Combined Effects of Color and Elastic Modulus on Antifouling Performance: A Study of Graphene Oxide/Silicone Rubber Composite Membranes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

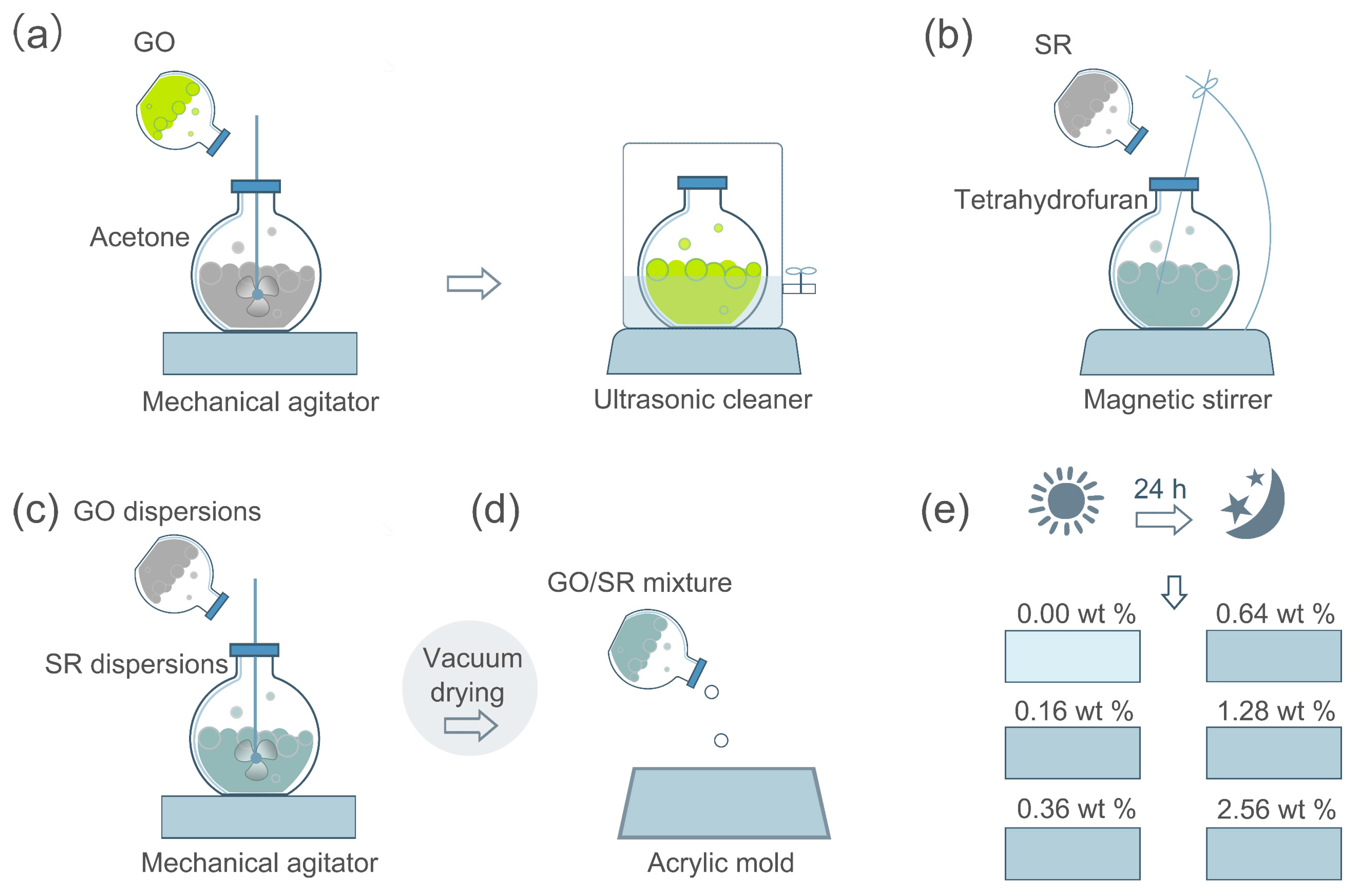

2.2. Membrane Preparation

