1. Introduction

Multi-component bulk metallic glasses (BMGs) are of particular interest for engineering applications because of their positive combination of remarkable mechanical, physical and chemical properties [

1,

2,

3,

4,

5]. In addition, multi-component BMGs have high thermal stability against crystallization and a wide super cooled liquid region [

1,

2,

3], which helps in the thermoplastic processing of these alloys without crystallization [

6].

The complete characterization of BMGs is a necessary prerequisite for their technological application. Metallic glasses are metastable phases and, when heated to a sufficiently high temperature, they tend to a more stable condition,

i.e., they crystallize [

7,

8]. Therefore, investigations of the thermal stability of BMGs and their structure evolution during heating is of primary importance not only in order to analyze their stability against crystallization but also for controlling their microstructure, and finally for improving their properties [

9]. This is particularly important when partially crystallized materials are considered, where a fundamental parameter that has to be taken into account is the temperature range of stability of the phase formed [

10,

11].

Another important point of interest in the development of BMGs as structural materials is the evaluation of their mechanical behavior. Metallic glasses show large values of yield stress and elastic strain [

1,

2,

3,

5], however, the plastic deformation at room temperature of these materials is generally inhomogeneous and occurs via highly localized shear bands, which finally leads to catastrophic failure with limited microscopic deformability [

12]. Catastrophic shear banding in BMGs can be avoided by the creation of heterogeneous microstructures through compositional design to form BMG-matrix composites [

13,

14] or by the use of the proper mechanical pre-treatments, such as shot peening [

15], cold rolling [

16,

17,

18], channel-die compression [

19] or elastostatic pre-loading [

20]. Besides, for the improvement of the plastic deformability of BMGs, the analysis of the effects of shaping processes, such as rolling or forging, on structure, thermal stability and mechanical properties is of particular interest for the possible implementation of BMGs into a conventional industrial processing line.

In this work, structure and mechanical behavior of the Zr

58.5Ti

8.2Cu

14.2Ni

11.4Al

7.7 bulk metallic glass produced by copper mold casting have been investigated in detail. The Zr

58.5Ti

8.2Cu

14.2Ni

11.4Al

7.7 metallic glass was selected for the present investigation because this glassy material can be produced by different processing routes [

21] and, therefore, it may offer interesting opportunities for a possible commercial application. The thermal stability of the glass was studied by differential scanning calorimetry and the temperature dependence of the structure and the temperature ranges of stability of the different phases formed during heating were investigated by in-situ X-ray diffraction using a high-energy monochromatic synchrotron beam. The mechanical properties of the glass were investigated by room temperature compression tests. Finally, the effectiveness of cold rolling as a mechanical pre-treatment for improving the mechanical behavior and as a suitable shaping process for the present BMG was evaluated.

