Evaluation of Surface Roughness by Image Processing of a Shot-Peened, TIG-Welded Aluminum 6061-T6 Alloy: An Experimental Case Study

Abstract

:1. Introduction

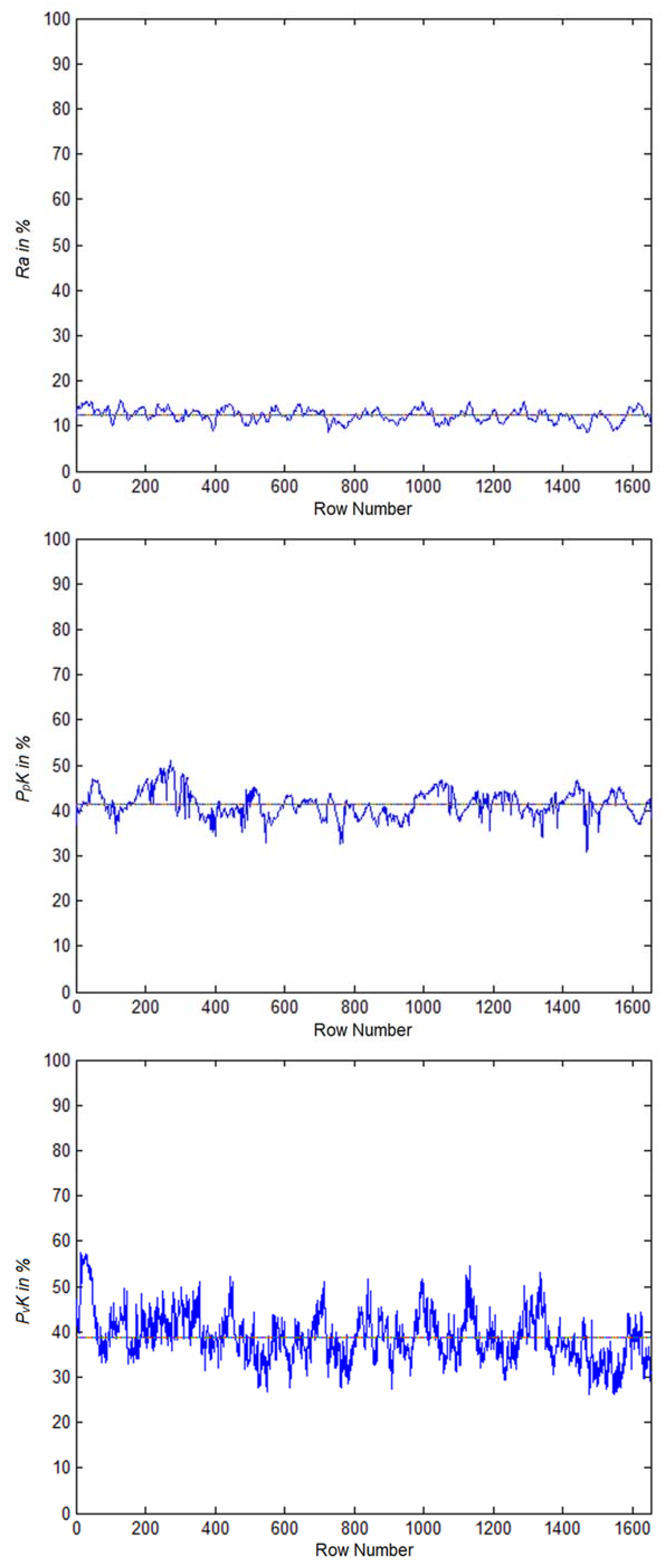

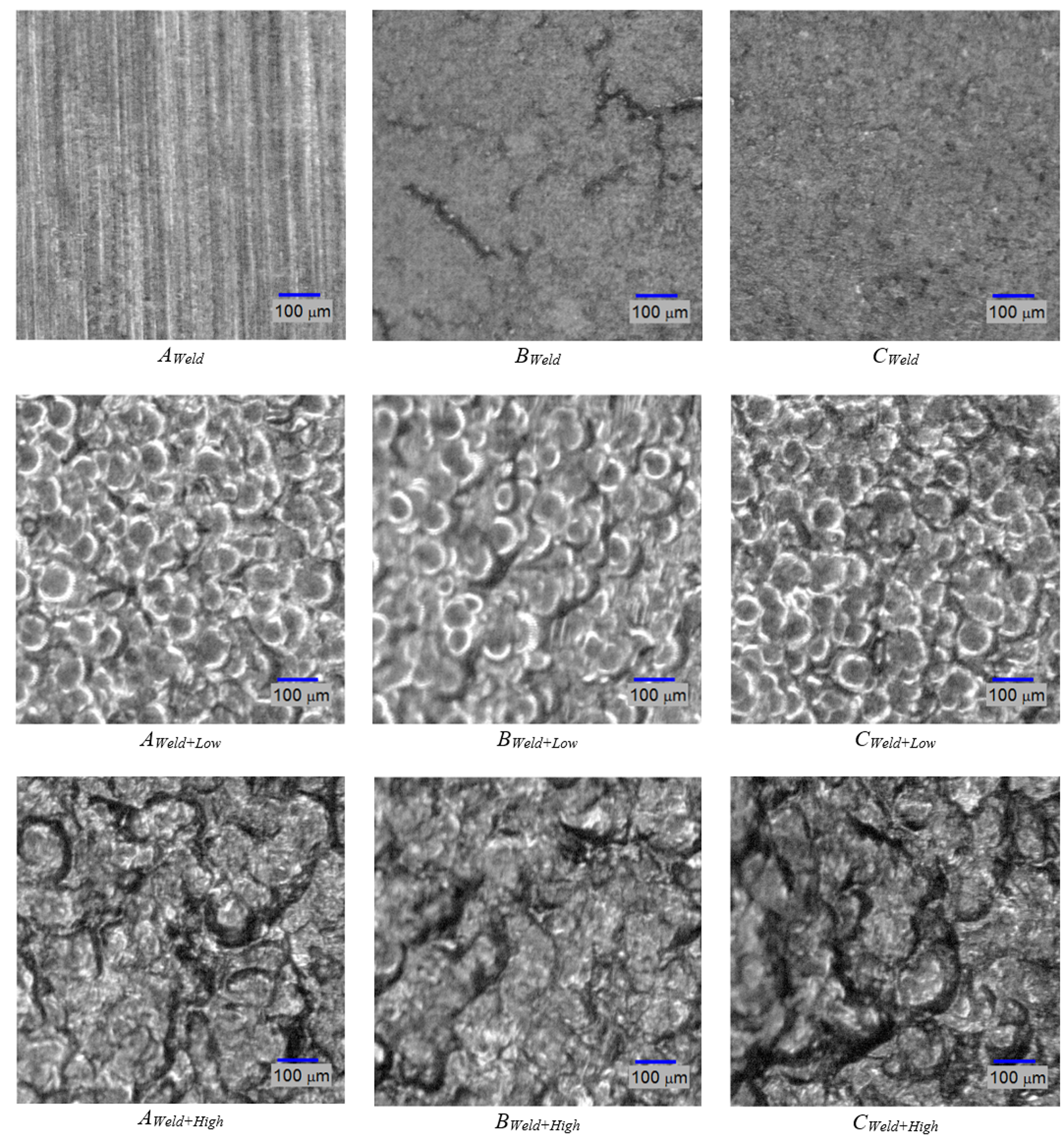

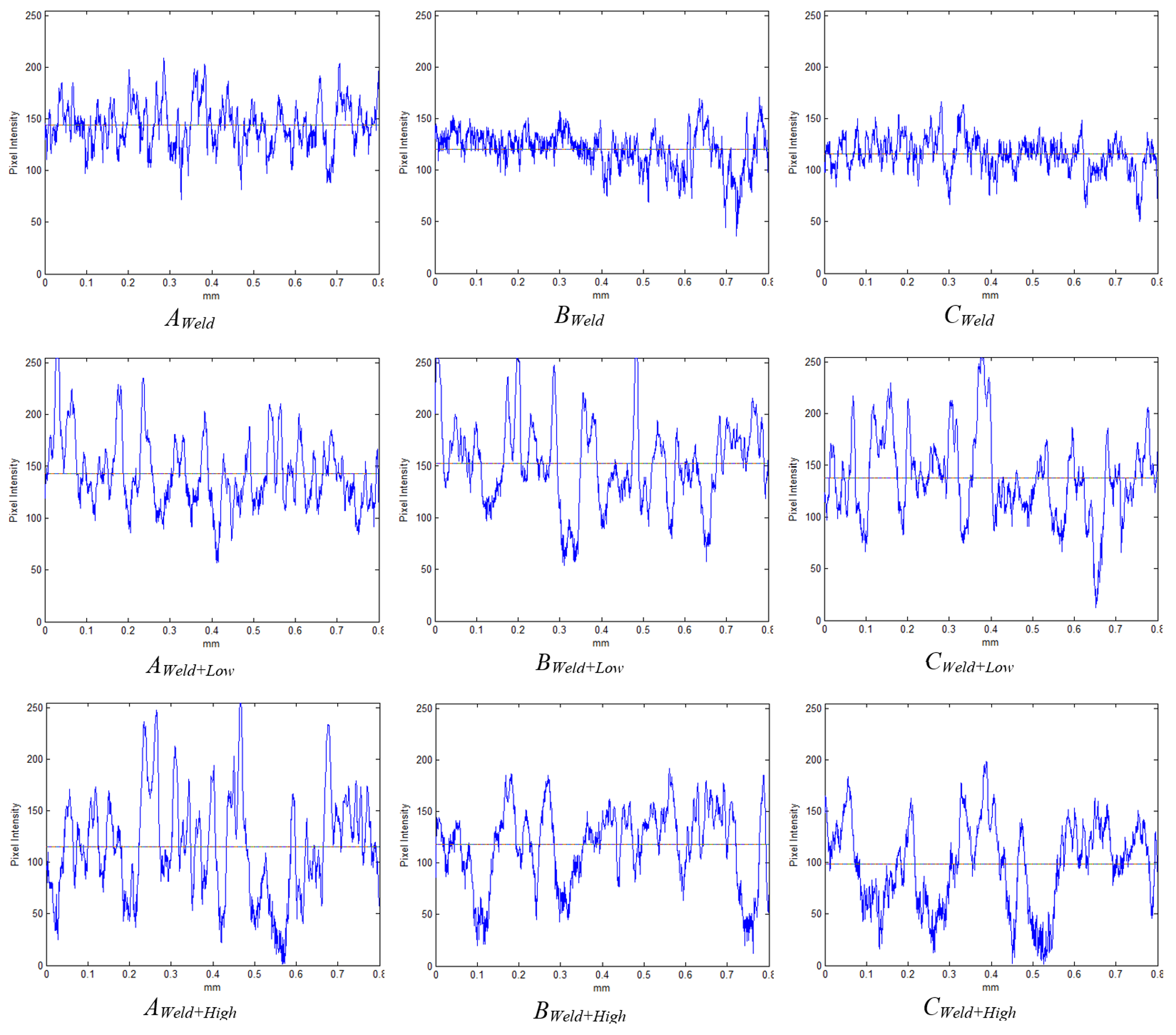

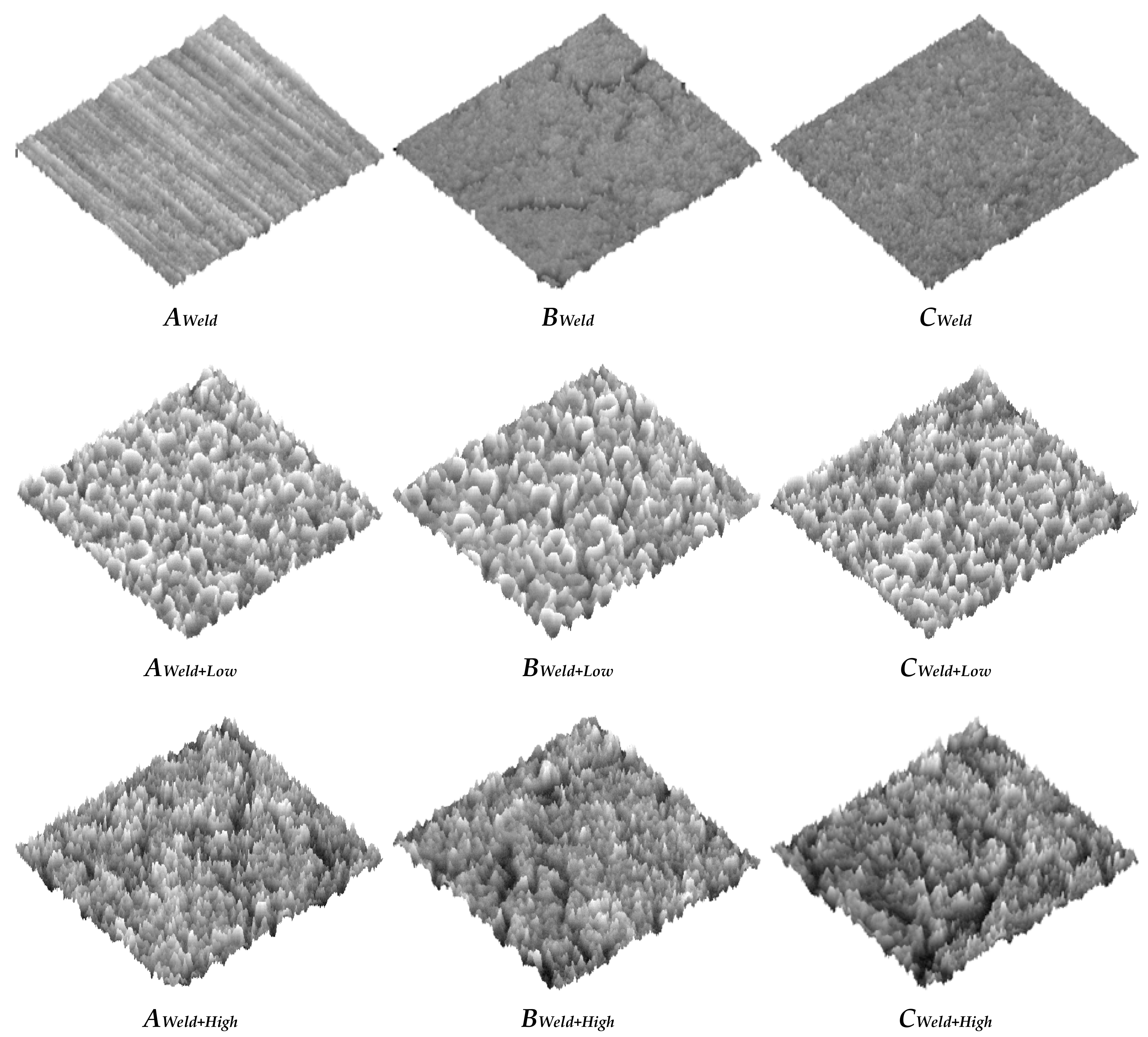

2. Methodology

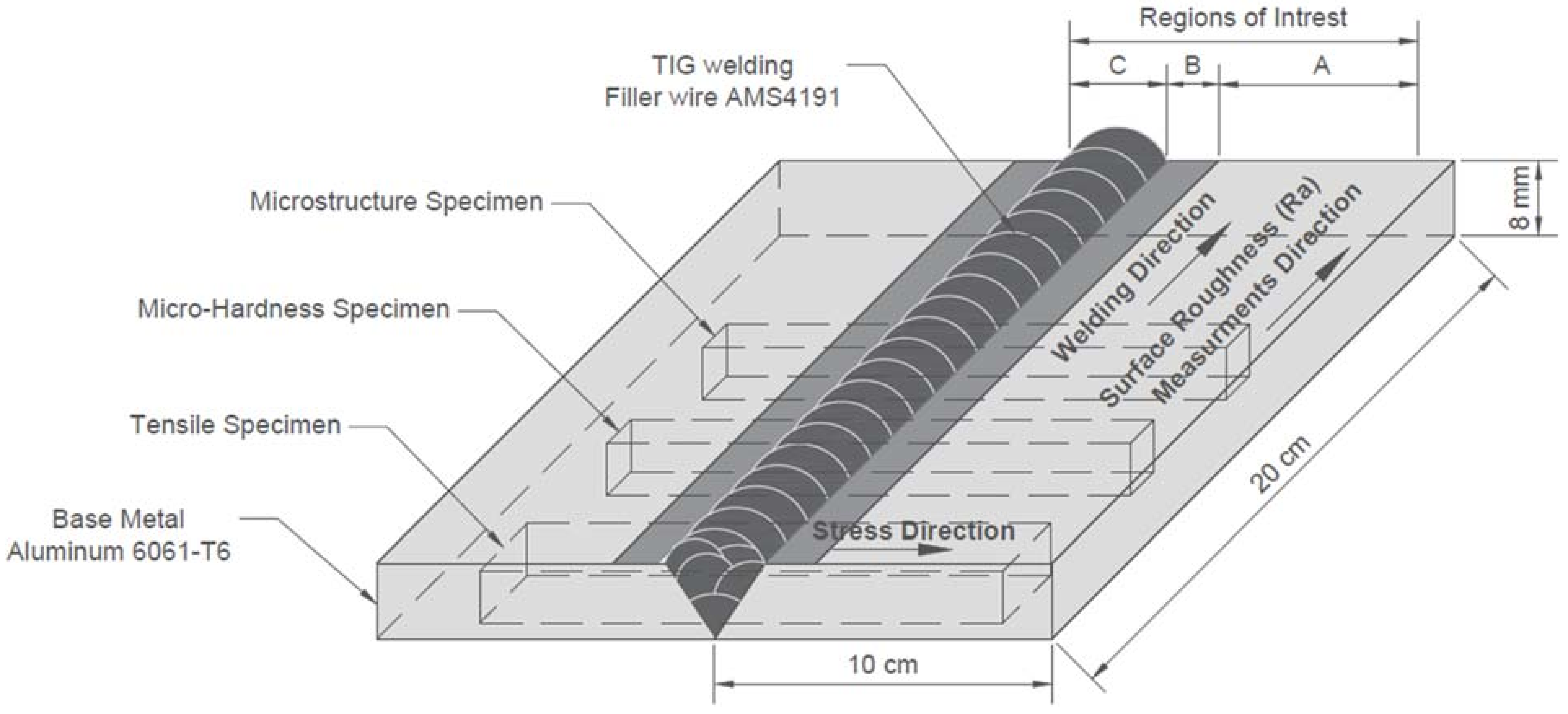

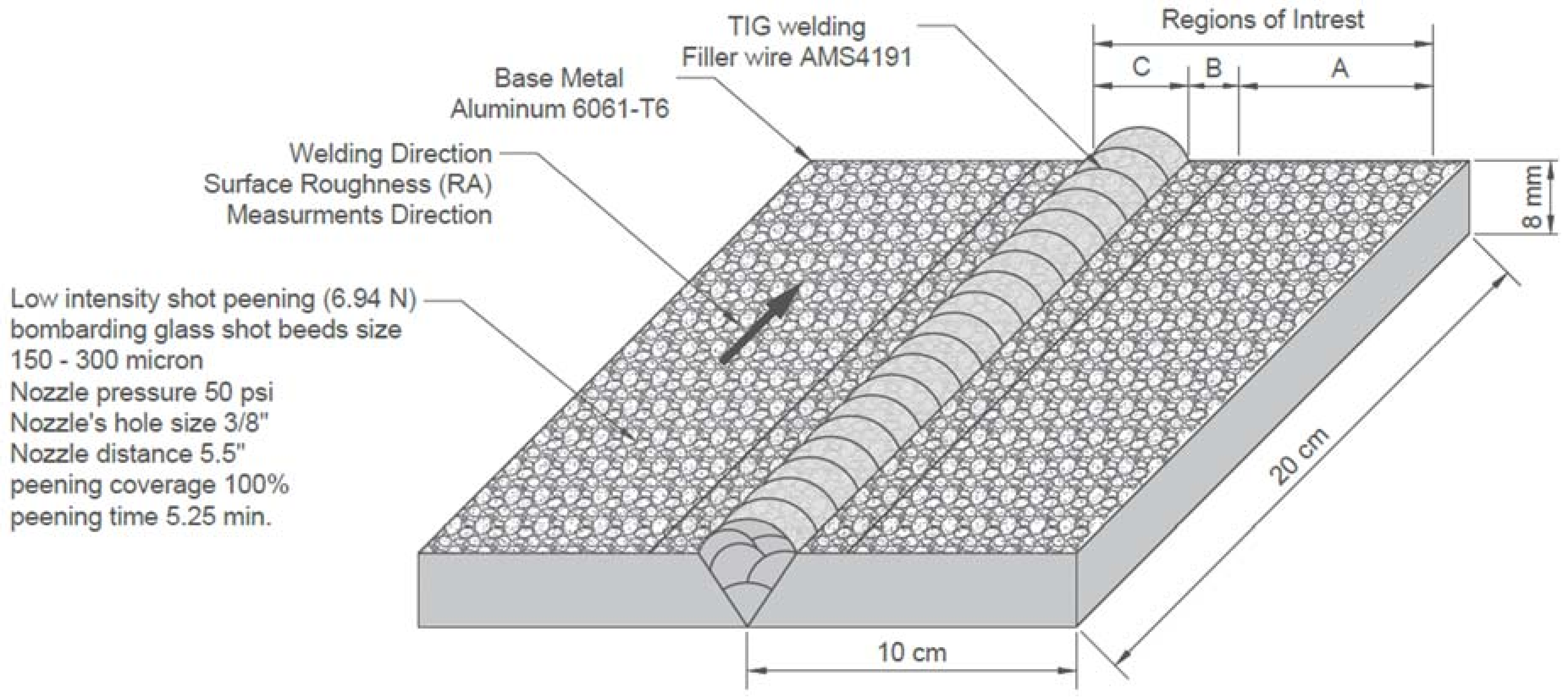

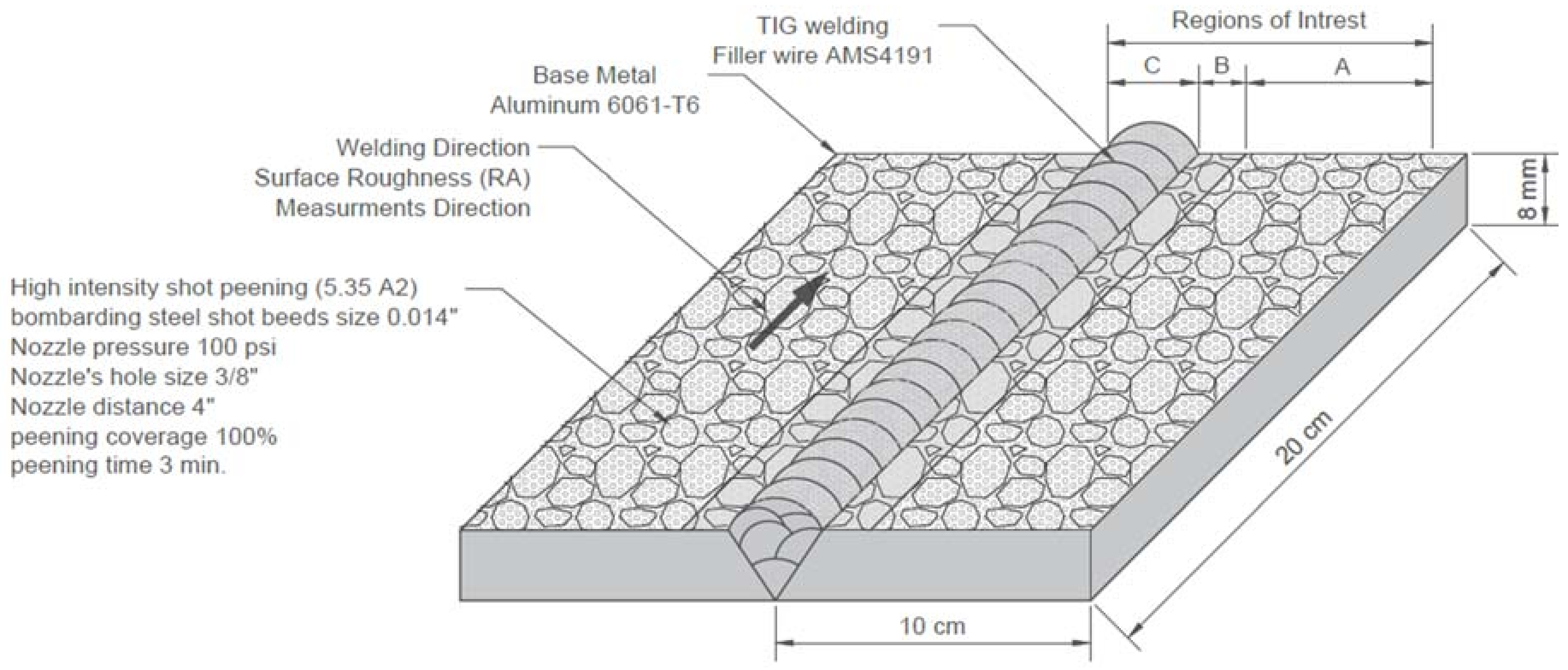

2.1. Materials, Properties, and Testing Specimens

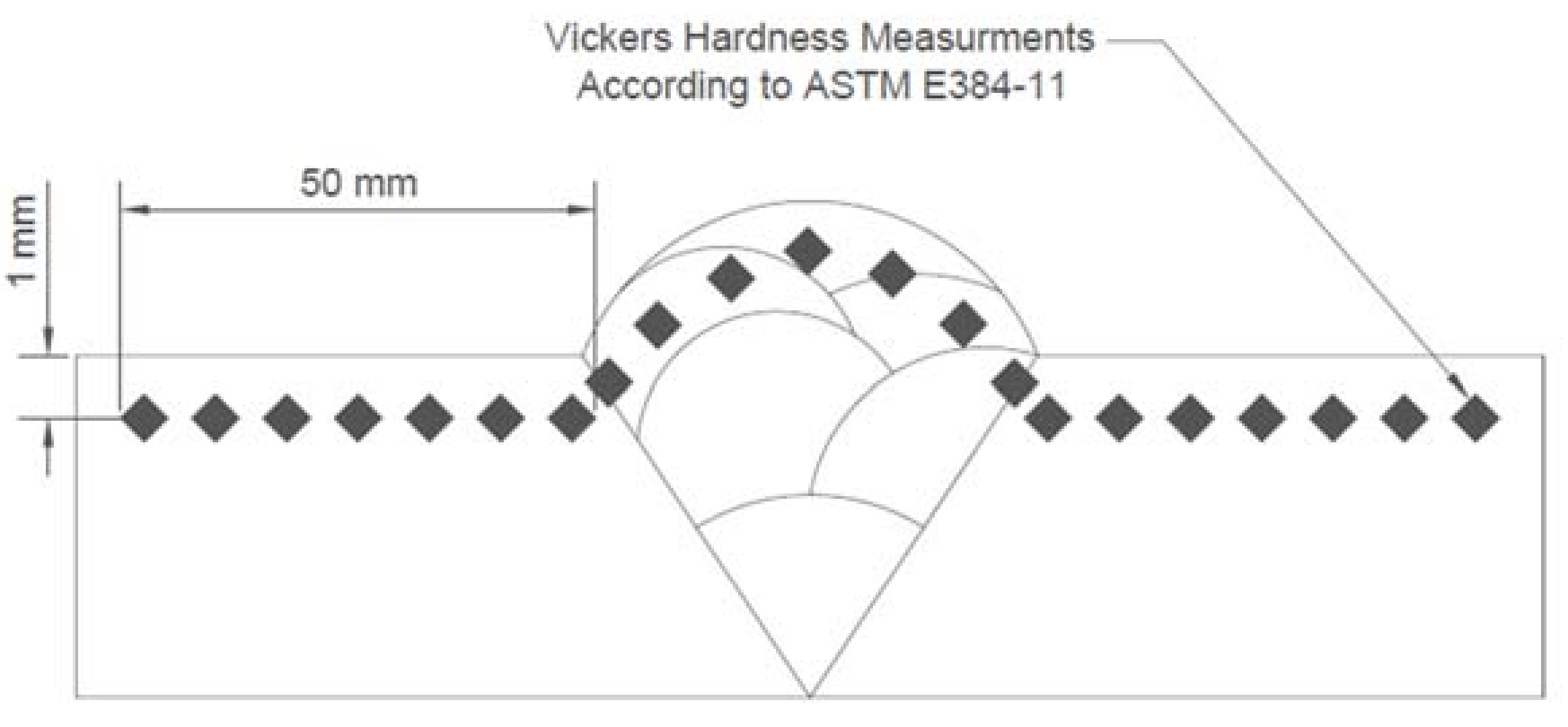

2.2. Characterization

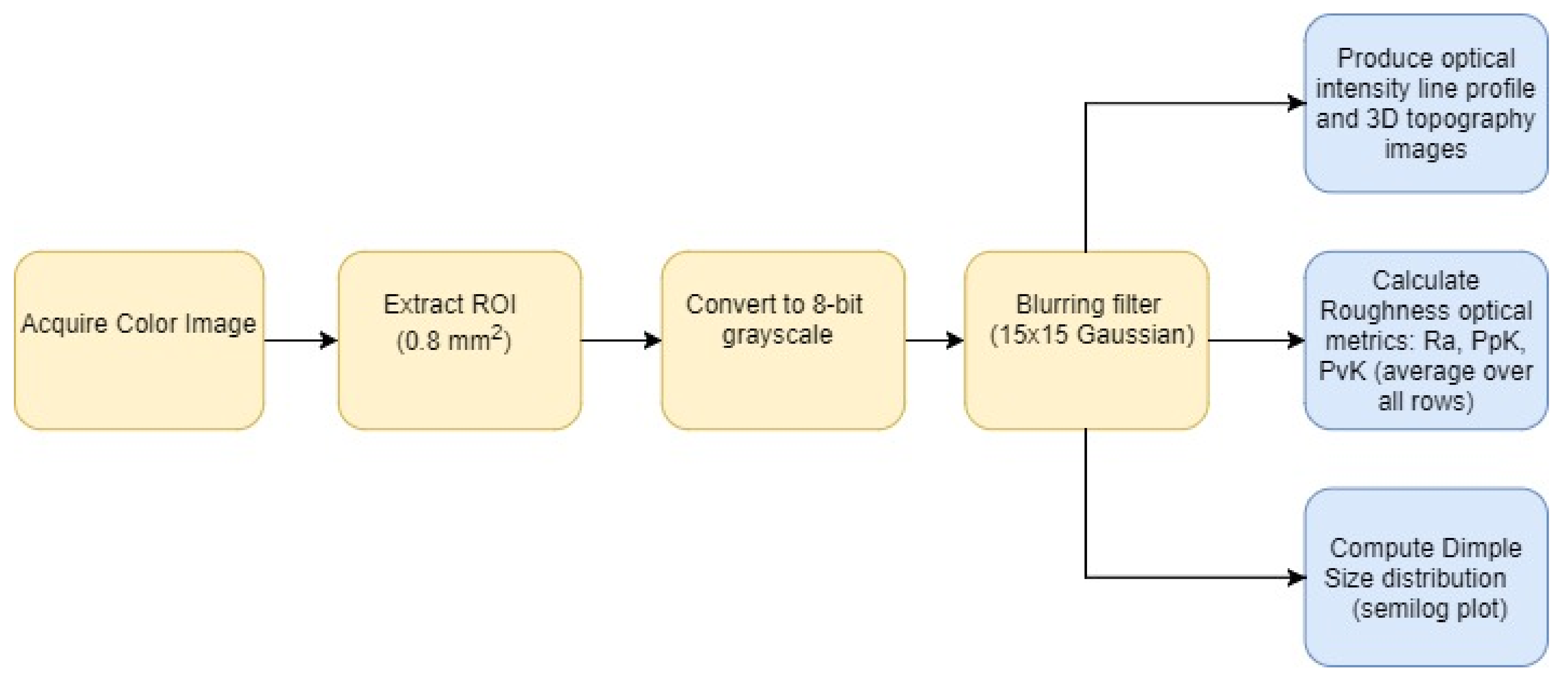

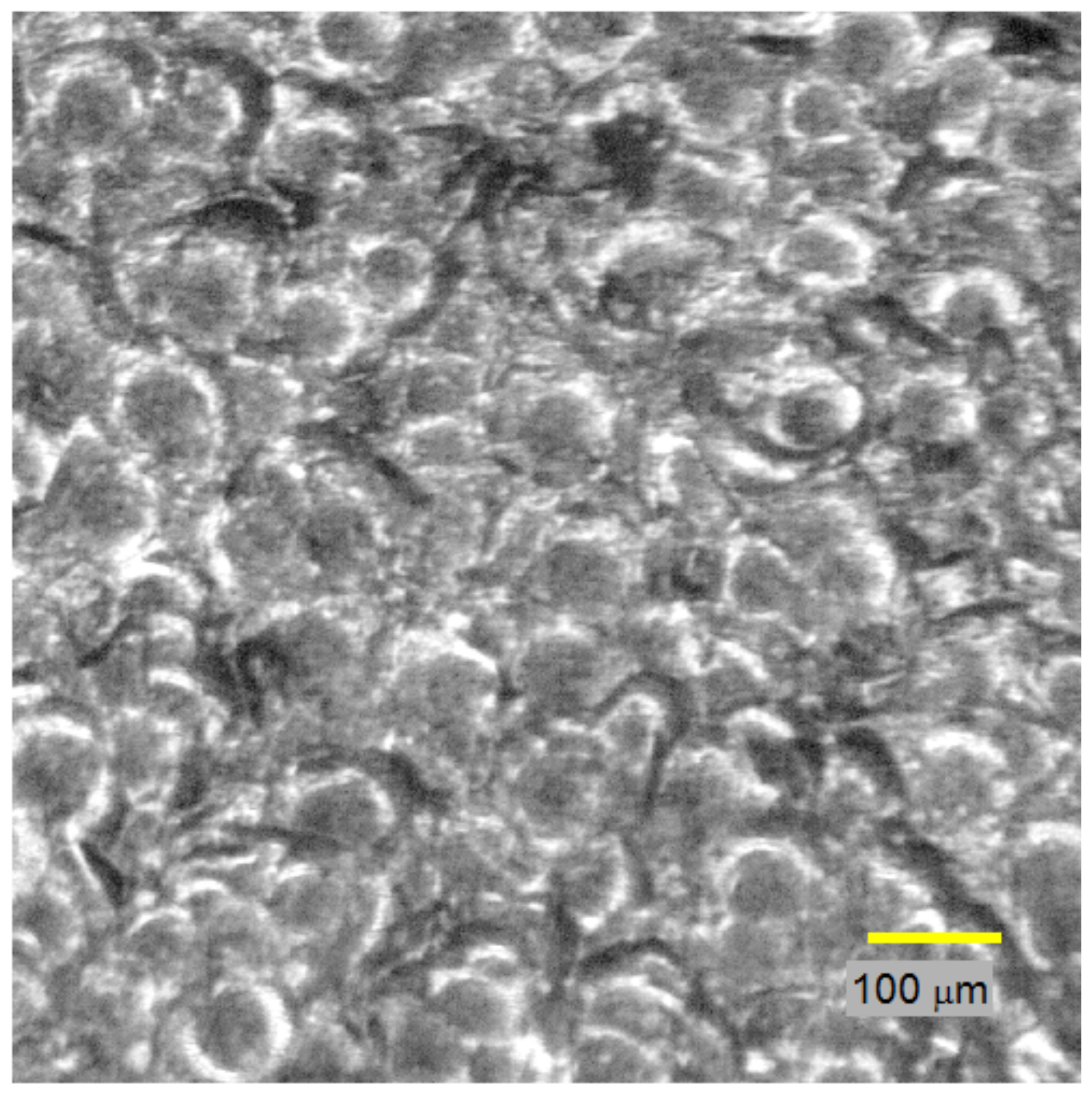

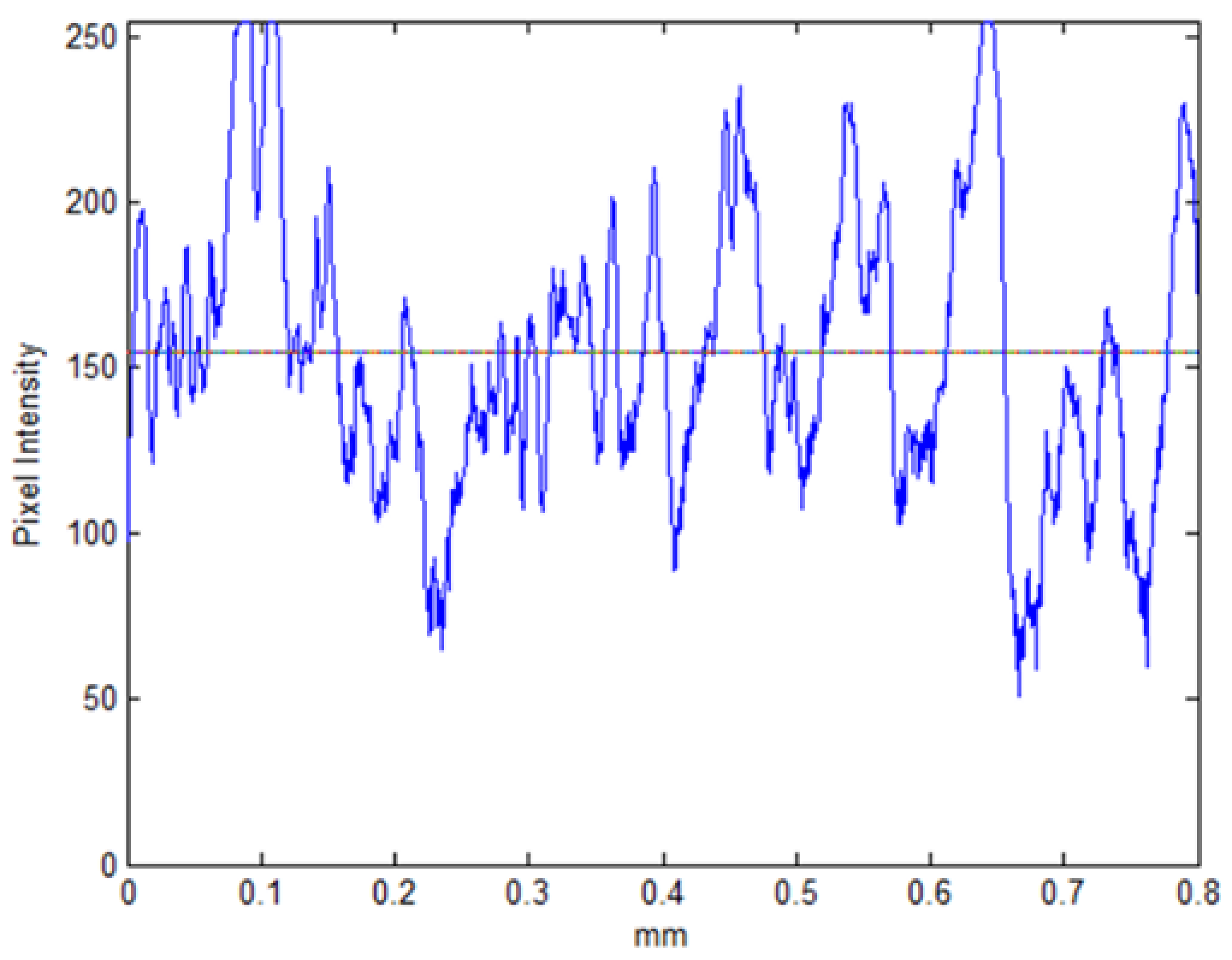

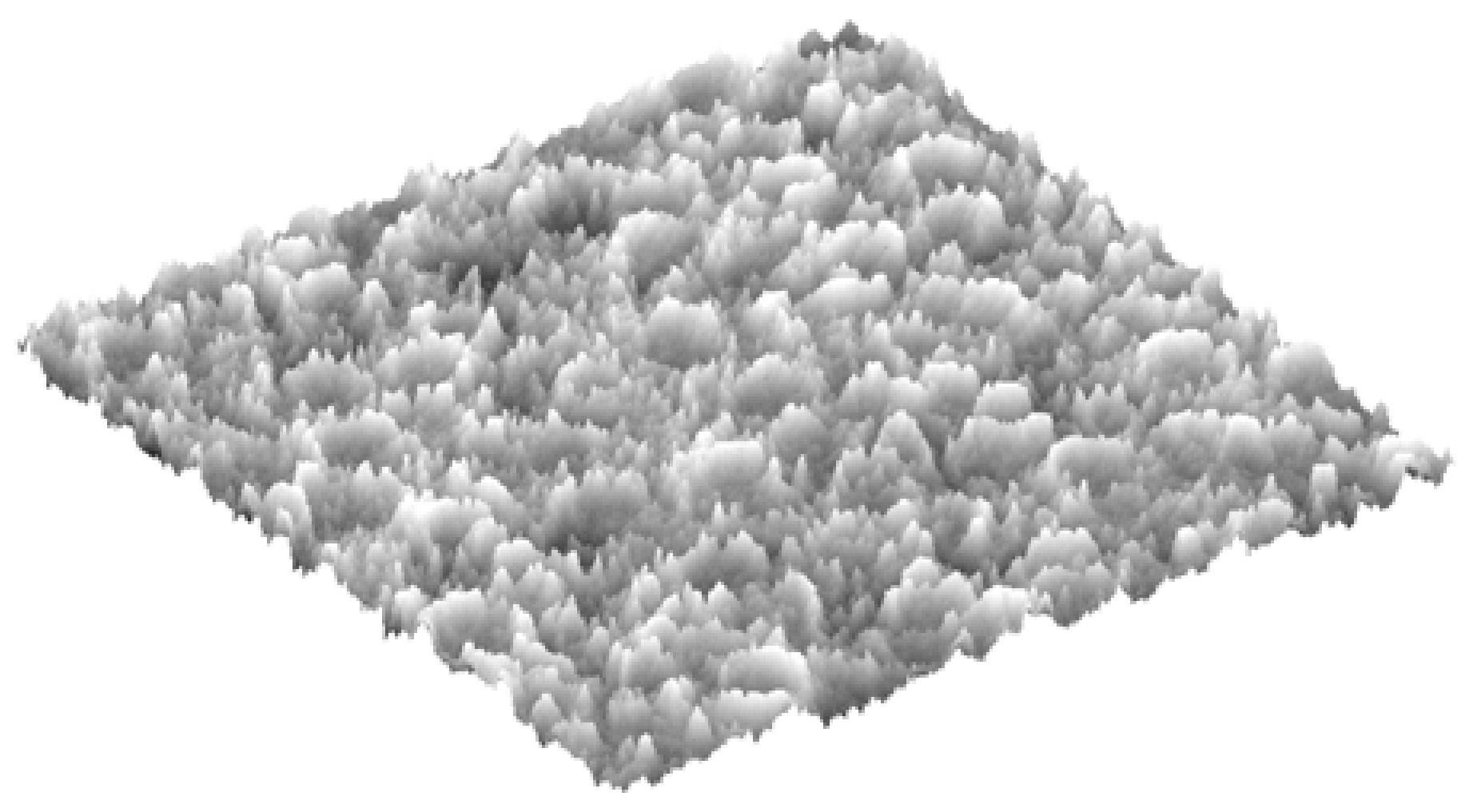

