In order to obtain significant outcome, indentation locations over the intended surface should be carefully determined through the proper stratified design with the consideration of the trend and frequency of hardness distribution in both the radial and circumferential directions. Data evaluation included both of the descriptive graphical response surface methodology, to visualize the individual and the interaction of the involved parameters and the appropriate statistical parameters such as Means, T-Test, one-way ANOVA and Correlation, to determine the adequacy and significance of possible evolving trends.

3.1. Apparatus Calibration and Hardness Variability of the Reference Block

Calibration of the measuring device using its reference block is one of the important factors affecting the hardness measurement. The hardness reference block is of ultimate importance, supplying the criteria to determine the standard value of a product, to verify hardness of testing machines and to specify accuracy of quality control measurements. This procedure may provide the mutual benefit of examining the accuracy of both the reference block and the measuring device. Therefore, to increase the credibility of the recorded hardness, the device was calibrated using the reference hardness block that is provided by manufacturer. As shown in

Figure 1, the indentation locations were determined as the intersection of a stratified design that includes eight circumferential sectors and three radial layers. This led to 24 indentation locations to give a high level of reliability and repeatability of the measuring device. According to ISO 6507—part 3 [

1,

2,

3], only five indentations are required as a minimum number. Many other investigations [

6,

8,

9] have been carried out to determine the best way of the reference block calibration and its uncertainty. It has been reported [

9] that more than 6 or even 12 strata were recommended for reliable hardness measurement since, in their opinion, only five indentations proposed by [

8] did not seem to be sufficient to gain statistically reliable calibration values.

Figure 1.

Stratifying design for hardness reference block.

Figure 1.

Stratifying design for hardness reference block.

In order to find out how to locate the test indentation positions and, at the same time, to determine the number of indentations sufficient for a significant measure, the reference block was mapped as indicated in

Figure 1. The surface of the reference block was divided into eight circumferential sectors and three diagonal concentric circles (layers). This yielded a stratification design of a total of 24 hardness indentations map locations. The influence of stratified conditions on the measured hardness values was statistically and graphically judged.

General descriptive statistics of the measurement is listed in

Table 2. Although the data mean value (81.74 HRB) is very close to the nominal value (82 HRB), some experimental error and outliers have affected the results and their statistical features. However, the “Detect Anomaly” features in the SPSS statistical program is used to identify the unusual cases within the data. The Anomaly Detection procedure searches for unusual cases based on deviations from the norms of their cluster groups. The algorithm is designed for generic anomaly detection; that is, the definition of an anomalous case is not specific to any particular application. Algorithm steps are usually: Modeling, Scoring and Reasoning. More details about the procedures can be found in [

10].

Table 2.

Descriptive statistics of the reference block hardness measurement.

Table 2.

Descriptive statistics of the reference block hardness measurement.

| No. Cases | Minimum | Maximum | Mean | Std. Dev. |

|---|

| Entire data | Filtered data | Entire data | Filtered data | Entire data | Filtered data | Entire data | Filtered data | Entire data | Filtered data |

|---|

| Hi | 24 | 16 | 67.90 | 76.3 | 96.10 | 87.00 | 81.74 | 82.90 | 6.644 | 3.090 |

A criterion 5% exclusion percentage with the highest anomaly index value is selected for the outlier identification. Tracking out and removal of the eight detected outlier data points has enormously improved the data trends and their statistical measures. Considering that i and j are the sector and layer sequence respectively, the removed eight outlier points p(i,j) were: (1,1), (1,3), (2,2), (3,1), (3,2), (3,3), (6,1), (8,3). As listed in