2. Results and Discussion

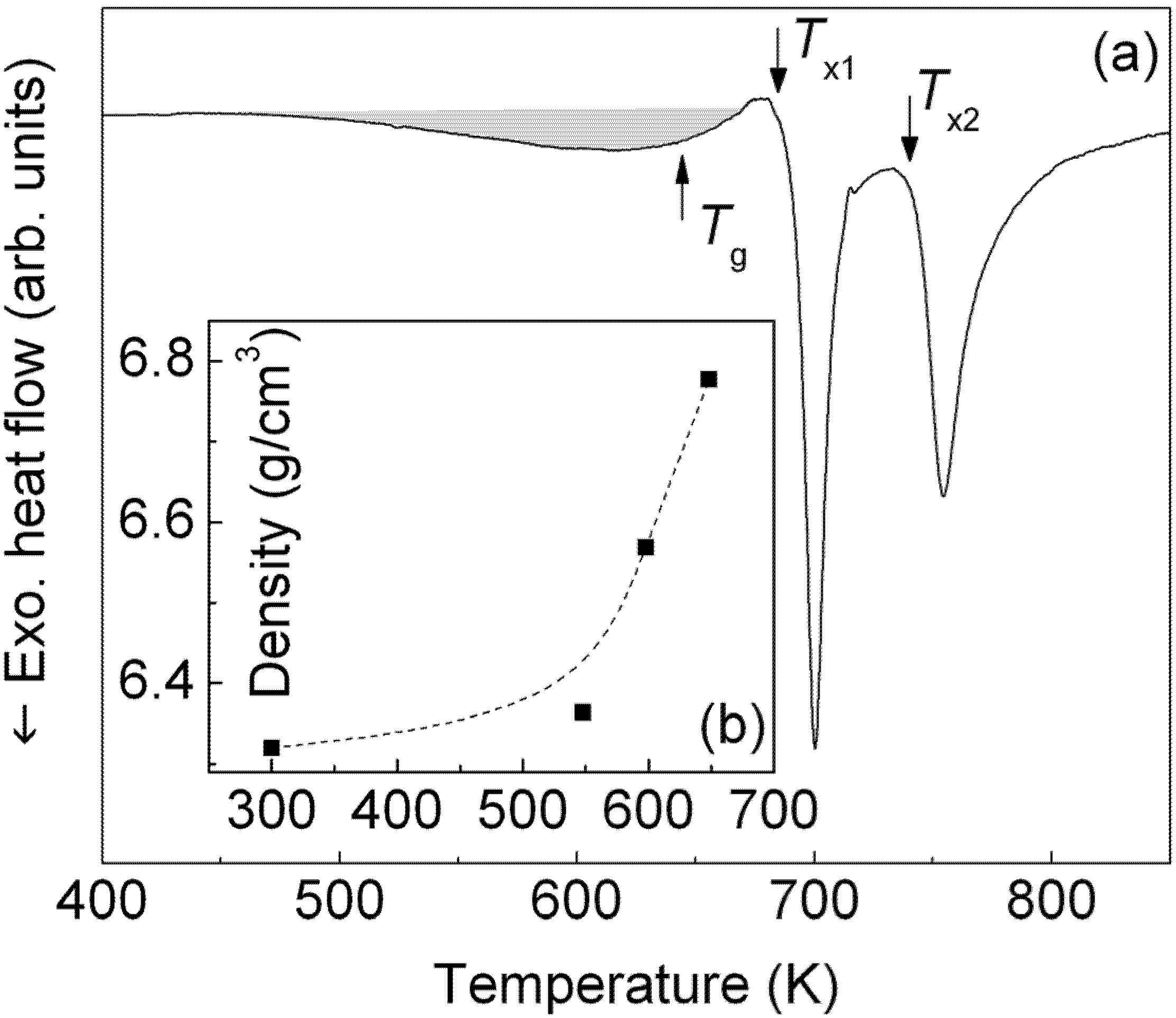

Figure 1a shows the isochronal (40 K/min) DSC scan of the as-cast Zr

58.5Ti

8.2Cu

14.2Ni

11.4Al

7.7 rod. Within the range of temperatures considered in this work, the DSC curve consists of a broad exothermic signal in the range 500–600 K (see shadowed area in

Figure 1a), which can be ascribed to structural relaxation [

22]. The broad exotherm is followed by an endothermic event associated with the glass transition at

Tg = 629 K, which indicates the transformation from the solid-state glass into the supercooled liquid (SCL), before two exothermic heat flow events due to the crystallization of the SCL occur at higher temperatures (

Tx1 = 681 K and

Tx2 = 740 K). The supercooled liquid region,

ΔTx =

Tx1 −

Tg, which reflects the thermal stability against crystallization of the SCL, is 52 K. The thermal stability data are in good agreement with those reported in previous studies for melt-spun ribbons and ball-milled powders with the same composition [

21] (see

Table 1).

Figure 1.

(a) Isochronal (40 K/min) DSC scan of the as-cast rod; and (b) density of the metallic glass as a function of the annealing temperature.

Figure 1.

