scholar] [CrossRef]

- Arvanitidis, J.; Christofilos, D.; Papagelis, K.; Andrikopoulos, K.S.; Takenobu, T.; Iwasa, Y.; Kataura, H.; Ves, S.; Kourouklis, G.A. Pressure screening in the interior of primary shells in double-wall carbon nanotubes. Phys. Rev. B 2005, 71, 125404. [Google Scholar] [CrossRef]

- A radial pressure large enough to cause corrugation can be achieved by electron-beam irradiation [149]; the self-healing nature of eroded carbon walls gives rise to a spontaneous contraction that exerts a high pressure on the inner walls to yield their radial corrugation [60].

- Krasheninnikov, A.V.; Nordlund, K. Ion and electron irradiation-induced effects in nanostructured materials. J. Appl. Phys. 2010, 107, 071301. [Google Scholar] [CrossRef]

- The authors in Reference [63] say that this conclusion was motivated by an experimental fact that cross sections of MWNTs synthesized in the presence of nitrogen are polygonal shapes rather than circular shapes [151,152]. It was argued that the polygonization may result from the interlayer thermal contraction upon cooling or interwall adhesion energy owing to the increased interwall commensuration [151].

- Ducati, C.; Koziol, K.; Friedrichs, S.; Yates, T.J.V.; Shaffer, M.S.; Midgley, P.A.; Windle, A.H. Crystallographic order in multi-walled carbon nanotubes synthesized in the presence of nitrogen. Small 2006, 2, 774–784. [Google Scholar] [CrossRef] [PubMed]

- Koziol, K.; Shaffer, M.; Windle, A. Three-dimensional internal order in multiwalled carbon nanotubes grown by chemical vapor deposition. Adv. Mater. 2005, 17, 760–763. [Google Scholar] [CrossRef]

- Prior to structural optimization, the initial cross sections of all the MWNTs are of circular shape and the interwall spacing is 0.359 nm, which is 0.19 nm larger than the equilibrium spacing of two graphene sheets (=0.34 nm).

- Majumder, M.; Chopra, N.; Andrews, R.; Hinds, B.J. Nanoscale hydrodynamics: Enhanced flow in carbon nanotubes. Nature 2005, 438, 44. [Google Scholar] [CrossRef] [PubMed]

- Noy, A.; Park, H.G.; Fornasiero, F.; Holt, J.K.; Grigoropoulos, C.P.; Bakajin, O. Nanofluidics in carbon nanotubes. Nano Today 2007, 2, 22–29. [Google Scholar] [CrossRef]

- Whitby, M.; Quirke, N. Fluid flow in carbon nanotubes and nanopipes. Nat. Nanotechnol. 2007, 2, 87–94. [Google Scholar] [CrossRef] [PubMed]

- Frackowiak, E.; Beguin, F. Electrochemical storage of energy in carbon nanotubes and nanostructured carbons. Carbon 2002, 40, 1775–1787. [Google Scholar] [CrossRef]

- Shima, H.; Yoshioka, H. Electronic spectral shift of oxygen-filled (6,6) carbon nanotubes. Chem. Phys. Lett. 2011, 513, 224–228. [Google Scholar] [CrossRef]

- Shima, H.; Yoshioka, H.; Onoe, J. Geometry-driven shift in the Tomonaga-Luttinger exponent of deformed cylinders. Phys. Rev. B 2009, 79, 201401. [Google Scholar] [CrossRef]

- Ono, S.; Shima, H. Tuning the electrical resistivity of semiconductor thin films by nanoscale corrugation. Phys. Rev. B 2009, 79, 235407. [Google Scholar] [CrossRef]

- Shima, H.; Yoshioka, H.; Onoe, J. Curvature effects on collective excitations in dumbbell-shaped hollow nanotubes. Physica E 2010, 42, 1151–1154. [Google Scholar] [CrossRef]

- Ono, S.; Shima, H. Low-temperature resistivity anomalies in periodic curved surfaces. Physica E 2010, 42, 1224–1227. [Google Scholar] [CrossRef]

