2.45 GHz Microwave Processing and Its Influence on Glass Fiber Reinforced Plastics

Abstract

:1. Introduction

2. Materials, Equipment, and Methods

2.1. Materials

2.1.1. Fiber Material

2.1.2. Resin System

2.1.3. Tooling Material

2.2. Equipment

2.2.1. Conventional Heating Equipment

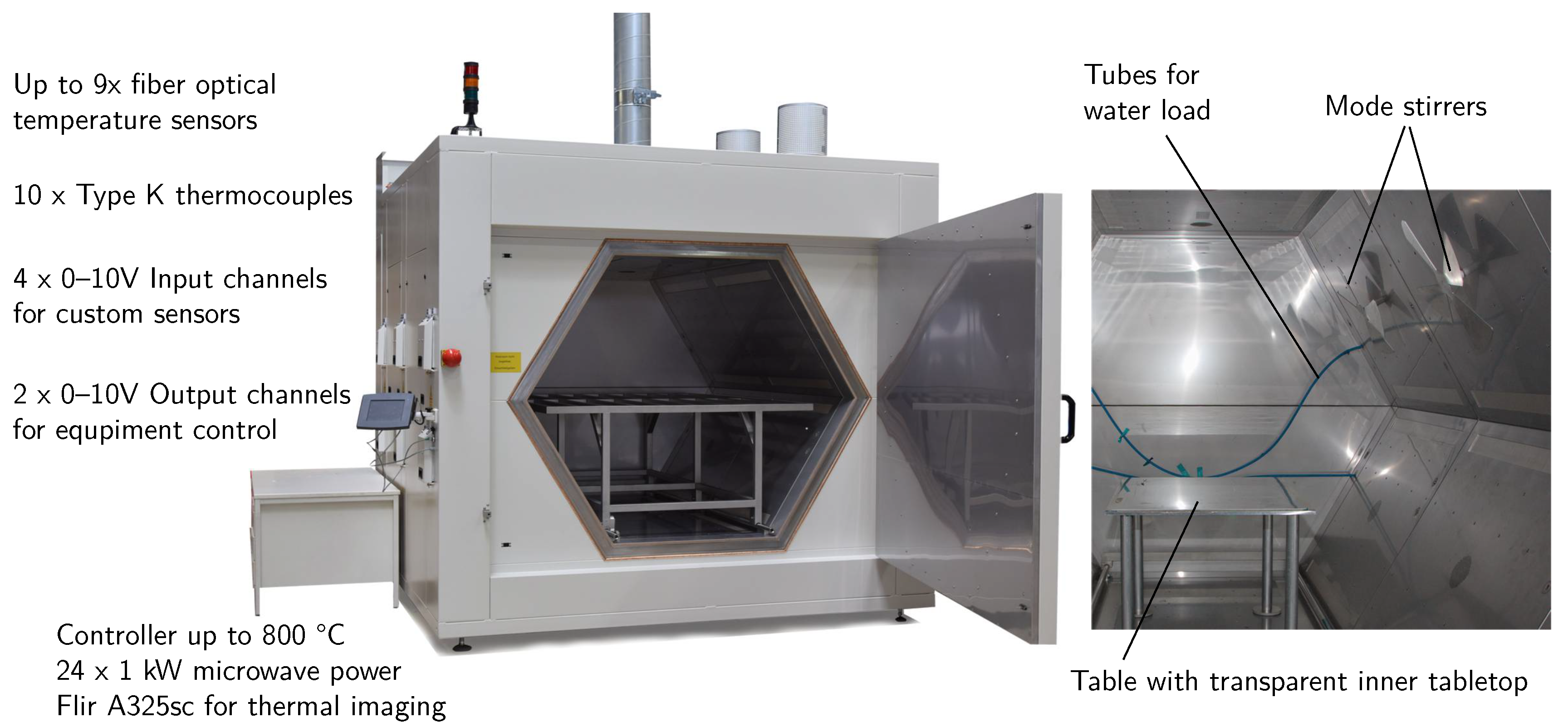

2.2.2. Microwave Equipment

2.2.3. Microwave Process Control

2.2.4. Temperature Measurement Equipment

2.3. Specimen Production

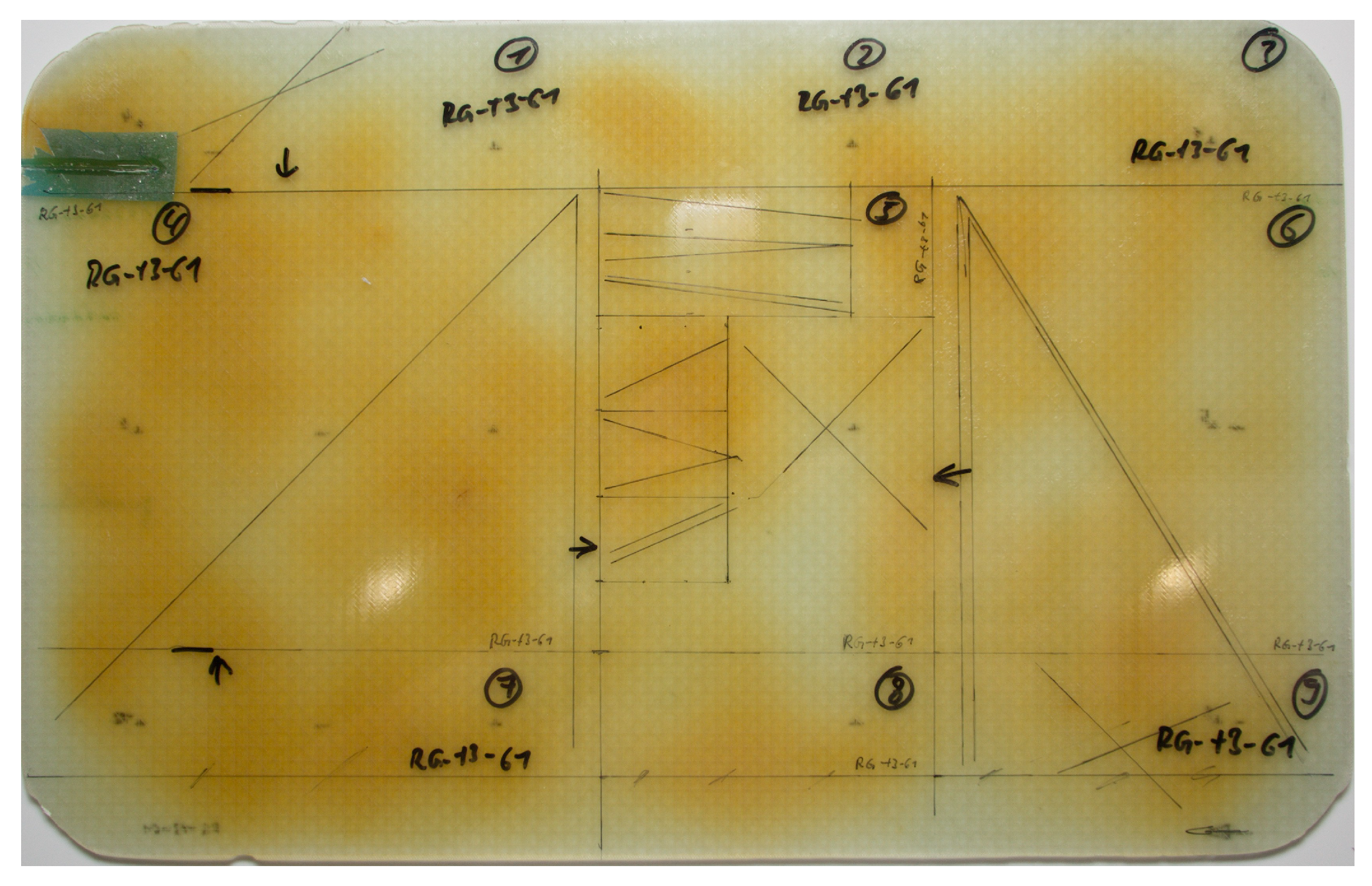

2.3.1. Plate Manufacturing—Preforming

2.3.2. Plate Manufacturing—Infiltration Process

