Thermoelectric Mixed Thick-/Thin Film Microgenerators Based on Constantan/Silver

Abstract

:1. Introduction

2. Materials and Methods

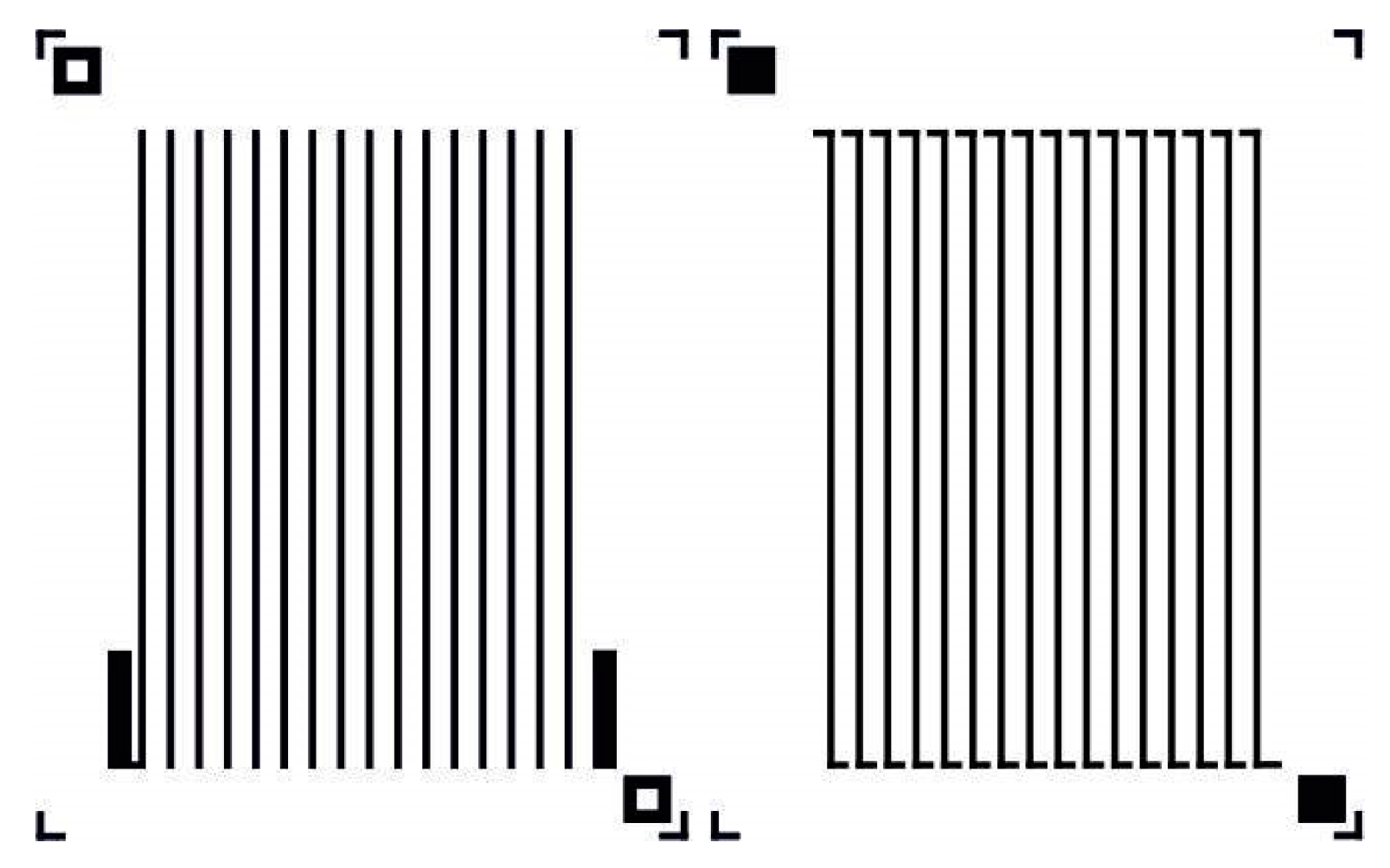

