Perpendicular Magnetic Anisotropy in Heusler Alloy Films and Their Magnetoresistive Junctions

Abstract

:1. Introduction

2. Heusler-Alloy Junctions

2.1. Heusler Alloys

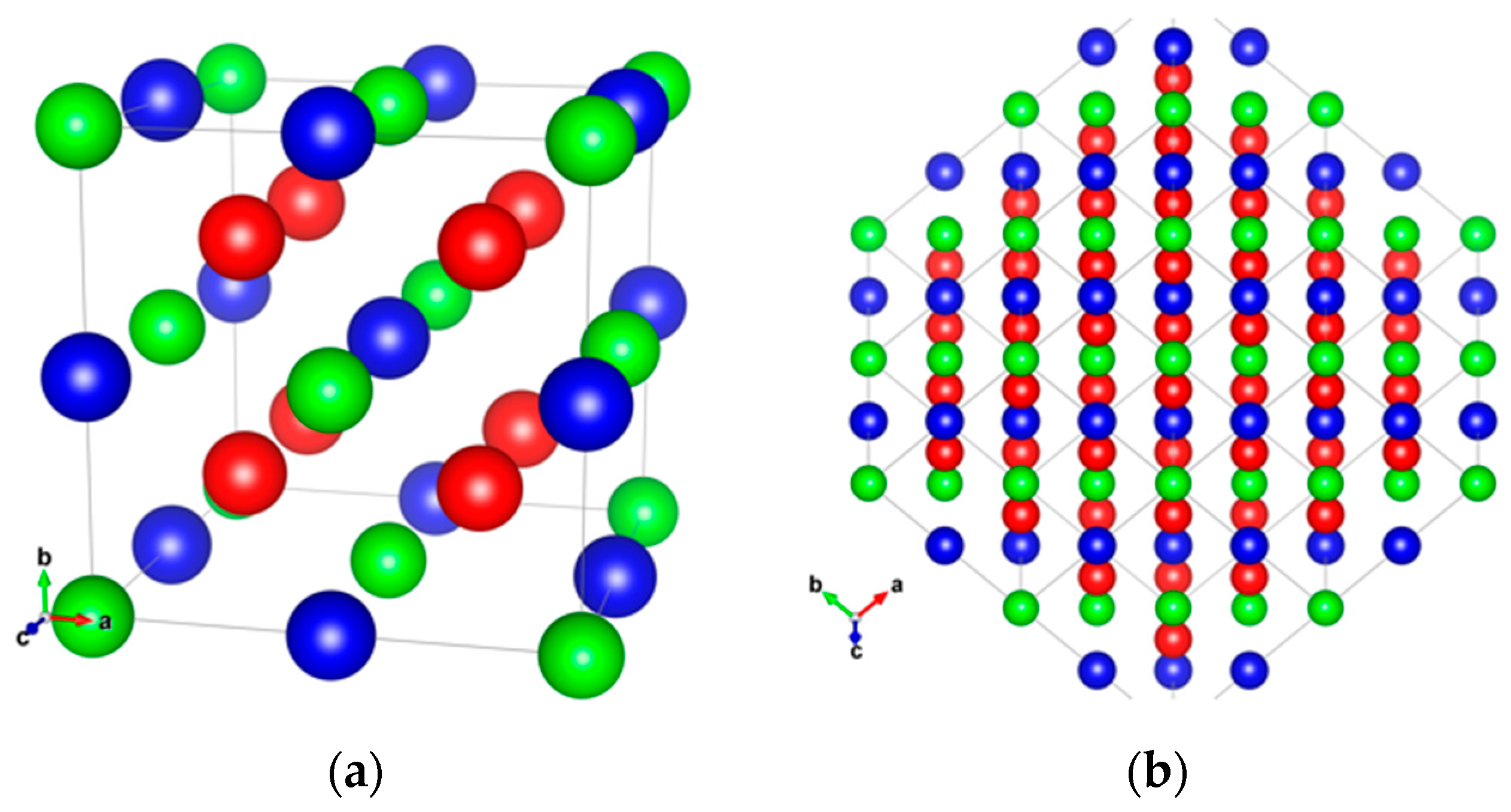

2.1.1. Crystalline Structures

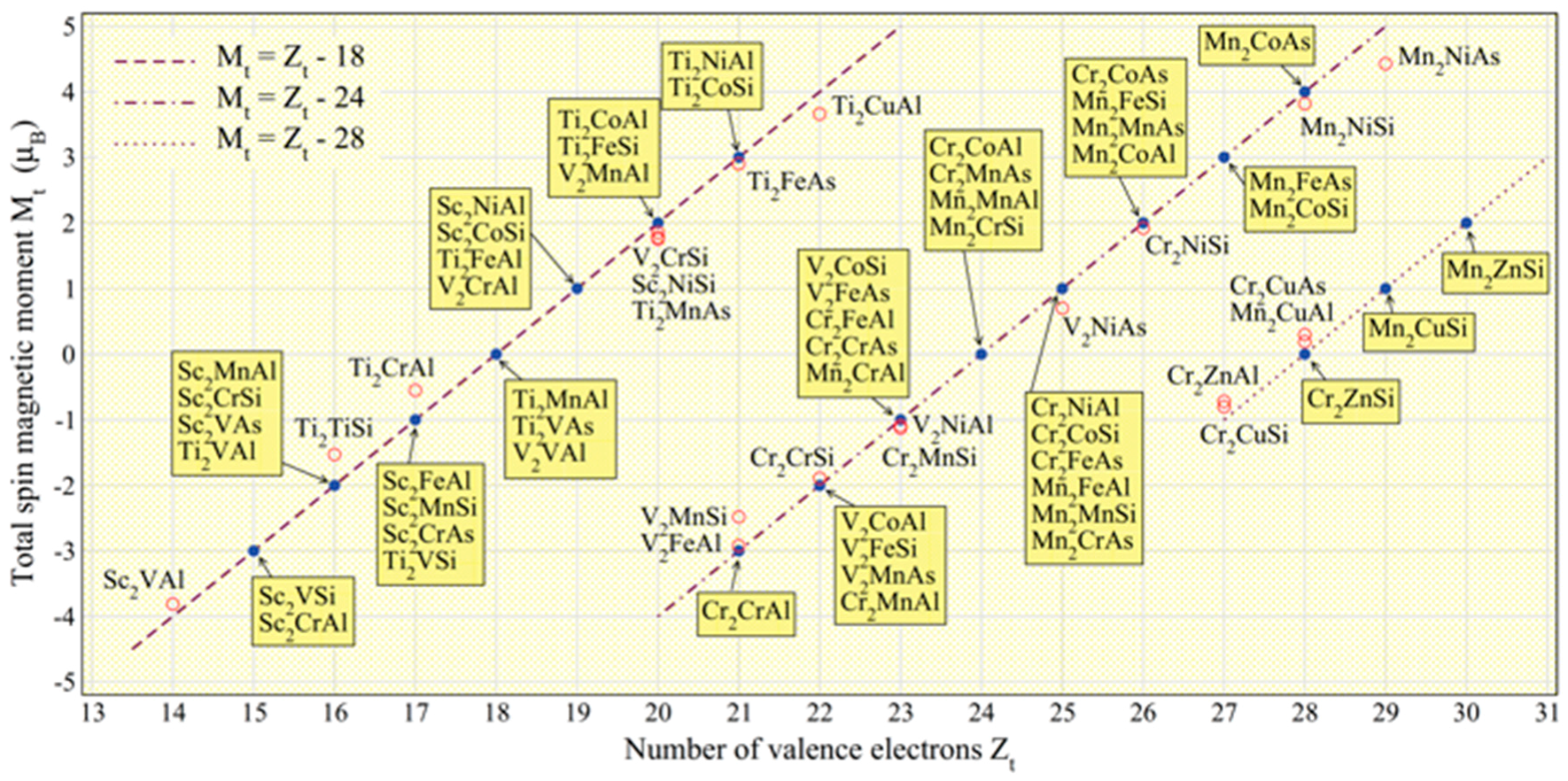

2.1.2. Magnetic Properties

2.2. Heusler Alloy Junctions with In-Plane Magnetic Anisotropy

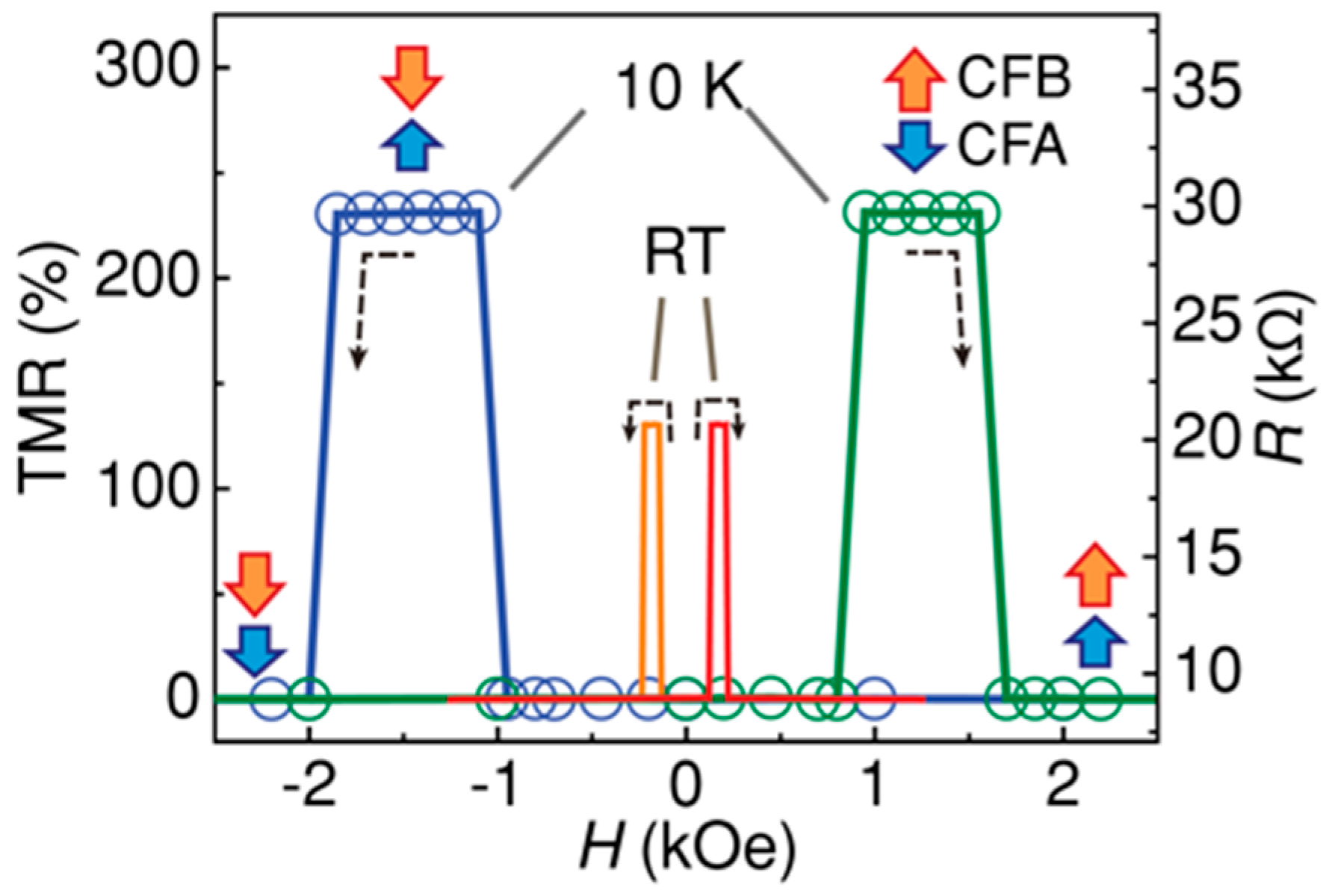

2.2.1. Tunnelling Magnetoresistive Junctions

2.2.2. Giant Magnetoresistive Junctions

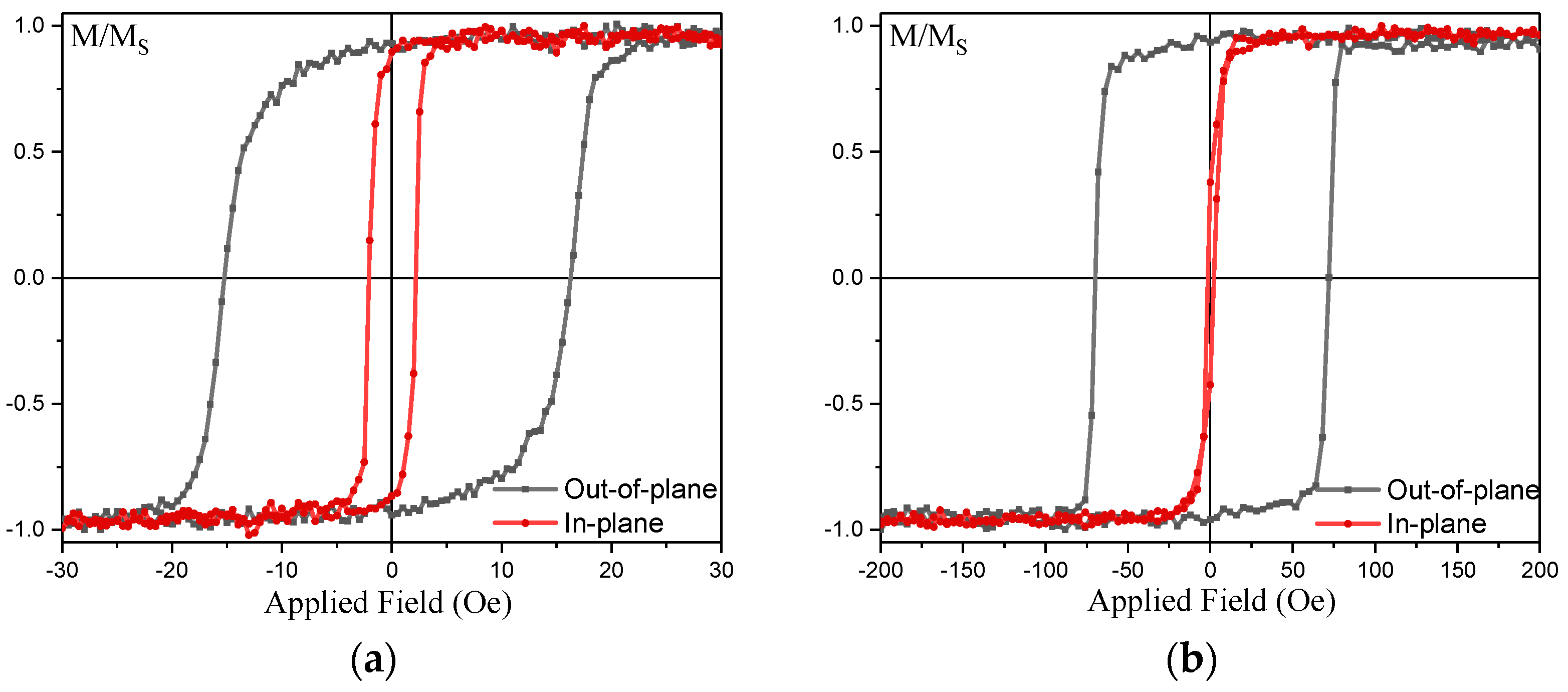

2.3. Heusler Alloy Junctions with Perpendicular Magnetic Anisotropy

2.3.1. Tunnelling Magnetoresistive Junctions