2.3.3. Plate Manufacturing—Curing Processes

2.4. Quality Control and Testing

2.4.1. Quality Control

2.4.2. Measurements

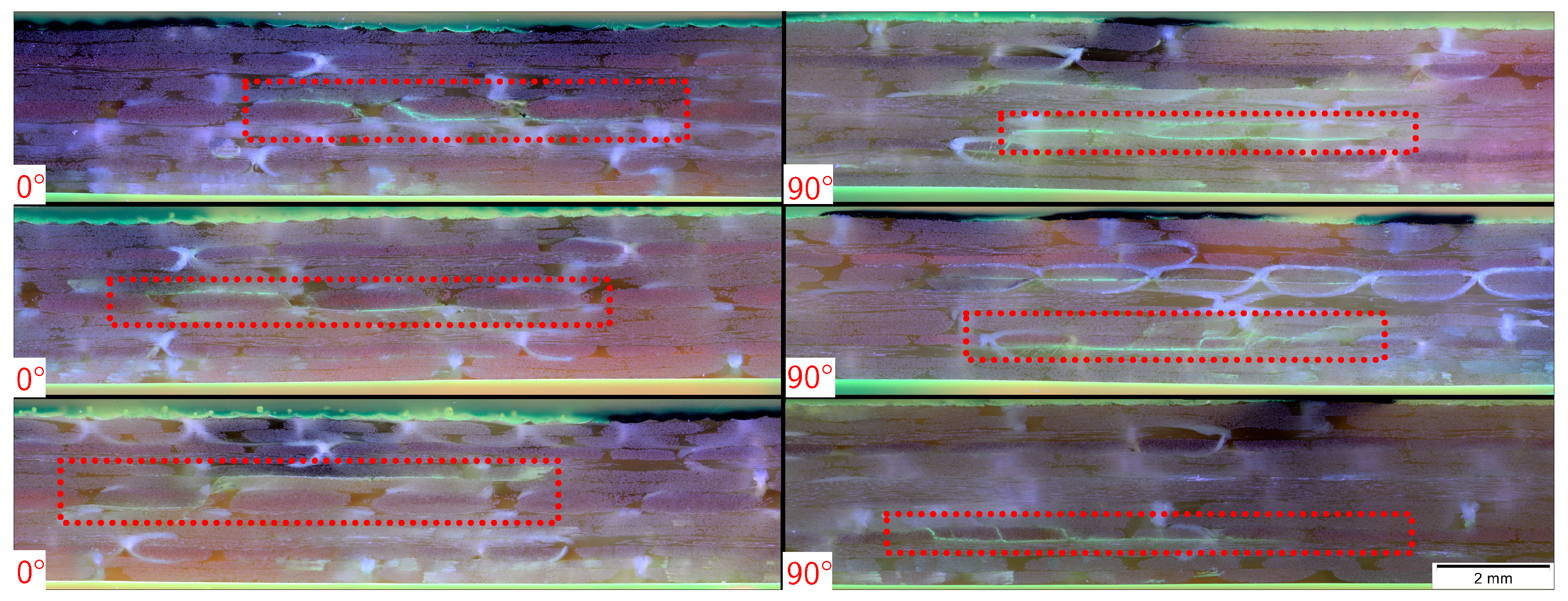

2.4.3. Interlaminar Shear Strength Investigation

3. Results and Discussion

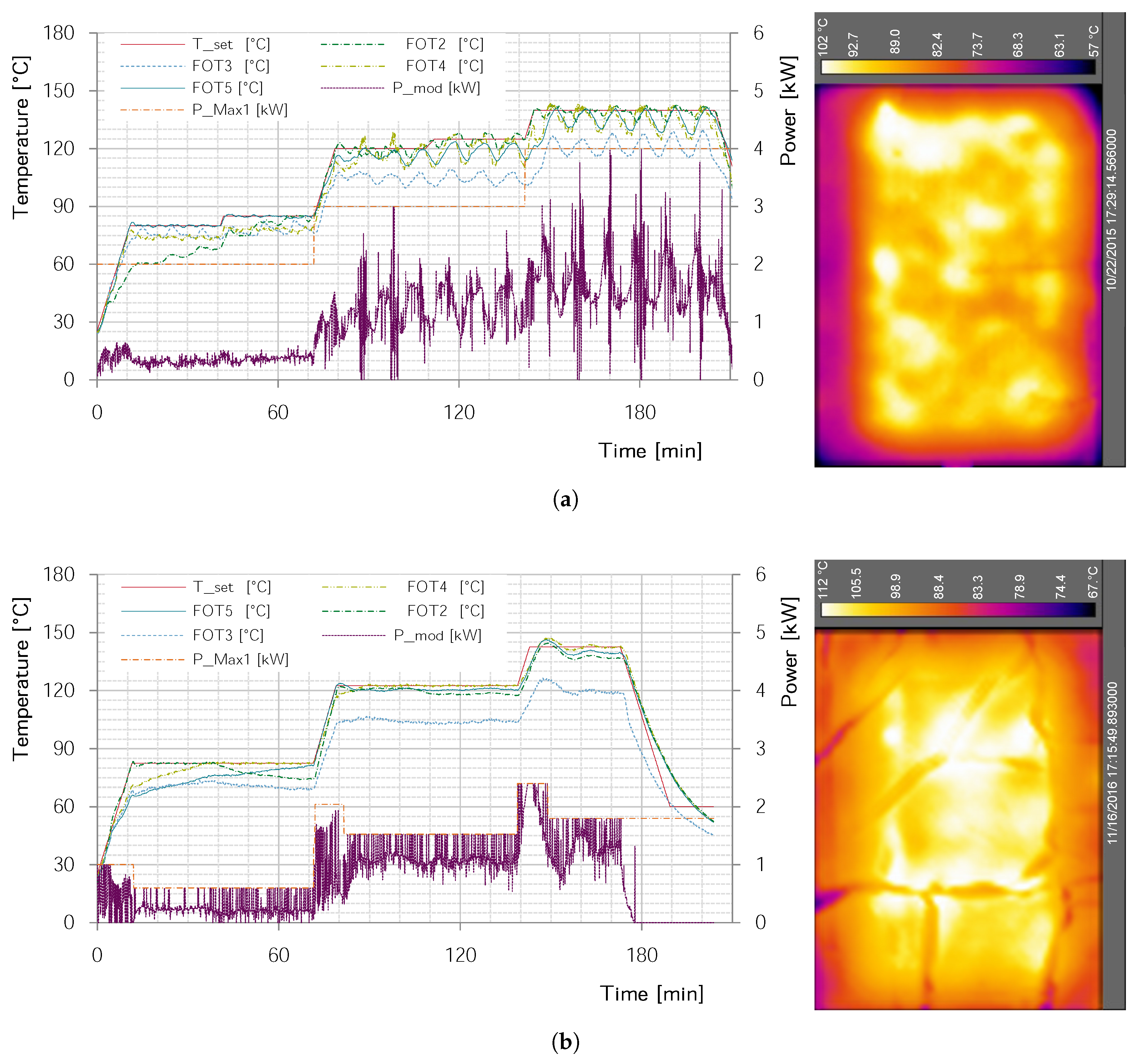

3.1. Processing of Microwave Specimens

3.1.1. Preforming of Microwave Specimens

3.1.2. Curing Process in the Microwave

3.2. Influence of Start Temperature—Comparison of Reference Plates

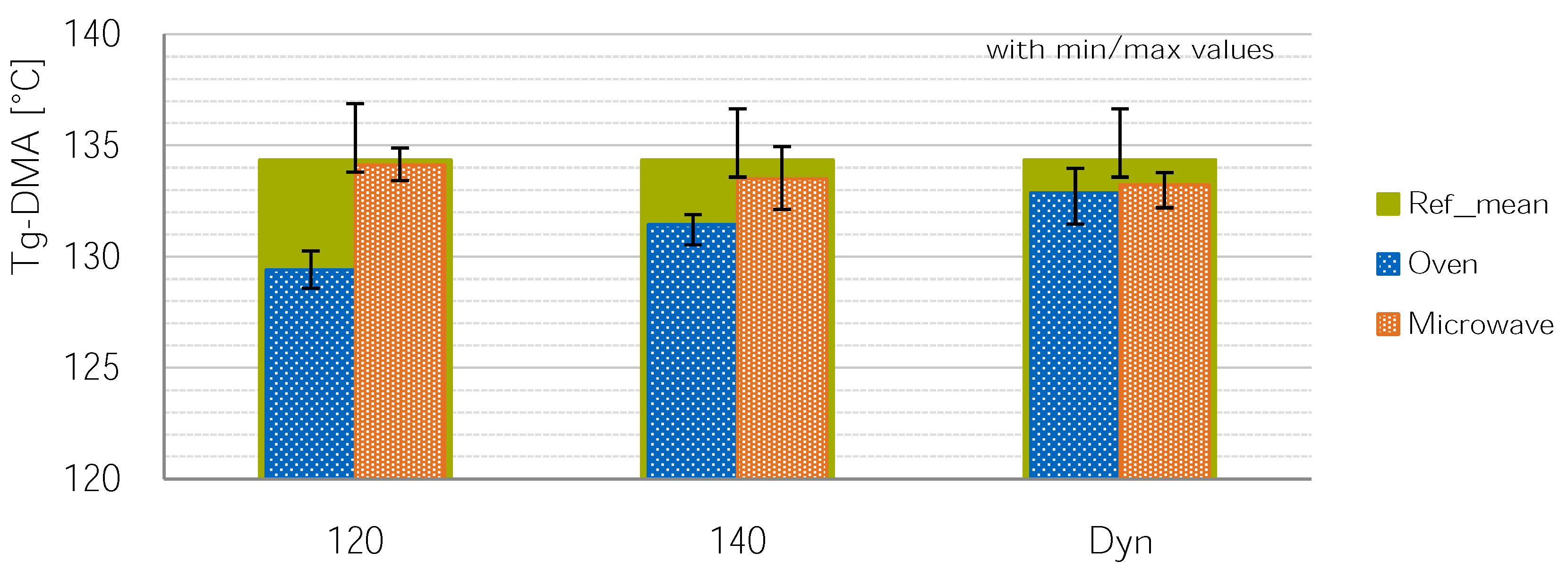

3.3. Development of for Different Cure Cycles and Heating Methods

