Phase Stability and Elasticity of TiAlN

Abstract

:1. Introduction

2. Properties of Ti1−xAlxN Alloys from ab Initio Simulations

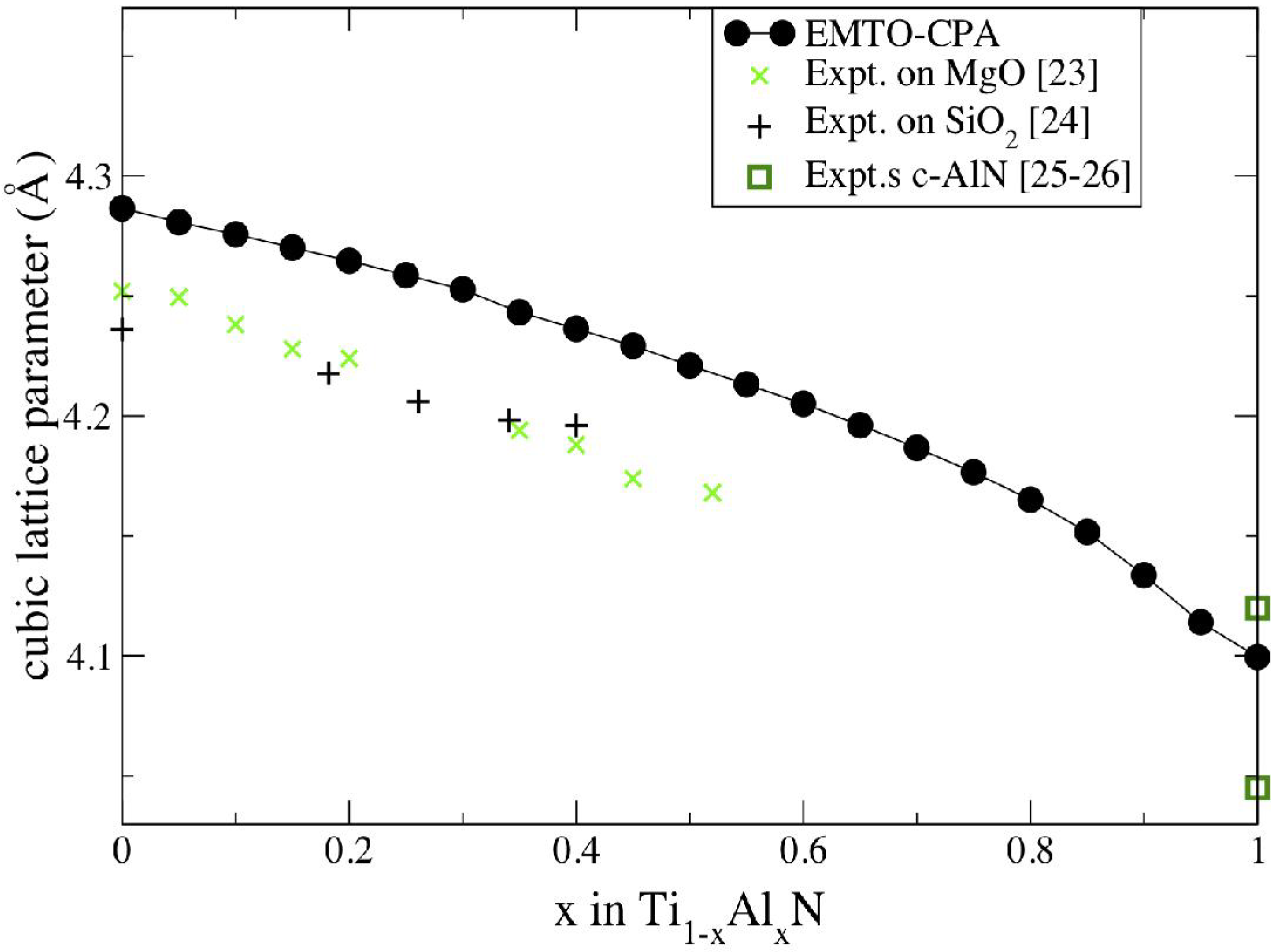

2.1. Basic Thermodynamic Properties of Ti1−xAlxN: Lattice Parameters and Mixing Enthalpies

2.2. Decomposition Thermodynamics of Ti1−xAlxN at Ambient and Elevated Pressure

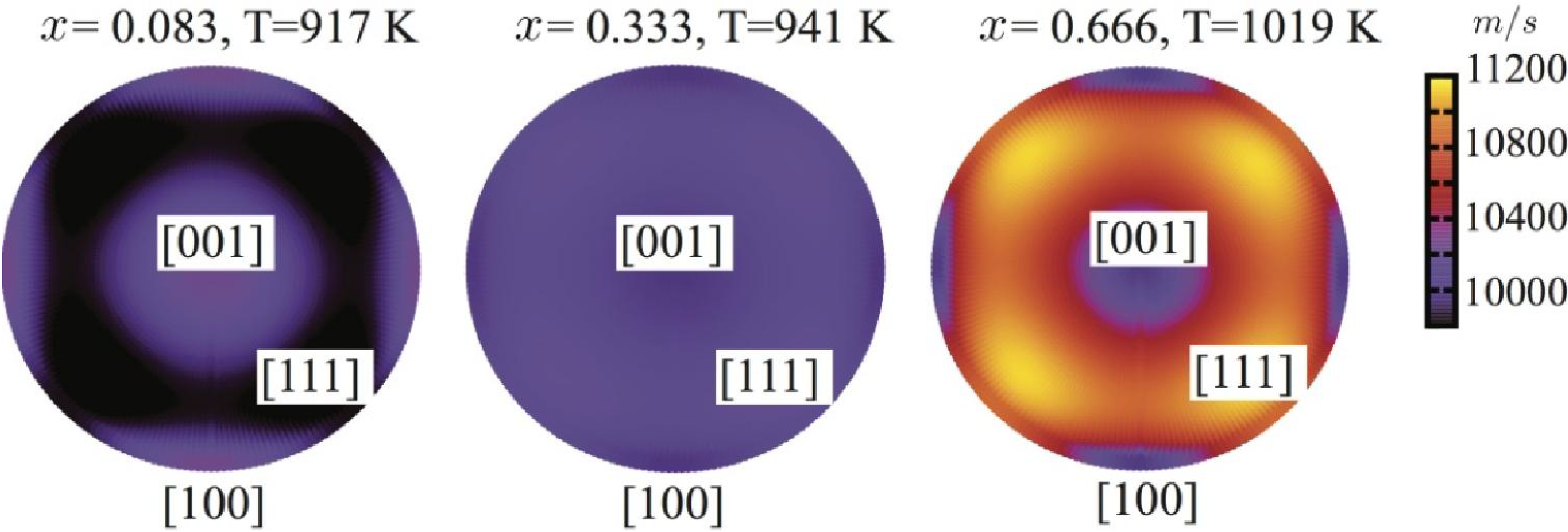

2.3. Elastic Properties of Ti1−xAlxN Solid Solutions

3. Improved Thermal Stability from Multilayered Architecturing of Ti1−xAlxN Alloys

3.1. Thermal Stability of Monolithic Ti0.34Al0.66N