2.1. Design

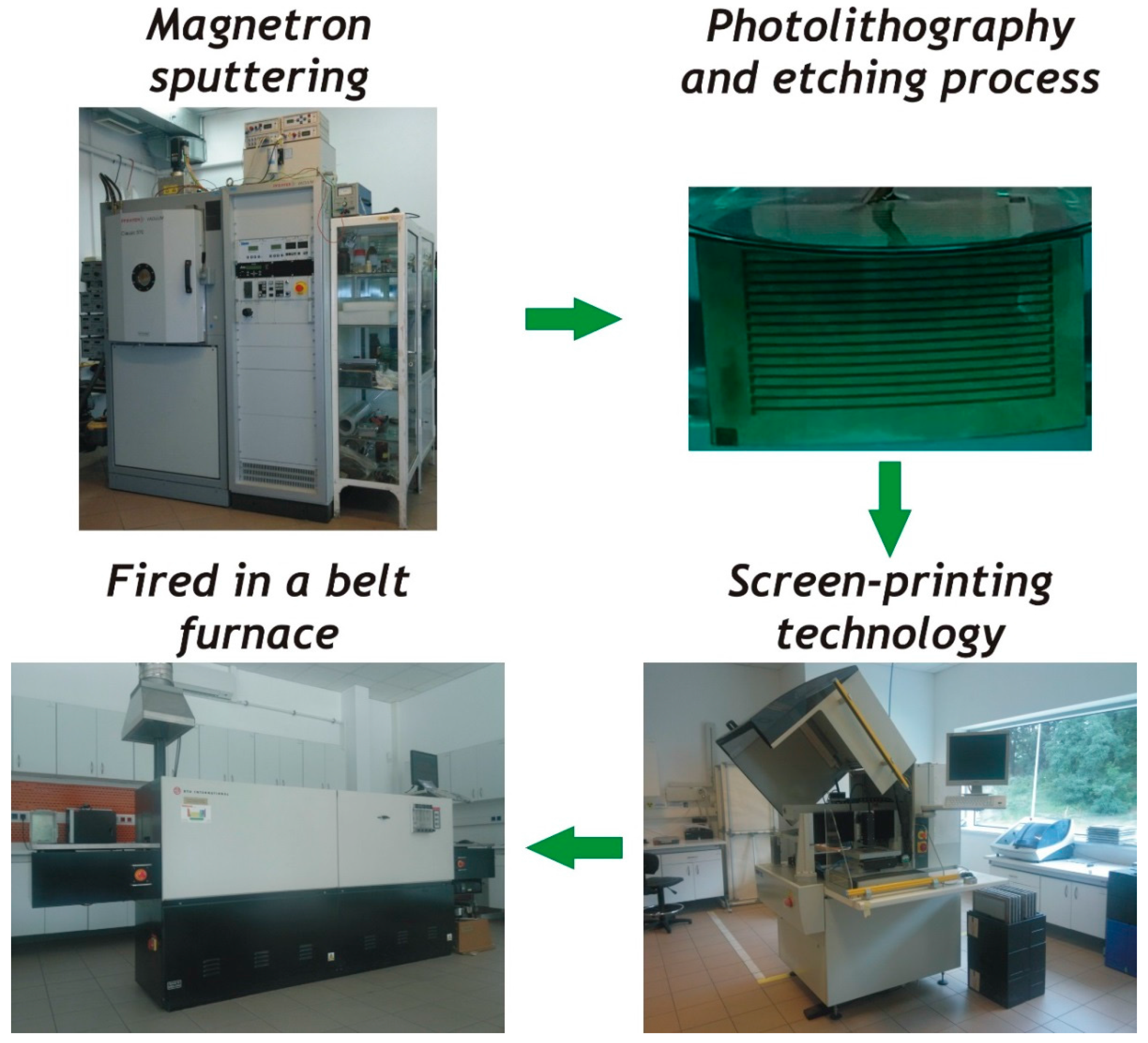

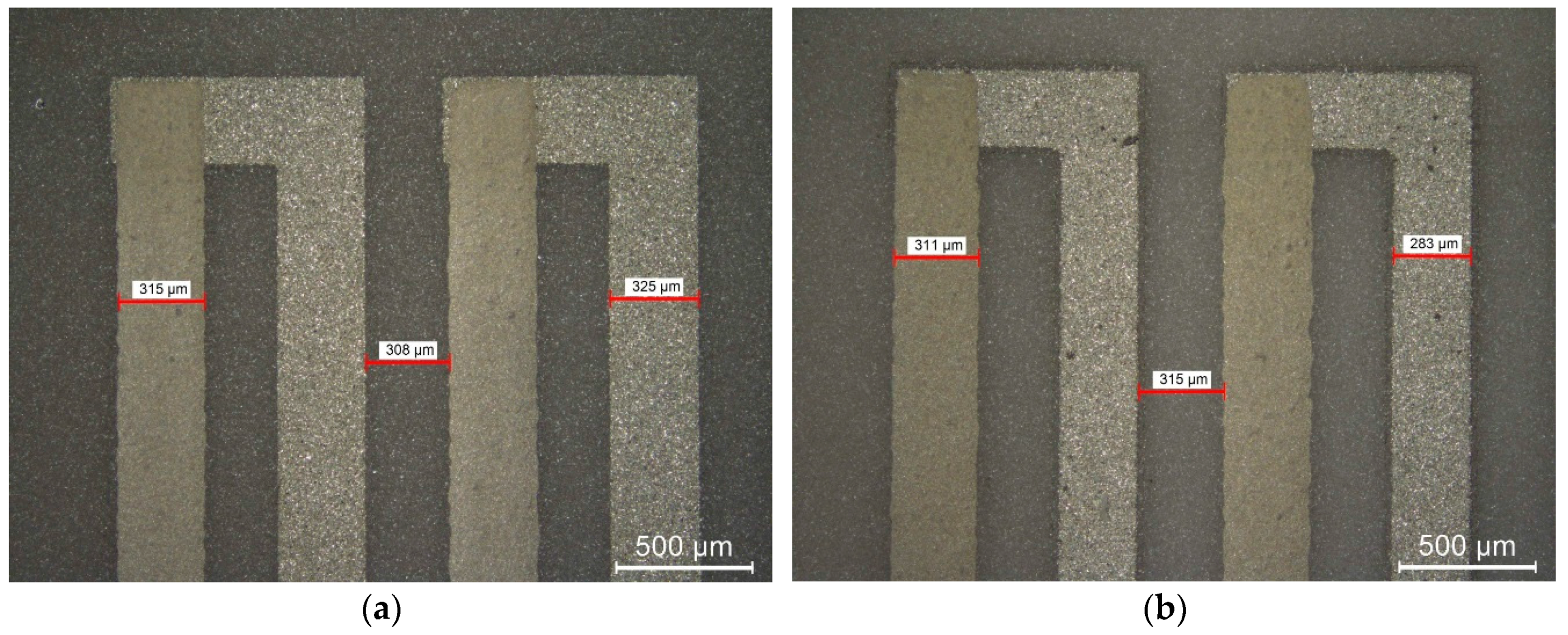

2.2. Fabrication of Test Structures

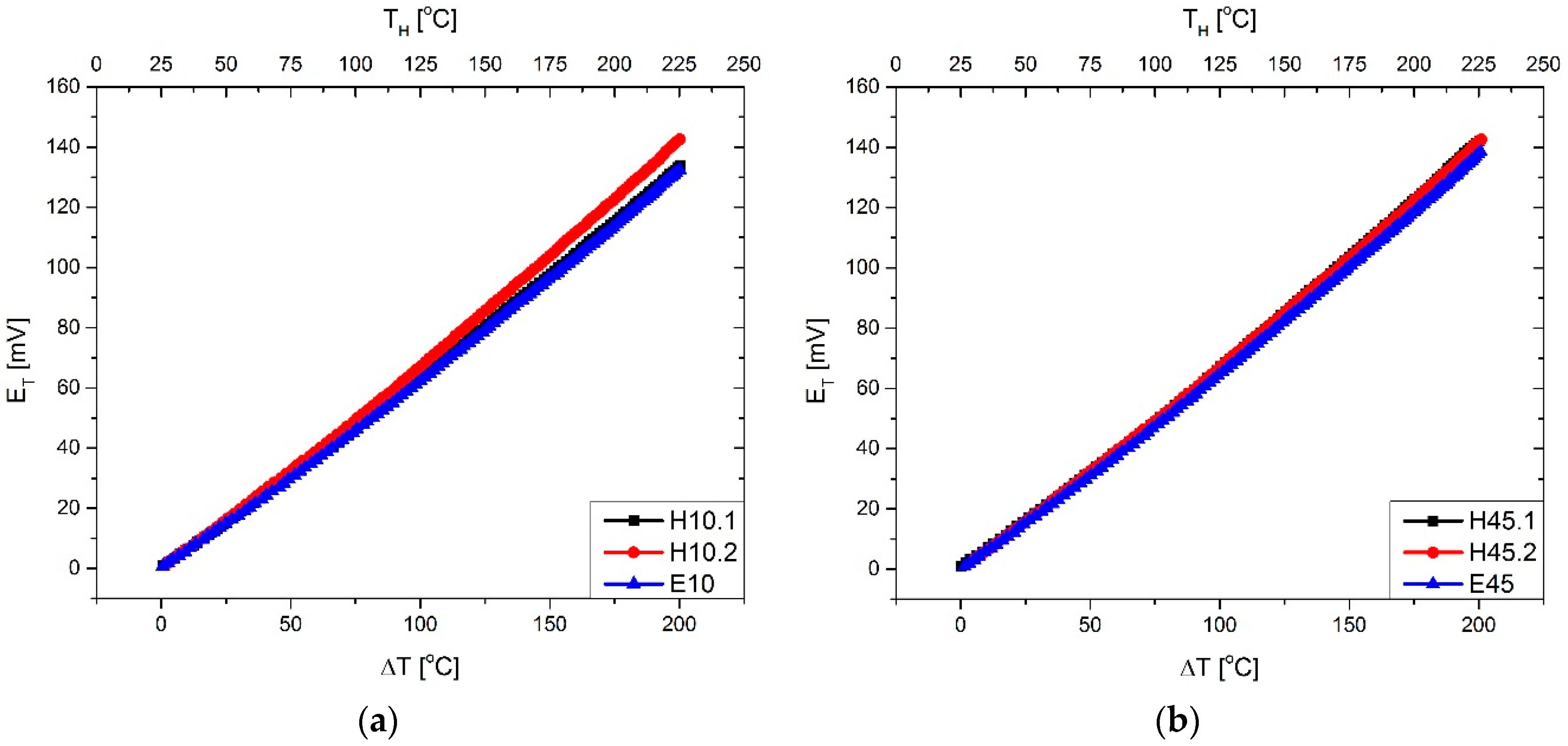

