Morphology and Mechanical Properties of Polyamide 6/Polystyrene Blends Prepared by Diffusion and Subsequent Polymerization of Styrene in Polyamide 6 Pellets

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

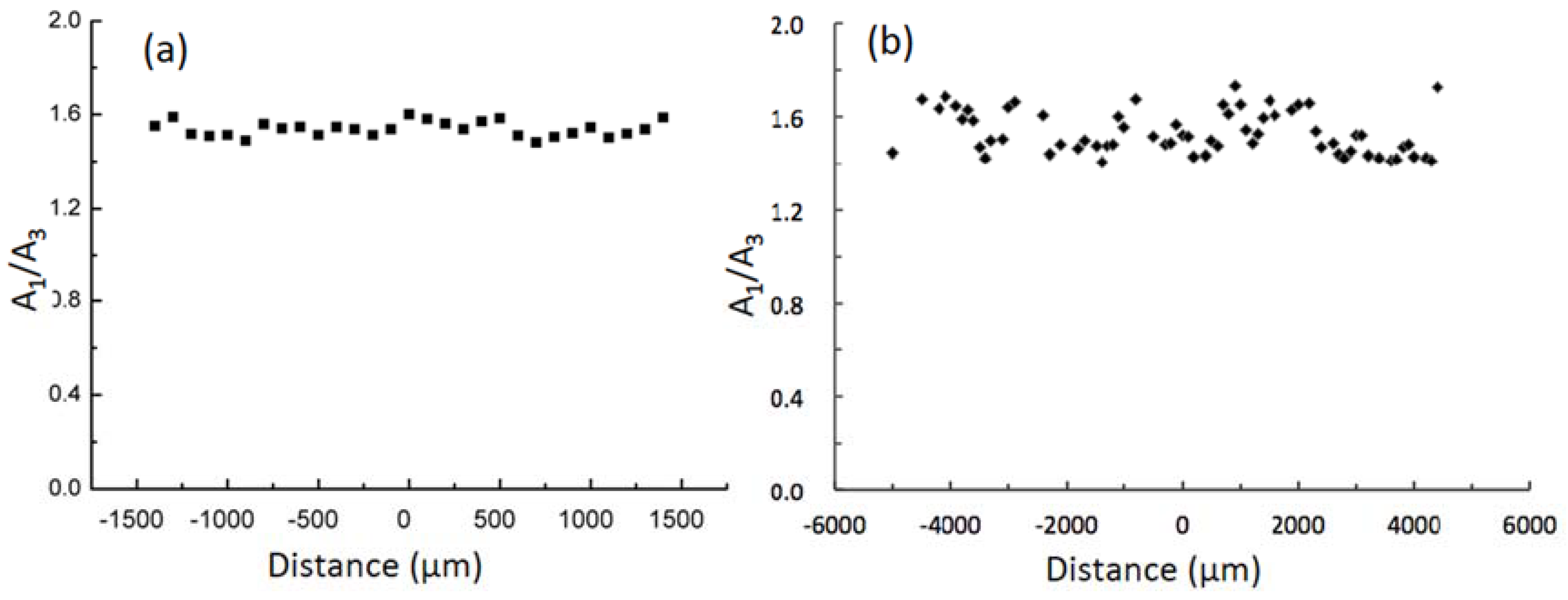

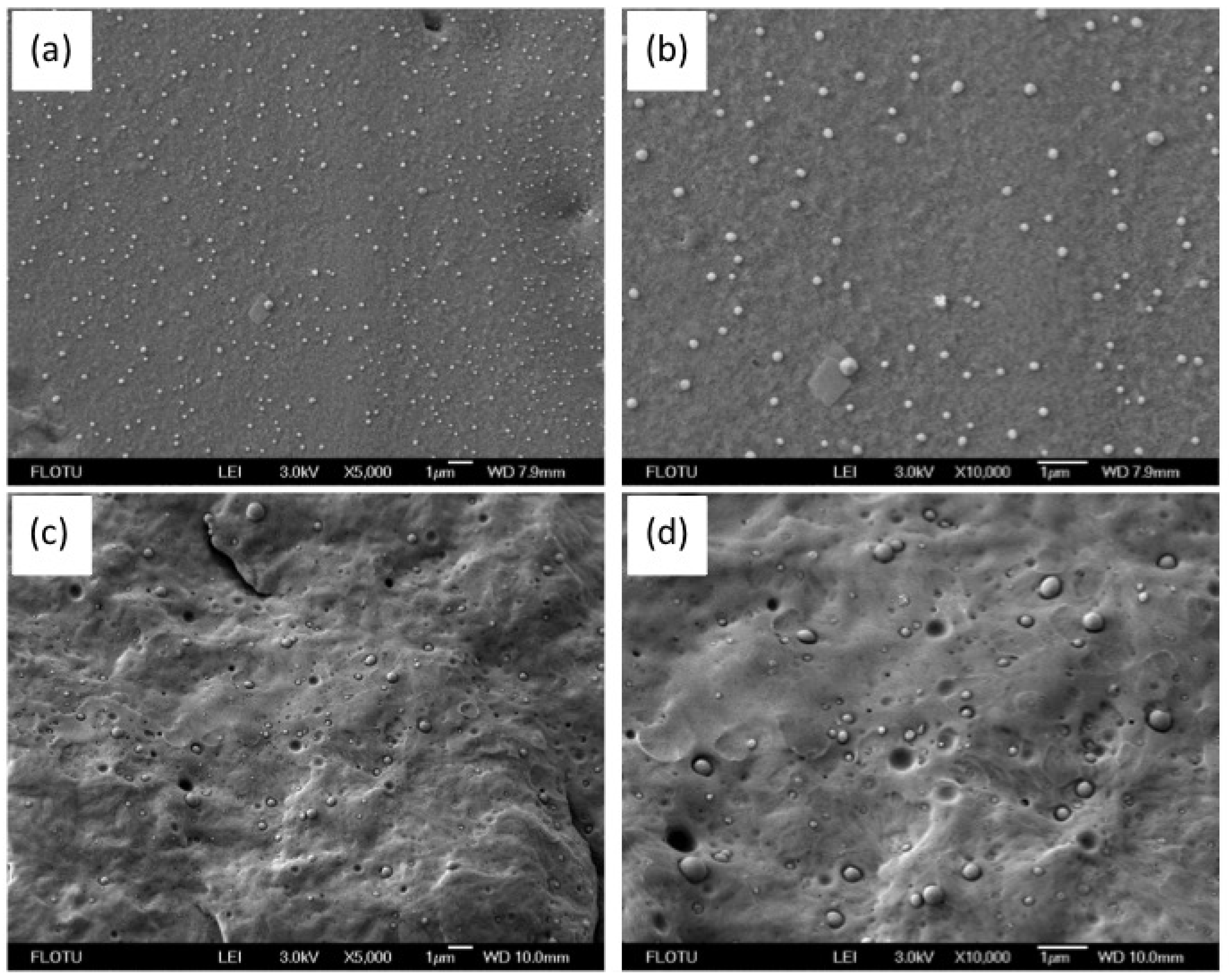

3.1. Distribution of PS and Morphology of PA6/PS Pellets and Molded Bars

