Experimental and Numerical Studies on Fiber Deformation and Formability in Thermoforming Process Using a Fast-Cure Carbon Prepreg: Effect of Stacking Sequence and Mold Geometry

Abstract

:1. Introduction

2. Experimental

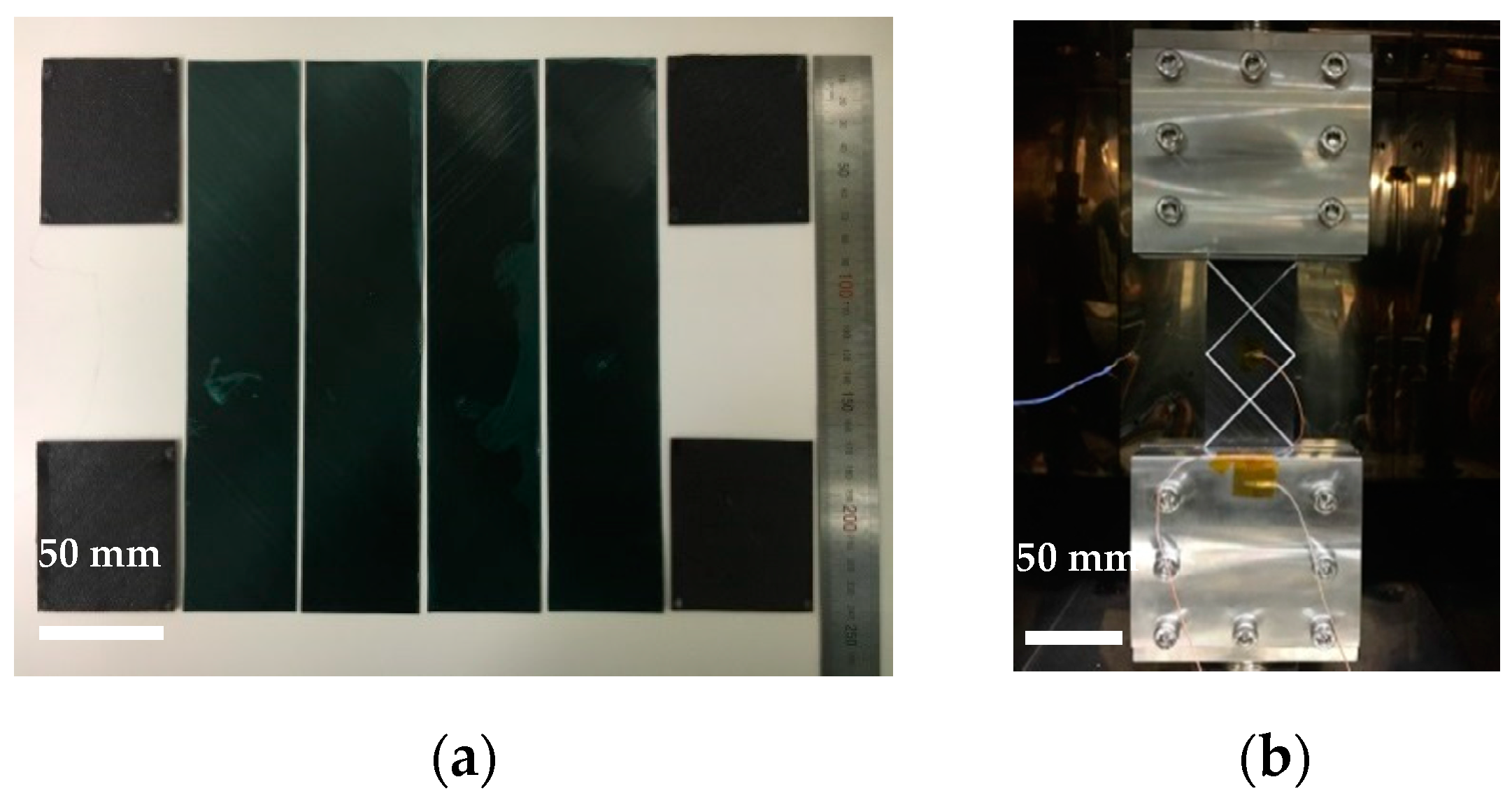

2.1. Materials and Sample Preparation

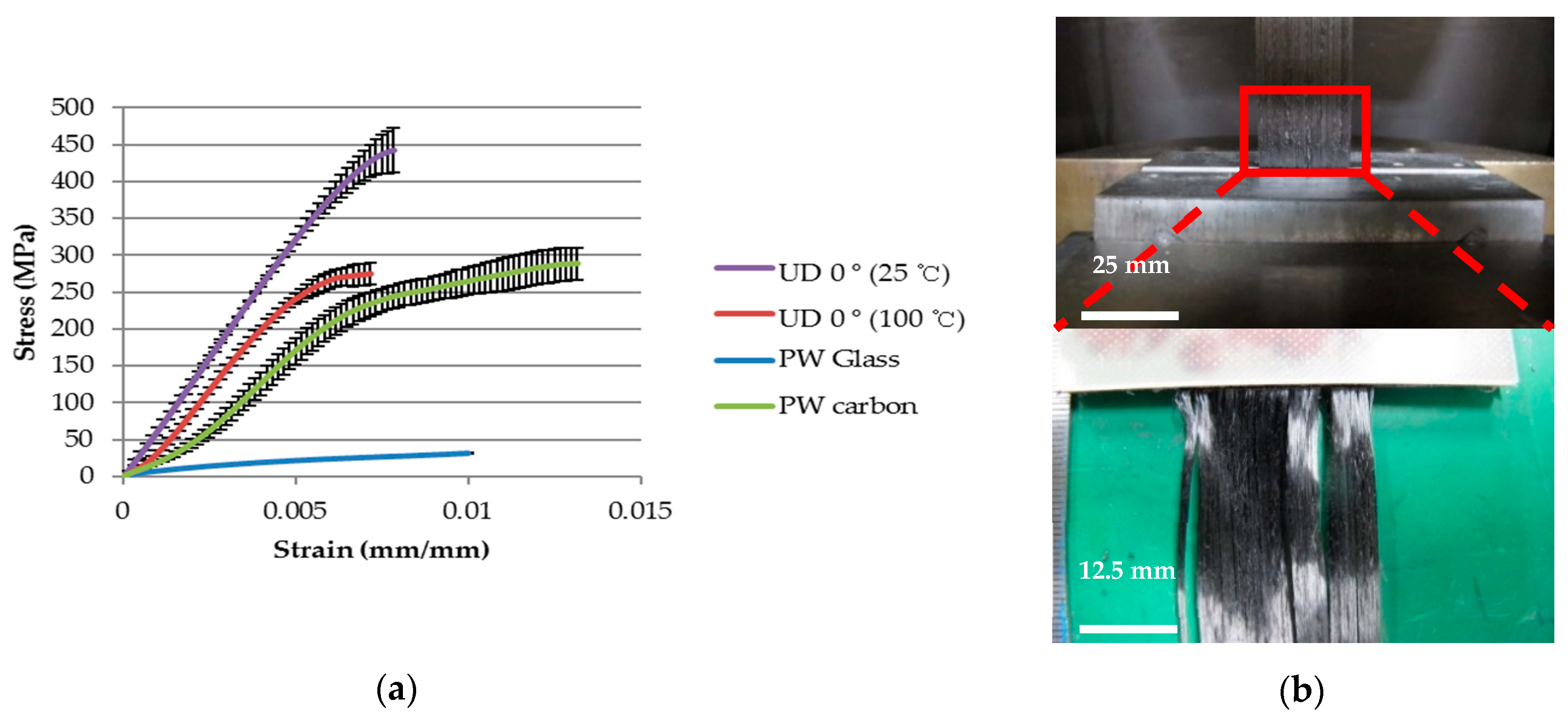

2.2. Measurement of the Non-Linear Mechanical Behaviors of the Prepreg at Elevated Temperatures

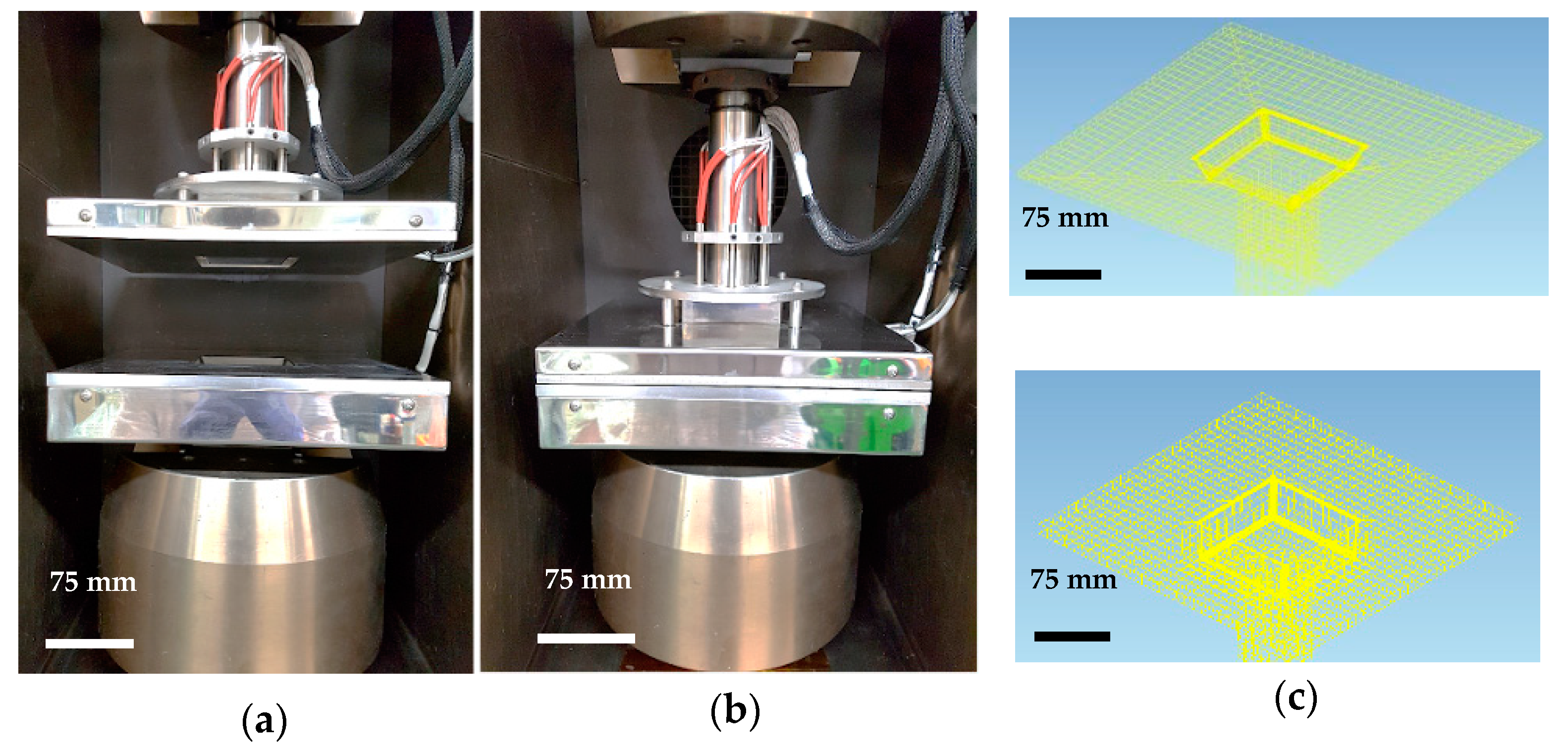

2.3. Mold Geometry

2.4. Thermoforming Apparatus and Procedure

2.5. Forming Simulation

3. Results and Discussion

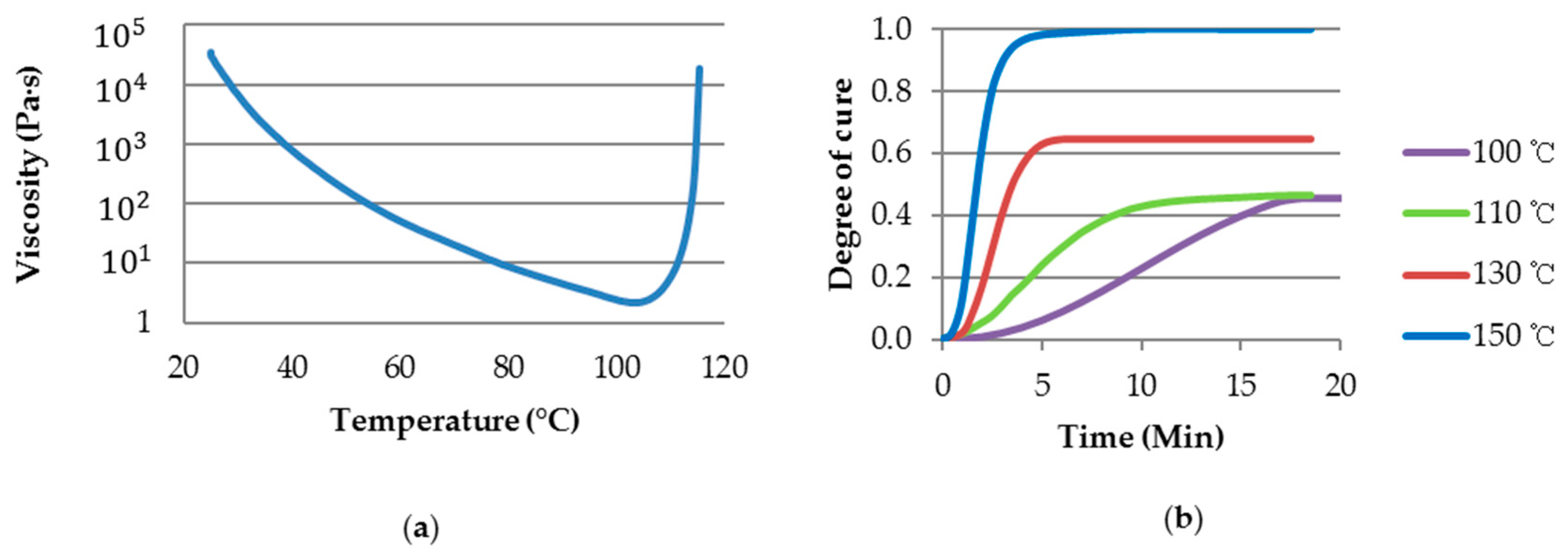

3.1. Material Properties of the Resin

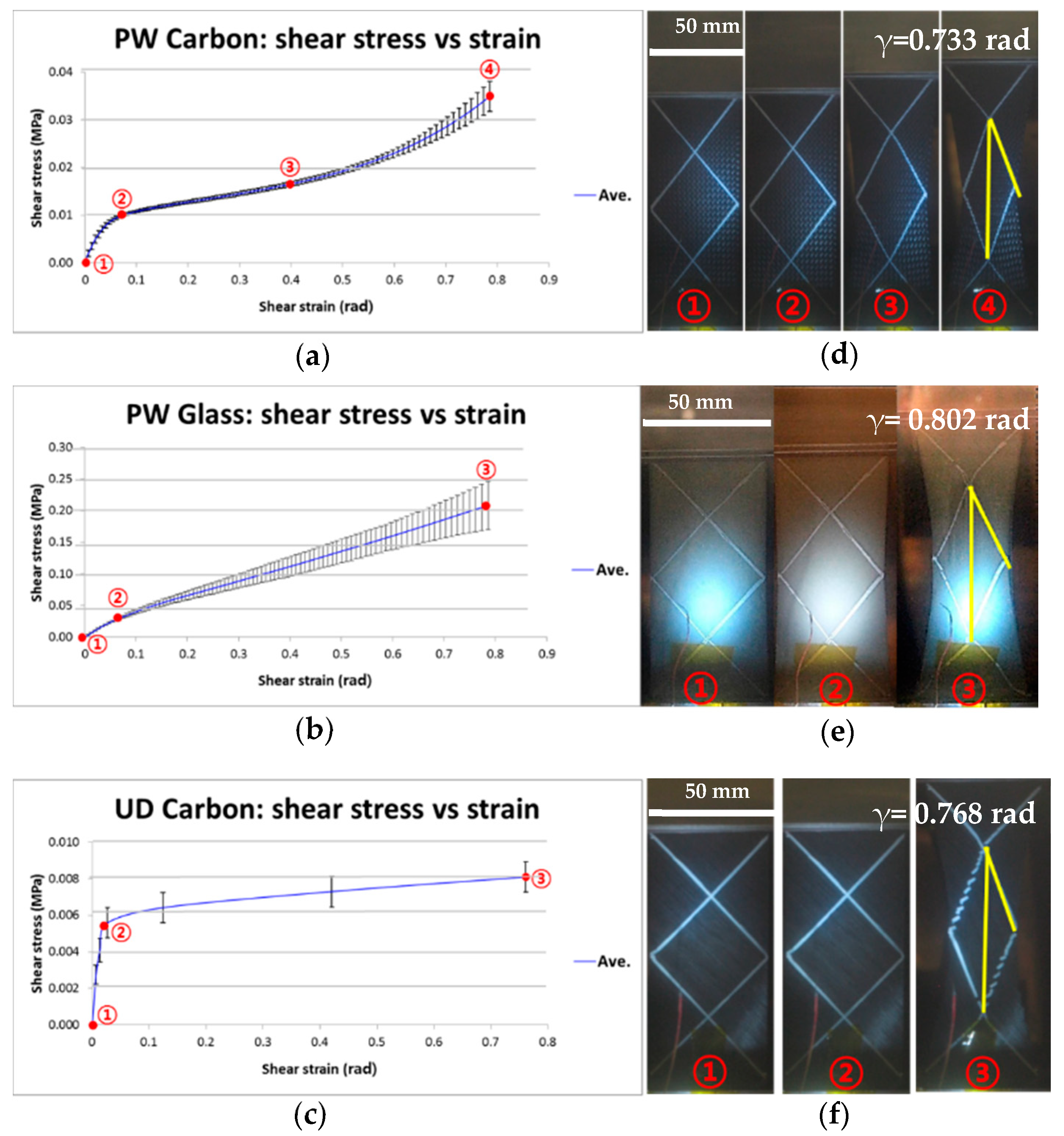

3.2. Mechanical Properties of Prepreg at the Process Temperature

