Effect of Die Geometry on the Formability of 5052 Aluminum Alloy in Electromagnetic Impaction Deformation

Abstract

:1. Introduction

2. Material and Experiment Procedures

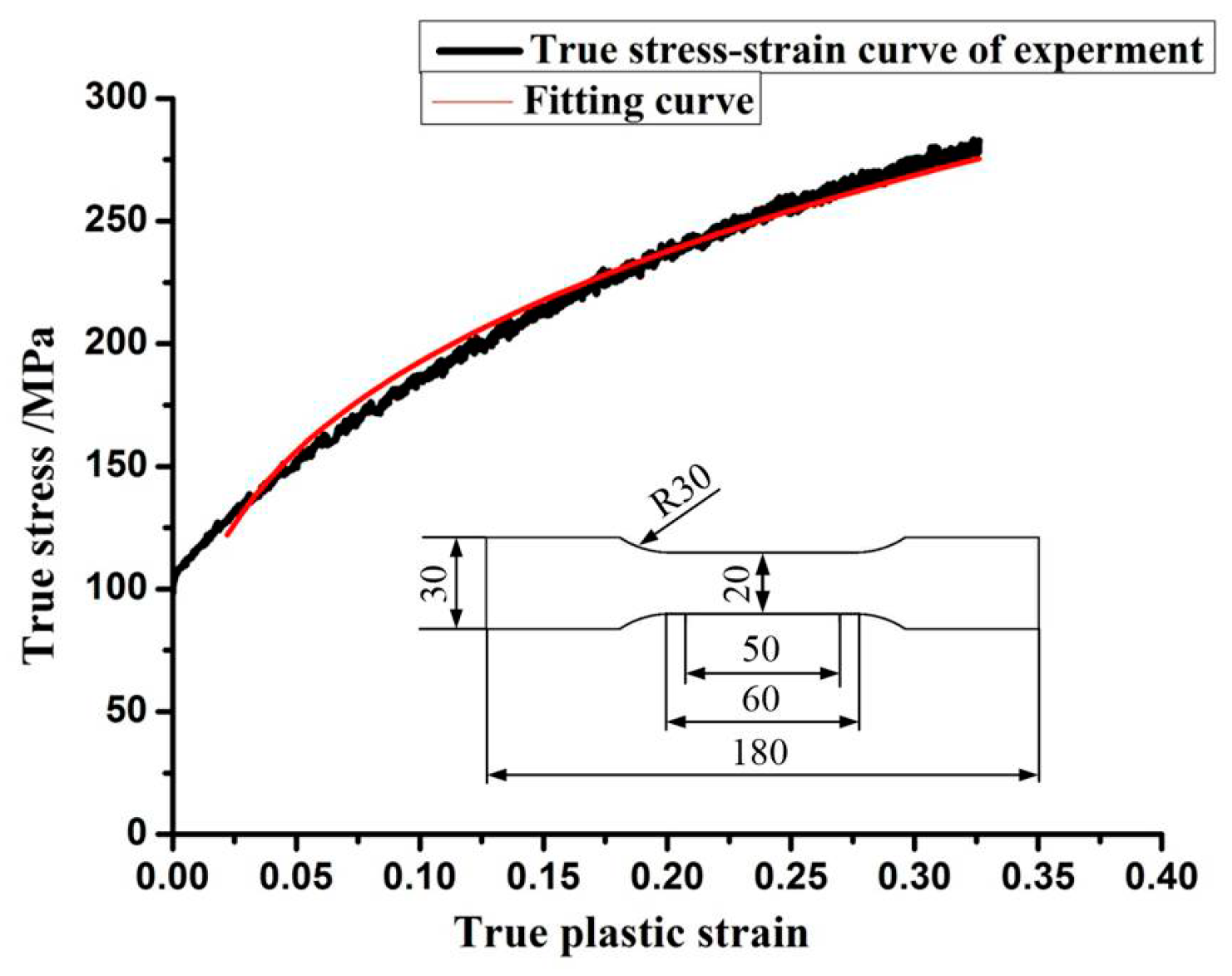

2.1. Material

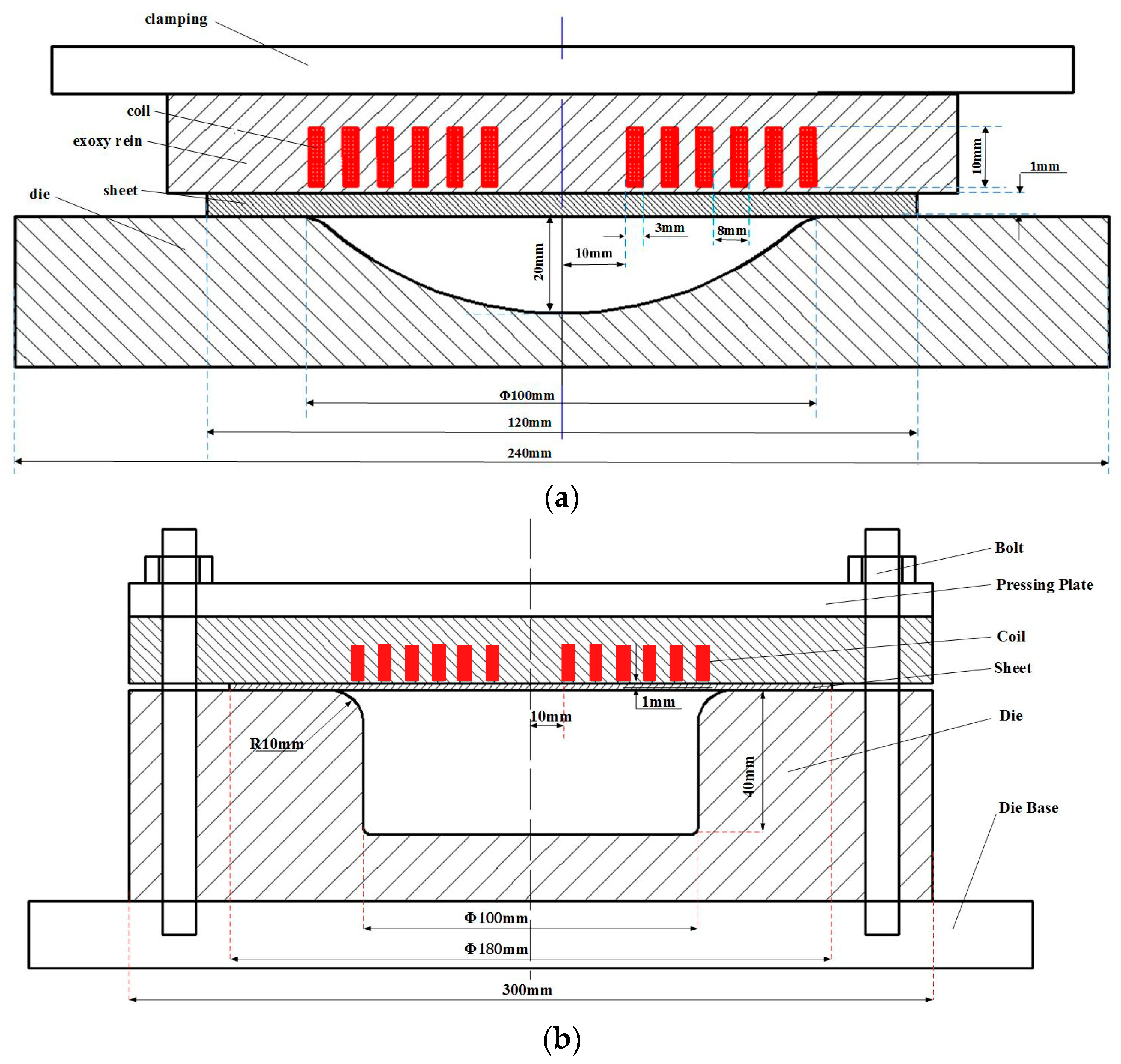

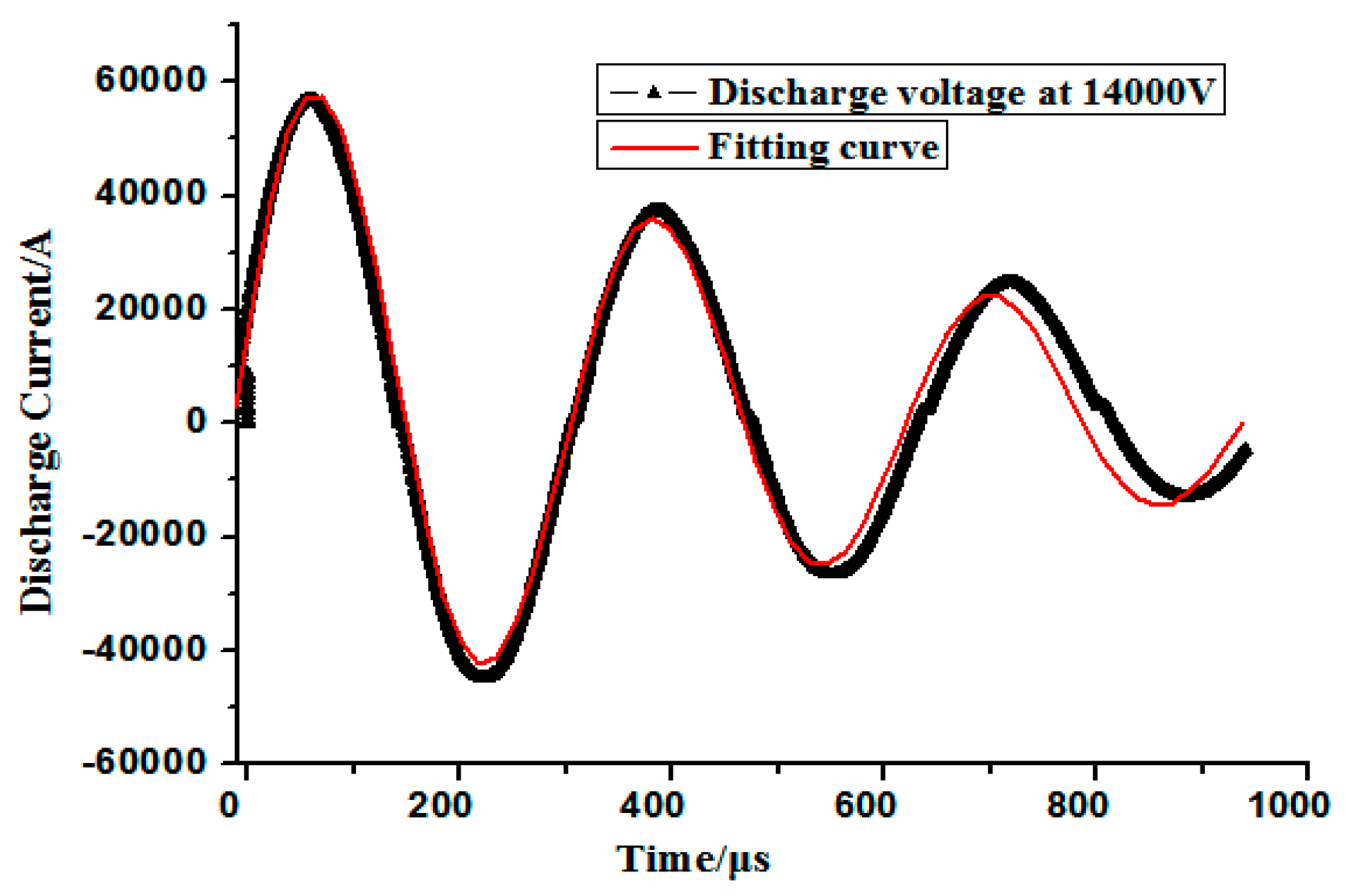

2.2. Electromagnetic Impaction Forming Experiments

3. Numerical Simulation

3.1. Magnetic Field Model

3.2. Constitutive Model

