Effect of Strain Heterogeneities on Microstructure, Texture, Hardness, and H-Activation of High-Pressure Torsion Mg Consolidated from Different Powders

Abstract

:1. Introduction

2. Materials and Methods

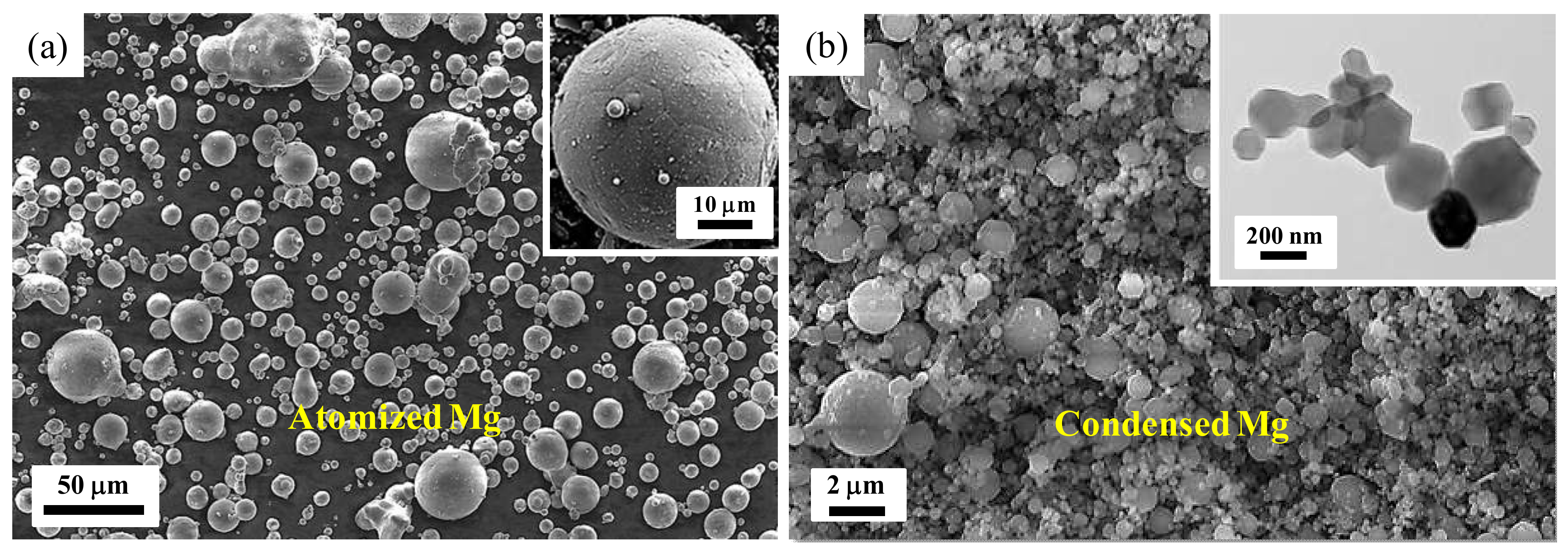

2.1. Materials and Consolidation by HPT

2.2. Characterization

3. Results