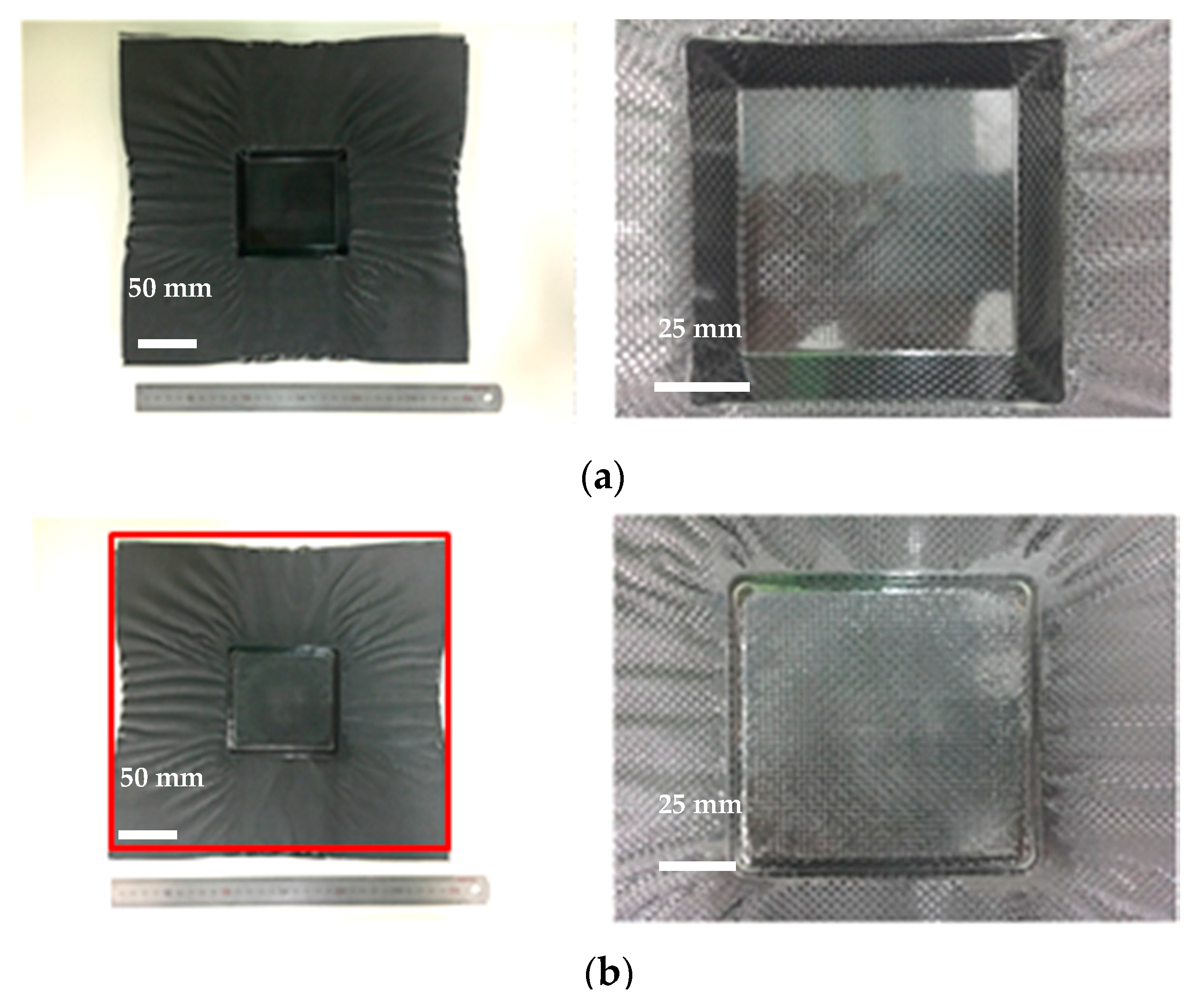

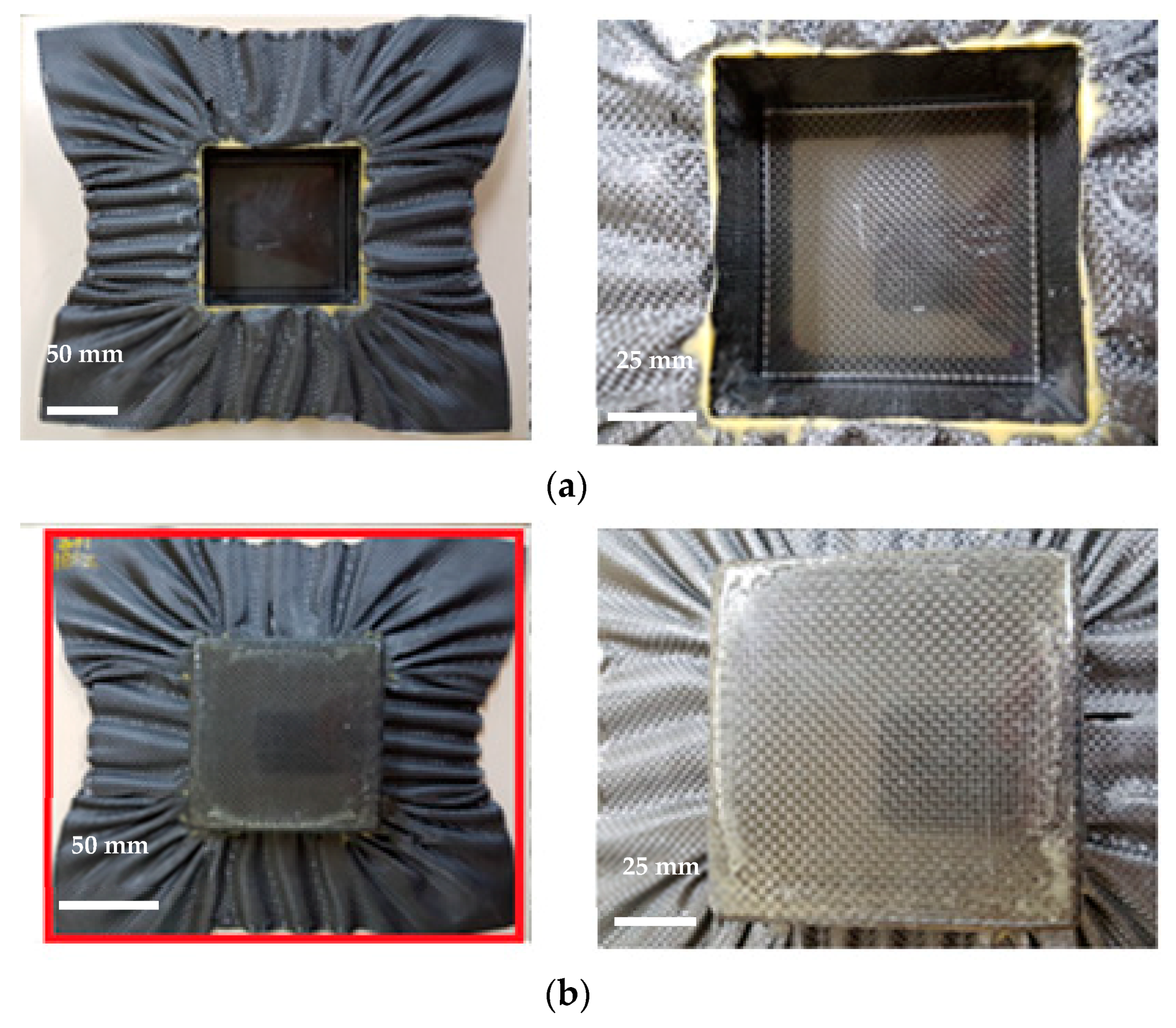

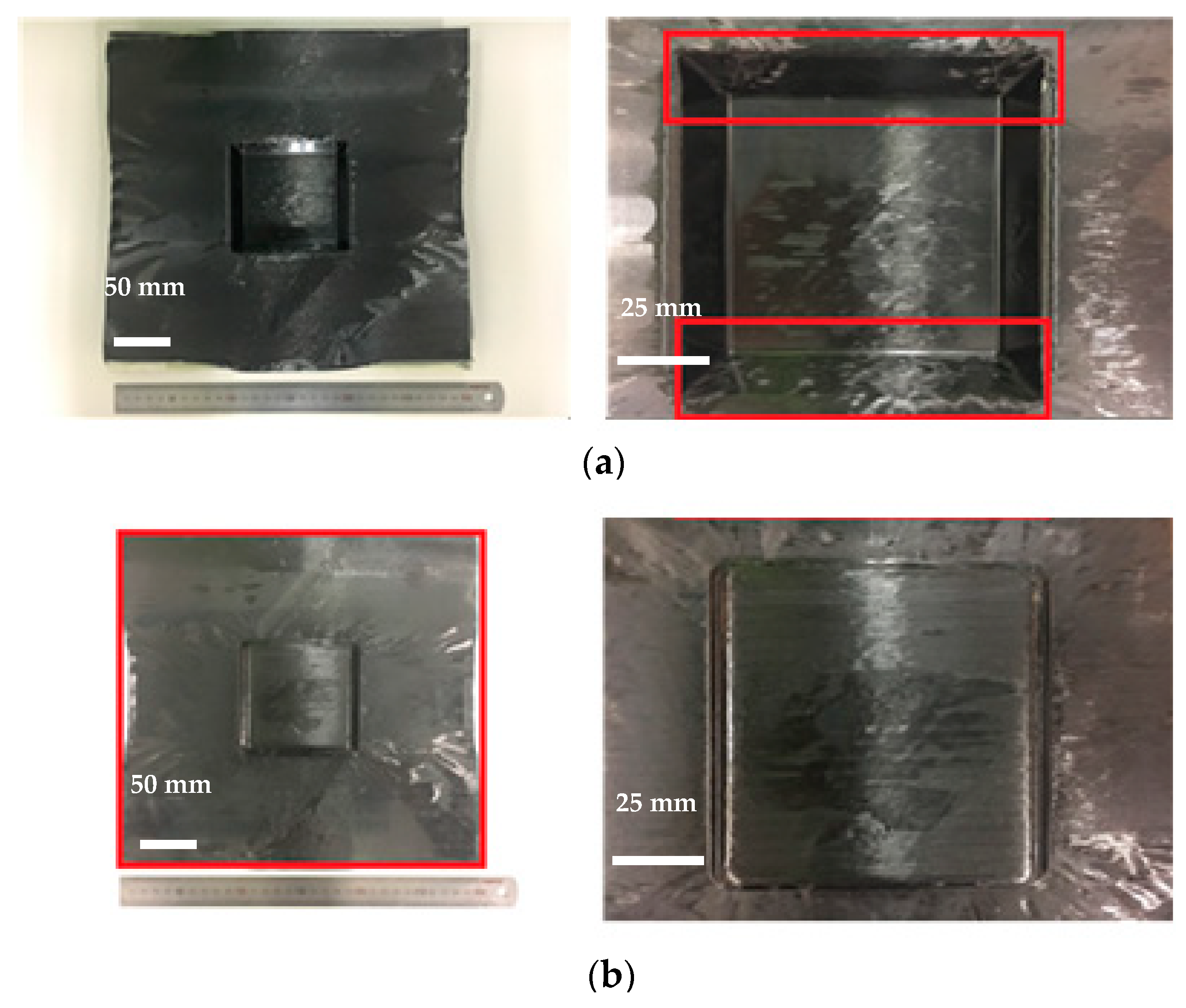

3.3. Square-Cup Drawing Test

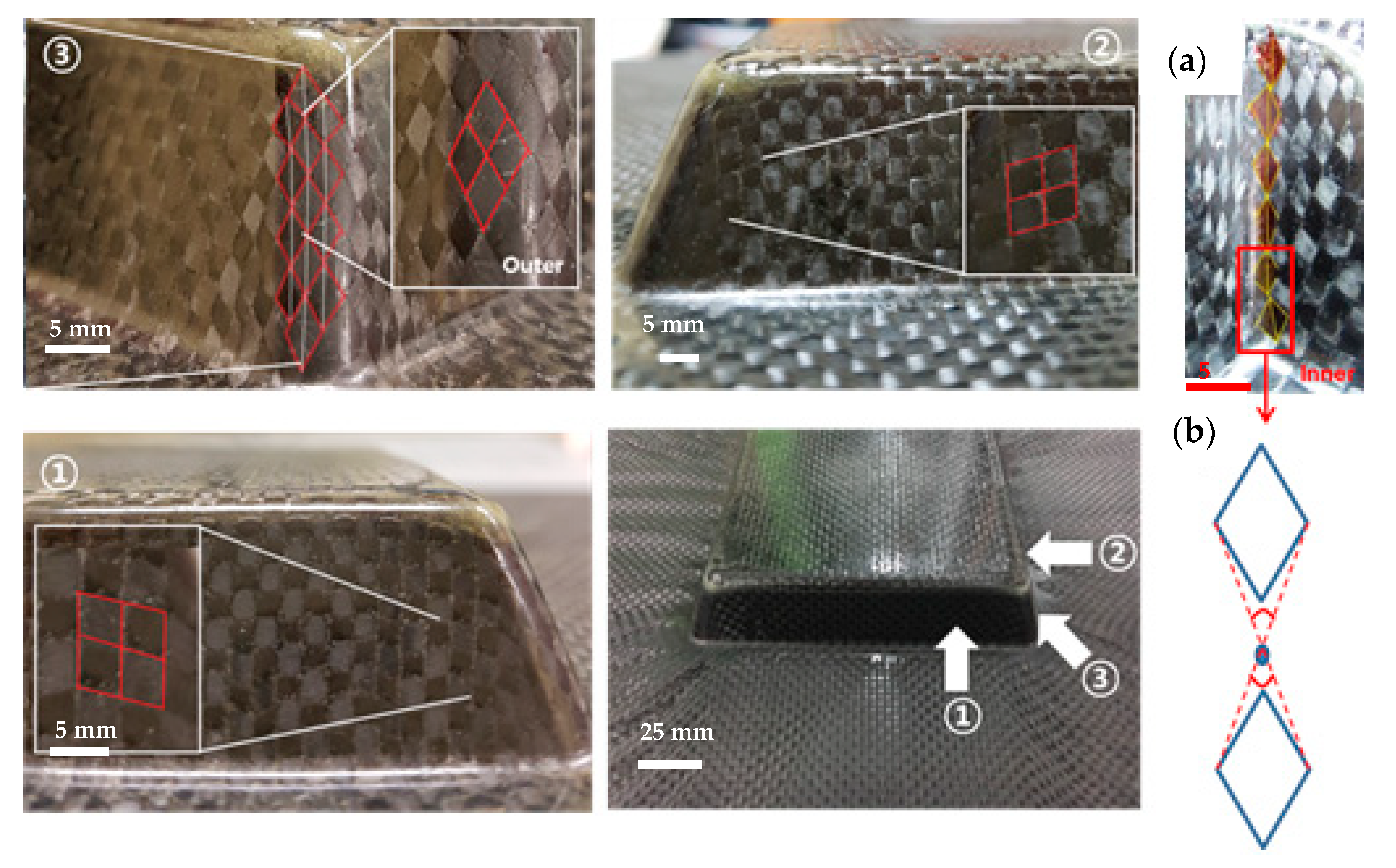

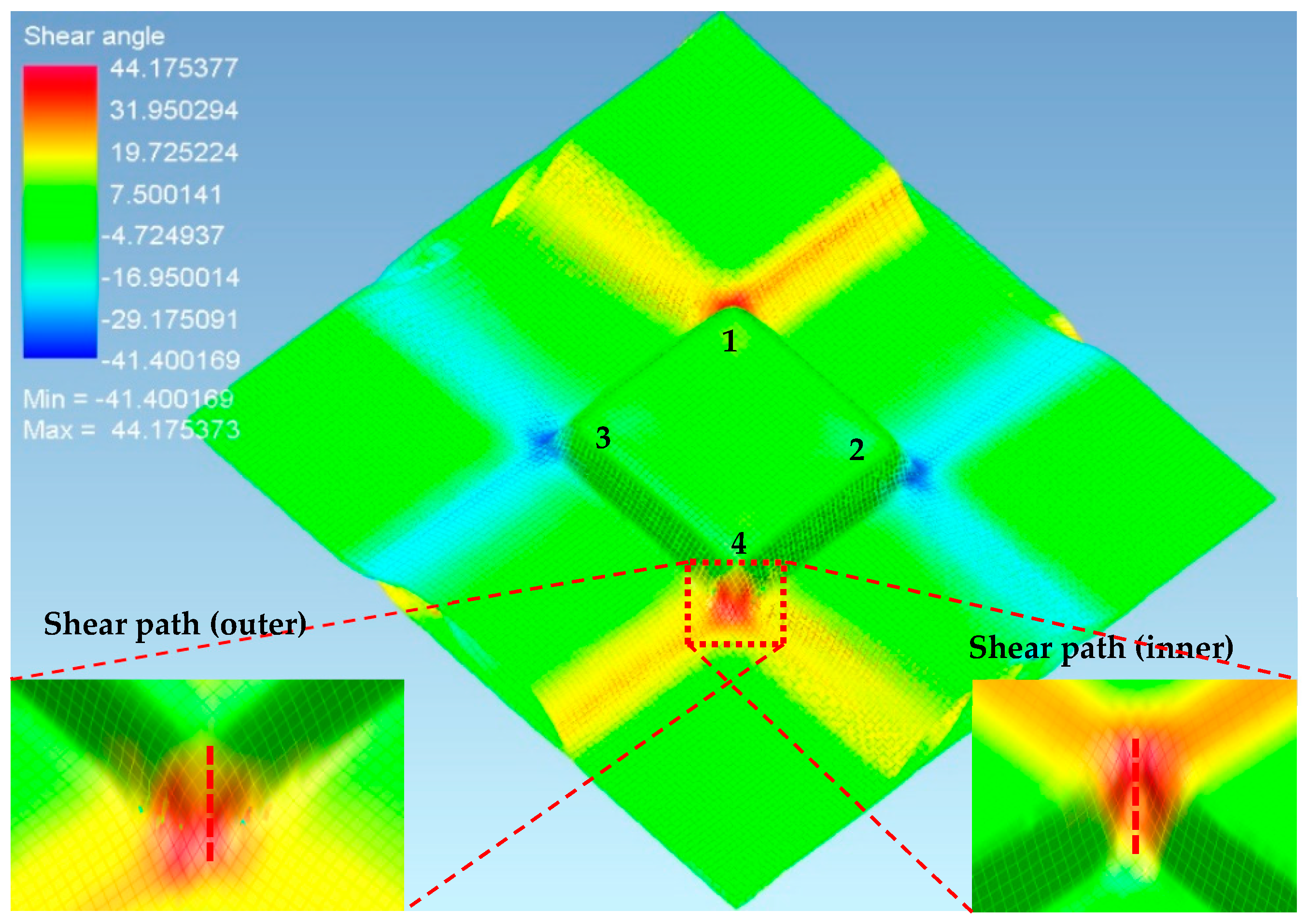

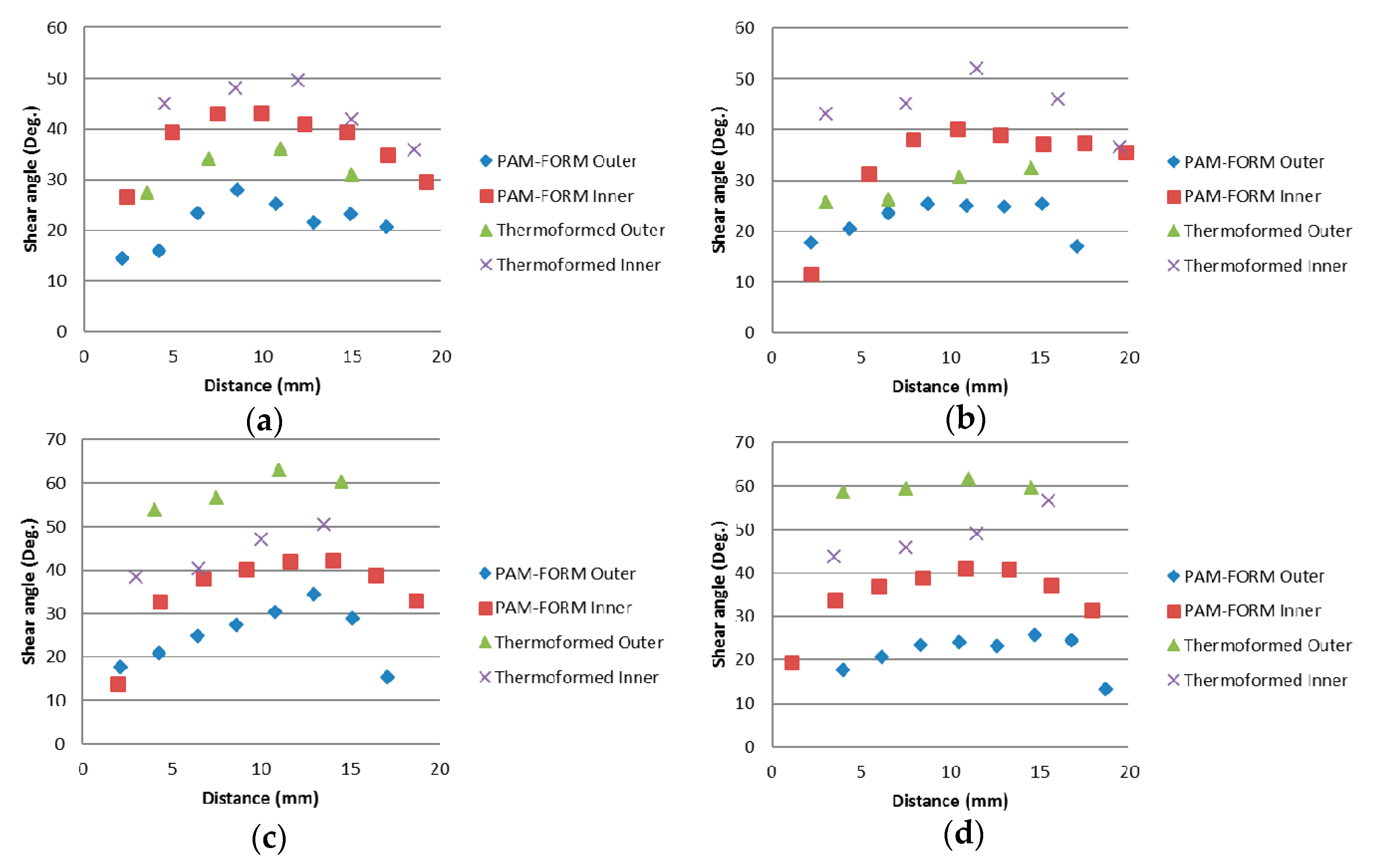

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- International Council on Clean Transportation. Global Passenger Vehicle Standards. 2014. Available online: http://theicct.org/info-tools/global-passenger-vehicle-standards (accessed on 15 December 2016).

- Sherwood, J.A.; Fetfatsidis, K.A.; Gorczyca, J.L.; Berger, L. Fabric thermostamping in polymer matrix composite. In Manufacturing Techniques for Polymer Matrix Composites (PMCs); Advani, S.G., Hsiao, K.-T., Eds.; Elsevier: New York, NY, USA, 2012; pp. 139–179. [Google Scholar]