(a) Isochronal (40 K/min) DSC scan of the as-cast rod; and (b) density of the metallic glass as a function of the annealing temperature.

Table 1.

Temperature of the glass transition (Tg), onset of the first (Tx1) and the second (Tx2) crystallization peak and extension of the supercooled liquid region (ΔTx = Tx1 − Tg) for the Zr58.5Ti8.2Cu14.2Ni11.4Al7.7 cast rod, melt-spun ribbon and ball-milled powder.

Table 1.

Temperature of the glass transition (Tg), onset of the first (Tx1) and the second (Tx2) crystallization peak and extension of the supercooled liquid region (ΔTx = Tx1 − Tg) for the Zr58.5Ti8.2Cu14.2Ni11.4Al7.7 cast rod, melt-spun ribbon and ball-milled powder.

| Tg (K) | Tx1 (K) | Tx2 (K) | Tx (K) | Reference |

|---|

| Cast rod | 629 | 681 | 740 | 52 | This work |

| Melt-spun ribbon | 637 | 688 | 742 | 51 | [21] |

| Ball-milled powder | 636 | 685 | 737 | 49 | [21] |

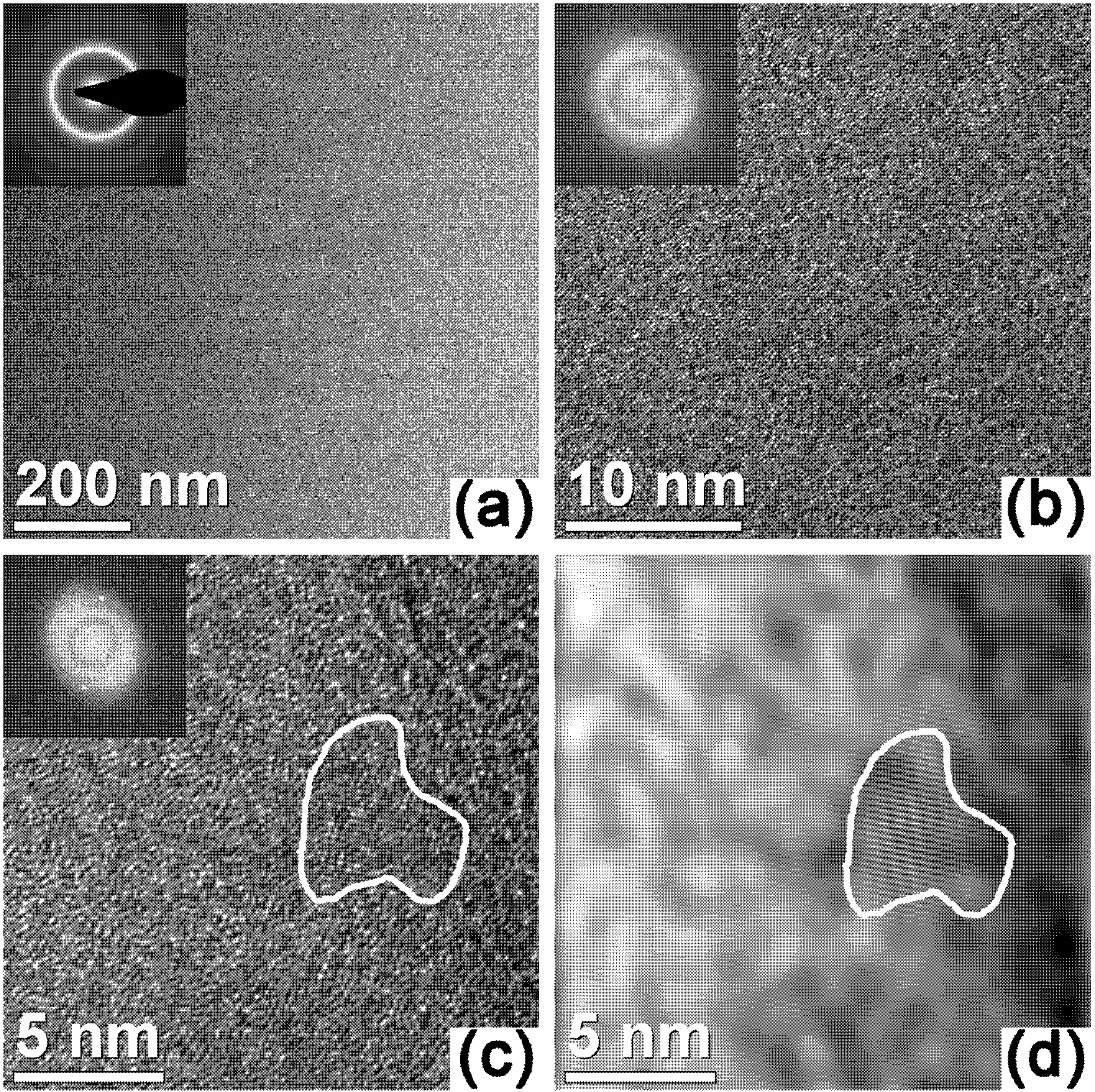

The XRD pattern of the as-cast rod taken at room temperature is shown in

Figure 2 (300 K). The pattern displays only the broad diffuse maxima typical for an amorphous material without additional peaks due to crystalline phases. The amorphous nature of the as-cast material is confirmed by the TEM results in

Figure 3a. The bright-field image is featureless with no traces of diffraction contrast due to second-phase particles. In addition, the corresponding selected area electron diffraction pattern (inset in

Figure 3a) shows the typical diffuse diffraction rings characteristic of amorphous materials. As well, high-resolution TEM (

Figure 3b) shows the characteristic disordered structure of amorphous materials and no bright spots indicative of the presence of crystalline phases can be observed in the fast Fourier transform (FFT) of the image (inset in

Figure 3b). Only few and dispersed ordered regions of about 3–5 nm can be observed at a higher magnification (

Figure 3c). This is particularly clear in