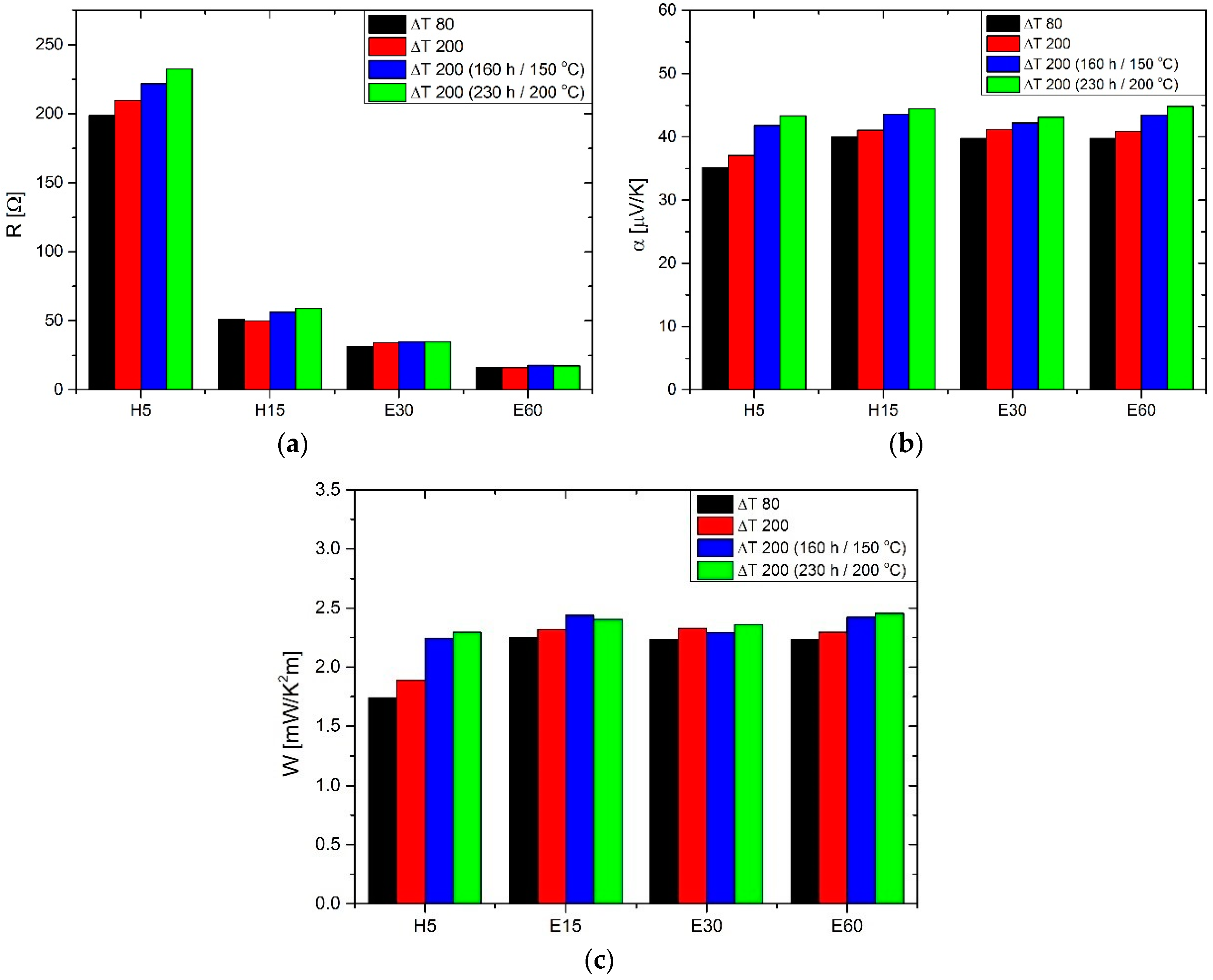

3. Results

4. Discussion

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Brand, O.; Fedder, G.K.; Hierold, C.; Korvink, J.G.; Tabata, O. Thermoelectrics Energy Conversion, Basic Concepts and Device Applications; Pineda, D.D., Rezania, A., Eds.; Wiley-VCH: Weinheim, Germany, 2017. [Google Scholar]

- Ohta, T.; Kajikawa, T.; Kumashiro, Y. Characteristics of (Bi,Sb)2(Te,Se)3-based thick-film thermoelectric elements for power generation. Electr. Eng. Jpn. 1990, 110, 213–219. [Google Scholar] [CrossRef]