2.3.2. Giant Magnetoresistive Junctions

3. Towards Device Implementation

4. Materials and Methods

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Baibich, M.N.; Broto, J.M.; Fert, A.; Nguyen Van Dau, F.; Petroff, F.; Etienne, P.; Creuzet, G.; Friederich, A.; Chazelas, J. Giant magnetoresistance of (001)Fe/(001)Cr magnetic superlattices. Phys. Rev. Lett. 1988, 61, 2472–2475. [Google Scholar] [CrossRef] [PubMed]

- Binasch, G.; Grünberg, P.; Saurenbach, F.; Zinn, W. Enhanced magnetoresistance in layered magnetic structures with antiferromagnetic interlayer exchange. Phys. Rev. B 1989, 39, 4828(R)–4830(R). [Google Scholar] [CrossRef]

- Hirohata, A.; Takanashi, K. Future perspectives for spintronic devices. J. Phys. D Appl. Phys. 2014, 47, 193001. [Google Scholar] [CrossRef]

- Fullerton, E.E.; Schuller, I.K. The 2007 Nobel Prize in Physics: Magnetism and Transport at the Nanoscale. ACS Nano 2007, 1, 384–389. [Google Scholar] [CrossRef] [PubMed]

- Terris, B.D.; Thomson, T. Nanofabricated and self-assembled magnetic structures as data storage media. J. Phys. D Appl. Phys. 2005, 38, R199–R222. [Google Scholar] [CrossRef]

- Bhatti, S.; Sbiaa, R.; Hirohata, A.; Ohno, H.; Fukami, S.; Piramanayagam, S.N. Spintronics based random access memory: A review. Mater. Today 2017, 20, 530–548. [Google Scholar] [CrossRef]

- Parkin, S.S.P.; Li, Z.G.; Smith, D.J. Giant magnetoresistance in antiferromagnetic Co/Cu multilayers. Appl. Phys. Lett. 1991, 58, 2710–2712. [Google Scholar] [CrossRef]

- Jullière, M. Tunneling between ferromagnetic films. Phys. Lett. A 1975, 54, 225–226. [Google Scholar] [CrossRef]

- Miyazaki, T.; Tezuka, N. Giant magnetic tunneling effect in Fe/Al2O3/Fe junction. J. Magn. Magn. Mater. 1995, 139, L231–L234. [Google Scholar] [CrossRef]

- Moodera, J.S.; Kinder, L.R.; Wong, T.M.; Meservey, R. Large magnetoresistance at room temperature in ferromagnetic thin film tunnel junctions. Phys. Rev. Lett. 1995, 74, 3273–3276. [Google Scholar] [CrossRef] [PubMed]