3.1. Structural Characterizations of the Consolidated Products

3.1.1. X-ray Diffraction (XRD)

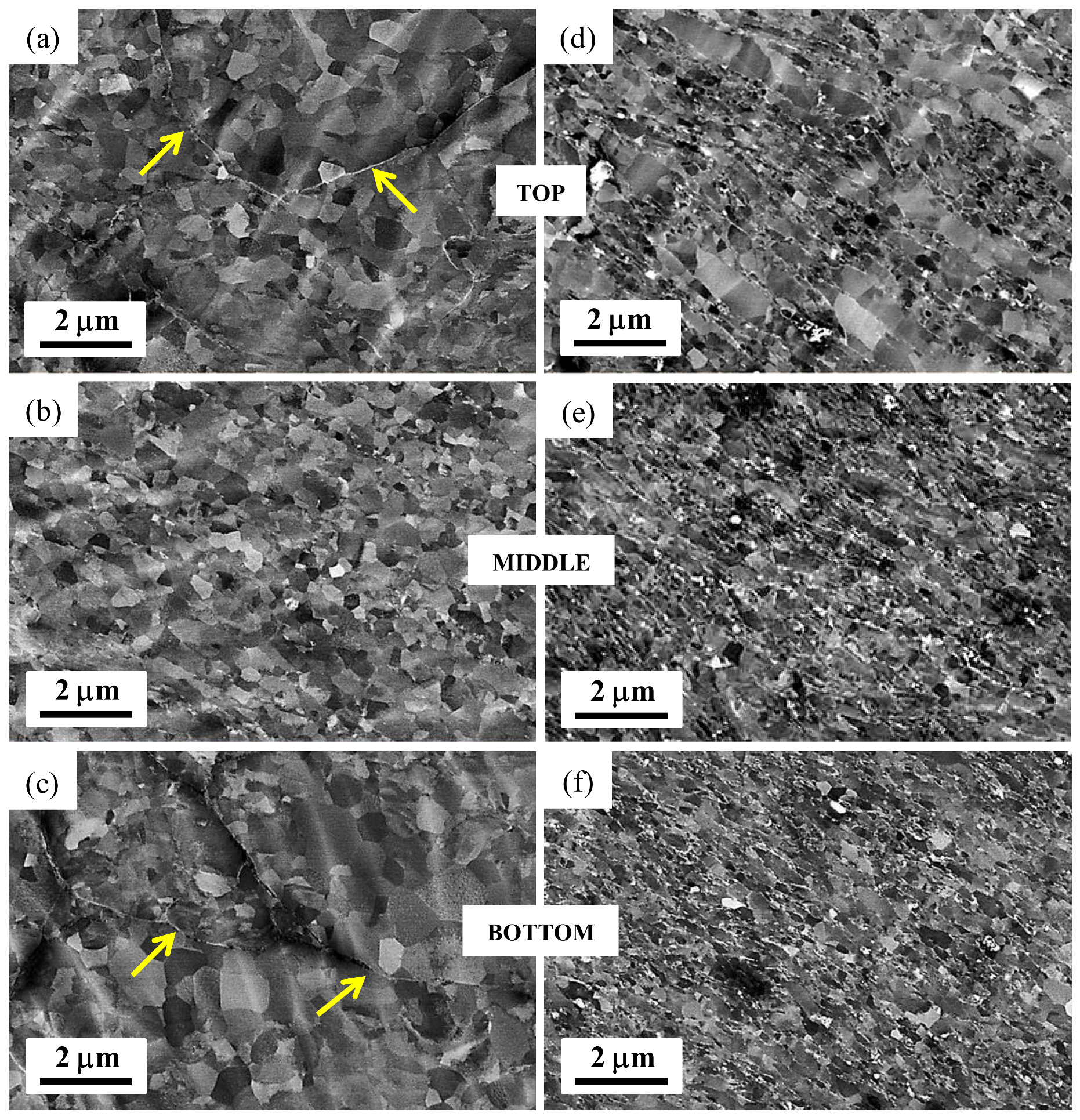

3.1.2. SEM Observations

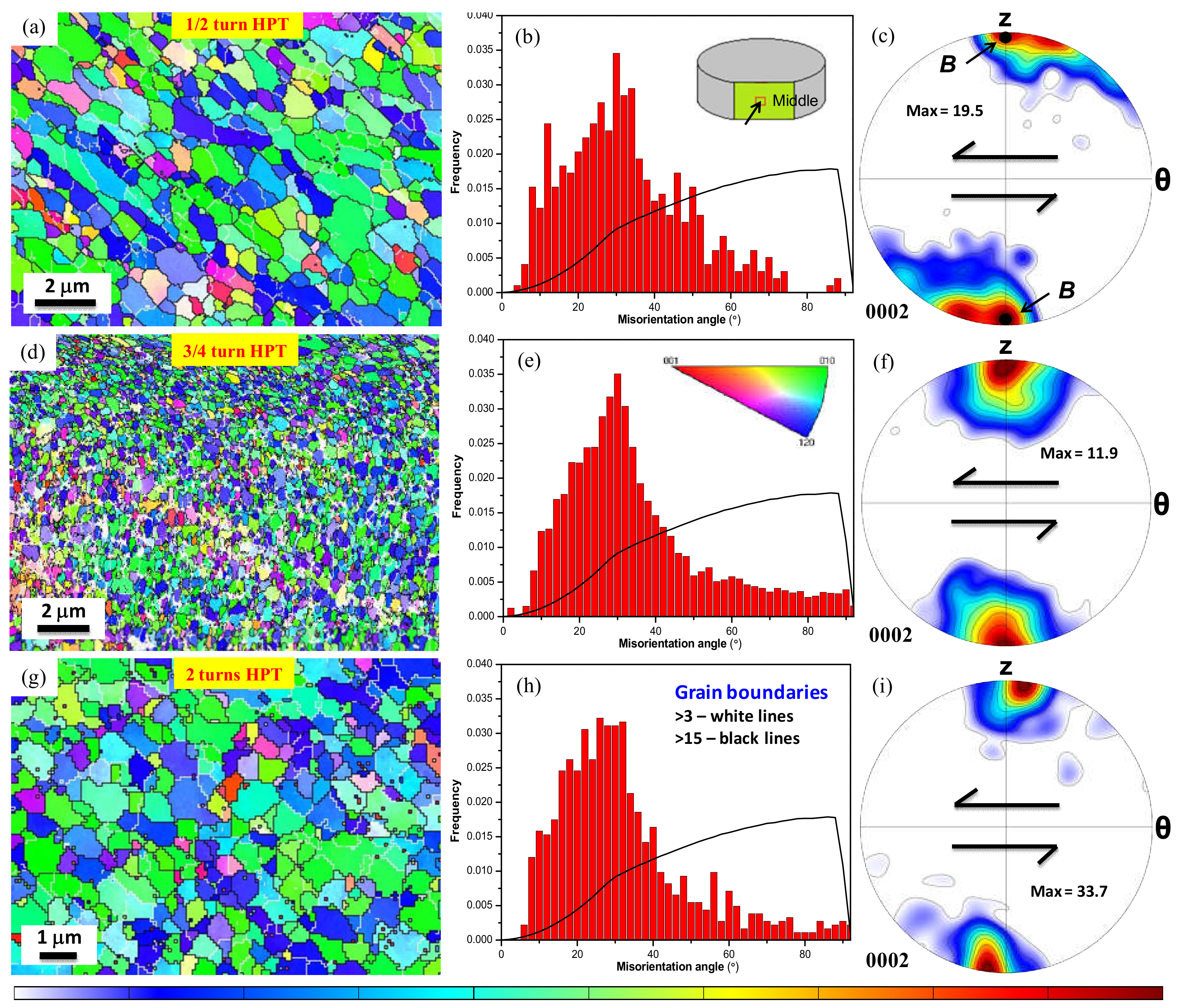

3.2. EBSD and TKD Characterizations

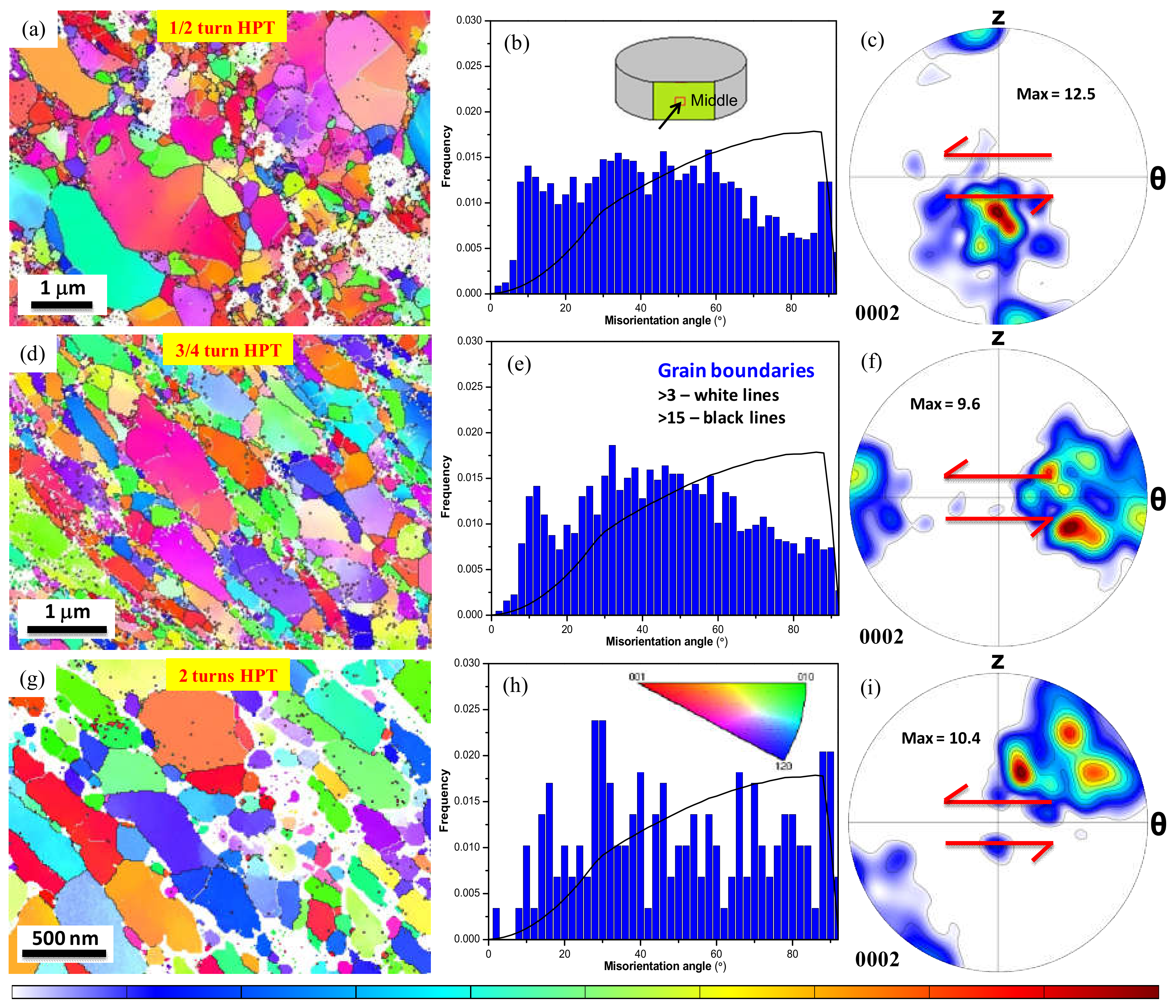

3.2.1. Micro-HPT Product Consolidated from Atomized Powder