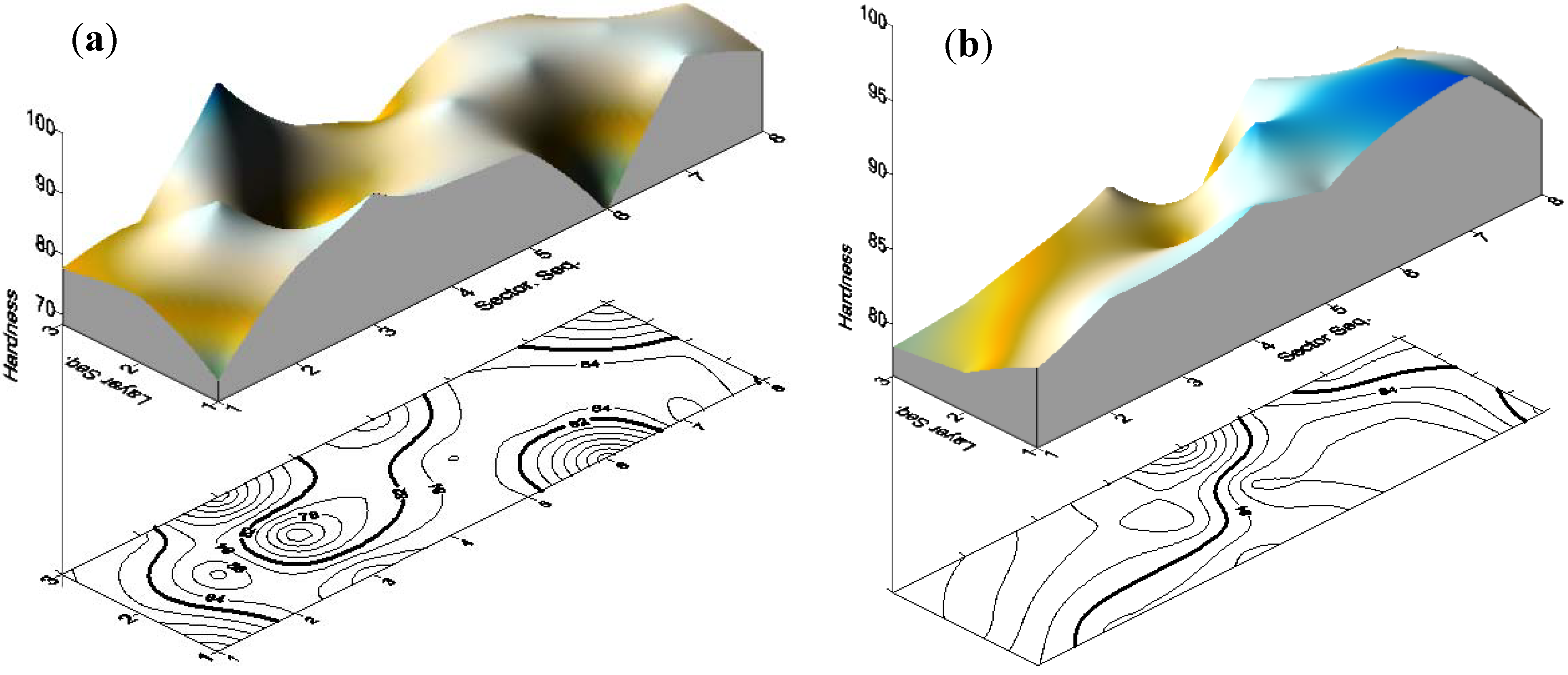

Table 2, the standard deviation was reduced from 6.644 for entire data (unfiltered) to only 3.09 for the filtered data. Data enhancement can be further observed through the data distribution over the sector-layer response surface and contour plots as shown in

Figure 2. For the unfiltered data,

Figure 2(a), higher measured hardness values can be observed especially at sector numbers 3 and 6. Outliers removal led to less variation and more homogenous hardness values as indicated by

Figure 2(b). The relevant data map before and after filtration process is shown in

Figure 3.

Many statistical features are applied to statistically examine the data nature and significance. As listed in

Table 3, standard deviation is improved for most sectors as well as for the entire set of data. Improvement was reflected in the values of standard deviation parameters of all layers,

Table 4, where a reduction of about 74, 43 and 58 percent is attained for layers numbers 1, 2 and 3 respectively. As seen by

T-test analysis,

Table 5, filtered data indicated not only lower standard deviation value but also more compact 95% confidence interval and standard error of estimates with higher

t-value. It is observed that the data was principally affected by the impact of the low measured hardness values.