- Wei, H.X.; Qin, Q.H.; Ma, M.; Sharif, R.; Han, X.F. 80% tunneling magnetoresistance at room temperature for thin Al–O barrier magnetic tunnel junction with CoFeB as free and reference layers. J. Appl. Phys. 2007, 101, 09B501. [Google Scholar] [CrossRef]

- Parkin, S.S.P.; Kaiser, C.; Panchkula, A.; Rice, P.M.; Hughes, B.; Samant, M.; Yang, S.-H. Giant tunnelling magnetoresistance at room temperature with MgO(100) tunnel barriers. Nat. Mater. 2004, 3, 862–867. [Google Scholar] [CrossRef] [PubMed]

- Yuasa, S.; Nagahama, T.; Fukushima, A.; Suzuki, Y.; Ando, K. Giant room-temperature magnetoresistance in single-crystal Fe/MgO/Fe magnetic tunnel junctions. Nat. Mater. 2004, 3, 868–871. [Google Scholar] [CrossRef] [PubMed]

- Butler, W.H.; Zhang, X.-G.; Schulthess, T.C.; MacLaren, J.M. Spin-dependent tunneling conductance of Fe|MgO|Fe sandwiches. Phys. Rev. B 2001, 63, 054416. [Google Scholar] [CrossRef]

- Mathon, J.; Umerski, A. Theory of tunneling magnetoresistance of an epitaxial Fe/MgO/Fe(001) junction. Phys. Rev. B 2001, 63, 220403(R). [Google Scholar] [CrossRef]

- Ikeda, S.; Hayakawa, J.; Ashizawa, Y.; Lee, Y.M.; Miura, K.; Hasegawa, H.; Tsunoda, M.; Matsukura, F.; Ohno, H. Tunnel magnetoresistance of 604% at 300 K by suppression of Ta diffusion in CoFeB/MgO/CoFeB pseudo-spin-valves annealed at high temperature. Appl. Phys. Lett. 2008, 93, 082508. [Google Scholar] [CrossRef]

- Rizal, C.; Fullerton, E.E. Perpendicular magnetic anisotropy and microstructure properties of nanoscale Co/Au multilayers. J. Phys. D Appl. Phys. 2017, 50, 355002. [Google Scholar] [CrossRef]

- Dieny, B.; Chshiev, M. Perpendicular magnetic anisotropy at transition metal/oxide interfaces and applications. Rev. Mod. Phys. 2017, 89, 025008. [Google Scholar] [CrossRef]

- Institute of Electrical and Electronics Engineers. Available online: http://www.ewh.ieee.org/r6/scv/mag/MtgSum/Meeting2012_05_Presentation.pdf (accessed on 20 August 2017).

- Schmidt, G.; Ferrand, D.; Molenkamp, L.W.; Filip, A.T.; van Wees, B.J. Fundamental obstacle for electrical spin injection from a ferromagnetic metal into a diffusive semiconductor. Phys. Rev. B 2000, 62, 4790(R)–4793(R). [Google Scholar] [CrossRef]

- Nagamine, Y.; Maehara, H.; Tsunekawa, K.; Djayaprawira, D.D.; Watanabe, N. Ultralow resistance-area product of 0.4 Ω(μm)2 and high magnetoresistance above 50% in CoFeB/MgO/CoFeB magnetic tunnel junctions. Appl. Phys. Lett. 2006, 89, 162507. [Google Scholar] [CrossRef]

- Ikeda, S.; Miura, K.; Yamamoto, H.; Mizunuma, K.; Gan, H.D.; Endo, M.; Kanai, S.; Hayakawa, J.; Matsukura, F.; Ohno, H. A perpendicular-anisotropy CoFeB–MgO magnetic tunnel junction. Nat. Mater. 2010, 9, 721–724. [Google Scholar] [CrossRef] [PubMed]

- Everspin. Available online: https://www.everspin.com/news/everspin-256mb-st-mram-perpendicular-mtj-sampling (accessed on 20 August 2017).

