One-Bath Pretreatment for Enhancing the Color Yield and Anti-Static Properties of Inkjet Printed Polyester Using Disperse Inks

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of P[St-BA-F6] Latex

2.3. Latex Characterization

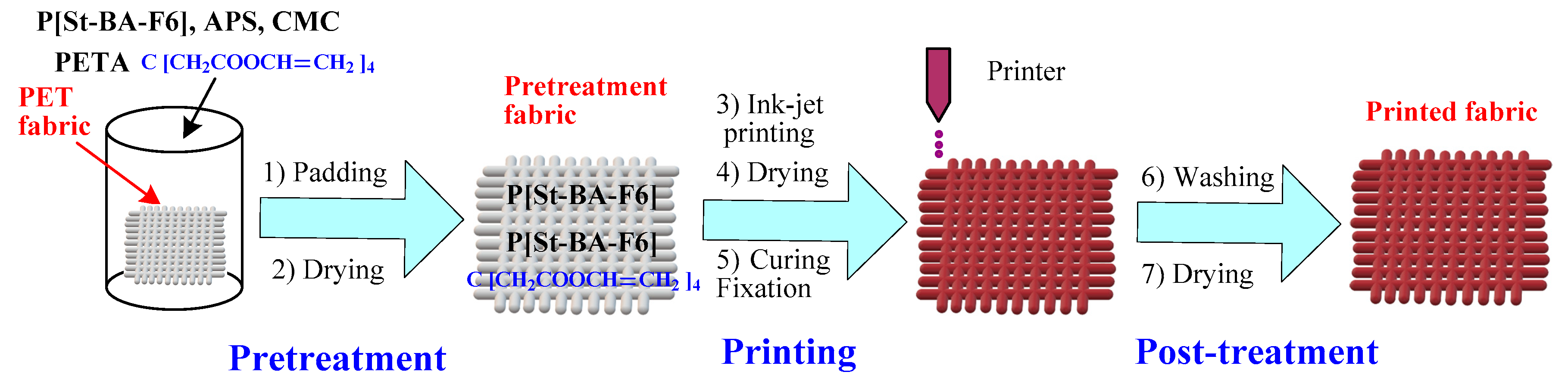

2.4. P[St-BA-F6] Latex Pretreatment and Printing of PET Fabric

3. Results