3.2. The Multilayer Structure Influence on the Thermal Stability of Ti0.34Al0.66N

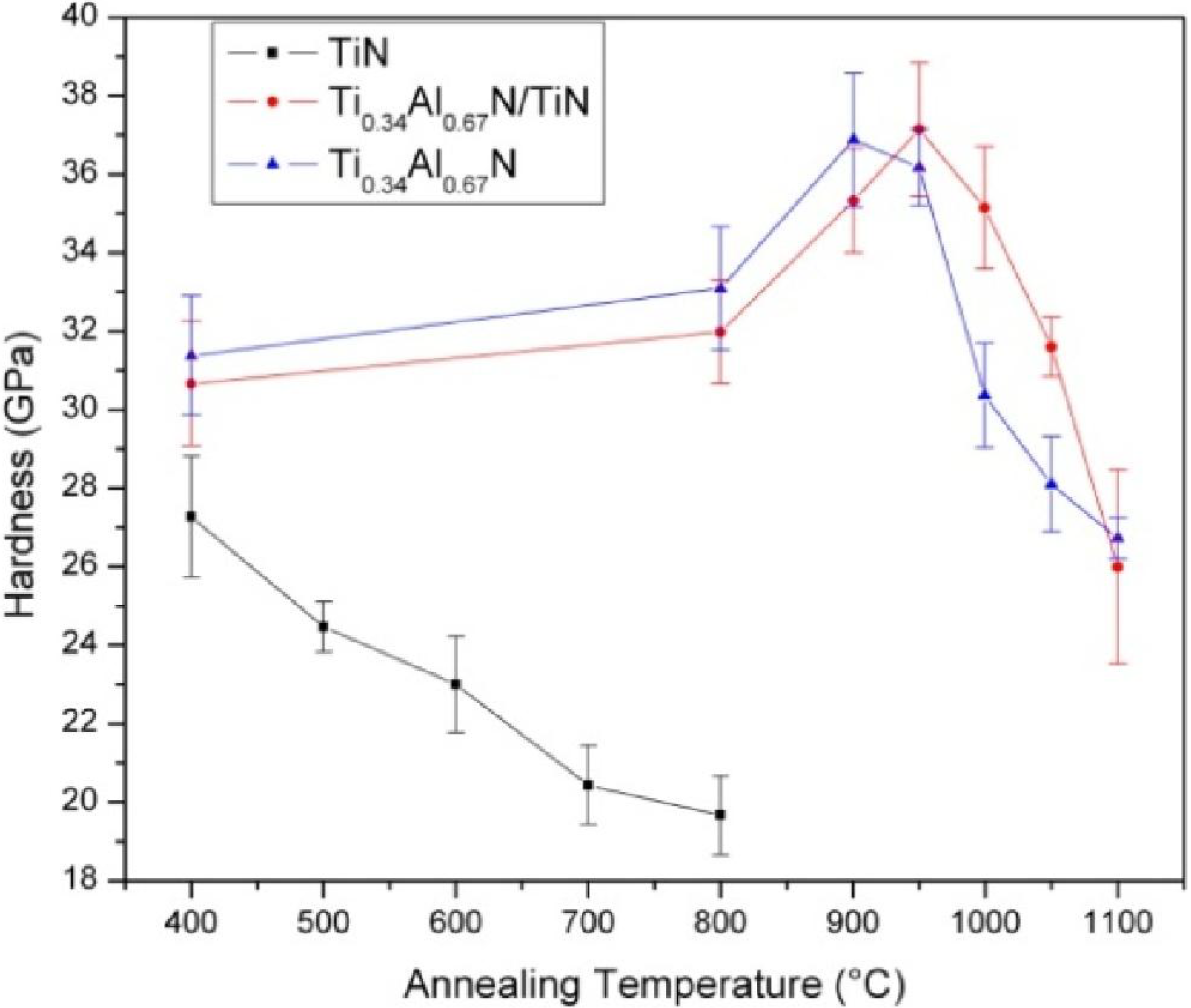

3.3. Mechanical Stability of TiAlN

3.4. Multilayer Structure Influence on Mechanical Stability of Ti0.34Al0.66N

3.5. Effects on Alloying Elements and Nitrogen Vacancies on the Phase Stability of TiAlN

4. Conclusions

Acknowledgements

References

- Mayrhofer, P.H.; Mitterer, C.; Hultman, L.; Clemens, H. Microstructural design of hard coatings. Prog. Mater. Sci. 2006, 51, 1032–1114. [Google Scholar] [CrossRef]

- Alling, B.; Karimi, A.; Abrikosov, I.A. Electronic origin of the isostructural decomposition in cubic M1−xAlxN (M = Ti, Cr, Sc, Hf): A first-principles study. Surf. Coat. Technol. 2008, 203, 883–886. [Google Scholar] [CrossRef]

- Beenoh-Marchwicka, G.; Kröl-Stepniewska, L.; Posadowski, P. Structure of thin-films prepared by the cosputtering of titanium and aluminum or titanium and silicon. Thin Solid Films 1981, 82, 313–320. [Google Scholar] [CrossRef]

- Knotek, O.; Bosch, W.; Leyendecker, T. Reactive sputtering of wear resistant CrN and TiAlN coatings at high deposition rates. In Proceedings of 7th International Conference Vacuum Metallurgy, Linz, Austria, 1985.