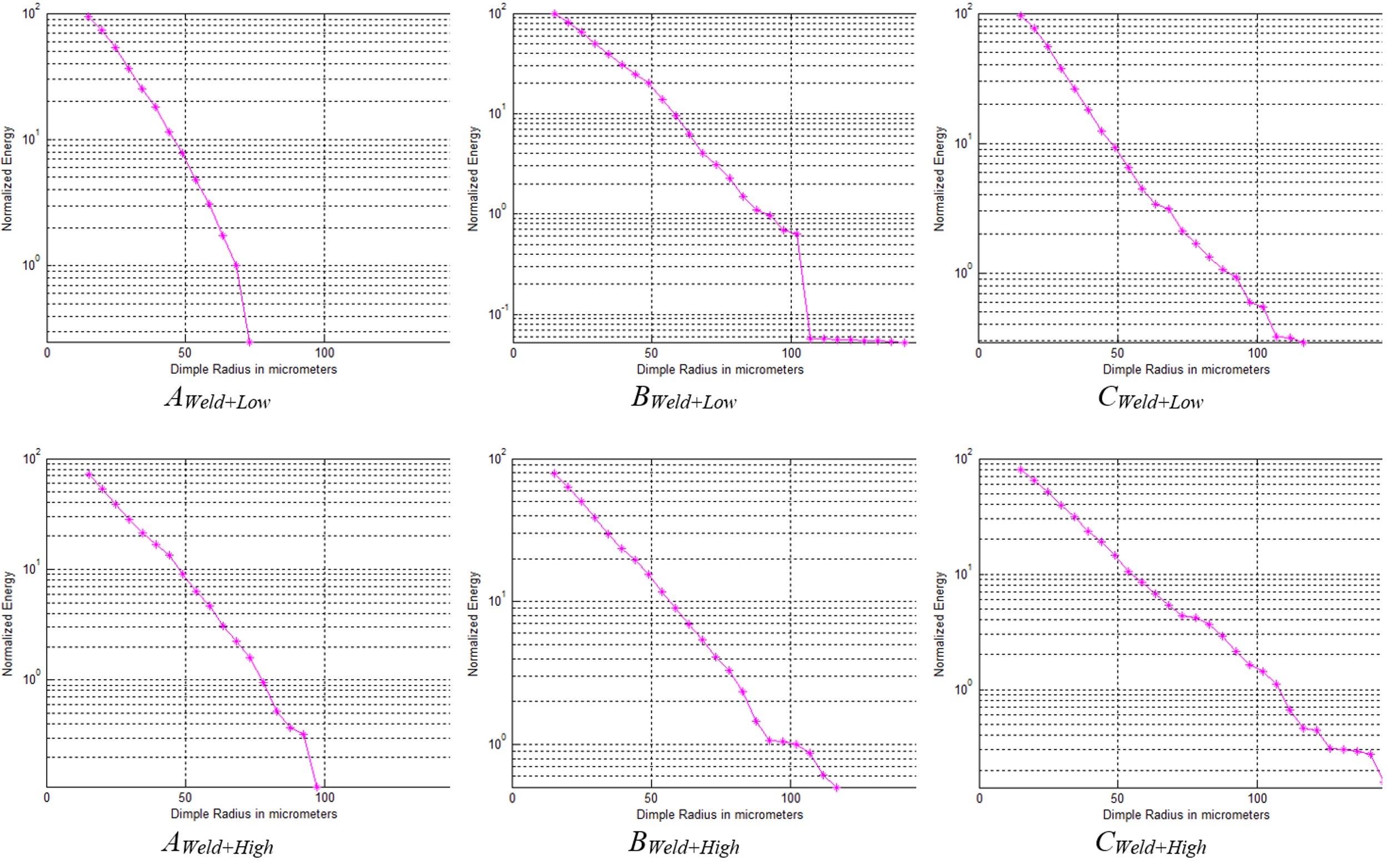

2.3. Image Processing

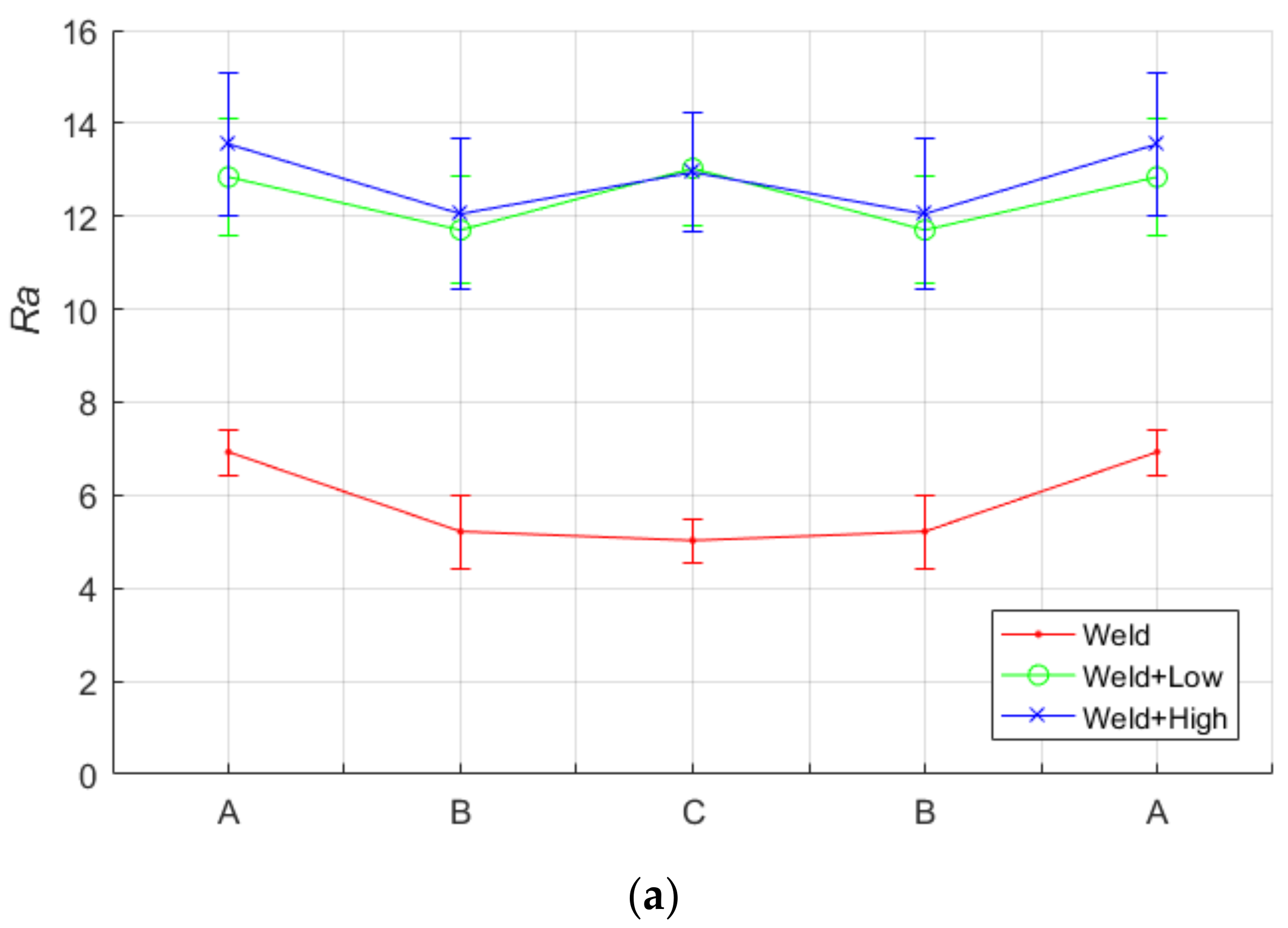

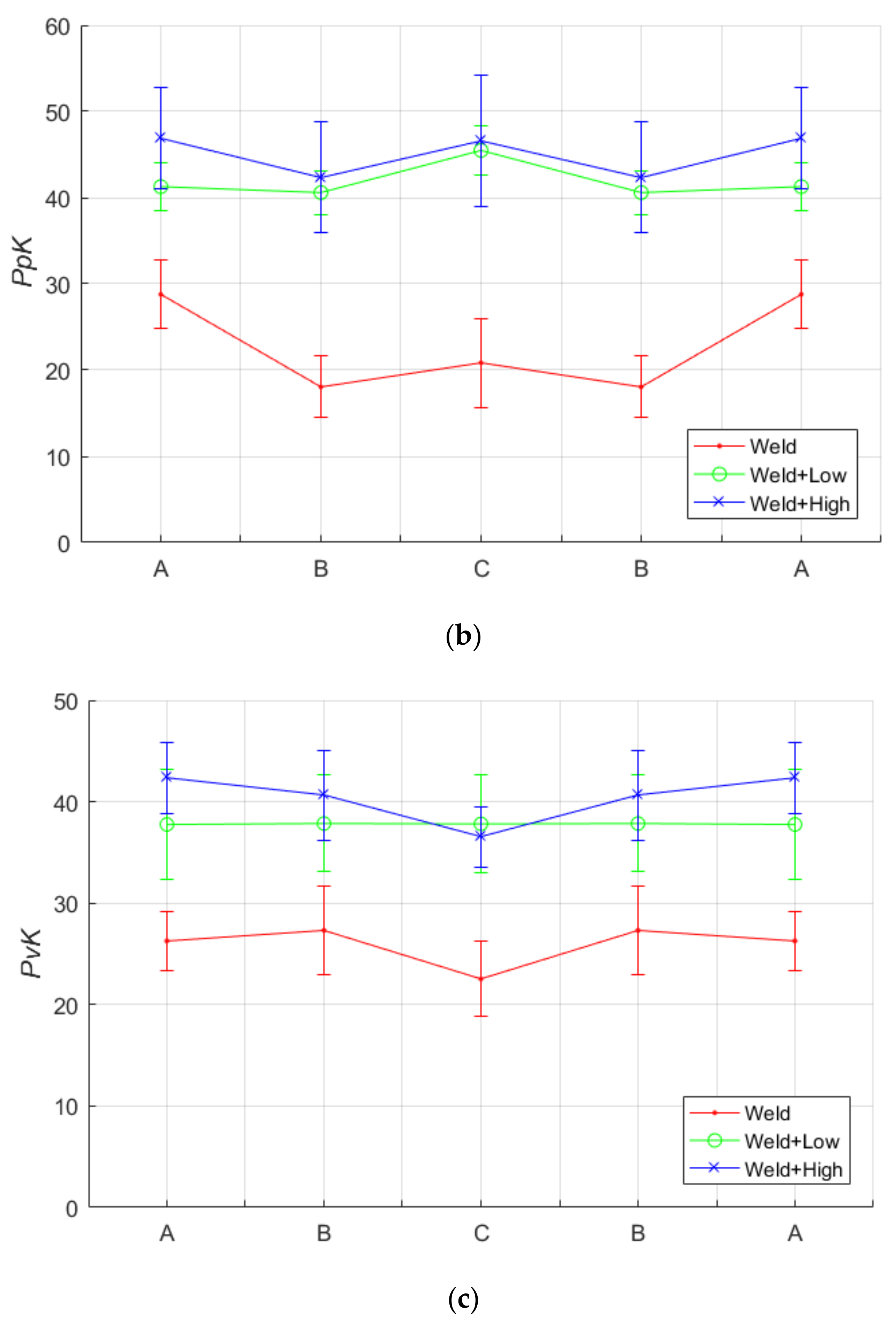

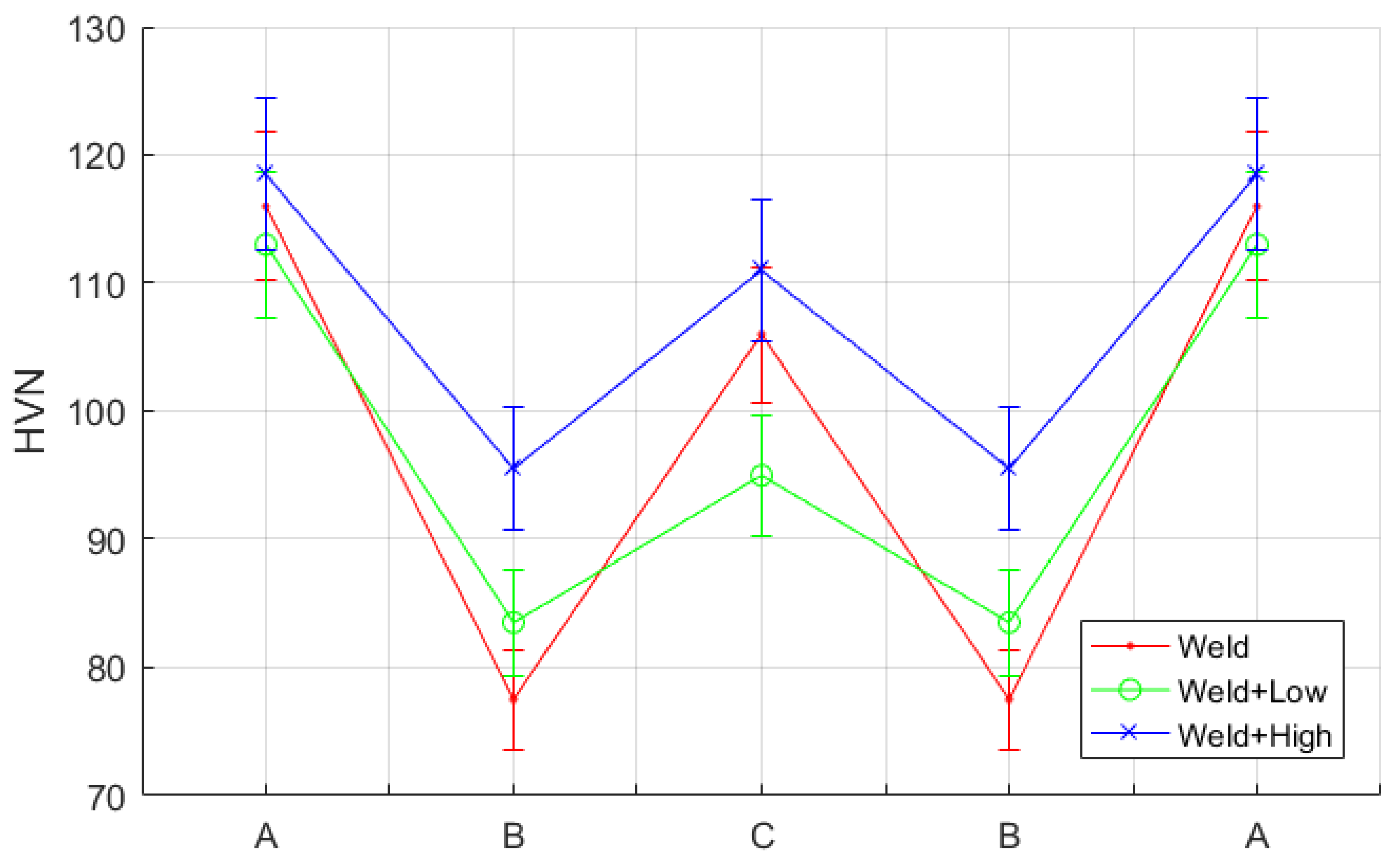

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shin, J.; Kim, T.; Kim, D.; Kim, D.; Kim, K. Castability and Mechanical Properties of New 7xxx Aluminum Alloys for Automotive Chassis/body Applications. J. Alloy. Compd. 2017, 698, 577–590. [Google Scholar] [CrossRef]

- Ashraf, P.M.; Shibli, S.M.A. Development of Cerium Oxide and Nickel Oxide-Incorporated Aluminium Matrix for Marine Applications. J. Alloy. Compd. 2009, 484, 477–482. [Google Scholar] [CrossRef]

