Experimental Study of Macro and Microgeometric Defects in Drilled Carbon Fiber Reinforced Plastics by Laser Beam Machining

Abstract

:1. Introduction

2. Materials and Methods

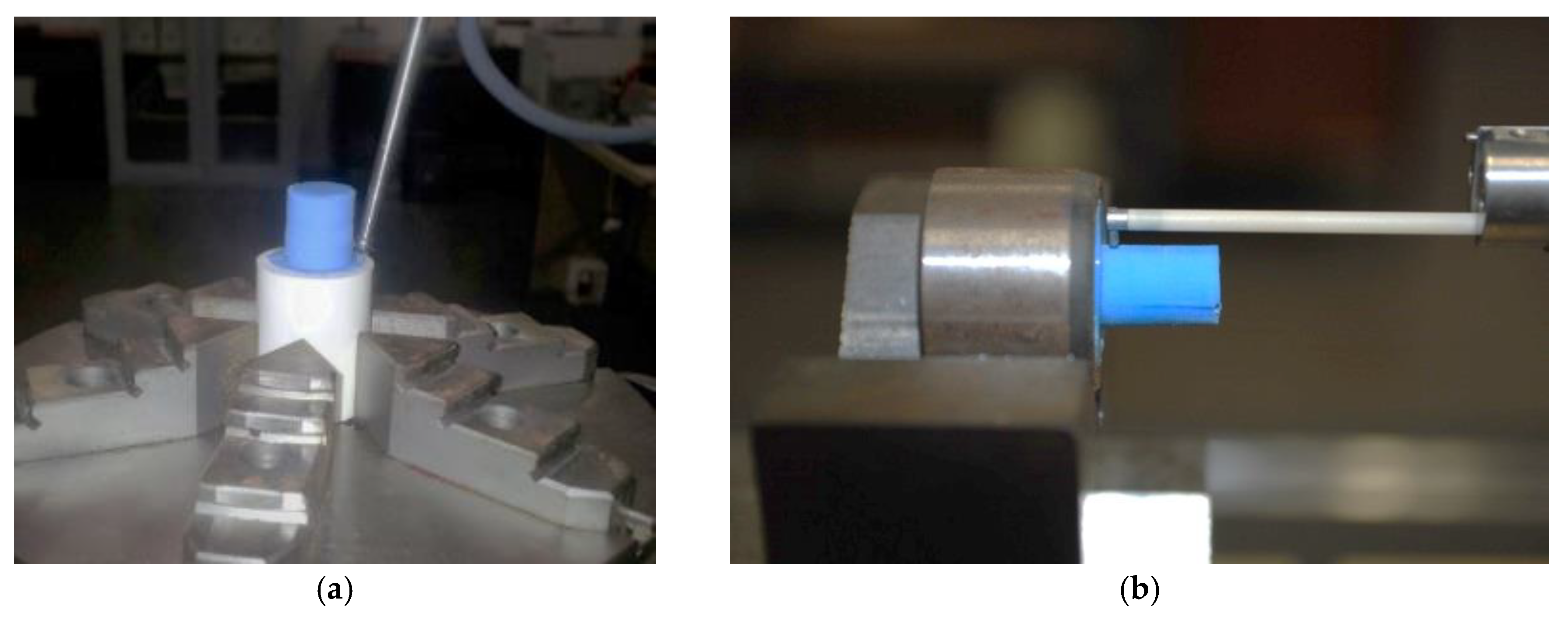

2.1. Experimental Procedure

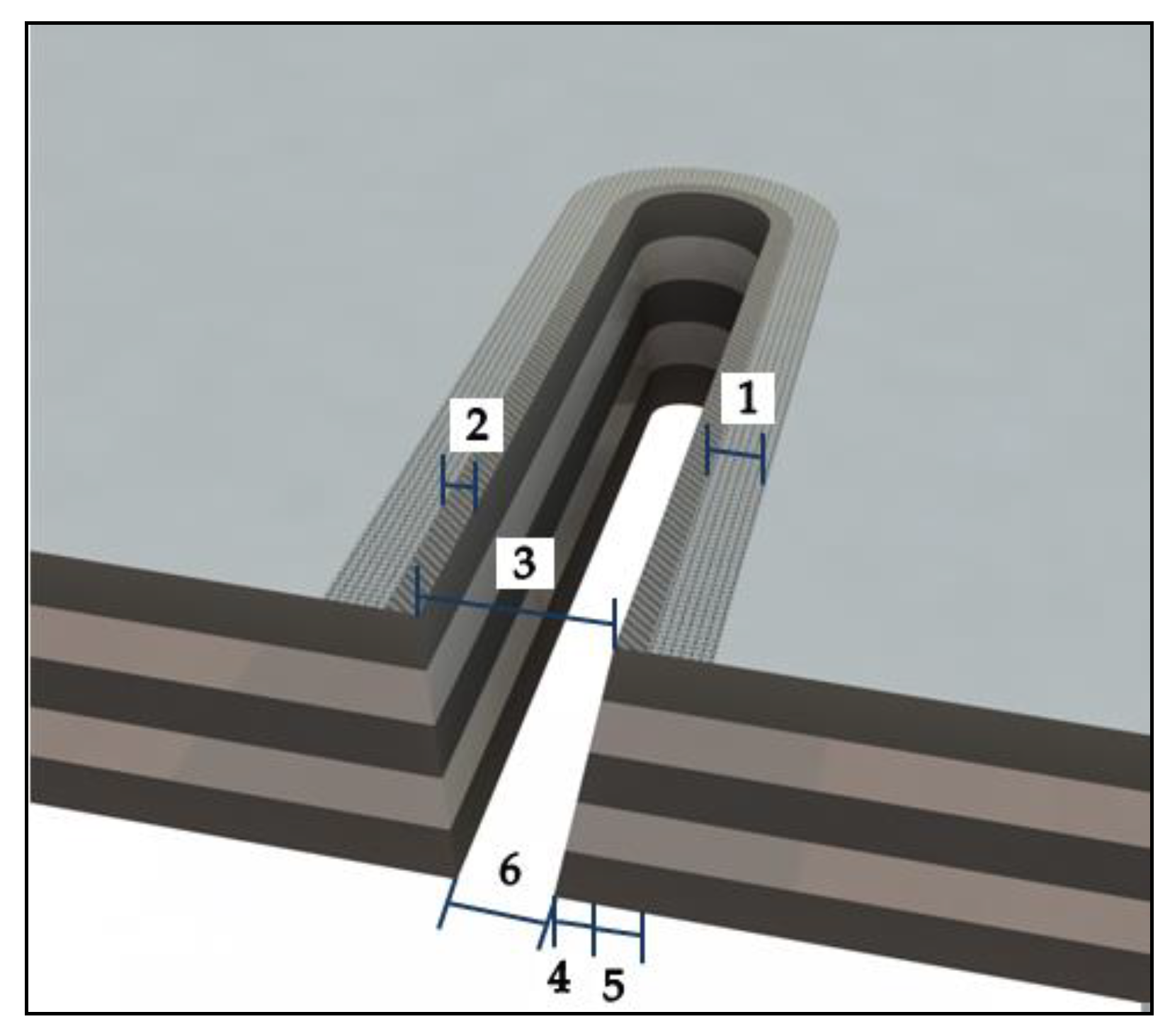

2.2. Macro and Micro-Geometrical Evaluation

2.3. SOM/SEM Evaluation

3. Results and Discussion

3.1. Results of the Analysis

3.2. Analysis of Macro and Micro-Geometrical Deviations

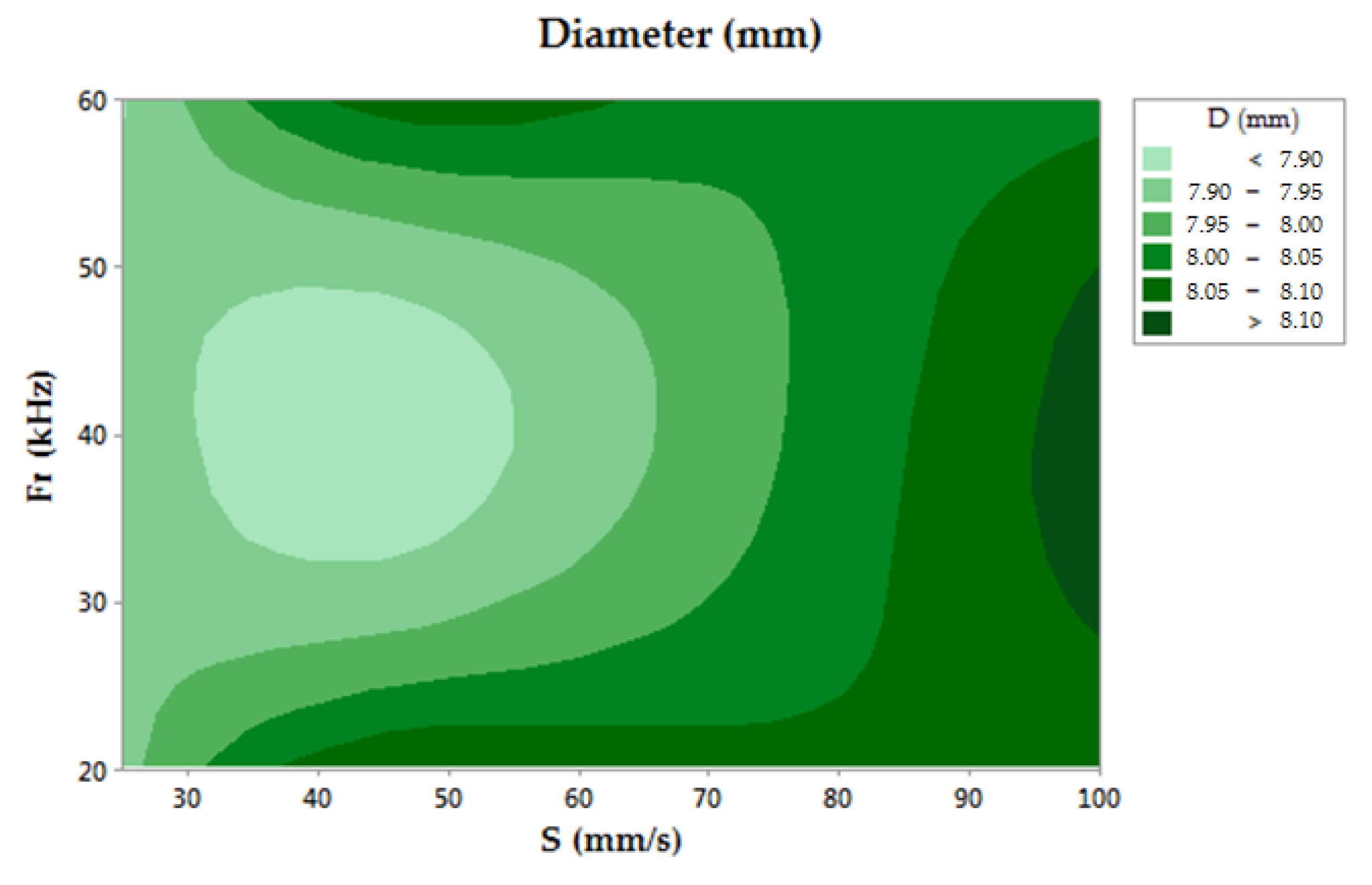