- Taira, H.; Shima, H. Torsion-induced persistent current in a twisted quantum ring. J. Phys. Condens. Matter 2010, 22, 075301. [Google Scholar] [CrossRef] [PubMed]

- Taira, H.; Shima, H. Flux-free conductance modulation in a helical Aharonov-Bohm interferometer. J. Phys. Condens. Matter 2010, 22, 245302. [Google Scholar] [CrossRef] [PubMed]

- Ono, S.; Shima, H. Flexible control of the Peierls transition in metallic C60 polymers. EPL 2011, 96, 27011. [Google Scholar] [CrossRef]

- Ono, S.; Shima, H. Phonon dispersion and electron-phonon interaction in peanut-shaped fullerene polymers. J. Phys. Soc. Jpn. 2011, 80, 064704. [Google Scholar] [CrossRef]

- Cao, G.; Chen, X. Buckling of single-walled carbon nanotubes upon bending: Molecular dynamics and finite element simulations. Phys. Rev. B 2006, 73, 155435. [Google Scholar] [CrossRef]

- Interestingly, a buckled SWNT in the TBR is fully reversible. If bending is stopped before the second discontinuity occurs, unbending recovers the cross-sectional shapes at the buckling point.

- Pantano, A.; Boyce, M.C.; Parks, D.M. Nonlinear structural mechanics based modeling of carbon nanotube deformation. Phys. Rev. Lett. 2003, 91, 145501–145504. [Google Scholar] [CrossRef] [PubMed]

- Chang, T.; Hou, J. Molecular dynamics simulations on buckling of multiwalled carbon nanotubes under bending. J. Appl. Phys. 2006, 100, 114327. [Google Scholar] [CrossRef]

- Arroyo, M.; Arias, I. Rippling and a phase-transforming mesoscopic model for multiwalled carbon nanotubes. J. Mech. Phys. Solids 2008, 56, 1224–1244. [Google Scholar] [CrossRef] [Green Version]

- Ruoff, R.S.; Lorents, D.C. Mechanical and thermal properties of carbon nanotubes. Carbon 1995, 33, 925–930. [Google Scholar] [CrossRef]

- Kuzumaki, T.; Hayashi, T.; Ichinose, H.; Miyazawa, K.; Ito, K.; Ishida, Y. In-situ observed deformation of carbon nanotubes. Philos. Mag. A 1998, 77, 1461–1469. [Google Scholar] [CrossRef]

- Arroyo, M.; Belytschko, T. Nonlinear mechanical response and rippling of thick multiwalled carbon nanotubes. Phys. Rev. Lett. 2003, 91, 215505. [Google Scholar] [CrossRef] [PubMed]

- Li, X.Y.; Yang, W.; Liu, B. Bending induced rippling and twisting of multiwalled carbon nanotubes. Phys. Rev. Lett. 2007, 98, 205502. [Google Scholar] [CrossRef] [PubMed]

- Arias, I.; Arroyo, M. Size-dependent nonlinear elastic scaling of multiwalled carbon nanotubes. Phys. Rev. Lett. 2008, 100, 085503. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Zou, J.; Zhang, S.L. Bilinear responses and rippling morphologies of multi-walled carbon nanotubes under torsion. Appl. Phys. Lett. 2008, 93, 031915. [Google Scholar] [CrossRef]

- Zou, J.; Huang, X.; Arroyo, M.; Zhang, S.L. Effective coarse-grained simulations of super-thick multi-walled carbon nanotubes under torsion. J. Appl. Phys. 2009, 105, 033516. [Google Scholar] [CrossRef] [Green Version]

- Nikiforov, I.; Zhang, D.B.; James, R.D.; Dumitricǎ, T. Wavelike rippling in multiwalled carbon nanotubes under pure bending. Appl. Phys. Lett. 2010, 96, 123107. [Google Scholar] [CrossRef]

- Liu, J.Z.; Zheng, Q.; Jiang, Q. Effect of a rippling mode on resonances of carbon nanotubes. Phys. Rev. Lett. 2001, 86, 4843–4846. [Google Scholar] [CrossRef] [PubMed]

- The Yoshimura pattern is a special kind of surface deformation mode occurring in thin-walled cylindrical shells subjected to large lateral load. It is named after Prof. Yoshimura [182], a Japanese theoretician of fracture mechanics, and its profile is characterized by a periodic diamond-like corrugation.