3.2.2. Nano-HPT Product Consolidated from Condensed Powder

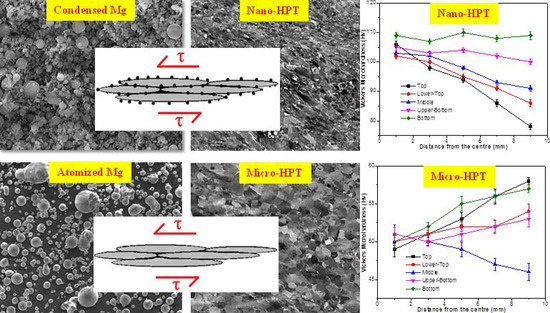

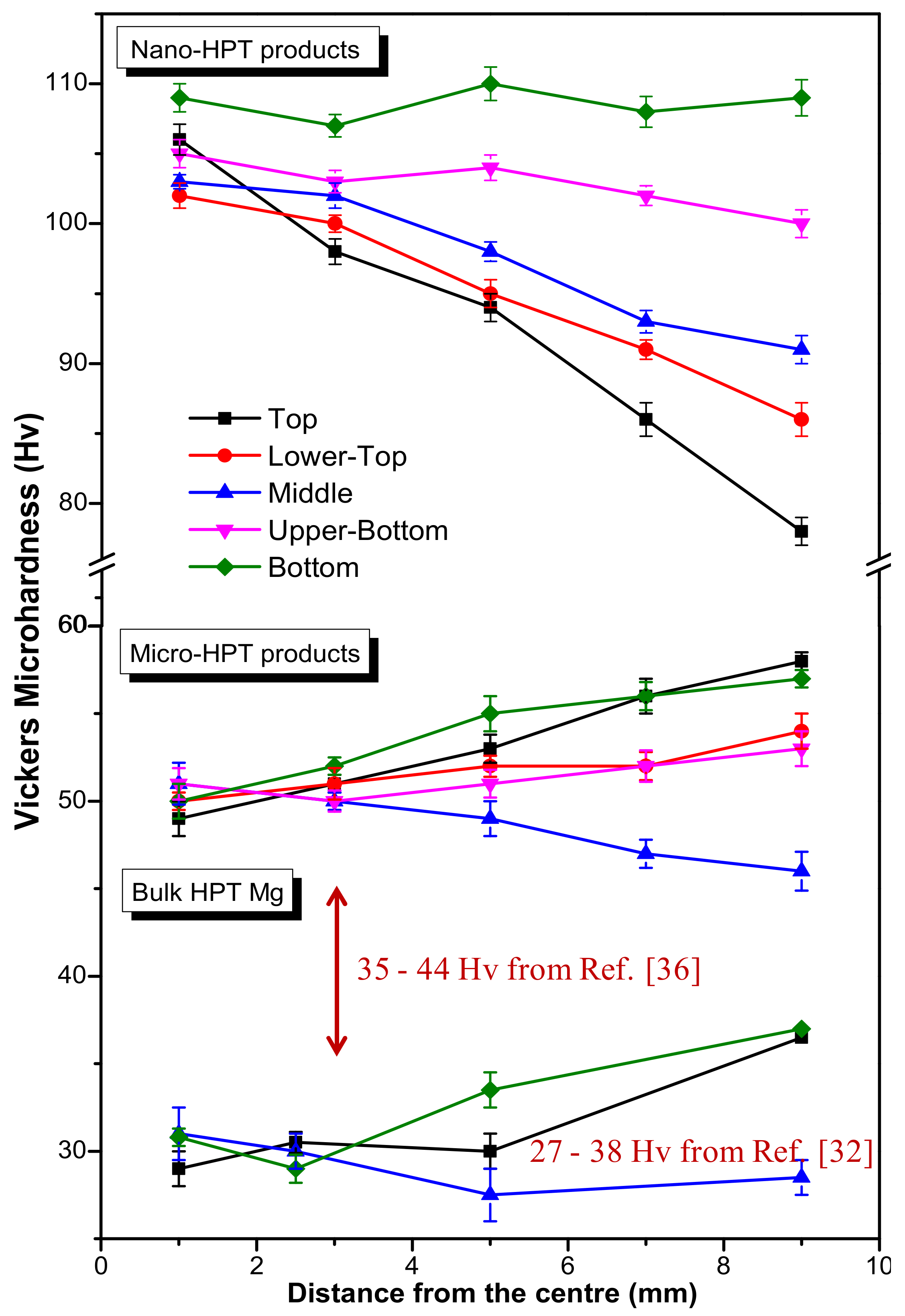

3.3. Microhardness Evolution

3.4. Hydrogen Activation

4. Discussion

4.1. Differences in Consolidation Mechanisms, Grain Sizes, and Texture Developments

4.2. Effectiveness of Powder Consolidation: Strain Heterogeneities, Associated Microstructure, and Hardness Evolutions

4.3. H-Sorption Properties

5. Conclusions

- The nature of the initial powder precursors had significant influences on the microstructure and texture evolutions in the two types of HPT products as well as on the development of local strain heterogeneities.