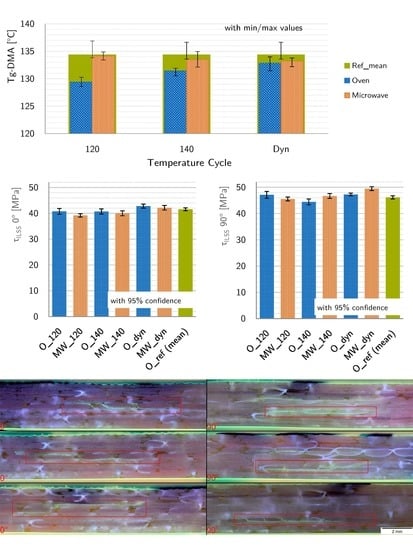

3.4. ILSS Properties

3.4.1. Number of Specimens and Modes of Failure

3.4.2. Oven Specimen Behavior

3.4.3. Microwave Specimen Behavior

3.4.4. Comparison between Oven and Microwave Specimens

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Appendix A

| Orientation 0° | (MPa) | Count (−) | SD (MPa) | 95% Conf. (MPa) | t-Test Row to Row Above |

| O_120 | 40.8 | 14 | 1.95 | 1.13 | |

| MW_120 | 39.2 | 26 | 1.56 | 0.63 | |

| O_140 | 40.7 | 18 | 2.00 | 1.00 | |

| MW_140 | 40.0 | 27 | 2.37 | 0.94 | |

| O_dyn | 42.8 | 20 | 1.68 | 0.78 | |

| MW_dyn | 42.2 | 19 | 1.86 | 0.90 | |

| O_ref (mean) | 41.6 | 41 | 1.70 | 0.54 | |

| Orientation 90° | (MPa) | Count (−) | SD (MPa) | 95% Conf. (MPa) | t-Test Row to Row Above |

| O_120 | 47.1 | 17.0 | 2.51 | 1.29 | |

| MW_120 | 45.5 | 20.0 | 1.57 | 0.73 | |

| O_140 | 44.4 | 16.0 | 2.08 | 1.11 | |

| MW_140 | 46.7 | 25.0 | 2.18 | 0.90 | |

| O_dyn | 47.3 | 26.0 | 1.27 | 0.51 | |

| MW_dyn | 49.5 | 18.0 | 1.48 | 0.73 | |

| O_ref (mean) | 46.1 | 43.0 | 1.95 | 0.60 |

| Orientation 0° | (MPa) | Count (−) | SD (MPa) | 95% Conf. (MPa) | t-Test Row to Row Above |