- Knotek, O.; Münz, W.D.; Leyendecker, T. Industrial deposition of binary, ternary, and quartenary nitrides of titanium, zirconium, and aluminium. J. Vac. Sci. Technol. A 1987, 5, 2173–2179. [Google Scholar] [CrossRef]

- Jehn, H.; Hoffmann, S.; Rückborn, V.E.; Münz, W.D. Morphology and properties of sputtered (Ti;Al)N layers on high speed steel substrates as a function of deposition temperature and sputtering atmosphere. J. Vac. Sci. Technol. A 1986, 4, 2701–2705. [Google Scholar] [CrossRef]

- Münz, W.D. Titanium aluminum nitride films: A new alternative to TiN coatings. J. Vac. Sci. Technol. A 1986, 4, 2717–2725. [Google Scholar] [CrossRef]

- McIntyre, D.; Greene, J.E.; Håkansson, G.; Sundgren, J.E.; Münz, W.D. Oxidation of metastable single-phase polycrystalline Ti0.5Al0.5N films––Kinetics and mechanisms. J. Appl. Phys. 1990, 67, 1542–1553. [Google Scholar]

- Jehn, H.; Hoffman, S.; Münz, W.D. (Ti;Al)N coatings—An example of ternary nitride hard coatings. Metal 1988, 42, 658–669. [Google Scholar]

- Knutsson, A.; Johansson, M.P.; Karlsson, L.; Odén, M. Thermally enhanced mechanical properties of arc evaporated Ti0.34Al0.66N/TiN multilayer coatings. J. Appl. Phys. 2010, 108, 044312:1–044312:7. [Google Scholar]

- Hörling, A.; Hultman, L.; Odén, M.; Sjölén, J.; Karlsson, L. Thermal stability of arc evaporated high aluminum-content Ti1−xAlxN thin films. J. Vac. Sci. Technol. A 2002, 20, 1815–1823. [Google Scholar]

- Hörling, A.; Hultman, L.; Odén, M.; Sjölén, J.; Karlsson, L. Mechanical properties and machining performance of Ti1−xAlxN-coated cutting tools. Surf. Coat. Technol. 2005, 191, 384–392. [Google Scholar] [CrossRef]

- Rachbauer, R.; Massl, S.; Stergar, E.; Holec, D.; Kiener, D.; Keckes, J.; Patscheider, J.; Stiefel, M.; Leitner, H.; Mayrhofer, P.H. Decomposition pathways in age hardening of Ti-Al-N films. J. Appl. Phys. 2011, 110, 023515:1–023515:10. [Google Scholar] [CrossRef]

- Martin, R.M. Electronic Structure: Basic Theory and Practical Methods; Cambridge University Press: Cambridge, UK, 2004. [Google Scholar]

- Alling, B.; Ruban, A.V.; Karimi, A.; Peil, O.E.; Simak, S.I.; Hultman, L.; Abrikosov, I.A. Mixing and decomposition thermodynamics of c-Ti1−xAlxN from first-principles calculations. Phys. Rev. B 2007, 75, 045123:1–045123:13. [Google Scholar] [CrossRef]

- Vitos, L.; Abrikosov, I.A.; Johansson, B. Anisotropic lattice distortions in random alloys from first-principles theory. Phys. Rev. Lett. 2001, 87, 156401:1–156401:4. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Music, D.; Schneider, J.M. Ab initio calculated binodal and spinodal of cubic Ti1−xAlxN. Appl. Phys. Lett. 2006, 88, 071922:1–071922:3. [Google Scholar] [CrossRef]