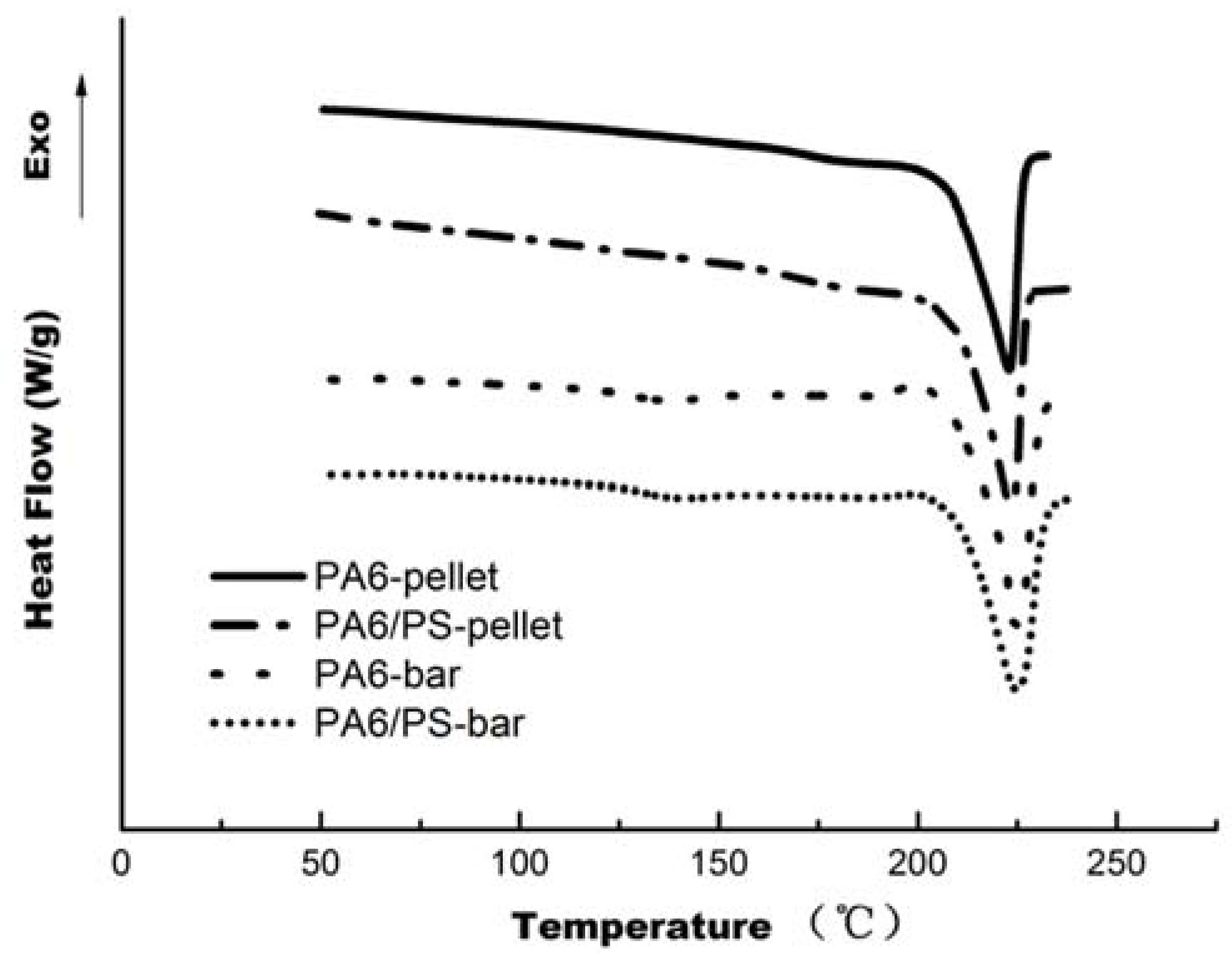

3.2. Crystallization Behavior of PA6 in PA6/PS Pellets and Molded Bars

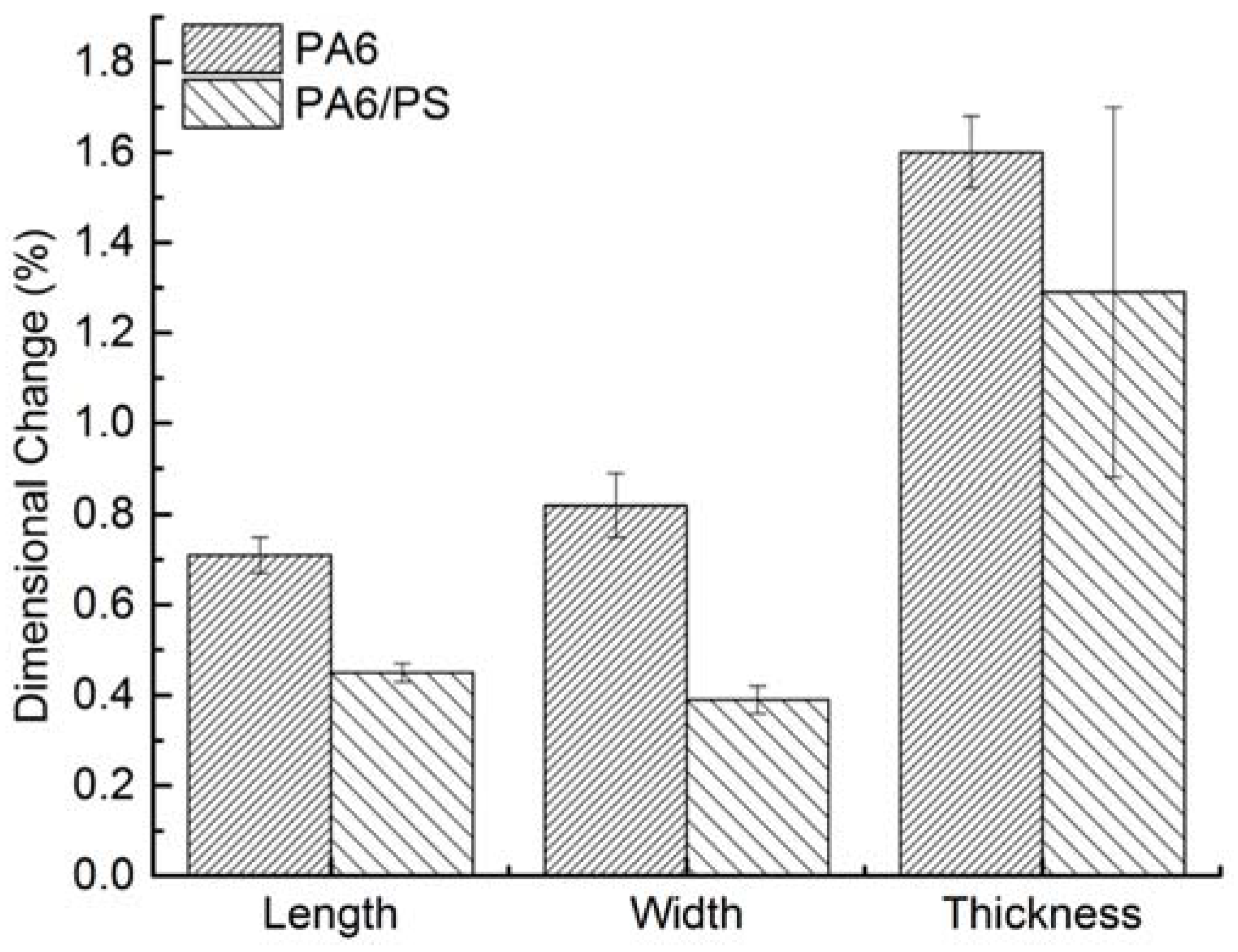

3.3. Water Sorption and Dimensional Changes of Injection Molded PA6/PS Blend Bars

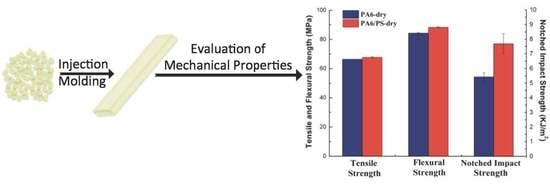

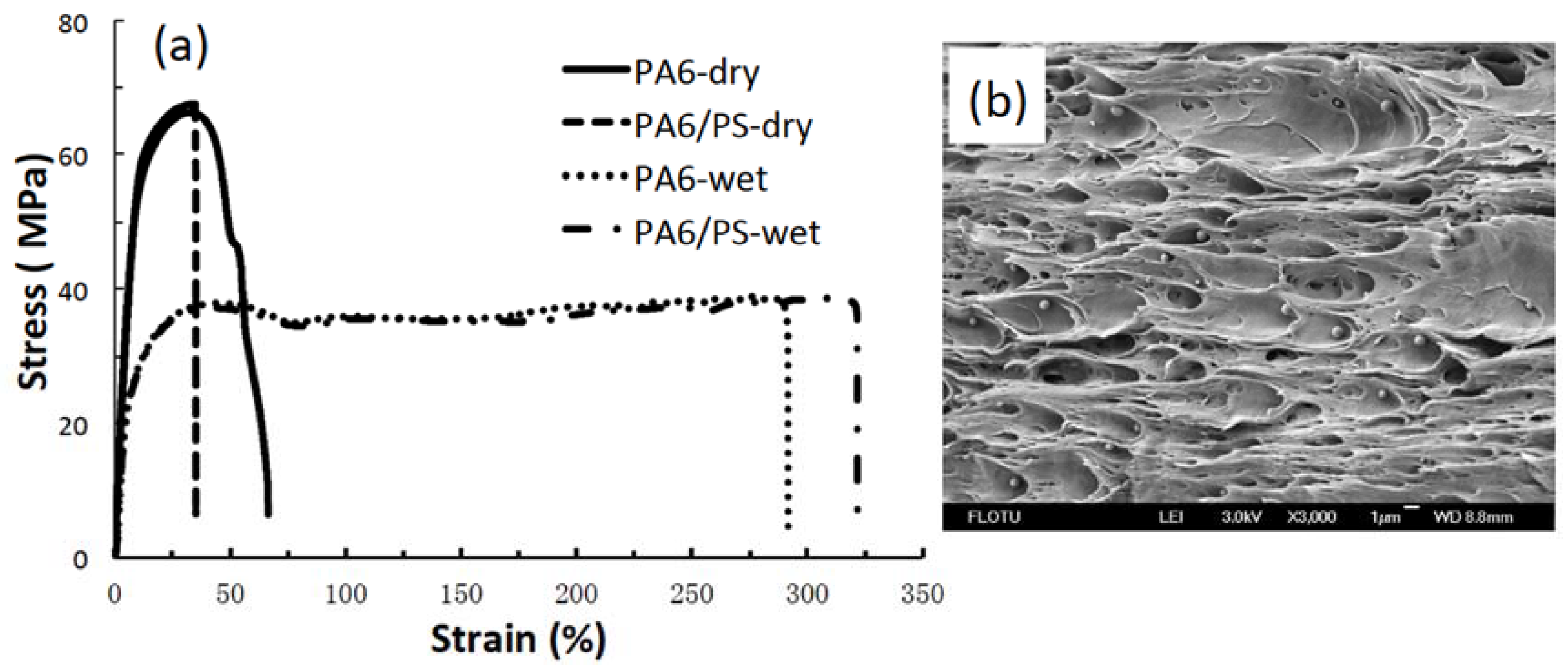

3.4. Mechanical Properties of Injection Molded PA6/PS Blend Bars