| O_120 | 40.8 | 14 | 1.95 | 1.13 | |

| O_140 | 40.7 | 18 | 2.00 | 1.00 | |

| O_dyn | 42.8 | 20 | 1.68 | 0.78 | |

| O_ref (mean) | 41.6 | 41 | 1.70 | 0.54 | |

| MW_120 | 39.2 | 26 | 1.56 | 0.63 | |

| MW_140 | 40.0 | 27 | 2.37 | 0.94 | |

| MW_dyn | 42.2 | 19 | 1.86 | 0.90 | |

| O_ref (mean) | 41.6 | 41 | 1.70 | 0.54 | |

| Orientation 90° | (MPa) | Count (−) | SD (MPa) | 95% Conf. (MPa) | t-Test Row to Row Above |

| O_120 | 47.1 | 17 | 2.51 | 1.29 | |

| O_140 | 44.4 | 16 | 2.08 | 1.11 | |

| O_dyn | 47.3 | 26 | 1.27 | 0.51 | |

| O_ref (mean) | 46.1 | 43 | 1.95 | 0.60 | |

| MW_120 | 45.5 | 20 | 1.57 | 0.73 | |

| MW_140 | 46.7 | 25 | 2.18 | 0.90 | |

| MW_dyn | 49.5 | 18 | 1.48 | 0.73 | |

| O_ref (mean) | 46.1 | 43 | 1.95 | 0.60 |

| Build-Up | Areal weight (g/m2) | Tolerance (±%) | Material | |

|---|---|---|---|---|

| Top | Powder | 15 | 20 | Momentive Epikote Resin 05390 |

| 45 | 300 | 5 | E-Glass 300 tex | |

| 90 | 3 | 5 | E-Glass 68 tex | |

| 0 | 3 | 5 | E-Glass 68 tex | |

| Bottom | −45 | 300 | 5 | E-Glass 300 tex |

| Stitching | 6 | ±1 g/m | pes 76 dtex |

| Build-Up | Areal weight (g/m2) | Tolerance (±%) | Material | |

|---|---|---|---|---|

| Top | 0 | 520 | 5 | E-Glass 1,200 tex |

| 90 | 54 | 5 | E-Glass 68 tex | |

| Bottom | Powder | 15 | 20 | Momentive Epikote Resin 05390 |

| Stitching | 17 | ±3 g/m | pes 76 dtex |

References

- Mathes, V. The composites industry: Plenty of opportunities in heterogeneous market. Reinf. Plast. 2018, 62, 44–51. [Google Scholar] [CrossRef]

- Xu, X.; Wang, X.; Wei, R.; Du, S. Effect of microwave curing process on the flexural strength and interlaminar shear strength of carbon fiber/bismaleimide composites. Compos. Sci. Technol. 2016, 123, 10–16. [Google Scholar] [CrossRef]

- Xu, X.; Wang, X.; Liu, W.; Zhang, X.; Li, Z.; Du, S. Microwave curing of carbon fiber/bismaleimide composite laminates: Material characterization and hot pressing pretreatment. Mater. Des. 2016, 97, 316–323. [Google Scholar] [CrossRef]

- Nightingale, C. Microwave Assisted Curing of Epoxy Resins and Composites. Ph.D Thesis, University of Manchester, Manchester, UK, 2000. [Google Scholar]

- Nightingale, C.; Day, R.J. Flexural and interlaminar shear strength properties of carbon fibre/epoxy composites cured thermally and with microwave radiation. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1021–1030. [Google Scholar] [CrossRef]

- Yusoff, R. Microwave Assisted RTM Processing of Carbon/Epoxy Composites. Ph.D. Thesis, University of Manchester, Manchester, UK, 2004. [Google Scholar]

- Papargyris, D.; Day, R.J.; Nesbitt, A.; Bakavos, D. Comparison of the mechanical and physical properties of a carbon fibre epoxy composite manufactured by resin transfer moulding using conventional and microwave heating. Compos. Sci. Technol. 2008, 68, 1854–1861. [Google Scholar] [CrossRef]

- Xu, X.; Wang, X.; Cai, Q.; Wang, X.; Wei, R.; Du, S. Improvement of the Compressive Strength of Carbon Fiber/Epoxy Composites via Microwave Curing. J. Mater. Sci. Technol. 2016, 32, 226–232. [Google Scholar] [CrossRef]

- Li, Y.; Li, N.; Gao, J. Tooling design and microwave curing technologies for the manufacturing of fiber-reinforced polymer composites in aerospace applications. Int. J. Adv. Manuf. Technol. 2014, 70, 591–606. [Google Scholar] [CrossRef]

- Li, N.; Li, Y.; Hang, X.; Gao, J. Analysis and optimization of temperature distribution in carbon fiber reinforced composite materials during microwave curing process. J. Mater. Process. Technol. 2014, 214, 544–550. [Google Scholar] [CrossRef]

- Zhou, J.; Li, Y.; Li, N.; Hao, X.; Liu, C. Interfacial shear strength of microwave processed carbon fiber/epoxy composites characterized by an improved fiber-bundle pull-out test. Compos. Sci. Technol. 2016, 133, 173–183. [Google Scholar] [CrossRef]

- Kwak, M.; Robinson, P.; Bismarck, A.; Wise, R. Curing of Composite Materials Using the Recently Developed HEPHAISTOS Microwave. In Proceedings of the International Committee on Composite Materials, ICCM 18 Conference, Jeju Island, Korea, 21–26 August 2011. [Google Scholar]

- Kwak, M.; Robinson, P.; Bismarck, A.; Wise, R. Microwave curing of carbon—Epoxy composites: Penetration depth and material characterisation. Compos. Part A Appl. Sci. Manuf. 2015, 75, 18–27. [Google Scholar] [CrossRef]