3.3. Finite Element Modeling of Electromagnetic High-Speed Impaction

4. Results and Discussion

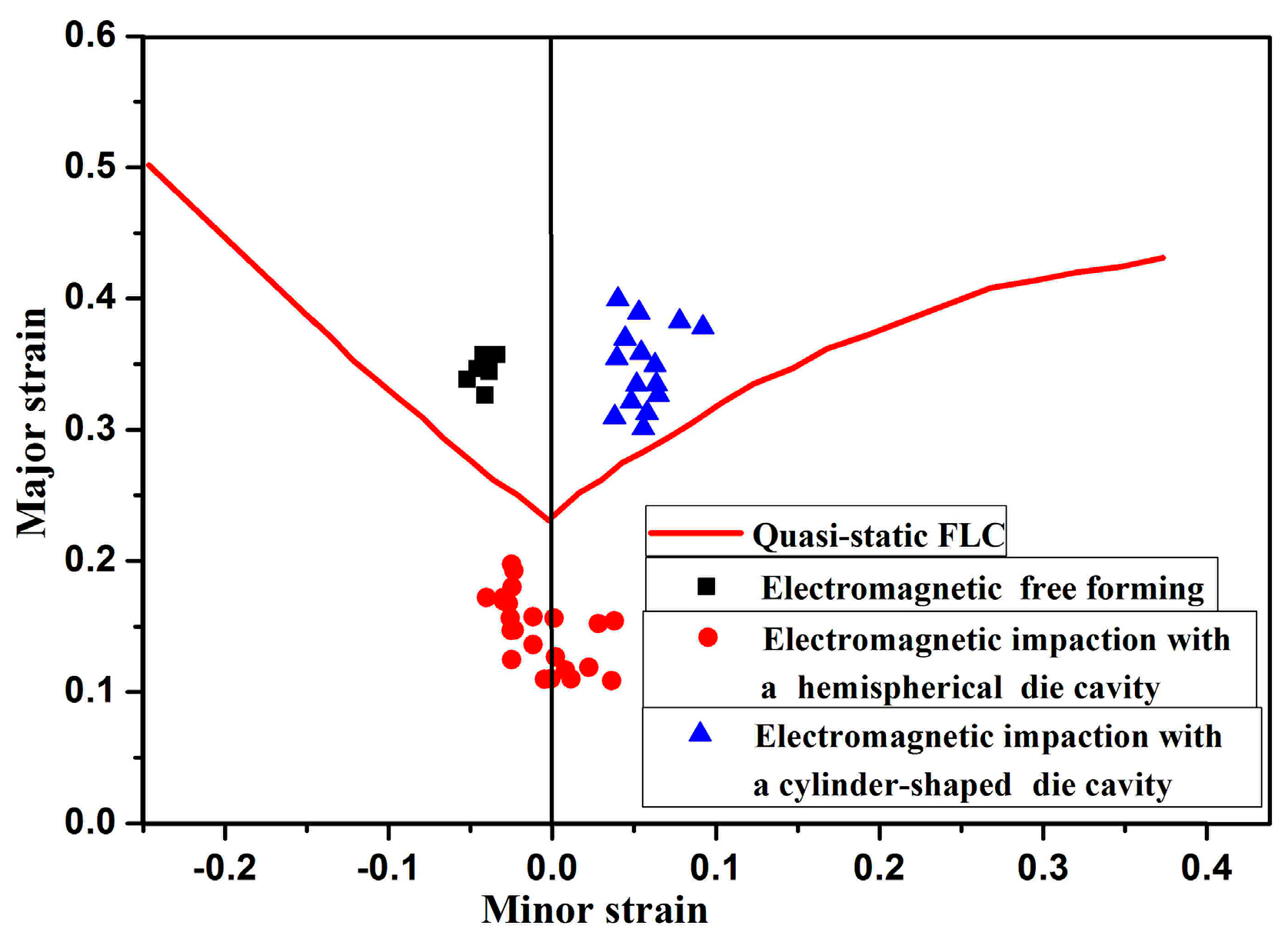

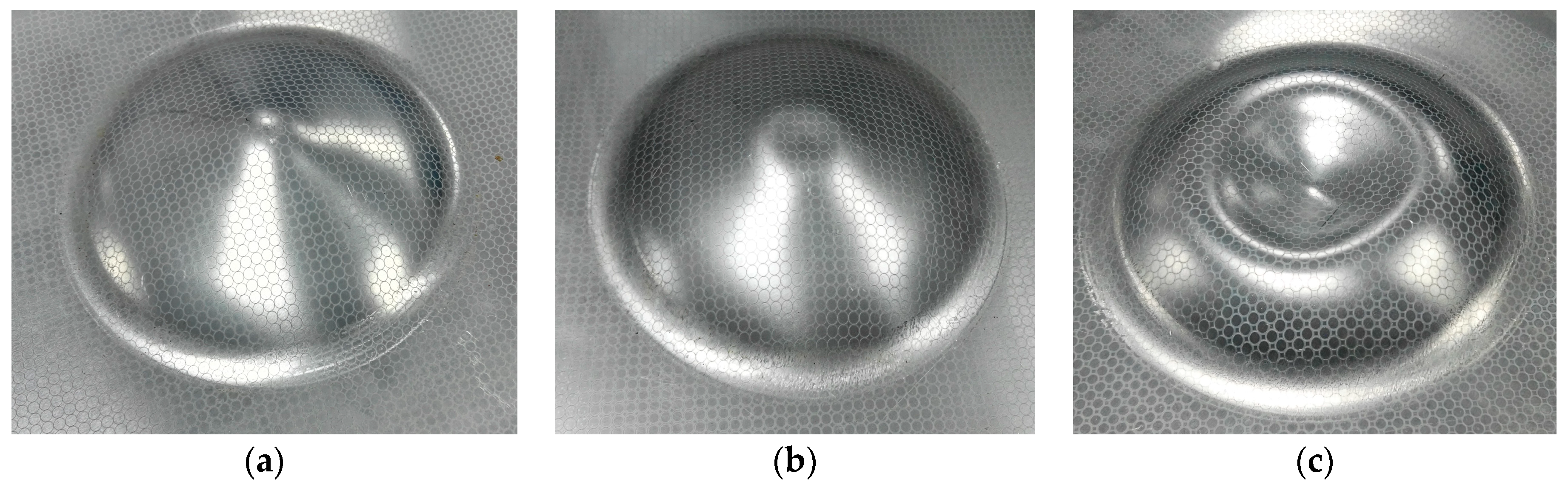

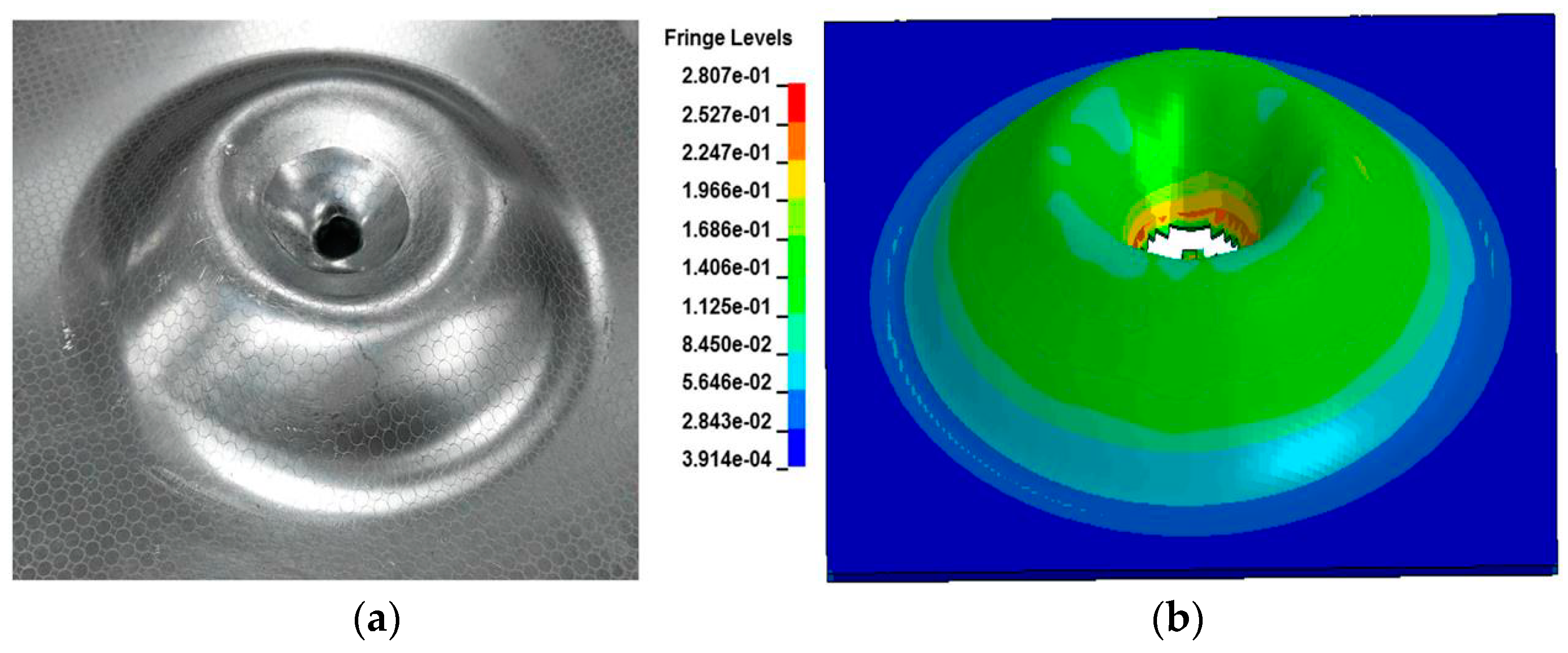

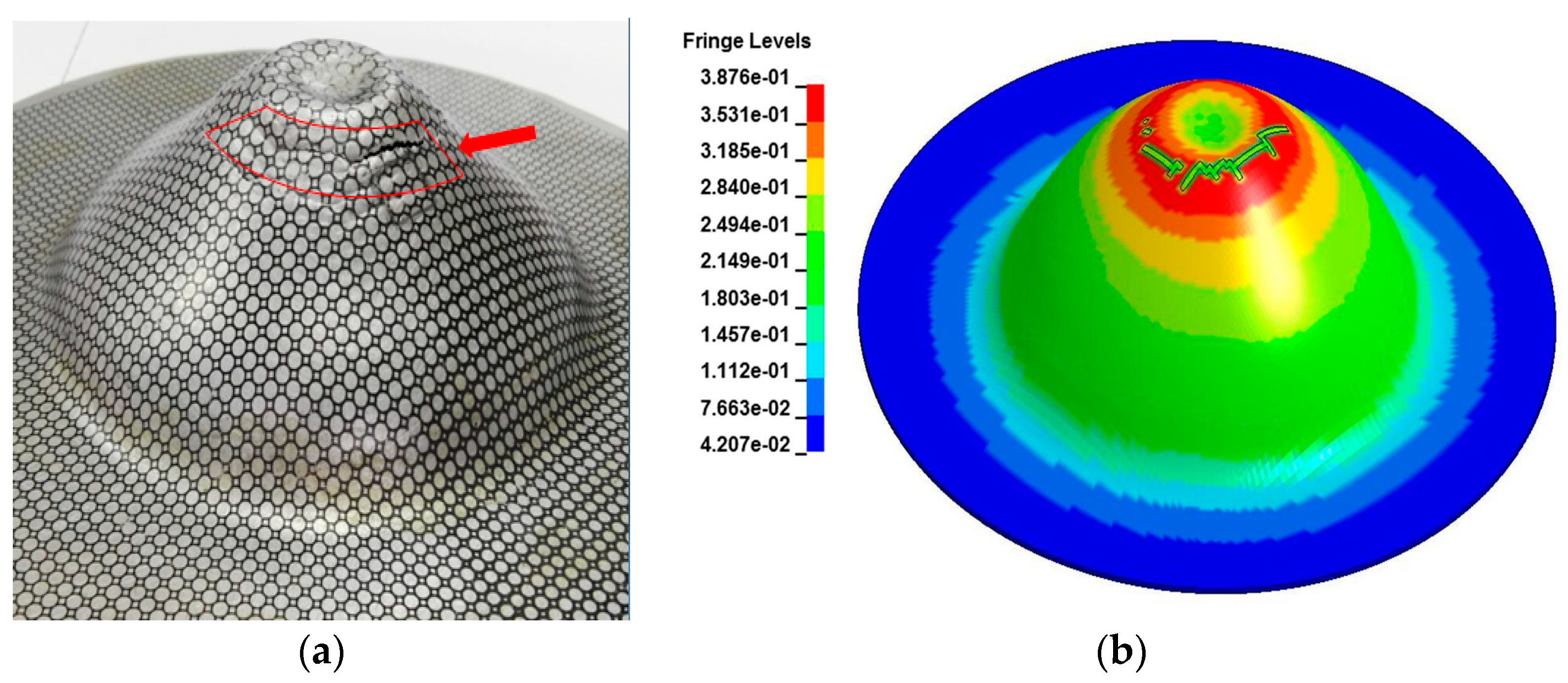

4.1. Forming Limits of 5052 Aluminum Alloy Formed Using Two Different Dies

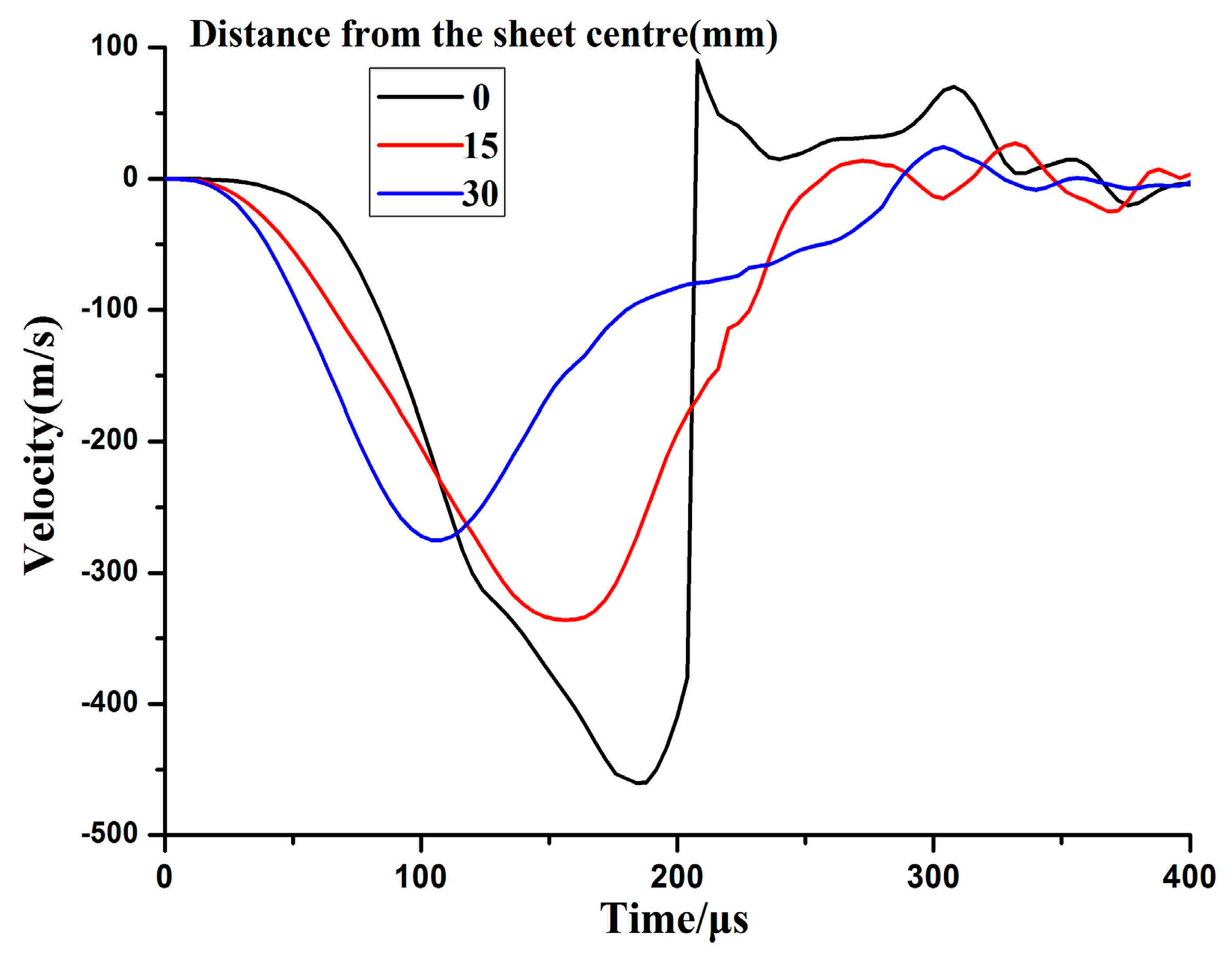

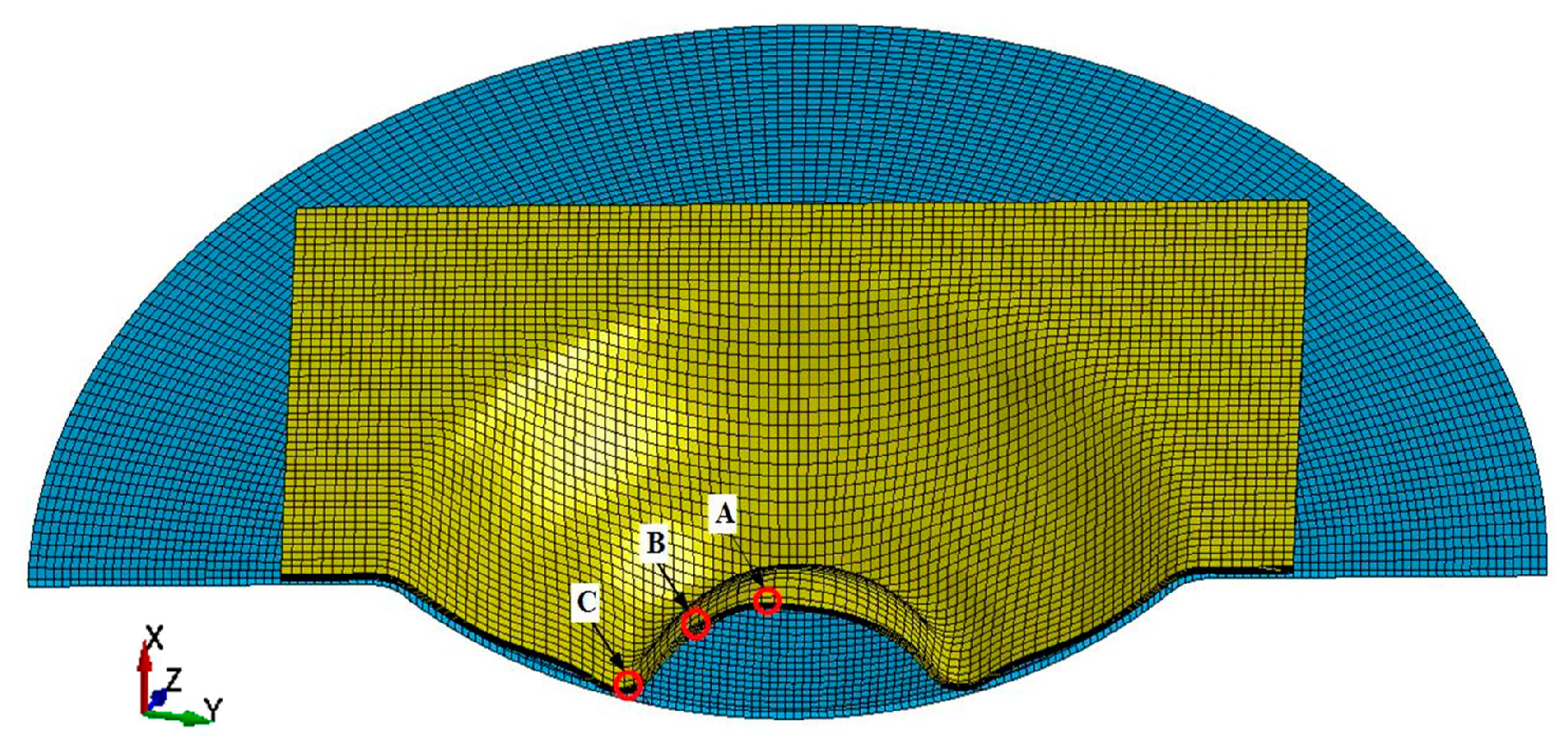

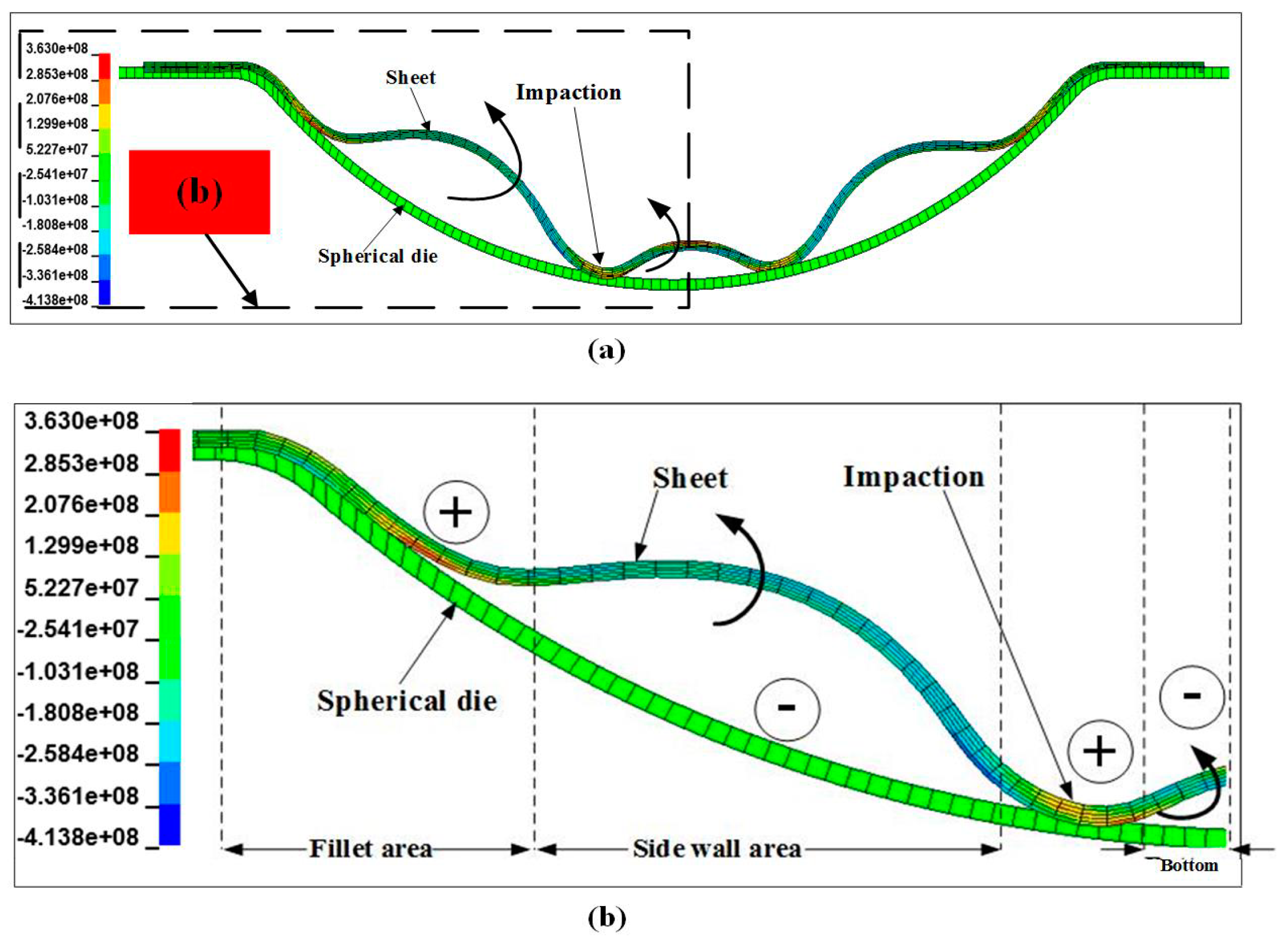