3.2.1. Diameter Evaluation

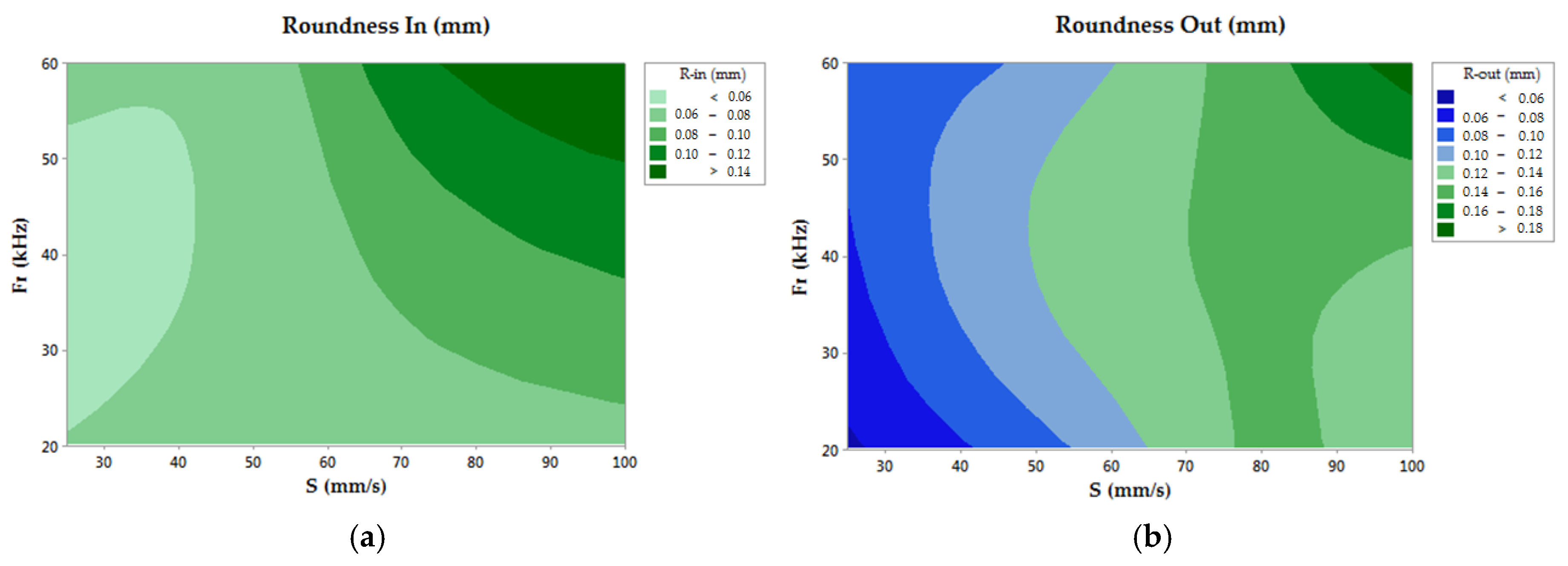

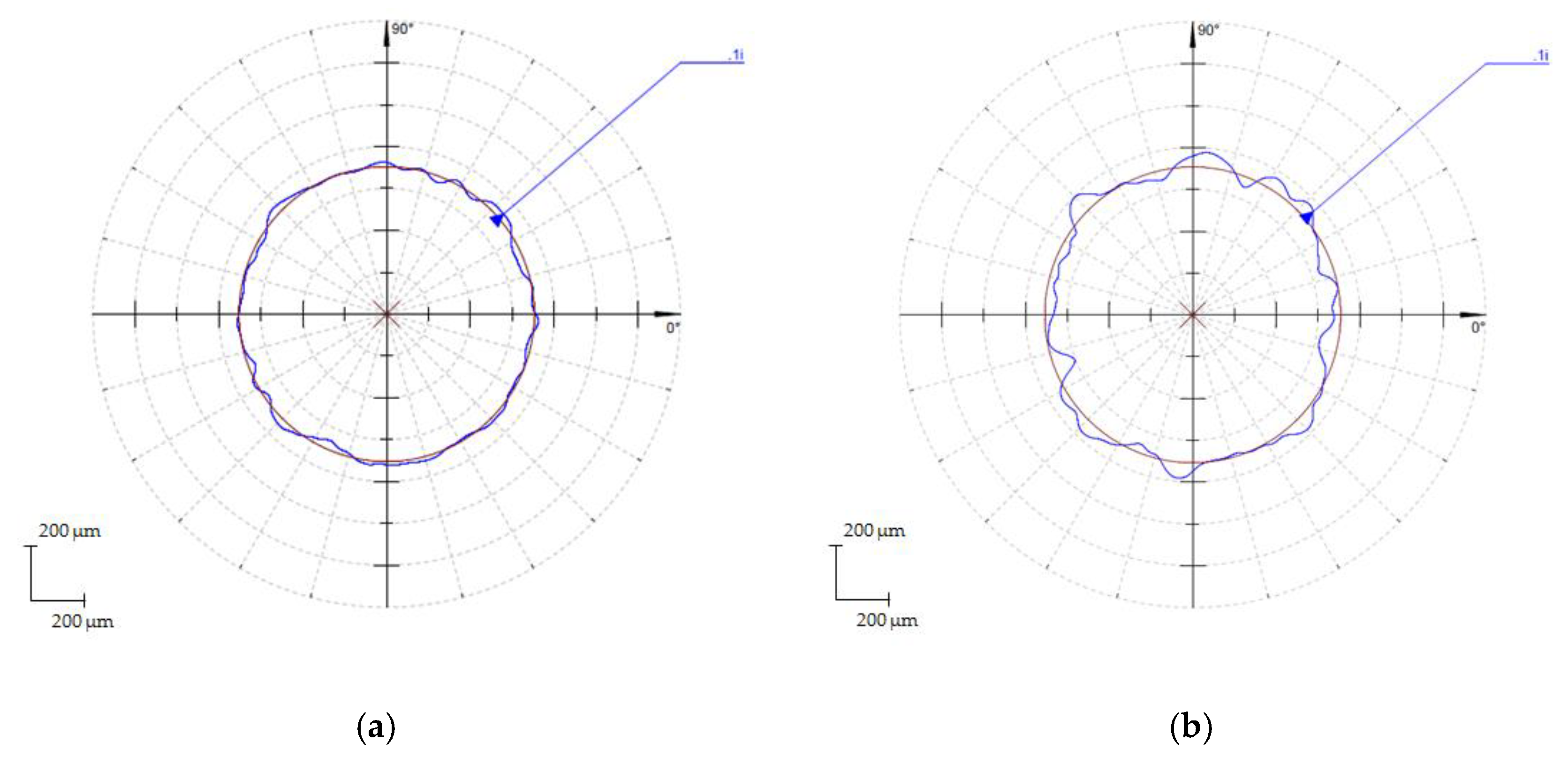

3.2.2. Roundness Evaluation

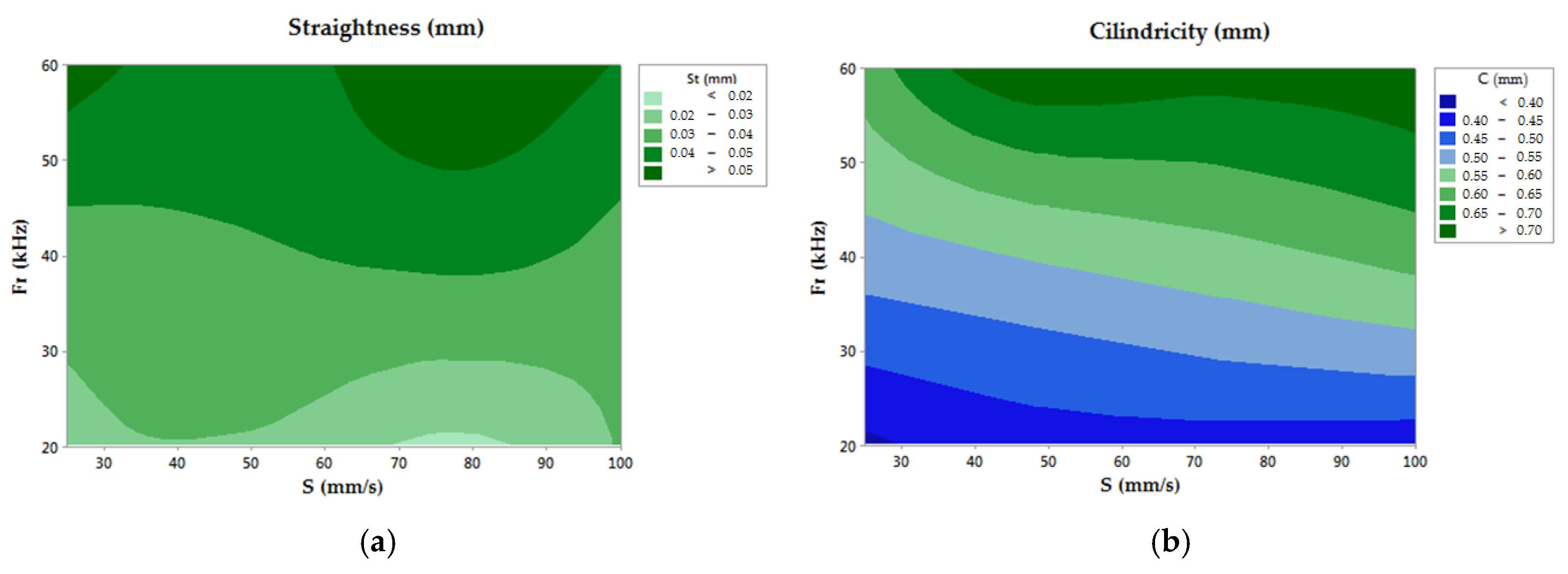

3.2.3. Straightness Evaluation

3.2.4. Cylindricity Evaluation

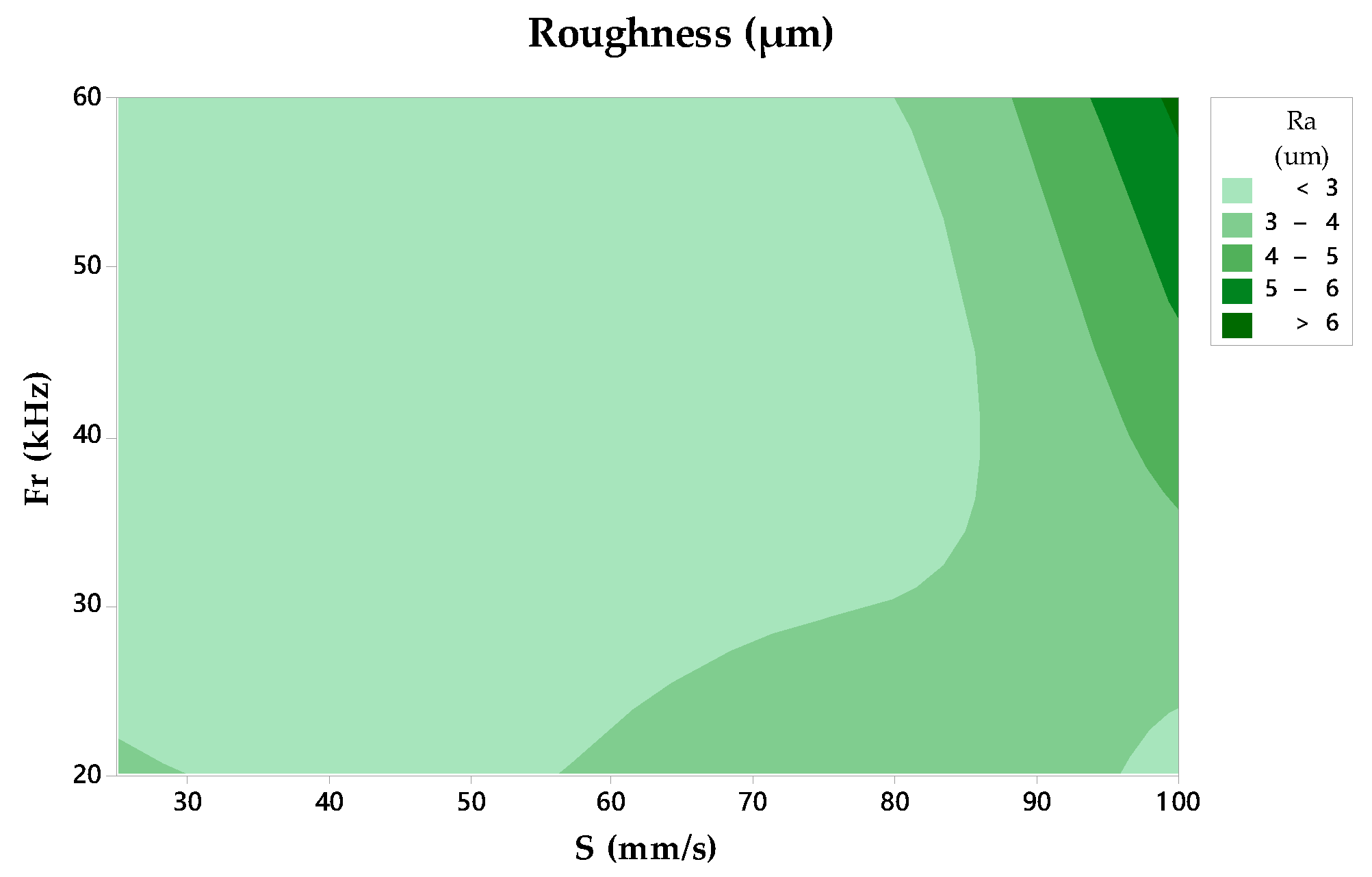

3.2.5. Surface Finish Evaluation

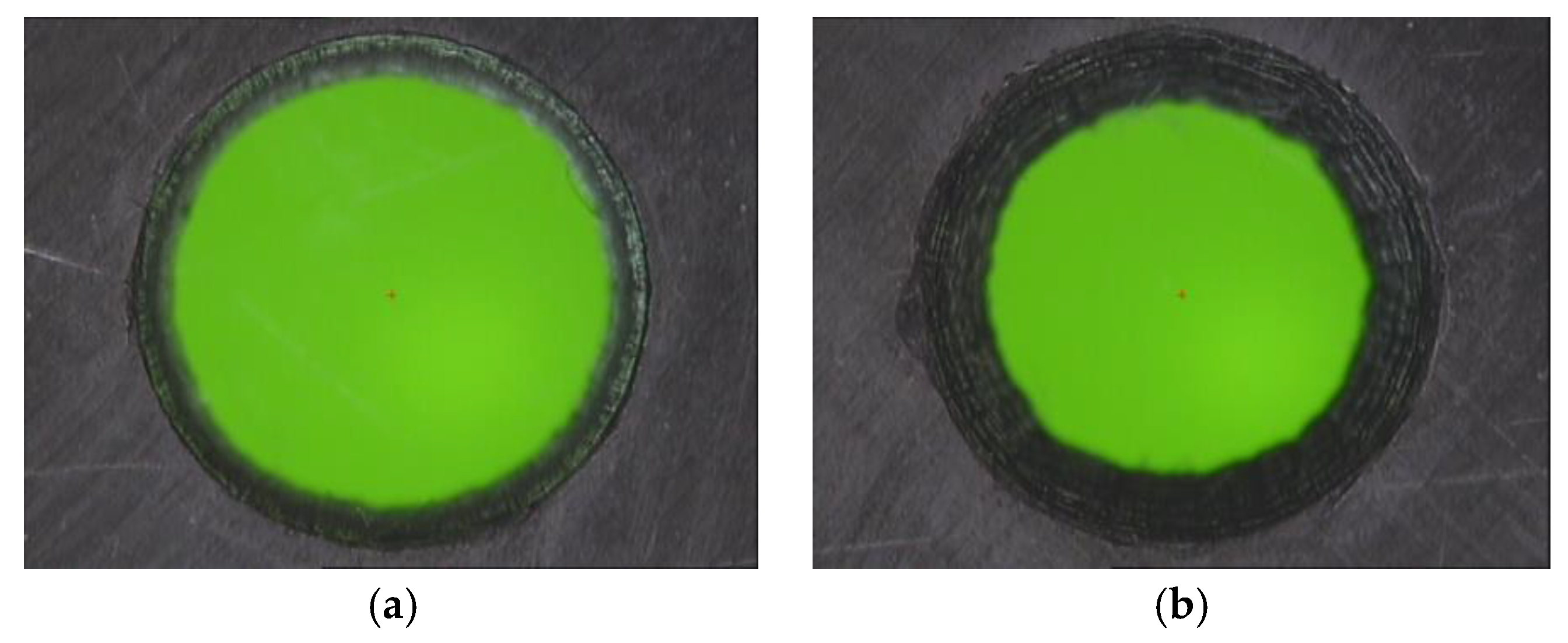

3.3. Damage and Defects Analysis on the Drilled Holes

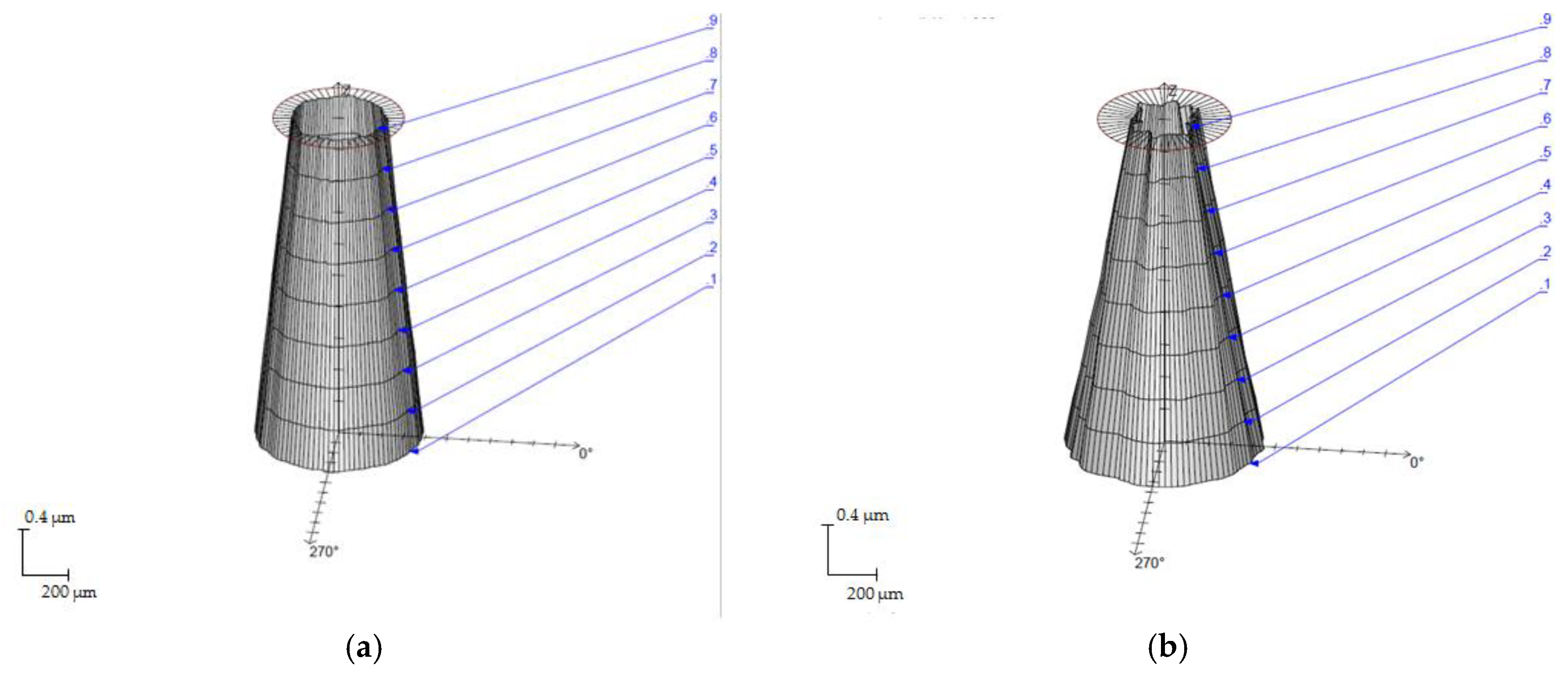

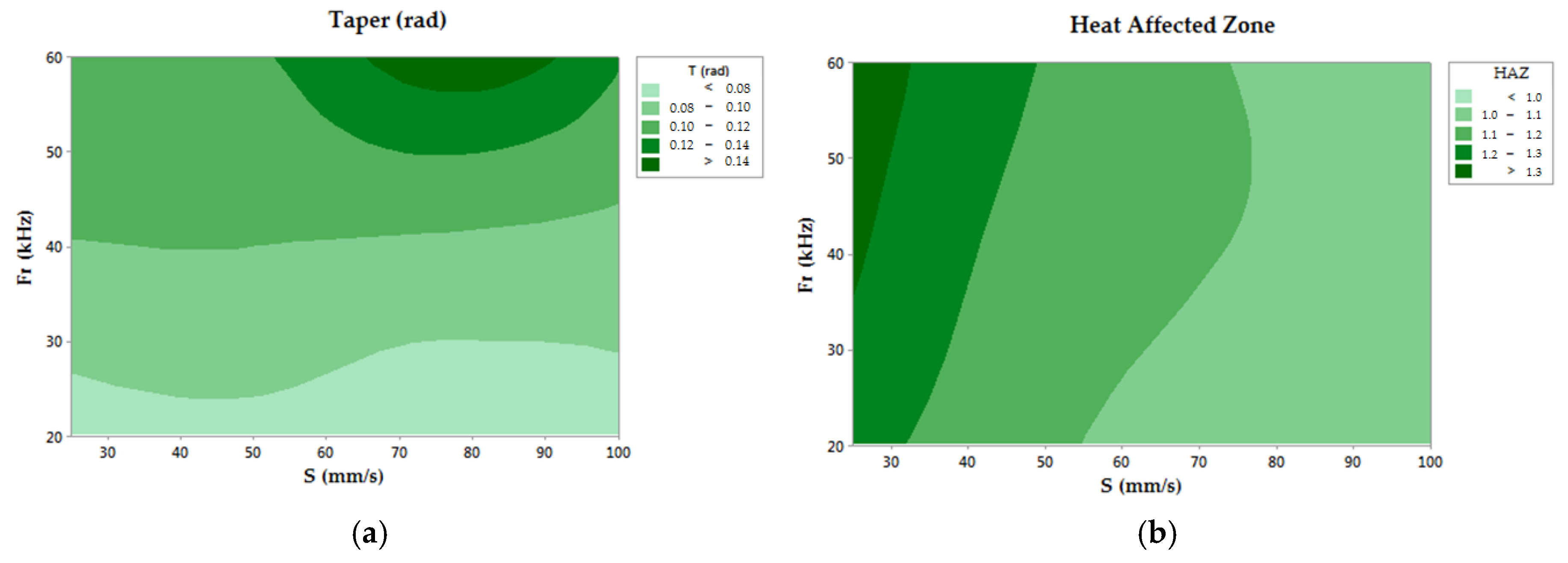

3.3.1. Taper Angle

