Polymerization Stress Development in Dental Composites: Effect of Cavity Design Factor

Abstract

:1. Introduction

2. Results and Discussion

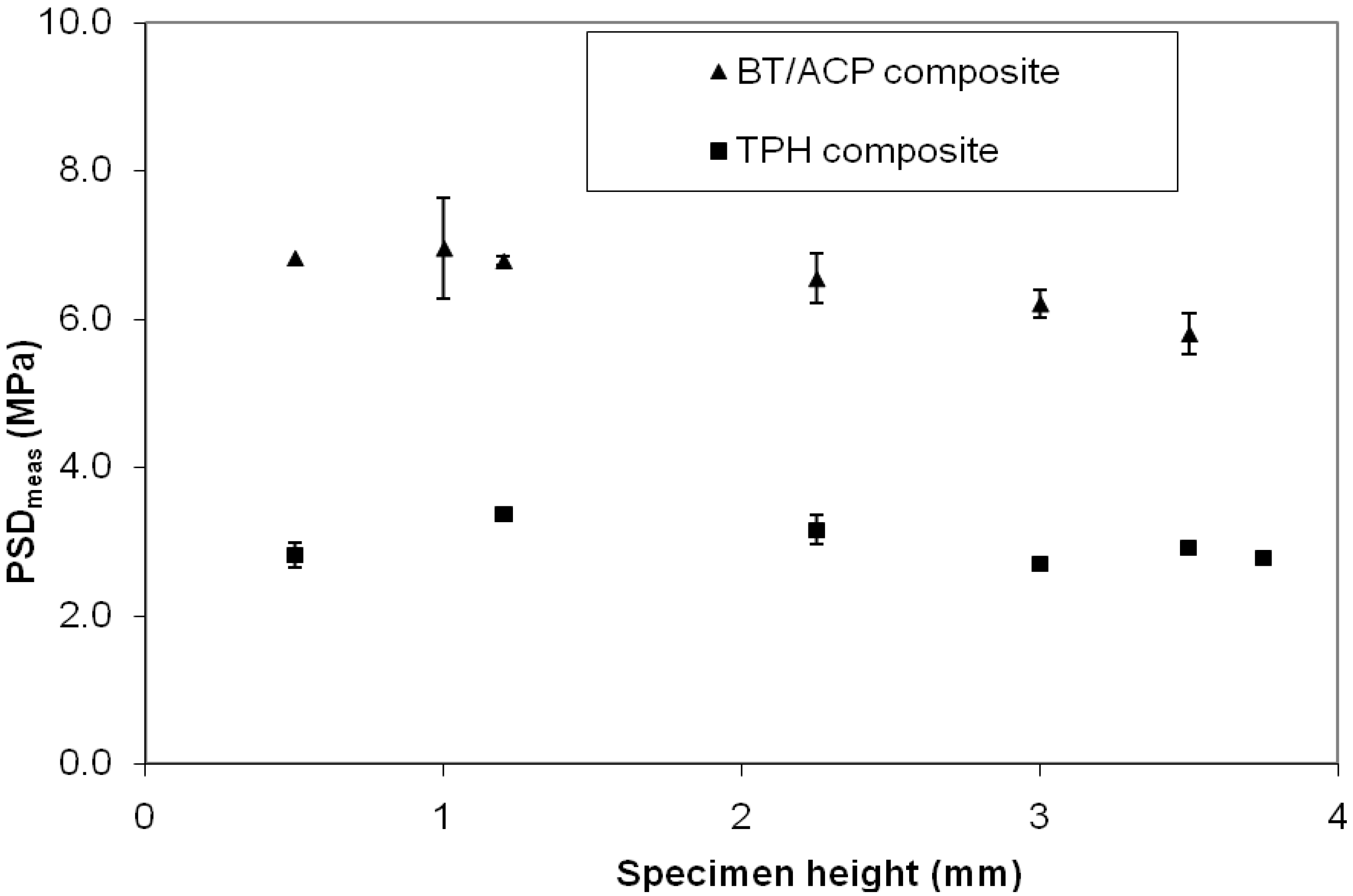

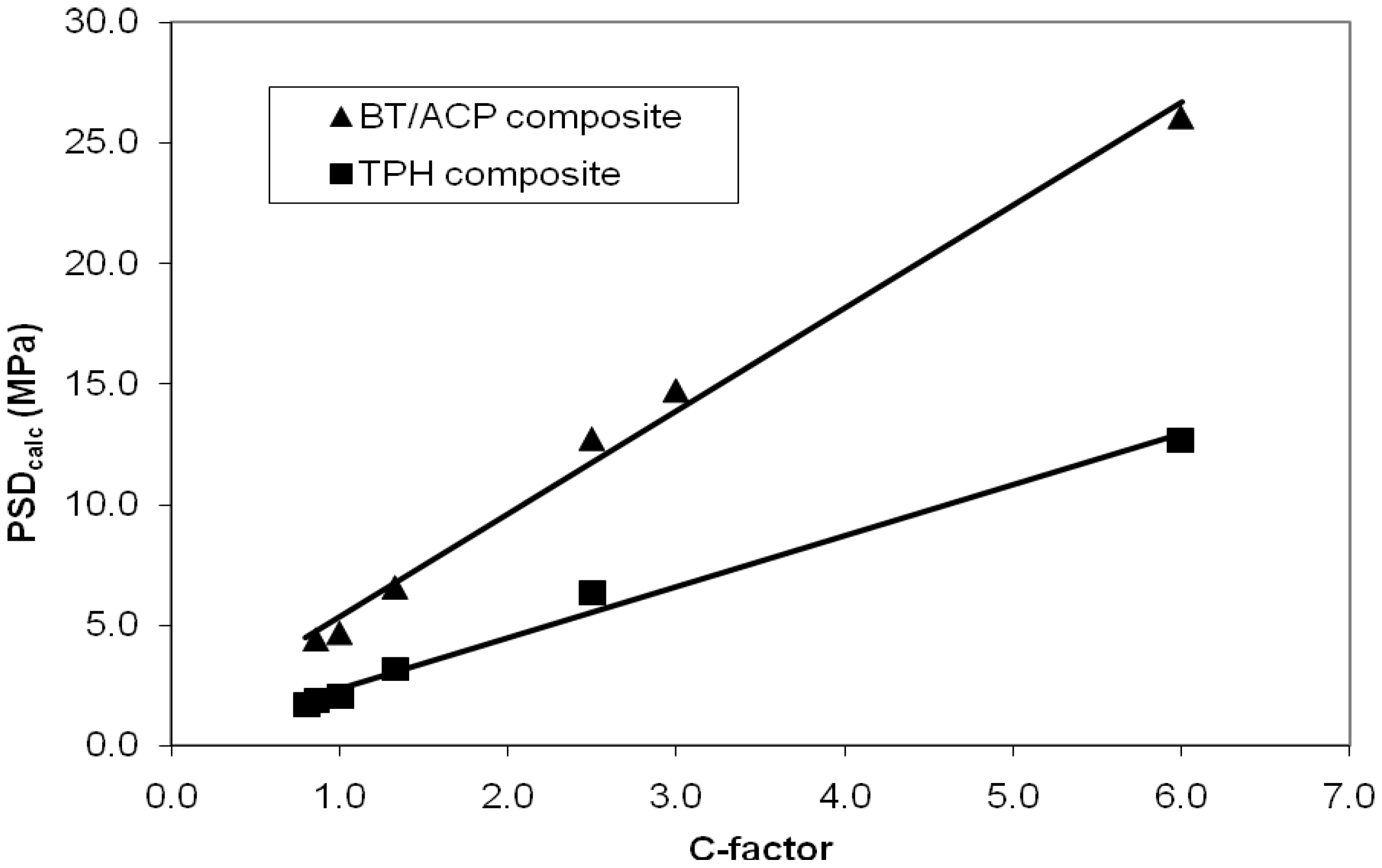

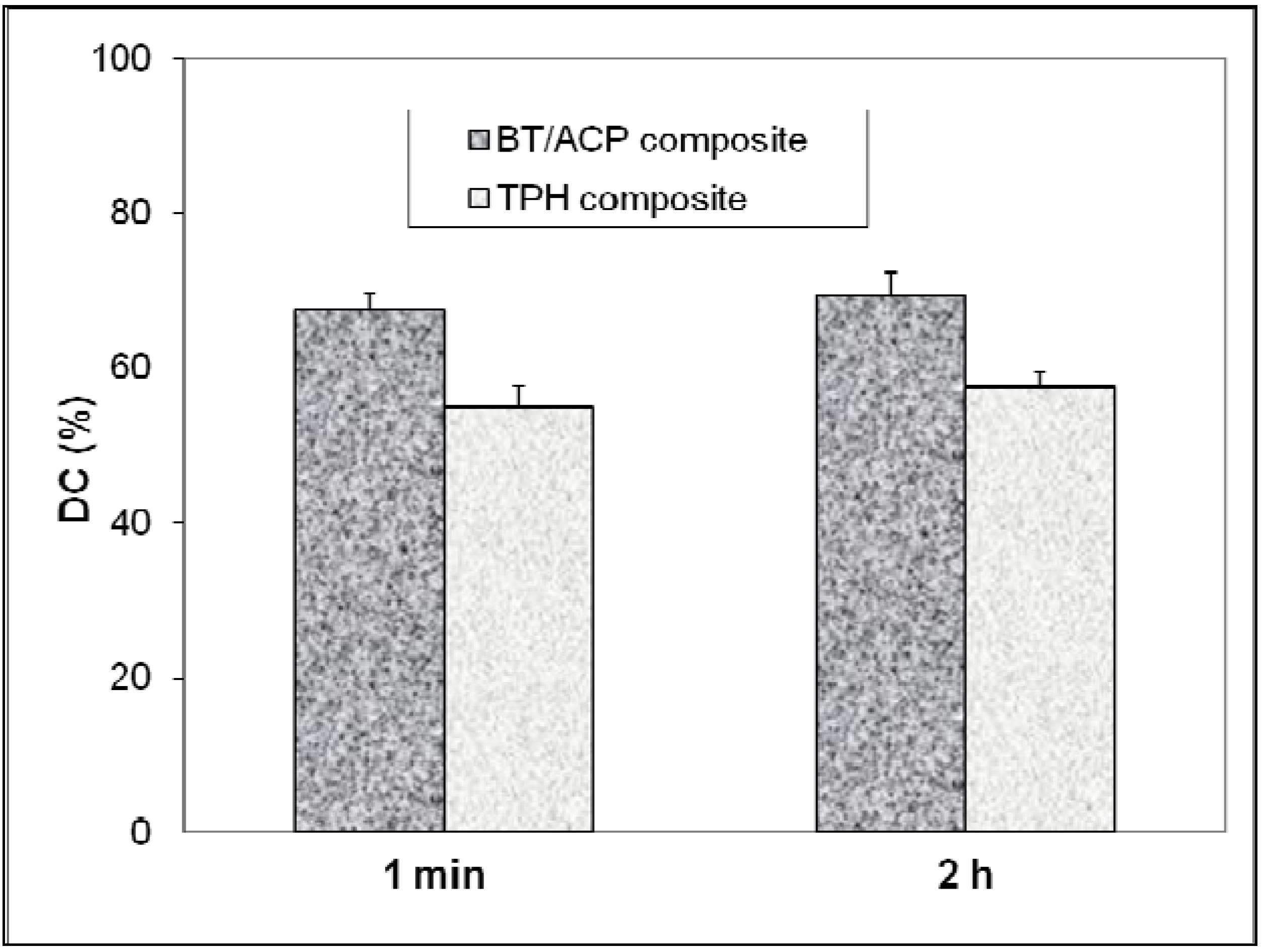

| C-Factor | Composite Height (mm) | BT/ACP Composite PSD (MPa) Measured Calculated | TPH Composite PSD (MPa) Measured Calculated |

| 0.80 | 3.75 | nd | 2.78 ± 0.07 1.67 |

| 0.86 | 3.50 | 5.80 ± 0.55 4.39 | 2.91 ± 0.05 1.87 |

| 1.00 | 3.00 | 6.21 ± 0.27 4.66 | 2.70 ± 0.07 2.03 |

| 1.33 | 2.25 | 6.55 ± 0.19 6.55 | 3.16 ± 0.19 3.16 |

| 2.50 | 1.20 | 6.79 ± 0.34 12.73 | 3.37 ± 0.08 6.32 |

| 3.00 | 1.00 | 6.96 ± 0.06 14.73 | nd |

| 6.00 | 0.50 | 6.83 ± 0.68 26.09 | 2.82 ± 0.17 12.69 |

3. Experimental Section

3.1. Resin formulation, ACP filler synthesis and characterization, composite preparation

3.2. Polymerization stress development (PSD) measurements

3.3. Degree of vinyl conversion (DC)

3.4. Statistical data analysis

4. Conclusions

Acknowledgements

References

- Bowen, R.L. Properties of silica-reinforced polymer for dental restorations. J. Am. Dent. Assoc. 1963, 66, 57–64. [Google Scholar] [CrossRef] [PubMed]