- Castaño, E.; Revuelto, E.; Martin, M.C.; Garcia-Alonso, A.; Gracia, F.J. Metallic thin-film thermocouple for thermoelectric microgenerators. Sens. Actuators A 1997, 60, 65–67. [Google Scholar] [CrossRef]

- Markowski, P.; Dziedzic, A. Planar and three-dimensional thick-film thermoelectric microgenerators. Microelectron. Reliab. 2008, 48, 890–896. [Google Scholar] [CrossRef]

- Koumoto, K.; Funahashi, R.; Guilmeau, E.; Miyazaki, Y.; Weindenkaff, A.; Wang, Y.; Wan, C. Thermoelectric ceramics for energy harvesting. J. Am. Ceram. Soc. 2013, 96, 1–23. [Google Scholar] [CrossRef]

- Rudež, R.; Markowski, P.; Presečnik, M.; Košir, M.; Dziedzic, A.; Bernik, S. Development of thick-film thermoelectric microgenerators based on p-type Ca3Co4O9 and n-type (ZnO)5∙In2O3 legs. Ceram. Int. 2015, 41, 13201–13209. [Google Scholar] [CrossRef]

- Dorey, R.A. Integrated powder-based thick films for thermoelectric, pyroelectric and piezoelectric energy harvesting devices. IEEE Sens. J. 2014, 14, 2177–2184. [Google Scholar] [CrossRef]

- Markowski, P.; Prociów, E.; Urbaniak, Ł. Thermoelectric properties of thin-film germanium-based layers. Microelectron. Int. 2015, 32, 115–121. [Google Scholar] [CrossRef]

- Xu, Y.; Qu, X.; Lu, S.; Bai, L.; Niu, L. Influence of external magnetic field on microstructure and electrical transport properties of Ca3−xLaxCo4O9+δ ceramics. Ceram. Int. 2016, 42, 11404–11410. [Google Scholar] [CrossRef]

- Orrill, M.; LeBlanc, S. Printed thermoelectric materials and devices; fabrication techniques, advantages and challenges. J. Appl. Polym. Sci. 2017, 133. [Google Scholar] [CrossRef]

- Appel, O.; Zilber, T.; Kalabukhov, S.; Beeri, O.; Gelbstein, Y. Morphological effects on the thermoelectric properties of Ti0.3Zr0.35Hf0.35Ni1+δSn alloys following phase separation. J. Mater. Chem. C 2015, 3, 11653–11659. [Google Scholar] [CrossRef]

- Kita, J.; Wiegaertner, S.; Moos, R.; Weigand, P.; Pliscott, A.; LaBranche, M.H.; Glicksman, H.D. Screen-printable type S thermocouple for thick-film technology. Procedia Eng. 2015, 120, 828–831. [Google Scholar] [CrossRef]

- Rebenklau, L.; Gierth, P.; Paproth, A.; Irrgang, K.; Lippmann, L.; Wodtke, A.; Niedermeyer, L.; Augsburg, K.; Bechtold, F. Temperature sensors based on thermoelectric effect. In Proceedings of the European Microelectronics Packaging Conference EMPC 2015, Friedrichshafen, Germany, 14–16 September 2015; pp. 1–5. [Google Scholar]

- Hrovat, M.; Zgonik, M.; Belavic, D.; Macek, S. Thick-film materials for heat flux sensors. J. Mater. Sci. Lett. 1992, 11, 89–90. [Google Scholar] [CrossRef]

- Kwikkers, T. Two thick film thermal sensors. Microelectron. Int. 1998, 5, 39–42. [Google Scholar] [CrossRef]

- Dziedzic, A.; Żdanowicz, T. Thick-film insolation sensor. In Proceedings of the 17th European Photovoltaic Solar Energy Conference, Munich, Germany, 22–26 October 2001; pp. 537–539. [Google Scholar]

- Dziedzic, A.; Młynarczyk, K.; Prociów, E. Thermal insolation sensor with thick/thin film thermopile. In Proceedings of the 26th International Spring Seminar on Electronics Technology, High Tatras, Slovakia, 8–11 May 2003; pp. 57–62. [Google Scholar]