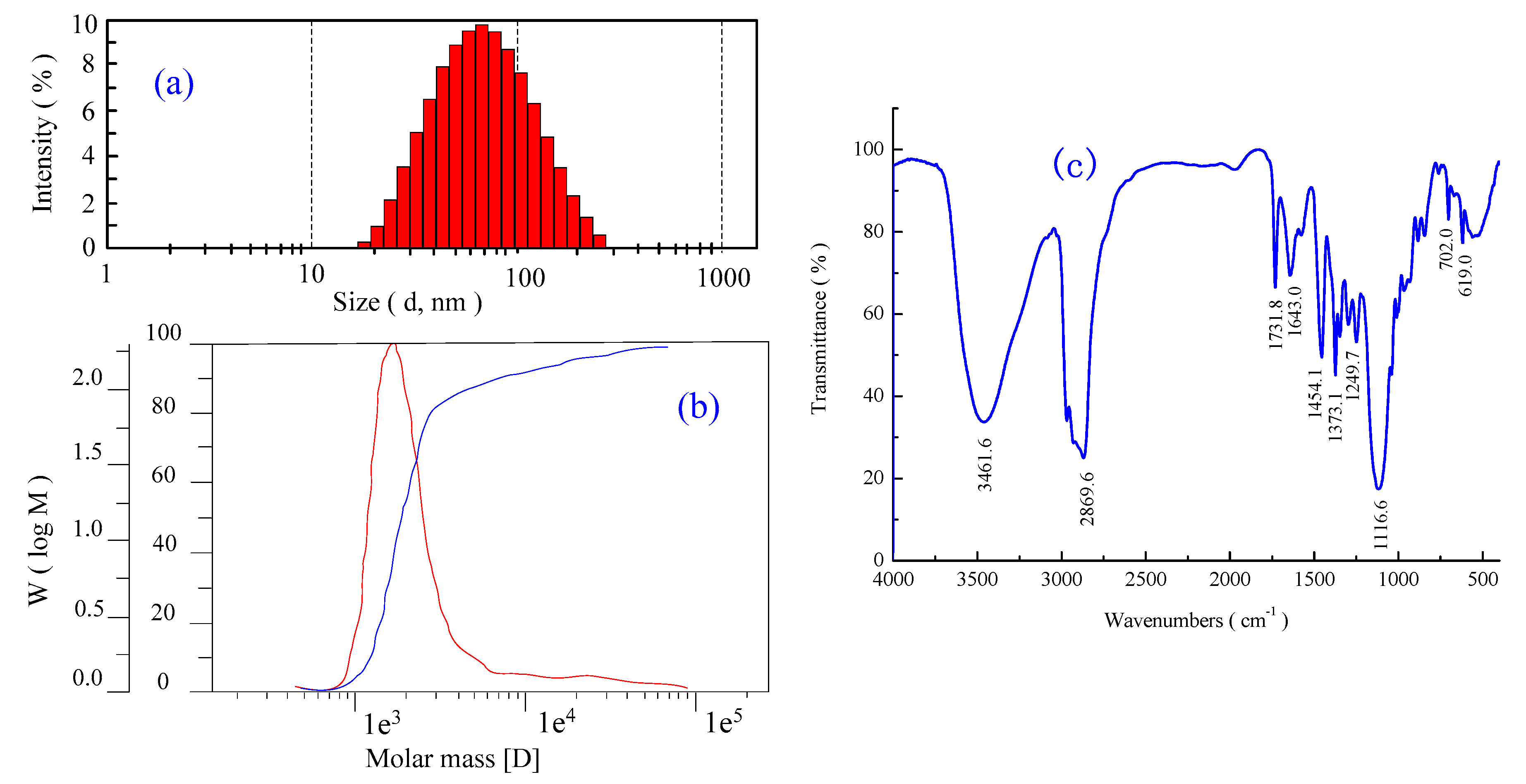

3.1. Structure Characteristic of P[St-BA-F6] Latex Particle

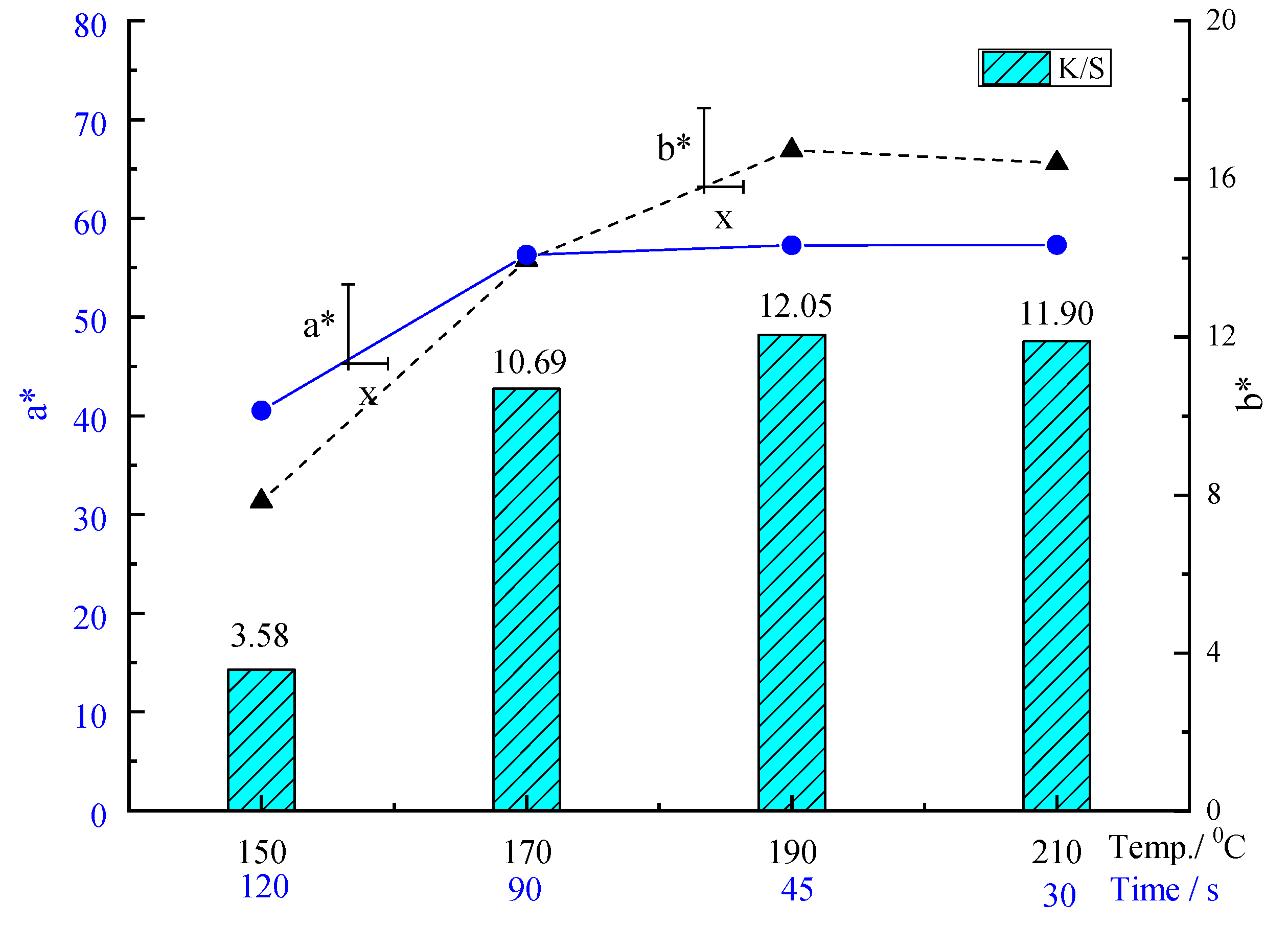

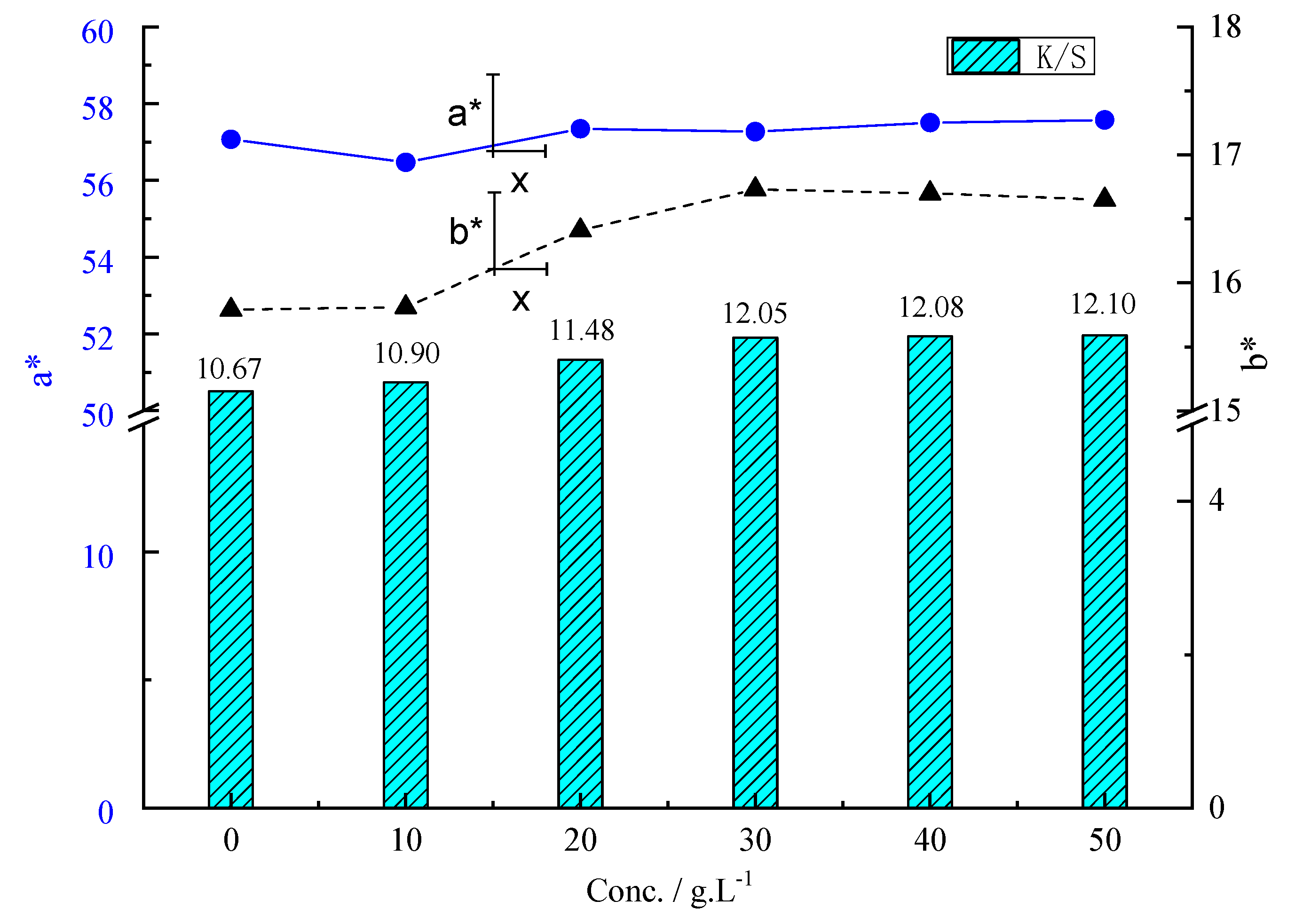

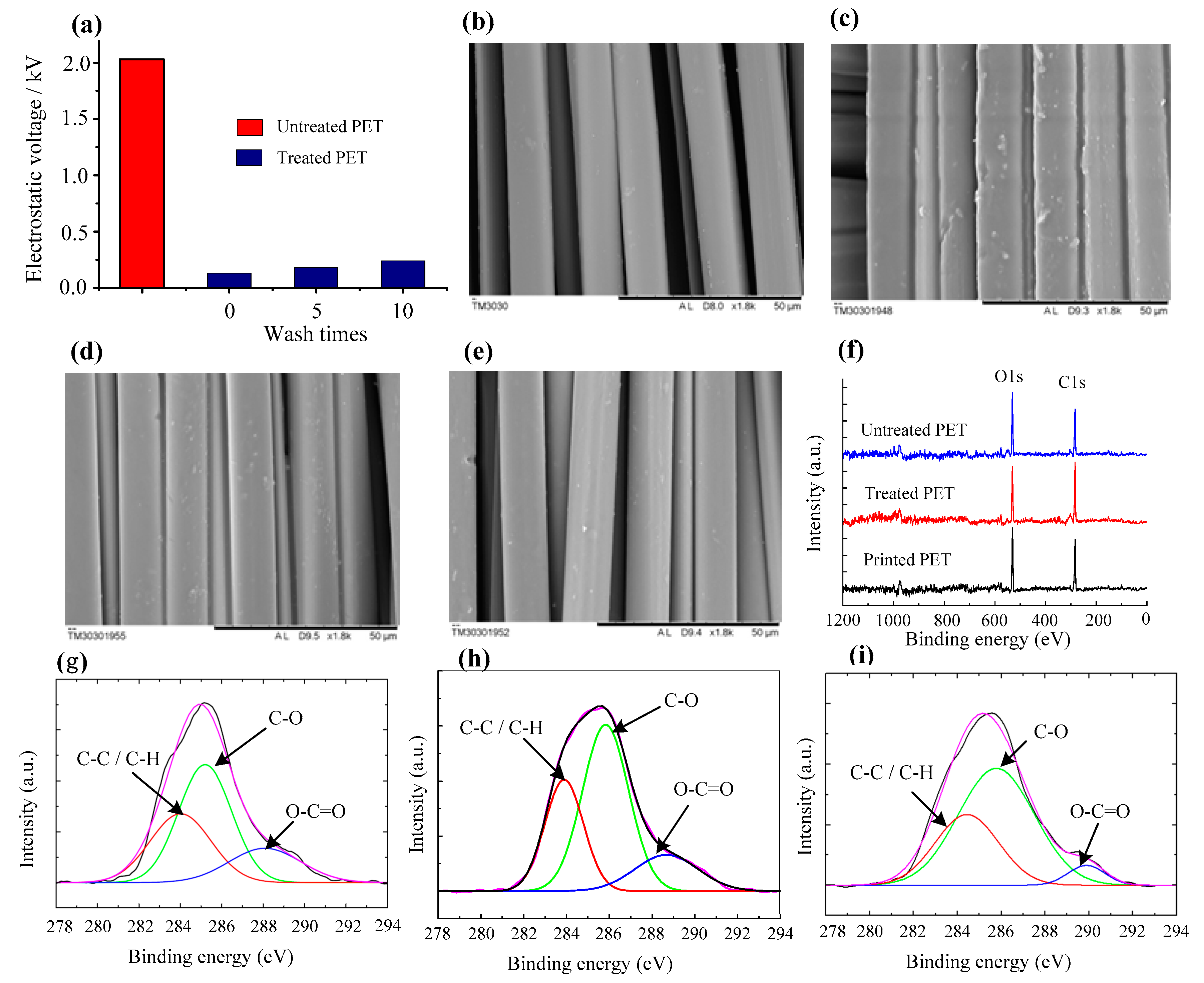

3.2. Effect of P[St-BA-F6]-Treated Fabric on Color Yield and Electrostatic Properties

3.3. Thermal Behavior on Untreated and Treated Fabrics