Table 6 summarizes the statistical

T-test Pairs, One-way ANOVA and Correlation Statistical parameters for filtered and unfiltered data. T-test pairs analysis indicates that the layer sequence may exhibit a possible slight correlation in such a way that lower specimen diameter seems to be harder.

Figure 2.

Response surface of the hardness measurement of the reference block. (a) Unfiltered data; and (b) Filtered data.

Figure 2.

Response surface of the hardness measurement of the reference block. (a) Unfiltered data; and (b) Filtered data.

Figure 3.

Hardness map distribution over sector and layer. (a) Unfiltered data; and (b) Filtered data.

Figure 3.

Hardness map distribution over sector and layer. (a) Unfiltered data; and (b) Filtered data.

Table 3.

MEANS statistical parameters of Hi-sector interaction.

Table 3.

MEANS statistical parameters of Hi-sector interaction.

| Sector | Filtered data | Unfiltered data |

|---|

| Mean | N | Std. Dev. | Mean | N | Std. Dev. |

|---|

| 1 | 79.20 | 1 | . | 76.20 | 3 | 3.89 |

| 2 | 81.60 | 2 | 3.68 | 84.03 | 3 | 4.95 |

| 3 | - | - | - | 85.97 | 3 | 12.78 |

| 4 | 82.63 | 3 | 2.74 | 82.63 | 3 | 2.74 |

| 5 | 82.23 | 3 | 5.25 | 82.23 | 3 | 5.25 |

| 6 | 85.15 | 2 | 1.20 | 79.40 | 3 | 9.995 |

| 7 | 84.73 | 3 | 2.95 | 84.73 | 3 | 2.95 |

| 8 | 82.45 | 2 | 1.20 | 78.70 | 3 | 6.55 |

| Total | 82.90 | 16 | 3.09 | 81.74 | 24 | 6.64 |

Table 4.

Means statistical parameters of Hi-layer interaction.

Table 4.

Means statistical parameters of Hi-layer interaction.

| Layer | Filtered data | Unfiltered data |

|---|

| Mean | N | Std. Dev. | Mean | N | Std. Dev. |

|---|

| 1 | 84.50 | 5 | 2.01 | 81.55 | 8 | 7.71 |

| 2 | 83.47 | 6 | 3.12 | 82.66 | 8 | 5.53 |

| 3 | 80.62 | 5 | 3.07 | 81.00 | 8 | 7.31 |

| Total | 82.90 | 16 | 3.09 | 81.74 | 24 | 6.64 |

Table 5.

T-test statistical parameters for filtered and unfiltered data.

Table 5.

T-test statistical parameters for filtered and unfiltered data.

| N | Mean | Std. Dev. | Std. Error | t-value | Sig. | 95% Conference interval |

|---|

| Lower | upper |

|---|

| 16 | 82.9 | 3.09 | 0.7726 | 107.3 | 0.00 | 81.25 | 84.55 |

| 24 | 81.74 | 6.64 | 1.356 | 50.27 | 0.00 | 78.93 | 84.54 |

Table 6.

T-test pairs, one-way ANOVA and correlation statistical parameters.

Table 6.