- Cerik, B.C. Damage Assessment of Marine Grade Aluminium Alloy-Plated Structures due to Air Blast and Explosive Loads. Thin-walled Struct. 2017, 110, 123–132. [Google Scholar] [CrossRef]

- Teimouri, R.; Amini, S.; Mohagheghian, N. Experimental Study and Empirical Analysis on Effect of Ultrasonic Vibration during Rotary Turning of Aluminum 7075 Aerospace Alloy. J. Manuf. Process. 2017, 26, 1–12. [Google Scholar] [CrossRef]

- Heinz, A.; Haszler, A.; Keidel, C.; Moldenhauer, S.; Benedictus, R.; Miller, W.S. Recent Development in Aluminium Alloys for Aerospace Applications. Mater. Sci. Eng. A 2000, 280, 102–107. [Google Scholar] [CrossRef]

- Milligan, J.; Brochu, M. Cladding AA7075 with a Cryomilled Al-12Si Alloy Using Spark Plasma Sintering. Mater. Sci. Eng. A 2013, 578, 323–330. [Google Scholar] [CrossRef]

- Xing, W.Q.; Yu, X.Y.; Li, H.; Ma, L.; Zuo, W.; Dong, P.; Wang, W.X.; Ding, M. Effect of Nano Al2O3 Additions on the Interfacial Behavior and Mechanical Properties of Eutectic Sn-9Zn Solder on Low Temperature Wetting and Soldering of 6061 Aluminum Alloys. J. Alloy. Compd. 2017, 695, 574–582. [Google Scholar] [CrossRef]

- Gómora, C.M.; Ambriz, R.R.; Curiel, F.F.; Jaramillo, D. Heat Distribution in Welds of a 6061-T6 Aluminum Alloy Obtained by Modified Indirect Electric Arc. J. Mater. Process. Technol. 2017, 243, 433–441. [Google Scholar] [CrossRef]

- Liang, Y.; Hu, S.; Shen, J.; Zhang, H.; Wang, P. Geometrical and Microstructural Characteristics of the TIG-CMT Hybrid Welding in 6061 Aluminum Alloy Cladding. J. Mater. Process. Technol. 2017, 239, 18–30. [Google Scholar] [CrossRef]

