Impact of Electrode Surface Morphology in ZnO-Based Resistive Random Access Memory Fabricated Using the Cu Chemical Displacement Technique

Abstract

:1. Introduction

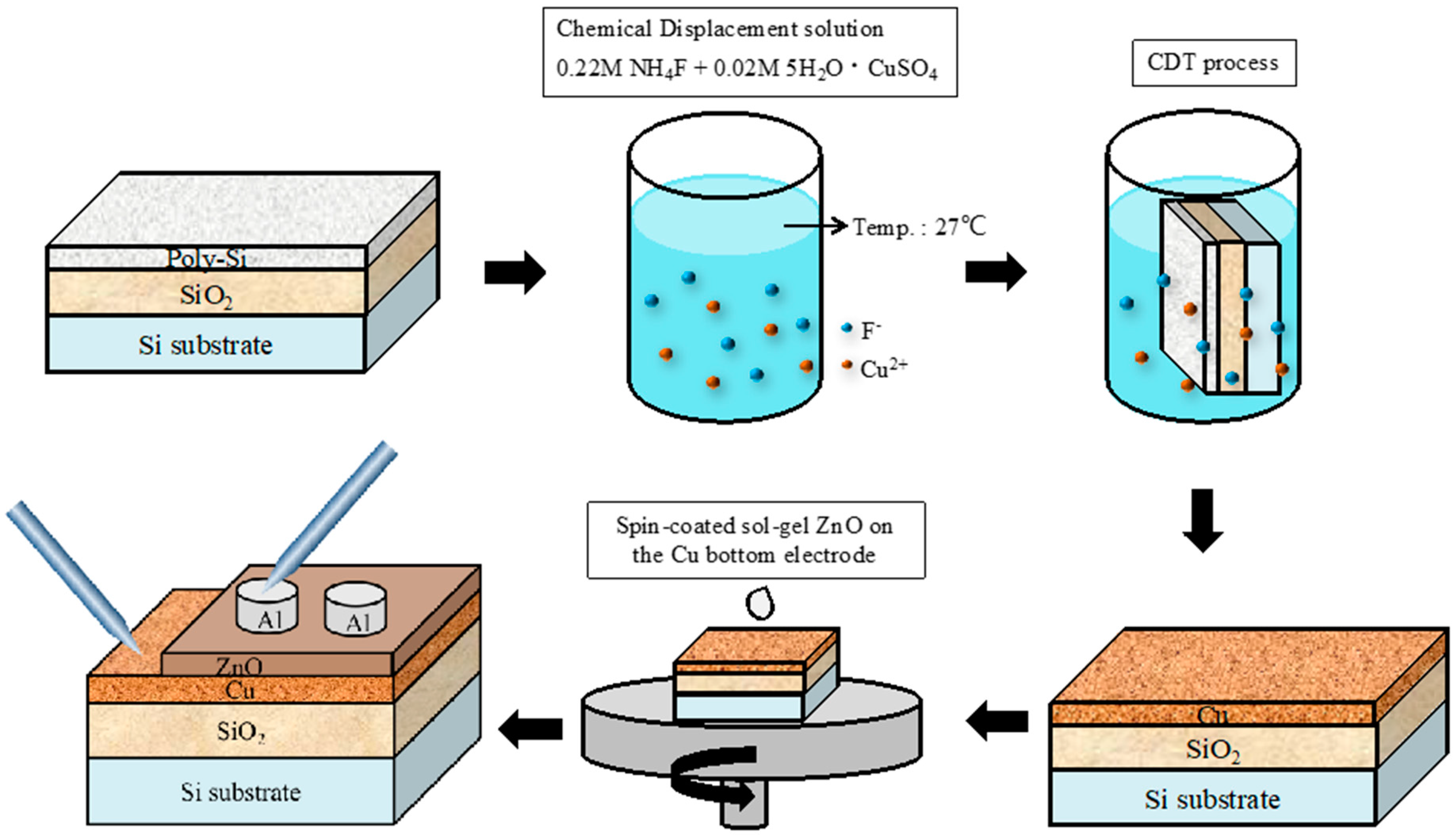

2. Materials and Methods

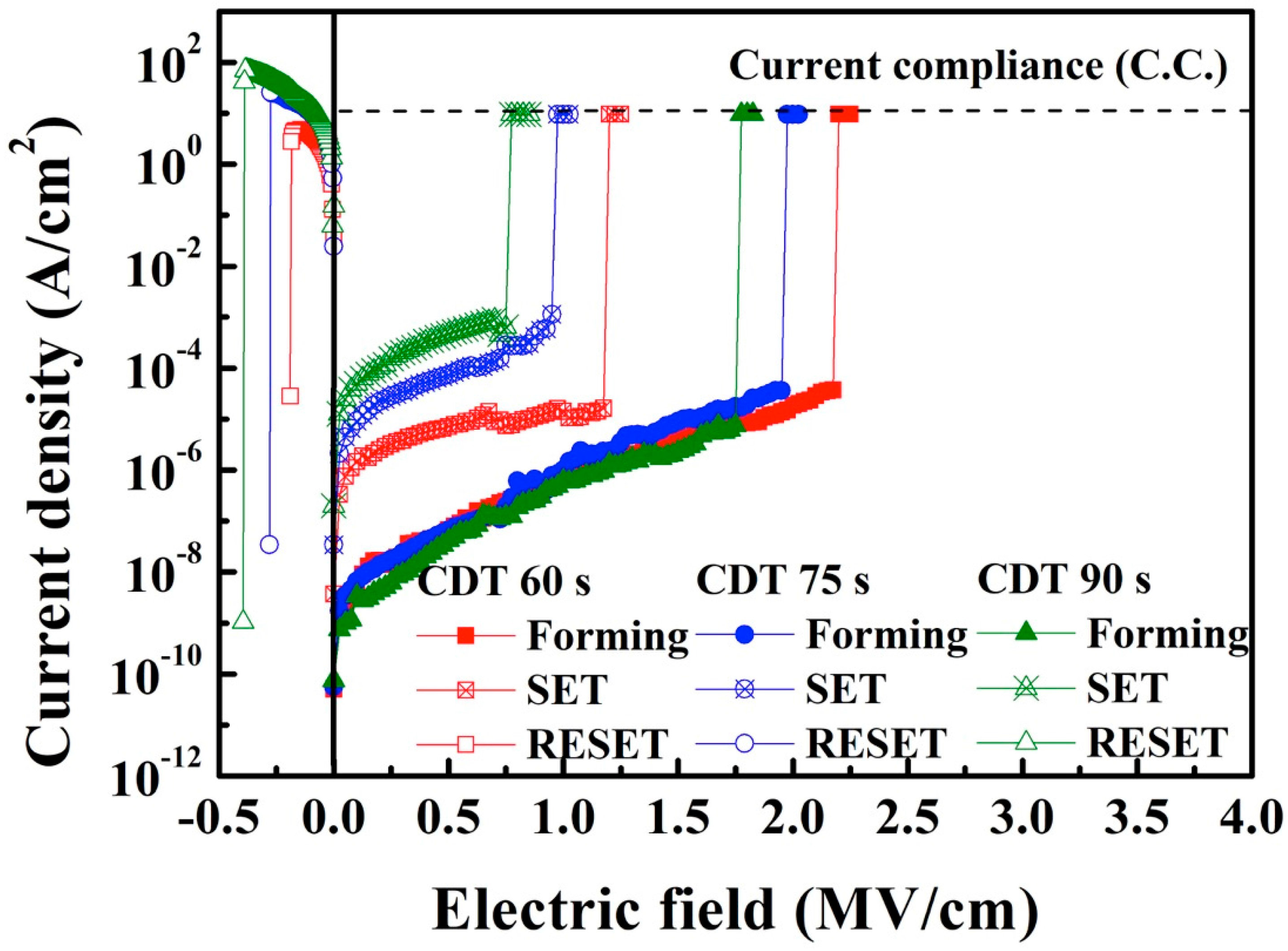

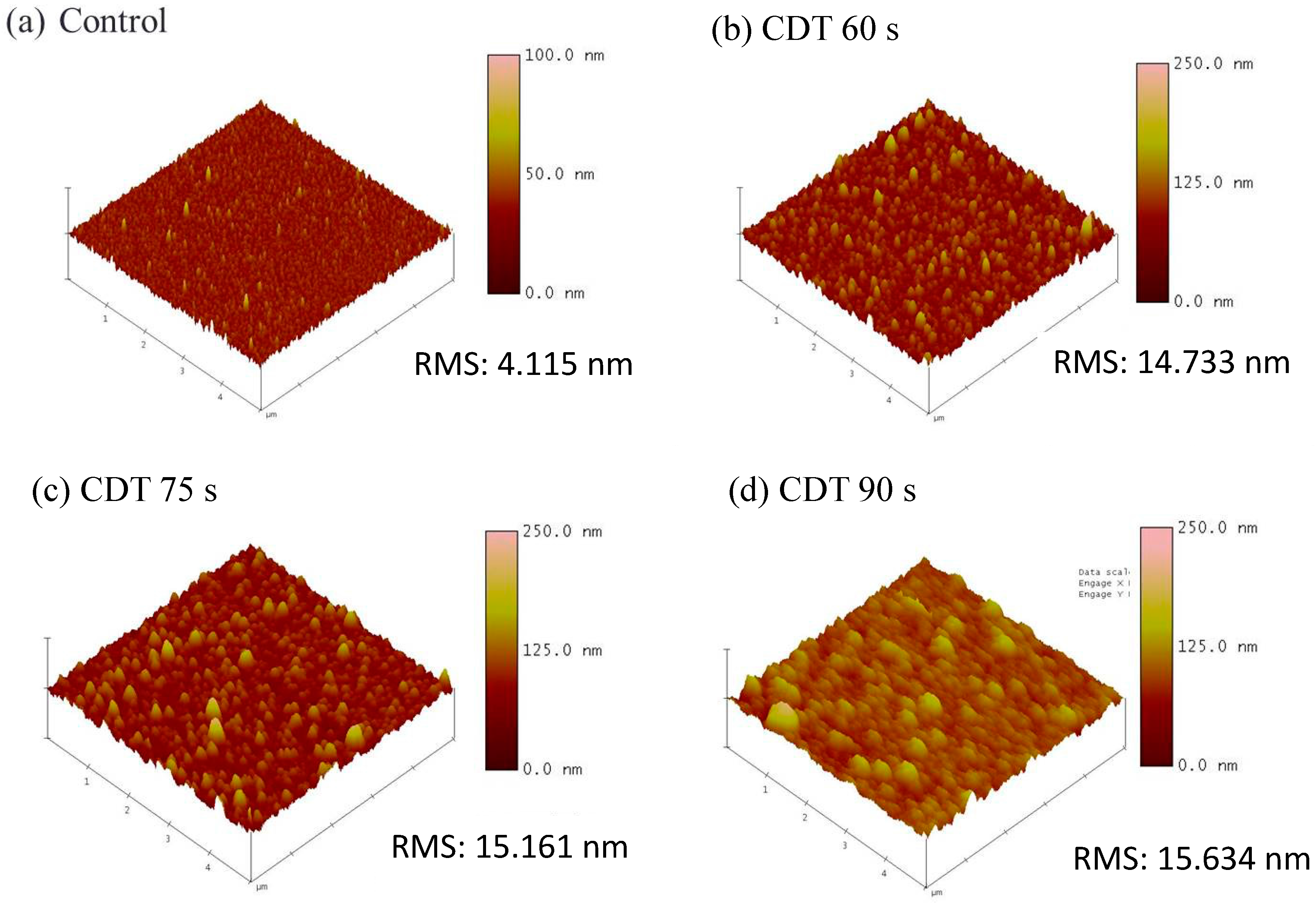

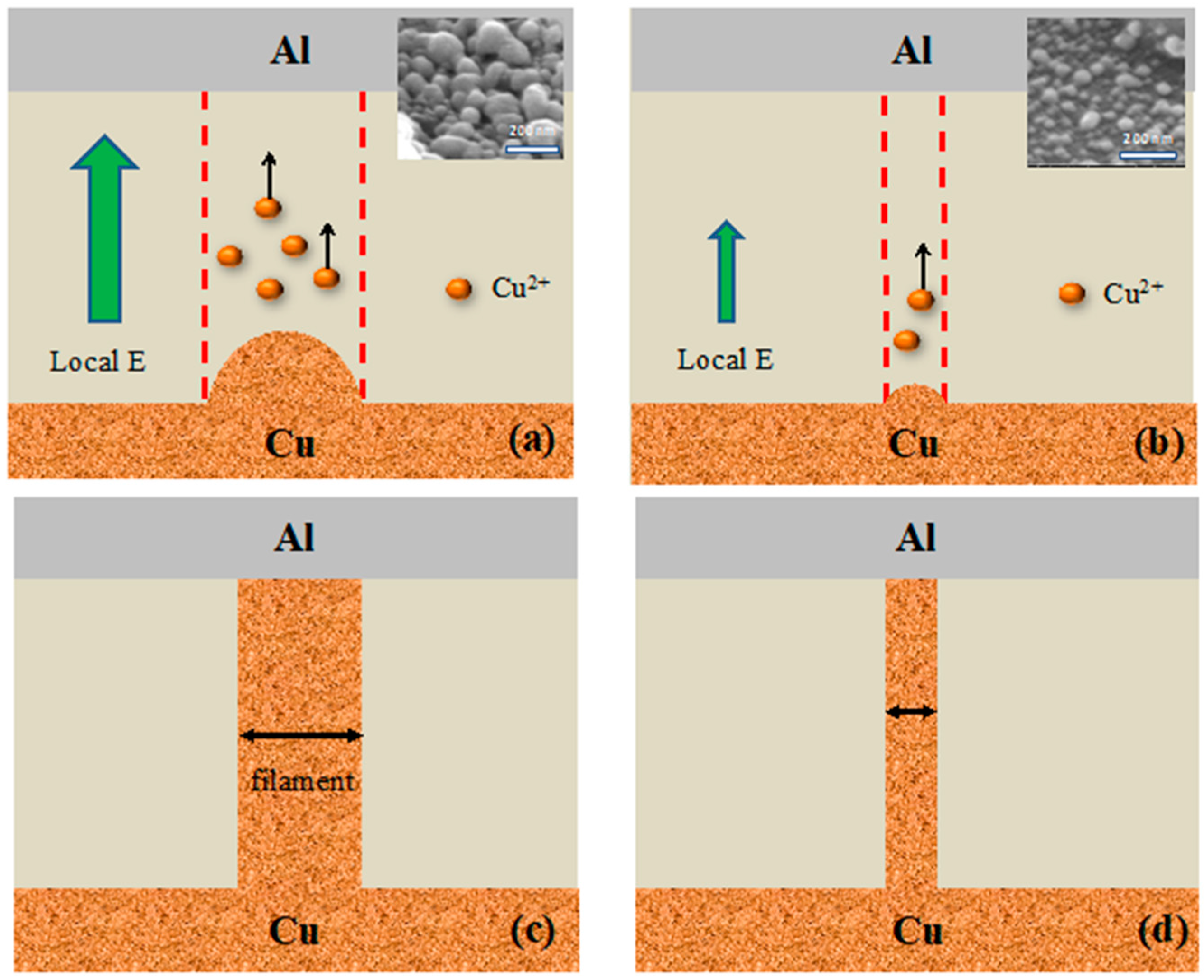

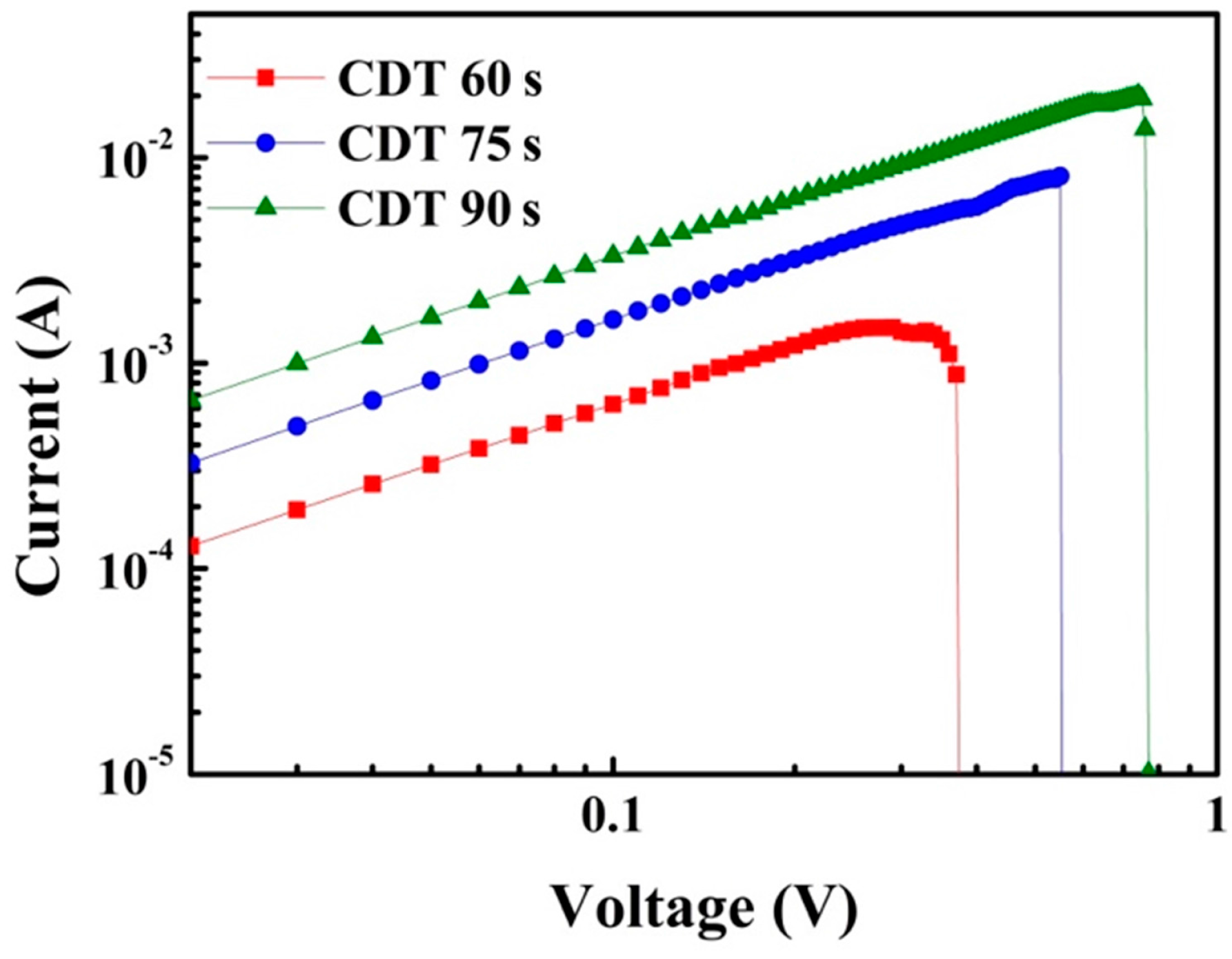

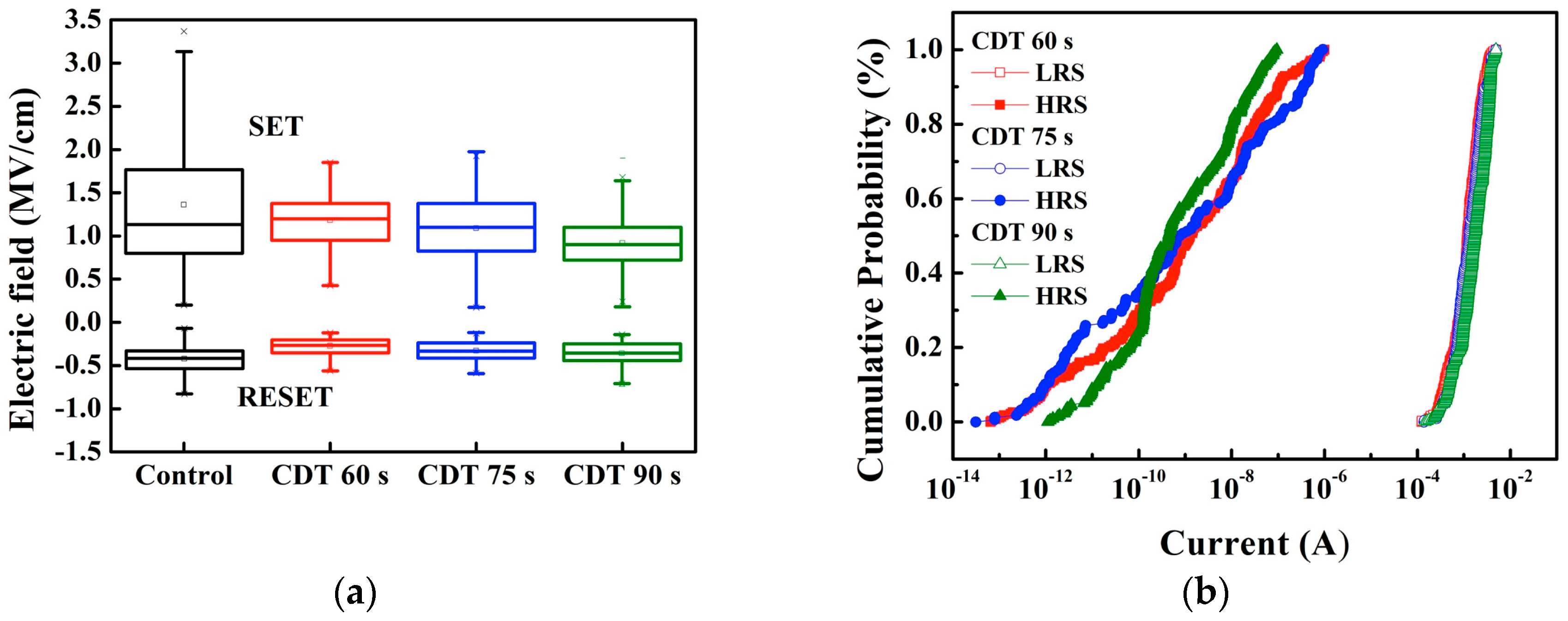

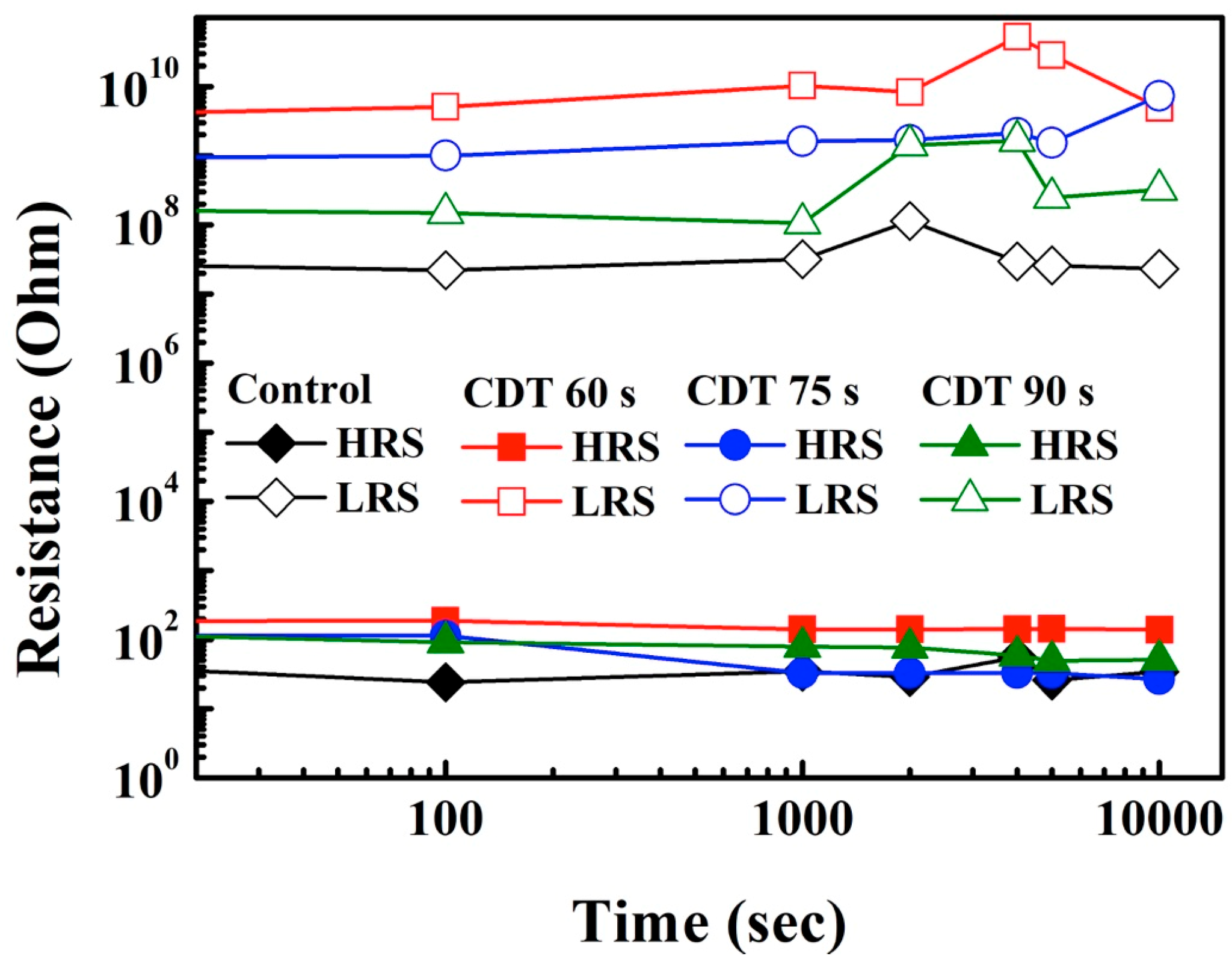