- Gaille, F. Manufacturing pRocess Development for Composite Materials Using Microwave Technology. Ph.D.Thesis, Universität Stuttgart, Stuttgart, Germany, 2012. [Google Scholar]

- Boey, F.Y.; Lee, W.L. Microwave radiation curing of a thermosetting composite. J. Mater. Sci. Lett. 1990, 9, 1172–1173. [Google Scholar] [CrossRef]

- Bai, S.L.; Djafari, V.; Andréani, M.; François, D. A comparative study of the mechanical behaviour of an epoxy resin cured by microwaves with one cured thermally. Eur. Polym. J. 1995, 31, 875–884. [Google Scholar] [CrossRef]

- Boey, F.Y.; Yap, B.H.; Chia, L. Microwave curing of epoxy-amine system—Effect of curing agent on the rate enhancement. Polym. Test. 1999, 18, 93–109. [Google Scholar] [CrossRef]

- Boey, F.Y.; Yap, B.H. Microwave curing of an epoxy–amine system: Effect of curing agent on the glass-transition temperature. Polym. Test. 2001, 20, 837–845. [Google Scholar] [CrossRef]

- Zhou, J.; Shi, C.; Mei, B.; Yuan, R.; Fu, Z. Research on the technology and the mechanical properties of the microwave processing of polymer. IUMRS BB 2003, 137, 156–158. [Google Scholar] [CrossRef]

- Boey, F.Y.; Yue, C.Y. Interfacial strength of a microwave-cured epoxy-glass composite. J. Mater. Sci. Lett. 1991, 10, 1333–1334. [Google Scholar] [CrossRef]

- Yue, C.Y.; Looi, H.C. Influence of thermal and microwave processing on the mechanical and interfacial properties of a glass/epoxy composite. Composites 1995, 26, 767–773. [Google Scholar] [CrossRef]

- Tanrattanakul, V.; SaeTiaw, K. Comparison of microwave and thermal cure of epoxy-anhydride resins: Mechanical properties and dynamic characteristics. J. Appl. Polym. Sci. 2005, 97, 1442–1461. [Google Scholar] [CrossRef]

- Wallace, M.; Attwood, D.; Day, R.J.; Heatley, F. Investigation of the microwave curing of the PR500 epoxy resin system. J. Mater. Sci. 2006, 41, 5862–5869. [Google Scholar] [CrossRef]

- Boey, F.Y.; Lee, T.H. Electromagnetic radiation curing of an epoxy/fibre glass reinforced composite. Int. J. Radiat. Appl. Instrum. Part C Radiat. Phys. Chem. 1991, 38, 419–423. [Google Scholar] [CrossRef]

- Bai, S.L.; Djafari, V. Interfacial properties of microwave cured composites. Composites 1995, 26, 645–651. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T.W. Microwave and conventional curing of thick-section thermoset composite laminates: Experiment and simulation. Polym. Compos. 2001, 22, 197–212. [Google Scholar] [CrossRef]

- Mooteri, P.S.; Sridhara, B.K.; Rao, S.; Prakash, M.R.; Rao, R.M.V.G.K. Studies on Mechanical Behavior of Microwave and Thermally Cured Glass Fiber Reinforced Polymer Composites. J. Reinf. Plast. Compos. 2006, 25, 503–512. [Google Scholar] [CrossRef]

- Tanrattanakul, V.; Jaroendee, D. Comparison between microwave and thermal curing of glass fiber–epoxy composites: Effect of microwave-heating cycle on mechanical properties. J. Appl. Polym. Sci. 2006, 102, 1059–1070. [Google Scholar] [CrossRef]

- Rao, R.M.V.G.K. Studies on Tensile and Interlaminar Shear Strength Properties of Thermally Cured and Microwave Cured Glass-Epoxy Composites. J. Reinf. Plast. Compos. 2006, 25, 783–795. [Google Scholar] [CrossRef]

- Maenz, S.; Muhlstadt, M.; Jandt, K.D.; Bossert, J. Mechanical properties of microwave cured glass fibre epoxy composites prepared by resin transfer moulding. J. Compos. Mater. 2015, 49, 2839–2847. [Google Scholar] [CrossRef]

- Colangelo, F.; Russo, P.; Cimino, F.; Cioffi, R.; Farina, I.; Fraternali, F.; Feo, L. Epoxy/glass fibres composites for civil applications: Comparison between thermal and microwave crosslinking routes. Compos. Part B Eng. 2017, 126, 100–107. [Google Scholar] [CrossRef]

- Chaowasakoo, T.; Sombatsompop, N. Mechanical and morphological properties of fly ash/epoxy composites using conventional thermal and microwave curing methods. Compos. Sci. Technol. 2007, 67, 2282–2291. [Google Scholar] [CrossRef]

- Herkner, T. News from the Aviation Industry: Presentation. In Proceedings of the 3rd Microwave Symposium, Karlsruhe, Germany, 14 October 2015. [Google Scholar]

- Link, G.; Kayser, T.; Köster, F.; Weiß, R.; Betz, S.; Wiesehöfer, R.; Sames, T.; Boulkertous, N.; Teufl, D.; Zaremba, S.; et al. Faserverbund-Leichtbau mit Automatisierter Mikrowellenprozesstechnik hoher Energieeffizienz (FLAME): Schlussbericht des BMBF-Verbundprojektes (KIT Scientific Reports; 7701); KIT Scientific Reports; KIT Scientific Publishing: Karlsruhe, Germany, 2015; Volume 7701. [Google Scholar] [CrossRef]

