Microstructure and Sliding Wear Behaviour of In-Situ TiC-Reinforced Composite Surface Layers Fabricated on Ductile Cast Iron by Laser Alloying

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

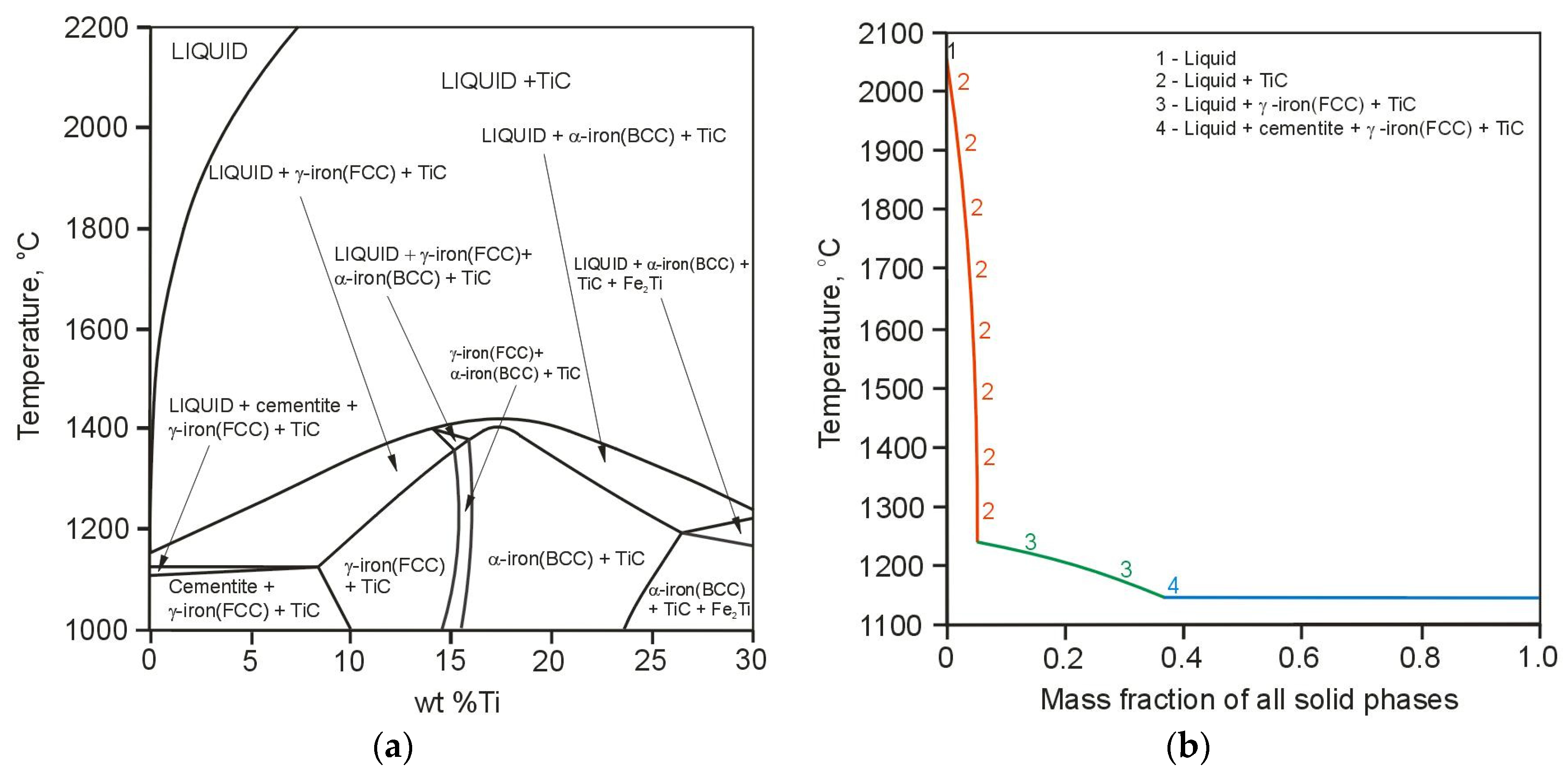

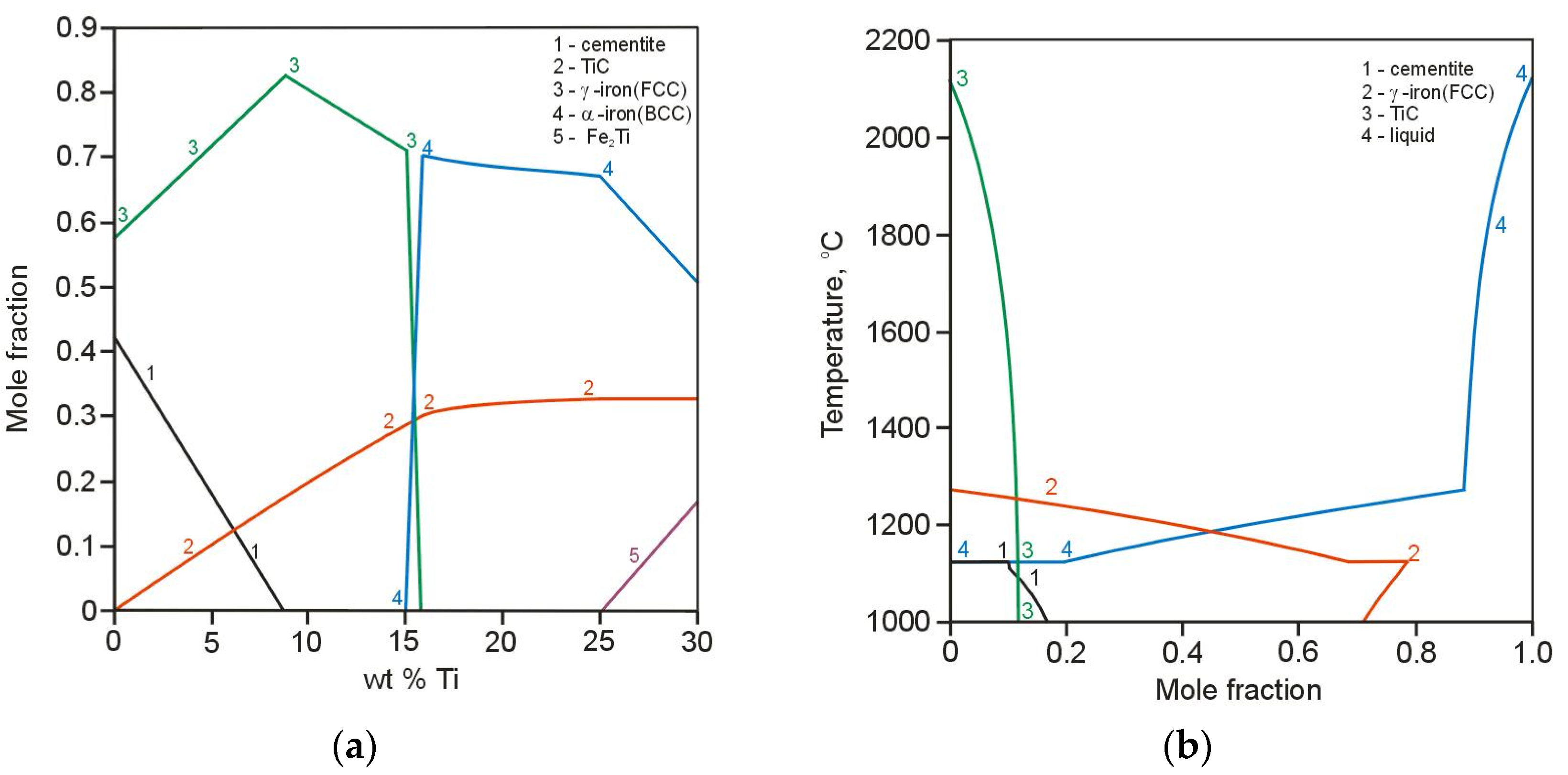

3.1. Thermodynamic Calculations

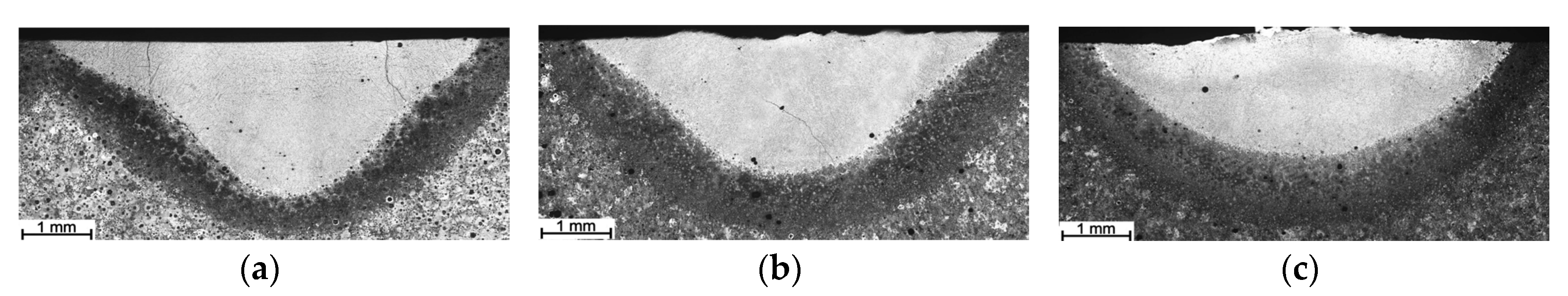

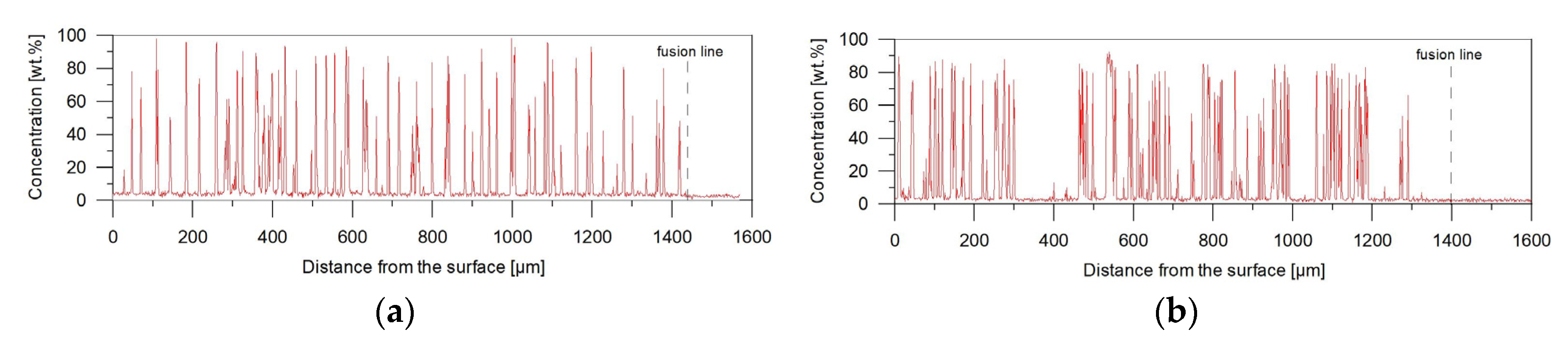

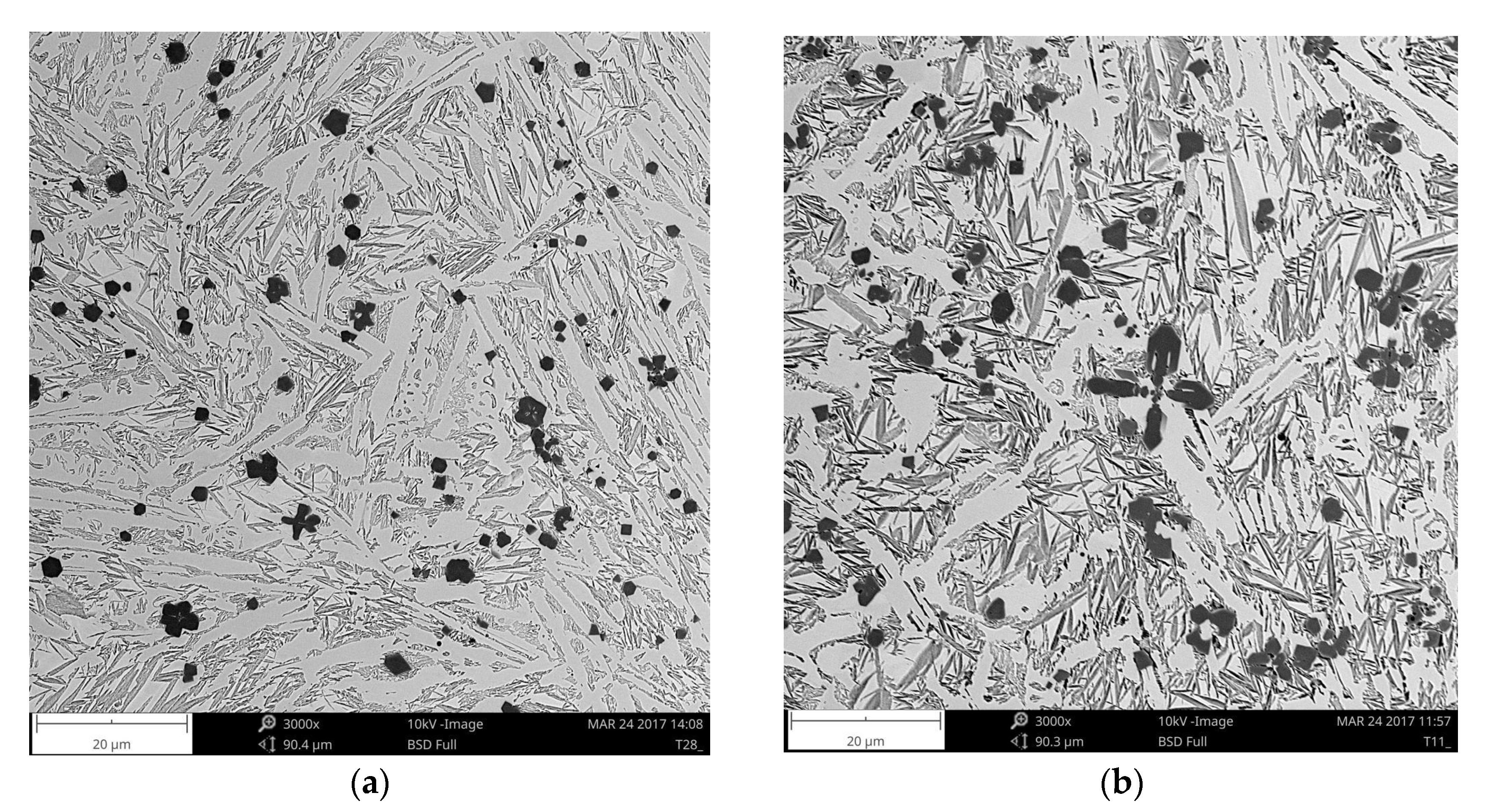

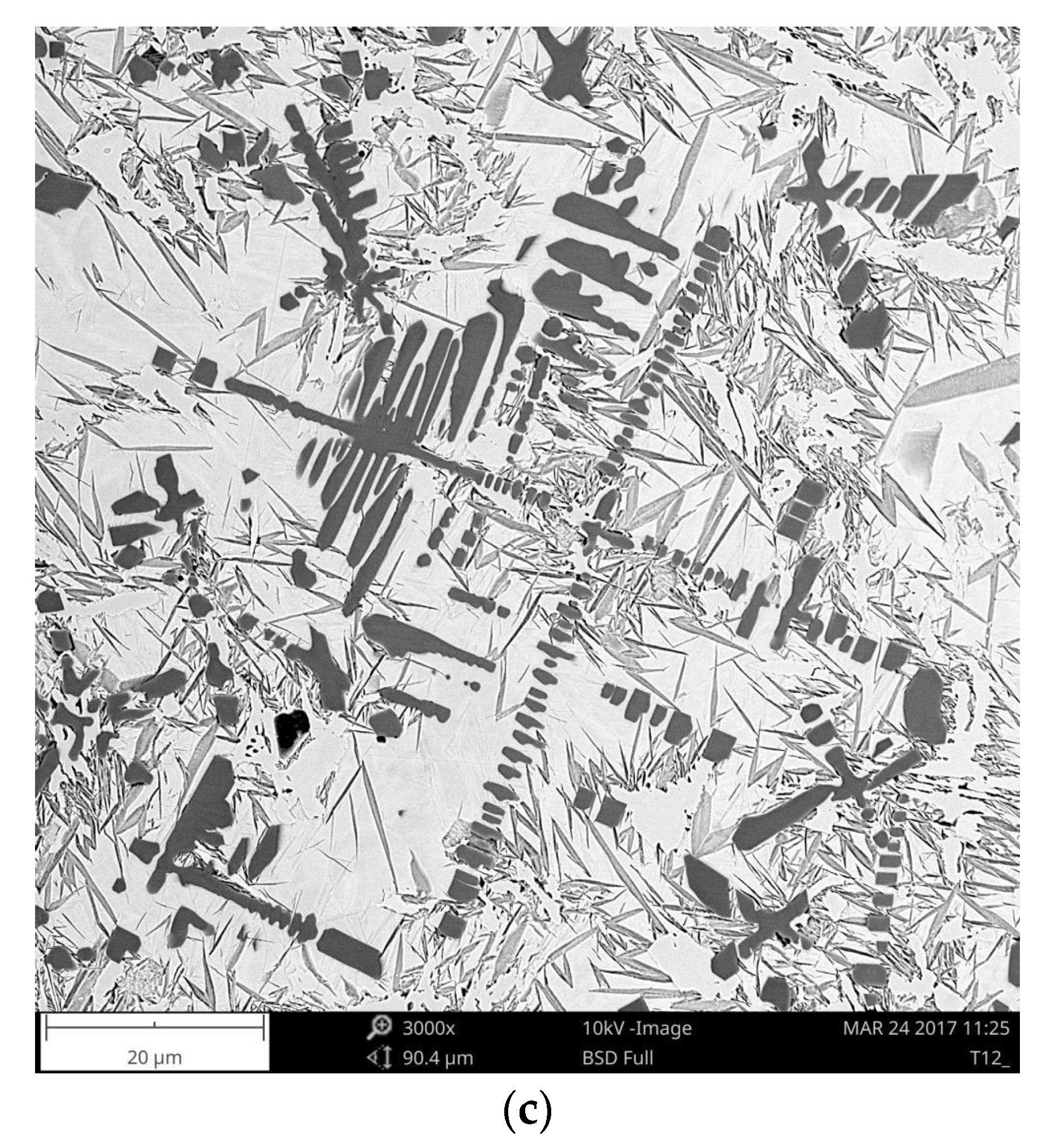

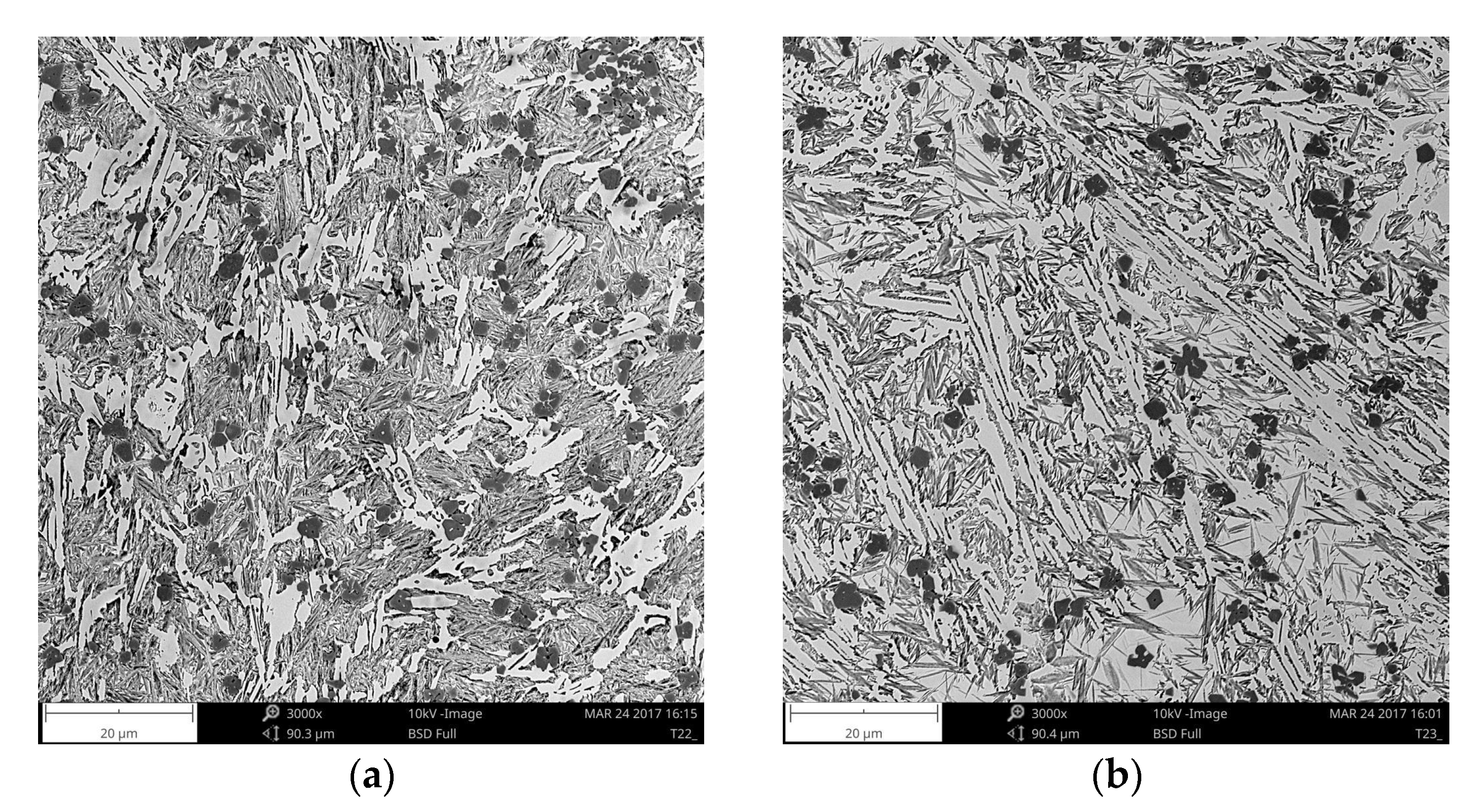

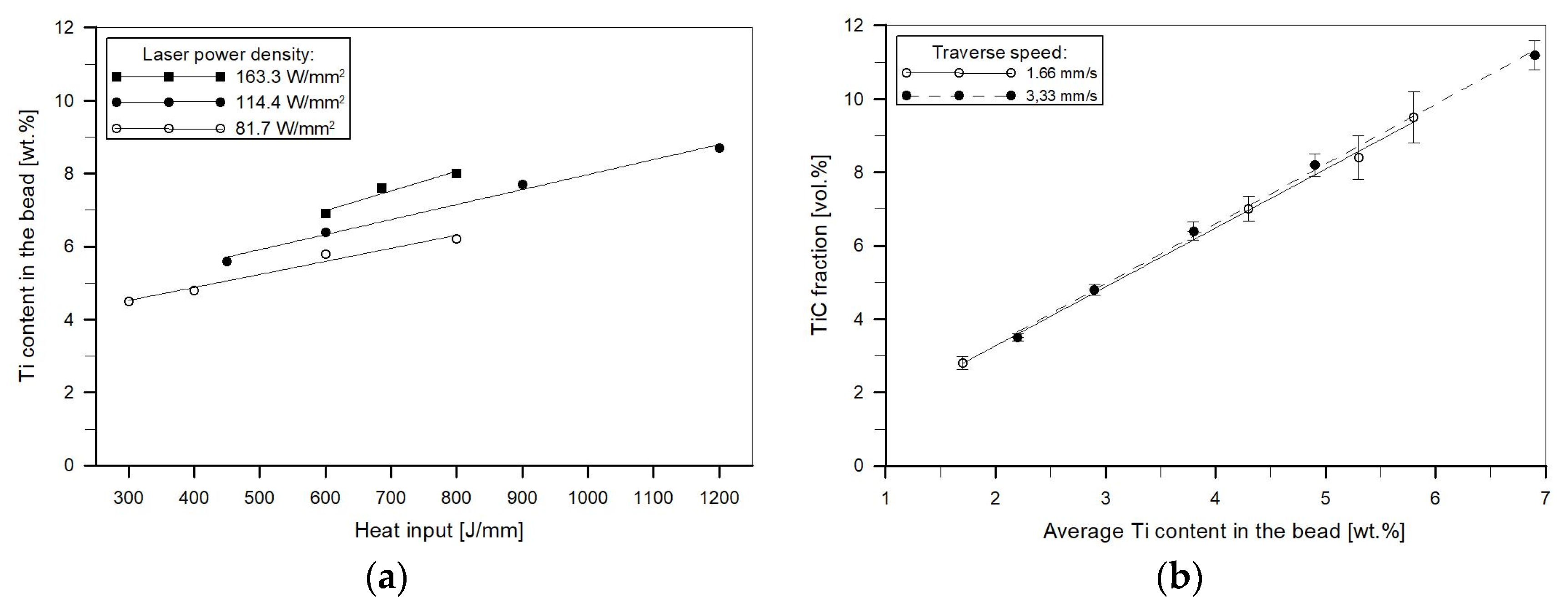

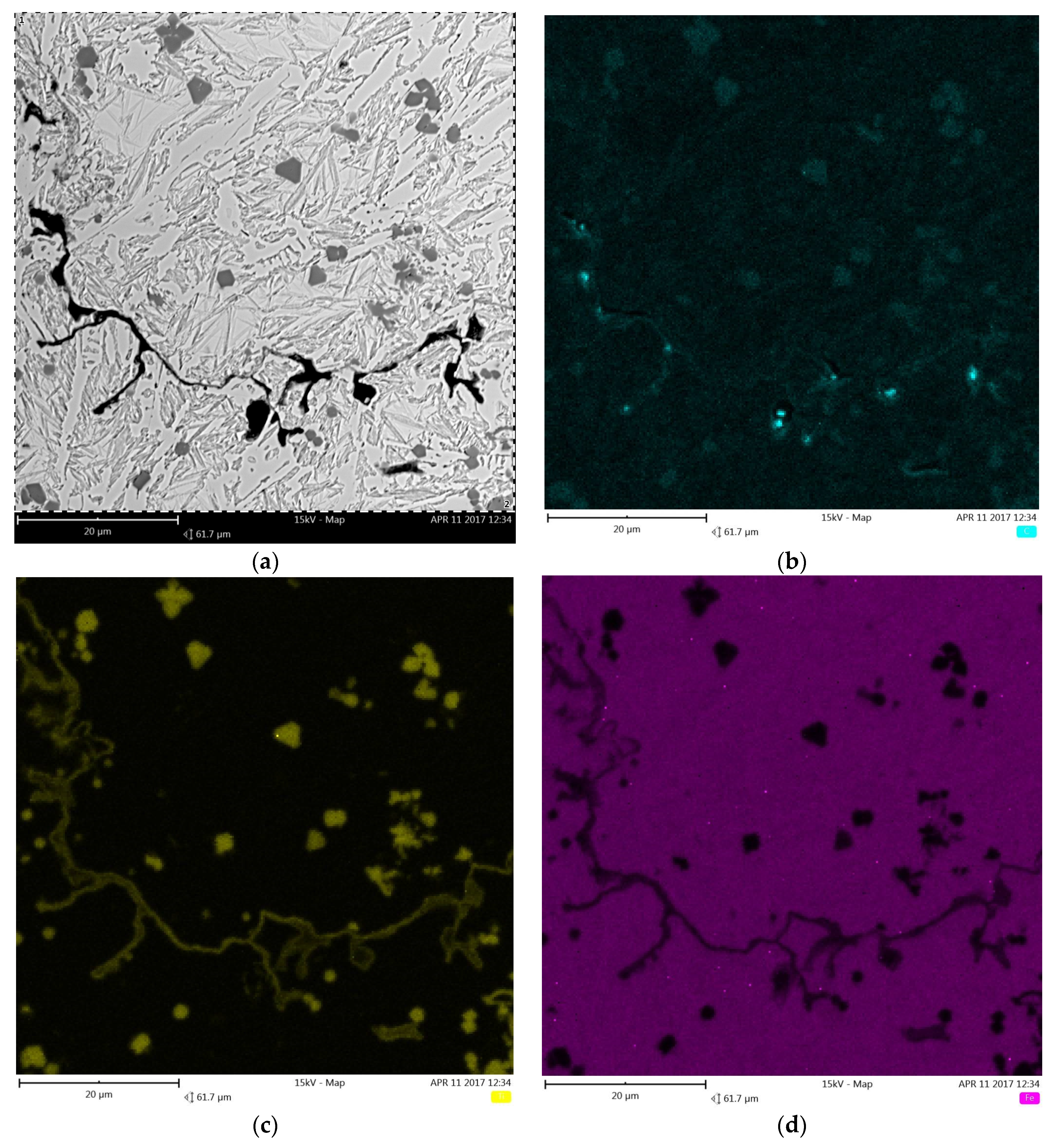

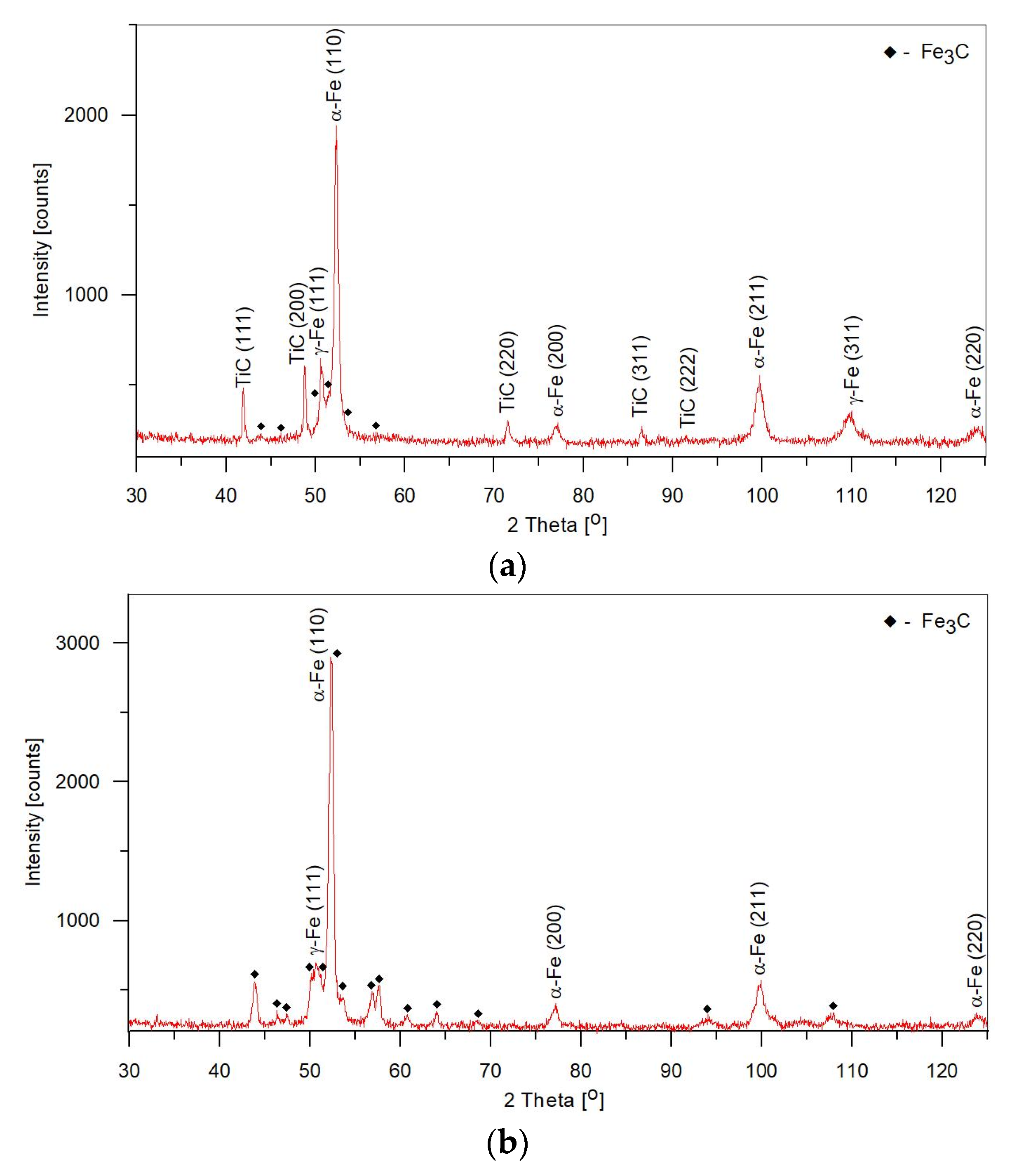