- Zunger, A.; Wei, S.H.; Ferreira, L.G.; Bernard, J.E. Special quasirandom structures. Phys. Rev. Lett. 1990, 65, 353–356. [Google Scholar] [CrossRef] [PubMed]

- Ruban, A.V.; Abrikosov, I.A. Configurational thermodynamics of alloys from first principles: Effective clustering interactions. Rep. Prog. Phys. 2008, 71, 046501:1–046501:4. [Google Scholar] [CrossRef]

- Kresse, G.; Hafner, J. Ab-initio molecular-dynamics for liquid metals. Phys. Rev. B 1993, 47, 558–561. [Google Scholar] [CrossRef]

- Kresse, G.; Furthmüller, J. Efficiency of ab-inition total energy calculations form metals and semiconductors using a plane-wave basis set. Comp. Mater. Sci. 1996, 6, 15–50. [Google Scholar] [CrossRef]

- Kresse, G.; Furthmüller, J. Efficient iterative schemes for ab initio-energy calculations using a plane-wave basis set. Phys. Rev. B 1996, 54, 11169–11186. [Google Scholar] [CrossRef]

- Adibi, F.; Petrov, I.; Greene, J.E.; Wahlström, U.; Sundgren, J.E. Design and characterization of a compact 2-target ultrahigh-vacuum magnetron sputter deposition system––Application to the growth of epitaxial Ti1−xAlxN and TiN/ Ti1−xAlxN superlattices. J. Vac. Sci. Technol. A 1993, 11, 136–142. [Google Scholar] [CrossRef]

- Wahlström, U.; Hultman, L.; Sundgren, J.E.; Adibi, F.; Petrov, I.; Greene, J.E. Crystal-growth and microstructure of polycrystalline Ti1-xAlxN alloy-films deposited by ultra-high vacuum dual target magnetron sputtering”. Thin Solid Films 1993, 235, 62–70. [Google Scholar]

- Powder Diffraction File c-AlN: [25-1495] TiN: [6-642]; JCPDS International Center for Powder Diffraction Data: Swarthmore, PA, USA, 1994.

- Vollstädt, H.; Ito, E.; Akaishi, M.; Akimoto, S.; Fukunaga, O. High-pressure synthesis of rock-salt type of AlN. Proc. Jpn. Acad. Ser. B Phys. Biol. Sci. 1990, 66, 7–9. [Google Scholar] [CrossRef]

- Alling, B.; Odén, M.; Hultman, L.; Abrikosov, I.A. Pressure enhancement of the isostructural cubic decomposition in Ti1−xAlxN. Appl. Phys. Lett. 2009, 95, 181906:1–181906:3. [Google Scholar] [CrossRef]

- Alling, B.; Ruban, A.V.; Karimi, A.; Hultman, L.; Abrikosov, I.A. Unified cluster expansion method applied to the configurational thermodynamics of cubic Ti1−xAlxN. Phys. Rev. B 2011, 83, 104203:1–104203:8. [Google Scholar] [CrossRef]

- Holec, D.; Rovere, F.; Mayrhofer, P.H.; Barna, P.B. Pressure-dependent stability of cubic and wurtzite phases within the TiN-AlN and CrN-AlN systems. Scripta Mater. 2010, 62, 349–352. [Google Scholar] [CrossRef]

- Xia, Q.; Xia, H.; Ruoff, A.L. Pressure-induced rocksalt phase of aluminum nitride: A metastable structure at ambient conditions. J. Appl. Phys. 1995, 73, 8198–8200. [Google Scholar] [CrossRef]

- Zen, E. Validity of “Vegard’s Law”. Am. Mineral. 1956, 41, 523–524. [Google Scholar]

- M’Saoubi, R.; Ruppi, S. Wear and thermal behavior of CVD alpha-Al203 and MTCVD Ti(C,N) coatings during machining. CIRP Ann. 2009, 58, 57–60. [Google Scholar] [CrossRef]

- Seol, D.J.; Hu, S.J.; Li, Y.I.; Shen, J.; Oh, K.H.; Chen, L.Q. Computer simulation of spinodal decomposition in constrained films. Acta Mater. 2003, 51, 5173–5185. [Google Scholar] [CrossRef]