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Zhu, R.; Hoshi, T.; Chishima, Y.; Muroga, Y.; Hagiwara, T.; Yano, S.; Sawaguchi, T. Microstructure and Mechanical Properties of Polypropylene/Poly(methyl methacrylate) Nanocomposite Prepared Using Supercritical Carbon Dioxide. Macromolecules 2011, 44, 6103–6112. [Google Scholar] [CrossRef]

- Kausar, A.; Zulfiqar, S.; Sarwar, M.I. Self-assembled Nanoblends of Functional Polystyrene and a Reactive Aramid: Morphological and Thermomechanical Profile. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Liu, Z.; Dong, Z.; Han, B.; Wang, J.; He, J.; Yang, G. Composites Prepared by the Polymerization of Styrene within Supercritical CO2 -Swollen Polypropylene. Chem. Mater. 2002, 14, 4619–4623. [Google Scholar] [CrossRef]

- Hu, G.-H.; Cartier, H.; Plummer, C. Reactive Extrusion: Toward Nanoblends. Macromolecules 1999, 32, 4713–4718. [Google Scholar] [CrossRef]

- Shimizu, H.; Li, Y.; Kaito, A.; Sano, H. Formation of Nanostructured PVDF/PA11 Blends Using High-Shear Processing. Macromolecules 2005, 38, 7880–7883. [Google Scholar] [CrossRef]