- Takagishi, M.; Yamada, K.; Iwasaki, H.; Fuke, H.N.; Hashimoto, S. Magnetoresistance ratio and resistance area design of CPP-MR film for 2–5 Tb/in2 read sensors. IEEE Trans. Magn. 2010, 46, 2086–2089. [Google Scholar] [CrossRef]

- Fuke, H.N.; Hashimoto, S.; Takagishi, M.; Iwasaki, H.; Kawasaki, S.; Miyake, K.; Sahashi, M. Magnetoresistance of FeCo nanocontacts with current-perpendicular-to-plane spin-valve structure. IEEE Trans. Magn. 2007, 43, 2848–2850. [Google Scholar] [CrossRef]

- Schwarz, K. CrO2 predicted as a half-metallic ferromagnet. J. Phys. F 1986, 16, L211–L215. [Google Scholar] [CrossRef]

- Yamase, A.; Shiratori, K. Band structure in the high temperature phase of Fe3O4. J. Phys. Soc. Jpn. 1984, 53, 312–317. [Google Scholar] [CrossRef]

- Okimoto, Y.; Katsufuji, T.; Ishikawa, T.; Urushibara, A.; Arima, T.; Tokura, Y. Anomalous variation of optical spectra with spin polarization in double-exchange ferromagnet: La1−xSrxMnO3. Phys. Rev. Lett. 1995, 75, 109–112. [Google Scholar] [CrossRef] [PubMed]

- Moodera, J.S.; Meservey, R.H. Spin-polarized tunneling. In Magnetoelectronics; Johnson, M., Ed.; Elsevier: Amsterdam, The Netherlands, 2004; pp. 163–204. ISBN 0-12-088487-9. [Google Scholar]

- Ohno, H. Ferromagnetic III–V semiconductors and their hetero-structures. In Semiconductor Spintronics and Quantum Computation; Awschalom, D.D., Loss, D., Samarth, N., Eds.; Springer: Berlin, Germany, 2002; pp. 1–30. ISBN 3-540-42176-9. [Google Scholar]

- Akinaga, H.; Manago, T.; Shirai, M. Material design of half-metallic Zinc-blende CrAs and the synthesis by molecular-beam epitaxy. Jpn. J. Appl. Phys. 2000, 39, L1118–L1120. [Google Scholar] [CrossRef]

- De Groot, R.A.; Mueller, F.M.; van Engen, P.G.; Buschow, K.H.J. New class of materials: Half-metallic ferromagnets. Phys. Rev. Lett. 1983, 50, 2024–2027. [Google Scholar] [CrossRef]

- Dietl, T.; Ohno, H.; Matsukura, F.; Cibert, J.; Ferrand, D. Zener model description of ferromagnetism in Zinc-Blende magnetic semiconductors. Science 2000, 287, 1019–1022. [Google Scholar] [CrossRef] [PubMed]

- Soulen, R.J., Jr.; Byers, J.M.; Osofsky, M.S.; Nadgorny, B.; Ambrose, T.; Cheng, S.F.; Broussard, C.T.; Tanaka, P.R.; Nowak, J.; Moodera, J.S.; et al. Measuring the spin polarization of a metal with a superconducting point contact. Science 1998, 282, 85–88. [Google Scholar] [CrossRef]

- Galanakis, I. Theory of Heusler and full-Heusler compounds. In Heusler Alloys; Felser, C., Hirohata, A., Eds.; Springer: Berlin, Germany, 2016; pp. 3–36. ISBN 978-3-319-21449-8. [Google Scholar]

- Hirohata, A.; Kikuchi, M.; Tezuka, N.; Inomata, K.; Claydon, J.S.; Xu, Y.B.; van der Laan, G. Heusler alloy/semiconductor hybrid structures. Curr. Opin. Solid State Mater. Sci. 2006, 10, 93–107. [Google Scholar] [CrossRef]

- Hirohata, A.; Sukegawa, H.; Yanagihara, H.; Žutić, I.; Seki, T.; Mizukami, S.; Swaminathan, R. Roadmap for emerging magnetic materials for spintronic device applications. IEEE Trans. Magn. 2015, 51, 0800511. [Google Scholar] [CrossRef]

- Heusler, F. Mangan-Aluminium-Kupferlegierungen. Verh. DPG 1903, 5, 219. [Google Scholar]

- Gutfleisch, O.; Gottschall, T.; Fries, M.; Benke, D.; Radulov, I.; Skokov, K.P.; Wende, H.; Gruner, M.; Acet, M.; Entel, P.; et al. Mastering hysteresis in magnetocaloric materials. Philos. Trans. R. Soc. A 2016, 85, 4358–4360. [Google Scholar] [CrossRef] [PubMed]

- Yu, G.-H.; Xu, Y.-L.; Liu, Z.-H.; Qiu, H.-M.; Zhu, Z.-Y.; Huang, X.-P.; Pan, L.-Q. Recent progress in Heusler-type magnetic shape memory alloys. Rare Met. 2015, 34, 527–539. [Google Scholar] [CrossRef]

- Hirohata, A.; Sagar, J.; Lari, L.; Fleet, L.R.; Lazarov, V.K. Heusler alloy films for spintronic devices. Appl. Phys. A 2013, 111, 423–430. [Google Scholar] [CrossRef]