3.3.2. Heat Affected Zone

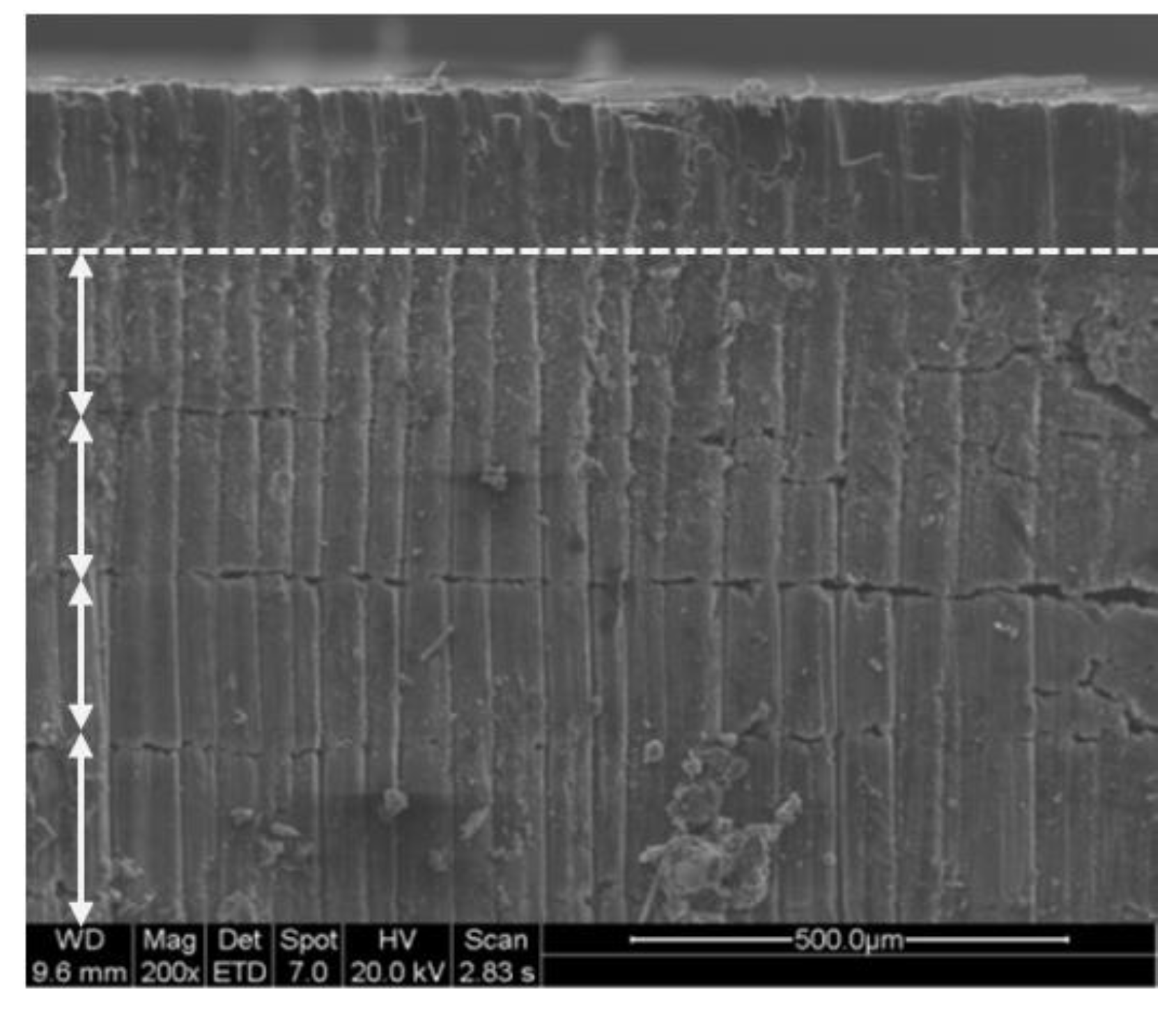

3.4. SEM Analysis

5. Conclusions

- The roundness measurements obtained at the inlet and outlet of the drill reveal that smaller dimensional deviations were obtained when selecting low scanning speeds and pulse frequencies. In addition, it was found that the deviation of the roundness at the exit is always greater (increasing in some tests up to 250%), mainly due to the influence of the focal distance.

- Pulsed frequency and scanning speed also affected straightness and cylindricity in a great depth, especially for the latter. The straightness deviation decreased with frequency and the deviation of cylindricity presented higher values relating to the taper defect, especially when the pulsed frequency was increased.

- The roughness of the drilled holes did not seem to have a significant relationship with the parameters evaluated. However, reduced scanning speeds had better surface quality values. Specifically, for S = 20 mm/s, measurements of about 2 μm were obtained. Roughness values were considered low compared to those obtained through other machining processes.

- The taper angle was closely related to the frequency and affected by the speed of scanning, where an increase in the energy of the pulse decreased the appearance of the defect. The minimum value of the angle was obtained in trial 1 with 0.069 rad. However, this drill presented high damage caused by temperature.

- This study showed the direct influence of the parameters proposed in the experiment. However, the scanning speed determined the appearance of defects in the surface of the material. In this study, no damage was recorded when selecting high speeds and low pulse frequencies (S = 100 mm/s and Fr = 20 kHz).

- Similar to the evaluation of the surface finish, the influence of the cutting parameters in the evaluation of the diameter could not be clearly stated with this test. However, the selection of reduced scanning speeds seemed to offer a higher dimensional accuracy of the hole.