T-test pairs, one-way ANOVA and correlation statistical parameters.

| Layer | Filtered data | Unfiltered data |

|---|

| N | Corr. | Sig. | One-way ANOVA | N | Corr. | Sig. | One-way ANOVA |

|---|

| F-ratio | Sig. | F-ratio | Sig. |

|---|

| Pair 1 (Hi & Sector) | 16 | 0.364 | 0.165 | 0.566 | 0.749 | 24 | 0.004 | 0.986 | 0.621 | 0.691 |

| Pair 2 (Hi & Layer) | 16 | −0.513 | 0.042 | 2.581 | 0.114 | 24 | −0.035 | 0.873 | 0.121 | 0.887 |

3.2. Hardness Variability of AISI 4140 Steel

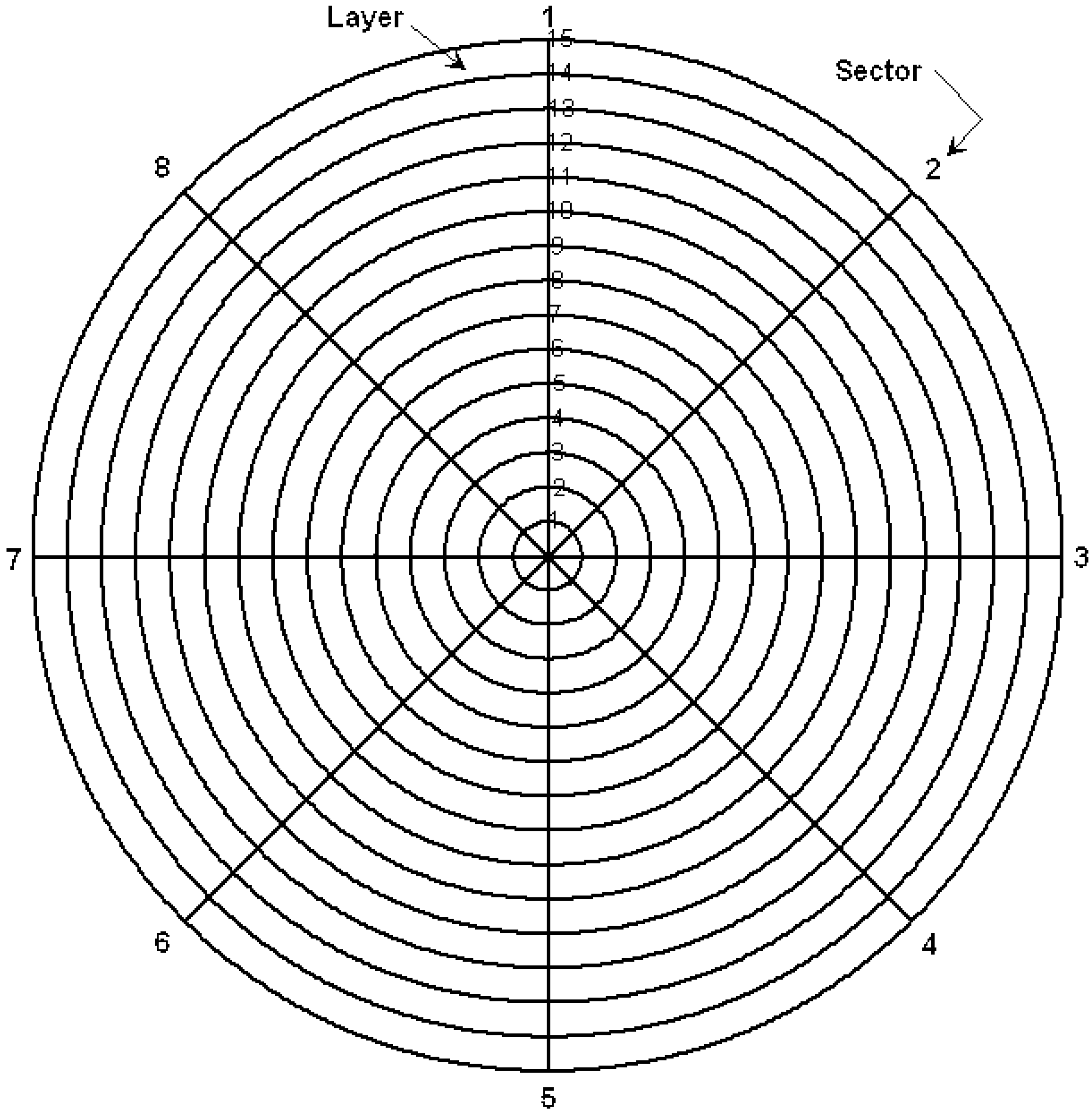

Based on the evolved outcome and findings, a stratified design over the cross-section circular faces of AISI 4140 is proposed as shown in

Figure 4. Eight circumferential sectors of 45 deg angular space and fifteen radial layers have led to a total of 120 data readings located at the circumference-radial lines intersections as shown in

Figure 4.

