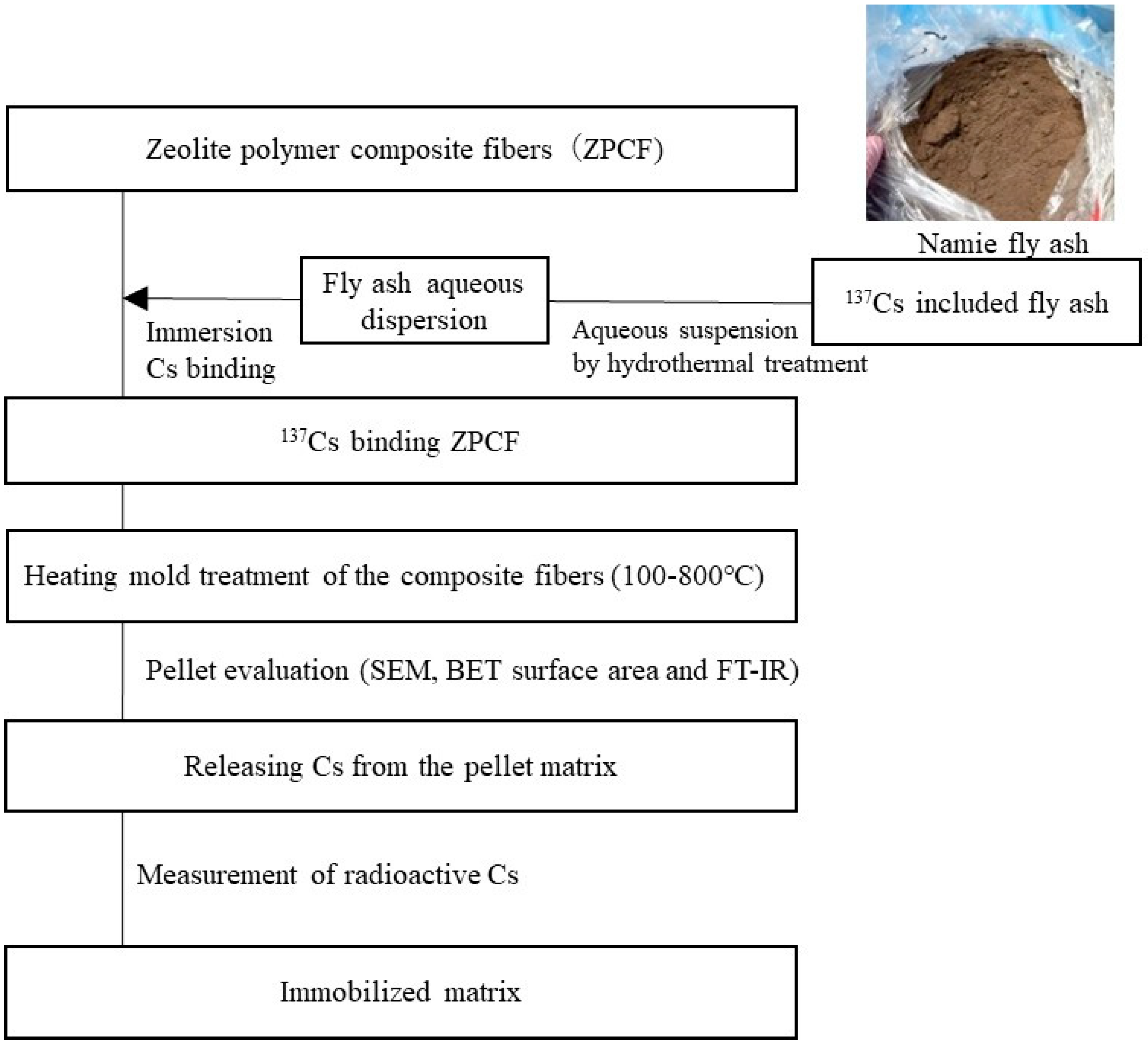

3.1. Immobilization of Radioactive Cesium by Heating Mold Processing of Composite Fibers

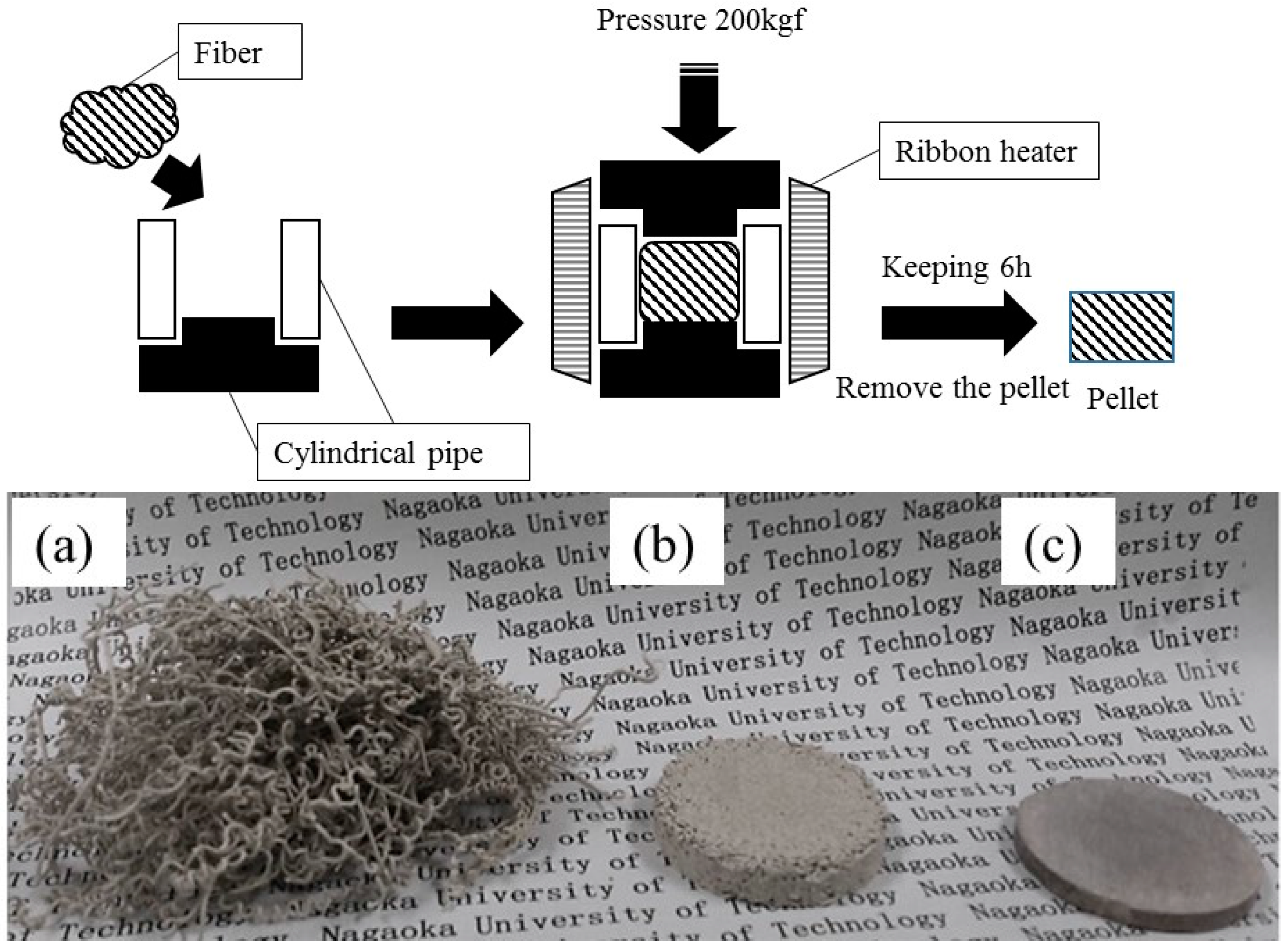

As shown in

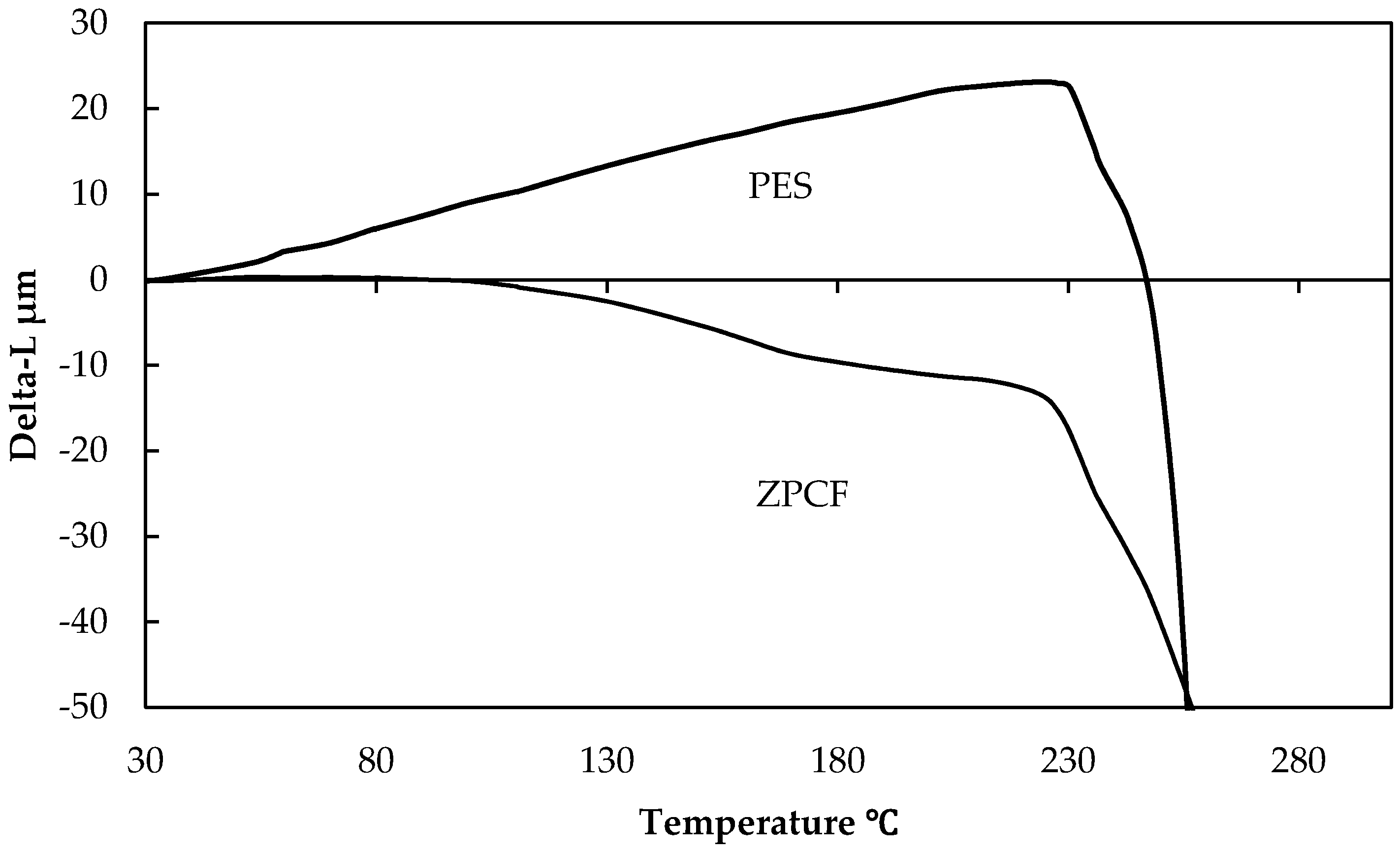

Figure 2, for the schematic illustration of heating mold processes, the radioactive Cs was bound by the ZPCF in the dispersed fly ash solution. Then, the compacted pellet was shaped from the fibrous sample by heating it at different temperatures under pressure. The DSC curves of the PES fiber are shown in

Figure 3 for the ZPCF and PES without zeolite. Endothermic peaks were found at 220 °C and 227 °C for the PES and the ZPCF in each DSC curve. This indicated that heating at over 230 °C led to the PES being melted. In the ZPCF, the observed temperature was found to be a little bit higher relative to that of the PES. It was noted that in the higher 220 °C and 227 °C range, the heat molding was reasonable to process and enabled the pellet form, while a pellet prepared at lower than 220 °C was only compressed by pressure. Additionally, it was apparent that the pellet form could be made to different densities at the 100 °C and 300 °C process temperatures. As shown in

Figure 4, this was also supported by TMA measurement data. As a result of TMA measurement, the PES was found to be softened and melted from around 234–250 °C. Therefore, the TMA measurements were automatically stopped at over 250 °C. Here, the thermal DSC and TMA analyses could not obtain results at over 400 °C.