- Smetana, W.; Nicolics, J. Application of integrated thick-film thermocouples for a laser power detector. Sens. Actuators A 1993, 37, 565–570. [Google Scholar] [CrossRef]

- Markowski, P.; Prociów, E.; Dziedzic, A. Mixed thick/thin-film thermocouples for thermoelectric microgenerators and laser power sensor. Opt. Appl. 2009, 39, 681–690. [Google Scholar]

- Briones, E.; Briones, J.; Cuadrado, A.; Martinez-Anton, J.C.; McMurtry, S.; Hehn, M.; Montaigne, F.; Alda, J.; Gonzalez, F.J. Seebeck nanoantennas for solar energy harvesting. Appl. Phys. Lett. 2014, 105, 093108. [Google Scholar] [CrossRef] [Green Version]

- Schubert, F.; Gollner, M.; Kita, J.; Linseis, F.; Moos, R. First steps to develop a sensor for a Tian-Calvert calorimeter with increased sensitivity. J. Sens. Sens. Syst. 2016, 5, 205–212. [Google Scholar] [CrossRef]

- Navone, C.; Soulier, M.; Testard, J.; Simon, J.; Caroff, T. Optimization and fabrication of a thick printed thermoelectric device. J. Electron. Mater. 2011, 40, 789–793. [Google Scholar] [CrossRef]

- Fan, H.N.; Singh, R.; Akbarzadeh, A. Electric power generation from thermoelectric cells using a solar dish concentrator. J. Electron. Mater. 2011, 40, 1311–1320. [Google Scholar] [CrossRef]

- Nozariasbmarz, A.; Rad, A.T.; Zamanipour, Z.; Krasinski, J.S.; Tayebi, L.; Vashaee, D. Enhancement of thermoelectric power of silicon germanium films grown by electrophoresis deposition. Scr. Mater. 2013, 69, 549–552. [Google Scholar] [CrossRef]

- Saini, S.; Mele, P.; Miyazaki, K.; Tiwari, A. On-chip thermoelectric module comprised of oxide thin film legs. Energy Convers. Manag. 2016, 114, 251–257. [Google Scholar] [CrossRef]

- Gima, Z.T.; Gururangan, K.; Evans, J.; Wright, P. Annular screen printed thermoelectric generators for ultra-low-power sensor applications. J. Phys. Conf. Ser. 2016, 773, 012115-1–012115-4. [Google Scholar] [CrossRef]

- Ting, W.-Y.; Young, T.-F. Characteristics of nano crystallite Te-Bi composited thermoelectrics for cooling by screen-printing. In Proceedings of the 12th IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Los Angeles, CA, USA, 9–12 April 2017; pp. 231–234. [Google Scholar]

- Skwarek, A.; Synkiewicz, B.; Kulawik, J.; Guzdek, P.; Witek, K. High temperature thermogenerators made on DBC substrate using vapour phase soldering. Solder. Surf. Mt. Technol. 2015, 27, 125–128. [Google Scholar] [CrossRef]

- Chen, Q.; Longtin, J.P.; Tankiewicz, S.; Sampath, S.; Gambino, R.J. Ultrafast laser micromachining and patterning of thermal spray multilayers for thermopile fabrication. J. Micromech. Microeng. 2004, 14, 506–513. [Google Scholar] [CrossRef]

- Markowski, P. Thick-film photoimageable and laser-shaped as for thermoelectric microgenerators. Microelectron. Int. 2011, 28, 43–50. [Google Scholar] [CrossRef]

- Ou, W.; Plőtner, M.; Fischer, W.-J. Microfabrication of thermoelectric generators on flexible foil substrates as a power source for autonomous microsystems. J. Micromech. Microeng. 2001, 11, 146–152. [Google Scholar]

- Navone, C.; Soulier, M.; Plissonnier, M.; Seiler, A.L. Development of (Bi,Sb)2(Te,Se)3-based thermoelectric modules by a screen-printing process. J. Electron. Mater. 2010, 39, 1755–1759. [Google Scholar] [CrossRef]