- Ahn, J.; Chen, L.; He, E.; Davies, C.M.; Dear, J.P. Effect of Filler Metal Feed Rate and Composition on Microstructure and Mechanical Properties of Fibre Laser Welded AA 2024-T3. J. Manuf. Process. 2017, 25, 26–36. [Google Scholar] [CrossRef]

- Zalnezhad, E.; Sarhan, A.A.D.M.; Hamdi, M. Prediction of TiN Coating Adhesion Strength on Aerospace AL7075-T6 Alloy Using Fuzzy Rule Based System. Int. J. Precis. Eng. Manuf. 2012, 13, 1453–1459. [Google Scholar] [CrossRef]

- Chang, H.W.; Kelly, P.M.; Shi, Y.N.; Zhang, M.X. Thermal Stability of Nanocrystallized Surface Produced by Surface Mechanical Attrition Treatment in Aluminum Alloys. Surf. Coat. Technol. 2012, 206, 3970–3980. [Google Scholar] [CrossRef]

- Liu, Y.; Jin, B.; Lu, J. Mechanical Properties and Thermal Stability of Nanocrystallized Pure Aluminum Produced by Surface Mechanical Attrition Treatment. Mater. Sci. Eng. A 2015, 636, 446–451. [Google Scholar] [CrossRef]

- Heydari Astaraee, A.; Miresmaeili, R.; Bagherifard, S.; Guagliano, M.; Aliofkhazraei, M. Incorporating the Principles of Shot Peening for a Better Understanding of Surface Mechanical Attrition Treatment (SMAT) by Simulations and Experiments. Mater. Des. 2017, 116, 365–373. [Google Scholar] [CrossRef]

- Pandey, V.; Chattopadhyay, K.; Srinivas, N.C.S.; Singh, V. Low Cycle Fatigue Behavior of AA7075 with Surface Gradient Structure Produced by Ultrasonic Shot Peening. Procedia Struct. Integr. 2016, 2, 3288–3295. [Google Scholar] [CrossRef]

- He, Y.Z.; Wang, D.P.; Wang, Y.; Zhang, H. Correction of Buckling Distortion by Ultrasonic Shot Peening Treatment for 5A06 Aluminum Alloy Welded Structure. Trans. Nonferrous Met. Soc. China 2016, 26, 1531–1537. [Google Scholar]

- Hatamleh, O.; Lyons, J.; Forman, R. Laser and Shot Peening Effects on Fatigue Crack Growth in Friction Stir Welded 7075-T7351 Aluminum Alloy Joints. Int. J. Fatigue 2007, 29, 421–434. [Google Scholar] [CrossRef]

- Sathyajith, S.; Kalainathan, S. Effect of Laser Shot Peening on Precipitation Hardened Aluminum Alloy 6061-T6 Using Low Energy Laser. Opt. Lasers Eng. 2012, 50, 345–348. [Google Scholar] [CrossRef]