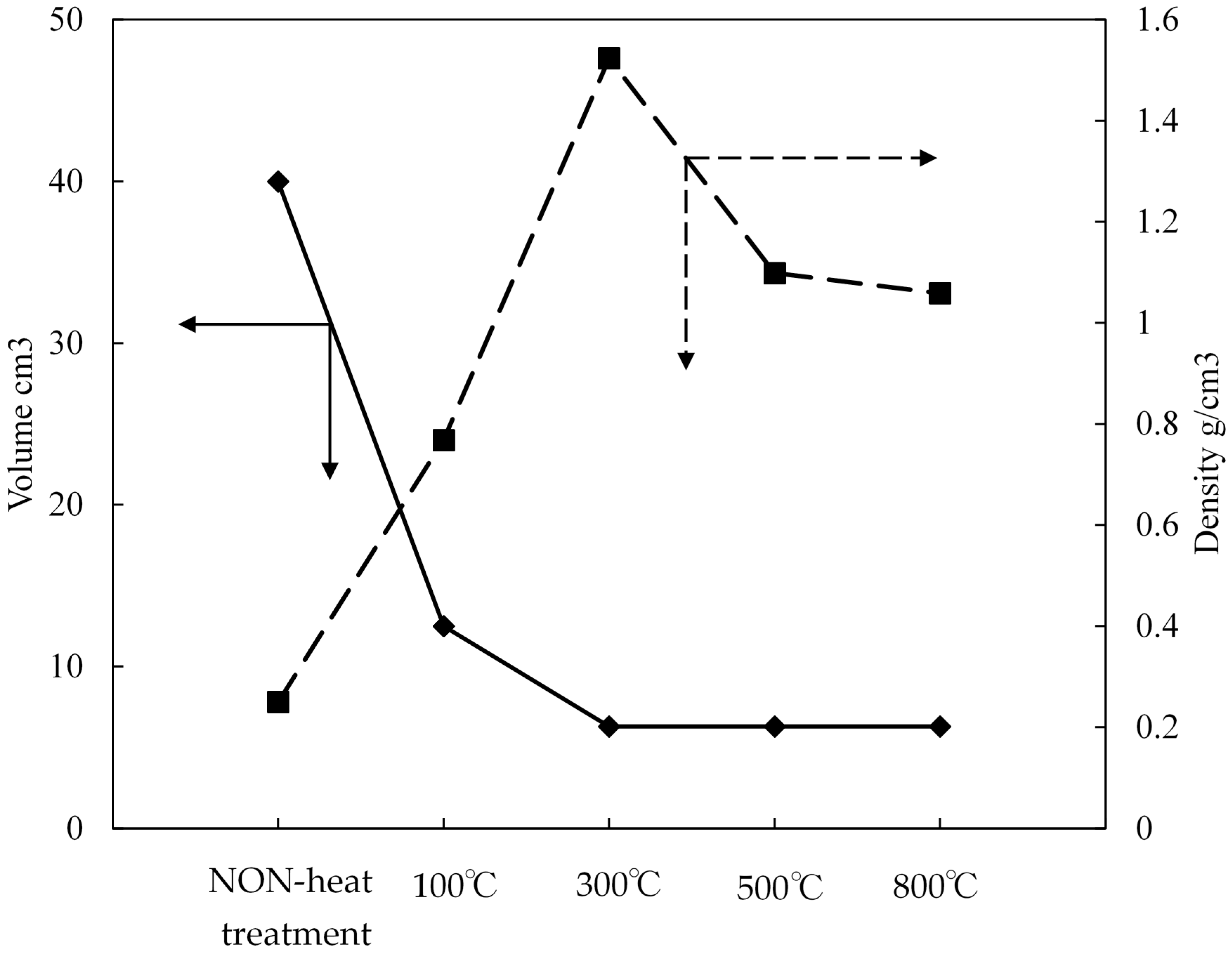

Figure 5 presents the relation between the volume (cm

3) and density (g/cm

3) changes of the pellets. The ZPCF volume was decreased from 40 cm

3 to 12.5 cm

3 under the compressed heat molding process at 100 °C. Then, at over 300–800 °C, the volume changed by 6.3 cm

3. The comparison indicated that the molding at 300 °C showed significant volume reduction to about one-sixth in the fabricated pellet. In addition, the pellet density increased from 0.25 to 1.52 g/cm

3 after compression processing was implemented in the range of room temperature to 300 °C. This exactly was due to PES melting in the dense pellet formation as supported by

Figure 3 and

Figure 4. When the temperature was changed from 300 °C to 500 °C and 800 °C, the pellet density was decreased from 1.52 g/cm

3 to 1.13 g/cm

3 and then 1.1 g/cm

3, respectively. Absolutely, the decrease was attributable to the polymer decomposition of the organic plastic PES. This was also supported in

Figure 4 by the gradual decrease of the TMA results at over 300 °C in both curves.

Figure 6 portrays SEM images of the surface and cross sections of ZPCF treated at different temperatures for the molding processing. Low-temperature molding at 100 °C revealed that the zeolite powders were embedded in the PES medium as they were in the case of the non-heating mold. However, at temperatures higher than 300 °C, the images showed that the PES amounts decreased concomitantly with increasing temperature. At temperatures higher than 500 °C, the fibers were in a brittle state. Moreover, the polymer layer disappeared, reflecting the organic PES matrix’s decomposition. A cross-section view (