- The HPT consolidation of the atomized powder particles led to heterogeneous microstructures across the through thickness: recrystallized equiaxed 1 µm grains at the middle section that sustained the highest strain and rather heterogeneously deformed microstructures at the top and bottom regions of the disk.

- The HPT consolidation of the condensed powder particles led to a Mg + 5%MgO composite having a rather more homogeneously deformed microstructure consisting of elongated recovered nanometric Mg domains pinned by the nano-sized Mg oxide particles. Some strain heterogeneities have, however, developed from bottom to top of the disk where the average thickness of the elongated recovered grains varied from about 100 to 500 nm.

- Due to the plastic shear deformation and subsequent dynamic recrystallization, a strong basal texture has developed in the micro-HPT product. Comparatively, the presence of oxides that promoted dynamic recovery and possible powder particle sliding, have hindered the evolution towards the ideal shear texture in the nano-HPT product.

- The hardness being essentially affected by the local grain size and local amount of oxide particles, the hardness of the nano-HPT product obtained from the fine condensed and passivated powder exhibited twice higher hardness than the micro-HPT product: 108 Hv and 55 Hv, respectively. Also, the hardness values in our micro-HPT product obtained from the atomized powder precursor are always higher than the ones reported on HPT deformed disk of pure Mg for which the precursor was a bulk sample [32,36].

- The local hardness varied in the consolidated products with the local amount of strain and depended on the mechanism of deformation accommodation. For the micro-HPT product obtained from the atomized powder, the increasing amount of local strain hardened the materials until dynamic recrystallization occurred. Comparatively, for the nano-HPT product obtained from the nano-sized Mg/MgO core-shell powder, the dynamic recovery process led a continuous decrease in local hardness with the amount of strain.

- After HPT deformation, likely due to an increase in nucleation sites for the hydride formation, the kinetics of the H pick up was significantly improved. For example, the nano-HPT product took only 5 min to reach 4 wt.% H-uptake compared to 68 min for its initial condensed powder precursor. For the heterogeneous micro-HPT product, the fastest kinetics was reported for the central part of the product that was properly deformed and developed a finer recrystallized microstructure. Unfortunately, this faster kinetics was always accompanied with a lower H-storage capacity. For example, in the case of the condensed nano-sized powder, the capacity was reduced from 7.2 wt.% to 5.7 wt.% after HPT.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zehetbauer, M.J.; Zhu, Y.T. Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 2006, 58, 33–39. [Google Scholar] [CrossRef] [Green Version]

- Zehetbauer, M.; Grössinger, R.; Krenn, H.; Krystian, M.; Pippan, R.; Rogl, P.; Waitz, T.; Würschum, R. Bulk nanostructured functional materials by severe plastic deformation. Adv. Eng. Mater. 2010, 12, 692–700. [Google Scholar] [CrossRef]

- Alexandrov, I.V.; Zhu, Y.T.; Lowe, T.C.; Valiev, R.Z. Severe plastic deformation: New technique for powder consolidation and grain size refinement. Powder Metall. 1998, 41, 11–13. [Google Scholar] [CrossRef]

- Xia, K. Consolidation of particles by severe plastic deformation: Mechanism and applications in processing bulk ultrafine and nanostructured alloys and composites. Adv. Eng. Mater. 2010, 12, 724–729. [Google Scholar] [CrossRef]

- Bachmaier, A.; Pippan, R. Generation of metallic nanocomposites by severe plastic deformation. Int. Mater. Rev. 2013, 58, 41–62. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Mishral, R.S.; Grozal, J.; Mukherjee, A.K. Processing of nanostructured nickel by severe plastic deformation consolidation of ball-milled powder. Scr. Mater. 1996, 34, 1443–1448. [Google Scholar] [CrossRef]

- Sort, J.; Zhilyaev, A.; Zielinska, M.; Nogués, J.; Surinach, S.; Thibault, J.; Baró, M.D. Microstructural effects and large microhardness in cobalt processed by high pressure torsion consolidation of ball milled powders. Acta Mater. 2003, 51, 6385–6393. [Google Scholar] [CrossRef]

- Edalati, K.; Horita, Z.; Fujiwara, H.; Ameyama, K. Cold consolidation of ball-milled titanium powders using high-pressure torsion. Metall. Mater. Trans. A 2010, 41, 3308–3317. [Google Scholar] [CrossRef]