- Yoshimura, Y. On the Mechanism of Buckling of a Circular Cylindrical Shell under Axial Compression; The reports of the Institute of Science and Technology; University of Tokyo: Tokyo, Japan, 1951; Volume 5, pp. 179–198, in Japanese. [Google Scholar]

- Interestingly, the energetics ofMWNT bucking under bending are altered by inserting cross-linking (i.e., sp3 covalent bonding) between adjacent walls, as presented in References [184,185].

- Huang, X.; Zhang, S. Load-driven morphological evolution in covalently bridged multiwalled carbon nanotubes. Appl. Phys. Lett. 2010, 96, 203106. [Google Scholar] [CrossRef]

- Duchamp, M.; Meunier, R.; Smajda, R.; Mionic, M.; Magrez, A.; Seo, J.W.; Forró, L.; Song, B.; Tománek, D. Reinforcing multiwall carbon nanotubes by electron beam irradiation. J. Appl. Phys. 2010, 108, 084314. [Google Scholar] [CrossRef]

- Chang, T. Torsional behavior of chiral single-walled carbon nanotubes is loading direction dependent. Appl. Phys. Lett. 2007, 90, 201910. [Google Scholar] [CrossRef]

- Geng, J.; Chang, T. Nonlinear stick-spiral model for predicting mechanical behavior of single-walled carbon nanotubes. Phys. Rev. B 2006, 74, 245428. [Google Scholar] [CrossRef]

- Liang, H.; Upmanyu, M. Axial-strain-induced torsion in single-walled carbon nanotubes. Phys. Rev. Lett. 2006, 96, 165501. [Google Scholar] [CrossRef] [PubMed]

- Cohen-Karni, T.; Segev, L.; Srur-Lavi, O.; Cohen, S.R.; Joselevich, E. Torsional electromechanical quantum oscillations in carbon nanotubes. Nat. Nanotechnol. 2006, 1, 36–41. [Google Scholar] [CrossRef] [PubMed]

- Nagapriya, K.S.; Berber, S.; Cohen-Karni, T.; Segev, L.; Srur-Lavi, O.; Tománek, D.; Joselevich, E. Origin of torsion-induced conductance oscillations in carbon nanotubes. Phys. Rev. B 2008, 78, 165417. [Google Scholar] [CrossRef]

- Zhang, D.B.; Dumitrica, T. Effective strain in helical rippled carbon nanotubes: A unifying concept for understanding electromechanical response. ACS Nano 2010, 4, 6966–6972. [Google Scholar] [CrossRef] [PubMed]

- During torsional rippling, the innermost core tube stores a very high strain energy despite the nearly zero rippling amplitude. Owing to the strong confinement, the strain energy in this layer cannot be released via rippling, which may lead to bond breaking and subsequent brittle cracking when the torsional deformation continues to increase [175,177].

- Deng, F.; Zheng, Q.S.; Wang, L.F.; Nan, C.W. Effects of anisotropy, aspect ratio, and nonstraightness of carbon nanotubes on thermal conductivity of carbon nanotube composites. Appl. Phys. Lett. 2007, 90, 021914. [Google Scholar] [CrossRef]

- Chang, C.W.; Okawa, D.; Majumdar, A.; Zettl, A. Solid-state thermal rectifier. Science 2006, 314, 1121–1124. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.W.; Okawa, D.; Garcia, H.; Majumdar, A.; Zettl, A. Nanotube phonon waveguide. Phys. Rev. Lett. 2007, 99, 045901. [Google Scholar] [CrossRef] [PubMed]