- Braga, R.R.; Ferracane, J.L. Alternatives in polymerization contraction stress management. Crit. Rev. Oral. Biol. Med. 2004, 15, 176–184. [Google Scholar] [CrossRef] [PubMed]

- Bowen, R.L. Adhesive bonding of various materials to hard tooth tissues; VI. Forces developing in direct-filling materials during hardening. J. Amer. Dent. Assoc. 1967, 74, 439–445. [Google Scholar] [CrossRef]

- Bowen, R.L.; Nemoto, K.; Rapson, J.E. Adhesive bonding of various materials to hard tooth tissues: Forces developing in composite materials during hardening. J. Amer. Dent. Assoc. 1983, 106, 475–477. [Google Scholar] [CrossRef]

- Ferracane, J.L. Developing a more complete understanding of stresses produced in dental composites during polymerization. Dent. Mater. 2005, 21, 36–42. [Google Scholar] [CrossRef] [PubMed]

- Kinomoto, Y.; Torii, M. Photoelastic analysis of polymerization contraction stresses between self- and light-cured composites. J. Dent. 1998, 26, 165–171. [Google Scholar] [CrossRef] [PubMed]

- Shono, Y.; Ogawa, T.; Terashita, M.; Carvlho, R.M.; Pashley, E.L.; Pashley, D.H. Regional measurement of resin-dentin bonding as an array. J. Dent. Res. 1999, 78, 699–705. [Google Scholar] [CrossRef] [PubMed]

- Labella, R.; Lambrechts, P.; Van Meerbeek, B.; Vanherle, G. Polymerization shrinkage and elasticity of flowable composites and filled adhesives. Dent. Mater. 1999, 15, 128–137. [Google Scholar] [CrossRef] [PubMed]

- Venhoven, B.A.M.; de Gee, A.J.; Davidson, C.L. Light initiation of dental resins: dynamics of the polymerization. Biomaterials 1996, 176, 2313–2318. [Google Scholar] [CrossRef]

- Feilzer, A.J.; de Gee, A.J.; Davidson, C.L. Setting stress in composite resin in relation to configuration of the restoration. J. Dent. Res. 1987, 66, 1636–1639. [Google Scholar] [CrossRef] [PubMed]

- Hansen, E.K. Effect of scotchbond dependent on cavity cleaning, cavity diameter and cavosurface angle. scand. J. Dent. Res. 1984, 92, 141–147. [Google Scholar]

- Giacetti, L.; Scaminaci-Russo, D.; Bambi, C.; Grandini, R. A review of polymerization shrinkage stress: Current techniques for posterior direct resin restorations. J. Contemp. Dent. Pract. 2006, 7, 1–13. [Google Scholar] [PubMed]

- Braga, R.R.; Ferracane, J.L. Contraction stress related to degree of conversion and reaction kinetics. J. Dent. Res. 2002, 81, 114–118. [Google Scholar] [CrossRef] [PubMed]

- Calheiros, F.C.; Braga, R.R.; Kawano, Y.; Ballester, R.Y. Relationship between contraction stress and degree of conversion in restorative composites. Dent. Mater. 2004, 20, 939–946. [Google Scholar] [CrossRef] [PubMed]

- Stansbury, J.W.; Trujillo-Lemon, M.; Lu, H.; Ding, X.; Lin, Y.; Ge, J. Conversion-dependent shrinkage stress and strain in dental resins and composites. Dent. Mater. 2005, 21, 56–67. [Google Scholar] [CrossRef] [PubMed]

- Kleverlaan, C.J.; Feilzer, A.J. Polymerization shrinkage and contraction stress of dental resin composites. Dent. Mater. 2005, 21, 1150–1157. [Google Scholar] [CrossRef] [PubMed]

- Choi, K.K.; Ruy, G.J.; Choi, S.M.; Lee, M.J.; Park, S.J.; Ferracane, J.L. Effects of cavity configuration on composite restoration. Oper. Dent. 2004, 29, 462–469. [Google Scholar] [PubMed]

- Uno, S.; Tanaka, T.; Inoue, S.; Sano, S. The influence of configuration factors on cavity adaptation in compomer restorations. Dent. Mater. J. 1999, 18, 19–31. [Google Scholar] [CrossRef] [PubMed]

- Feilzer, A.J.; de Gee, A.J.; Davidson, C.L. Quantitative determination of stress reduction by flow in composite restorations. Dent. Mater. 1990, 6, 167–171. [Google Scholar] [CrossRef] [PubMed]