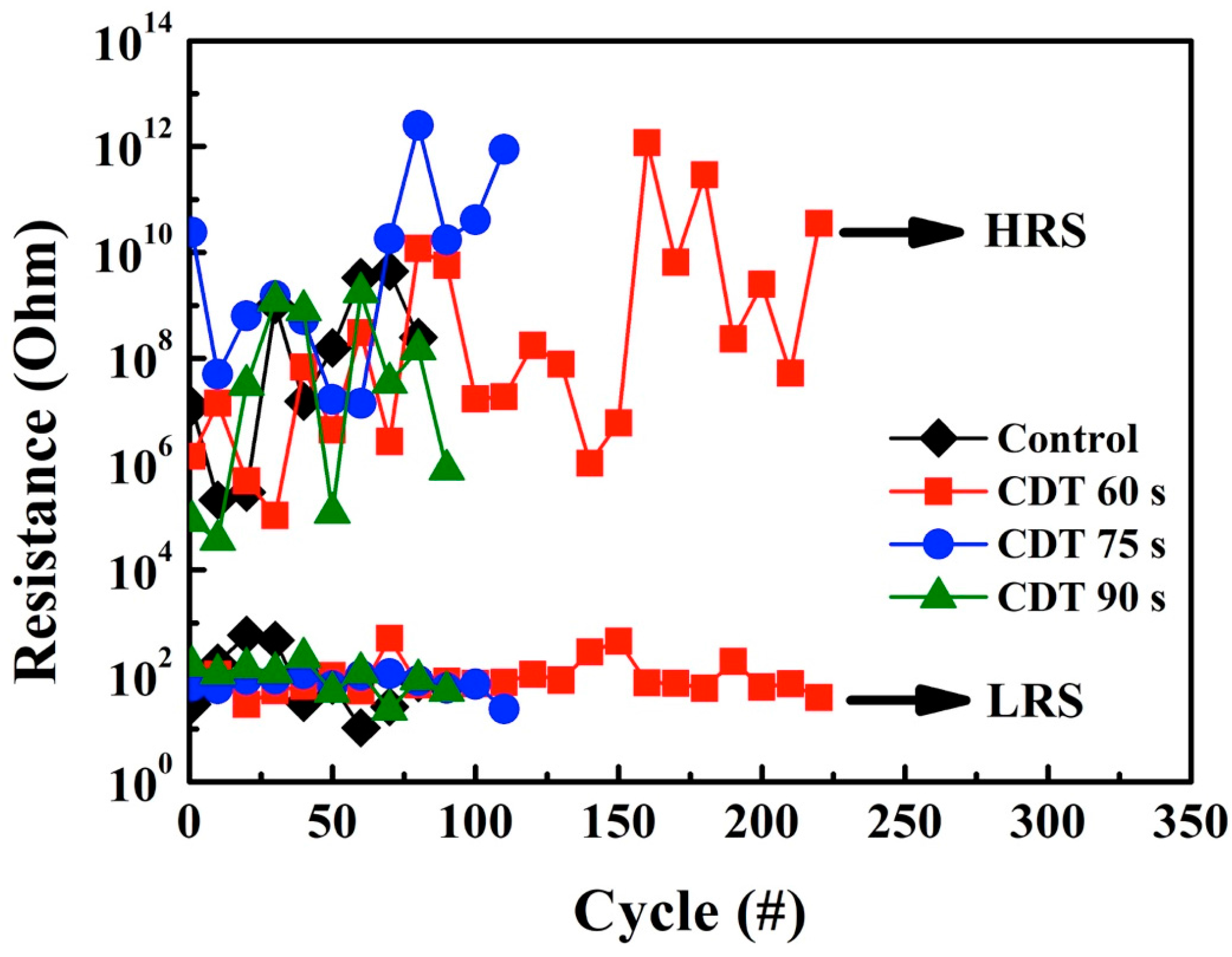

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ahn, J.; Kim, T.W. Threshold Voltage Shift Variation of Vertical NAND Flash Memory Devices Dependent on Polysilicon Channel Layer Thickness. J. Nanosci. Nanotechnol. 2017, 17, 7331–7334. [Google Scholar] [CrossRef]

- Wu, C.-Y.; Huang, H.Y.; Wu, C.-C. Low-Temperature Formed Quaternary NiZrSiGe Nanocrystal Memory. Int. J. Electrochem. Sic. 2015, 10, 6500–6508. [Google Scholar]