- Li, D.; Han, B. Phase Behavior of Supercritical CO2/Styrene/Poly(vinyl chloride) System and Synthesis of Polystyrene/Poly(vinyl chloride) Composites. Macromolecules 2000, 33, 4555–4560. [Google Scholar] [CrossRef]

- Kausar, A.; Zulfiqar, S.; Sarwar, M.I. Effect of Miscibility and Interaction on the Properties of Polymethylmethacrylate/Aramid Nanoblends: Polymethylmethacrylate/Aramid Nanoblends. Polym. Adv. Technol. 2014, 25, 196–203. [Google Scholar] [CrossRef]

- Naylor, A.; Howdle, S.M. The Preparation of Novel Blends of Ultra High Molecular Weight Polyethylene with Polymethacrylate Based Copolymers Using Supercritical Carbon Dioxide. J. Mater. Chem. 2005, 15, 5037–5042. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, J.; Dai, X.; Han, B.; Dong, Z.; Yang, G.; Zhang, X.; Xu, J. Synthesis of Composites of Silicon Rubber and Polystyrene Using Supercritical CO2 as a Swelling Agent. J. Mater. Chem. 2002, 12, 2688–2691. [Google Scholar] [CrossRef]

- Li, D.; Liu, Z.M.; Han, B.X.; Song, L.P.; Yang, G.Y.; Jiang, T. Preparation of Nanometer Dispersed Polypropylene/Polystyrene Interpenetrating Network Using Supercritical CO2 as a Swelling Agent. Polymer 2002, 43, 5363–5367. [Google Scholar] [CrossRef]

- Li, D.; Han, B. Impregnation of Polyethylene (PE) with Styrene Using Supercritical CO2 as the Swelling Agent and Preparation of PE/Polystyrene Composites. Ind. Eng. Chem. Res. 2000, 39, 4506–4509. [Google Scholar] [CrossRef]

- Yao, X.-R.; Yu, J.; Guo, Z.-X. Preparation of Isotactic Polypropylene/Polystyrene Blends by Diffusion and Subsequent Polymerization of Styrene in Isotactic Polypropylene Pellets. Polymer 2011, 52, 667–675. [Google Scholar] [CrossRef]

- Wang, W.-J.; Huang, C.-H.; Guo, Z.-X.; Yu, J. Preparation of POE/PS Blends with Fine Particle Sizes by Diffusion and Subsequent Polymerization of Styrene in POE Pellets. Chin. J. Polym. Sci. 2017, 35, 939–949. [Google Scholar] [CrossRef]

- Huang, C.-H.; Chen, Y.-L.; Guo, Z.-X.; Yu, J. Diffusion and Polymerization Behavior of Styrene in Polyethylene Pellets of Different Molecular Structures. Chem. J. Chin. Univ. 2017. [Google Scholar] [CrossRef]

- Huang, C.-H.; Guo, Z.-X.; Yu, J. Diffusion and Polymerization Behavior of Styrene in Polypropylene Pellets of Different Aggregation State. Chem. J. Chin. Univ. 2018. [Google Scholar] [CrossRef]

- Chen, F.; Guo, Z.-X.; Yu, J. Polymerization Kinetics of Styrene in Isotactic Polypropylene Pellets and Evolution of Phase Morphology during Polymerization. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Chen, F.; Guo, Z.-X.; Yu, J. Polypropylene/Polystyrene Blends Prepared by Diffusion and Subsequent Polymerization in Polypropylene Pellets after Injection Molding. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Chen, F.; Guo, Z.-X.; Yu, J. Control of Surface Morphology of Polypropylene/Polystyrene Blend Pellets Prepared by Diffusion and Subsequent Polymerization of Styrene in Isotactic Polypropylene Pellets. Chin. Chem. Lett. 2016, 27, 1641–1643. [Google Scholar] [CrossRef]

