Materials for Powder-Based AC-Electroluminescence

Abstract

:1. Introduction

- Smaller phosphor particles for better printability, thinner stacks and smaller driving voltages

- Fully transparent systems

- Higher luminous output and total efficiency

- New transparent electrodes in order to save or replace expensive indium tin oxide (ITO)

- Less degradation, higher durability, introduction of new encapsulation approaches or humidity barriers and getters

- New phosphors for more colourful systems

- More simple (single-layer) structures, also high-temperature resistant

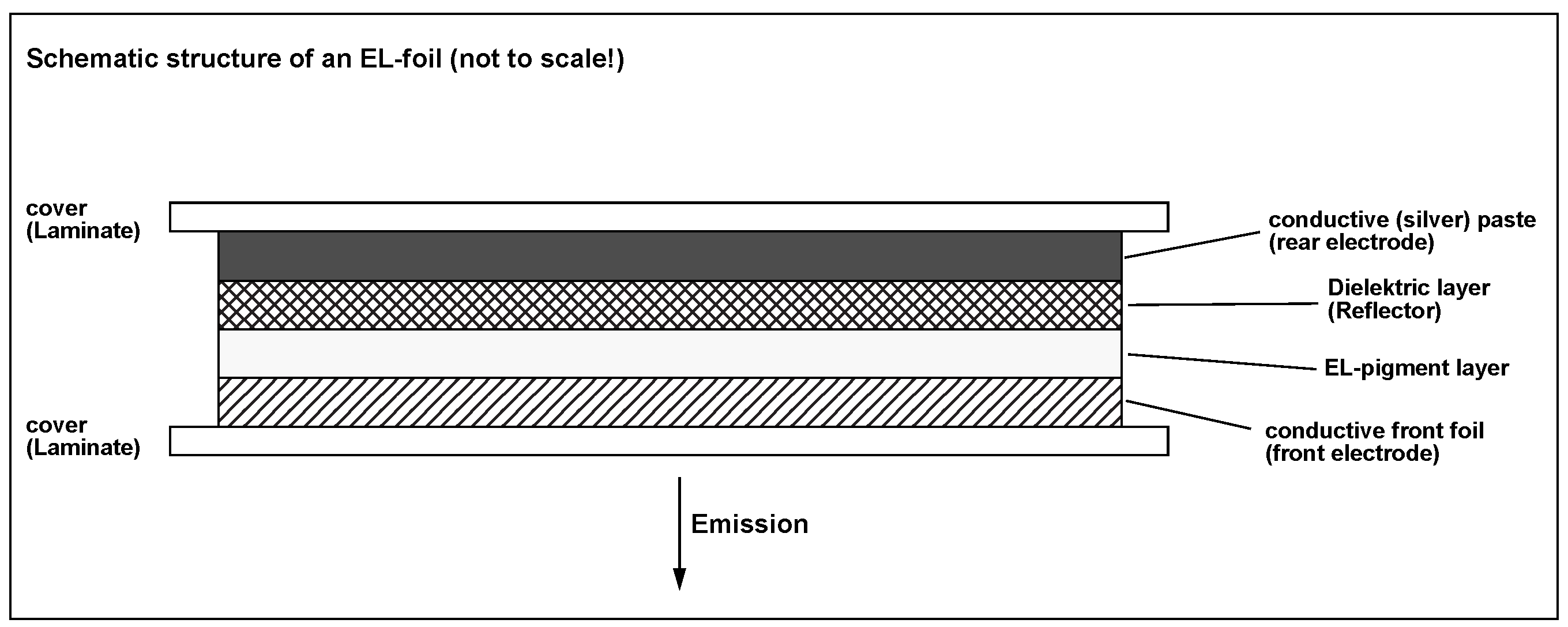

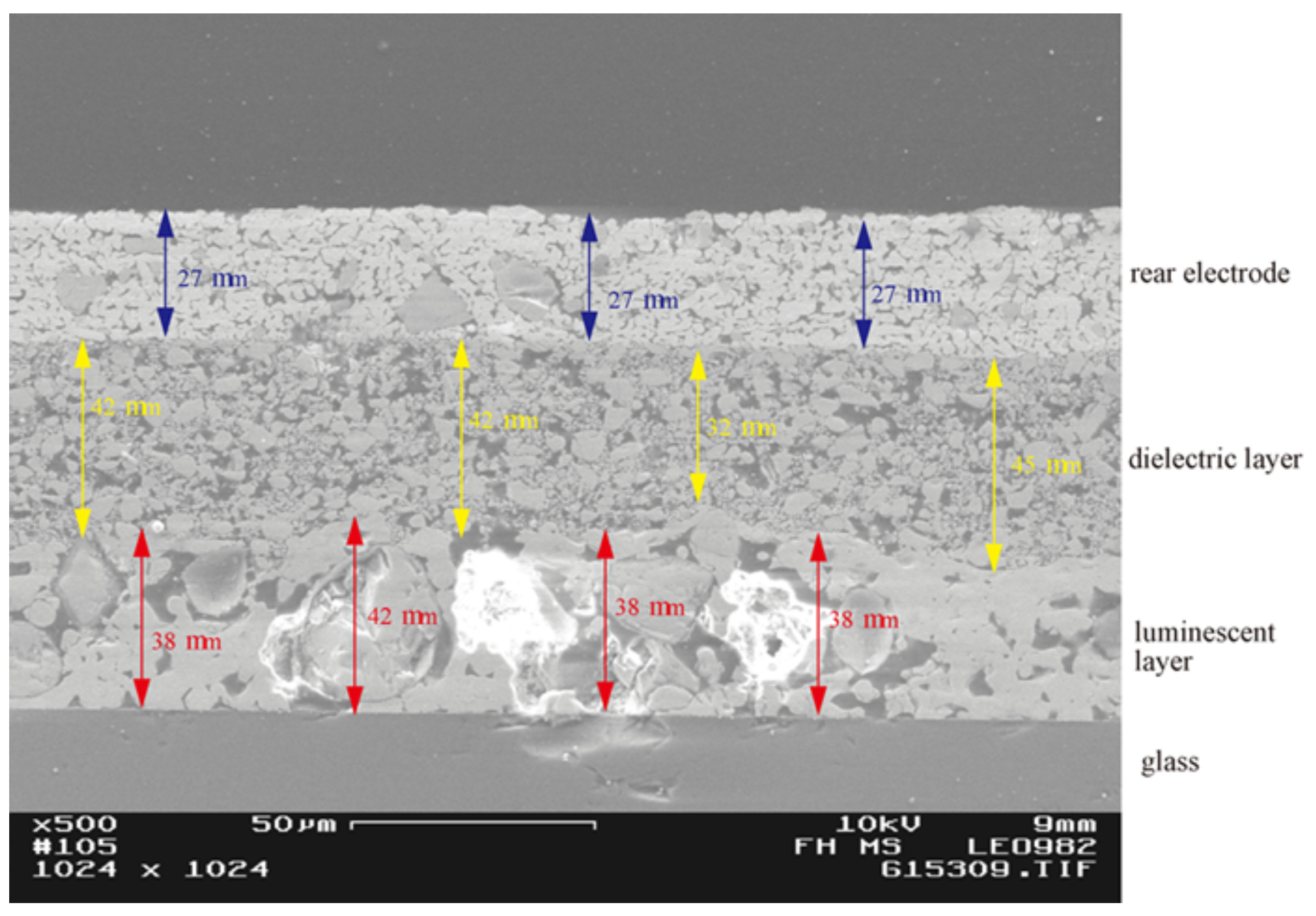

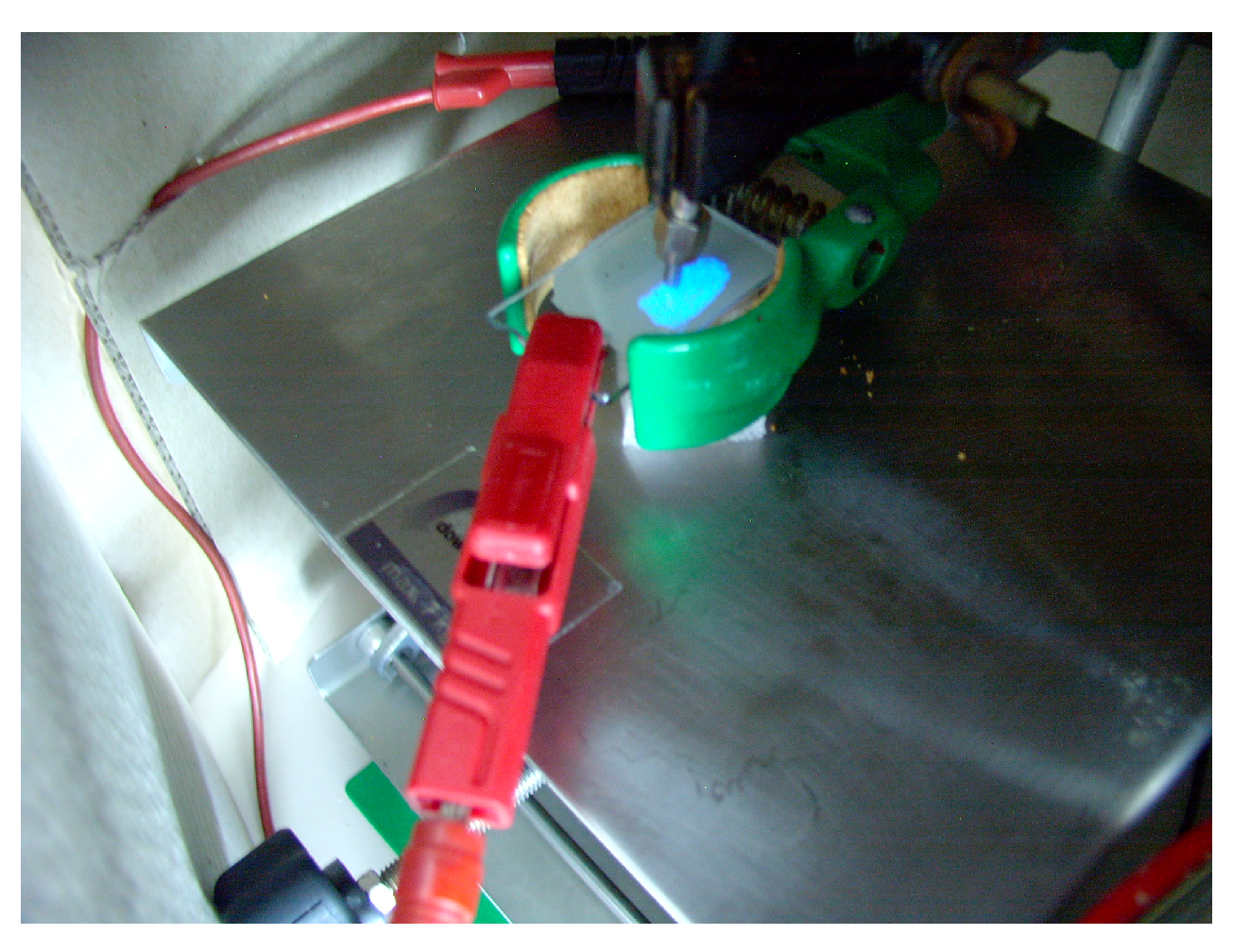

2. Structure of AC-EL Foil Lamps

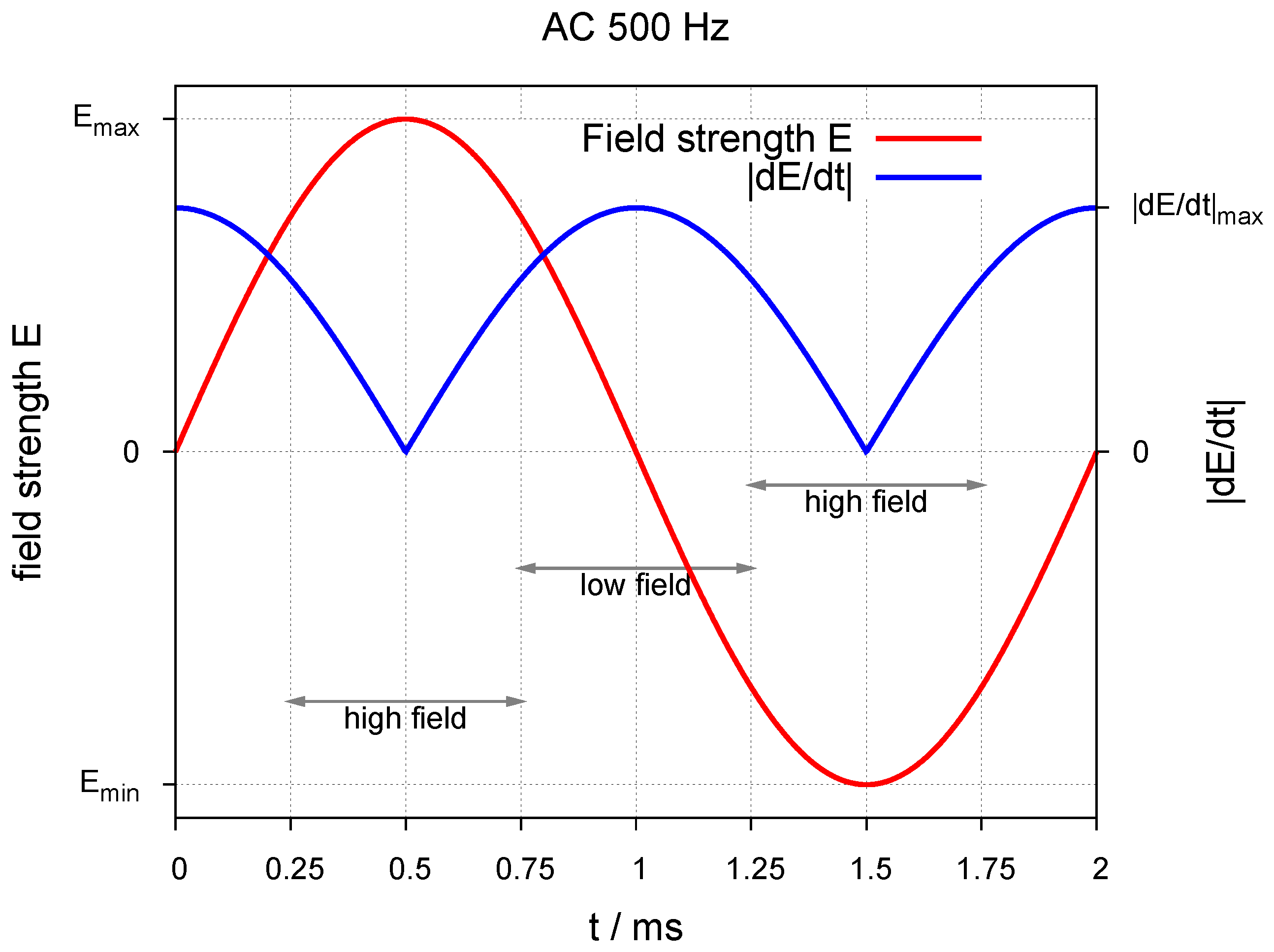