- Herkner, T. Microwave Curing of Composites. In Proceedings of the the 25th Annual International SICOMP Conference, Pitea, Sweden, 3 June 2014. [Google Scholar]

- Gaille, F.; Ringwald, H.; Drechsler, K. New Composite Manufacturing Process with Microwave Technology. In Proceedings of the SEICO 09; SAMPE Europe 30th International Jubilee Conference and Forum, Paris, France, 23–25 March 2009; pp. 403–411. [Google Scholar]

- Beaumont, M.; Filsinger, J. Potential of Microwave Heating for Out-of-Autoclave Composite Manufacturing of Aerospace Structures. In Proceedings of the SAMPE 2011 Technical Conference Proceedings: State of the Industry: Advanced Materials, Applications, and Processing Technology, Long Beach, CA, USA, 23–26 May 2011. [Google Scholar]

- Li, N.; Li, Y.; Hao, X.; Gao, J. A comparative experiment for the analysis of microwave and thermal process induced strains of carbon fiber/bismaleimide composite materials. Compos. Sci. Technol. 2015, 106, 15–19. [Google Scholar] [CrossRef]

- Teufl, D.; Zaremba, S.; Drechsler, K. Evaluation of tooling concepts for the use in microwave processing of fiber reinforced plastics. In Proceedings of the SETEC 14; SAMPE Europe 9th International Technical Conference & Table Top Exhibition, Tampere, Finland, 10–11 September 2014; SAMPE EUROPE Business Office: Riehen, Switzerland, 2014; pp. 63–71. [Google Scholar]

- Kazilis, M. Novel Technologies for Composites: Presentation. In Proceedings of the 3rd Microwave Symposium, Karlsruhe, Germany, 14 October 2015. [Google Scholar]

- Teufl, D. Composite Tooling for Micorwave Processes: Presentation. In Proceedings of the 3rd Microwave Symposium, 14 October 2015. [Google Scholar]

- Moret, M. Final Report Summary-MU-TOOL (Novel Tooling for Composites Curing under Microwave Heating). Project Reference: 286717; Funded under: FP7-SME; 2015; Available online: https://cordis.europa.eu/result/rcn/158268_en.html (accessed on 24 April 2018).

- Betz, S.; Köster, F. Energy and Time Efficient Microwave Curing for CFRP Parts Manufactured by Filament Winding: Presentation. In Proceedings of the 3rd Microwave Symposium, 14 October 2015. [Google Scholar]

- Link, G. Final Report Innovative, Modular Microwave Technology for the Production of Fiber Composite Structures (German Version). Projekt Reference: 01RI05133,-135-140,-282. Project Time 1 September 2009 to 31 May 2011. Available online: http://www.cleaner-production.de/fileadmin/assets/01RI05133_-_Abschlussbericht.pdf (accessed on 17 May 2018).

- DIN EN ISO 14130: Fibre-Reinforced Plastic Composites—Determination of Apparent Interlaminar Shear Strength by Short-Beam Method; DIN Deutsches Institut für Normung e.V.: Berlin, Germany, 1997.

- SAERTEX GmbH & Co. KG. Manufacturer’s Website. 2018. Available online: https://www.saertex.com/en (accessed on 24 April 2018).

- Hexion. Manufacturer’s Website. 2018. Available online: https://www.hexion.com/ (accessed on 24 April 2018).

- Sika®. Manufacturer’s Website. 2018. Available online: https://www.sika.com/ (accessed on 24 April 2018).

- SCHOTT, AG. Manufacturer’s Website. 2018. Available online: https://www.schott.com/english/index.html (accessed on 24 April 2018).

- Weiss Technik. Information to Industrial Ovens by Weiss Technik Formerly Known as Vötsch. 2018. Available online: https://www.weiss-technik.com/en/productarea/industrial-ovens-drying-ovens-for-flammable-material-vtl/ (accessed on 24 April 2018).

- Weiss Technik. Information to Microwave Applicators by Weiss Technik Formerly Known as Vötsch. 2018. Available online: https://www.weiss-technik. com/en/productarea/vhm-hephaistos-patented-mircowave-technology/ (accessed on 24 April 2018).

- Feher, L.; Thumm, M. Microwave Innovation for Industrial Composite Fabrication—The HEPHAISTOS Technology. IEEE Trans. Plasma Sci. 2004, 32, 73–79. [Google Scholar] [CrossRef]

- Feher, L.E. Energy Efficient Microwave Systems; Springer: Berlin, Heidelberg, 2009. [Google Scholar]

- Karlsruhe Institute of Technology: Institute for Pulsed Power and Microwave Technology. Institute’s Website. 2018. Available online: https://www.ihm.kit.edu/english/index.php (accessed on 24 April 2018).

- Buck, A. Energieeffizienzbewertung einer Industriellen Mikrowellenanlage. Bachelor’s Thesis, Technical University of Munich, München, Germany, 2015. [Google Scholar]

- Flir A325sc. Manufacturer’s Website with Information. 2018. Available online: http://www.flir.de/science/display/?id=46623 (accessed on 24 April 2018).

- Optocon AG. Manufacturer’s Website. 2018. Available online: http://www.optocon.de/en/welcome/-24.04.2018 (accessed on 24 April 2018).