- Koeheler, J.S. Attempt to design a strong solid. Phys. Rev. B 1970, 2, 547–551. [Google Scholar] [CrossRef]

- Tasnadi, F.; Abrikosov, I.A.; Rogström, L.; Almer, J.; Johansson, M.P.; Odén, M. Significant elastic anisotropy in Ti1−xAlxN alloys. Appl. Phys. Lett. 2010, 97, 231902:1–231902:3. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Music, D.; Schneider, J.M. Influence of the Al distribution on the structure; elastic properties; and phase stability of supersaturated Ti1−xAlxN. J. Appl. Phys. 2006, 100, 094906:1–094906:5. [Google Scholar]

- Cowley, J.M. An approximative theory of order in alloys. Phys. Rev. 1950, 77, 669–675. [Google Scholar] [CrossRef]

- Newnham, R.E. Properties of Materials: Anisotropy, Symmetry, Structure; Oxford University Press: Oxford, UK, 2005; pp. 249–252. [Google Scholar]

- Mayrhofer, P.H.; Hörling, A.; Karlsson, L.; Sjölén, J.; Mitterer, C.; Hultman, L. Self-organized nanostructures in the Ti-Al-N system. Appl. Phys. Lett. 2003, 83, 2049–2051. [Google Scholar] [CrossRef]

- Hultman, L.; Engström, C.; Odén, M. Mechanical and thermal stability of TiN/NbN superlattice thin films. Surf. Coat. Technol. 2000, 133-134, 227–233. [Google Scholar]

- Jankowski, A.F.; Tsakalakos, T. The effect of strain on the elastic constants of noble metals. J. Appl. F Met. Phys. 1985, 15, 1279–1292. [Google Scholar] [CrossRef]

- Almer, J.; Odén, M.; Håkansson, G. Microstructure, stress and mechanical properties of arc-evaporated Cr-C-N coatings. Thin Solid Films 2001, 385, 190–197. [Google Scholar] [CrossRef]

- Knutsson, A.; Johansson, M.P.; Persson, P.O.A.; Hultman, L.; Odén, M. Thermal decomposition products in arc evaporated TiAlN/TiN multilayers. Appl. Phys. Lett. 2008, 93, 143110:1–143110:3. [Google Scholar] [CrossRef]

- Odén, M.; Rogström, L.; Knutsson, A.; Terner, M.R.; Hedström, P.; Almer, J.; Ilavsky, J. In situ small-angle X-ray scattering study of nanostructure evolution during decomposition of arc evaporated TiAlN coatings. Appl. Phys. Lett. 2009, 94, 053114:1–053114:3. [Google Scholar] [CrossRef]

- Rachbauer, R.; Stergar, E.; Massl, S.; Mosera, M.; Mayrhofer, P.H. Three-dimensional atom probe investigations of Ti-Al-N thin films. Scripta Mater. 2009, 61, 725–728. [Google Scholar] [CrossRef]

- Christensen, N.E.; Gorczyca, I. Calculated structural phase transitions of aluminum nitride under pressure. Phys. Rev. B 1993, 47, 4307–4314. [Google Scholar] [CrossRef]

- Ueno, M.; Onodera, A.; Shimomura, O.; Takemura, K. X-ray observation of the structural phase transition of aluminum nitride under high pressure. Phys. Rev. B 1992, 45, 10123–10126. [Google Scholar] [CrossRef]

- Ljungcrantz, H.; Odén, M.; Hultman, L.; Greene, J.E.; Sundgren, J.E. Nanoindentation studies of single-crystal (001)-, (011)-, and (111)-oriented TiN layers on MgO. J. Appl. Phys. 1996, 80, 6725–6733. [Google Scholar] [CrossRef]

- Odén, M.; Ljungcrantz, H.; Hultman, L. Characterization of the induced plastic zone in a single crystal TiN(001) Film by nanoindentation and transmission electron microscopy. J. Mater. Res. 1997, 12, 2134–2142. [Google Scholar] [CrossRef]