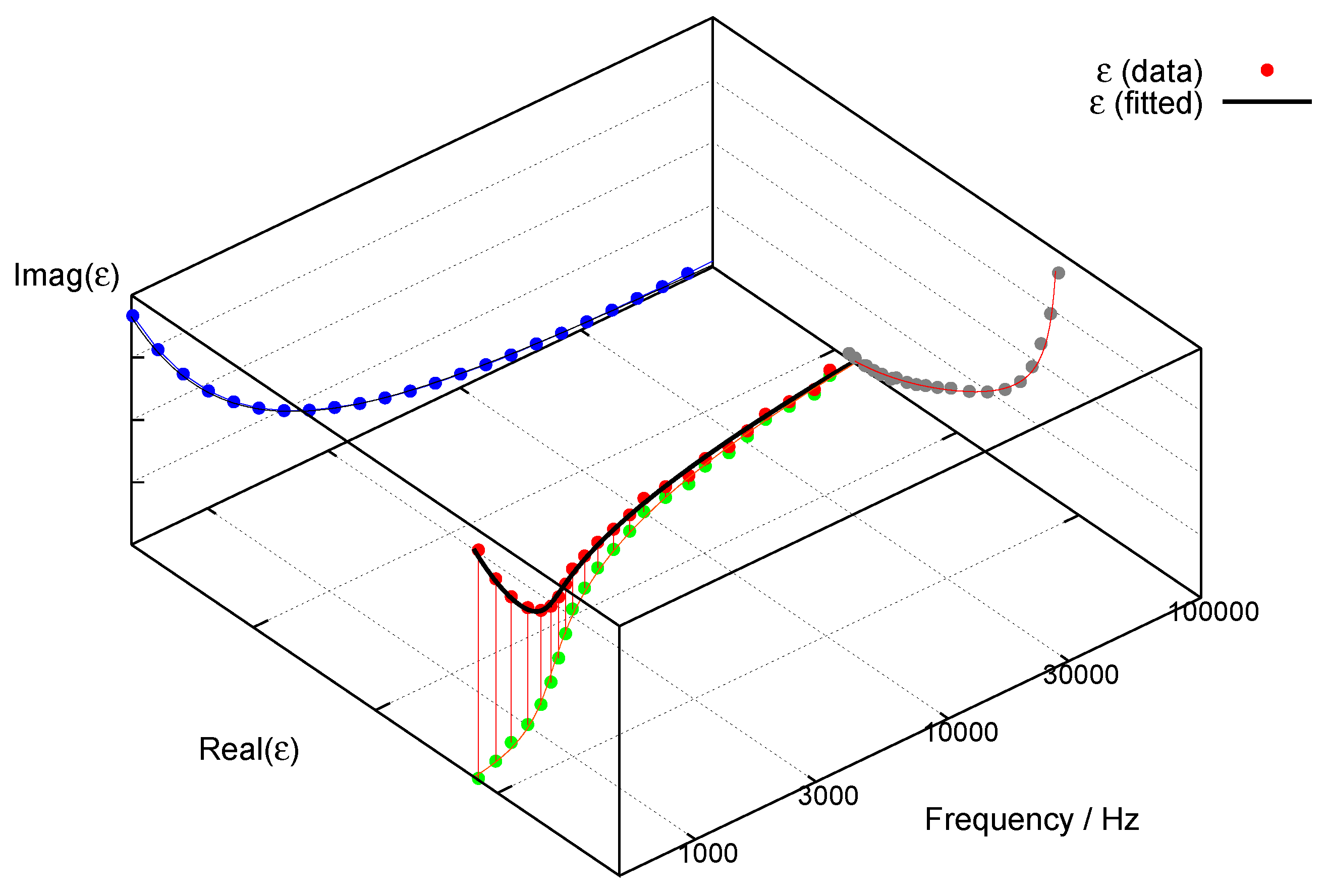

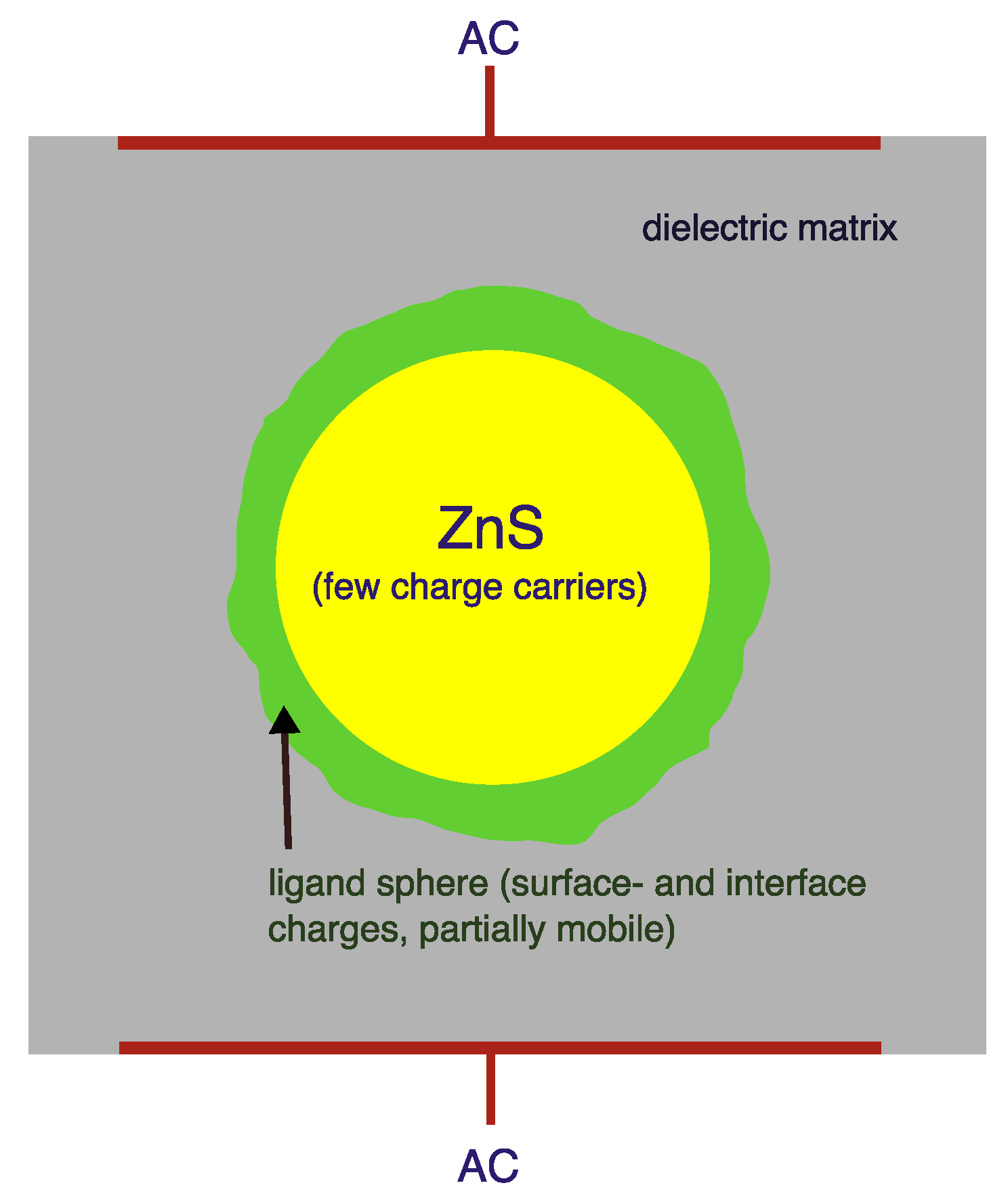

3. Physical Background

4. Materials for AC-Electroluminescence

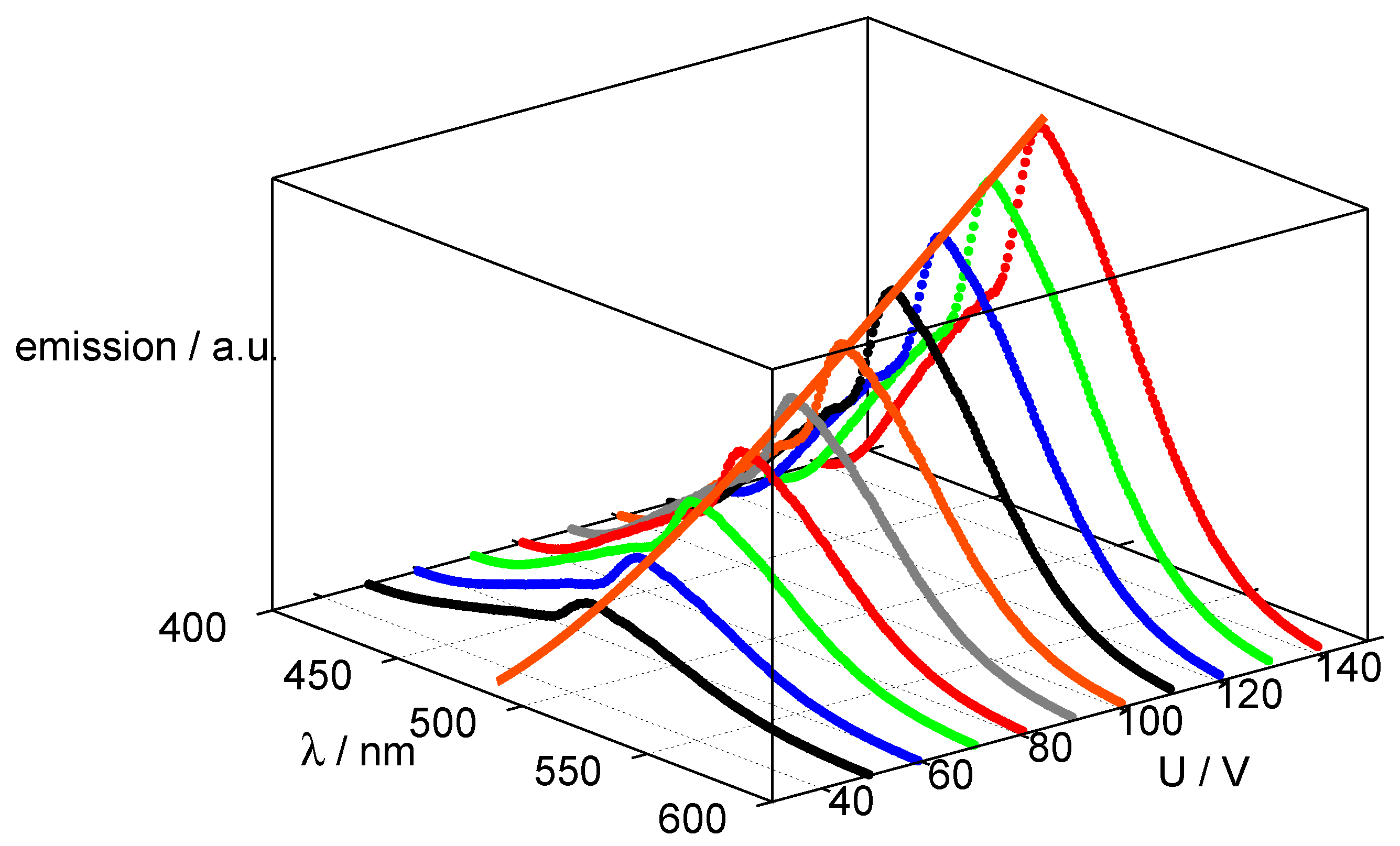

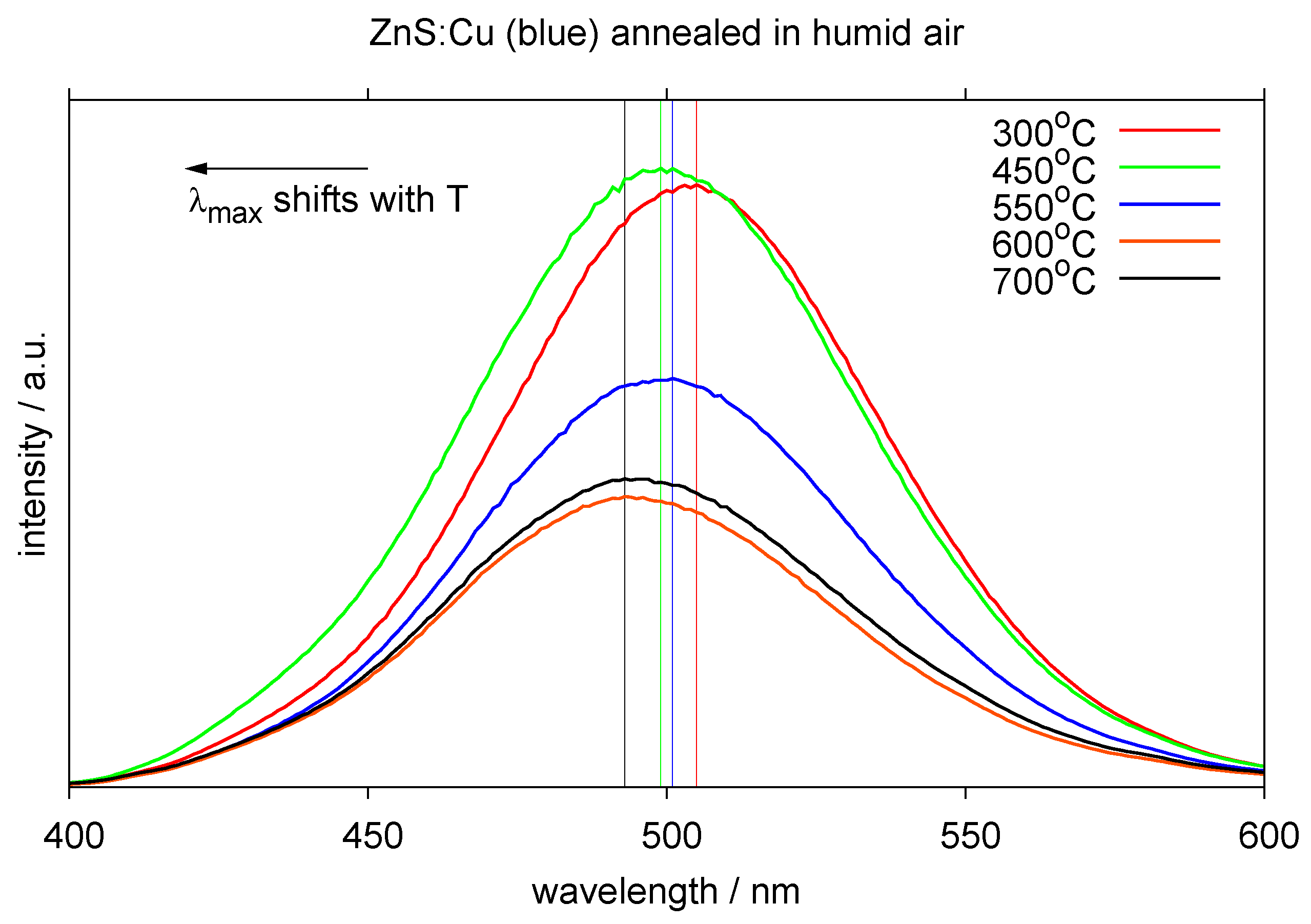

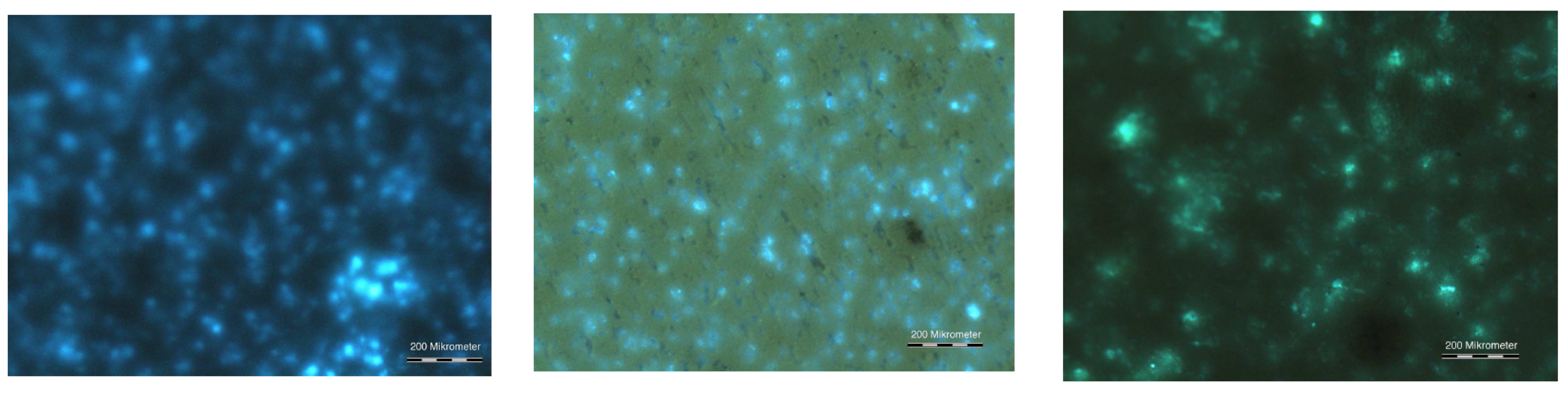

4.1. Phosphors

ZnS

CaS and SrS

Coatings

4.2. Dielectrics

BaTiO3

Single layer solutions

4.3. Electrodes

5. Conclusions

Acknowledgements

References

- Destriau, G. AC electroluminescence in ZnS. J. Chim. Phys. 1936, 33, 587. [Google Scholar]