2.3. Diatom Attachment Testing

2.4. Characterization

3. Results and Discussions

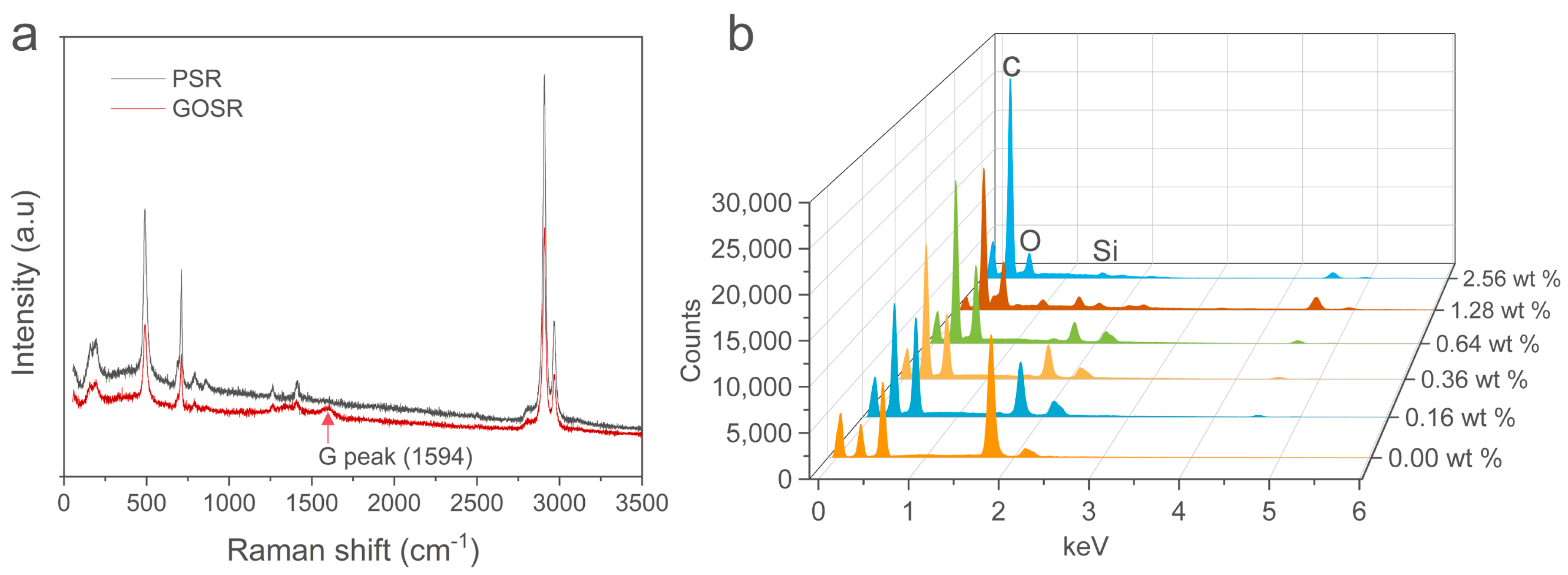

3.1. Membrane Composition Analysis

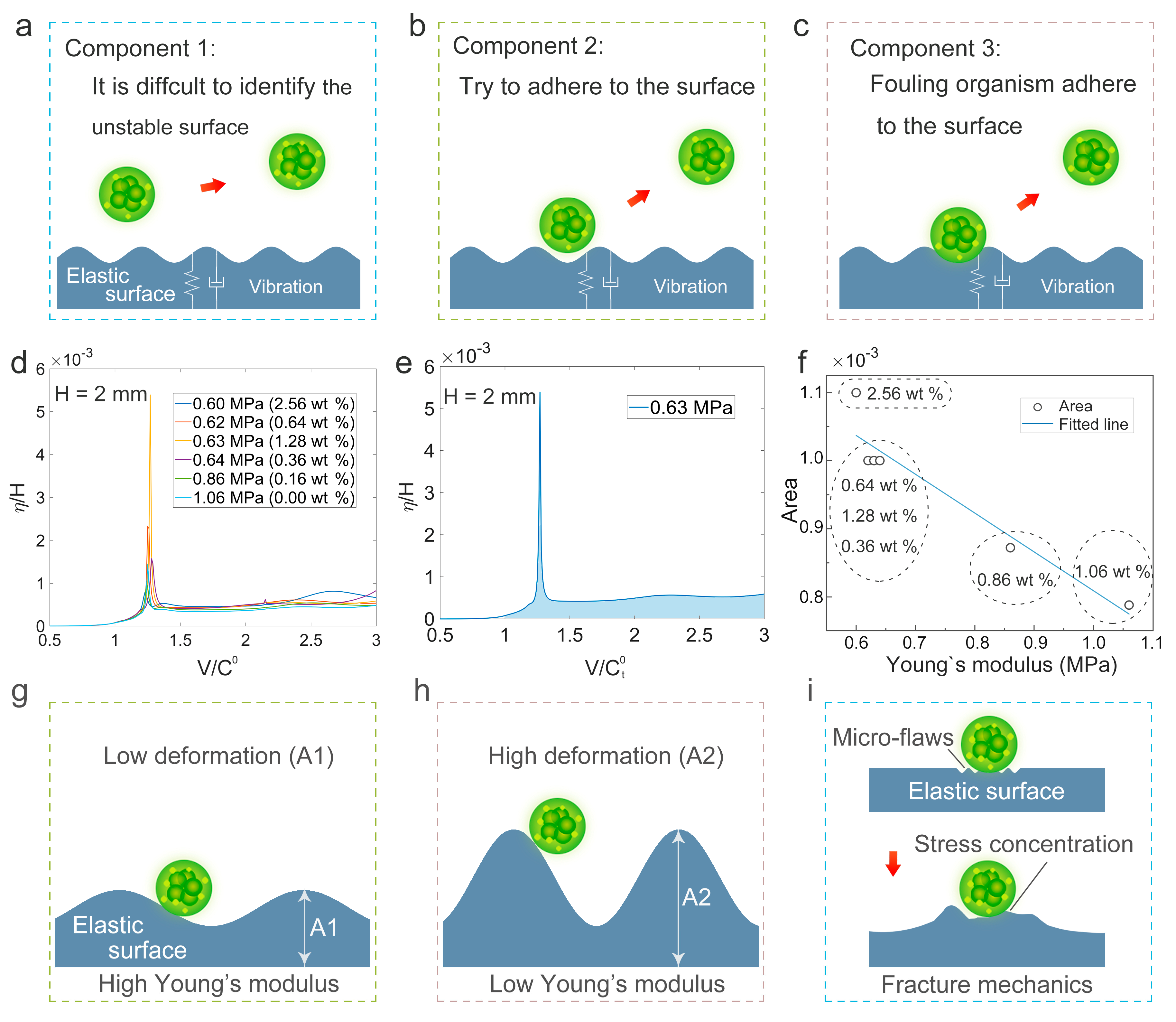

3.2. Membrane Properties

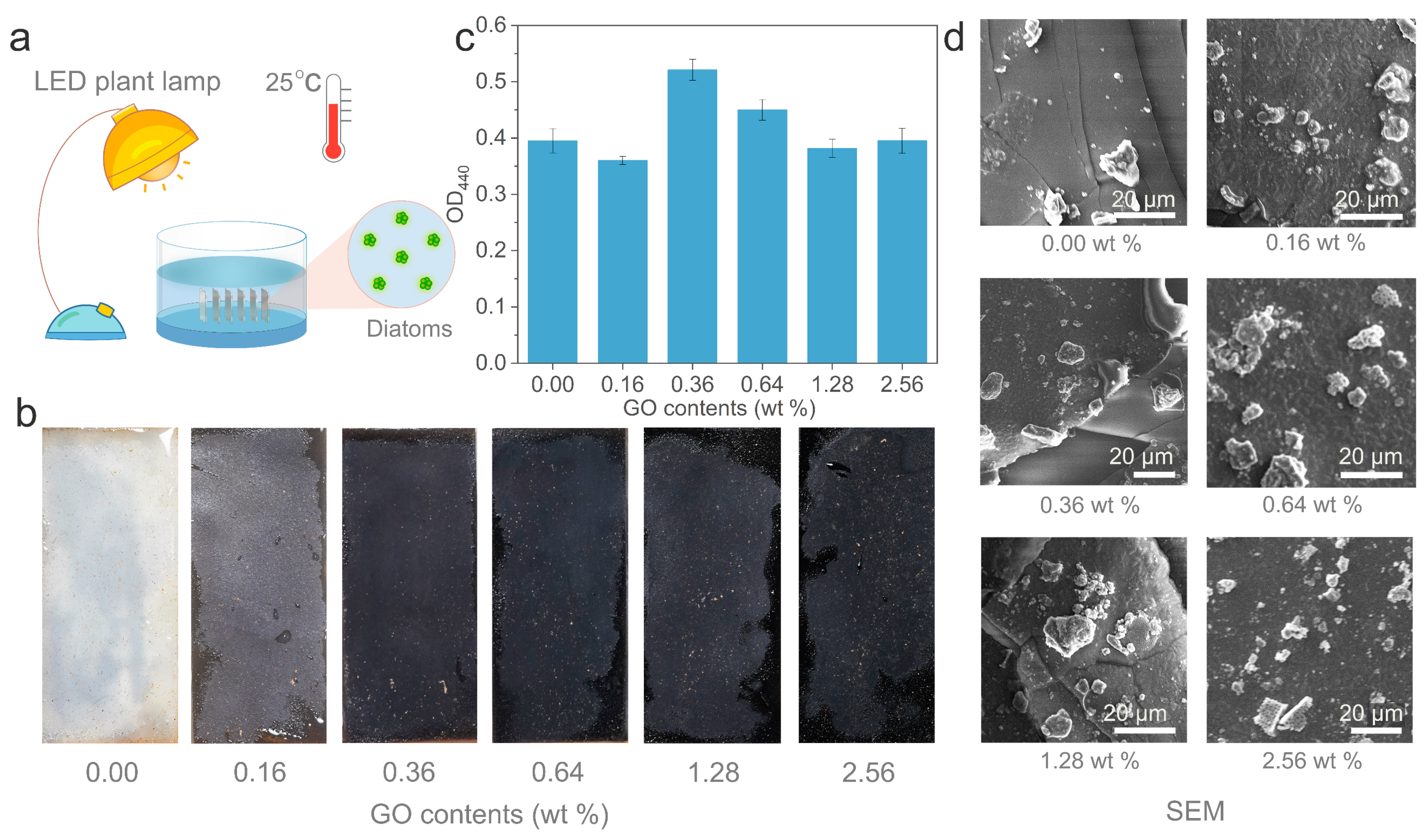

3.3. Diatom Adhesion Testing Under Static Conditions

3.4. Diatom Adhesion Testing Under Hydrodynamic Conditions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Selim, M.S.; Shenashen, M.A.; El-Safty, S.A.; Higazy, S.A.; Isago, H.; Elmarakbi, A. Recent progress in marine foul-release polymeric nanocomposite coatings. Prog. Mater. Sci. 2017, 87, 1–32. [Google Scholar] [CrossRef]

- Sullivan, T.; Regan, F. Marine diatom settlement on microtextured materials in static field trials. J. Mater. Sci. 2017, 52, 5846–5856. [Google Scholar] [CrossRef]