- Sagar, J.; Fleet, L.R.; Walsh, M.; Lari, L.; Boyes, E.D.; Whear, O.; Huminiuc, T.; Vick, A.; Hirohata, A. Over 50% reduction in the formation energy of Co-based Heusler alloy films by two-dimensional crystallisation. Appl. Phys. Lett. 2014, 105, 032401. [Google Scholar] [CrossRef]

- Fleet, L.R.; Cheglakov, G.; Yoshida, K.; Lazarov, V.K.; Nakayama, T.; Hirohata, A. Layer-by-layer crystallization of Co2FeSi Heusler alloy thin films. J. Phys. D Appl. Phys. 2012, 45, 032001. [Google Scholar] [CrossRef]

- Alhuwaymel, T.F.; Abdullah, R.M.; Whear, O.; Huminiuc, T.; Carpenter, R.; El-Gomati, M.; Hirohata, A. New bandgap measurement technique for a half-metallic ferromagnet. IEEE Trans. Magn. 2014, 50, 2600504. [Google Scholar] [CrossRef]

- Skaftouros, S.; Özdoğan, K.; Şaşoğlu, E.; Galanais, I. Generalized Slater-Pauling rule for the inverse Heusler compounds. Phys. Rev. B 2013, 87, 024420. [Google Scholar] [CrossRef]

- Block, T.; Felser, C.; Jakob, G.; Ensling, J.; Mühling, B.; Gütlich, P.; Cava, R.J. Large negative magnetoresistance effects in Co2Cr0.6Fe0.4Al. J. Solid State Chem. 2003, 176, 646–651. [Google Scholar] [CrossRef]

- Inomata, K.; Okamura, S.; Goto, R.; Tezuka, N. Large tunneling magnetoresistance at room temperature using a Heusler alloy with the B2 structure. Jpn. J. Appl. Phys. 2004, 42, L419–L422. [Google Scholar] [CrossRef]

- Okamura, S.; Goto, R.; Sugimoto, S.; Tezuka, N.; Inomata, K. Structural, magnetic, and transport properties of full-Heusler alloy Co2(Cr1−xFex)Al thin films. J. Appl. Phys. 2004, 96, 6561–6564. [Google Scholar] [CrossRef]

- Marukame, T.; Kasahara, T.; Matsuda, K.-I.; Uemura, T.; Yamamoto, M. High tunnel magnetoresistance in epitaxial Co2Cr0.6Fe0.4Al/MgO/CoFe tunnel junctions. IEEE Trans. Magn. 2005, 41, 2603–2605. [Google Scholar] [CrossRef]

- Miura, Y.; Shirai, M.; Nagao, K. First-principles study on half-metallicity of disordered Co2(Cr1−xFex)Al. J. Appl. Phys. 2004, 95, 7225–7227. [Google Scholar] [CrossRef]

- Marukame, T.; Yamamoto, M. Tunnel magnetoresistance in fully epitaxial magnetic tunnel junctions with a full-Heusler alloy thin film of Co2Cr0.6Fe0.4Al and a MgO tunnel barrier. J. Appl. Phys. 2007, 101, 083906. [Google Scholar] [CrossRef]

- Miura, Y.; Nagao, K.; Shirai, M. Atomic disorder effects on half-metallicity of the full-Heusler alloys Co2(Cr1-xFex)Al: A first-principles study. Phys. Rev. B 2004, 69, 144413. [Google Scholar] [CrossRef]

- Block, T.; Carey, M.J.; Gurney, B.A.; Jepsen, O. Band-structure calculations of the half-metallic ferromagnetism and structural stability of full- and half-Heusler phases. Phys. Rev. B 2004, 70, 205114. [Google Scholar] [CrossRef]

- Hirohata, A.; Kurebayashi, H.; Okamura, S.; Kikuchi, M.; Masaki, T.; Nozaki, T.; Tezuka, N.; Inomata, K. Structural and magnetic properties of epitaxial L21-structured Co2(Cr,Fe)Al films grown on GaAs(001) substrates. J. Appl. Phys. 2005, 97, 103714. [Google Scholar] [CrossRef]

- Wang, W.; Sukegawa, H.; Shan, R.; Mitani, S.; Inomata, K. Giant tunneling magnetoresistance up to 330% at room temperature in sputter deposited Co2FeAl/MgO/CoFe magnetic tunnel junctions. Appl. Phys. Lett. 2009, 95, 182502. [Google Scholar] [CrossRef]

- Scheike, T.; Sukegawa, H.; Inomata, K.; Ohkubo, T.; Hono, K.; Mitani, S. Chemical ordering and large tunnel magnetoresistance in Co2FeAl/MgAl2O4/Co2FeAl(001) junctions. Appl. Phys. Exp. 2016, 9, 053004. [Google Scholar] [CrossRef]