- Skrtic, D.; Antonucci, J.M.; Eanes, E.D. Amorphous calcium phosphate-based bioactive polymeric composites for mineralized tissue regeneration. J. Res. Natl. Inst. Stands. Technol. 2003, 108, 167–182. [Google Scholar] [CrossRef]

- Skrtic, D.; Antonucci, J.M. Effect of bifunctional co-monomers on mechanical strength and water sorption of amorphous calcium phosphate- and silanized glass-filled bis-GMA-based composites. Biomaterials 2003, 24, 2881–2888. [Google Scholar] [CrossRef] [PubMed]

- Skrtic, D.; Antonucci, J.M. Dental composites based on amorphous calcium phosphate - resin composition/physicochemical properties study. J. Biomat. Appl. 2007, 21, 375–393. [Google Scholar] [CrossRef]

- Lu, H.; Stansbury, J.W.; Dickens, S.H.; Eichmiller, F.C.; Bowman, C.N. Probing the origins and control of shrinkage stress in dental resin-composites: I. Shrinkage stress characterization Technique. J. Mater. Sci. Mater. Med. 2004, 15, 1097–1103. [Google Scholar] [CrossRef] [PubMed]

- Alster, D.; Feilzer, A.J.; de Gee, A.J.; Davidson, C.L. Polymerization contraction stress in thin resin composite layers as a function of layer thickness. Dent. Mater. 1997, 13, 146–150. [Google Scholar] [CrossRef]

- Choi, K.K.; Condon, J.R.; Ferracane, J.L. The effects of adhesive thickness on polymerization contraction stress of composite. J. Dent. Res. 2000, 79, 812–817. [Google Scholar] [CrossRef] [PubMed]

- Watts, D.C.; Satterthwaite, J.D. Axial shrinkage stress depends upon both c-factor and composite mass. Dent. Mater. 2008, 24, 1–8. [Google Scholar] [CrossRef]

- Lee, S.H.; Chang, J.; Ferracane, J.L.; Lee, I.B. Influence of instrument compliance and specimen thickness on the polymerization shrinkage stress measurement of light-cured ccomposites. Dent. Mater. 2007, 23, 1093–1100. [Google Scholar] [CrossRef] [PubMed]

- Munksgaard, E.C.; Hansen, E.K.; Kato, H. Wall-to-wall polymerization contraction of composite resins versus filler content. Scand. J. Dent. Res. 1987, 95, 526–531. [Google Scholar] [PubMed]

- Feilzer, A.J.; de Gee, A.J.; Davidson, C.L. Relaxation of polymerization contraction shear stress by hygroscopic expansion. J. Dent. Res. 1990, 69, 36–39. [Google Scholar] [CrossRef] [PubMed]

- Braem, M.; Davidson, C.L.; Vanherle, G.; Van Doren, V.; Lambrechts, P. The relationship between testing methodology and elastic behavior of composites. J. Dent. Res. 1987, 66, 1036–1039. [Google Scholar] [CrossRef] [PubMed]

- Watts, D.C.; Marouf, A.S.; Al-Hindi, A.M. Photo-polymerization shrinkage stress kinetics in resin composites: Methods development. Dent. Mater. 2003, 19, 1–11. [Google Scholar]

- Stansbury, J.W.; Dickens, S.H. Determination of double bond conversion in dental resins by near infrared spectroscopy. Dent. Mater. 2001, 17, 71–79. [Google Scholar] [CrossRef] [PubMed]

© 2009 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Antonucci, J.M.; Giuseppetti, A.A.; O’Donnell, J.N.R.; Schumacher, G.E.; Skrtic, D. Polymerization Stress Development in Dental Composites: Effect of Cavity Design Factor. Materials 2009, 2, 169-180. https://doi.org/10.3390/ma2010169

Antonucci JM, Giuseppetti AA, O’Donnell JNR, Schumacher GE, Skrtic D. Polymerization Stress Development in Dental Composites: Effect of Cavity Design Factor. Materials. 2009; 2(1):169-180. https://doi.org/10.3390/ma2010169

Chicago/Turabian StyleAntonucci, Joseph M., Anthony A. Giuseppetti, Justin N.R. O’Donnell, Gary E. Schumacher, and Drago Skrtic. 2009. "Polymerization Stress Development in Dental Composites: Effect of Cavity Design Factor" Materials 2, no. 1: 169-180. https://doi.org/10.3390/ma2010169