- Zhao, Y.; Massion, R.; Grosdidier, T.; Toth, L.S. Gradient structure in high pressure torsion compacted iron powder. Adv. Eng. Mater. 2015, 17, 1748–1753. [Google Scholar] [CrossRef]

- Stolyarov, V.V.; Zhu, Y.T.; Lowe, T.C.; Islamgaliev, R.K.; Valiev, R.Z. Processing nanocrystalline Ti and its nanocomposites from micrometer-sized Ti powder using high pressure torsion. Mater. Sci. Eng. A 2000, 282, 78–85. [Google Scholar] [CrossRef]

- Bachmaier, A.; Hohenwarter, A.; Pippan, R. New procedure to generate stable nanocrystallites by severe plastic deformation. Scr. Mater. 2009, 61, 1016–1019. [Google Scholar] [CrossRef]

- Bachmaier, A.; Pippan, R. Effect of oxide particles on the stabilization and final microstructure in aluminium. Mater. Sci. Eng. A 2011, 528, 7589–7595. [Google Scholar] [CrossRef] [PubMed]

- Zou, J.X.; Perez-Brokate, C.F.; Arruffat, R.; Bolle, B.; Fundenberger, J.J.; Zeng, X.Q.; Grosdidier, T.; Ding, W.J. Nanostructured bulk Mg+MgO composite synthesized through arc plasma evaporation and high pressure torsion for H-storage application. Mater. Sci. Eng. B 2014, 183, 1–5. [Google Scholar] [CrossRef]

- Grosdidier, T.; Fundenberger, J.J.; Zou, J.X.; Pan, Y.C.; Zeng, X.Q. Nanostructured Mg based hydrogen storage bulk materials prepared by high pressure torsion consolidation of arc plasma evaporated ultrafine powders. Int. J. Hydrogen Energy 2015, 40, 16985–16991. [Google Scholar] [CrossRef]

- Kulekci, M.K. Magnesium and its alloys applications in automotive industry. Int. J. Adv. Manuf. Tech. 2008, 39, 851–865. [Google Scholar] [CrossRef]

- Avedesian, M.M.; Baker, H. ASM Speciality Handbook: Magnesium and Magnesium Alloys; ASM International: Ohio, OH, USA, 1999; pp. 78–84. [Google Scholar]

- Dobrzański, L.A.; Tański, T.; Čížek, L.; Brytan, Z. Structure and properties of magnesium cast alloys. J. Mater. Process. Technol. 2007, 192, 567–574. [Google Scholar] [CrossRef]

- Tun, K.S.; Gupta, M. Improving mechanical properties of magnesium using nano-yttria reinforcement and microwave assisted powder metallurgy method. Compos. Sci. 2007, 67, 2657–2664. [Google Scholar] [CrossRef]

- Mondet, M.; Barraud, E.; Lemonnier, S.; Guyon, J.; Allain, N.; Grosdidier, T. Microstructure and mechanical properties of AZ91 magnesium alloy developed by Spark Plasma Sintering. Acta Mater. 2016, 119, 55–67. [Google Scholar] [CrossRef]

- Shen, J.; Imai, H.; Chen, B.; Ye, X.; Umeda, J.; Kondoh, K. Deformation mechanisms of pure Mg materials fabricated by using pre-rolled powders. Mater. Sci. Eng. A 2016, 658, 309–320. [Google Scholar] [CrossRef]

- Bettles, C.J. Magnesium powder metallurgy: Process and materials opportunities. J. Mater. Eng. Perform. 2008, 17, 297–301. [Google Scholar] [CrossRef]

- Umeda, J.; Kawakami, M.; Kondoh, K.; Ayman, E.S.; Imai, H. Microstructural and mechanical properties of titanium particulate reinforced magnesium composite materials. Mater. Chem. Phys. 2010, 123, 649–657. [Google Scholar] [CrossRef]

- Straffelini, G.; Dione Da Costa, L.; Menapace, C.; Zanella, C.; Torralba, J.M. Properties of AZ91 alloy produced by spark plasma sintering and extrusion. Powder Metall. 2013, 56, 405–410. [Google Scholar] [CrossRef]

- Burke, P. Investigation of the Sintering Fundamentals of Magnesium Powders. Ph.D. Thesis, Dalhousie University, Nova Scotia, NS, Canada, 2011. [Google Scholar]

- Moss, M.; Lapovok, R.; Bettles, C.J. The equal channel angular pressing of magnesium and magnesium alloy powders. JOM 2007, 59, 54–57. [Google Scholar] [CrossRef]

- Wu, X.; Xu, W.; Kubota, M.; Xia, K. Bulk Mg produced by back pressure equal channel angular consolidation (BP-ECAC). Mater. Sci. Forum 2008, 584, 114–118. [Google Scholar] [CrossRef]

- Cakmak, G.; Ozturk, T. ECAP processing and mechanical milling of Mg and Mg-Ti powders: A comparative study. J. Mater. Sci. 2011, 46, 5559–5567. [Google Scholar] [CrossRef]