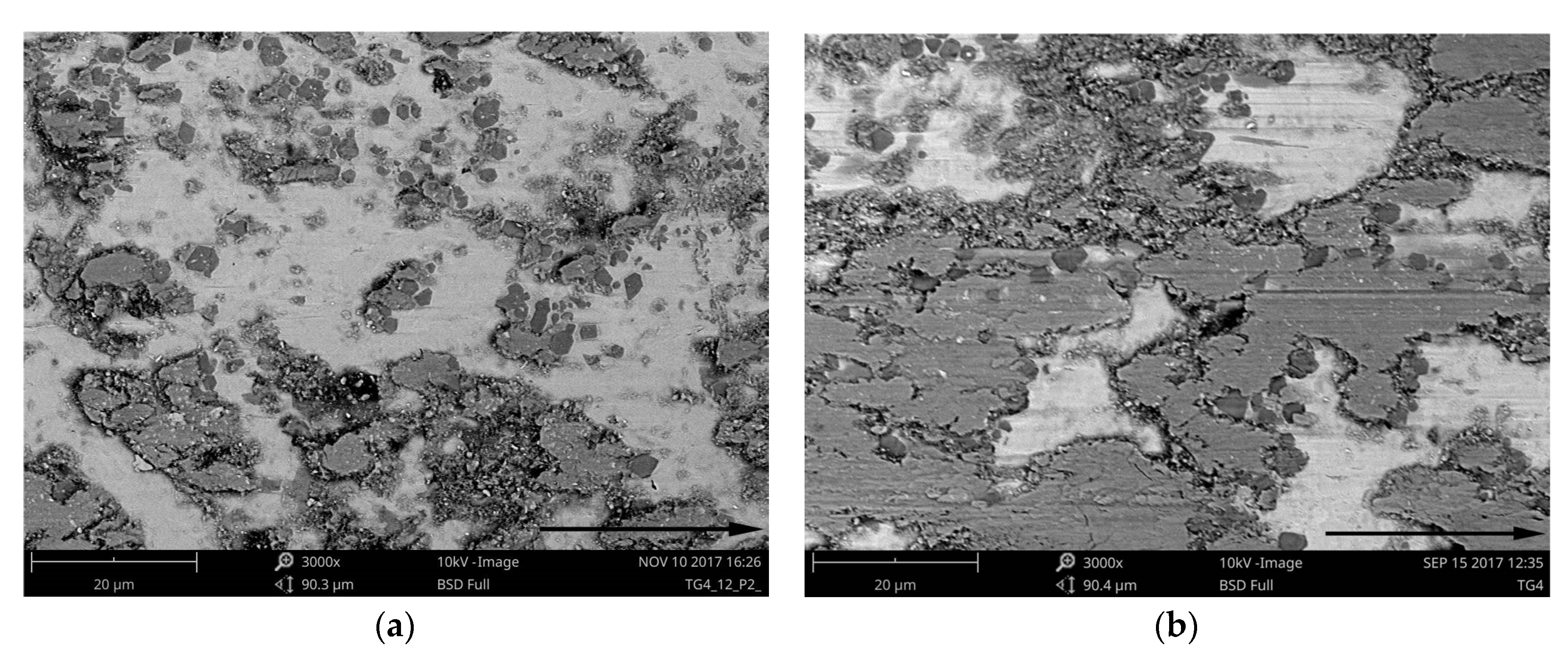

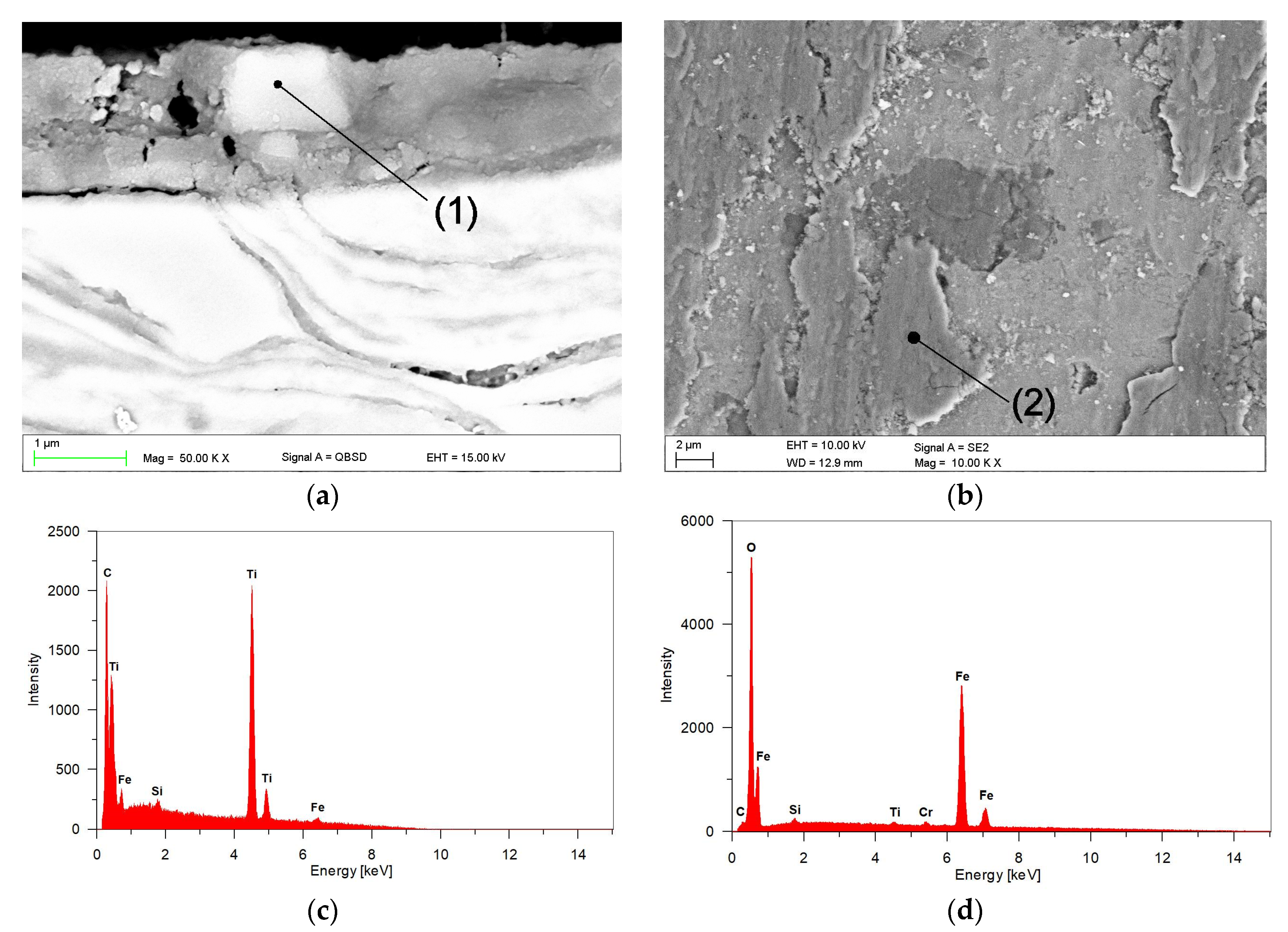

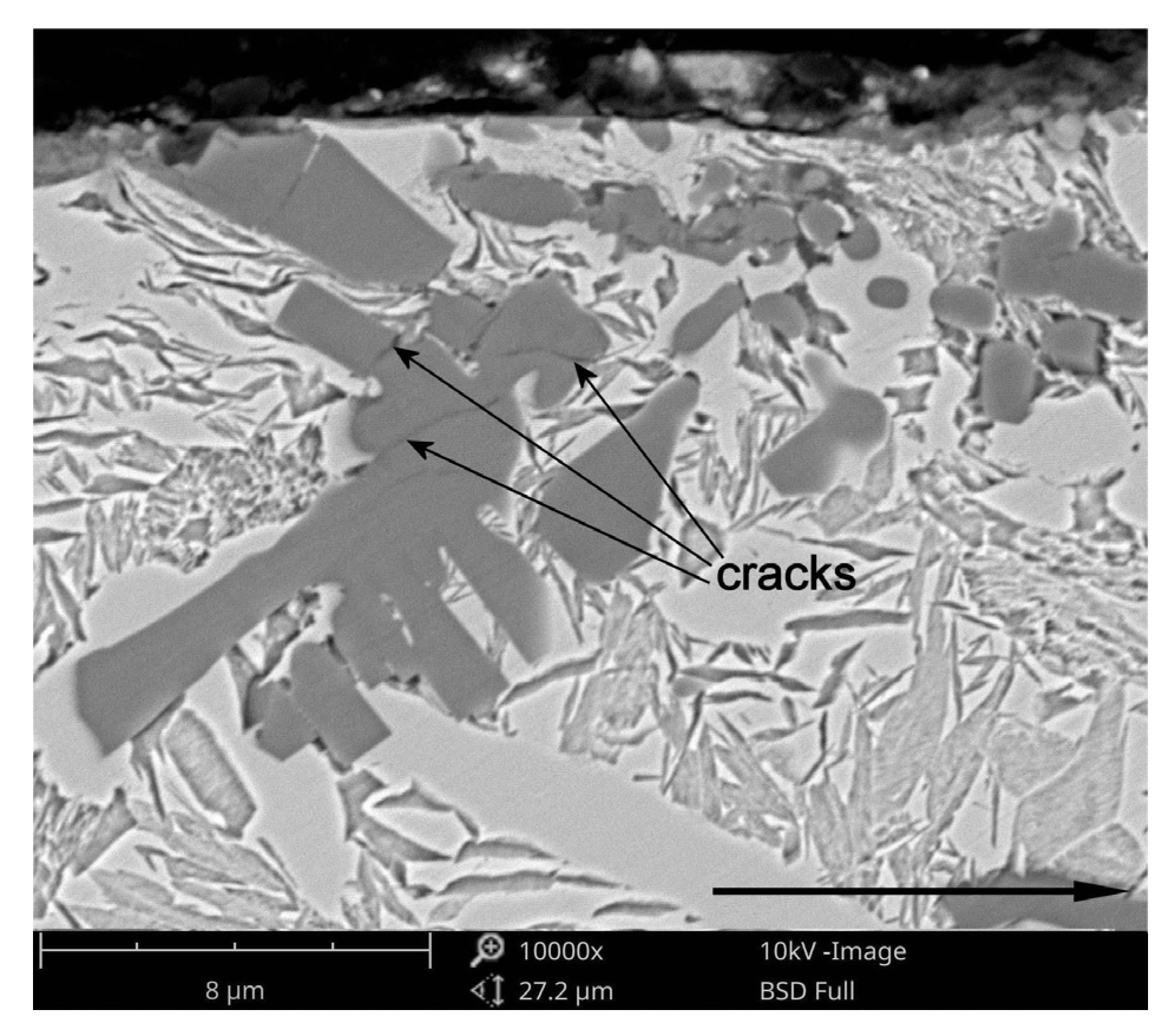

3.2. Macro and Micro Analysis

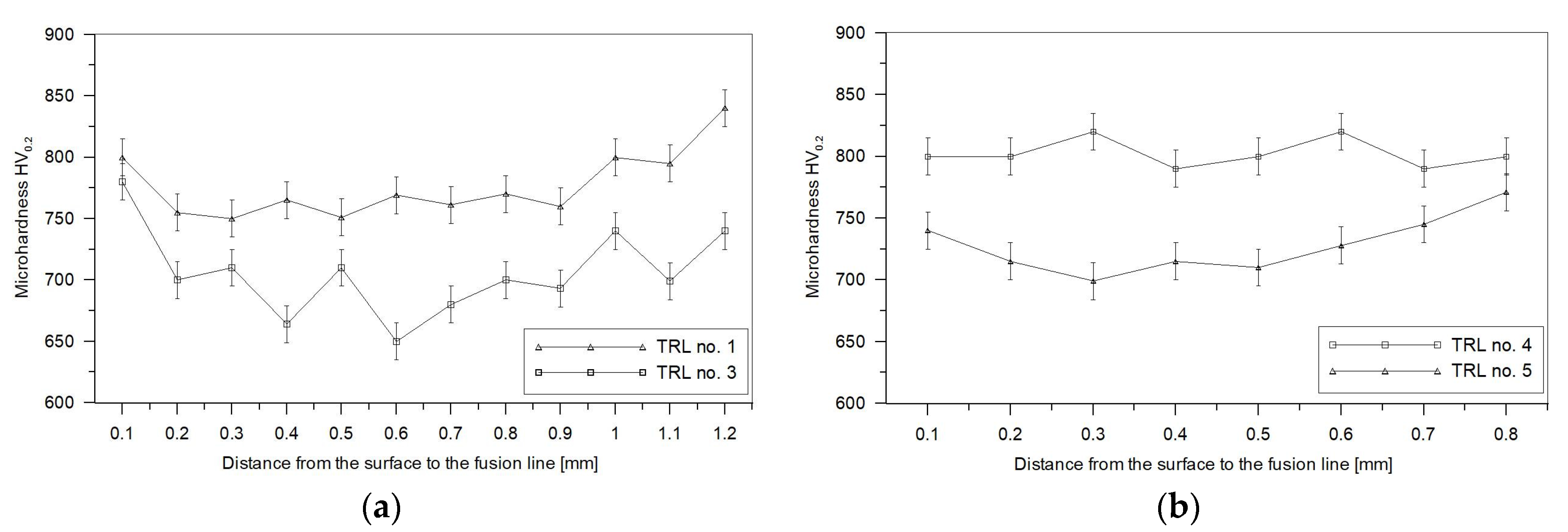

3.3. Hardness Analysis

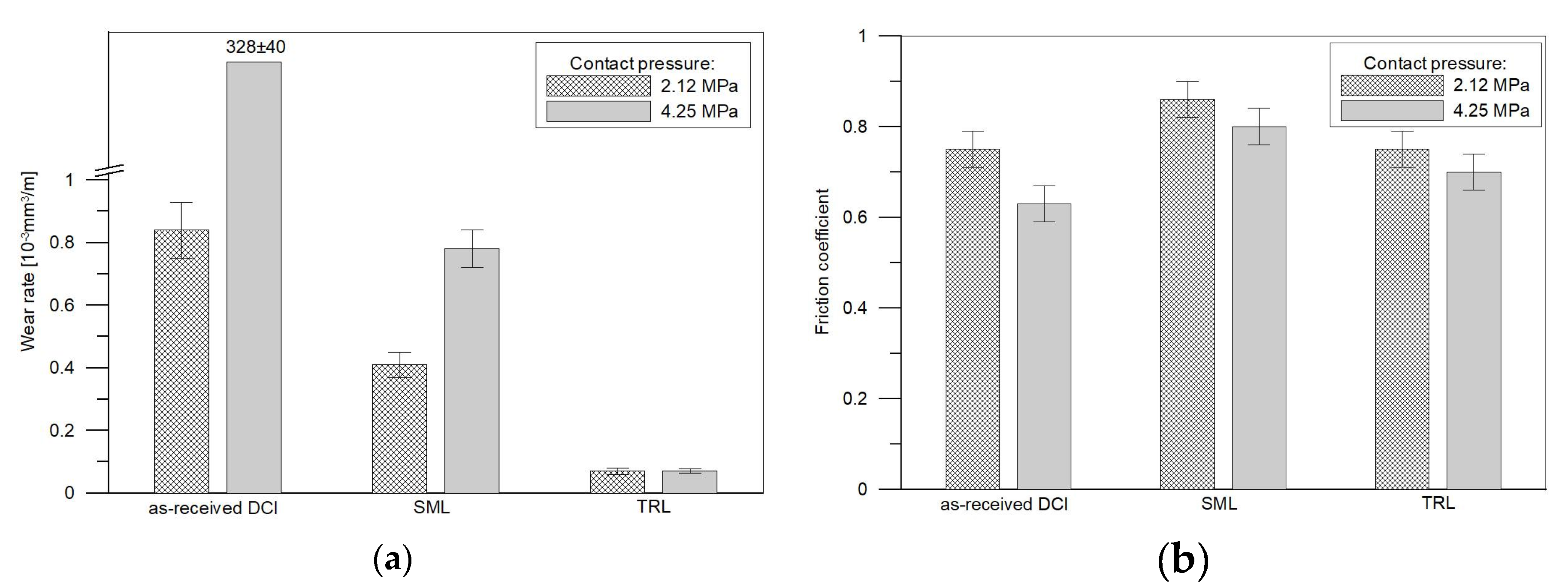

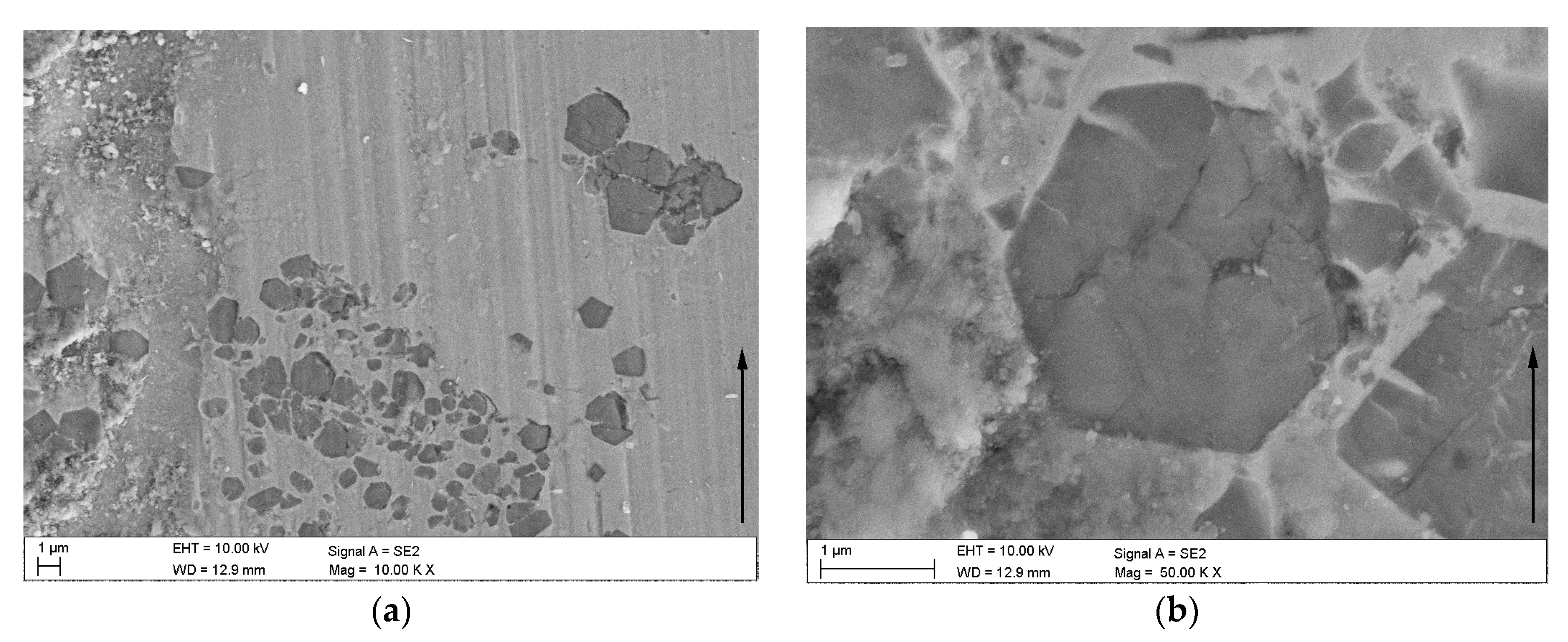

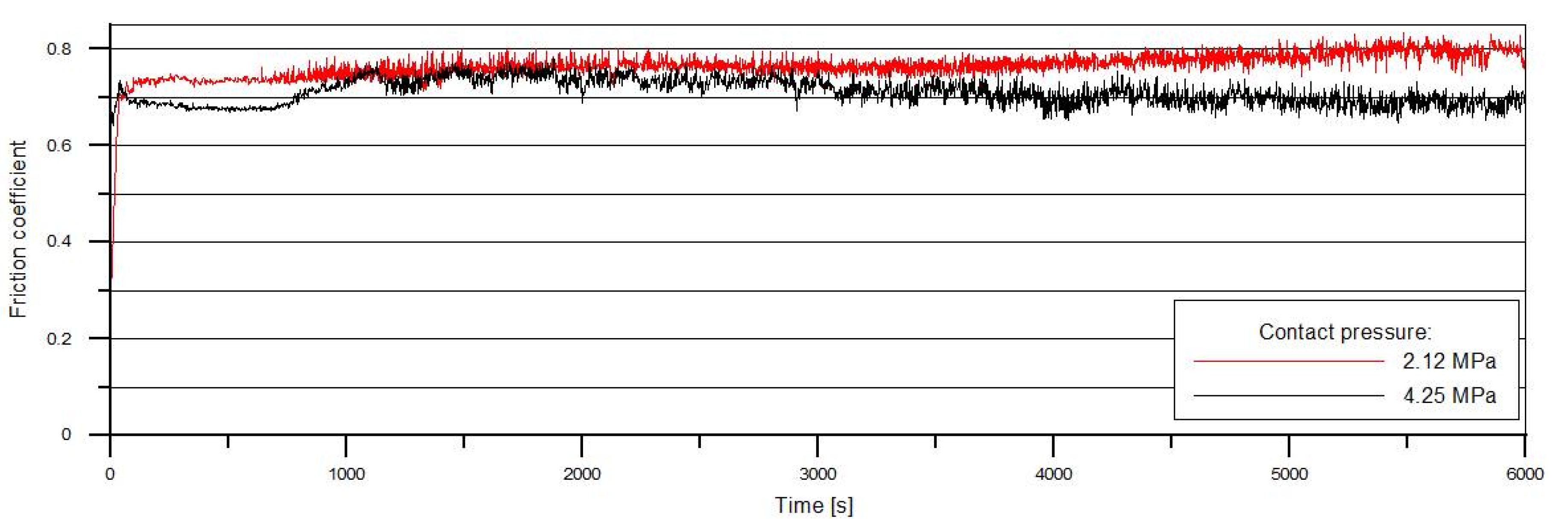

3.4. Sliding Wear Behaviour

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Cheng, T.W.; Liu, T.S.; Chen, L.H. Microstructural Features and Erosion Wear Resistance of Friction Stir Surface Hardened Spheroidal Graphite Cast Iron. Mater. Trans. 2012, 53, 167–172. [Google Scholar] [CrossRef]