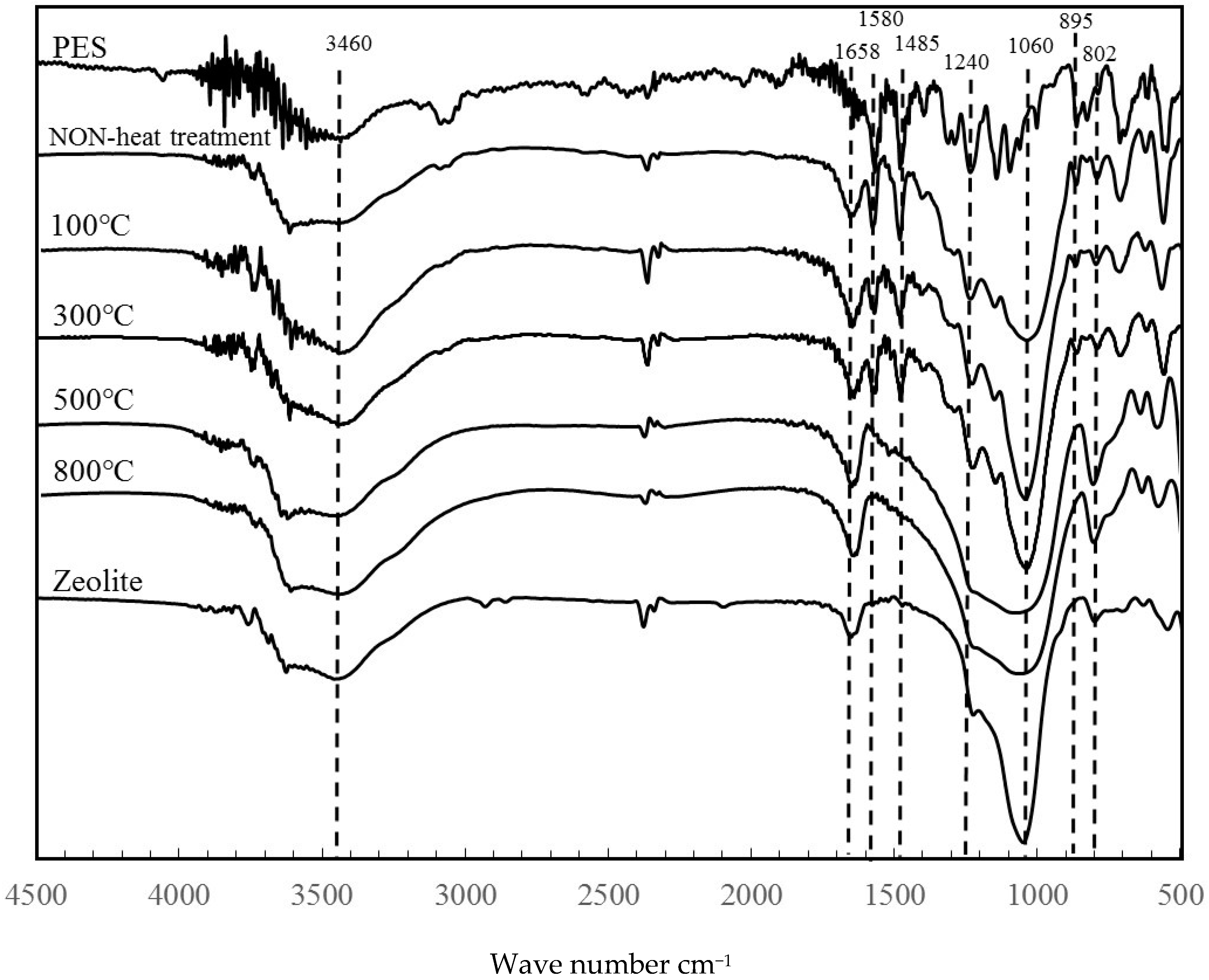

Figure 6 left) of a pellet revealed the dense structure of the compressed fiber at 500 °C (d) and 800 °C (e). The FT-IR spectral patterns for the 800 °C sample (

Figure 7) presented no peaks at 1580, 1485, and 895 cm

−1 corresponding to PES in the ZPCF and peaks at 3460, 1658, and 1060 cm

−1 corresponding to zeolite.

Table 1 presents the respective assignments for their FT-IR peaks. Actually, band broadening was apparent in spectra obtained at 500 °C and 800 °C. Moreover, PES peaks were nonexistent. It was inferred from these results that the SiO

2 component remained in the zeolite. The appearance of the 1658 cm

−1 peak in the heated pellets might be assigned to water adsorbed from the atmosphere after heating. It is noteworthy that the appearance of the peaks at 1580 and 1485 cm

−1 is temperature-dependent. At 800 °C, both PES peaks disappeared, meaning that the PES in the pellet was burned out of the material. Therefore, the spectra retained broad peaks at 1060 cm