- Chen, F.; Yao, X.; Guo, Z.; Yu, J. Diffusion and Polymerization Behavior of Styrene in High Density Polyethylene Pellets. Acta Polym. Sin. 2016, 1717–1723. [Google Scholar] [CrossRef]

- Banerjee, S.S.; Bhowmick, A.K. Novel Nanostructured Polyamide 6/Fluoroelastomer Thermoplastic Elastomeric Blends: Influence of Interaction and Morphology on Physical Properties. Polymer 2013, 54, 6561–6571. [Google Scholar] [CrossRef]

- Gong, L.; Yin, B.; Li, L.; Yang, M. Nylon-6/Graphene Composites Modified through Polymeric Modification of Graphene. Compos. Part B Eng. 2015, 73, 49–56. [Google Scholar] [CrossRef]

- Yuan, D.-B.; Gao, Y.-F.; Guo, Z.-X.; Yu, J. Improved Thermal Conductivity of Ceramic Filler-filled Polyamide Composites by Using PA6/PA66 1:1 Blend as Matrix. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Vlasveld, D.P.N.; Groenewold, J.; Bersee, H.E.N.; Picken, S.J. Moisture Absorption in Polyamide-6 Silicate Nanocomposites and its Influence on the Mechanical Properties. Polymer 2005, 46, 12567–12576. [Google Scholar] [CrossRef]

- Yan, X.; Zhang, Y.; Zhang, H.-M. Compatibilizing Effect of Graphene Oxide on Polyamide/Polystyrene Blends. Acta Polym. Sin. 2015, 6, 706–712. [Google Scholar] [CrossRef]

- Choi, J.-H.; Kim, H.-G.; Han, D.-H.; Lim, J.-C.; Oh, D.-H.; Min, K.-E. Effect of Processing Conditions on Compatibility of Nylon 6/Polystyrene Blend. J. Appl. Polym. Sci. 2006, 101, 1–7. [Google Scholar] [CrossRef]

- Huang, C.-H.; Chen, F.; Guo, Z.-X.; Yu, J. Preparation of Polyamide 6/Polystyrene Quasi-nanoblends by Diffusion and Subsequent Polymerization of Styrene in Water-sorbed Polyamide 6 Pellets. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Huang, C.-H.; Tan, Y.-L.; Guo, Z.-X.; Yu, J. Reducing Water Sorption of Injection-molded Polyamide 6 Bars by Polymerization-induced Diffusion of Styrene and Grafting with Polystyrene. J. Appl. Polym. Sci. 2018. [Google Scholar] [CrossRef]

- Guo, J.; Xu, Y.; Chen, X.; Hu, S.; He, M.; Qin, S. Influences of Organic Montmorillonite on the Combustion Behaviors and Thermal Stability of Polyamide 6/Polystyrene Blends. High Perform. Polym. 2015, 27, 392–401. [Google Scholar] [CrossRef]

- He, R.; Zhan, X.; Zhang, Q.; Chen, F. Toughening of Polyamide-6 with Little Loss in Modulus by Block Copolymer Containing Poly(Styrene-alt-Maleic Acid) Segment. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Li, H.M.; Shen, Z.G.; Zhu, F.M.; Lin, S.A. Polymer Blends of sPS/PA6 Compatibilized by Sulfonated Syndiotactic Polystyrene. Eur. Polym. J. 2002, 38, 1255–1263. [Google Scholar] [CrossRef]

- Villarreal, M.E.; Tapia, M.; Nuño-Donlucas, S.M.; Puig, J.E.; González-Núñez, R. Mechanical Properties of Polystyrene/Polyamide 6 Blends Compatibilized with the Ionomer Poly(Styrene-co-sodium Acrylate). J. Appl. Polym. Sci. 2004, 92, 2545–2551. [Google Scholar] [CrossRef]

- Park, C.D.; Jo, W.H.; Lee, M.S. Effect of Molecular Weight of Functionalized Polystyrene on the Compatibility of Blends of Polyamide 6 and Polystyrene. Polymer 1996, 37, 3055–3063. [Google Scholar] [CrossRef]