- Gao, Y.K. Improvement of Fatigue Property in 7050-T7451 Aluminum Alloy by Laser Peening and Shot Peening. Mater. Sci. Eng. A 2011, 528, 3823–3828. [Google Scholar] [CrossRef]

- Zhang, X.Q.; Chen, L.S.; Li, S.Z.; Duan, S.W.; Zhou, Y.; Huang, Z.L.; Zhang, Y. Investigation of the Fatigue Life of Pre- and Post-Drilling Hole in Dog-Bone Specimen Subjected to Laser Shot Peening. Mater. Des. 2015, 88, 106–114. [Google Scholar] [CrossRef]

- Luong, H.; Hill, M.R. The Effects of Laser Peening and Shot Peening on High Cycle Fatigue in 7050-T7451 Aluminum Alloy. Mater. Sci. Eng. A 2010, 527, 699–707. [Google Scholar] [CrossRef]

- Nam, Y.S.; Jeong, Y.I.; Shin, B.C.; Byun, J.H. Enhancing Surface Layer Properties of an Aircraft Aluminum Alloy by Shot Peening Using Response Surface Methodology. Mater. Des. 2015, 83, 566–576. [Google Scholar] [CrossRef]

- Honga, T.; Ooia, J.Y.; Shawb, B. A Numerical Simulation to Relate the Shot Peening Parameters to the Induced Residual Stresses. Eng. Fail. Anal. 2008, 15, 1097–1110. [Google Scholar] [CrossRef]

- Han, K.; Peric, D.; Crook, A.J.L.; Owen, D.R.J. A Combined Finite/discrete Element Sim- Ulation of Shot Peening Processes-Part I: Studies on 2D Interaction Laws. Eng. Comput. 2000, 17, 593–620. [Google Scholar] [CrossRef]

- Tu, F.; Delbergue, D.; Miao, H.; Klotz, T.; Brochu, M.; Bocher, P.; Levesque, M. A Sequential DEM-FEM Coupling Method for Shot Peening Simulation. Surf. Coat. Technol. 2017, 319, 200–212. [Google Scholar] [CrossRef]

- Hatamleh, O. Effects of Peening on Mechanical Properties in Friction Stir Welded 2195 Aluminum Alloy Joints. Mater. Sci. Eng. A 2008, 492, 168–176. [Google Scholar] [CrossRef]

- Hatamleh, O.; Hill, M.; Forth, S.; Garcia, D. Fatigue Crack Growth Performance of Peened Friction Stir Welded 2195 Aluminum Alloy Joints at Elevated and Cryogenic Temperatures. Mater. Sci. Eng. A 2009, 519, 61–69. [Google Scholar] [CrossRef]

- Hatamleh, O.; Forth, S.; Reynolds, A.P. Fatigue Crack Growth of Peened Friction Stir-Welded 7075 Aluminum Alloy under Different Load Ratios. J. Mater. Eng. Perform. 2010, 19, 99–106. [Google Scholar] [CrossRef]

- Sano, Y.; Masaki, K.; Gushi, T.; Sano, T. Improvement in Fatigue Performance of Friction Stir Welded A6061-T6 Aluminum Alloy by Laser Peening without Coating. Mater. Des. 2012, 36, 809–814. [Google Scholar] [CrossRef]

- Atieh, A.M.; Allaf, R.M.; AlHazaa, A.N.; Barghash, M.; Mubaydin, H. Effect of Pre- and Post-Weld Shot Peening on The Mechanical & Tribological Properties of Tig Welded Al 6061-T6 Alloy. Trans. Can. Soc. Mech. Eng. 2017, 41, 197–209. [Google Scholar]

- Yang, Q.; Zhou, W.; Gai, P.; Zhang, X.; Fu, X.; Chen, G.; Li, Z. Investigation on the Fretting Fatigue Behaviors of Ti-6Al-4V Dovetail Joint Specimens Treated with Shot-Peening. Wear 2017, 372–373, 81–90. [Google Scholar] [CrossRef]

- Xu, C.; Sheng, G.; Wang, H.; Jiao, Y.; Yuan, X. Effect of High Energy Shot Peening on the Microstructure and Mechanical Properties of Mg/Ti Joints. J. Alloy. Compd. 2017, 695, 1383–1391. [Google Scholar] [CrossRef]

- Zhang, G. J.; Yan, Z. H.; Wu, L. Visual Sensing of Weld Pool in Variable Polarity TIG Welding of Aluminium Alloy. Trans. Nonferrous Met. Soc. China 2006, 16, 522–526. [Google Scholar] [CrossRef]

- Xu, Y.; Lv, N.; Fang, G.; Du, S.; Zhao, W.; Ye, Z.; Chen, S. Welding Seam Tracking in Robotic Gas Metal Arc Welding. J. Mater. Process. Technol. 2017, 248, 18–30. [Google Scholar] [CrossRef]

- Bae, K.Y.; Lee, T.H.; Ahn, K.C. An Optical Sensing System for Seam Tracking and Weld Pool Control in Gas Metal Arc Welding of Steel Pipe. J. Mater. Process. Technol. 2002, 120, 458–465. [Google Scholar] [CrossRef]

- Nilsen, M.; Sikström, F.; Christiansson, A.; Ancona, A. Vision and Spectroscopic Sensing for Joint Tracing in Narrow Gap Laser Butt Welding. Opt. Laser Technol. 2017, 96, 107–116. [Google Scholar] [CrossRef]

- Gao, X.; Liu, Y.; You, D. Detection of Micro-Weld Joint by Magneto-Optical Imaging. Opt. Laser Technol. 2014, 62, 141–151. [Google Scholar] [CrossRef]

- Gao, X.; Chen, Y.; You, D.; Xiao, Z.; Chen, X. Detection of Microgap Weld Joint by Using Magneto-Optical Imaging and Kalman Filtering Compensated with RBF Neural Network. Mech. Syst. Signal Process. 2016, 84, 570–583. [Google Scholar] [CrossRef]

- Shankar, N.G.; Zhong, Z.W. Defect Detection on Semiconductor Wafer Surfaces. Microelectron. Eng. 2005, 77, 337–346. [Google Scholar] [CrossRef]

- Valavanis, I.; Kosmopoulos, D. Multiclass Defect Detection and Classification in Weld Radiographic Images Using Geometric and Texture Features. Expert Syst. Appl. 2010, 37, 7606–7614. [Google Scholar] [CrossRef]

- Chu, H.H.; Wang, Z.Y. A Vision-Based System for Post-Welding Quality Measurement and Defect Detection. Int. J. Adv. Manuf. Technol. 2016, 86, 3007–3014. [Google Scholar] [CrossRef]

- Kafieh, R.; Lotfi, T.; Amirfattahi, R. Automatic Detection of Defects on Polyethylene Pipe Welding Using Thermal Infrared Imaging. Infrared Phys. Technol. 2011, 54, 317–325. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.F.; Wang, Q.L.; Xu, D.; Tan, M. Measurement and Defect Detection of the Weld Bead Based on Online Vision Inspection. IEEE Trans. Instrum. Meas. 2010, 59, 1841–1849. [Google Scholar]

- Elbehiery, H.; Hefnawy, A.; Elewa, M. Surface Defects Detection for Ceramic Tiles Using Image Processing and Morphological Techniques. Proc. World Acad. Sci. Eng. Technol. 2005, 5, 158–162. [Google Scholar]

- Vachtsevanos, G.J.; Dar, I.M.; Newman, K.E.; Sahinci, E. Inspection System and Method for Bond Detection and Validation of Surface Mount Devices. U.S. Patent 5,963,662, 5 October 1999. [Google Scholar]

- Bonser, G.R.; Lawson, S.W. Defect Detection in Partially Completed SAW and TIG Welds Using Online Radioscopy and Image Processing. Process Control Sens. Manuf. 1998, 3399, 231. [Google Scholar]

- Kumar, G.S.; Natarajan, U.; Ananthan, S.S. Vision Inspection System for the Identification and Classification of Defects in MIG Welding Joints. Int. J. Adv. Manuf. Technol. 2012, 61, 923–933. [Google Scholar] [CrossRef]

| Chemical Composition (wt %) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Si | Fe | Cu | Mg | Mn | Ti | Zn | Cr | Al |

| 0.8 | 0.7 | 0.4 | 1.2 | 0.15 | 0.15 | 0.25 | 0.35 | Rem. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atieh, A.M.; Rawashdeh, N.A.; AlHazaa, A.N. Evaluation of Surface Roughness by Image Processing of a Shot-Peened, TIG-Welded Aluminum 6061-T6 Alloy: An Experimental Case Study. Materials 2018, 11, 771. https://doi.org/10.3390/ma11050771

Atieh AM, Rawashdeh NA, AlHazaa AN. Evaluation of Surface Roughness by Image Processing of a Shot-Peened, TIG-Welded Aluminum 6061-T6 Alloy: An Experimental Case Study. Materials. 2018; 11(5):771. https://doi.org/10.3390/ma11050771

Chicago/Turabian StyleAtieh, Anas M., Nathir A. Rawashdeh, and Abdulaziz N. AlHazaa. 2018. "Evaluation of Surface Roughness by Image Processing of a Shot-Peened, TIG-Welded Aluminum 6061-T6 Alloy: An Experimental Case Study" Materials 11, no. 5: 771. https://doi.org/10.3390/ma11050771