- Wu, C.-C.; Yang, W.-L.; Chang, Y.-M.; Liu, S.-H.; Hsiao, Y.-P. Plasma-Enhanced Storage Capability of SONOS Flash Memory. Int. J. Electrochem. Sci. 2013, 8, 6678–6685. [Google Scholar]

- Kan, J.J.; Park, C.; Ching, C.; Ahn, J.; Xie, Y.; Pakala, M.; Kang, S.H. A Study on Practically Unlimited Endurance of STT-MRAM. IEEE Trans. Electron Devices 2017, 64, 3639–3646. [Google Scholar] [CrossRef]

- Huang, F.; Wang, Y.; Liang, X.; Qin, J.; Zhang, Y.; Yuan, X.F.; Wang, Z.; Peng, B.; Deng, L.J.; Liu, Q.; et al. HfO2-Based Highly Stable Radiation-Immune Ferroelectric Memory. IEEE Electron Device Lett. 2017, 38, 330–333. [Google Scholar] [CrossRef]

- Kim, E.; Kang, N.S.; Yang, H.J.; Sutou, Y.; Song, Y.H. Novel device structure for phase change memory toward low-current operation. Jpn. J. Appl. Phys. 2015, 54, 094302. [Google Scholar] [CrossRef]

- Liu, S.H.; Yang, W.L.; Wu, C.C.; Chao, T.S.; Ye, M.R.; Su, Y.Y.; Wang, P.Y.; Tsai, M.J. High-Performance Polyimide-Based ReRAM for Nonvolatile Memory Application. IEEE Electron Device Lett. 2013, 34, 123–125. [Google Scholar] [CrossRef]

- Gong, T.C.; Luo, Q.; Xu, X.X.; Yuan, P.; Ma, H.L.; Chen, C.B.; Liu, Q.; Long, S.B.; Lv, H.B.; Liu, M. Uniformity and Retention Improvement of TaOx-Based Conductive Bridge Random Access Memory by CuSiN Interfacial Layer Engineering. IEEE Electron Device Lett. 2017, 38, 1232–1235. [Google Scholar] [CrossRef]

- Portal, J.M.; Bocquet, M.; Onkaraiah, S.; Moreau, M.; Aziza, H.; Deleruyelle, D.; Torki, K.; Vianello, E.; Levisse, A.; Giraud, B.; et al. Design and Simulation of a 128 kb Embedded Nonvolatile Memory Based on a Hybrid RRAM (HfO2)/28 nm FDSOI CMOS Technology. IEEE Trans. Nanotechnol. 2017, 16, 677–686. [Google Scholar] [CrossRef]

- Hsiao, Y.-P.; Yang, W.-L.; Wu, C.-C.; Lin, L.-M.; Chin, F.-T.; Lin, Y.-H.; Yang, K.-L. Improving high-resistance state uniformity and leakage current for polyimide-based resistive switching memory by rubbing post-treatment. Jpn. J. Appl. Phys. 2016, 55, 01AA09. [Google Scholar] [CrossRef]

- Hsiao, Y.-P.; Yang, W.-L.; Lin, L.-M.; Chin, F.-T.; Lin, Y.-H.; Yang, K.-L.; Wu, C.-C. Improving retention properties by thermal imidization for polyimide-based nonvolatile resistive random access memories. Microelectron. Reliab. 2015, 55, 2188–2197. [Google Scholar] [CrossRef]