Figure 3d, which shows the inverse FFT of

Figure 3c after the Fourier mask filtering.

The structure evolution of the Zr

58.5Ti

8.2Cu

14.2Ni

11.4Al

7.7 bulk metallic glass during heating is shown in

Figure 2, where the sequence of individual scans collected at different temperatures illustrating diffracted intensity vs. scattering vector (

Q = 4πsinθ/λ) are plotted as a function of temperature. The XRD patterns reveal that, besides the amorphous phase, no additional phases are formed up to 660 K. When the sample is heated to 680 K, corresponding to the onset of the first crystallization DSC peak in

Figure 1a, the pattern displays the presence of additional diffraction contributions at

Q = 25, 26 and 43 nm

−1 that overlap to the main amorphous maxima. The occurrence of these small, broad diffraction peaks indicates the formation of an ordered phase of nanoscale dimensions. The intensity of the small peaks grows with increasing temperature, which permits to unambiguously identify the phase formed at temperatures above 680 K as an icosahedral quasicrystalline (QC) phase. In addition to the diffraction signals of the QC phase, the diffuse diffraction maximum of the glassy phase is visible, indicating the presence of a residual amorphous phase. The QC phase is metastable and transforms to NiZr

2-type phases with cubic (space group

) and tetragonal (space group I4/mcm) crystalline structures at temperatures above 726 K (coinciding with the second crystallization event). A similar structural evolution has been observed for the corresponding alloy with the same composition produced by melt spinning and ball milling [

21].

Figure 2.

XRD patterns (λ = 0.01249 nm) of the as-cast Zr58.5Ti8.2Cu14.2Ni11.4Al7.7 bulk metallic glass as a function of temperature.

Figure 2.

XRD patterns (λ = 0.01249 nm) of the as-cast Zr58.5Ti8.2Cu14.2Ni11.4Al7.7 bulk metallic glass as a function of temperature.

Figure 3.