- Markowski, P. Thermocouples fabrication using laser shaping technique. Microelectron. Mater. Technol. 2012, 2, 243–255. [Google Scholar]

- Markowski, P. Thermoelectric energy harvester fabricated in thick-film/LTCC technology. Microelectron. Int. 2014, 31, 176–185. [Google Scholar] [CrossRef]

- Markowski, P. Multilayer thick-film thermoelectric microgenerator based on LTCC technology. Microelectron. Int. 2016, 33, 155–161. [Google Scholar] [CrossRef]

- Markowski, P.; Dziedzic, A.; Prociów, E. Thick/thin film thermocouples as power source for autonomous microsystems—Preliminary results. Microelectron. Int. 2005, 22, 3–7. [Google Scholar] [CrossRef]

- Markowski, P.; Dziedzic, A.; Prociów, E. Thermoelectric microgenerators made in mixed thick/thin film technology. Elektronika 2006, 47, 7–8. [Google Scholar]

- Markowski, P.; Dziedzic, A.; Prociów, E. Mixed thick-/thin-film thermoelectric microgenerators. In Proceedings of the 2nd Electronic Systemintegration Technology Conference, London, UK, 1–4 September 2008; pp. 601–606. [Google Scholar] [CrossRef]

- Bharani, R.H. Single Crystal Growth of Constantan by Vertical Bridgman Method; EPFL: Lausanne, Switzerland, 2011. [Google Scholar]

- Gierczak, M.; Dziewięcki, S.; Markowski, P. The automatic system for the characterization of thermoelectric microgenerators. Elektronika 2015, 56, 34–37. [Google Scholar] [CrossRef]

| Magnetron Sputtering Time [min] | Width of the Constantan Layer [µm] | Thickness of the Constantan Layer, tCu-Ni [µm] | Etching Time [s] |

|---|---|---|---|

| 5 | 327 | 0.4 | 28 |

| 10 | 325 | 0.6 | 33 |

| 15 | 327 | 1.0 | 34 |

| 30 | 311 | 2.4 | 159 |

| 45 | 315 | 2.8 | 330 |

| 60 | 283 | 3.2 | 420 |

| Structure | Resistance [Ω] | Structure | Resistance [Ω] |

|---|---|---|---|

| H5 | 3180 | E5 | 2540 |

| H10 | 1310 | E10 | 1290 |

| H15 | 820 | E15 | 1200 |

| H30 | 480 | E30 | 500 |

| H45 | 365 | E45 | 320 |

| H60 | 290 | E60 | 260 |

| Structure | Seebeck Coefficient, α [µV/K] | Structure | Seebeck Coefficient, α [µV/K] |

|---|---|---|---|

| H5 | 35.1 | E5 | 36.9 |

| H10 | 40.2 | E10 | 37.5 |

| H15 | 39.9 | E15 | 37.2 |

| H30 | 39.8 | E30 | 39.8 |

| H45 | 41.1 | E45 | 37.9 |

| H60 | 39.8 | E60 | 39.8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gierczak, M.; Prażmowska-Czajka, J.; Dziedzic, A. Thermoelectric Mixed Thick-/Thin Film Microgenerators Based on Constantan/Silver. Materials 2018, 11, 115. https://doi.org/10.3390/ma11010115

Gierczak M, Prażmowska-Czajka J, Dziedzic A. Thermoelectric Mixed Thick-/Thin Film Microgenerators Based on Constantan/Silver. Materials. 2018; 11(1):115. https://doi.org/10.3390/ma11010115

Chicago/Turabian StyleGierczak, Mirosław, Joanna Prażmowska-Czajka, and Andrzej Dziedzic. 2018. "Thermoelectric Mixed Thick-/Thin Film Microgenerators Based on Constantan/Silver" Materials 11, no. 1: 115. https://doi.org/10.3390/ma11010115