- Yoon, E.Y.; Lee, D.J.; Kim, T.S.; Chae, H.J.; Jenei, P.; Gubicza, J.; Ungár, T.; Janecek, M.; Vratna, J.; Lee, S.; Kim, H.S. Microstructures and mechanical properties of Mg-Zn-Y alloy consolidated from gas-atomized powders using high-pressure torsion. J. Mater. Sci. 2012, 47, 7117–7123. [Google Scholar] [CrossRef]

- Sakai, G.; Nakamura, K.; Horita, Z.; Langdon, T.G. Developing high-pressure torsion for use with bulk samples. Mater. Sci. Eng. A 2005, 406, 268–273. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Langdon, T.G. Development of structural heterogeneities in a magnesium alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2011, 528, 4500–4506. [Google Scholar] [CrossRef]

- Panda, S.; Toth, L.S.; Fundenberger, J.J.; Perroud, O.; Guyon, J.; Zou, J.; Grosdidier, T. Analysis of heterogeneities in strain and microstructure in aluminum alloy and magnesium processed by high-pressure torsion. Mater. Charact. 2017, 123, 159–165. [Google Scholar] [CrossRef]

- Panda, S.; Fundenberger, J.J.; Zhao, Y.; Zou, J.; Toth, L.S.; Grosdidier, T. Effect of initial powder type on the hydrogen storage properties of high-pressure torsion consolidated Mg. Int. J. Hydrogen Energy 2017, 42, 22438–22448. [Google Scholar] [CrossRef]

- Skripnyuk, V.M.; Rabkin, E.; Estrin, Y.; Lapovok, R. The effect of ball milling and equal channel angular pressing on the hydrogen absorption/desorption properties of Mg-4.95 wt.% Zn-0.71 wt.% Zr (ZK60) alloy. Acta Mater. 2004, 52, 405–414. [Google Scholar] [CrossRef]

- Skripnyuk, V.M.; Rabkin, E.; Estrin, Y.; Lapovok, R. Improving hydrogen storage properties of magnesium based alloys by equal channel angular pressing. Int. J. Hydrogen Energy 2009, 34, 6320–6324. [Google Scholar] [CrossRef]

- Edalati, K.; Yamamoto, A.; Horita, Z.; Ishihara, T. High-pressure torsion of pure magnesium: Evolution of mechanical properties, microstructures and hydrogen storage capacity with equivalent strain. Scr. Mater. 2011, 64, 880–883. [Google Scholar] [CrossRef]

- Huot, J.; Skryabina, N.Y.; Fruchart, D. Application of severe plastic deformation techniques to magnesium for enhanced hydrogen sorption properties. Metals 2012, 31, 329–343. [Google Scholar] [CrossRef]

- Skryabina, N.; Medvedeva, N.; Gabov, A.; Fruchart, D.; Nachev, S.; de Rango, P. Impact of Severe Plastic Deformation on the stability of MgH2. J. Alloys Compd. 2015, 645, S14–S17. [Google Scholar] [CrossRef]

- Shao, H.; Wang, Y.; Xu, H.; Li, X. Hydrogen storage properties of magnesium ultrafine particles prepared by hydrogen plasma-metal reaction. Mater. Sci. Eng. B 2004, 110, 221–226. [Google Scholar] [CrossRef]

- MDI JADE 7 Materials Data XRD Pattern Processing, Identification, and Quantification. Available online: http://www.materialsdata.com/ (accessed on 30 May 2018).

- Fundenberger, J.J.; Bouzy, E.; Goran, D.; Guyon, J.; Yuan, H.; Morawiec, A. Orientation mapping by transmission-SEM with an on-axis detector. Ultramicroscopy 2016, 161, 17–22. [Google Scholar] [CrossRef] [PubMed]

- Beausir, B.; Fundenberger, J.J. ATOM—Analysis Tools for Orientation Maps. Université de Lorraine: Metz, France, 2015. Available online: http://www.atex-software.eu/ (accessed on 31 July 2018).

- Fundenberger, J.J.; Beausir, B. JTEX—Software for Texture Analysis. Université de Lorraine: Metz, France, 2015. Available online: http://www.atex-software.eu/ (accessed on 31 July 2018).