- Li, H.; Sui, X.; Xie, X.-M. High-strength and Super-tough PA6/PS/PP/SEBS Quaternary Blends Compatibilized by Using a Highly Effective Multi-phase Compatibilizer: Toward Efficient Recycling of Waste Plastics. Polymer 2017, 123, 240–246. [Google Scholar] [CrossRef]

- Kelnar, I.; Rotrekl, J.; Kotek, J.; Kaprálková, L.; Hromádková, J. Effect of Montmorillonite on Structure and Properties of Nanocomposite with PA6/PS/Elastomer Matrix. Eur. Polym. J. 2009, 45, 2760–2766. [Google Scholar] [CrossRef]

- Zhang, X.Q.; Son, Y. Effects of Maleated Syndiotactic Polystyrene on the Morphology, Mechanical Properties, and Crystallization Behavior of Syndiotactic Polystyrene/Polyamide 6 Blends. J. Appl. Polym. Sci. 2003, 89, 2502–2506. [Google Scholar] [CrossRef]

- Jannasch, P.; Wesslen, B. Stress-strain Behavior and Impact Strength of Polystyrene/Polyamide-6 Blends Compatibilized with Poly(styrene-g-ethylene oxide). J. Appl. Polym. Sci. 1998, 70, 1887–1891. [Google Scholar] [CrossRef]

- Kelnar, I.; Stephan, M.; Jakisch, L.; Fortelny, I. Influence of the Component Reactivity on the Properties of Ternary Reactive Blends Nylon 6/Rigid Brittle Polymer/Elastomer. J. Appl. Polym. Sci. 2000, 78, 1597–1603. [Google Scholar] [CrossRef]

- Kelnar, I.; Rotrekl, J.; Kotek, J.; Kaprálková, L. Effect of Montmorillonite Modification on the Behaviour of Polyamide/Polystyrene Blends. Polym. Int. 2008, 57, 1281–1286. [Google Scholar] [CrossRef]

| PA6 Pellet | 223.0 | 66.1 |

| PA6/PS Pellet | 223.5 | 69.1 |

| PA6 Bar | 224.7 | 77.1 |

| PA6/PS Bar | 225.0 | 73.3 |

| Young’s Modulus/MPa | Tensile Strength/MPa | Elongation at Break/% | Flexural Strength/MPa | Notched Impact Strength/(KJ/m2) | |

|---|---|---|---|---|---|

| PA6-dry | 281.0 ± 15.2 | 66.4 ± 0.0 | 42.9 ± 29.2 | 84.3 ± 0.5 | 5.5 ± 0.3 |

| PA6/PS-dry | 278.4 ± 4.7 | 67.7 ± 0.3 | 34.8 ± 0.5 | 88.3 ± 0.3 | 7.8 ± 0.7 |

| PA6-wet | 186.6 ± 15.9 | 38.0 ± 0.7 | 295.4 ± 21.9 | - | - |

| PA6/PS-wet | 192.9 ± 18.8 | 37.1 ± 0.9 | 293.9 ± 39.4 | - | - |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, Y.-L.; Huang, C.-H.; Guo, Z.-X.; Yu, J. Morphology and Mechanical Properties of Polyamide 6/Polystyrene Blends Prepared by Diffusion and Subsequent Polymerization of Styrene in Polyamide 6 Pellets. Materials 2018, 11, 776. https://doi.org/10.3390/ma11050776

Tan Y-L, Huang C-H, Guo Z-X, Yu J. Morphology and Mechanical Properties of Polyamide 6/Polystyrene Blends Prepared by Diffusion and Subsequent Polymerization of Styrene in Polyamide 6 Pellets. Materials. 2018; 11(5):776. https://doi.org/10.3390/ma11050776

Chicago/Turabian StyleTan, Yin-Le, Cheng-Huan Huang, Zhao-Xia Guo, and Jian Yu. 2018. "Morphology and Mechanical Properties of Polyamide 6/Polystyrene Blends Prepared by Diffusion and Subsequent Polymerization of Styrene in Polyamide 6 Pellets" Materials 11, no. 5: 776. https://doi.org/10.3390/ma11050776