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhao, Y.; Li, M.; Zhang, L.P.; Tian, A.L.; Zhang, Y.; Fu, S.H. Influence of diffusion behavior of disperse dye ink on printing accuracy for warp-knitted polyester fabrics. Text. Res. J. 2019, 89, 162–171. [Google Scholar] [CrossRef]

- Hajipour, A.; Shams-Nateri, A. The effect of fabric density on the quality of digital printing on polyester. Fiber Polym. 2017, 18, 2462–2468. [Google Scholar] [CrossRef]

- Wang, C.Y.; Wang, C.X. Surface Pretreatment of Polyester Fabric for Ink Jet Printing with Radio Frequency O-2 Plasma. Fiber Polym. 2010, 11, 223–228. [Google Scholar] [CrossRef]

- Zhang, C.M.; Zhao, M.H.; Wang, L.B.; Qu, L.J.; Men, Y.J. Surface modification of polyester fabrics by atmospheric-pressure air/He plasma for color strength and adhesion enhancement. Appl. Surf. Sci. 2017, 400, 304–311. [Google Scholar] [CrossRef]

- Zhang, C.M.; Zhang, X.P. Nano-modification of plasma treated inkjet printing fabrics. Int. J. Cloth. Sci. Technol. 2015, 27, 159–169. [Google Scholar] [CrossRef]