- Del Valle, J.A.; Perez-Prado, M.T.; Ruano, O.A. Deformation mechanisms responsible for the high ductility in a Mg AZ31 alloy analyzed by electron backscattered diffraction. Metall. Mater. Trans. A 2005, 36, 1427–1438. [Google Scholar] [CrossRef]

- Edalati, K.; Horita, Z. Significance of homologous temperature in softening behavior and grain size of pure metals processed by high-pressure torsion. Mater. Sci. Eng. A 2011, 528, 7514–7523. [Google Scholar] [CrossRef]

- Beausir, B.; Toth, L.S.; Neale, K.W. Ideal orientations and persistence characteristics of hexagonal close packed crystals in simple shear. Acta Mater. 2007, 55, 2695–2705. [Google Scholar] [CrossRef]

- Bonarski, B.J.; Schafler, E.; Mingler, B.; Skrotzki, W.; Mikulowski, B.; Zehetbauer, M.J. Texture evolution of Mg during high-pressure torsion. J. Mater. Sci. 2008, 43, 7513–7518. [Google Scholar] [CrossRef]

- Skrotzki, W.; Scheerbaum, N.; Oertel, C.G.; Brokmeier, H.G.; Suwas, S.; Toth, L.S. Recrystallization of high-purity aluminium during equal channel angular pressing. Acta Mater. 2007, 55, 2211–2218. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Nurislamova, G.V.; Kim, B.K.; Baro, M.D.; Szpunar, J.A.; Langdon, T.G. Experimental parameters influencing grain refinement and microstructural evolution during high-pressure torsion. Acta Mater. 2003, 51, 753–765. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Toth, L.S.; Gu, C.F.; Beausir, B.; Fundenberger, J.J.; Hoffman, M. Geometrically necessary dislocations favor the Taylor uniform deformation mode in ultra-fine-grained polycrystals. Acta Mater. 2016, 117, 35–42. [Google Scholar] [CrossRef]

- Leiva, D.R.; Huot, J.; Ishikawa, T.T.; Bolfarini, C.; Kiminami, C.S.; Jorge, A.M.; Botta, W.J. Hydrogen activation behavior of commercial magnesium processed by different severe plastic deformation routes. Mater. Sci. Forum 2011, 667, 1047–1051. [Google Scholar] [CrossRef]

- Edalati, K.; Novelli, M.; Itano, S.; Li, H.W.; Akiba, E.; Horita, Z.; Grosdidier, T. Effect of gradient-structure versus uniform nanostructure on hydrogen storage of Ti-V-Cr alloys: Investigation using ultrasonic SMAT and HPT processes. J. Alloys Compd. 2018, 737, 337–346. [Google Scholar] [CrossRef]

- Gerard, N. Role of nucleation in some hydrogen formation kinetics. J. Less Comm. Met. 1987, 131, 13–23. [Google Scholar] [CrossRef]

- Tien, H.Y.; Tanniru, M.; Wu, C.Y.; Ebrahimi, F. Effect of hydride nucleation rate on the hydrogen capacity of Mg. Int. J. Hydrogen Energy 2009, 34, 6343–6349. [Google Scholar] [CrossRef]

- Töpler, J.; Buchner, H.; Säufferer, H.; Knorr, K.; Prandl, W. Measurements of the diffusion of hydrogen atoms in magnesium and Mg2Ni by neutron scattering. J. Less Comm. Met. 1982, 88, 397–404. [Google Scholar] [CrossRef]

| Samples | Mg (wt.%) | MgO (wt.%) | Mg(OH)2 (wt.%) | Lattice Constants (nm) | Intensity Ratio (I0002/I10̅10) |

|---|---|---|---|---|---|

| Atomized Mg | 100 | - | - | a = b = 0.3208, c = 0.5209 | 1.24 |

| 2 turns micro-HPT | 100 | - | - | a = b = 0.3200, c = 0.5192 | 4.11 |

| Condensed Mg | 93 | 5 | 2 | a = b = 0.3207, c = 0.5206 | 1.08 |

| 2 turns nano-HPT | 92 | 5 | 3 | a = b = 0.3194, c = 0.5185 | 1.73 |

| HPT products | Calculated Density (dc, g cm−3) | Theoretical Density (dt, g cm−3) | Relative Density (dc/dt, %) |

|---|---|---|---|

| 2 turns micro-HPT | 1.596 | 1.738 | 91.8 ± 0.5 |

| 2 turns nano-HPT | 1.715 | 1.784 (5 wt.% MgO) | 96.1 ± 0.8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Panda, S.; Toth, L.S.; Zou, J.; Grosdidier, T. Effect of Strain Heterogeneities on Microstructure, Texture, Hardness, and H-Activation of High-Pressure Torsion Mg Consolidated from Different Powders. Materials 2018, 11, 1335. https://doi.org/10.3390/ma11081335

Panda S, Toth LS, Zou J, Grosdidier T. Effect of Strain Heterogeneities on Microstructure, Texture, Hardness, and H-Activation of High-Pressure Torsion Mg Consolidated from Different Powders. Materials. 2018; 11(8):1335. https://doi.org/10.3390/ma11081335

Chicago/Turabian StylePanda, Subrata, Laszlo S. Toth, Jianxin Zou, and Thierry Grosdidier. 2018. "Effect of Strain Heterogeneities on Microstructure, Texture, Hardness, and H-Activation of High-Pressure Torsion Mg Consolidated from Different Powders" Materials 11, no. 8: 1335. https://doi.org/10.3390/ma11081335