- Knibbs, R.H.; Morris, J.B. The effects of fibre orientation on the physical properties of composites. Composites 1974, 5, 209–218. [Google Scholar] [CrossRef]

- Fuller, J.D.; Wisnom, M.R. Exploration of the potential for pseudo-ductility in thin ply CFRP angle-ply laminates via an analytical method. Compos. Sci. Technol. 2015, 112, 8–15. [Google Scholar] [CrossRef]

- Wang, P.; Hamila, N.; Boisse, P. Thermoforming simulation of multilayer composites with continuous fibres and thermoplastic matrix. Compos. Part B 2013, 52, 127–136. [Google Scholar] [CrossRef]

- Sorrentino, L.; Bellini, C. Potentiality of Hot Drape Forming to produce complex shape parts in composite material. Int. J. Adv. Manuf. Technol. 2016, 85, 945–954. [Google Scholar] [CrossRef]

- Wang, P.; Hamila, N.; Pineau, P.; Boisse, P. Thermomechanical analysis of thermoplastic composite prepregs using bias-extension test. J. Thermoplast. Compos. Mater. 2014, 27, 679–698. [Google Scholar] [CrossRef]

- Lee, W.; Padvoiskis, J.; Cao, J.; de Luycker, E.; Boisse, P.; Morestin, F.; Chen, J.; Sherwood, J. Bias-extension of woven composite fabrics. Int J Mater Form. 2008, 1, 895–898. [Google Scholar] [CrossRef]

- Guzman, E.; Hamila, N.; Boisse, P. Thermomechanical analysis, modelling and simulation of the forming of pre-impregnated thermoplastics composites. Compos. Part A 2014, 78, 211–222. [Google Scholar] [CrossRef]