−1 and at 802 cm

−1 for the Si–O–Si and Al–O bands of zeolite, respectively. As seen in

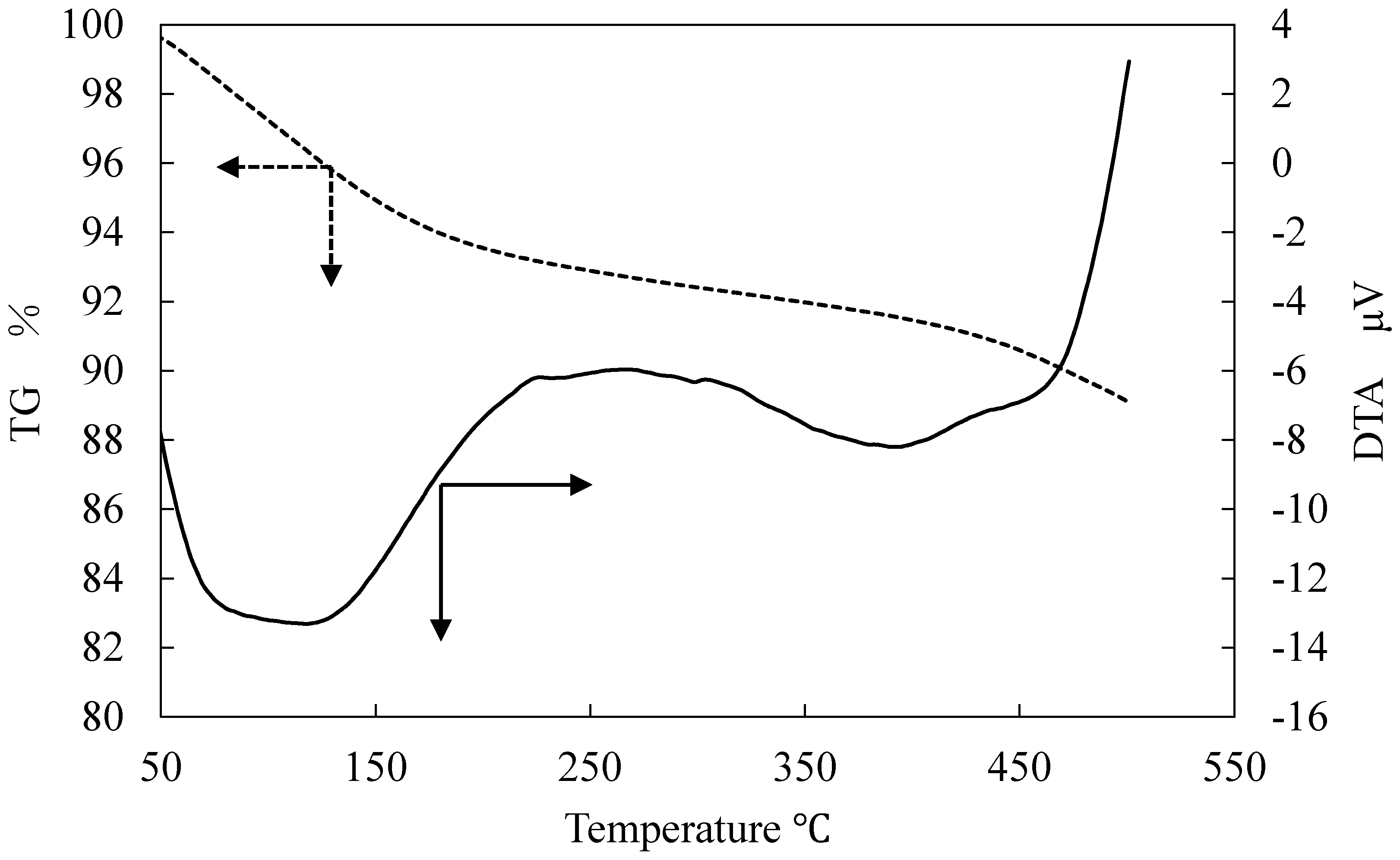

Figure 8 for the TG-DTA measurement of ZPCF in the range of 50–500 °C, an endothermic peak and depletion of TG considered to be dehydrated from zeolite were observed up to 250 °C. After 450 °C, the exothermic peak and a decline of TG can be confirmed in the 350–500 °C range. This was presumed to be caused by the combustion of PES.

To evaluate the porous and dense properties of the fibers and pellets, nitrogen (N

2) adsorption and desorption were measured at different pressures.

Figure 9 portrays the N

2 adsorption isotherm of the PES and ZPCF in the absence (a) and presence (b) of heat molding processing. According to the isotherms, their samples presented that the adsorption behavior followed that of the type 2 isotherm, reflecting the presence of a macroporous structure [

5] (Kobayashi et al., 2016). Compared to the PES and zeolite shown in

Figure 9a, it was apparent that the PES fiber had a lower capacity for N

2 adsorption amounts relative to the zeolite powder. As

Figure 9b shows, the pellets molded at 500 °C and 800 °C showed similar isotherm curves to that of zeolite, as was true also for the non-heat treatment. In the different pellet samples at 500 °C and 800 °C, the amounts of adsorption of N

2 were changed, although the shapes of the isotherms were almost similar. However, it was seen that the values of the pellet at 800 °C were lower than those at 500 °C. This strongly suggested that the numbers of the mesopores in the pellet at 800 °C were much lower than the numbers of mesopores in the pellet at 500 °C. This meant that the 800 °C molding destroyed the porous structure of the pellet. However, it is noteworthy that the curve of the pellet heated at 300 °C had lower amounts of N

2 adsorption. Consequently, the melted PES penetrated and covered the zeolite pores causing the zeolite volume to decrease. As seen in

Figure 4 and

Figure 8, this was strongly suggested by the TMA and DTA results. Also, the FT-IR results of different temperatures showed decomposition of the PES components at temperatures over 500 °C. It is noteworthy that the N

2 adsorption amounts were somewhat higher at the temperatures of 500 °C and 800 °C, which indicates that the PES component in the pellets decomposed gradually because the temperature was higher than around 300 °C and that it increased concomitantly with increasing temperature to 800 °C. Therefore, the PES component decomposition occurred gradually with increasing temperature. The results obtained at 800 °C showed that the zeolite surface was exposed without envelopment by the PES layer.