TEM data for the as-cast Zr

58.5Ti

8.2Cu

14.2Ni

11.4Al

7.7 glassy alloy: (

a) bright-field image of the as-cast material and (

inset) corresponding selected area electron diffraction pattern; (

b,

c) high-resolution TEM micrographs and (

insets) corresponding fast Fourier transforms (FFT); (

d) inverse FFT of

Figure 3(c) after the Fourier mask filtering.

Figure 3.

TEM data for the as-cast Zr

58.5Ti

8.2Cu

14.2Ni

11.4Al

7.7 glassy alloy: (

a) bright-field image of the as-cast material and (

inset) corresponding selected area electron diffraction pattern; (

b,

c) high-resolution TEM micrographs and (

insets) corresponding fast Fourier transforms (FFT); (

d) inverse FFT of

Figure 3(c) after the Fourier mask filtering.

Although no phase changes can be observed in

Figure 2 at temperatures below 680 K, the glassy structure undergoes structural changes in this temperature regime. This behavior can be observed in

Figure 4, which shows the temperature dependence of the position, intensity and width of the main amorphous maximum at about

Q = 26 nm

−1. The position of the amorphous maximum, decreases linearly with increasing temperature up to about 530 K (

Figure 4a) as a result of the thermal expansion, which is linked to the increase of the mean atomic spacing (

i.e., dilatation) [

23]. Above 530 K, at temperatures corresponding to the broad exothermic event in

Figure 1a, the peak position remains almost constant. This behavior can be attributed to the additional effect of free volume annihilation that, by inducing shorter atomic distances and thus densification [

23], counterbalances the effect of thermal expansion. An analogous effect can be observed for the intensity and width of the amorphous maximum (

Figure 4b and c). At temperatures below 530 K, the intensity decreases and the width increases with increasing temperature. This is due to the Debye-Waller effect, which describes the attenuation of the X-ray scattering caused by the thermal agitation [

24]. Above 530 K, this effect is no longer visible due to the additional contribution of the free volume annihilation and to the consequent densification of the material, as demonstrated by the increase of the density of the metallic glass with increasing annealing temperature (

Figure 1b).

Figure 4.

Temperature dependence of the (

a) position; (

b) intensity; and (

c) width of the main amorphous maximum at about

Q = 26 nm

−1 in

Figure 2.

Figure 4.

Temperature dependence of the (

a) position; (

b) intensity; and (

c) width of the main amorphous maximum at about

Q = 26 nm

−1 in

Figure 2.

A typical room temperature stress-strain curve for the as-cast Zr

58.5Ti

8.2Cu

14.2Ni

11.4Al

7.7 BMG under quasistatic compressive loading is shown in

Figure 5. The specimen exhibits an elastic regime of 1.85% before yielding, which occurs at

σy~1,500 MPa. The Young’s modulus, estimated by ultrasonic measurements, is 77 GPa. After yielding the stress increases with increasing strain and the sample shows an apparent work-hardening behavior up to 1,630 MPa and 2.6% strain. With further increase of strain, the stress-strain curve displays a work-softening behavior up to fracture, which occurs at

σf = 1,570 MPa and at

εf = 3.3% strain.

Figure 5.

Room temperature stress-strain curves for the as-cast and cold-rolled Zr58.5Ti8.2Cu14.2Ni11.4Al7.7 BMG under quasistatic compressive loading.

Figure 5.

Room temperature stress-strain curves for the as-cast and cold-rolled Zr58.5Ti8.2Cu14.2Ni11.4Al7.7 BMG under quasistatic compressive loading.