- SEM analysis detected characteristic defects associated with the laser machining of composites on the hole’s surface. Thus, charring localization, absence of matrix, and deposition of matrix remains on it was recorded. These defects occurred due to the high temperatures produced during the process.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Soo-Jin, P. Carbon Fibers, 1st ed.; Springer: New York, NY, USA, 2014. [Google Scholar]

- Antar, M.; Chantzis, D.; Marimuthu, S.; Hayward, P. High speed EDM and laser drilling of aerospace alloys. Procedia CIRP 2016, 42, 526–531. [Google Scholar] [CrossRef]

- Liu, D.F.; Tang, Y.J.; Cong, W.L. A review of mechanical drilling for composite laminates. Compos. Struct. 2012, 94, 1265–1279. [Google Scholar] [CrossRef]

- Madhavan, V.; Lipczynski, G.; Lane, B.; Whitenton, E. Fiber orientation angle effects in machining of unidirectional CFRP laminated composites. J. Manuf. Process. 2015, 20, 431–442. [Google Scholar] [CrossRef]

- Li, M.J.; Soo, S.L.; Aspinwall, D.K.; Pearson, D.; Leahy, W. Influence of lay-up configuration and feed rate on surface integrity when drilling carbon fibre reinforced plastic (CFRP). Procedia CIRP 2014, 13, 399–404. [Google Scholar] [CrossRef]

- Feito, N.; Diáz-Álvarez, J.; Cantero, J.L.; Miguélez, M.H. Influence of special tool geometry in drilling woven CFRPs materials. Procedia Eng. 2015, 132, 632–638. [Google Scholar] [CrossRef]

- Tsao, C.C. Investigation into the effects of drilling parameters on delamination by various step-core drills. J. Mater. Process. Technol. 2008, 206, 405–411. [Google Scholar] [CrossRef]

- Teti, R. Machining of composite materials. CIRP Ann. Manuf. Technol. 2002, 51, 611–634. [Google Scholar] [CrossRef]

- Abrate, S.; Walton, D.A. Machining of composite materials. Part I: Traditional methods. Compos. Manuf. 1992, 3, 75–83. [Google Scholar] [CrossRef]

- König, W.; Wulf, C.; Grass, P.; Willerscheid, H. Machining of fibre reinforced plastics. Ann. CIRP 1985, 34, 537–548. [Google Scholar] [CrossRef]

- Lachaud, F.; Piquet, R.; Collombet, F.; Surcin, L. Drilling of composite structures. J. Compos. Struct. 2001, 52, 511–526. [Google Scholar] [CrossRef]

- Abrate, S.; Walton, D.A. Machining of composite materials. Part II: Non-traditional methods. Compos. Manuf. 1992, 3, 85–94. [Google Scholar] [CrossRef]

- Krishnaraj, V.; Zitoune, R.; Davim, J.P. Drilling of Polymer-Matrix Composites, 1st ed.; Springer: Heidelberg, Germany, 2013. [Google Scholar]

- Abrão, A.M.; Campos-Rubio, J.C.; Faria, P.E.; Davim, J.P. The effect of cutting tool geometry on thrust force and delamination when drilling glass fibre reinforced plastic composite. Mater. Des. 2008, 29, 508–513. [Google Scholar] [CrossRef]

- Wang, J. A machinability study of polymer matrix composites using abrasive waterjet cutting technology. J. Mater. Process. Technol. 1999, 94, 30–35. [Google Scholar] [CrossRef]

- Rashed, C.A.; Romoli, L.; Tantussi, F.; Fuso, F.; Burgener, M.; Cusanelli, G. Water jet guided laser as an alternative to EDM for micro-drilling of fuel injector nozzles: A comparison of machined surfaces. J. Manuf. Process. 2013, 15, 524–532. [Google Scholar] [CrossRef]

- Phadnis, V.A.; Roy, A.; Silberschmidt, V.V. A finite element model of ultrasonically assisted drilling in carbon/epoxy composites. Procedia CIRP 2013, 8, 141–146. [Google Scholar] [CrossRef]

- Hejjaji, A.; Singh, D.; Kubber, S.; Kalyanasundaram, D.; Gururaja, S. Machining damage in FRPs: Laser versus conventional drilling. Compos. Part A Appl. Sci. Manuf. 2016, 82, 42–52. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettere, C. The influence of stitching and unconventional fibres orientation on the tensile properties of CFRP laminates. Compos. Part B 2017, 110, 248–254. [Google Scholar] [CrossRef]

- Dubey, A.K.; Yadava, V. Laser beam machining—A review. Int. J. Mach. Tools Manuf. 2008, 48, 609–628. [Google Scholar] [CrossRef]

- Mishra, S.; Yadava, V. Laser beam micromachining (LBMM)–A review. Opt. Lasers Eng. 2015, 73, 89–122. [Google Scholar] [CrossRef]

- Wang, H.J.; Lin, H.; Wang, C.Y.; Zheng, L.J.; Hu, X.Y. Laser drilling of structural ceramics—A review. J. Eur. Ceram. Soc. 2017, 37, 1157–1173. [Google Scholar] [CrossRef]

- Arrizubieta, I.; Lamikiz, A.; Martínez, S.; Ukar, E.; Tabernero, I.; Girot, F. Internal characterization and hole formation mechanism in the laser percussion drilling process. Int. J. Mach. Tools Manuf. 2013, 75, 55–62. [Google Scholar] [CrossRef]

- Cena, A.A.; Mathew, P. Analysis and prediction of laser cutting parameters of fibre reinforced plastics (FRP) composite materials. Int. J. Mach. Tools Manuf. 2002, 42, 105–113. [Google Scholar] [CrossRef]

- Cenna, A.A.; Mathew, P. Evaluation of cut quality of fibre-reinforced plastics—A review. Int. J. Mach. Tools Manuf. 1997, 37, 723–736. [Google Scholar] [CrossRef]

- Goeke, A.; Emmelmann, C. Influence of laser cutting parameters on CFRP part quality. Phys. Procedia. 2010, 5, 253–258. [Google Scholar] [CrossRef]

- Saini, S.K.; Dubey, A.K.; Upadhyay, B.N.; Choubey, A. Study of hole characteristics in laser trepan drilling of ZTA. Opt. Laser Technol. 2018, 103, 330–339. [Google Scholar] [CrossRef]

- Tagliaferri, F.; Leopardi, G.; Semmler, U.; Kuhl, M.; Palumbo, B. Study of the influences of laser parameters on laser assisted machining processes. Procedia CIRP 2013, 8, 170–175. [Google Scholar] [CrossRef]

- Choudhury, I.A.; Chuan, P.C. Experimental evaluation of laser cut quality of glass fibre reinforced plastic composite. Opt. Lasers Eng. 2013, 51, 1125–1132. [Google Scholar] [CrossRef]