- Howard, B.T.; Ivey, H.F.; Lehmann, W. Voltage dependence of electroluminescent brightness. Phys. Rev. 1954, 96, 799–800. [Google Scholar] [CrossRef]

- Lehmann, W. Frequency dependence of electroluminescent brightness of impurity-quenched phosphors. Phys. Rev. 1956, 101, 489–490. [Google Scholar] [CrossRef]

- Piper, W.W.; Williams, F.E. Theory of electroluminecence. Phys. Rev. 1955, 98, 1809–1813. [Google Scholar] [CrossRef]

- Kitai, A. Solid State Luminescence; Chapman & Hall: London, UK, 1993. [Google Scholar]

- Vecht, A. Developments in electroluminescent panels. J. Cryst. Growth 1982, 59, 81–97. [Google Scholar] [CrossRef]

- Grzeskowiak, N.E.; Winkel, J.F. Structure and location of electroluminescent light emission within ZnS/Cu ACEL powder phosphor particles. J. Electrochem. Soc. 2007, 154, J289–J294. [Google Scholar] [CrossRef]

- Maeda, K. Electroluminescence of insulated particles. J. Phys. Soc. Jpn. 1958, 13, 1352–1361. [Google Scholar] [CrossRef]

- Wright, A.; Viney, I. A structural evaluation of ZnS-based electroluminescent phosphors and devices: A comparison with performance. Philos. Mag. B 2001, 81, 279–297. [Google Scholar] [CrossRef]

- Fischer, A. Destriau electroluminescence models: A rebuttal. Lett. Nuovo Cimento 1975, 12, 309. [Google Scholar] [CrossRef]

- Fischer, A.G. Electroluminescent lines in ZnS powder particles. J. Electrochem. Soc. 1963, 110, 733–748. [Google Scholar] [CrossRef]

- Havriliak, S.; Negami, S. A complex plane representation of dielectric and mechanical relaxation processes in some polymers. Polymer 1967, 8, 161. [Google Scholar] [CrossRef]

- Davidson, J.D.; Wagner, J.F.; Khormaei, R.I.; King, C.N.; Williams, R. Electrical characteruzation and modeling of alternating-current thin-film electroluminescent devices. IEEE T. Electron. Dev. 1992, 39, 1122–1128. [Google Scholar] [CrossRef]

- Vij, D. (Ed.) Handbook of Electroluminescent Materials; Institute of Physics: Bristol, UK, 2004.

- Szepesi, Z.; Lehmann, W.; Leksell, D. Preparation and characteristics of white EL dispaly panels. J. Electron. Mater. 1978, 7, 515–524. [Google Scholar] [CrossRef]

- Bredol, M. Handbook of Luminescence, Display Materials and Devices; Nalwa, H.S., Rohwer, L.S., Eds.; American Scientific Publishers: Valencia, CA, USA, 2003; Volume 2, Chapter Chemistry and Physics of Cathodoluminescent Materials; pp. 457–492. [Google Scholar]

- Hasegawa, K. Electroluminescent Phosphor, Process for Producing the Same, and Electroluminescent Device Containing the Same. US Pat. 7,400,085 B2, 2005. [Google Scholar]

- Yen, W.M.; Shionoya, S.; Yamamoto, H. (Eds.) Phosphor Handbook, 2nd ed.; CRC press: Boca Raton, FL, USA, 1999.

- Warkentin, M.; Bridges, F.; Carter, S.A.; Anderson, M. Electroluminescence materials ZnS:Cu,Cl and ZnS:Cu,Mn,Cl studied by EXAFS spectroscopy. Phys. Rev. B: Condens. Matter Mater. Phys. 2007, 75, 075301. [Google Scholar] [CrossRef]

- Chen, F.; Kitai, A.; Xiang, Y. Temperature-dependent degradation of AC powder EL. J. Electrochem. Soc. 2009, 156, H585–H587. [Google Scholar] [CrossRef]

- Corrado, C.; Jiang, Y.; Oba, F.; Kozina, M.; Bridges, F.; Zhang, J. Synthesis, structural, and optical properties of stable ZnS:Cu,Cl nanocrystals. J. Phys. Chem. A 2009, 113, 3830–3839. [Google Scholar] [CrossRef] [PubMed]

- Datta, A.; Panda, S.K.; Chaudhuri, S. Phase transformation and optical properties of Cu-doped ZnS nanorods. J. Solid State Chem. 2008, 181, 2332–2337. [Google Scholar] [CrossRef]

- Withnall, R.; Silver, J.; Ireland, T.; Fern, G.; Marsh, P. Structure and morphology of ACEL ZnS:Cu,Cl phosphor powder etched by hydrochloric acid. J. Electrochem. Soc. 2009, 156, J326–J332. [Google Scholar] [CrossRef]

- Sharma, G.; Han, S.D.; Kim, J.D.; Khatkar, S.P.; Rhee, Y.W. Electroluminescent efficiency of alternating current thick film devices using ZnS:Cu,Cl phosphor. Mater. Sci. Eng. B 2006, 131, 271–276. [Google Scholar] [CrossRef]

- Lehmann, W. Investigations on long-living Destriau-type electroluminescent phosphors. J. Electron. Mater. 1982, 11, 341–354. [Google Scholar] [CrossRef]

- Manzoor, K.; Vadera, S.; Kumar, N.; Kutty, T. Multicolor electroluminescent devices using doped ZnS nanocrystals. Appl. Phys. Lett. 2004, 84, 284–286. [Google Scholar] [CrossRef]

- Manzoor, K.; Aditya, V.; Vadera, S.; Kumar, N.; Kutty, T. Enhanced electroluminescence properties of doped ZnS nanorods formed by the self-assembly of colloidal nanocrystals. Solid State Commun. 2005, 135, 16–20. [Google Scholar] [CrossRef]