- Gorczyca, J. A Study of the Frictional Behavior of a Plain-Weave Fabric during the Thermostamping Process. Ph.D. Thesis, Department of Mechanical Engineering, University of Massachusetts Lowell, Lowell, MA, USA, January 2004. [Google Scholar]

- Ersoy, N.; Potter, K.; Wisnom, M.R.; Clegg, M.J. An experimental method to study the frictional processes during composites manufacturing. Compos. Part A 2005, 36, 1536–1544. [Google Scholar] [CrossRef]

- Thije, R.H.W.; Akkerman, R.; Ubbink, M.; van der Meer, L. A lubrication approach to friction in thermoplastic composites forming processes. Compos. Part A 2011, 42, 950–960. [Google Scholar] [CrossRef]

- Zhang, W.; Ren, H.; Lu, J.; Zhang, Z.; Su, L.; Wang, J.; Zeng, D.; Su, X.; Cao, J. Experimental Methods to Characterize the Woven Composite Prepreg Behavior during the Preforming Process. In Proceedings of the Thirty-First Technical Conference of the American Society for Composites 2016, Williamsburg, VA, USA, 19–21 September 2016. [Google Scholar]

- Cao, J.; Akkerman, R.; Boisse, P.; Chen, J.; Cheng, H.S.; de Graaf, E.F.; Gorczyca, J.L.; Harrison, P.; Hivet, G.; Launay, J.; et al. Characterization of mechanical behavior of woven fabrics: Experimental methods and benchmark results. Compos. Part A 2008, 39, 1037–1053. [Google Scholar] [CrossRef]

- Groh, F.; Kappel, F.; Hühne, C.; Brymerski, W. Experimental Investigation of Process Induced Deformations of Automotive Composites with Focus on Fast Curing Epoxy Resins. In Proceedings of the 20th International Conference on Comosite Materials (ICCM-20), Copenhagen, Denmark, 19–24 July 2015. [Google Scholar]

- Geissberger, R.; Maldonado, J.; Bahamonde, N.; Keller, A.; Dransfeld, C.; Masania, K. Rheological modelling of thermoset composite processing. Compos. Part B 2017, 124, 182–189. [Google Scholar] [CrossRef]

- Seong, D.G.; Kim, S.; Um, M.K.; Song, S.S. Flow-induced deformation of unidirectional carbon fiber preform during the mold filling stage in liquid composite molding process. J. Compos. Mater. 2017, 52, 1265–1277. [Google Scholar] [CrossRef]

- Boisse, P. Simulations of Composite Reinforcement Forming, Woven Fabric Engineering; Dubrovski, P.D., Ed.; InTech: Rijeka, Croatia, 2010; ISBN 978-9-53-307194-7. Available online: https://hal.archives-ouvertes.fr/hal-01635297/document (accessed on 26 October 2016).

