Gradient Nanostructured Tantalum by Thermal-Mechanical Ultrasonic Impact Energy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimen Preparation

2.2. Ultrasonic Nanocrystal Surface Modification (UNSM) and Local Heat Treatment (LHT)

2.3. Wear Behavior in Dry Conditions

2.4. Characterizations

3. Results and Discussion

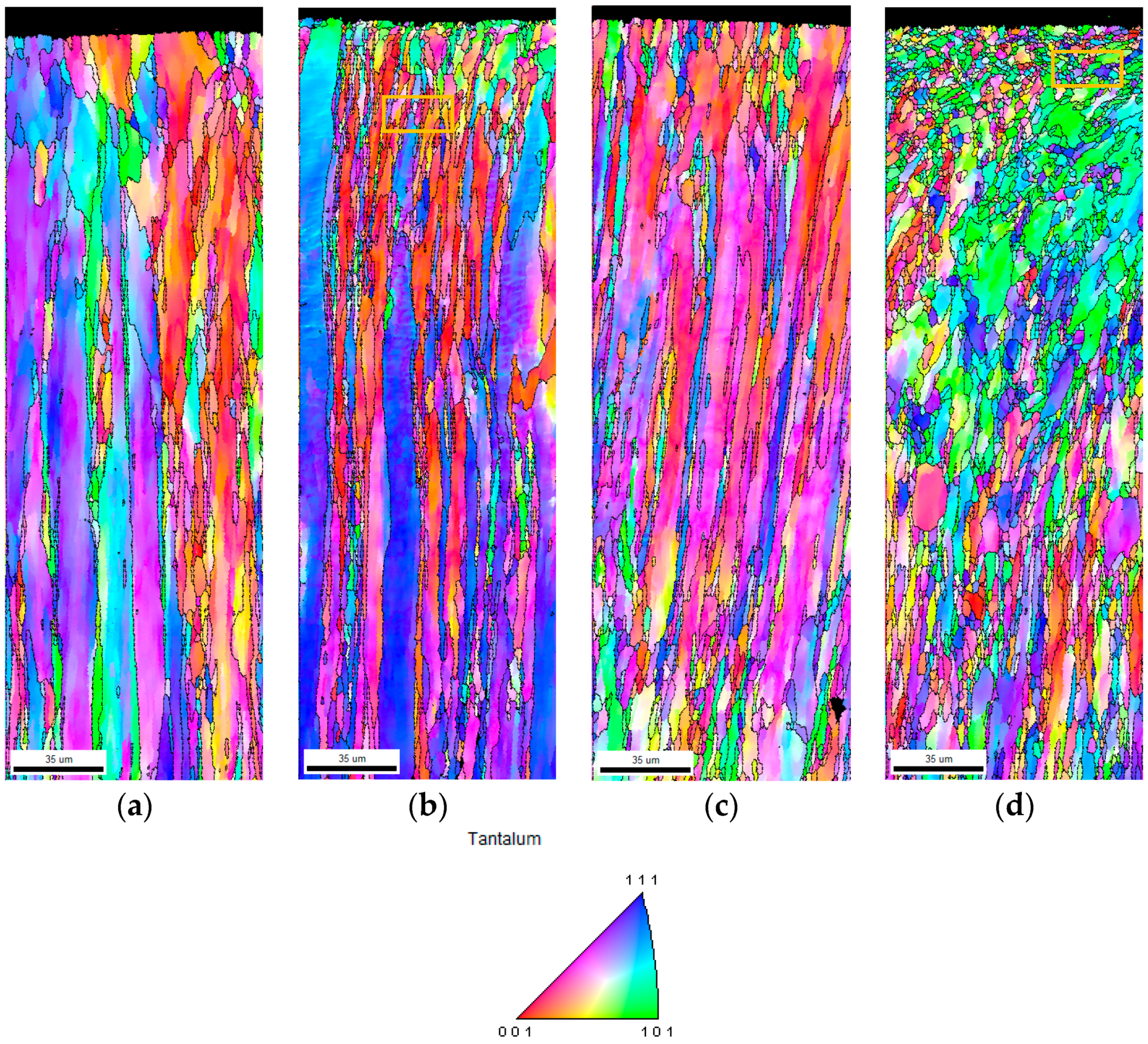

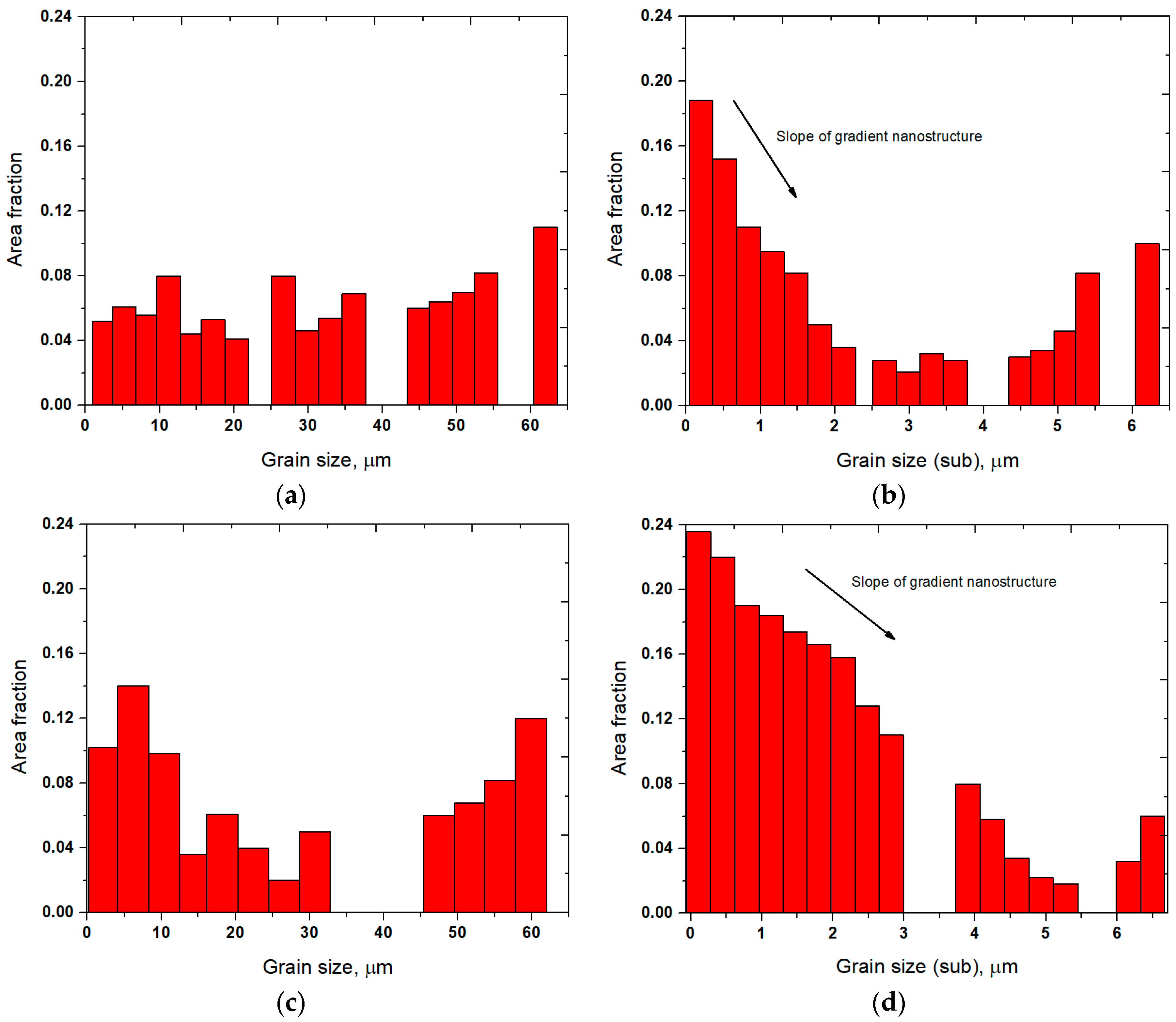

3.1. Microstructural Evolution by EBSD

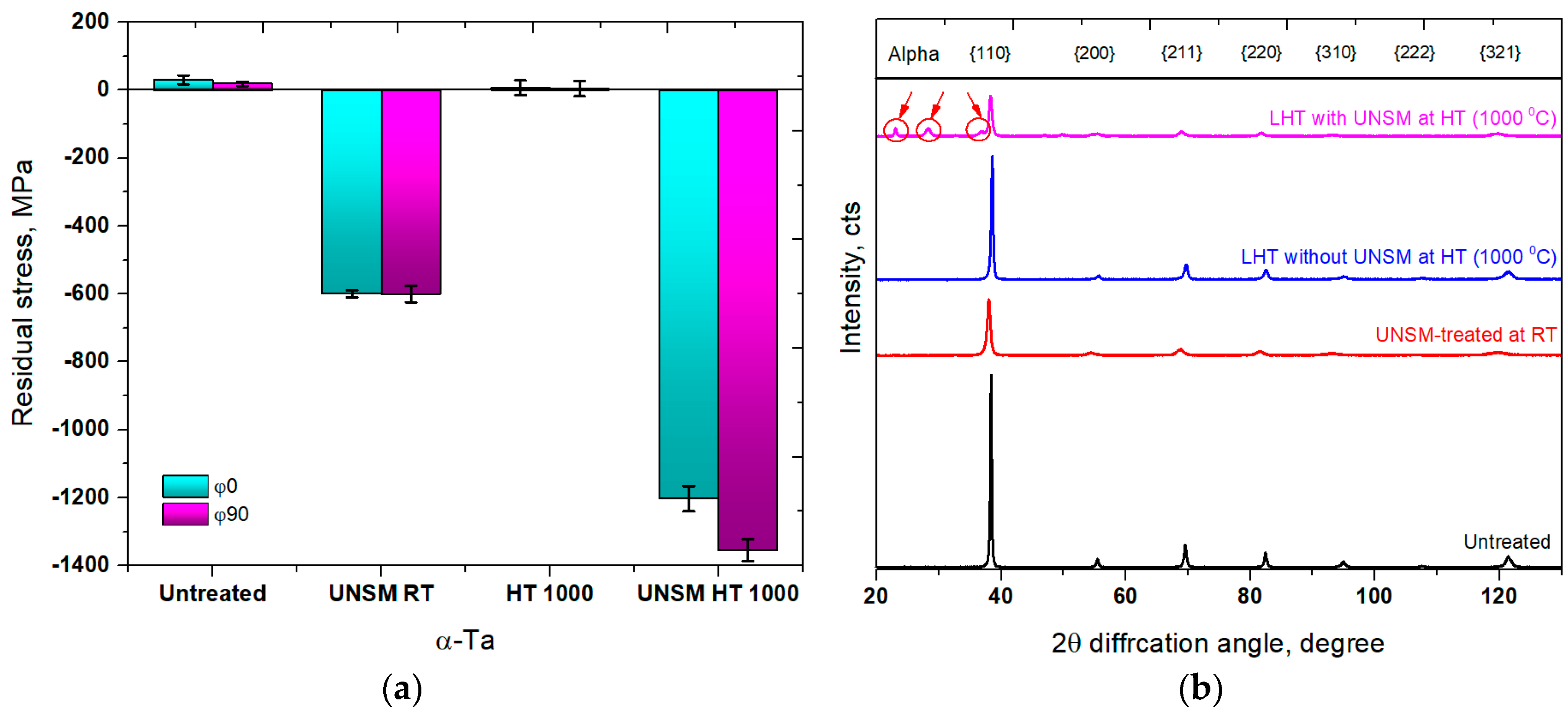

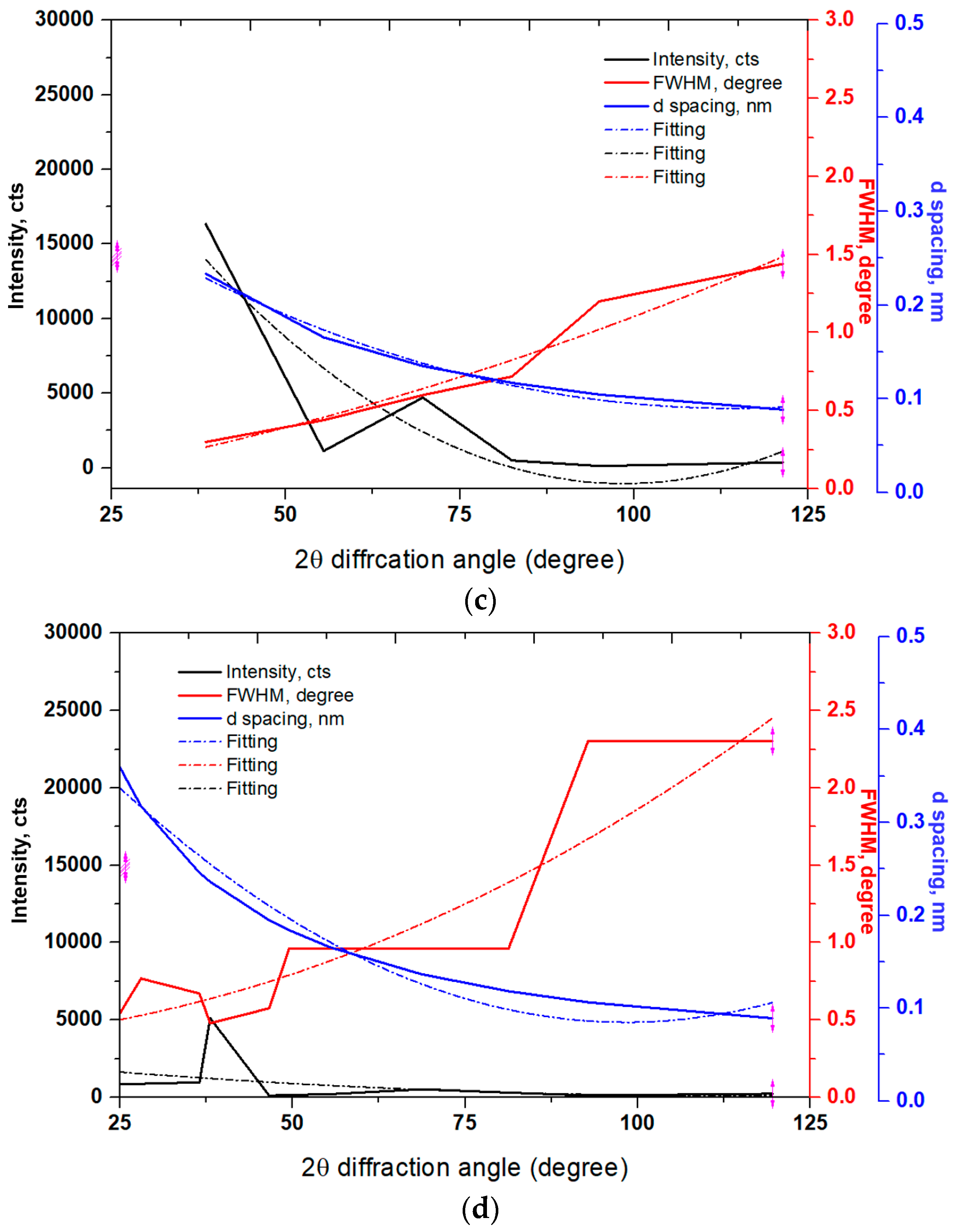