4.2. The Process of High-Speed Impaction Electromagnetic Deformation

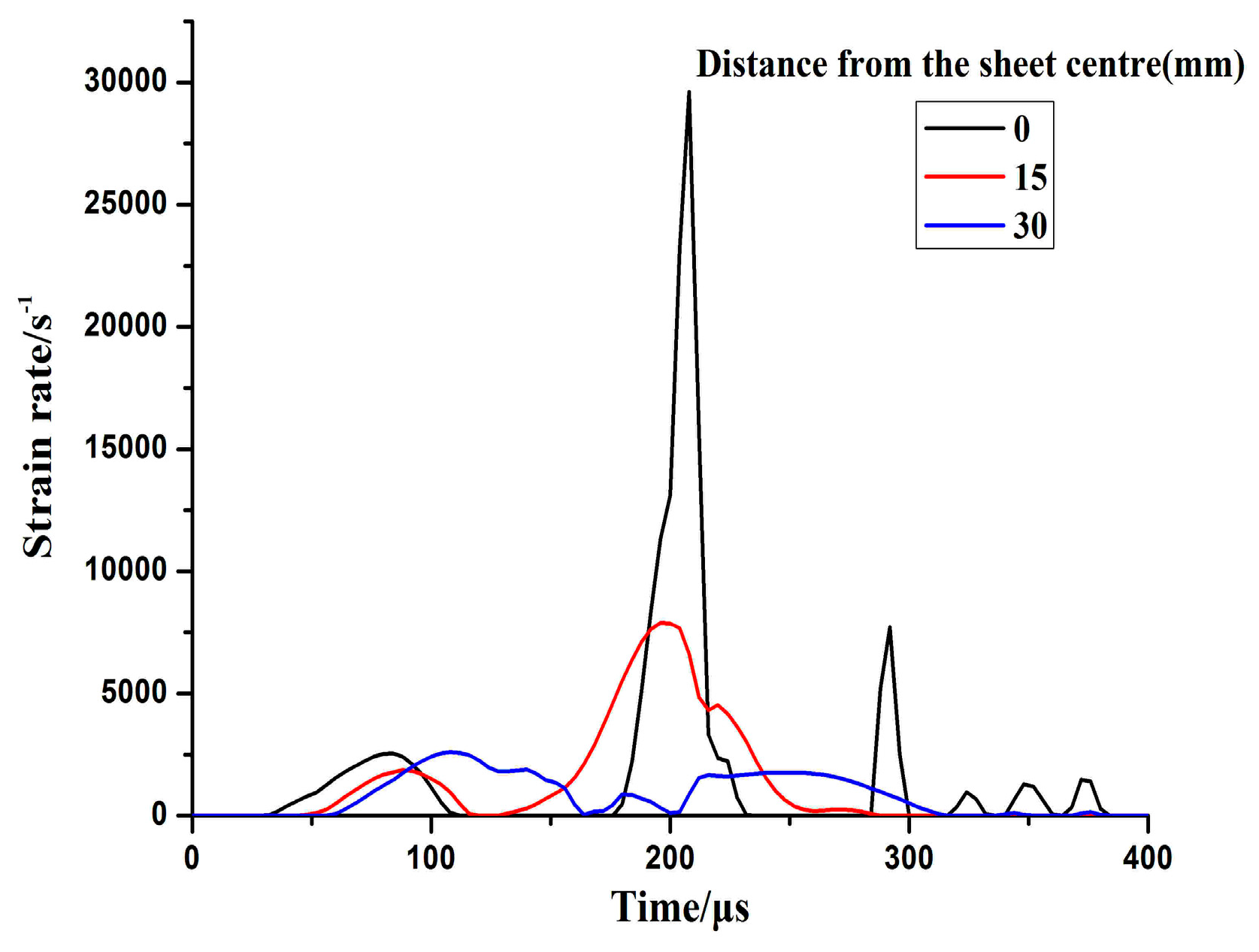

4.3. Strain Rate

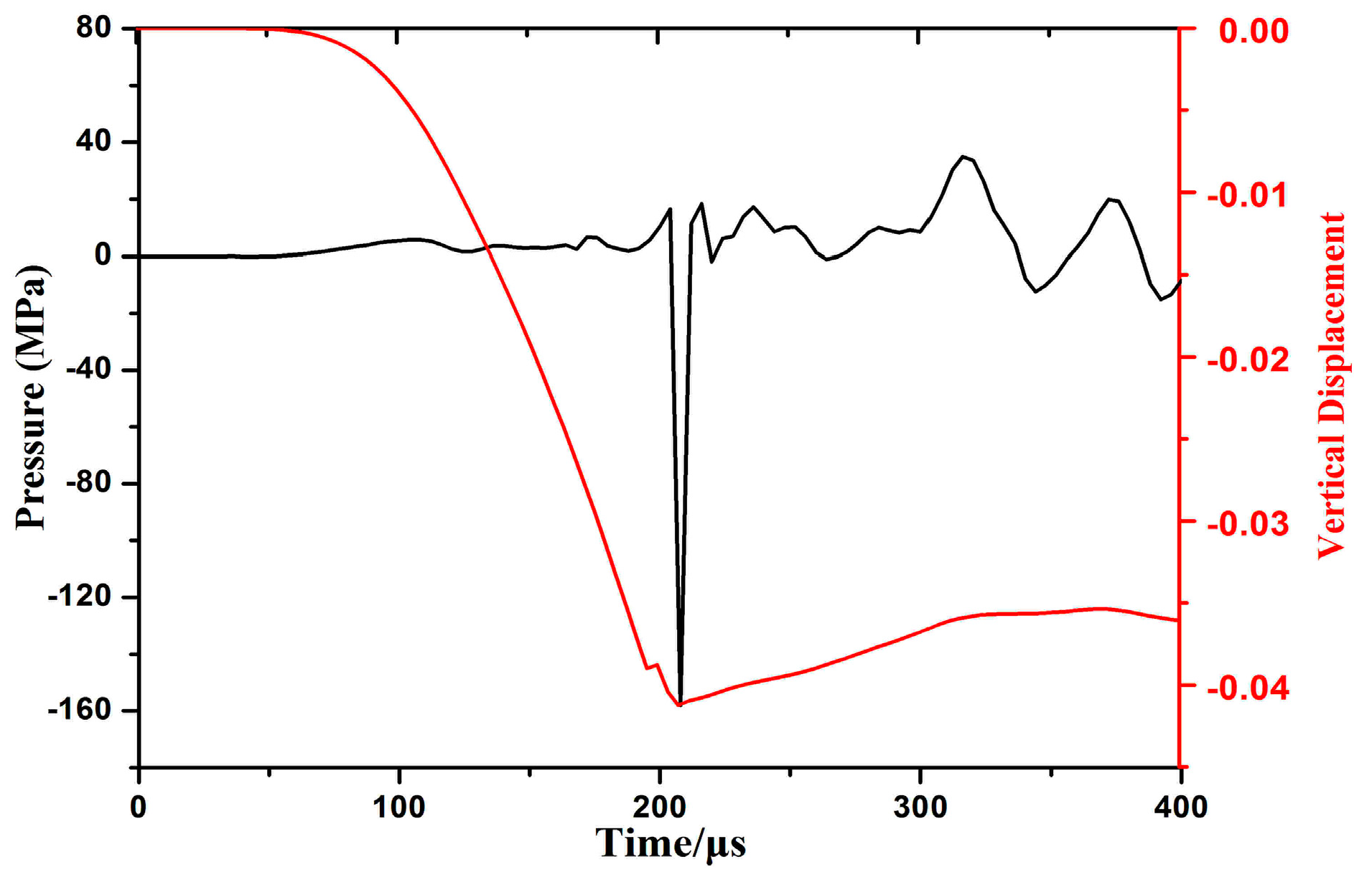

4.4. Impaction Pressure Stress

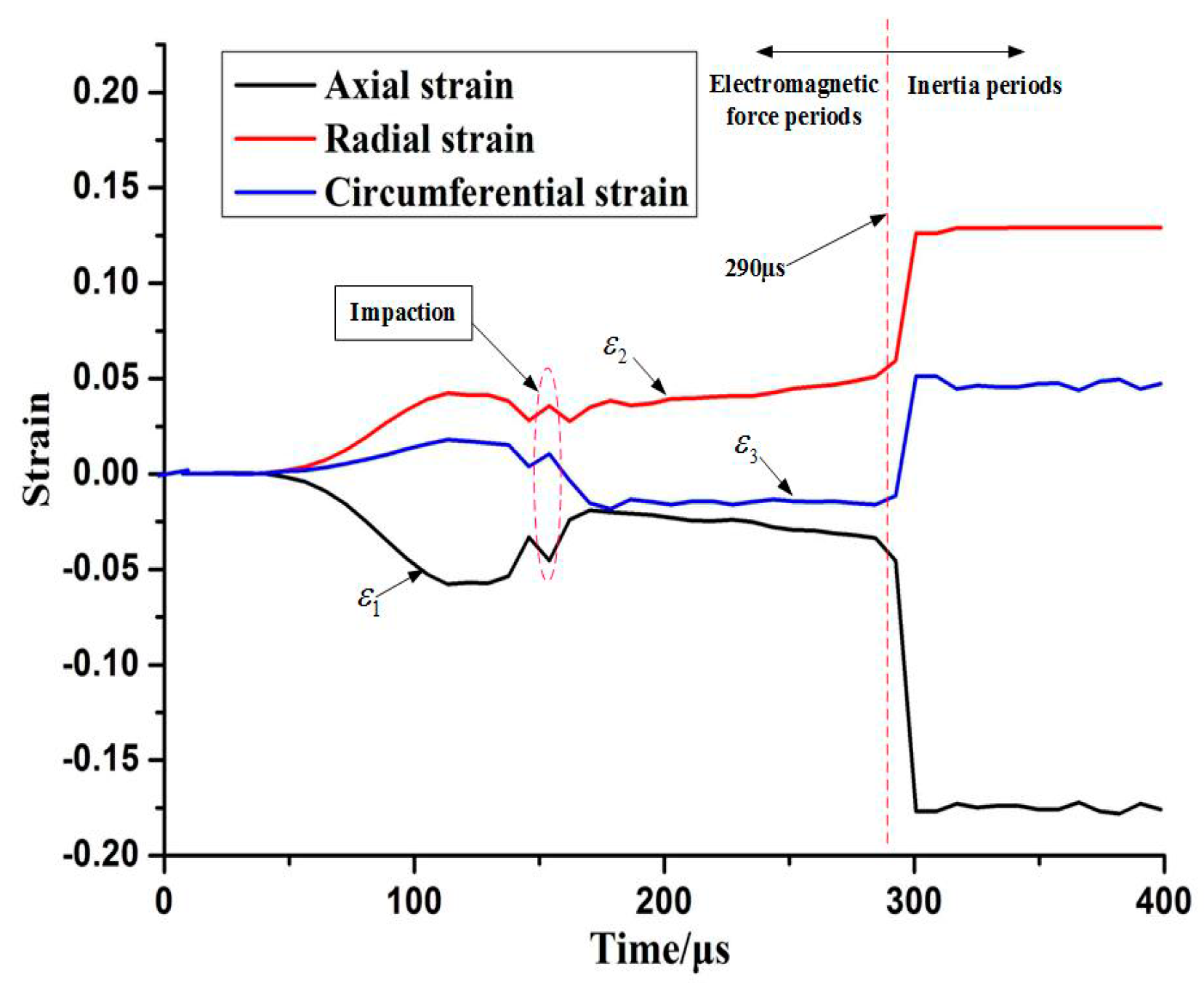

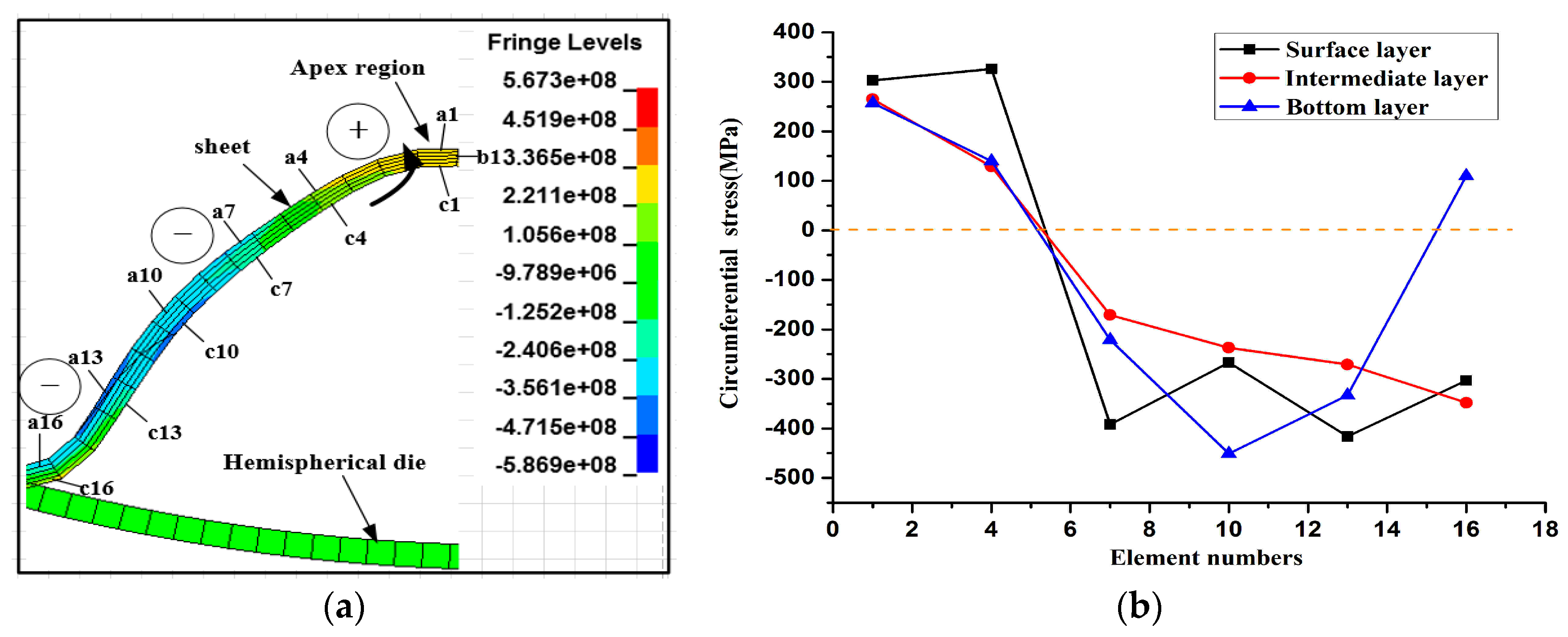

4.5. Stress State

4.6. Discussion on the Influence of Die Geometry on Formability

4.7. Verification

5. Conclusions

- (1)