- Lacoursière-Roussel, A.; Dan, G.B.; Cristescu, M.E.; Guichard, F.; Mckindsey, C.W. Effect of shipping traffic on biofouling invasion success at population and community levels. Biol. Invasions 2016, 18, 3681–3695. [Google Scholar] [CrossRef]

- Scianni, C.; Brown, C.; Nedelcheva, R.; Dobroski, N. Hull husbandry practices and biofouling management of vessels operating in California. In Proceedings of the Oceans IEEE, San Diego, CA, USA, 23–27 September 2013. [Google Scholar]

- CLSC. Marine Invasive Species Program. Available online: http://www.slc.ca.gov/Programs/MISP.html (accessed on 3 February 2019).

- Xu, Y.; He, H.; Schulz, S.; Liu, X.; Fusetani, N.; Xiong, H.; Qian, P.Y. Potent antifouling compounds produced by marine Streptomyces. Bioresour. Technol. 2009, 101, 1331–1336. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.L.; Maki, J.S.; Dan, R.; Teo, L.M. Early marine bacterial biofilm on a copper-based antifouling paint. Int. Biodeter. Biodegr. 2013, 83, 71–76. [Google Scholar] [CrossRef]

- Jelic-Mrcelic, G.; Sliskovic, M.; Antolic, B. Biofouling communities on test panels coated with TBT and TBT-free copper based antifouling paints. Biofouling 2006, 22, 293–302. [Google Scholar] [CrossRef] [PubMed]

- Alzieu, C. Environmental problems caused by TBT in France: Assessment, regulations, prospects. Mar. Environ. Res. 1991, 32, 7–17. [Google Scholar] [CrossRef]

- Antizar-Ladislao, B. Environmental levels, toxicity and human exposure to tributyltin (TBT)-contaminated marine environment. A review. Environ. Int. 2008, 34, 292–308. [Google Scholar] [CrossRef] [PubMed]

- Minchin, D.; Oehlmann, J.; Duggan, C.B.; Stroben, E.; Keatinge, M. Marine TBT antifouling contamination in Ireland, following legislation in 1987. Mar. Pollut. Bull. 1995, 30, 633–639. [Google Scholar] [CrossRef]

- Blanck, H.; Dahl, B. Recovery of marine periphyton communities around a swedish marina after the ban of TBT use in antifouling paint. Mar Pollut Bull 1998, 36, 437–442. [Google Scholar] [CrossRef]

- Selim, M.S.; Elmarakbi, A.; Azzam, A.M.; Shenashen, M.A.; El-Saeed, A.M.; El-Safty, S.A. Eco-friendly design of superhydrophobic nano-magnetite/silicone composites for marine foul-release paints. Prog. Org. Coat. 2018, 116, 21–34. [Google Scholar] [CrossRef]

- Selim, M.S.; El-Safty, S.A.; Fatthallah, N.A.; Shenashen, M.A. Silicone/graphene oxide sheet-alumina nanorod ternary composite for superhydrophobic antifouling coating. Prog. Org. Coat. 2018, 121, 160–172. [Google Scholar] [CrossRef]

- Wang, B.; Wu, Z.; Zhang, D.; Wang, R.M.; Song, P.; Xiong, Y.; He, Y. Antibacterial silicylacrylate copolymer emulsion for antifouling coatings. Prog. Org. Coat. 2018, 118, 122–128. [Google Scholar] [CrossRef]

- Mo, F.; Ren, H.; Chen, S.; Ge, Z. Novel zwitterionic polyurethanes with good biocompatibility and antibacterial activity. Mater. Lett. 2015, 145, 174–176. [Google Scholar] [CrossRef]