- Lin, P.Y.; Zhang, Z.H.; Kong, S.H.; Zhou, H.; Liang, Y.; Tong, X.; Ren, X.Q. Mechanical Properties of Vermicular Graphite Cast Iron Processed by Selective Laser Surface Alloying with Ultra-fine ZrO Ceramic Particulates. Acta Metall. Sin. 2016, 29, 985–992. [Google Scholar] [CrossRef]

- Pagano, N.; Angelini, V.; Ceschini, L.; Campana, G. Laser remelting for enhancing tribological preferences of a ductile iron. Procedia CIRP 2016, 41, 987–991. [Google Scholar] [CrossRef]

- Heydarzadeh Sohi, M.; Ebrahimi, M.; Ghasemi, H.M.; Shahripour, A. Microstructural study of surface melted and chromium surface alloyed ductile iron. Appl. Surf. Sci. 2012, 258, 7248–7353. [Google Scholar] [CrossRef]

- Sun, G.; Zhou, R.; Li, P.; Feng, A.; Zhang, Y. Laser surface alloying of C-B-W-Cr powders on nodular cast iron rolls. Surf. Coat. Technol. 2011, 205, 2747–2754. [Google Scholar] [CrossRef]

- Janicki, D.; Górka, J.; Kwaśny, W.; Gołombek, K.; Kondracki, M.; Żuk, M. Diode laser surface alloying of armor steel with tungsten carbide. Arch. Metall. Mater. 2017, 62, 473–481. [Google Scholar] [CrossRef]

- Lisiecki, A. Titanium matrix composite Ti/TiN produced by diode laser gas nitriding. Metals 2015, 5, 54–69. [Google Scholar] [CrossRef]

- Tański, T.; Pakieła, W.; Janicki, D.; Tomiczek, B.; Król, M. Properties of the aluminium alloy EN AC-51100 after laser surface treatment. Arch. Metall. Mater. 2016, 61, 199–204. [Google Scholar] [CrossRef]