- Manzoor, K.; Aditya, V.; Vadera, S.; Kumar, N.; Kutty, T. Spontaneous organization of ZnS nanoparticles into monocrystalline nanorods with highly enhanced dopant-related emission. J. Phys. Chem. Solids 2005, 66, 1164–1170. [Google Scholar] [CrossRef]

- Hikmet, R.; Talapin, D.; Weller, H. Study of conduction mechanism and electroluminescence in CdSe/ZnS quantum dot composites. J. Appl. Phys. 2003, 93, 3509–3514. [Google Scholar] [CrossRef]

- Yang, H.; Holloway, P.H.; Ratna, B.B. Photoluminescent and electroluminescent properties of Mn-doped ZnS nanocrystals. J. Appl. Phys. 2003, 93, 586–592. [Google Scholar] [CrossRef]

- Walters, R.J.; Bourianoff, G.I.; Atwater, H.A. Field-effect electroluminescence in silicon nanocrystals. Nat. Mater. 2005, 4, 143–146. [Google Scholar] [CrossRef] [PubMed]

- Kapian, S.F.; Kartenko, N.F.; Kurdyokov, D.A.; Medvedev, A.V.; Golubev, V.G. Electroluminescent three–dimensional photonic crystals based on opal-phosphor composites. Appl. Phys. Lett. 2005, 86, 071108. [Google Scholar]

- Matras, K.; Bredol, M.; Szatkowski, A.; Sakhno, O.; Stumpe, J.; Bogdal, D. Composites from luminescent nanosized ZnS and optical polymer. Mol. Cryst. Liq. Cryst. 2008, 485, 28–31. [Google Scholar] [CrossRef]

- Satoh, T.; Miyashita, H.; Nishiyama, A.; Hirate, T. Low operation voltage in AC type inorganic electroluminescence devices using ZnO nanorods layer. Proc. ASID ’06 2006, 511. [Google Scholar]

- Wood, V.; Halpert, J.E.; Panzer, M.J.; Bawendi, M.G.; Bulović, V. Alternating current driven electroluminescence from ZnSe/ZnS:Mn/ZnS nanocrystals. Nano Lett. 2009, 9, 2367–2371. [Google Scholar] [CrossRef] [PubMed]

- Moore, D.; Wang, Z.L. Growth of anisotropic one-dimensional ZnS nanostructures. Soft Matter 2006, 16, 3898–3905. [Google Scholar] [CrossRef]

- Lee, J.Y.; Kim, D.S.; Kang, J.H.; Yoon, S.W.; Lee, H.; Park, J. Novel Zn1−xMnxSe (x=0.1-0.4) One-Dimensional Nanostructures: Nanowires, Zigzagged Nanobelts and Toothed Nanosaws. J. Phys. Chem. B 2006, 110, 25869–25874. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Daemen, L.L.; Zhao, Y.; Zha, C.; Downs, R.T.; Wang, X.; Wang, Z.L.; Hemley, R.J. Morphology-tuned wurtzite-type ZnS nanobelts. Nat. Mater. 2005, 4, 922. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Chen, B.; Gilbert, B.; Banfield, J.F. Kinetically controlled formation of a novel nanoparticulate ZnS with mixed cubic and hexagonal stacking. J. Mater. Chem. 2006, 16, 249–254. [Google Scholar] [CrossRef]

- Khare, A.; Bhushan, S. Electroluminescence studies of chemically deposited(Zn-Cd)S:Cu,F films. Cryst. Res. Technol. 2006, 41, 689–697. [Google Scholar] [CrossRef]

- Kryshtab, T.; Khomchenko, V.; Andraca-Adame, J.; Zavyalova, L.; Roshchina, N.; Rodionov, V.; Khachatryan, V. Preparation and properties of thin ZnS:Cu films phosphors. Thin Solid Films 2006, 515, 513–516. [Google Scholar] [CrossRef]

- Bol, A.A.; van Beek, R.; Meijerink, A. On the incorporation of trivalent rare earth ions in II-VI semiconductor nanocrystals. Chem. Mater. 2002, 14, 1121–1126. [Google Scholar] [CrossRef]

- Hu, H.; Zhang, W. Synthesis and properties of transition metals and rare-earth metals doped ZnS nanoparticles. Opt. Mater. 2006, 28, 536–550. [Google Scholar] [CrossRef]

- Planelles-Aragó, J.; Julián-López, B.; Cordoncillo, E.; Escribano, P.; Pellé, F.; Viana, B.; Sanchez, C. Lanthanide doped ZnS quantum dots dispersed in silica glasses: an easy one pot sol-gel synthesis for obtaining novel photonic materials. J. Mater. Chem. 2008, 18, 5193–5199. [Google Scholar] [CrossRef]

- Bhushan, S.; Chandra, F.S. Electroluminescence and photoluminescence of CaS phosphors. J. Phys. D: Appl. Phys. 1984, 17, 589–595. [Google Scholar] [CrossRef]

- Singh, V.P.; Sivakumar, P.; Aguilera, A.; Morton, D.C.; Forsythe, E. An Analytical Model for Electron Transport and Luminance in SrS:Cu,Ag ACTFEL Display Device. IEEE T. Electron. Dev. 2004, 51, 357–363. [Google Scholar] [CrossRef]

- Han, S.; Singh, I.; Singh, D.; Lee, Y.; Sharma, G.; Han, C. Crystal growth of electroluminescent ZnS:Cu,Cl phosphor and its TiO2 coating by sol-gel method for thick-film EL device. J. Lumin. 2005, 115, 97–103. [Google Scholar] [CrossRef]

- Sigai, A.G. Method or coating phosphor particles. US Pat. 4,585,673, 1985. [Google Scholar]

- Simopoulos, N.T.; Simopoulos, G.N. Electroluminescent Lamps and Phosphors. US Pat. 4,855,189, 1987. [Google Scholar]

- Klinedienst, K.A.; Gary, R.A. Method for Coating Phosphor Particles Using Aluminum Isopropoxide Precursors and an Isothermal Fluidized Bed. US Pat. 4,999,219, 1989. [Google Scholar]

- Klinedienst, K.A.; Gary, R.A.; Lichtensteiger, S.E. Method for Making Moisture Insensitive Zinc Sulfide Based Luminescent Materials. US Pat. 5,080,928, 1990. [Google Scholar]

- Klinedienst, K.A.; Gary, R.A.; Lichtensteiger, S.E. Moisture Insensitive Zinc Sulfide Electroluminescent Materials and an Electroluminescent Device Made Therefrom. US Pat. 5,220,243, 1991. [Google Scholar]

- Dutta, A.; Dullea, L.V.; Dale, E.A. Process for coating small solids. US Pat. 4,990,371, 1989. [Google Scholar]