- The influence of boundary conditions on formability was investigated in sheet high-speed electromagnetic impaction deformation. When the sheet impacted with the cylindrical die cavity, the major strain of 5052 aluminum alloy improved by approximately 26.67% compared with that of the conventional forming limit. However, when the sheet impacted at high speed with the hemispherical die, the formability of 5052 aluminum alloy was not increased significantly, but instead, decreased by approximately 25% compared with that of the conventional forming limit. Therefore, the high-speed impaction electromagnetic deformation may not improve formability when the deformation of workpiece’s sidewall and bottom was severely constrained by die geometry. Our findings will provide a reference in electromagnetic forming in the future to manufacture ideal hemispherical parts.

- (2)

- The maximum effective strain rate was approximately 30,000 s−1 when the sheet impacted to the cylindrical die at high speed. However, this rate was only 1700 s−1 when the specimen impacted to the hemispherical die at the same energy level. The plastic flow of sheet’s center region was inhibited, and the strain state changed from biaxial stretching to plane strain. The fracture or necking locations of the sheet evidently differed between the hemispherical die and cylindrical die in electromagnetic impaction deformation.

- (3)

- The impaction pressure was strongly dependent on the discharge energy and the die geometry in sheet electromagnetic impaction deformation. The stress state effect of “extrusion-stretching” resulted in the fracture of the sheet’s center region, which caused the formability decrease with the hemispherical die. In order to improve formability in the high-speed impaction electromagnetic deformation, it was necessary to get the higher strain rate and impaction pressure between the sheet and the die.