Statistical features of the measured hardness values over both cross-section sides A and B along with their aggregated set are listed in

Table 7. Although a significant statistical judgment is observed for readings taken on side B, the use of the entire data for both sides seems to improve the significance and the adequacy of the data set.

Figure 4.

Stratifying design for hardness measurements over cross section surface.

Figure 4.

Stratifying design for hardness measurements over cross section surface.

Table 7.

Statistical analysis for entire data of both sides of AISI 4140 (Hm = HRB 99).

Table 7.

Statistical analysis for entire data of both sides of AISI 4140 (Hm = HRB 99).

| Side | Range | Mean | Std. Dev. | Std. Error | t-value | Sig. | 95% Conference interval |

|---|

| Min | Max | Lower | Upper |

|---|

| A | 89 | 110.7 | 100.8 | 6.79 | 0.619 | 162.8 | 0.000 | 99.57 | 102.03 |

| B | 90 | 111.3 | 105.9 | 4.61 | 0.421 | 251.7 | 0.000 | 105.07 | 106.74 |

| A+B | 89 | 111.3 | 103.35 | 6.33 | 0.408 | 253.0 | 0.000 | 102.55 | 104.16 |

When data for each side is individually dealt with, the “Detect Anomaly” analysis, with the specified criterion measures, as in the last section, suggested the exclusion removal of six data points from each side. However, when data for both sides were considered, ten cases from side B and two cases from side A were suggested for exclusion. As indicated in

Table 8, statistical measures are rarely affected after outlier removal. With increasing data points, it is expected that the outlier impact is diluted and this justifies the emerged trend for the reference block when only 24-cases are considered.