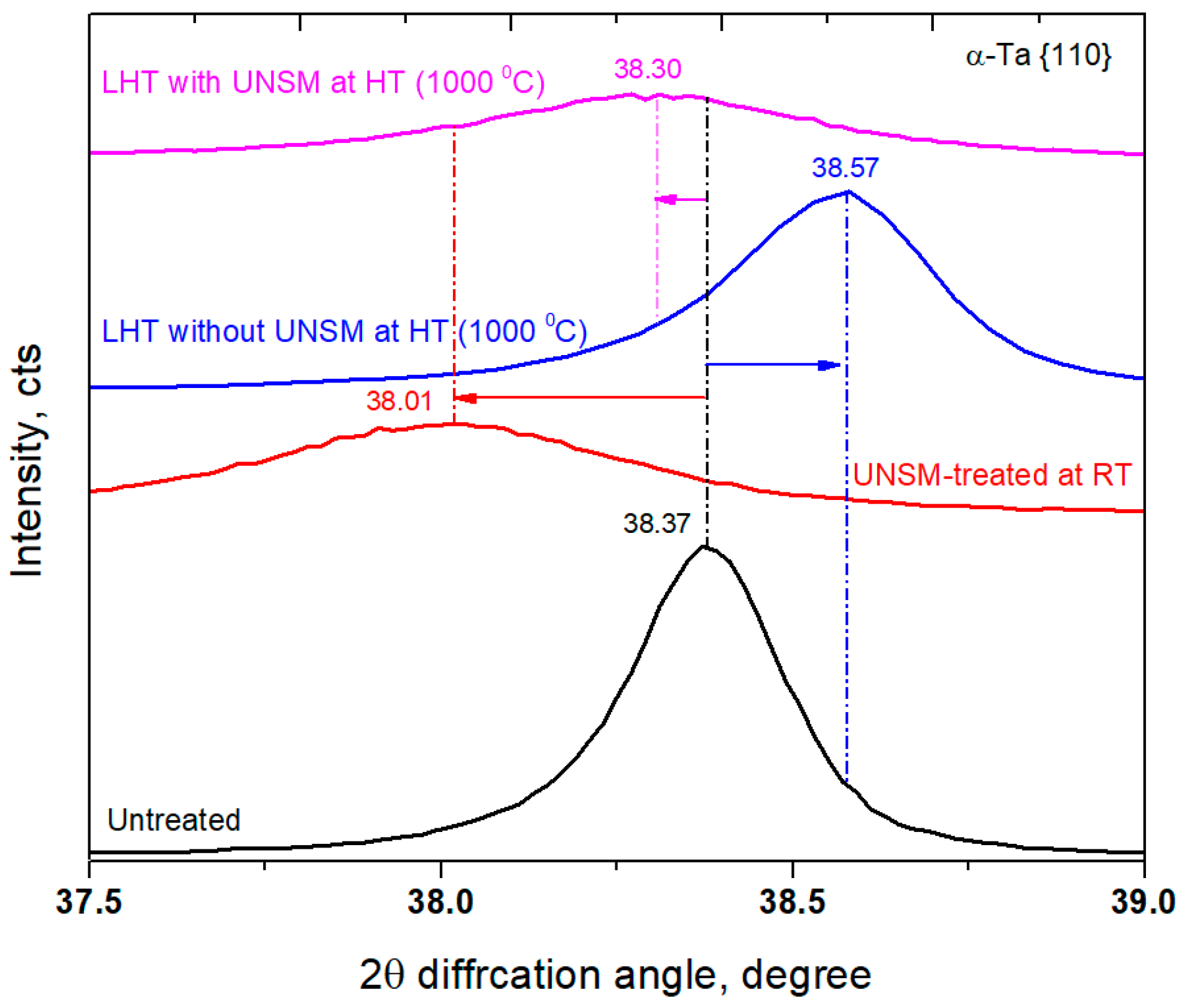

3.2. Residual Stress and XRD Pattern

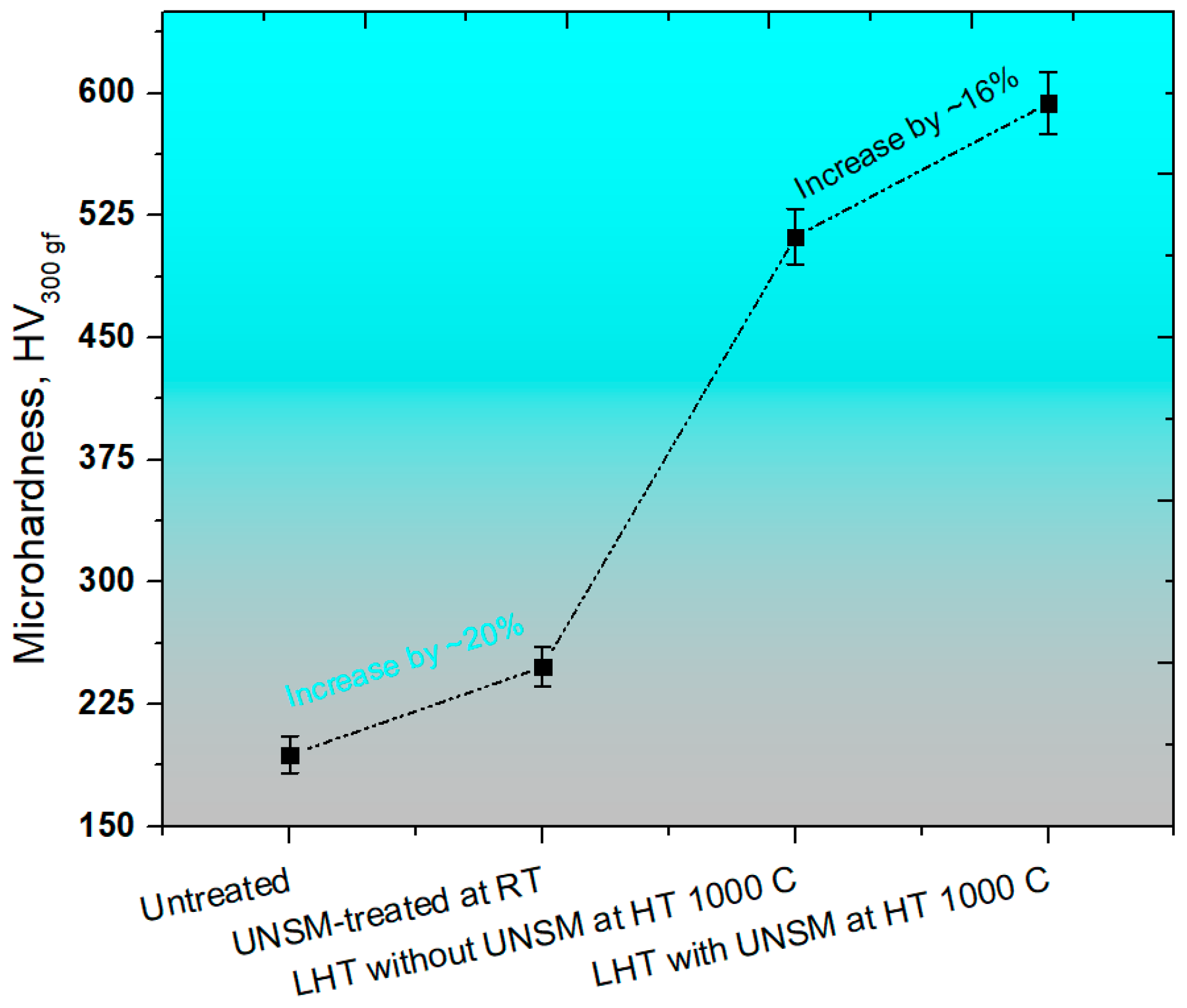

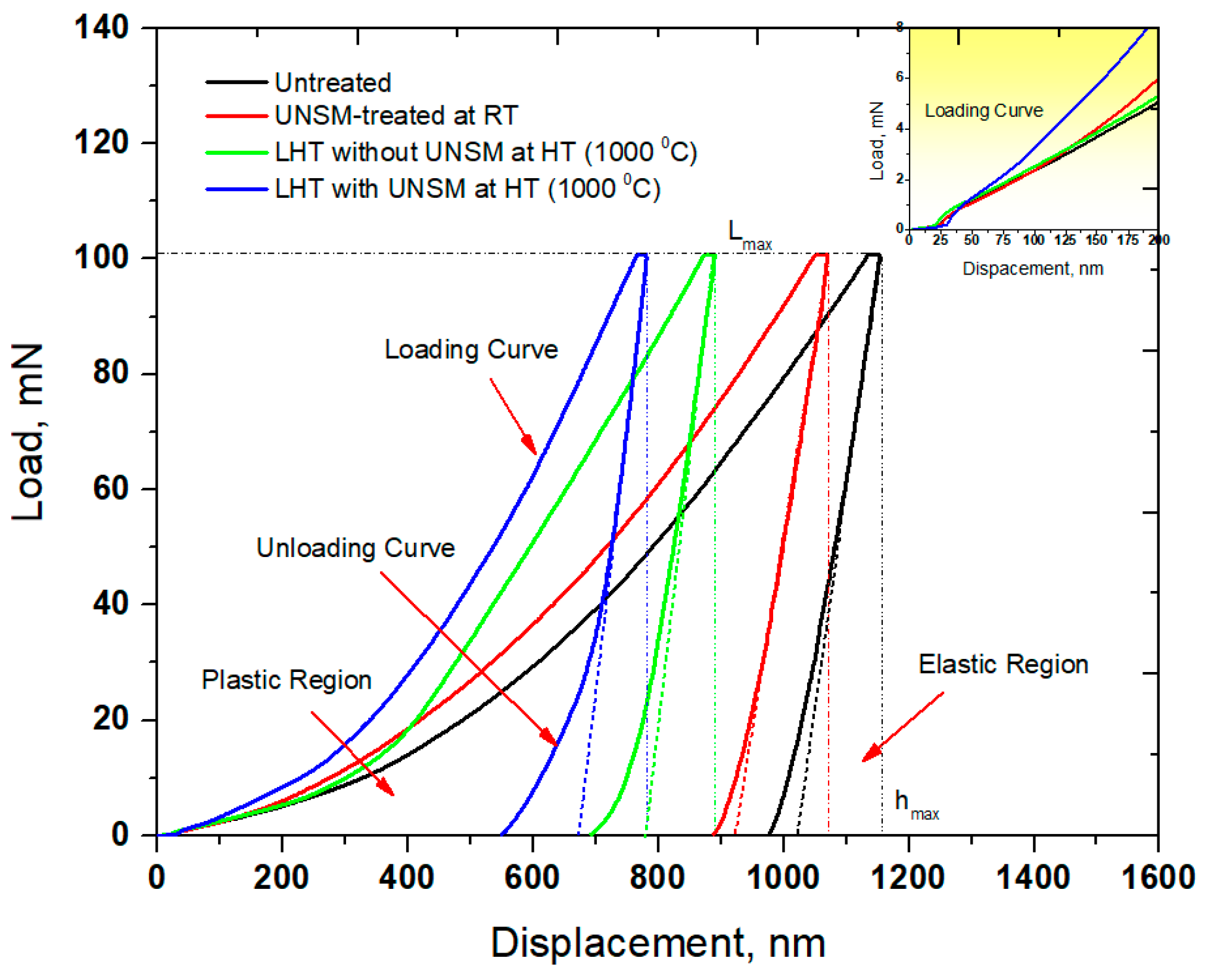

3.3. Microhardness and Nanoindentation

- for tensile residual stress

- for compressive residual stress

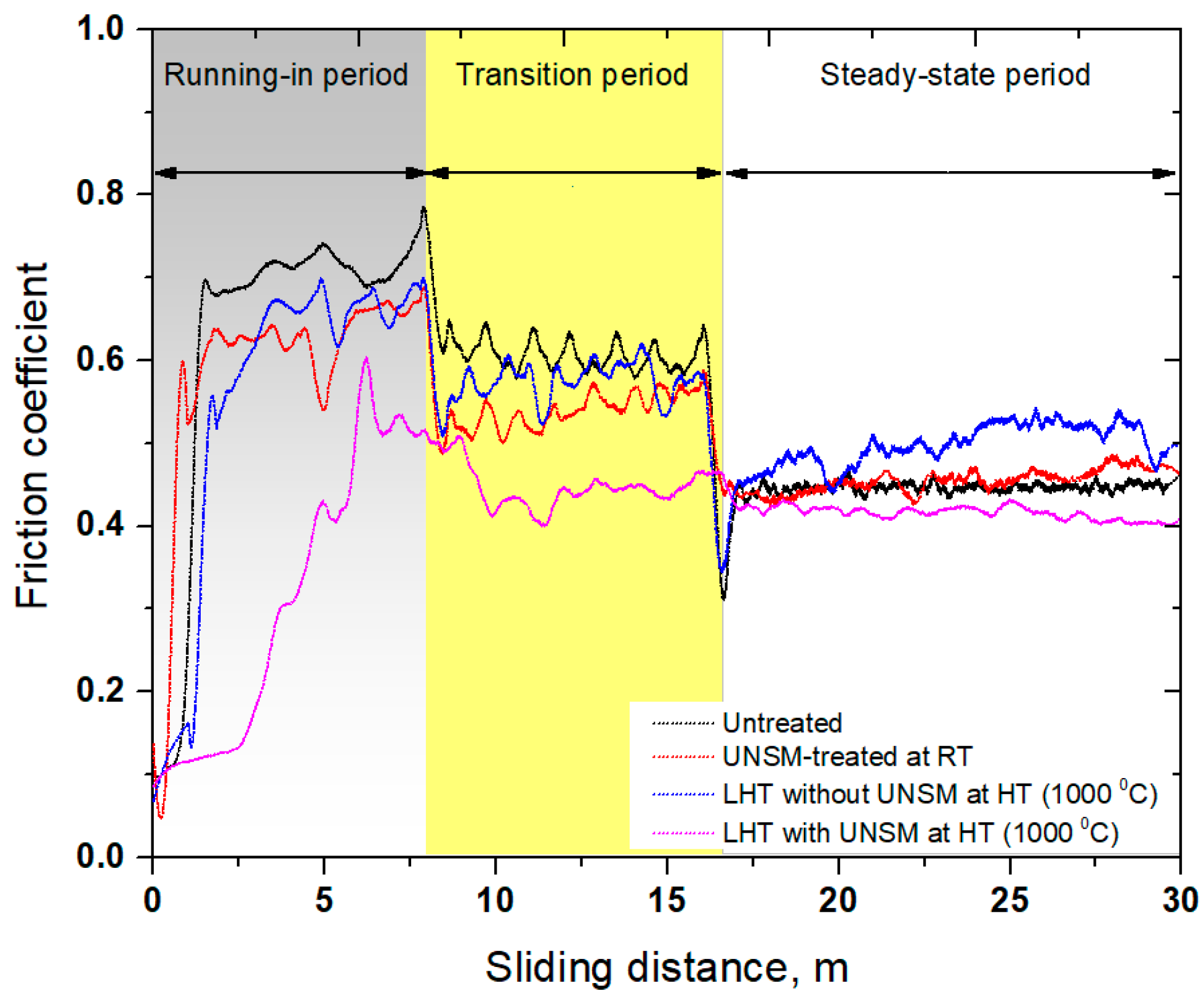

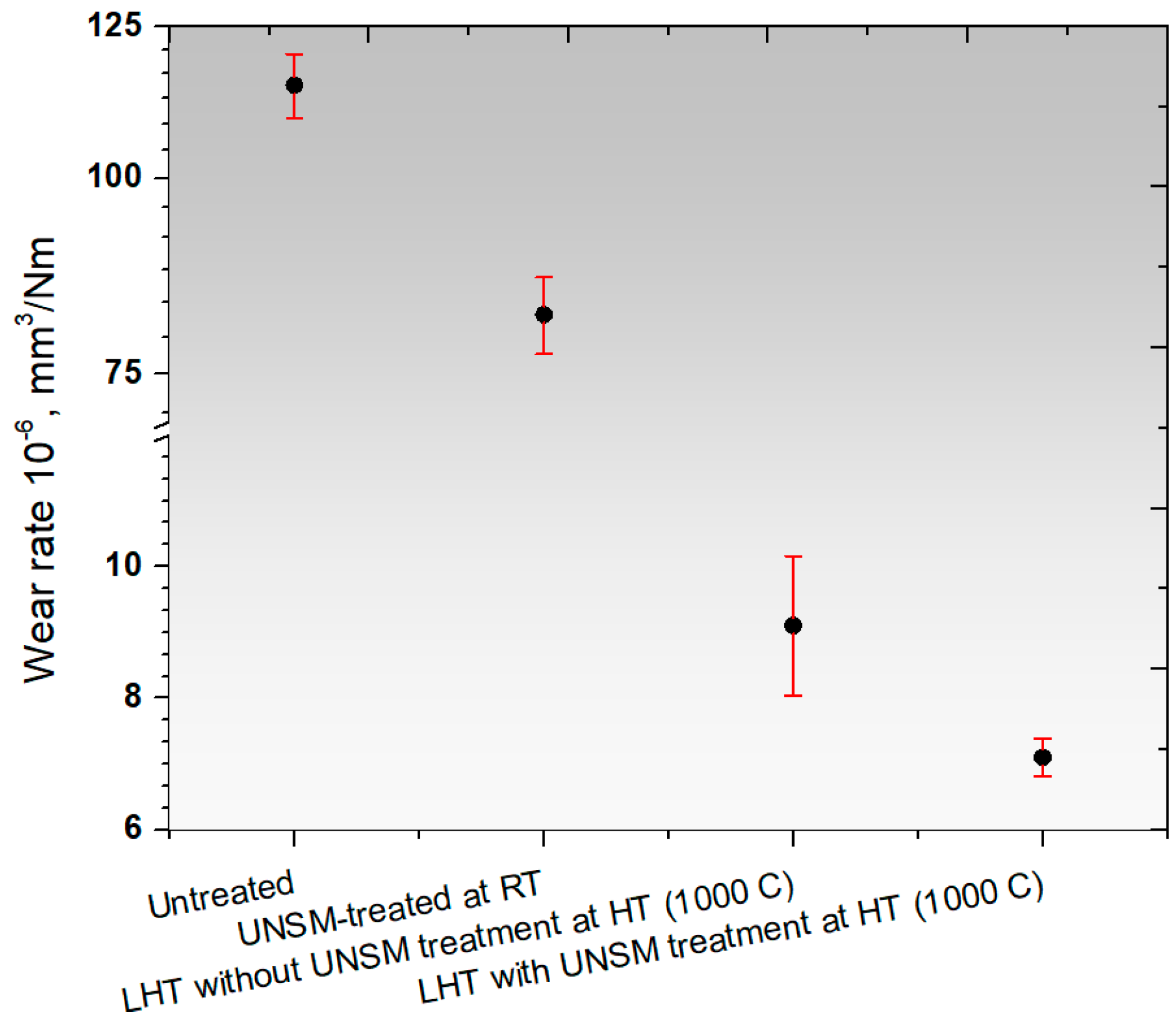

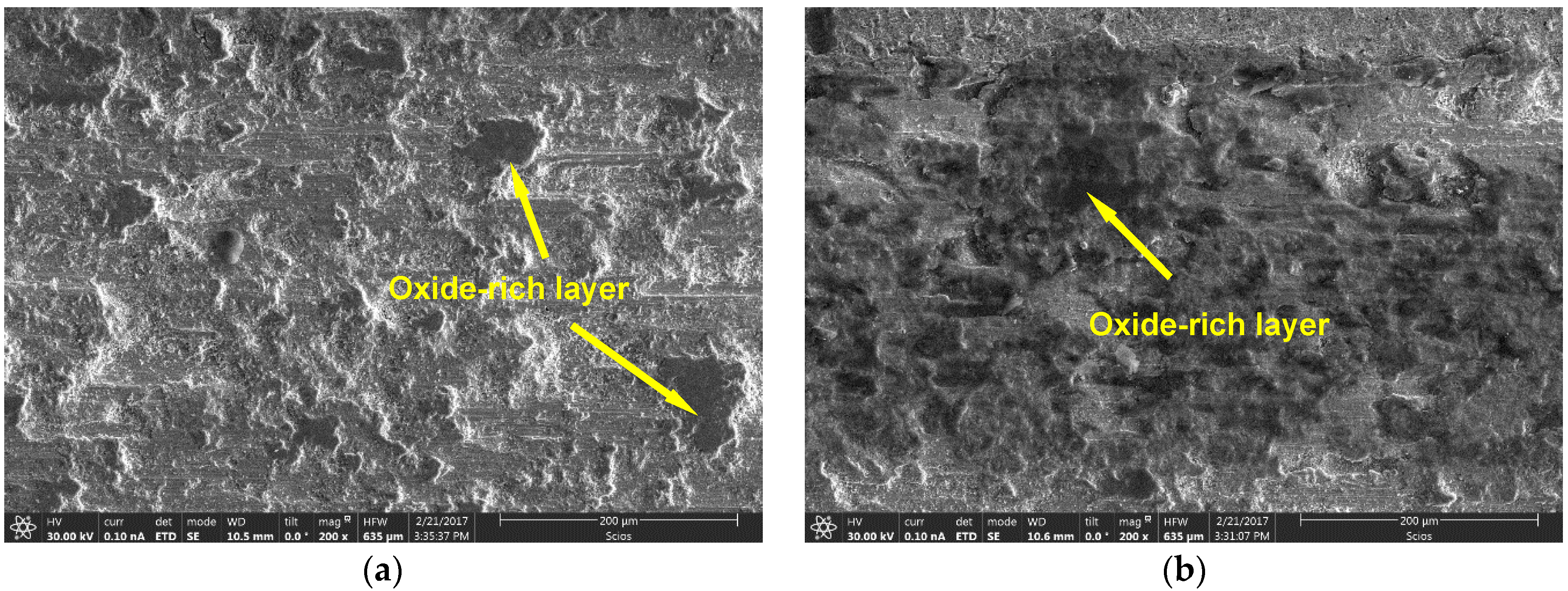

3.4. Friction and Wear Performance