Table 2 presents the BET surface area and weight reduction of the ZPCF pellets heated at different temperatures. The BET surface area of the ZPCF was 32 m

2/g before heat molding processing. The value was remarkably lower at 300 °C because the melted PES enveloped the porous structure of the zeolite. The pellet structure became denser. At 500 °C, however, the surface area value increased to 32 m

2/g, suggesting that little zeolite remained after heating. Furthermore, since the heating treatment decomposed the PES component and thereby exposed the zeolite surface, the experimental results of the ZPCF weight reduction at 500 °C and 800 °C were, respectively, 30.8% and 33.3% after heat molding processing. This was due to the polymer being well-decomposed at over 500 °C. However, the value of weight reduction at 300 °C was 2.17 wt %, meaning that the PES had decomposed only a little.

Figure 4 depicts the TMA results, which show that the PES of the thermoplastic polymer was melted at temperatures higher than 300 °C. Then, the melting PES seemed to cover the zeolite powder. Therefore, from the weight reduction results, one can reasonably infer that the melted PES surrounding the zeolite powders produced an enveloping layer that decreased the zeolite surface area.

Table 2 contains the adsorbent concentration the radioactive Cs of the pellet matrix. At 500 °C and 800 °C, the values of the radioactive Cs were 21,200 and 22,400 Bq/kg. The results of radioactive Cs concentration were higher at 500 °C and 800 °C than those at 100–300 °C. This was due to weight reduction by the PES decomposition.

3.2. Immobilization of Radioactive Cesium in ZPCF Pellets

Table 3 presents values of the radioactive Cs amounts observed with and without heat molding processing. The ZPCF adsorbed up to 14,000 Bq/kg of Cs. The Cs concentration amounts were increased as the temperature increased after heat molding processing. It was seen that the increment was observed between 300 °C and 500 °C for radioactive Cs concentration. The increased concentration derived from the fact that the PES weight was lower at higher temperatures. Also, the weight reduction between 300 °C and 500 °C was remarkable.

Table 3 contains values for the eluted concentration of radioactive Cs from the pellets when they were washed in distilled water. The values of the eluted Cs in water phase were measured. It was noted that the values of the radioactive Cs concentration from the pellet were less than 1 Bq/L at 100 °C and 300 °C. In contrast, the values were 60 and 62 Bq/L for the washed pellet molded at 500 °C. This result strongly indicated that adsorbed radioactive Cs was released from the matrix to the water.

The ZPCF’s form can be changed to a pellet by heat molding processing. Therefore, it was interesting to observe the radioactive Cs immobilization’s efficiency in the matrix. To measure changes in the radioactive Cs concentration, Cs release tests were conducted in water for each sample.