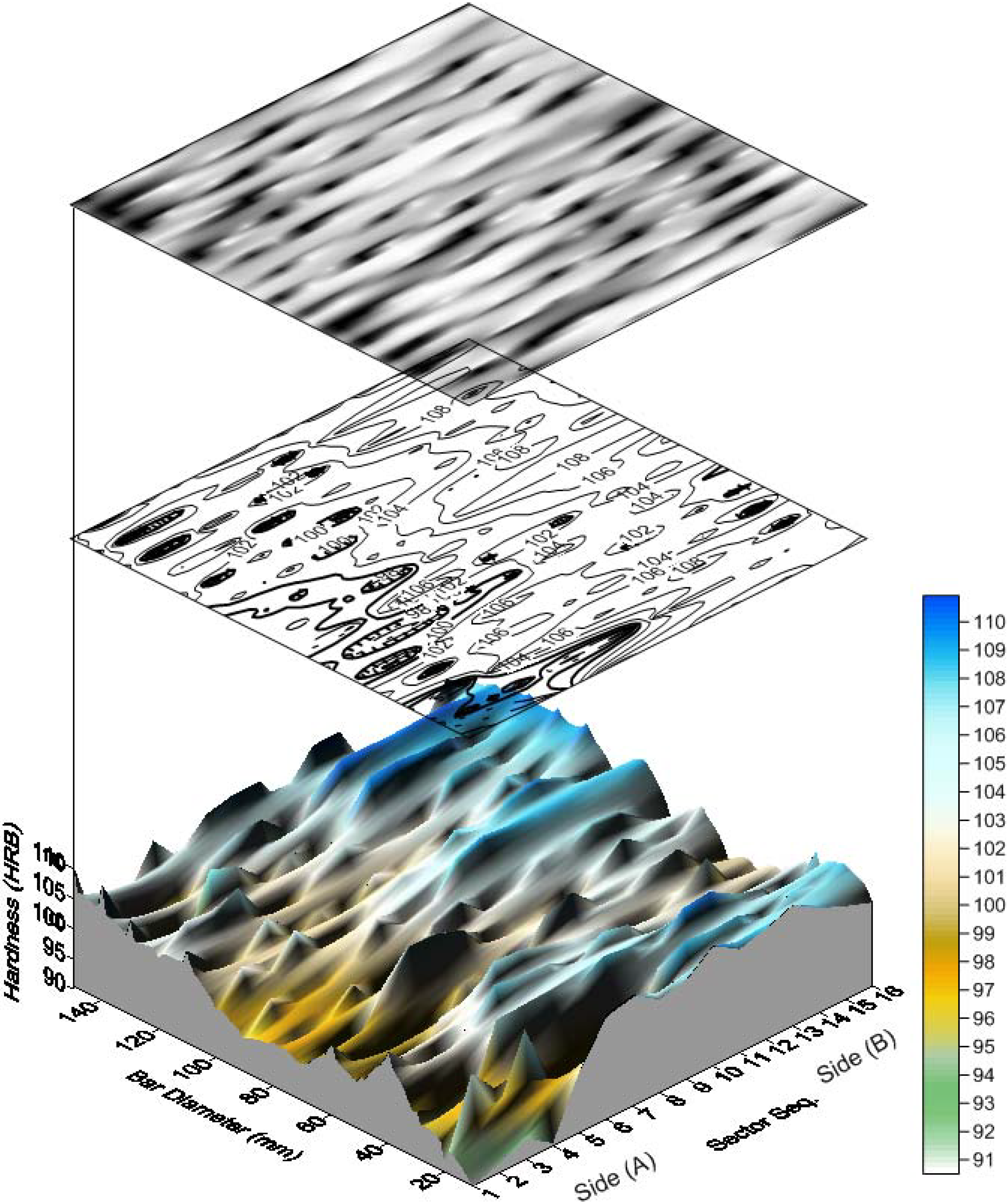

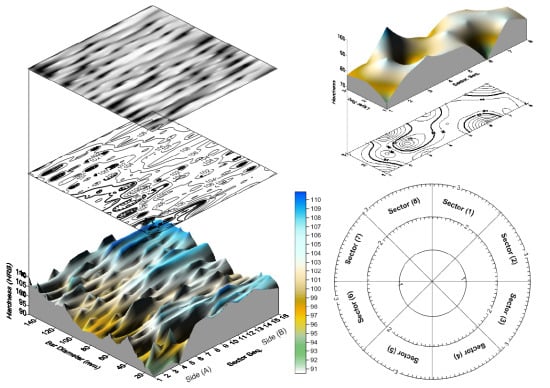

Figure 5 shows surface map, surface contour and response surface of the entire data of both section sides. This is accompanied by a color scale to indicate the hardness levels as judged by the color intensity. A hardness increasing trend at larger diameters or outer layers is observed over both sides. Also, it is generally shown that over side B, the recorded hardness values have greater values (compare mean values of both sides in