- Mahlau, L. Untersuchung und Anpassung der GFK-Prüfkörperfertigung zur Qualitätssicherung der Mikrowellenaushärtung. Bachelor’s Thesis, Technical University of Munich, München, Germany, 2015. [Google Scholar]

- Spunfab, Ltd. Manufacturer’s Website. 2018. Available online: http://www.spunfab.com/ (accessed on 24 April 2018).

- AB-Tec GmbH & Co. KG. Manufacturer’s Website. 2018. Available online: http://www.ab-tec.com/ (accessed on 24 April 2018).

- Promat—Etex Building Performance GmbH. Manufacturer’s Website. 2018. Available online: http://www.promat-hpi.com/de-DE-24.04.2018 (accessed on 24 April 2018).

- Marand, E.; Baker, K.R.; Graybeal, J.D. Comparison of reaction mechanisms of epoxy resins undergoing thermal and microwave cure from in situ measurements of microwave dielectric properties and infrared spectroscopy. Macromolecules 1992, 25, 2243–2252. [Google Scholar] [CrossRef]

- Wei, J.; Hawley, M.C.; Demeuse, M.T. Kinetics modeling and time-temperature-transformation diagram of microwave and thermal cure of epoxy resins. Polym. Eng. Sci. 1995, 35, 461–470. [Google Scholar] [CrossRef]

| Mixture | Neat Resin Specimen * | ||||

|---|---|---|---|---|---|

| Property | Value | Unit | Property | Value | Unit |

| Potlife, 100 g/RT | >24 | h | Tensile strength | 78 | MPa |

| Mixed viscosity, 25 C | 600 | mPa.s | Tensile E-Modulus | 3200 | MPa |

| Mixed viscosity, 50 C | 100 | mPa.s | Elongation at break | 3.3 | % |

| (50 C acc. to viscosity curve provided by Sika) | Impact resistance | 18 | kJ/m2 | ||

| Tg (ISO 11357) | 139 | C | |||

| Start | RT | 50 C | 85 C (min) | 120 C (min) | 140 C (min) | 170 C (min) | Cycletime (min) |

|---|---|---|---|---|---|---|---|

| O_120 | No | Yes | 75 | 60 | - | - | 170 |

| MW_120 | Yes | No | 60 | 45 | - | - | 141 |

| O_140 | Yes | No | 75 | 75 | 45 | - | 238 |

| MW_140 | Yes | No | 60 | 60 | 30 | - | 194 |

| O_dyn | Yes | No | 70 C to 110 C with 1 C/min | 35 | 122 | ||

| MW_dyn | Yes | No | 70 C to 100 C with 1 C/min | 20 | 99 | ||

| O_ref | Yes | Yes | 195 | 195 | 195 | - | 628 |

| Property | M | SD | M | SD | t-Test | |

|---|---|---|---|---|---|---|

| tg | (C) | 134.59 | 0.192 | 133.82 | 0.271 | |

| (MPa) | 42.15 | 1.53 | 41.38 | 1.44 | ||

| (MPa) | 46.88 | 2.1 | 45.59 | 1.67 |

| O_120 | O_140 | O_dyn | O_ref | MW_120 | MW_140 | MW_dyn | ||

|---|---|---|---|---|---|---|---|---|

| Mean | (C) | 129.4 | 131.4 | 132.9 | 134.4 | 134.1 | 133.5 | 133.2 |

| min | (C) | 128.6 | 130.5 | 131.5 | 133.6 | 133.4 | 132.1 | 132.2 |

| max | (C) | 130.3 | 131.9 | 134 | 136.7 | 134.9 | 135 | 133.8 |

| Count | (-) | 8 | 6 | 9 | 14 | 12 | 5 | 3 |

| SD | (C) | 0.57 | 0.52 | 0.75 | 0.98 | 0.43 | 1.22 | n.g. |

| 95%-conf | (C) | 0.47 | 0.55 | 0.58 | 0.56 | 0.27 | 1.52 | 2.23 |

| O_120 | MW_120 | O_140 | MW_140 | O_dyn | MW_dyn | O_ref | ||

|---|---|---|---|---|---|---|---|---|

| (MPa) | 40.8 | 39.2 | 40.7 | 40.0 | 42.8 | 42.2 | 41.7 | |

| 95% Conf. | (MPa) | 1.13 | 0.63 | 1.00 | 0.94 | 0.78 | 0.90 | 0.48 |

| (MPa) | 47.1 | 45.5 | 44.4 | 46.7 | 47.3 | 49.5 | 46.1 | |

| 95% Conf. | (MPa) | 1.29 | 0.73 | 1.11 | 0.90 | 0.51 | 0.73 | 0.60 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teufl, D.; Zaremba, S. 2.45 GHz Microwave Processing and Its Influence on Glass Fiber Reinforced Plastics. Materials 2018, 11, 838. https://doi.org/10.3390/ma11050838

Teufl D, Zaremba S. 2.45 GHz Microwave Processing and Its Influence on Glass Fiber Reinforced Plastics. Materials. 2018; 11(5):838. https://doi.org/10.3390/ma11050838

Chicago/Turabian StyleTeufl, Daniel, and Swen Zaremba. 2018. "2.45 GHz Microwave Processing and Its Influence on Glass Fiber Reinforced Plastics" Materials 11, no. 5: 838. https://doi.org/10.3390/ma11050838