- Xue, P.; Peng, X.; Cao, J. A non-orthogonal constitutive model for characterizing woven composites. Compos. Part A 2003, 34, 183–193. [Google Scholar] [CrossRef]

- Liang, B.; Hamila, N.; Peillon, M.; Boisse, P. Analysis of thermoplastic prepreg bending stiffness during manufacturing and of its influence on wrinkling simulations. Compos. Part A 2014, 67, 111–122. [Google Scholar] [CrossRef]

- Alshahrani, H.; Hojjati, M. A new test method for the characterization of the bending behavior of textile prepregs. Compos. Part A 2017, 97, 128–140. [Google Scholar] [CrossRef]

- Creech, G. Mesoscopic Finite Element Modelling of Non-Crimp Fabrics for Drape and Failure Analyses. Ph.D. Thesis, Cranfield University, Cranfield, UK, 2006. [Google Scholar]

- Lee, W.; Um, M.K.; Byun, J.H. Numerical study on thermo-stamping of woven fabric composites based on double-dome stretch forming. Int. J. Mater. Form. 2010, 3, 1217–1227. [Google Scholar] [CrossRef]

- Lee, W.; Cao, J. Numerical simulations on double-dome forming of woven composites using the coupled non-orthogonal constitutive model. Int. J. Mater. Form. 2009, 2, 145–148. [Google Scholar]

- Cartwright, B.K.; de Luca, P.; Wang, J.; Stellbrink, K.; Paton, R. Some proposed experimental tests for use in finite element simulation of composite forming. In Proceedings of the 12th International Conference on Composite Materials (ICCM-12), Paris, France, 5–9 July 1999. [Google Scholar]

- Dusi, M.R.; Lee, W.I.; Ciriscioli, P.R.; Springer, G.S. Cure Kinetics and Viscosity of Fiberite 976 Resin. J. Compos. Mater. 1987, 21, 243–261. [Google Scholar] [CrossRef]

- Ersoy, N.; Garstka, T.; Potter, K.; Wisnom, M.; Porter, D.; Stringer, G. Modelling of the spring-in phenomenon in curved parts made of a thermosetting composite. Compos. Part A 2010, 41, 410–418. [Google Scholar] [CrossRef]

- Lightfoot, J.; Wisnom, M.; Potter, K. Defects in woven preforms: Formation mechanisms and the effects of laminate design and layup protocol. Compos. Part A 2013, 51, 99–107. [Google Scholar] [CrossRef]

- Launay, J.; Hivet, G.; Duong, A.; Boisse, P. Experimental analysis of the influence of tensions on in plane shear behaviour of woven composite reinforcements. Compos. Sci. Technol. 2008, 68, 506–515. [Google Scholar] [CrossRef]

- Prodromou, A.; Chen, J. On the relationship between shear angle and wrinkling of textile composite preforms. Compos. Part A 1997, 28, 491–503. [Google Scholar] [CrossRef]

- Wang, P.; Legrand, X.; Boisse, P.; Hamila, N.; Soulat, D. Experimental and numerical analyses of manufacturing process of a composite square box part: Comparison between textile reinforcement forming and surface 3D weaving. Compos. Part B 2015, 78, 26–34. [Google Scholar] [CrossRef]

| Model Name | Type | Thickness (Standard Deviation) (mm) | Resin Content (vol %) | Weight (g/m2) |

|---|---|---|---|---|

| 7628 | Plain woven (PW) glass | 0.305 (±3.1 × 10−6) | 42 | 209 |

| CF-3327 | Plain woven (PW) carbon | 0.269 (±5.7 × 10−6) | 42 | 200 |

| CU-190 | Unidirectional (UD) carbon | 0.202 (±3.8 × 10−6) | 38 | 190 |

| Ply | Pattern 1 | Pattern 2 |

|---|---|---|

| 1 | Carbon PW | UD 0° |

| 2 | UD 0° | UD +45° |

| 3 | UD +45° | UD −45° |

| 4 | UD −45° | Glass PW |

| 5 | Glass PW | Glass PW |

| 6 | Glass PW | Glass PW |

| 7 | UD −45° | Glass PW |

| 8 | UD +45° | UD −45° |

| 9 | UD 0° | UD +45° |

| 10 | Carbon PW | UD 0° |

| Prepreg | UD Carbon 0° | PW Carbon | PW Glass | UD Carbon 90° |

|---|---|---|---|---|

| Strength (MPa) | 280.1 (±18.3) | 72.2 (±5.3) | 30.0 (±1.1) | 1.4 × 10−3 (±1.6 × 10−4) |

| Modulus (GPa) | 60.4 (±3.7) | 11.2 (±1.1) | 0.57 (±0.04) | 2.9 × 10−2 (±2.6 × 10−3) |

| Prepreg | UD Carbon 0° | UD Carbon 90° | PW Carbon |

|---|---|---|---|

| Coefficient of friction | 0.050 | 0.063 | 0.202 |

| Standard deviation | 0.007 | 0.010 | 0.011 |

| No. | Interface | Coefficient of Friction (COF) | Standard Deviation |

|---|---|---|---|

| 1 | PW carbon/UD 0° | 0.180 | 0.002 |

| 2 | UD 0°/UD +45° | 0.078 | 0.002 |

| 3 | UD +45°/UD −45° | 0.074 | 0.005 |

| 4 | PW glass/UD −45° | 0.162 | 0.004 |

| 5 | PW glass/PW glass | 0.157 | 0.004 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bae, D.; Kim, S.; Lee, W.; Yi, J.W.; Um, M.K.; Seong, D.G. Experimental and Numerical Studies on Fiber Deformation and Formability in Thermoforming Process Using a Fast-Cure Carbon Prepreg: Effect of Stacking Sequence and Mold Geometry. Materials 2018, 11, 857. https://doi.org/10.3390/ma11050857

Bae D, Kim S, Lee W, Yi JW, Um MK, Seong DG. Experimental and Numerical Studies on Fiber Deformation and Formability in Thermoforming Process Using a Fast-Cure Carbon Prepreg: Effect of Stacking Sequence and Mold Geometry. Materials. 2018; 11(5):857. https://doi.org/10.3390/ma11050857

Chicago/Turabian StyleBae, Daeryeong, Shino Kim, Wonoh Lee, Jin Woo Yi, Moon Kwang Um, and Dong Gi Seong. 2018. "Experimental and Numerical Studies on Fiber Deformation and Formability in Thermoforming Process Using a Fast-Cure Carbon Prepreg: Effect of Stacking Sequence and Mold Geometry" Materials 11, no. 5: 857. https://doi.org/10.3390/ma11050857