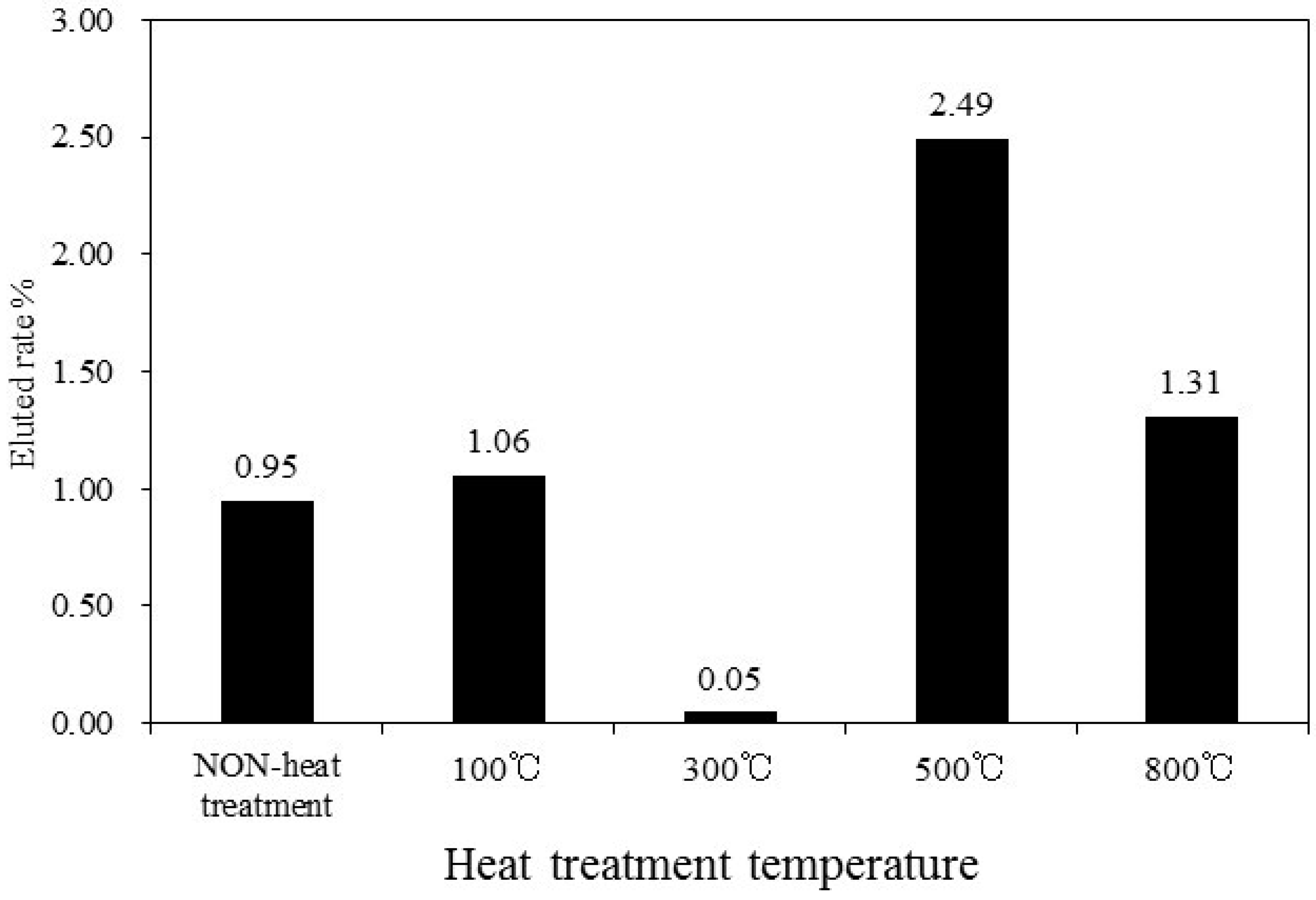

Figure 10 shows the elution rate (%) of non-radioactive Cs. After the pellet was washed with diluted water for 6 h, the elution rate (%) was evaluated. Furthermore,

Table 3 shows the rate of radioactive Cs elution from pellet matrixes molded at different temperatures. These results indicated that elution of the Cs from the fibers and pellets depends strongly upon the heat molding process temperature. The rate of elution of the Cs was extremely low, about 0.05%, at 300 °C relative to 0.95% at 100 °C and 2.49% at 500 °C. Therefore, it was apparent that the melted PES influenced the Cs release. These results exhibited the same tendency as that for results of the surface area as presented in

Table 2. Therefore, for the 300 °C treatment, envelopment within the polymer layer was effective for Cs immobilization in the pellet matrix. At 800 °C, because heat processing greatly decomposed the PES layer surrounding the zeolite powders, a compacted pellet might be effective to fix the Cs component with the zeolite powder.

Table 3 presents results of radioactive Cs release tests conducted for 6 h and 24 h using different Becquerel per kilogram amounts of ZPCF. The table shows radioactive amounts as evaluated at 0 h and at different times before and after water washing. The elution rates (%) are values obtained at 24 h. The elution rates were similar to those found for non-radioactive Cs. For example, the ZPCF had 14,200 Bq/kg before washing for the non-heat treatment sample. The sample was 14,000 Bq/kg at 6 h and 24 h after washing in water. For the pellet sample prepared at 300 °C, the value of 15,300 Bq/kg after washing represented almost no change from the original 15,500 Bq/kg. However, after mold treatment at 500 °C, the value of 21,200 Bq/kg was increased to 29,800 Bq/kg at 6 h and 24 h.

Table 3 shows that the observed weight reduction was about 30% after the elution tests for 500 °C and 800 °C, demonstrating that the component remaining after burning the PES from the pellet was a soluble substance, such as calcium salt. The radioactive Cs concentration was increased in the pellet. Furthermore, the case at 800 °C showed a similar phenomenon.

Figure 11 summarizes the relationship between the rate of Cs release and the surface area m

2/g. Apparently, the lower elution was due to the lesser surface area. When the molding temperature was increased from 300 to 500 °C, the surface area was also increased. The increase was due to decomposition of the PES and then exposure to the porous zeolite site. This meant that the high porosity of the PES plastic shape had kept the elution of Cs and decomposition much lower from the heat molding system on the experimental time scale. At 300 °C, the reason for the lower density was the melting of the PES that covered the porous zeolite site, meaning that a covering effect decreases Cs elution. In the case of the 100 °C molding treatment, the PES was not melted, keeping a higher surface area. Thus, the leaking of the radioactive Cs, which was equivalently the same level as that at 300 °C, becomes of a lower concentration of the immobilization, at about 20,000 Bq/kg. However, that of the non-radioactive Cs concentration was at 86.1 g/kg, meaning that it was extremely higher than that of radioactive Cs. Therefore, the leaking Cs occurred at 1.06%.

In conclusion, heat molding processing of ZPCF containing Cs efficiently immobilized radioactive Cs in pellets formed at temperatures lower than 300 °C. However, at temperatures higher than 300 °C, the immobilization effect was less pronounced. Furthermore, the results showed that the heat molding processing reduced the pellet volume. The results presented herein suggest that the ZPCF was a better matrix material for fixing radioactive Cs.