The occurrence of large Poisson’s ratios has been proposed for explaining the enhanced plastic deformability of some BMGs [

25,

26]. For materials with a large Poisson’s ratio, the release of local stress concentrations is more likely to occur via shear deformation rather than through crack nucleation, leading to improved plastic deformation [

5]. More specifically, metallic glasses having values of Poisson’s ratio larger than 0.31–0.32 are tough, while BMGs with smaller values are brittle [

26]. The present Zr

58.5Ti

8.2Cu

14.2Ni

11.4Al

7.7 BMG displays a Poisson’s ratio of 0.377 and, therefore, it falls into the category of the tough BMGs.

The room-temperature plasticity observed in

Figure 5 may also be linked to the presence of the nanocrystals in the as-cast structure (

Figure 3c and d). In certain BMGs derived from shape memory alloys, a deformation-induced precipitation of nanocrystals has been suggested as a process competing with the formation of the shear transformation zones (the fundamental units of plasticity in metallic glasses at low temperatures [

27]), which leads to a small plastic strain even in tension [

28]. This mechanism may be active during deformation of the Zr

58.5Ti

8.2Cu

14.2Ni

11.4Al

7.7 BMG. Although few in number, the nanocrystals may nevertheless interfere with the process of irreversible deformation, effectively limiting shear bands from propagating catastrophically and explaining the observed macroscopic plastic deformation.