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Navid, A.A.; Hodge, A.M. Nanostructured alpha and beta tantalum formation—Relationship between plasma parameters and microstructure. Mater. Sci. Eng. A 2012, 536, 49–56. [Google Scholar] [CrossRef]

- Robin, A.; Rosa, J.L. Corrosion behaviour of niobium, tantalum and their alloys in boiling sulfuric acid solutions. Int. J. Refract. Metals Hard Mater. 1997, 15, 317–323. [Google Scholar] [CrossRef]

- Chamelot, P.; Palau, P.; Massot, L.; Savall, A.; Taxil, P. Electrodeposition process of tantalum (V) species in molten fluorides containing oxide ions. Electrochim. Acta 2002, 47, 3423–3429. [Google Scholar] [CrossRef]

- Levine, B.R.; Sporer, S.; Poggie, R.A.; Della Valle, C.J.; Jacobs, J.J. Experimental and clinical performance of porous tantalum in orthopaedic surgery. Biomaterials 2006, 27, 4671–4681. [Google Scholar] [CrossRef] [PubMed]

- Sandim, H.R.Z.; Padiha, A.F.; Randle, V.; Blum, W. Grain subdivision and recrystallization in oligocrystalline tantalum during cold swaging and subsequent annealing. Int. J. Refract. Metals Hard Mater. 1999, 17, 431–435. [Google Scholar] [CrossRef]

- Abdulstaar, M.; Mhaede, M.; Wollmann, M.; Wagner, L. Investigating the effects of bulk and surface severe plastic deformation on the fatigue, corrosion behaviour and corrosion fatigue of AA5083. Surf. Coat. Technol. 2014, 254, 244–251. [Google Scholar] [CrossRef]

- Serra, G.; Moralis, L.; Elias, C.N.; Semenova, I.P.; Valiev, R.; Salimgareeva, G.; Pithon, M.; Lacerda, R. Nanostructured severe plastic deformation processed titanium for orthodontic mini-implants. Mater. Sci. Eng. C 2013, 33, 4197–4202. [Google Scholar] [CrossRef] [PubMed]

- Unal, O.; Varol, R. Surface severe plastic deformation of AISI 304 via conventional shot peening, severe shot peening and repeening. Appl. Surf. Sci. 2015, 351, 289–295. [Google Scholar] [CrossRef]

- Fu, T.; Zhan, Z.; Zhang, L.; Yang, Y.; Liu, Z.; Liu, J.; Li, L.; Yu, X. Effect of surface mechanical attrition treatment on corrosion resistance of commercial pure titanium. Surf. Coat. Technol. 2015, 280, 129–135. [Google Scholar] [CrossRef]