- David, M.M.; Johnson, D.L. Diamond-like carbon coatings on inorganic phosphors. US Pat. 6,548,172, 2001. [Google Scholar]

- Nakamura, T.; Kamiya, M.; Watanabe, H.; Nakanishi, Y. Preparation and characterization of zinc sulfide phosphors coated with barium titanate using sol-gel method. J.Electrochem.Soc. 1995, 142, 949–952. [Google Scholar] [CrossRef]

- Park, Y.; Kim, Y.; Kim, H. The effect of grain size on dielectric behavior of BaTiO3 based X7R materials. Mater. Lett. 1996, 28, 101–106. [Google Scholar] [CrossRef]

- Wang, X.H.; Chen, R.Z.; Gui, Z.L.; Li, L.T. The grain size efect on dielectric properties of BaTiO3 based ceramics. Mater. Sci. Eng. 2003, B99, 199–202. [Google Scholar] [CrossRef]

- Day, V.; Eberspacher, T.; Klemperer, W.; Liang, S. Synthesis and characterization of BaTi(OC6H5)6 * 2DMF, a single-source precursor to BaTiO3 gels, powders, and thin films. Chem.Mater. 1995, 7, 1607–1608. [Google Scholar] [CrossRef]

- Guo, W.; Datye, A.K.; Ward, T.L. Synthesis of barium titanate powders by aerosol pyrolysis of a Pechini–type precursor solution. J. Mater. Chem. 2005, 15, 470–477. [Google Scholar] [CrossRef]

- Park, S.; Kim, H.S.; J.-Y-Park.; Lee, J.; Chung, Y.J.; Lee, J.H. Effects of solution combusted BaTiO3 nanopowders within dielectric layer on the electrical and the optical characteristics for AC powder EL devices. J. Korean Phys. Soc 2009, 54, 1123–1126. [Google Scholar] [CrossRef]

- González, M.B.; Wu, A.; Vilarinho, P.M. Influence of solvents on the microstructure and dielectric properties of Ba0.5Sr0.5TiO3 thin films prepared by a diol-based sol-gel process. Chem. Mater. 2006, 18, 1737–1744. [Google Scholar] [CrossRef]

- Caruntu, G.; Rarig, R., Jr.; Dumitru, I.; O’Connor, C.J. Annealing effects on the crystallite size and dielectric properties of ultrafine Ba1−xSrxTiO3 (O<x<1) powders synthesized through an oxalate-complex precursor. J. Mater. Chem. 2006, 16, 752–758. [Google Scholar]

- Silver, J.; Withnall, R.; Harris, P.G.; Marsh, P.J.; Kirk, R.; Guinn, F. Novel, flexible AC electroluminescent lamps for innovative display applications. SID Symp. Digest Tech. Papers 2008, 39, 182–185. [Google Scholar] [CrossRef]

- Dang, Z.M.; Wang, L.; Wang, H.Y.; Nan, C.W.; Xie, D.; Yin, Y.; Tjong, S. Rescaled temperature dependence of dielectric behavior of ferroelectric polymer composites. Appl. Phys. Lett. 2005, 86, 1–3. [Google Scholar] [CrossRef]

- Iijima, M.; Sato, N.; Lenggoro, I.W.; Kamiya, H. Surface modification of BaTiO3 particles by silane coupling agents in different solvents and their effect on dielectric properties of BaTiO3/epoxy composites. Colloids Surf. A 2009, 352, 88–93. [Google Scholar] [CrossRef]

- Hoffman, L.C. Electroluminescent Vitreous Enamel. US 2,986,530, 1959. [Google Scholar]

- Hoffman, L.C. Electroluminescent Vitreous Enamel and Lamp. US 2,965,784, 1960. [Google Scholar]

- Khomchenko, V. Electroluminescent panels based on glass. Gass and Ceramics (Steklo i Keramika) 1964, 21, 329–331. [Google Scholar] [CrossRef]

- Bredol, M.; Kynast, U.; Klamka, M.; Zielniok, D. Verfahren zum präparativen Aufschließen von schwermetallhaltigen Gläsern. DE 102 25 279, 2002. [Google Scholar]

- Mäuser, H. Verbundscheibe mit einem elektrisch steuerbaren Funktionselement. DE 10164063B4, 2001. [Google Scholar]

- Withnall, R.; Silver, J.; Fern, G.R.; Marsh, P.J.; Ireland, T.G.; Evans, P.S.A.; Southee, D.J.; Hay, G.I.; Harrison, D.J.; Breen, K.F.B. Low cost, flexible electroluminescent displays with a novel electrode architecture printed by offset lithography. SID Symp. Digest Tech. Papers 2006, 37, 1491–1494. [Google Scholar] [CrossRef]

- Hartner, S.; Ali, M.; Schulz, C.; Winterer, M.; Wiggers, H. Electrical properties of aluminum-doped zinc oxide (AZO) nanoparticles synthesized by chemical vapor synthesis. Nanotechnology 2009, 20, 445701. [Google Scholar] [CrossRef] [PubMed]

- Cranton, W.M.; Wilson, S.L.; Ranson, R.; Koutsogeorgis, D.C.; Chi, K.; Hedgley, R.; Scott, J.; Lipiec, S.; Spiller, A.; Speakman, S. Excimer laser processing of inkjet-printed and sputter-deposited transparent conducting SnO2:Sb for flexible electronics. Thin Solid Films 2007, 515, 8534–8538. [Google Scholar] [CrossRef]

- Wu, J.; Pisula, W.; Müllen, K. Graphenes as potential material for electronics. Chem. Rev. 2007, 107, 718–747. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhi, L.; Müllen, K. Transparent, conductive graphene electrodes for dye-sensitized solar cells. Nano Lett. 2008, 8, 323–327. [Google Scholar] [CrossRef] [PubMed]

© 2010 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license http://creativecommons.org/licenses/by/3.0/.

Share and Cite

Bredol, M.; Schulze Dieckhoff, H. Materials for Powder-Based AC-Electroluminescence. Materials 2010, 3, 1353-1374. https://doi.org/10.3390/ma3021353

Bredol M, Schulze Dieckhoff H. Materials for Powder-Based AC-Electroluminescence. Materials. 2010; 3(2):1353-1374. https://doi.org/10.3390/ma3021353

Chicago/Turabian StyleBredol, Michael, and Hubert Schulze Dieckhoff. 2010. "Materials for Powder-Based AC-Electroluminescence" Materials 3, no. 2: 1353-1374. https://doi.org/10.3390/ma3021353