Author Contributions

Funding

Conflicts of Interest

References

- Cui, X.H.; Mo, J.H.; Li, J.J.; Zhao, J.; Zhu, Y.; Huang, L.; Li, Z.W.; Zhong, K. Electromagnetic incremental forming (EMIF): A novel aluminum alloy sheet and tube forming technology. J. Mater. Process. Technol. 2014, 214, 409–427. [Google Scholar] [CrossRef]

- Fang, J.X.; Mo, J.H.; Li, J. Microstructure difference of 5052 aluminum alloys under conventional drawing and electromagnetic pulse assisted incremental drawing. Mater. Charact. 2017, 129, 88–97. [Google Scholar] [CrossRef]

- Tamhane, A.A.; Altynova, M.M.; Daehn, G.S. Effect of sample size on ductility in electromagnetic ring expansion. Scr. Metall. Mater. 1996, 34, 1345–1350. [Google Scholar] [CrossRef]

- Li, F.; Mo, J.; Li, J.; Huang, L.; Zhou, H. Formability of Ti–6Al–4V titanium alloy sheet in magnetic pulse bulging. Mater. Des. 2013, 52, 337–344. [Google Scholar] [CrossRef]

- Rohatgi, A.; Soulami, A.; Stephens, E.V.; Davies, R.W.; Smith, M.T. An investigation of enhanced formability in AA5182-O Al during high-rate free-forming at room-temperature: Quantification of deformation history. J. Mater. Process. Technol. 2014, 214, 722–732. [Google Scholar] [CrossRef]

- Imbert, J.M.; Winkler, S.L.; Worswick, M.J.; Oliveira, D.A.; Golovashchenko, S. The Effect of Tool–Sheet Interaction on Damage Evolution in Electromagnetic Forming of Aluminum Alloy Sheet. J. Eng. Mater. Technol. 2005, 127, 145–153. [Google Scholar] [CrossRef]

- Balanethiram, V.S.; Daehn, G.S. Hyperplasticity: Increased forming limits a high workpiece velocity. Scr. Mater. 1994, 30, 515–520. [Google Scholar] [CrossRef]

- Ozturk, F.; Lee, D. Experimental and numerical analysis of out-of-plane formability test. J. Mater. Process. Technol. 2005, 170, 247–253. [Google Scholar] [CrossRef]

- Seth, M.; Vohnout, V.J.; Daehn, G.S. Formability of steel sheet in high velocity impact. J. Mater. Process. Technol. 2005, 168, 390–400. [Google Scholar] [CrossRef]

- Lei, Y.; Meng, Z.H.; Hu, J.H.; Feng, F.; Huang, S.Y. Experimental Investigation on High Rate Forming for Two Kinds of Typical High-strength Steel in Car Manufacture. China Mech. Eng. 2013, 24, 2529–2533. [Google Scholar]

- Meng, Z.H.; Huang, S.Y.; Hu, J.H.; Xia, Z.L.; Xia, X.F. Experimental Research on Warm and Electromagnetic Hybrid Forming of Magnesium Alloy Sheet. J. Mech. Eng. 2011, 10, 38–42. [Google Scholar] [CrossRef]

- Werdelmann, P.; Rosendahl, J.; Peier, D.; Kulig, S. Assessing the effective energy for magnetic forming processes by means of measurements and numerical calculation. In Proceedings of the 3rd International Conference on High Speed Forming, Dortmund, Germany, 11–12 March 2008; pp. 299–306. [Google Scholar]

- Luo, W.Y.; Huang, L.; Li, J.J.; Liu, X.L.; Wang, Z.Q. A novel multi-layer coil for a large and thick-walled component by electromagnetic forming. J. Mater. Process. Technol. 2014, 214, 2811–2819. [Google Scholar] [CrossRef]

- Mamalis, A.G.; Manolakos, D.E.; Kladas, A.G.; Koumoutsos, A.K. Electromagnetic Forming Tools and Processing Conditions: Numerical Simulation. Mater. Manuf. Process. 2006, 21, 411–423. [Google Scholar] [CrossRef]

- Yu, H.; Li, C. Effects of current frequency on electromagnetic tube compression. Mater. Process. Technol. 2009, 209, 1053–1059. [Google Scholar]

- Liu, D.H.; Li, C.F.; Yu, H.P. Numerical modeling and deformation analysis for electromagnetically assisted deep drawing of AA5052 sheet. Trans. Nonferrous Met. Soc. China 2009, 19, 1294–1302. [Google Scholar] [CrossRef]

- Yu, H.; Li, C.; Deng, J. Sequential coupling simulation for electromagnetic–mechanical tube compression by finite element analysis. J. Mater. Process. Technol. 2009, 209, 707–713. [Google Scholar]

- Fan, Z.S.; Yu, H.P.; Li, C.F. Plastic deformation behavior of bi-metal tubes during magnetic pulse cladding: FE analysis and experiments. J. Mater. Process. Technol. 2016, 229, 230–243. [Google Scholar] [CrossRef]

- He, M.; Li, F.G.; Wang, Z.G. Forming limit stress diagram prediction of aluminum alloy 5052 based on GTN model parameters determined by in situ tensile test. Chin. J. Aeronaut. 2011, 24, 378–386. [Google Scholar] [CrossRef]

- Golovashchenko, S.F. Material Formability and Coil Design in Electromagnetic Forming. J. Mater. Eng. Perform. 2007, 16, 314–320. [Google Scholar] [CrossRef]

- Oliveira, D.A.; Worswick, M.J.; Finn, M.; Newman, D. Electromagnetic forming of aluminum alloy sheet: free-form and cavity fill experiments and model. J. Mater. Process. Technol. 2005, 170, 350–362. [Google Scholar] [CrossRef]

- Hassannejadasl, A.; Green, D.E.; Golovashchenko, S.F.; Samei, J.; Maris, C. Numerical modelling of electrohydraulic free-forming and die-forming of DP590 steel. J. Mater. Process. Technol. 2014, 16, 391–404. [Google Scholar] [CrossRef]

| Chemical Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Al |

|---|---|---|---|---|---|---|---|---|

| Mass fraction (%) | 0.06 | 0.29 | 0.01 | 0.06 | 2.5 | 0.16 | 0.01 | Balanced |

| Forming Coil (Copper) Parameters | 5052 Aluminum Alloys Parameters | |||||||||||

| Relative Permeability | Resistivity (Ω·m) | Inductance (H) | Relative Permeability | Resistivity (Ω·m) | ρ (kg/m3) | E (GPa) | Poisson’s Ratio | |||||

| 1 | 1.72 × 10−8 | 1.12 × 10−5 | 1 | 4.93 × 10−8 | 2700 | 72 | 0.3 | |||||

| C-S constitutive model parameters | GTN damage model parameters [6,19] | |||||||||||

| K | n | p | m | f0 | fc | fF | fN | SN | q1 | q2 | q3 | |

| 376.8 | 0.3 | 6500 | 0.25 | 0.002918 | 0.030103 | 0.04854 | 0.0249 | 0.1 | 0.3 | 1.5 | 1 | 2.25 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, F.; Li, J.; Chen, R.; Yuan, P.; Su, H.; Zhang, Q.; Huang, P.; Zheng, Z. Effect of Die Geometry on the Formability of 5052 Aluminum Alloy in Electromagnetic Impaction Deformation. Materials 2018, 11, 1379. https://doi.org/10.3390/ma11081379

Feng F, Li J, Chen R, Yuan P, Su H, Zhang Q, Huang P, Zheng Z. Effect of Die Geometry on the Formability of 5052 Aluminum Alloy in Electromagnetic Impaction Deformation. Materials. 2018; 11(8):1379. https://doi.org/10.3390/ma11081379

Chicago/Turabian StyleFeng, Fei, Jianjun Li, Rongchuang Chen, Peng Yuan, Hongliang Su, Qixian Zhang, Pan Huang, and Zhizhen Zheng. 2018. "Effect of Die Geometry on the Formability of 5052 Aluminum Alloy in Electromagnetic Impaction Deformation" Materials 11, no. 8: 1379. https://doi.org/10.3390/ma11081379