- Zhang, C.M.; Zhao, M.H.; Wang, L.B.; Yu, M. Effect of atmospheric-pressure air/He plasma on the surface properties related to ink-jet printing polyester fabric. Vacuum 2017, 137, 42–48. [Google Scholar] [CrossRef]

- Ma, C.Q.; Zhao, S.L.; Huang, G. Anti-static charge character of the plasma treated polyester filter fabric. J. Electrostat. 2010, 68, 111–115. [Google Scholar] [CrossRef]

- Noppakundilograt, S.; Buranagul, P.; Graisuwan, W.; Koopipat, C.; Kiatkamjornwong, S. Modified chitosan pretreatment of polyester fabric for printing by ink jet ink. Carbohyd. Polym. 2010, 82, 1124–1135. [Google Scholar] [CrossRef]

- Bu, G.J.; Wang, C.X.; Fu, S.H.; Tian, A.L. Water-soluble cationic chitosan derivative to improve pigment-based inkjet printing and antibacterial properties for cellulose substrates. J. Appl. Polym. Sci. 2012, 125, 1674–1680. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, S.Y. Surface modification of PET film and fabric by oligo-chitosan treatment. Fiber Polym. 2014, 15, 2489–2494. [Google Scholar] [CrossRef]

- Eser, B.; Ozguney, A.T.; Ozerdem, A. Investigation of the usage of different thickening agents in ink-jet printing with reactive dyes. Ind. Text. 2012, 63, 85–90. [Google Scholar]

- Karim, M.N.; Afroj, S.; Rigout, M.; Yeates, S.G.; Carr, C. Towards UV-curable inkjet printing of biodegradable poly (lactic acid) fabrics. J. Mater. Sci. 2015, 50, 4576–4585. [Google Scholar] [CrossRef] [Green Version]

- Kan, C.W.; Yuen, C.W.M.; Tsoi, W.Y. Using atmospheric pressure plasma for enhancing the deposition of printing paste on cotton fabric for digital ink-jet printing. Cellulose 2011, 18, 827–839. [Google Scholar] [CrossRef]

- Chen, S.G.; Zhang, S.B.; Galluzzi, M.; Li, F.; Zhang, X.C.; Yang, X.H.; Liu, X.Y.; Cai, X.H.; Zhu, X.L.; Du, B.; et al. Insight into multifunctional polyester fabrics finished by one-step eco-friendly strategy. Chem. Eng. J. 2019, 358, 634–642. [Google Scholar] [CrossRef]

- Chaudhary, H.; Gupta, D.; Gupta, C. Multifunctional dyeing and finishing of polyester with Sericin and Basic dyes. J. Text. I 2017, 108, 314–324. [Google Scholar] [CrossRef]

- Castillo, G.A.; Wilson, L.; Efimenko, K.; Dickey, M.D.; Gorman, C.B.; Genzer, J. Amidation of Polyesters Is Slow in Nonaqueous Solvents: Efficient Amidation of Poly(ethylene terephthalate) with 3-Aminopropyltriethoxysilane in Water for Generating Multifunctional Surfaces. ACS Appl. Mater. Inter. 2016, 8, 35641–35649. [Google Scholar] [CrossRef]

- Lv, J.; Zhou, Q.; Liu, G.; Gao, D.; Wang, C. Preparation and properties of polyester fabrics grafted with O-carboxymethyl chitosan. Carbohydr. Polym. 2014, 113, 344–352. [Google Scholar] [CrossRef]

- Drobota, M.; Persin, Z.; Zemljic, L.F.; Mohan, T.; Stana-Kleinschek, K.; Doliska, A.; Bracic, M.; Ribitsch, V.; Harabagiu, V.; Coseri, S. Chemical modification and characterization of poly(ethylene terephthalate) surfaces for collagen immobilization. Cent. Eur. J. Chem. 2013, 11, 1786–1798. [Google Scholar] [CrossRef]