- Xin, H.; Han, Q.; Yao, X.H. Buckling and axially compressive properties of perfect and defective single-walled carbon nanotubes. Carbon 2007, 45, 2486–2495. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Xiang, Y.; Wang, C.M. Buckling of defective carbon nanotubes. J. Appl. Phys. 2009, 106, 113503. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Wang, C.M.; Xiang, Y. A molecular dynamics investigation of the torsional responses of defective single-walled carbon nanotubes. Carbon 2010, 48, 4100–4108. [Google Scholar] [CrossRef]

- Kulathunga, D.D.T.K.; Ang, K.K.; Reddy, J.N. Molecular dynamics analysis on buckling of defective carbon nanotubes. J. Phys. Condens. Matter 2010, 22, 345301. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Li, L.; Wang, J.S. Tuning thermal transport in nanotubes with topological defects. Appl. Phys. Lett. 2011, 99, 091905. [Google Scholar] [CrossRef]

- Gülseren, O.; Yildirim, T.; Ciraci, S. Tunable adsorption on carbon nanotubes. Phys. Rev. Lett. 2001, 87, 116802. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Srivastava, D.; Cho, K. Generalized chemical reactivity of curved surfaces: Carbon nanotubes. Nano Lett. 2003, 3, 1273–1277. [Google Scholar] [CrossRef]

- Haddon, R.C. Chemistry of the fullerenes: The manifestation of strain in a class of continuous aromatic molecules. Science 1993, 261, 1545–1550. [Google Scholar] [CrossRef] [PubMed]

- Mylvaganam, K.; Zhang, L.C. Deformation-promoted reactivity of single-walled carbon nanotubes. Nanotechnology 2006, 17, 410. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Liu, Z.F. Pressure induced reactivity change on the side-wall of a carbon nanotube: A case study on the addition of singlet O2. Carbon 2006, 44, 928–938. [Google Scholar] [CrossRef]

- The relevant literature has been probed with great care by Boehm in 1997 [207] and Monthioux and Kuznetsov in 2006 [208]. The first half of this Appendix is based on the two excellent reviews.

- Boehm, H.P. The first observation of carbon nanotubes. Carbon 1997, 35, 581–584. [Google Scholar] [CrossRef]

- Monthioux, M.; Kuznetsov, V.L. Who should be given the credit for the discovery of carbon nanotubes? Carbon 2006, 44, 1621–1623. [Google Scholar] [CrossRef]

- Radushkevich, L.V.; Lukyanovich, V.M. O strukture ugleroda, obrazujucegosja pri termiceskom razlozenii okisi ugleroda na zeleznom kontakte. Zurn. Fisic. Chim. 1952, 26, 88–95, Translated into Russ. J. Phys. Chem. 1952, 26, 88–95. [Google Scholar]