- Wonsuk, C.; Hoon-Young, K.; Jin-Woo, J.; Won-Seok, C.; Sun-Hak, C. Vibration-assisted femtosecond Laser drilling with controllable taper angles for AMOLED fine metal mask fabrication. Materials 2017, 10, 212. [Google Scholar]

- Caprino, G.; Tagliaferri, V. Maximum cutting speed in laser cutting of fiber reinforced plastics. Int. J. Mach. Tools Manuf. 1988, 28, 389–398. [Google Scholar] [CrossRef]

- Klotzbach, A.; Hauser, M.; Beyer, E. Laser cutting of carbon fiber reinforced polymers using highly brilliant laser beam sources. Phys. Procedia 2011, 12, 572–577. [Google Scholar] [CrossRef]

- Leone, C.; Genna, S.; Tagliaferri, V. Fibre laser cutting of CFRP thin sheets by multi-passes scan technique. Opt. Lasers Eng. 2014, 53, 43–50. [Google Scholar] [CrossRef]

- Matthams, T.J.; Clyne, T.W. Mechanical properties of long-fibre thermoplastic composites with laser drilled microperforations: Effect of perforations in consolidated material. Compos. Sci. Technol. 1999, 59, 1169–1180. [Google Scholar] [CrossRef]

- Sola, D.; Grima, L. Laser machining and in vitro assessment of wollastonite-tricalcium phosphate eutectic glasses and glass-ceramics. Materials 2018, 11, 125. [Google Scholar] [CrossRef] [PubMed]

- Pan, C.T.; Hocheng, H. The anisotropic heat-affected zone in the laser grooving of fiber-reinforced composite material. J. Mater. Process. Technol. 1996, 62, 54–60. [Google Scholar] [CrossRef]

- Di Ilio, A.; Tagliaferri, V. Thermal damage in laser cutting of (0/90)2s aramid/epoxy laminates. Composites 1989, 20, 115–119. [Google Scholar] [CrossRef]

- Voisey, K.T.; Fouquet, S.; Roy, D.; Clyne, T.W. Fibre swelling during laser drilling of carbon fibre composites. Opt. Lasers Eng. 2006, 44, 1185–1189. [Google Scholar] [CrossRef]

| Type of Material | Composition | Production Method | Technical Specification |

|---|---|---|---|

| Layers of unidirectional carbon fiber with epoxy resin matrix and a symmetrical stacking sequence of (0/90/45/-45/45/-45) | Intermediate module fiber (66%) and epoxy resin (34%) | Pre-preg and autoclaved at 458° ± 5° at a pressure of 0.69 MPa | AIMS-05-01-XXX |

| Parameter | Levels | |||

|---|---|---|---|---|

| S (mm/s) | 25 | 50 | 75 | 100 |

| Fr (kHz) | 20 | 40 | 60 | |

| Power (W) | Wavelength (nm) | Spot Diameter (µm) | Working Mode | Scanning Distribution | Atmosphere |

|---|---|---|---|---|---|

| 10 | 1062 | 60 | Pulsed | Shaded | Environment |

| Test | S (mm/s) | Fr (kHz) | D (mm) | DIn (mm) | DOut (mm) | St (mm) | C (mm) | Ra (µm) | T (rad) | HAZ |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 25 | 20 | 7.934 | 0.041 | 0.057 | 0.028 | 0.388 | 3.15 | 0.069 | 1.233 |

| 2 | 25 | 40 | 7.929 | 0.035 | 0.077 | 0.036 | 0.524 | 2.20 | 0.099 | 1.314 |

| 3 | 25 | 60 | 7.896 | 0.045 | 0.084 | 0.056 | 0.622 | 2.38 | 0.118 | 1.355 |

| 4 | 50 | 20 | 8.103 | 0.046 | 0.092 | 0.029 | 0.430 | 2.84 | 0.074 | 1.119 |

| 5 | 50 | 40 | 7.878 | 0.043 | 0.121 | 0.039 | 0.556 | 2.39 | 0.100 | 1.160 |

| 6 | 50 | 60 | 8.081 | 0.045 | 0.105 | 0.045 | 0.722 | 2.80 | 0.118 | 1.194 |

| 7 | 75 | 20 | 8.066 | 0.046 | 0.138 | 0.018 | 0.429 | 3.78 | 0.070 | 1.031 |

| 8 | 75 | 40 | 7.996 | 0.055 | 0.142 | 0.042 | 0.583 | 2.50 | 0.097 | 1.096 |

| 9 | 75 | 60 | 8.024 | 0.070 | 0.144 | 0.057 | 0.719 | 2.76 | 0.152 | 1.097 |

| 10 | 100 | 20 | 8.048 | 0.047 | 0.123 | 0.031 | 0.418 | 2.68 | 0.070 | 1.000 1 |

| 11 | 100 | 40 | 8.127 | 0.062 | 0.138 | 0.037 | 0.616 | 4.37 | 0.094 | 1.049 |

| 12 | 100 | 60 | 8.032 | 0.079 | 0.192 | 0.049 | 0.729 | 6.22 | 0.122 | 1.049 |

| S | Fr | ||||

|---|---|---|---|---|---|

| Parameter | F-value | p-value | Parameter | F-value | p-value |

| D | 2.19 | 0.190 | D | 0.55 | 0.602 |

| R-In | 4.99 | 0.045 | R-In | 3.60 | 0.094 |

| R-Out | 12.80 | 0.005 | R-Out | 2.79 | 0.139 |

| St | 0.08 | 0.970 | St | 18.02 | 0.003 |

| C | 5.70 | 0.034 | C | 128.86 | 0.000 |

| Ra | 0.83 | 0.229 | Ra | 0.41 | 0.686 |

| T | 0.83 | 0.524 | T | 32.32 | 0.001 |

| HAZ | 143.19 | 0.000 | HAZ | 22.61 | 0.002 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mayuet Ares, P.F.; Vázquez Martínez, J.M.; Marcos Bárcena, M.; Gámez, A.J. Experimental Study of Macro and Microgeometric Defects in Drilled Carbon Fiber Reinforced Plastics by Laser Beam Machining. Materials 2018, 11, 1466. https://doi.org/10.3390/ma11081466

Mayuet Ares PF, Vázquez Martínez JM, Marcos Bárcena M, Gámez AJ. Experimental Study of Macro and Microgeometric Defects in Drilled Carbon Fiber Reinforced Plastics by Laser Beam Machining. Materials. 2018; 11(8):1466. https://doi.org/10.3390/ma11081466

Chicago/Turabian StyleMayuet Ares, Pedro F., Juan Manuel Vázquez Martínez, Mariano Marcos Bárcena, and Antonio J. Gámez. 2018. "Experimental Study of Macro and Microgeometric Defects in Drilled Carbon Fiber Reinforced Plastics by Laser Beam Machining" Materials 11, no. 8: 1466. https://doi.org/10.3390/ma11081466