Table 7 and

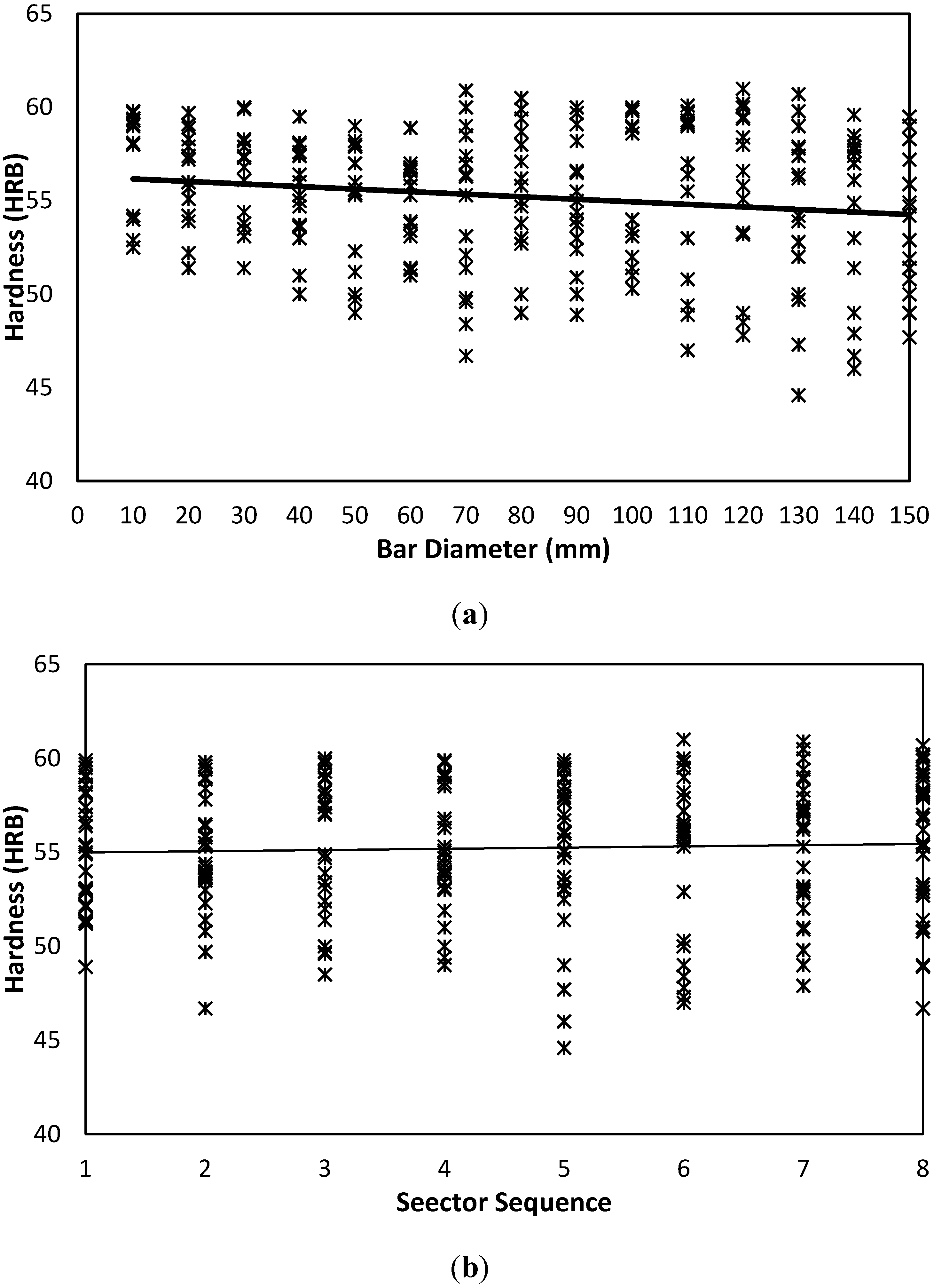

Table 8). Possible trends are shown when the plain raw data are plotted as in

Figure 6 and

Figure 7. A slight positive trend and dependency on the bar diameter is detected; see

Figure 6(a) and

Figure 7(a). However, as far as the hardness-sector sequence is concerned, (

Figure 6(b) and

Figure 7(b)), there is no solid evidence against the assumable random nature of the measured data. All the aforementioned findings are reflected by the statistical criteria as listed in

Table 9 using T-test Pairs, One-Way ANOVA and the partial correlation criteria.

Table 8.

Statistical analysis after outlier inclusion of AISI 4140 (Hm = HRB 99).

Table 8.