- Lee, J.; Chae, H.R.; Won, Y.J.; Lee, K.; Lee, C.H.; Lee, H.H.; Kim, I.C.; Lee, J.M. Graphene oxide nanoplatelets composite membrane with hydrophilic and antifouling properties for wastewater treatment. J. Membr. Sci. 2013, 448, 223–230. [Google Scholar] [CrossRef]

- Huang, Y.; Li, H.; Wang, L.; Qiao, Y.; Tang, C.; Jung, C.; Yoon, Y.; Li, S.; Yu, M. Ultrafiltration membranes with structure-optimized graphene-oxide coatings for antifouling Oil/Water separation. Adv. Mater. Interfaces 2015, 2, 1400433. [Google Scholar] [CrossRef]

- Shi, Y.; Chang, L.; He, D.; Shen, L.; Bao, N. Preparation of graphene oxide-cellulose acetate nanocomposite membrane for high-flux desalination. J. Mater. Sci. 2017, 52, 13296–13306. [Google Scholar] [CrossRef]

- Fu, J.; Zhang, H.; Guo, Z.; Feng, D.Q.; Thiyagarajan, V.; Yao, H. Combat biofouling with microscopic ridge-like surface morphology: a bioinspired study. J. R. Soc. Interface 2018, 15, 1–8. [Google Scholar] [CrossRef]

- Jin, H.; Zhang, T.; Bing, W.; Dong, S.; Tian, L. Antifouling performance and mechanism of elastic graphene–silicone rubber composite membranes. J. Mater. Chem. B 2019, 7, 488–497. [Google Scholar] [CrossRef]

- Bing, W.; Tian, L.; Wang, Y.; Jin, H.; Ren, L.; Dong, S. Bio-Inspired non-bactericidal coating used for antibiofouling. Adv. Mater. Technol. 2019, 4, 1800480. [Google Scholar] [CrossRef]

- Qian, P.Y.; Rittschof, D.; Sreedhar, B.; Chia, F.S. Macrofouling in unidirectional flow: Miniature pipes as experimental models for studying the effects of hydrodynamics on invertebrate larval settlement. Mar. Ecol. Prog. Ser. 1999, 191, 141–151. [Google Scholar] [CrossRef]

- Nishizaki, M.T.; Carrington, E. The effect of water temperature and flow on respiration in barnacles: patterns of mass transfer versus kinetic limitation. J. Exp. Biol. 2014, 217, 2101–2109. [Google Scholar] [CrossRef] [PubMed]

- Kaniyoor, A.; Ramaprabhu, S. A Raman spectroscopic investigation of graphite oxide derived graphene. Aip Adv. 2012, 2, 241. [Google Scholar] [CrossRef]

- Kudin, K.N.; Ozbas, B.; Prud’Homme, R.K.; Aksay, I.A.; Car, R. Raman spectra of graphite oxide and functionalized graphene sheets. Nano Lett. 2008, 8, 36. [Google Scholar] [CrossRef] [PubMed]

- Kwok, D.Y.; Neumann, A.W. Contact angle measurement and contact angle interpretation. Adv. Colloid Int. Sci. 1999, 81, 167–249. [Google Scholar] [CrossRef]

- Brady, R.F.; Singer, I.L. Mechanical factors favoring release from fouling release coatings. Biofouling 2000, 15, 73–81. [Google Scholar] [CrossRef] [PubMed]

- Compton, O.C.; Nguyen, S.T. Graphene oxide, highly reduced graphene oxide, and graphene: versatile building blocks for carbon-based materials. Small 2010, 6, 711–723. [Google Scholar] [CrossRef] [PubMed]

- Tian, L.; Jin, E.; Mei, H.; Ke, Q.; Li, Z.; Kui, H. Bio-inspired Graphene-enhanced Thermally Conductive Elastic Silicone Rubber as Drag Reduction Material. J. Bionic Eng. 2017, 14, 130–140. [Google Scholar] [CrossRef]

- Yan, X.; Gao, Q.; Liang, H.; Zheng, K. Effects of functional graphene oxide on the properties of phenyl silicone rubber composites. Polym. Test. 2016, 54, 168–175. [Google Scholar]