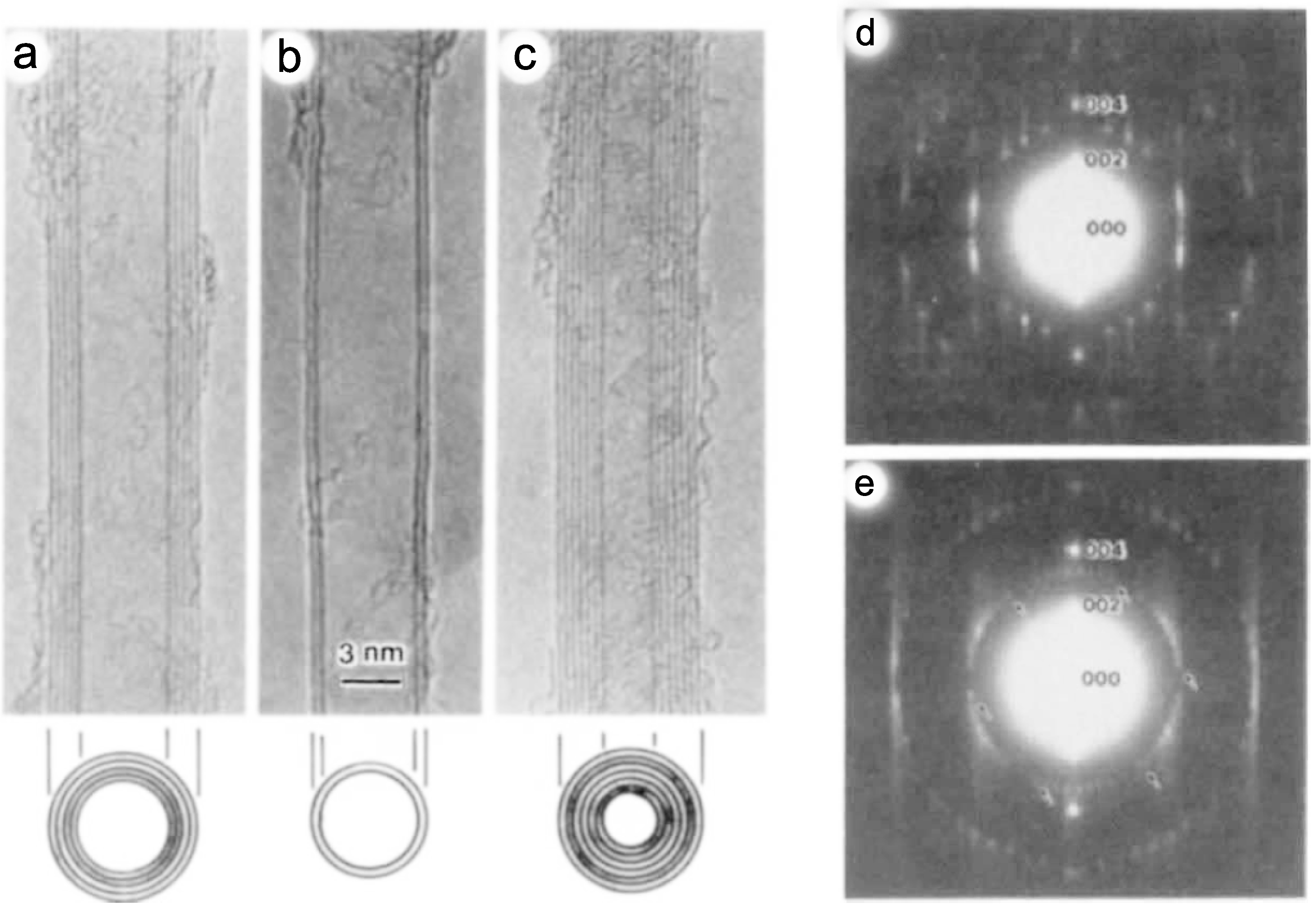

- Oberlin, A.; Endo, M.; Koyama, T. Filamentous growth of carbon through benzene decomposition. J. Cryst. Growth 1976, 32, 335–349. [Google Scholar] [CrossRef]

- Despite the omission of a scale bar, the magnification value indicated in the article allows one to estimate that the diameters of the carbon tubes imaged are in the range of 50 nm, i.e., definitely nanosized.

- Abrahamson, J.; Wiles, P.G.; Rhoades, B.L. Structure of carbon fibers found on carbon arc anodes. Carbon 1999, 37, 1873–1874. [Google Scholar] [CrossRef]

© 2012 by the author; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Shima, H. Buckling of Carbon Nanotubes: A State of the Art Review. Materials 2012, 5, 47-84. https://doi.org/10.3390/ma5010047

Shima H. Buckling of Carbon Nanotubes: A State of the Art Review. Materials. 2012; 5(1):47-84. https://doi.org/10.3390/ma5010047

Chicago/Turabian StyleShima, Hiroyuki. 2012. "Buckling of Carbon Nanotubes: A State of the Art Review" Materials 5, no. 1: 47-84. https://doi.org/10.3390/ma5010047