Statistical analysis after outlier inclusion of AISI 4140 (Hm = HRB 99).

| Side | Range | Mean | Std. Dev. | Std. Error | t-value | Sig. | 95% Conference interval |

|---|

| Min | Max | Lower | Upper |

|---|

| A | 89 | 110.6 | 100.7 | 6.90 | 0.646 | 155.9 | 0.000 | 99.40 | 101.97 |

| B | 95.3 | 111.3 | 106.3 | 4.07 | 0.381 | 279.0 | 0.000 | 105.50 | 107.01 |

| A+B | 89 | 111.3 | 103.4 | 6.49 | 0.430 | 240.0 | 0.000 | 102.56 | 104.25 |

Figure 5.

Surface map, contour and response surface of both sides.

Figure 5.

Surface map, contour and response surface of both sides.

Figure 6.

Hardness-Diameter-Sector sequence interrelations for side A. (a) Hardness-Diameter-AISI 4140-Side A; (b) Hardness-Sector-AISI 4140-Side A.

Figure 6.

Hardness-Diameter-Sector sequence interrelations for side A. (a) Hardness-Diameter-AISI 4140-Side A; (b) Hardness-Sector-AISI 4140-Side A.

Table 9.

T-test pairs, one-way ANOVA and correlation statistical parameters.

Table 9.

T-test pairs, one-way ANOVA and correlation statistical parameters.

| Layer | Side A | Side B |

|---|

| N | Correlation | Sig. | One-way ANOVA | N | Correlation | Significance | One-way ANOVA |

|---|

| F-ratio | Sig. | F-ratio | Sig. |

|---|

| Pair 1 (Hi & Diameter) | 120 | 0.160 | 0.080 | 0.983 | 0.476 | 120 | 0.141 | 0.125 | 2.497 | 0.004 |

| Pair 2 (Hi & Sector #) | 120 | 0.238 | 0.009 | 4.502 | 0.000 | 120 | −0.025 | 0.789 | 2.359 | 0.028 |

Figure 7.

Hardness-Diameter-Sector sequence interrelations for side B. (a) Hardness-Diameter-AISI 4140-Side B; (b) Hardness-Sector-AISI 4140-Side B.

Figure 7.

Hardness-Diameter-Sector sequence interrelations for side B. (a) Hardness-Diameter-AISI 4140-Side B; (b) Hardness-Sector-AISI 4140-Side B.

3.3. Hardness Variability of AISI 1020 Steel and AA 6082 Aluminum Alloy

To attain more universal conclusions and to verify the aforementioned findings, the same experimental procedures were carried out considering different materials with different hardness levels, chemical composition and mechanical properties, as indicated in

Table 1.

Hardness measured values for AISI 1020 carbon steel are shown in

Figure 8. Data distribution over both sides indicates a stochastic nature with tight confidence interval and mean. For AISI 1020, a similar qualitative trend to that of AISI is observed, where it is shown that hardness tends to have a slight and insignificant increasing trend with each bar diameter; see

Figure 8(a), and sector sequence,

Figure 8(b). However, for AA 6082 aluminum alloy,

Figure 9 data shows a slight negative trend with the bar diameter parameter,

Figure 9(a).

Figure 8.

Hardness variability as affected by bar diameter and sector sequence of AISI 1020. (a) Hardness-Diameter-AISI 1020-Both Sides; (b) Hardness-Sector-AISI 1020-Both Sides.

Figure 8.

Hardness variability as affected by bar diameter and sector sequence of AISI 1020. (a) Hardness-Diameter-AISI 1020-Both Sides; (b) Hardness-Sector-AISI 1020-Both Sides.

Figure 9.

Hardness variability as affected by bar diameter and sector sequence of AA 6082 Aluminum Alloy. (a) Hardness-Diameter-AA 6082-Both Sides. (b) Hardness-Sector-AA 6082-Both Sides.

Figure 9.

Hardness variability as affected by bar diameter and sector sequence of AA 6082 Aluminum Alloy. (a) Hardness-Diameter-AA 6082-Both Sides. (b) Hardness-Sector-AA 6082-Both Sides.