- Janicki, D. In-situ synthesis of titanium carbide particles in an iron matrix during diode-laser surface alloying of ductile cast iron. Mater. Technol. 2016, 51, 317–321. [Google Scholar] [CrossRef]

- Aikin, R.M. The mechanical properties of in-situ composites. JOM 1997, 49, 35. [Google Scholar] [CrossRef]

- Feng, H.; Zhou, Y.; Jia, D.; Meng, Q. Microstructure and mechanical properties of in situ TiB reinforced titanium matrix composites based on Ti–FeMo–B prepared by spark plasma sintering. Compos. Sci. Technol. 2004, 64, 2495–2500. [Google Scholar] [CrossRef]

- Svendsen, L.; Jarfors, A.E.W. In-situ formed aluminium composite. In Advance Light Alloys and Composites; NATO ASI Series; Ciach, R., Ed.; Springer: Dordrecht, The Netherlands, 1998; Volume 59. [Google Scholar]

- AlMangour, B.; Grzesiak, D.; Yong, J.M. In-situ formation of novel TiC-particle-reinforced 316L stainless steel bulk-form composites by selective laser melting. J. Alloy. Compd. 2017, 706, 409–418. [Google Scholar] [CrossRef]

- Karantzalis, A.E.; Lekatou, A.; Evaggelidou, M. Microstructure and sliding wear assessment of Co-TiC composite materials. Int. J. Cast Met. Res. 2014, 27, 73–79. [Google Scholar] [CrossRef]

- Liu, Y.; Qu, W.; Su, Y. Reinforcement Composite Coating Produced Using Graphite of the Cast Iron by Laser Cladding. Materials 2016, 9, 815. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.H.; Qu, S.Y.; Du, B.S.; Zou, Z.D. In situ synthesised TiC particles reinforced Fe based composite coating produced by laser cladding. Mater. Sci. Technol. 2009, 25, 388–392. [Google Scholar] [CrossRef]

- Emamian, A.; Corbin, S.F.; Khajepour, A. Tribology characteristics of in-situ laser deposition of Fe-TiC. Surf. Coat. Technol. 2012, 206, 4495–4501. [Google Scholar] [CrossRef]

- Singh, A.; Dahotre, N.B. Phase evolution during laser in-situ carbide coating. Metall. Mater. Trans. A 2005, 36, 797–803. [Google Scholar] [CrossRef]