- Wang, Q.; Yin, Y.; Sun, Q.; Sun, L.; Sun, J. Gradient nano microstructure and its formation mechanism in pure titanium produced by surface rolling treatment. J. Mater. Res. 2014, 29, 569–577. [Google Scholar] [CrossRef]

- Chaise, T.; Li, J.; Nelias, D.; Kubler, R.; Taheri, S.; Douchet, G.; Robin, V.; Gilles, P. Modeling of multiple impacts for the prediction of distortions and residual stresses induced by ultrasonic shot peening. J. Mater. Process. Technol. 2012, 212, 2080–2090. [Google Scholar] [CrossRef] [Green Version]

- Park, J.W.; Kim, Y.J.; Park, C.H.; Lee, D.H.; Ko, Y.G.; Jang, J.H.; Lee, C.S. Enhanced osteoblast response to an equal channel angular pressing-processed pure titanium substrate with microrough surface topography. Acta Biomater. 2009, 5, 3272–3280. [Google Scholar] [CrossRef] [PubMed]

- Kang, J.K.; Kim, J.G.; Park, H.W.; Kim, H.S. Multiscale architectured materials with composition and grain size gradients manufactured using high-pressure torsion. Sci. Rep. 2016, 6, 26590. [Google Scholar] [CrossRef] [PubMed]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2017, 60, 130–207. [Google Scholar] [CrossRef]

- Valiev, R.Z. Strength and ductility of nanostructured SPD metals. Metall. Mater. High Struct. Effic. 2004, 146, 79–90. [Google Scholar] [CrossRef]

- Huang, Y.; Maury, N.; Zhang, N.X.; Langdon, T.G. Microstructure and mechanical properties of pure tantalum processed by high-pressure torsion. IOP Conf. Ser. Mater. Sci. Eng. 2014, 63, 012100. [Google Scholar] [CrossRef]

- Mathaudhu, S.N.; Hartwig, K.T.; Barber, R.E. Fine grained tantalum for composite Nb3Sn superconductor diffusion barrier sheet. IEEE Trans. Appl. Supercond. 2007, 17, 2660–2663. [Google Scholar] [CrossRef]

- Mathaudhu, S.N.; Hartwig, K.T. Grain refinement and recrystallization of heavily worked tantalum. Mater. Sci. Eng. A 2006, 426, 128–142. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Wei, Q.M.; Niu, H.Z.; Li, Y.S.; Chen, C.; Yu, Z.T.; Bai, X.F.; Zhang, P.X. Formation of nanocrystalline structure in tantalum by sliding friction treatment. Int. J. Refract. Metals Hard Mater. 2014, 45, 71–75. [Google Scholar] [CrossRef]

- Amanov, A.; Pyun, Y.S.; Vasudevan, V.K. High strength and wear resistance of tantalum by ultrasonic nanocrystalline surface modification technique at high temperatures. IOP Conf. Ser. Mater. Sci. Eng. 2017, 63, 012100. [Google Scholar] [CrossRef]

- Amanov, A.; Lee, S.W.; Pyun, Y.S. Low friction and high strength of 316L stainless steel tubing for biomedical applications. Mater. Sci. Eng. C 2017, 71, 176–185. [Google Scholar] [CrossRef] [PubMed]

- Amanov, A.; Penkov, O.V.; Pyun, Y.S.; Kim, D.E. Effects of ultrasonic nanocrystalline surface modification on the tribological propertied of AZ91D magnesium alloy. Tribol. Int. 2012, 54, 106–113. [Google Scholar] [CrossRef]

- Amanov, A.; Pyun, Y.S.; Kim, J.H.; Sasaki, S. The usability and preliminary effectiveness of ultrasonic nanocrystalline surface modification technique on surface properties of silicon carbide. Appl. Surf. Sci. 2014, 311, 448–460. [Google Scholar] [CrossRef]

- Amanov, A.; Kwon, H.G.; Pyun, Y.S. The possibility of reducing the reflectance and improving the tribological properties of Si wafer by UNSM technique. Tribol. Int. 2017, 105, 175–784. [Google Scholar] [CrossRef]

- Amanov, A. Wear resistance and adhesive failure of thermal spray coatings deposited onto graphite in response to ultrasonic nanocrystal surface modification technique. Appl. Surf. Sci. 2018, in press. [Google Scholar] [CrossRef]

- Amanov, A.; Pyun, Y.S. Local heat treatment with and without ultrasonic nanocrystal surface modification of Ti-6Al-4V alloy: Mechanical and tribological properties. Surf. Coat. Technol. 2017, 326, 343–354. [Google Scholar] [CrossRef]

- Amanov, A.; Umarov, R. The effects of ultrasonic nanocrystal surface modification temperature on the mechanical and fretting wear resistance of Inconel 690 alloy. Appl. Surf. Sci. 2018, 441, 515–529. [Google Scholar] [CrossRef]

- An, X.; Lin, Q.; Qu, S. Influence of stacking-fault energy on the accommodation of severe shear in Cu-Al alloys during equal-channel angular pressing. J. Mater. Res. 2009, 24, 3636–3646. [Google Scholar] [CrossRef]

- Lu, K. Making strong nanomaterials ductile with gradients. Science 2014, 345, 1455–1456. [Google Scholar] [CrossRef] [PubMed]

- Yin, Z.; Yang, X.; Ma, X.; Moering, J.; Yang, J.; Gong, Y.; Zhu, Y.; Zhu, X. Strength and ductility of gradient structured copper obtained by surface mechanical attrition treatment. Mater. Des. 2016, 105, 89–95. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.S.; Zhang, Q.; Zhao, Y.H.; Zhu, Y.T. Gradient structured copper by rotationally accelerated shot peening. J. Mater. Sci. Technol. 2017, 33, 758–761. [Google Scholar] [CrossRef]

- Yang, X.; Ma, X.; Moering, J.; Zhou, H.; Wang, W.; Gong, Y.; Tao, J.; Zhu, Y.; Zhu, X. Influence of gradient structure volume fraction on the mechanical properties of pure copper. Mater. Sci. Eng. A 2015, 645, 280–285. [Google Scholar]

- Wu, X.L.; Yang, M.X.; Yuan, F.P.; Chen, L.; Zhu, Y.T. Combining gradient structure and TRIP effect to produce austenite stainless steel with high strength and ductility. Acta Mater. 2016, 112, 337–346. [Google Scholar] [CrossRef]

- AlMangour, B.; Yang, J.M. Improving the surface quality and mechanical properties by shot-peening of 17-4 stainless steel fabricated by additive manufacturing. Mater. Des. 2016, 110, 914–924. [Google Scholar] [CrossRef]