- Karim, N.; Afroj, S.; Malandraki, A.; Butterworth, S.; Beach, C.; Rigout, M.; Novoselov, K.S.; Casson, A.J.; Yeates, S.G. All inkjet-printed graphene-based conductive patterns for wearable e-textile applications. J. Mater. Chem. C 2017, 5, 11640–11648. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim, N.A.; Eid, B.M.; Khalil, H.M.; Almetwally, A.A. A new approach for durable multifunctional coating of PET fabric. Appl. Surf. Sci. 2018, 448, 95–103. [Google Scholar] [CrossRef]

- Wang, C.; Guo, R.H.; Lan, J.W.; Tan, L.; Jiang, S.X.; Xiang, C. Preparation of multi-functional fabric via silver/reduced graphene oxide coating with poly(diallyldimethylammonium chloride) modification. J. Mater. Sci. Mater. Electron. 2018, 29, 8010–8019. [Google Scholar] [CrossRef]

- Karim, N.; Afroj, S.; Tan, S.; Novoselov, K.S.; Yeates, S.G. All inkjet-printed graphene-silver composite inks for highly conductive wearable E-textiles applications. Appl. Phys. 2019, 9, 8035. [Google Scholar] [CrossRef]

- Kugimoto, Y.; Wakabayashi, A.; Dobashi, T.; Ohnishi, O.; Doi, T.K.; Kurokawa, S. Preparation and characterization of composite coatings containing a quaternary ammonium salt as an anti-static agent. Prog. Org. Coat. 2016, 92, 80–84. [Google Scholar] [CrossRef]

- Afroj, S.; Karim, N.; Wang, Z.; Tan, S.; He, P.; Holwill, M.; Ghazaryan, D.; Fernando, A.; Novoselov, K.S. Engineering Graphene Flakes for Wearable Textile Sensors via Highly Scalable and Ultrafast Yarn Dyeing Technique. ACS Nano 2019, 13, 3847–3857. [Google Scholar] [CrossRef]

- Yan, J.; Yang, Y.W.; Ma, L.; Gan, M.Y.; Li, X. Synthesis and electrochemical properties of poly(2,3-dimethylaniline)/polyaniline composites. Polym. Compos. 2015, 36, 1541–1545. [Google Scholar] [CrossRef]

- Olmos, D.; Martin, E.V.; Gonzalez-Benito, J. New molecular-scale information on polystyrene dynamics in PS and PS-BaTiO3 composites from FTIR spectroscopy. Phys. Chem. Chem. Phys. 2014, 16, 24339–24349. [Google Scholar] [CrossRef]

- Masson, J.F.; Pelletier, L.; Collins, P. Rapid FTIR method for quantification of styrene-butadiene type copolymers in bitumen. J. Appl. Polym. Sci. 2001, 79, 1034–1041. [Google Scholar] [CrossRef]

- Qin, L.J.; Qiu, J.H.; Liu, M.Z.; Ding, S.L.; Shao, L.A.; Lu, S.Y.; Zhang, G.H.; Zhao, Y.; Fu, X. Mechanical and thermal properties of poly(lactic acid) composites with rice straw fiber modified by poly(butyl acrylate). Chem. Eng. J. 2011, 166, 772–778. [Google Scholar] [CrossRef]

- Wang, H.Y.; Liu, Y.W.; Sun, B.; Huang, S.J.; Tian, J.F. Aging Behavior of the Polyether Polyurethane Films Irradiated by UV. Adv. Mater. Res. 2013, 748, 16–21. [Google Scholar] [CrossRef]

- Xiao, S.; Xu, P.; Peng, Q.; Chen, J.; Huang, J.; Wang, F.; Noor, N. Layer-by-Layer Assembly of Polyelectrolyte Multilayer onto PET Fabric for Highly Tunable Dyeing with Water Soluble Dyestuffs. Polymers 2017, 9, 735. [Google Scholar] [CrossRef]