- Odén, M.; Almer, J.; Håkansson, G. The effects of bias voltage and annealing on the microstructure and residual stress of arc-evaporated Cr-N coatings. Surf. Coat. Technol. 1999, 120-121, 272–276. [Google Scholar]

- Chu, X.; Barnett, S.A. Model of superlattice yield stress and hardness enhancements. J. Appl. Phys. 1995, 77, 4403–4411. [Google Scholar] [CrossRef]

- Shinn, M.; Hultman, L.; Barnett, S.A. Growth, structure, and microhardness of epitaxial TiN/NbN superlattices. J. Mater. Res. 1992, 7, 901–911. [Google Scholar] [CrossRef]

- Embury, J.D.; Hirth, J.P. On dislocation storage and the mechanical response of fine scale microstructures. Acta Metal. 1994, 42, 2051–2056. [Google Scholar] [CrossRef]

- Misra, A.; Verdier, M.; Lu, Y.C.; Kung, H.; Mitchell, T.E.; Nastasi, M.A.; Embury, J.D. Structure and mechanical properties of Cu-X (X = Nb, Cr, Ni) nanolayered composites. Scripta Mater. 1998, 39, 555–560. [Google Scholar] [CrossRef]

- Lu, Y.C.; Kung, H.; Griffin, A.J.; Nastasi, M.A.; Mitchell, T.E. Observations of dislocations in cu/nb nanolayer composites after deformation. J. Mater. Res. 1997, 12, 1939–1941. [Google Scholar] [CrossRef]

- Alling, B.; Karimi, A.; Hultman, L.; Abrikosov, I.A. First-principles study of the effect of nitrogen vacancies on the decomposition pattern in cubic Ti1−xAlxN1−y. Appl. Phys. Lett. 2008, 92, 071903:1–071903:3. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Rachbauer, R.; Holec, D. Influence of Nb on the phase stability of TiAlN. Scripta Mater. 2010, 63, 807–810. [Google Scholar] [CrossRef]

- Rachbauer, R.; Holec, D.; Mayrhofer, P.H. Phase stability and decomposition products of TiAlTaN thin films. Appl. Phys. Lett. 2010, 97, 151901:1–151901:3. [Google Scholar] [CrossRef]

- Chen, L.; Holec, D.; Du, Y.; Mayrhofer, P.H. Influence of Zr on structure, mechanical and thermal properties of Ti-Al-N. Thin Solid Films 2011, 519, 5503–5510. [Google Scholar] [CrossRef] [PubMed]

- Reeswinkel, T.; Sangiovanni, D.G.; Chirita, V.; Hultman, L.; Schneider, J.M. Structure and mechanical properties of TiAlN-WNx thin films. Surf. Coat. Technol. 2011, 205, 4821–4827. [Google Scholar] [CrossRef]

- Lind, H.; Forsén, R.; Alling, B.; Ghafoor, N.; Tasnadi, F.; Johansson, M.P.; Abrikosov, I.A.; Odén, M. Improving thermal stability of hard coating films via a concept of multicomponent alloying. Appl. Phys. Lett. 2011, 99, 091903:1–091903:3. [Google Scholar] [CrossRef]

© 2011 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Abrikosov, I.A.; Knutsson, A.; Alling, B.; Tasnádi, F.; Lind, H.; Hultman, L.; Odén, M. Phase Stability and Elasticity of TiAlN. Materials 2011, 4, 1599-1618. https://doi.org/10.3390/ma4091599

Abrikosov IA, Knutsson A, Alling B, Tasnádi F, Lind H, Hultman L, Odén M. Phase Stability and Elasticity of TiAlN. Materials. 2011; 4(9):1599-1618. https://doi.org/10.3390/ma4091599

Chicago/Turabian StyleAbrikosov, Igor A., Axel Knutsson, Björn Alling, Ferenc Tasnádi, Hans Lind, Lars Hultman, and Magnus Odén. 2011. "Phase Stability and Elasticity of TiAlN" Materials 4, no. 9: 1599-1618. https://doi.org/10.3390/ma4091599