- Banerjee, W.; Liu, Q.; Long, S.B.; Lv, H.B.; Liu, M. Crystal that remembers: Several ways to utilize nanocrystals in resistive switching memory. J. Phys. D Appl. Phys. 2017, 50, 303002. [Google Scholar] [CrossRef]

- Chen, J.Y.; Huang, C.W.; Chiu, C.H.; Huang, Y.T.; Wu, W.W. Switching Kinetic of VCM-Based Memristor: Evolution and Positioning of Nanofilament. Adv. Mater. 2015, 27, 5028–5033. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Wang, W.; Li, Q.J.; Zhao, X.L.; Li, N.; Xu, H.; Liu, Q.; Liu, M. Highly improved resistive switching performances of the self-doped Pt/HfO2:Cu/Cu devices by atomic layer deposition. Sci. China Phys. Mech. Astron. 2016, 59, 127311. [Google Scholar] [CrossRef]

- Kim, H.J.; Yoon, K.J.; Park, T.H.; Kim, H.J.; Kwon, Y.J.; Shao, X.L.; Kwon, D.E.; Kim, Y.M.; Hwang, C.S. Filament Shape Dependent Reset Behavior Governed by the Interplay between the Electric Field and Thermal Effects in the Pt/TiO2/Cu Electrochemical Metallization Device. Adv. Electron. Mater. 2017, 3, 1600404. [Google Scholar] [CrossRef]

- Chin, F.T.; Lin, Y.H.; You, H.C.; Yang, W.L.; Lin, L.M.; Hsiao, Y.P.; Ko, C.M.; Chao, T.S. Advanced Cu chemical displacement technique for SiO2-based electrochemical metallization ReRAM application. Nanoscale Res. Lett. 2014, 9, 592. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.M.; Yang, W.L.; Lin, Y.H.; Hsiao, Y.P.; Chin, F.T.; Kao, M.F. A novel nanoscale-crossbar resistive switching memory using a copper chemical displacement technique. Phys. Status Solidi A 2017, 214, 1600595. [Google Scholar] [CrossRef]

- Sharma, Y.; Pavunny, S.P.; Fachini, E.; Scott, J.F.; Katiyar, R.S. Nonpolar resistive memory switching with all four possible resistive switching modes in amorphous LaHoO3 thin films. J. Appl. Phys. 2015, 118, 094506. [Google Scholar] [CrossRef]

- Sharma, Y.; Misra, P.; Pavunny, S.P.; Katiyar, R.S. Multilevel unipolar resistive memory switching in amorphous SmGdO3 thin film. Appl. Phys. Lett. 2014, 104, 073501. [Google Scholar] [CrossRef]

- Katiyar, R.K.; Sharma, Y.; Diestra, D.G.B.; Misra, P.; Kooriyattil, S.; Pavunny, S.P.; Morell, G.; Weiner, B.R.; Scott, J.F.; Katiyar, R.S. Unipolar resistive switching in planar Pt/BiFeO3/Pt structure. AIP Adv. 2015, 5, 037109. [Google Scholar] [CrossRef] [Green Version]

- Zhai1, H.; Kong, J.; Yang, J.; Xu, J.; Xu, Q.; Sun, H.; Li, A.; Wu, D. Resistive Switching Properties and Failure Behaviors of (Pt, Cu)/Amorphous ZrO2/Pt Sandwich Structures. J. Mater. Sci. Technol. 2016, 32, 676–680. [Google Scholar] [CrossRef]

- Jeon, H.; Park, J.; Jang, W.; Kim, H.; Song, H.; Kim, H.; Seo, H.; Jeon, H. Resistive switching behaviors of Cu/TaOx/TiN device with combined oxygen vacancy/copper conductive filaments. Curr. Appl. Phys. 2015, 15, 1005–1009. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, C.-C.; You, H.-C.; Lin, Y.-H.; Yang, C.-J.; Hsiao, Y.-P.; Liao, T.-P.; Yang, W.-L. Impact of Electrode Surface Morphology in ZnO-Based Resistive Random Access Memory Fabricated Using the Cu Chemical Displacement Technique. Materials 2018, 11, 265. https://doi.org/10.3390/ma11020265

Wu C-C, You H-C, Lin Y-H, Yang C-J, Hsiao Y-P, Liao T-P, Yang W-L. Impact of Electrode Surface Morphology in ZnO-Based Resistive Random Access Memory Fabricated Using the Cu Chemical Displacement Technique. Materials. 2018; 11(2):265. https://doi.org/10.3390/ma11020265

Chicago/Turabian StyleWu, Chi-Chang, Hsin-Chiang You, Yu-Hsien Lin, Chia-Jung Yang, Yu-Ping Hsiao, Tun-Po Liao, and Wen-Luh Yang. 2018. "Impact of Electrode Surface Morphology in ZnO-Based Resistive Random Access Memory Fabricated Using the Cu Chemical Displacement Technique" Materials 11, no. 2: 265. https://doi.org/10.3390/ma11020265