- Rezaei, F.; Dickey, M.D.; Bourham, M.; Hauser, P.J. Surface modification of PET film via a large area atmospheric pressure plasma: An optical analysis of the plasma and surface characterization of the polymer film. Surf. Coat. Technol. 2017, 309, 371–381. [Google Scholar] [CrossRef]

- Lu, Y.X.; Xue, L.L.; Li, F. Adhesion enhancement between electroless nickel and polyester fabric by a palladium-free process. Appl. Surf. Sci. 2011, 257, 3135–3139. [Google Scholar] [CrossRef]

| Functions | Reagent | Weight (g) |

|---|---|---|

| Anti-static agent | P[St-BA-F6] | 3.0 |

| Thickening agent | CMC | 0.6 |

| Penetrating agent | JFC | 0.1 |

| Cross-linking | PETA | 0.1 |

| Initiator | (NH4)2S2O8 | 0.02 |

| Solvent | H2O | 96.2 |

| Temp./Time | Electrostatic Voltage/kV | Static Half Period/s | ||

|---|---|---|---|---|

| Wash Times = 0 | Wash Times = 10 | Wash Times = 0 | Wash Times = 10 | |

| 150 °C/120 s | 0.06 | 0.57 | 0.10 | 26.69 |

| 170 °C/90 s | 0.09 | 0.48 | 0.15 | 2.54 |

| 190 °C/45 s | 0.13 | 0.46 | 0.24 | 4.93 |

| 210 °C/30 s | 0.09 | 0.58 | 0.56 | 5.11 |

| Conc./g·L−1 | Electrostatic Voltage/kV | Static Half Period/s | ||

|---|---|---|---|---|

| Wash Times = 0 | Wash Times = 10 | Wash Times = 0 | Wash Times = 10 | |

| Untreated | 2.06 | - | >60 | - |

| 10 | 0.32 | 1.49 | 0.42 | 8.21 |

| 20 | 0.20 | 1.28 | 0.36 | 7.38 |

| 30 | 0.13 | 0.46 | 0.24 | 4.93 |

| 40 | 0.12 | 0.43 | 0.23 | 4.54 |

| 50 | 0.10 | 0.42 | 0.20 | 4.79 |

| Inks | Fabric | K/S | Dry Rubbing | Wet Rubbing |

|---|---|---|---|---|

| Cyan | untreated | 4.27 | 4 | 4–5 |

| treated | 5.35 | 4–5 | 4–5 | |

| Magenta | untreated | 4.15 | 4 | 4 |

| treated | 5.53 | 4–5 | 4 | |

| Yellow | untreated | 5.56 | 4–5 | 4–5 |

| treated | 7.81 | 4–5 | 4–5 | |

| Black | untreated | 10.85 | 4 | 4 |

| treated | 11.66 | 4–5 | 4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, H.; Ai, L.; Yang, Z.; Zhu, Y. One-Bath Pretreatment for Enhancing the Color Yield and Anti-Static Properties of Inkjet Printed Polyester Using Disperse Inks. Materials 2019, 12, 1820. https://doi.org/10.3390/ma12111820

Cao H, Ai L, Yang Z, Zhu Y. One-Bath Pretreatment for Enhancing the Color Yield and Anti-Static Properties of Inkjet Printed Polyester Using Disperse Inks. Materials. 2019; 12(11):1820. https://doi.org/10.3390/ma12111820

Chicago/Turabian StyleCao, Hongmei, Li Ai, Zhenming Yang, and Yawei Zhu. 2019. "One-Bath Pretreatment for Enhancing the Color Yield and Anti-Static Properties of Inkjet Printed Polyester Using Disperse Inks" Materials 12, no. 11: 1820. https://doi.org/10.3390/ma12111820