- Amanov, A.; Pyun, Y.S.; Kim, J.H.; Suh, C.M.; Cho, I.S.; Kim, H.D.; Wang, Q.; Khan, M.K. Ultrasonic fatigue performance of high temperature structural material Inconel 718 alloys at high temperature after UNSM treatment. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 1266–1273. [Google Scholar] [CrossRef]

- Khan, M.K.; Fitzpatrick, M.E.; Wang, O.Y.; Pyun, Y.S.; Amanov, A. Effect of ultrasonic nanocrystal surface modification on residual stress and fatigue cracking in engineering alloys. Fatigue Fract. Eng. Mater. Struct. 2017, 39, 1–12. [Google Scholar] [CrossRef]

- Lee, Y.J.; Lee, T.H.; Kim, D.Y.; Nersisyan, H.H.; Han, M.H.; Kang, K.S.; Bae, K.K.; Shin, Y.J.; Lee, J.H. Microstructural and corrosion characteristics of tantalum coatings prepared by molten salt electrodeposition. Surf. Coat. Technol. 2013, 235, 819–826. [Google Scholar] [CrossRef]

- Ortiz, A.L.; Shaw, L. X-ray diffraction analysis of a severely plastically deformed aluminium alloy. Acta Mater. 2004, 52, 2185–2197. [Google Scholar] [CrossRef]

- Amanov, A.; Urmanov, B.; Amanov, T.; Pyun, Y.S. Strengthening of Ti-6Al-4V alloy by high temperature ultrasonic nanocrystal surface modification technique. Mater. Lett. 2017, 196, 198–201. [Google Scholar] [CrossRef]

- Islamgaliev, R.K.; Kuzel, R.; Mikov, S.N.; Igo, A.V.; Burianek, J.; Chmelik, F.; Valiev, R.Z. Structure of silicon processed by severe plastic deformation. Mater. Sci. Eng. A 1999, 266, 205–210. [Google Scholar] [CrossRef]

- Wang, M.; Vo, N.Q.; Campion, M.; Nguyen, T.D.; Setman, D.; Dillon, S.; Bellon, P.; Averback, R.S. Forced atomic mixing during severe plastic deformation: Chemical interactions and kinetically driven segregation. Acta Mater. 2014, 66, 1–11. [Google Scholar] [CrossRef]

- Tian, J.W.; Dai, K.; Villegas, J.C.; Shaw, L.; Liaw, P.K.; Klastrom, D.L.; Ortiz, A.L. Tensile properties of a nickel-base alloy subjected to surface severe plastic deformation. Mater. Sci. Eng. A 2008, 493, 176–183. [Google Scholar] [CrossRef]

- Satheesh Kumar, S.S.; Raghu, T. Mechanical behaviour and microstructural evolution of constrained groove pressed nickel sheets. J. Mater. Process. Technol. 2013, 213, 214–220. [Google Scholar] [CrossRef]

- Ungar, T. Microstructural parameters from X-ray diffraction peak broadening. Scr. Mater. 2004, 21, 777–781. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Rajan, T.V.; Sharma, C.P.; Sharma, A. Heat Treatment: Principles and Techniques, 2nd ed.; PHI: New Delhi, India, 2011. [Google Scholar]

- Chokshi, A.H.; Rosen, A.; Karch, J.; Gleiter, H. On the validity of the Hall-Petch relationship in nanocrystalline materials. Scr. Metall. 1989, 23, 1679–1683. [Google Scholar] [CrossRef]

- Wang, S.; Feng, S.K.; Chen, C.; Jia, Y.L.; Wang, M.P.; Li, Z.; Zhong, Z.H.; Lu, P.; Li, P.; Cao, S.F.; et al. A twin orientation relationship between {001} <210> and {111} <110> obtained in Ta-2.5W alloy during heavily cold rolling. Mater. Character. 2017, 125, 108–113. [Google Scholar] [CrossRef]

- Suresh, S.; Giannakopoulos, A.E. A new method for estimating residual stress by instrumented sharp indentation. Acta Mater. 1998, 46, 5755–5767. [Google Scholar] [CrossRef]

- Zhu, L.N.; Xu, B.S.; Wang, H.D.; Wang, C.B. Measurement of residual stress in quenched 1045 steel by nanoindentation method. Mater. Character. 2010, 61, 1359–1362. [Google Scholar] [CrossRef]

- Amanov, A.; Cho, I.S.; Pyoun, Y.S.; Lee, C.S.; Park, I.G. Micro-dimpled surface by ultrasonic nanocrystal surface modification and its tribological effects. Wear 2012, 286–287, 136–144. [Google Scholar] [CrossRef]

- Chen, X.; Han, Z.; Li, X.Y.; Lu, K. Lowering friction coefficients in Cu alloys with stable gradient nanostructures. Sci. Adv. 2016, 2, e1601942. [Google Scholar] [CrossRef] [PubMed]

- Ghidelli, M.; Sebastiani, M.; Collet, C.; Guillemet, R. Determination of the elastic moduli and residual stresses of freestanding Au-TiW bilayer thin films by nanoindentation. Mater. Des. 2016, 106, 436–445. [Google Scholar] [CrossRef]

- Amanov, A.; Pyun, Y.S.; Zhang, B.; Nohava, J. Preliminary study on the effect of micro-scale dimple size on friction and wear under oil-lubricated sliding contact. Tribol. Online 2011, 6, 284–290. [Google Scholar] [CrossRef]

| UTS, MPa | Yield Strength, MPa | Elastic Modulus, GPa | Poisson’s Ratio | Density, g/cm3 | Elongation, % |

|---|---|---|---|---|---|

| 900 | 170 | 186 | 0.35 | 16.6 | 5 |

| Frequency, kHz | Amplitude, µm | Static Load, N | Speed, mm ε | Tip Material | Tip Diameter, mm | Interval, µm |

|---|---|---|---|---|---|---|

| 20 | 40 | 30 | 2000 | WC | 2.38 | 70 |

| Applied Normal Load, N | Reciprocating Speed, cm/s | Sliding Distance, m | Temperature, °C | Contact Stress, GPa |

|---|---|---|---|---|

| 10 | 2.51 | 30 | 25 | 0.82 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chae, J.-M.; Lee, K.-O.; Amanov, A. Gradient Nanostructured Tantalum by Thermal-Mechanical Ultrasonic Impact Energy. Materials 2018, 11, 452. https://doi.org/10.3390/ma11030452

Chae J-M, Lee K-O, Amanov A. Gradient Nanostructured Tantalum by Thermal-Mechanical Ultrasonic Impact Energy. Materials. 2018; 11(3):452. https://doi.org/10.3390/ma11030452

Chicago/Turabian StyleChae, Jong-Min, Keun-Oh Lee, and Auezhan Amanov. 2018. "Gradient Nanostructured Tantalum by Thermal-Mechanical Ultrasonic Impact Energy" Materials 11, no. 3: 452. https://doi.org/10.3390/ma11030452