- Wieczerzak, K.; Bala, P.; Dziurka, R.; Stepien, M.; Tokarski, T.; Cios, G.; Gorecki, K. Experimental and thermodynamic study of selected in-situ composites from the Fe-Cr-Ni-Mo-C system. Arch. Metall. Mater. 2016, 61, 1241–1247. [Google Scholar] [CrossRef]

- Liyanage, J.T.; Fisher, G.; Gerlich, A.P. Microstructures and abrasive wear performance of PTAW deposited Ni-WC overlays using different Ni-alloy chemistries. Wear 2012, 274–275, 345–354. [Google Scholar] [CrossRef]

- Aparicio-Fernandez, R.; Springer, H.; Szczepaniak, A.; Zhang, H.; Raabe, D. In-situ metal matrix composite steels: Effect of alloying and annealing on morphology, structure and mechanical properties of TiB2 particle containing high modulus steels. Acta Mater. 2016, 107, 38–48. [Google Scholar] [CrossRef]

- Babu, S.S.; Kelly, S.M.; Martukanitz, R.P.; Murugananth, M. Design of process-material-shielding combinations for hard coatings using laser surface alloying. In Proceedings of the 7th International Conference on Trends in Welding Research, Pine Mountain, GA, USA, 16–20 May 2005; David, S.A., Debroy, L., Smartt, V., Eds.; ASM International: Materials Park, OH, USA, 2006. [Google Scholar]

- Janicki, D. Fabrication of high chromium white iron surface layers on ductile cast iron substrate by laser surface alloying. Strojniski Vestnik 2017, 63, 705–714. [Google Scholar] [CrossRef]

- Zarubova, N.; Kraus, V.; Cermak, J. Mechanisms of phase transformations during laser treatment of grey cast iron. J. Mater. Sci. 1992, 27, 3487–3496. [Google Scholar] [CrossRef]

- Janicki, D. Direct diode laser surface melting of nodular cast iron. Appl. Mech. Mater. 2015, 809–810, 423–428. [Google Scholar] [CrossRef]

- Coronado, J.J.; Sinatora, A. Abrasive wear study of white cast iron with different solidification rates. Wear 2009, 267, 2116–2121. [Google Scholar] [CrossRef]

- Pirch, N.; Kreutz, E.W.; Ollier, B.; He, X. The modelling of heat, mass and solute transport in surface processing with laser radiation. In Laser Processing: Surface Treatment and Film Deposition; NATO ASI Series; Mazumer, J., Conde, O., Villar, R., Steen, W., Eds.; Springer: Dordrecht, The Netherlands, 1996; Volume 307, pp. 177–193. [Google Scholar]

- Kou, S. Recent developments in transport phenomena in fusion welding. In Proceedings of the 6th International Conference on Trends in Welding Research, Pine Mountain, GA, USA, 15–19 April 2002; David, S.A., Debroy, L., Smartt, V., Eds.; ASM International: Materials Park, OH, USA, 2003. [Google Scholar]

- Yuan, K.; Liu, Y.; Yu, S. Effect of the Marangoni Convection on the TiC Synthesis in Laser-Melted Pool. J. Adv. Microsc. Res. 2015, 10, 223–226. [Google Scholar] [CrossRef]

- Khalili, A.; Goodarzi, M.; Mojtahedi, M.; Torkamany, M.J. Solidification microstructure of in-situ laser-synthesized Fe-TiC hard coating. Surf. Coat. Technol. 2016, 307, 747–752. [Google Scholar] [CrossRef]

- Janus, A.; Stachowicz, M. Thermodynamic stability of austenitic Ni-Mn-Cu cast iron. Metalurgija 2014, 3, 353–356. [Google Scholar]

- Roger, J.; Gardiola, B.; Andrieux, J.; Viala, J.C.; Dezellus, O. Synthesis of Ti matrix composites reinforced with TiC particles: Thermodynamic equilibrium and change in microstructure. J. Mater. Sci. 2017, 52, 4129–4141. [Google Scholar] [CrossRef]

- Holt, J.B.; Munir, Z.A. Combustion synthesis of titanium carbide: Theory and experiment. J. Mater. Sci. 1986, 21, 251–259. [Google Scholar] [CrossRef]

- Storms, E.K. The Refractory Carbides; Academic Press Inc.: New York, NY, USA, 1967; pp. 11–12. [Google Scholar]

- Guemmaz, M.; Mosser, A.; Boudoukha, L.; Grob, J.J.; Raiser, D.; Sens, J.C. Ion beam synthesis of non-stoichiometric titanium carbide: Composition structure and nanoindentation studies. Nucl. Instrum. Methods Phys. Res. Sect. B 1996, 111, 263–270. [Google Scholar] [CrossRef]

- Park, H.I.; Nakata, K.; Tomida, S. In situ formation of TiC particulate composite layer on cast iron by laser alloying of thermal sprayed titanium coating. J. Mater. Sci. 2000, 35, 747–755. [Google Scholar] [CrossRef]

- Lu, D.; Gu, M.; Shi, Z. Materials transfer and formation of mechanically mixed layer in dry sliding wear of metal matrix composites against steel. Tribol. Lett. 1999, 6, 57–61. [Google Scholar] [CrossRef]

| C | Si | Cu | Mn | Cr | Ni | S | P | Fe |

|---|---|---|---|---|---|---|---|---|

| 3.60 | 2.51 | 0.78 | 0.25 | 0.02 | 0.04 | 0.008 | 0.016 | balance |

| Processing Condition No./Bead No. | Laser Power (W) | Traverse Speed (mm/s) | Heat Input (J/mm) | Powder Feed Rate (mg/mm) | Cross-Sectional Bead Geometry | Ti Content (wt %) | TiC Fraction (vol %) | |

|---|---|---|---|---|---|---|---|---|

| Fusion Zone Depth (mm) | Fusion Area of the Bead (mm2) | |||||||

| A1 | 1500 | 1.25 | 1200 | 2.0 | 1.94 | 7.29 | 3.0 ± 0.20 | 4.8 ± 0.31 |

| A2 | 1500 | 1.25 | 1200 | 6.0 | 1.79 | 7.09 | 5.9 ± 0.61 | 9.4 ± 1.21 |

| A3 | 1500 | 1.25 | 1200 | 10.0 | 1.63 | 6.94 | 8.7 ± 1.09 | 14.8 ± 1.45 |

| A4 | 1500 | 1.25 | 1200 | 11.0 | 1.54 | 6.85 | N 2 | - |

| A5 | 1000 | 1.67 | 600 | 4.0 | 1.17 | 5.29 | 5.7 ± 0.94 | 9.3 ± 1.39 |

| A6 | 2000 | 3.33 | 600 | 4.0 | 1.34 | 5.55 | 5.5 ± 0.45 | 8.9 ± 0.61 |

| M1 1 | 1500 | 1.25 | 1200 | - | 2.24 | 7.59 | - | - |

| TRL no. | Processing Condition no. (Table 2) 1 | α-Fe (Martensite) Fraction (wt %) | Retained Austenite Fraction (wt %) | Cementite Fraction (vol %) | TiC Fraction (vol %) |

|---|---|---|---|---|---|

| 1 | A1 | 47.2 ± 1.2 | 6.2 ± 0.1 | 42.3 ± 1.9 | 6.44 ± 0.41 |

| 2 | A2 | 48.0 ± 1.9 | 13.4 ± 1.3 | 31.3 ± 2.2 | 11.0 ± 1.16 |

| 3 | A3 | 66.4 ± 1.1 | 15.3 ± 1.4 | 8.1 ± 2.9 | 15.4 ± 2.11 |

| 4 | A5 | 49.8 ± 1.3 | 20.7 ± 0.9 | 20.1 ± 2.5 | 14.1 ± 1.55 |

| 5 | A6 | 41.7 ± 1.6 | 30.9 ± 1.2 | 18.2 ± 2.0 | 13.8 ± 1.03 |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janicki, D. Microstructure and Sliding Wear Behaviour of In-Situ TiC-Reinforced Composite Surface Layers Fabricated on Ductile Cast Iron by Laser Alloying. Materials 2018, 11, 75. https://doi.org/10.3390/ma11010075

Janicki D. Microstructure and Sliding Wear Behaviour of In-Situ TiC-Reinforced Composite Surface Layers Fabricated on Ductile Cast Iron by Laser Alloying. Materials. 2018; 11(1):75. https://doi.org/10.3390/ma11010075

Chicago/Turabian StyleJanicki, Damian. 2018. "Microstructure and Sliding Wear Behaviour of In-Situ TiC-Reinforced Composite Surface Layers Fabricated on Ductile Cast Iron by Laser Alloying" Materials 11, no. 1: 75. https://doi.org/10.3390/ma11010075