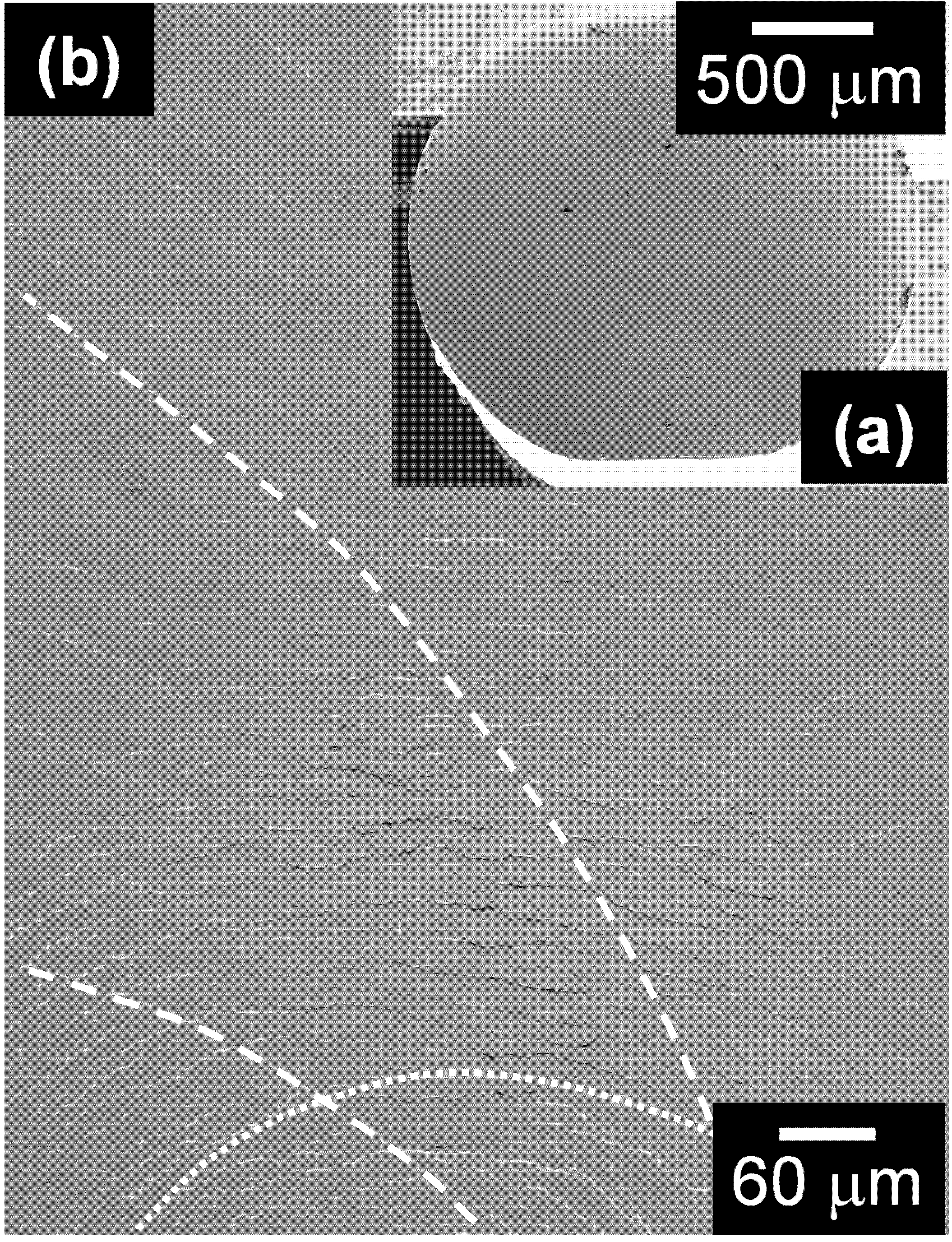

The Zr

58.5Ti

8.2Cu

14.2Ni

11.4Al

7.7 metallic glass not only displays interesting mechanical properties under compressive loading, but it also shows good damage tolerance when subjected to cold rolling. The cylindrical rod can be cold-rolled up to a diameter reduction of 10% without inducing visible cracks and, as a result, the cross-section of the sample is no longer round, as for the as-cast sample, but it displays two flat surfaces of about 600–700 μm (

Figure 6a). Plastic deformation during rolling is accommodated by the formation of two distinct families of shear bands (

Figure 6b): semicircular shear bands originating from the flat surfaces (indicated by dotted lines in

Figure 6b) and curved shear bands, which intersect the semicircular shear bands and extend towards the centre of the sample (dashed lines in

Figure 6b). Such a shear band morphology is in agreement with that observed for other cold-rolled Zr-based cylindrical BMGs [

17,

18] and can be ascribed to the heterogeneous plastic deformation that characterizes rolling of cylindrical specimens.

Besides for cold working and shaping of materials, cold rolling can be used to improve the mechanical behavior of BMGs [

16,

18]. The mechanical properties of the present Zr

58.5Ti

8.2Cu

14.2Ni

11.4Al

7.7 BMG are indeed improved by cold rolling (

Figure 5). The yield strength of the material cold-rolled up to a diameter reduction of 10% is about 1,470 MPa, only slightly reduced with respect to the as cast material (1,500 MPa). On the other hand, the compressive strength rises from 1,630 MPa for the as-cast material to 1,780 MPa for the cold-rolled sample, which gives rise to a clear work-hardening behavior. As well, rolling has a significant effect on the fracture strain, which increases from 3.3% for the as-cast sample to 8.3% for the rolled material. A possible explanation for the improved mechanical behavior is given by the propagation-arrest mechanism of shear bands resulting from the creation of a heterogeneous microstructure consisting of hard and soft regions during rolling [

18]. Most likely, the rolling-induced hard and soft regions necessitate different critical stresses to initiate deformation during the subsequent compressive test. The deformation of the soft regions may be activated at low stress, explaining the slightly lower yield strength of the cold-rolled sample compared to the as-cast material [

12,

18]. On the other hand, the hard regions may hinder or stop the propagation of the shear bands previously formed in the soft areas [

12,

18]. In order to accommodate further strain, new shear bands have to be generated in the hard regions, which require increasingly higher critical stresses for shear band nucleation and propagation [

18], explaining the work-hardening behavior visible in

Figure 5. This propagation-arrest mechanism may assist initiation, branching and arresting of multiple shear bands effectively impeding a single shear band from propagating catastrophically [

17,

18] and resulting in the improved plastic deformation characterizing the cold-rolled material with respect to the as-cast samples.

Figure 6.

Cross-section of the metallic glass cold-rolled to a diameter reduction of 10%, revealing the formation of different types of shear bands.

Figure 6.

Cross-section of the metallic glass cold-rolled to a diameter reduction of 10%, revealing the formation of different types of shear bands.