- Chaudhury, M.K.; Finlay, J.A.; Chung, J.Y.; Callow, M.E.; Callow, J.A. The influence of elastic modulus and thickness on the release of the soft-fouling green alga Ulva linza (syn. Enteromorpha linza) from poly(dimethylsiloxane) (PDMS) model networks. Bioflouling 2005, 21, 41–48. [Google Scholar] [CrossRef]

- Jia, H.; Wu, Z.; Liu, N. Effect of nano-ZnO with different particle size on the performance of PVDF composite membrane. Plast. Rubber Compos. 2017, 46, 1–7. [Google Scholar] [CrossRef]

- Scardino, A.J.; Zhang, H.; Cookson, D.J.; Lamb, R.N.; de Nys, R. The role of nano-roughness in antifouling. Biofouling 2009, 25, 757–767. [Google Scholar] [CrossRef] [PubMed]

- Molena, E.; Credi, C.; Marco, C.D.; Levi, M.; Turri, S.; Simeone, G. Protein antifouling and fouling-release in perfluoropolyether surfaces. Appl. Surf. Sci. 2014, 309, 160–167. [Google Scholar] [CrossRef]

- Shan, C.; Wang, J.; Yan, Z.; Chen, D. The effectiveness of an antifouling compound coating based on a silicone elastomer and colored phosphor powder against Navicula species diatom. J. Coat. Technol. Res. 2013, 10, 397–406. [Google Scholar]

- Geoffrey, S.; Herpe, S.; Emily, R.; Melissa, T. Short-term testing of antifouling surfaces: The importance of colour. Biofouling 2006, 22, 425–429. [Google Scholar]

- Brady, R.F. A fracture mechanical analysis of fouling release from nontoxic antifouling coatings. Prog. Org. Coat. 2001, 43, 188–192. [Google Scholar] [CrossRef]

- Kulik, V.M. Boundary conditions on a compliant wall in the turbulent flow. Thermophys. Aeromech. 2013, 20, 435–439. [Google Scholar] [CrossRef]

- Kulik, V.M.; Rodyakin, S.V.; Lee, I.; Chun, H.H. Deformation of a viscoelastic coating under the action of convective pressure pulsation. Thermophys. Aeromech. 2004, 11, 1–12. [Google Scholar]

- Kulik, V.M. Action of a turbulent flow on a hard compliant coating. Int. J. Heat Fluid Flow 2012, 33, 232–241. [Google Scholar] [CrossRef]

- Chaudhury, M.K.; Weaver, T.; Hui, C.Y.; Kramer, E.J. Adhesive contact of cylindrical lens and a flat sheet. J. Appl. Phys. 1996, 80, 30–37. [Google Scholar] [CrossRef]

- Griffith, A.A. The phenomena of rupture and flow in solids. Philos. Trans. R. Soc. London 1921, 221, 163–198. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, H.; Bing, W.; Tian, L.; Wang, P.; Zhao, J. Combined Effects of Color and Elastic Modulus on Antifouling Performance: A Study of Graphene Oxide/Silicone Rubber Composite Membranes. Materials 2019, 12, 2608. https://doi.org/10.3390/ma12162608

Jin H, Bing W, Tian L, Wang P, Zhao J. Combined Effects of Color and Elastic Modulus on Antifouling Performance: A Study of Graphene Oxide/Silicone Rubber Composite Membranes. Materials. 2019; 12(16):2608. https://doi.org/10.3390/ma12162608

Chicago/Turabian StyleJin, Huichao, Wei Bing, Limei Tian, Peng Wang, and Jie Zhao. 2019. "Combined Effects of Color and Elastic Modulus on Antifouling Performance: A Study of Graphene Oxide/Silicone Rubber Composite Membranes" Materials 12, no. 16: 2608. https://doi.org/10.3390/ma12162608