- Tezuka, N.; Ikeda, N.; Sugimoto, S.; Inomata, K. 175% tunnel magnetoresistance at room temperature and high thermal stability using Co2FeAl0.5Si0.5 full-Heusler alloy electrodes. Appl. Phys. Lett. 2006, 89, 252508. [Google Scholar] [CrossRef]

- Tezuka, N.; Ikeda, N.; Mitsuhashi, F.; Sugimoto, S. Improved tunnel magnetoresistance of magnetic tunnel junctions with Heusler Co2FeAl0.5Si0.5 electrodes fabricated by molecular beam epitaxy. Appl. Phys. Lett. 2009, 94, 162504. [Google Scholar] [CrossRef]

- Hirohata, A.; Otani, Y. Heusler alloys: Experimental approach towards room-temperature half-metallicity. In Epitaxial Ferromagnetic Films and Spintronic Applications; Hirohata, A., Otani, Y., Eds.; Research Signpost: Kerala, India, 2009; pp. 224–225. ISBN 978-81-308-0319-7. [Google Scholar]

- Mavropoulos, P.; Ležaić, M.; Blügel, S. Half-metallic ferromagnets for magnetic tunnel junctions by ab initio calculations. Phys. Rev. B 2005, 72, 174428. [Google Scholar] [CrossRef]

- Ambrose, T.; Krebs, J.J.; Prinz, G.A. Epitaxial growth and magnetic properties of single-crystal Co2MnGe Heusler alloy films on GaAs(001). Appl. Phys. Lett. 2000, 76, 3280. [Google Scholar] [CrossRef]

- Kubota, H.; Nakata, J.; Oogane, M.; Ando, Y.; Sakuma, A.; Miyazaki, T. Large magnetoresistance in magnetic tunnel junctions using Co-Mn-Al full Heusler alloy. Jpn. J. Appl. Phys. 2004, 43, L984–L986. [Google Scholar] [CrossRef]

- Sakuraba, Y.; Nakata, J.; Oogane, M.; Kubota, H.; Ando, Y.; Sakuma, A.; Miyazaki, T. Fabrication of Co2MnAl Heusler alloy epitaxial film using Cr buffer layer. Jpn. J. Appl. Phys. 2005, 44, 6535–6537. [Google Scholar] [CrossRef]

- Geiersbach, U.; Bergmann, A.; Westerholt, K. Structural, magnetic and magnetotransport properties of thin films of the Heusler alloys Cu2MnAl, Co2MnSi, Co2MnGe and Co2MnSn. J. Magn. Magn. Mater. 2002, 240, 546–549. [Google Scholar] [CrossRef]

- Hashimoto, M.; Herfort, J.; Schönherr, H.-P.; Ploog, K.H. Epitaxial Heusler alloy Co2FeSi/GaAs(001) hybrid structures. Appl. Phys. Lett. 2005, 87, 102506. [Google Scholar] [CrossRef]

- Holmes, S.N.; Pepper, M. Magnetic and electrical properties of Co2MnGa grown on GaAs(001). Appl. Phys. Lett. 2002, 81, 1651–1653. [Google Scholar] [CrossRef]

- Singh, L.J.; Barber, Z.H.; Miyoshi, Y.; Branford, W.R.; Cohen, L.F. Structural and transport studies of stoichiometric and off-stoichiometric thin films of the full Heusler alloy Co2MnSi. J. Appl. Phys. 2004, 95, 7231–7233. [Google Scholar] [CrossRef]

- Wang, W.H.; Przybylski, M.; Kuch, W.; Chelaru, L.I.; Wang, J.; Lu, Y.F.; Barthel, J.; Meyerheim, H.L.; Kirschner, J. Magnetic properties and spin polarization of Co2MnSi Heusler alloy thin films epitaxially grown on GaAs(001). J. Phys. Rev. B 2005, 71, 144416. [Google Scholar] [CrossRef]

- Picozzi, S.; Continenza, A.; Freeman, A.J. Co2MnX (X = Si, Ge, Sn) Heusler compounds: An ab initio study of their structural, electronic, and magnetic properties at zero and elevated pressure. Phys. Rev. B 2002, 66, 094421. [Google Scholar] [CrossRef]

- Sakuraba, Y.; Nakata, J.; Oogane, M.; Kubota, H.; Ando, Y.; Sakuma, A.; Miyazaki, T. Huge Spin-polarization of L21-ordered Co2MnSi epitaxial Heusler alloy film. Jpn. J. Appl. Phys. 2005, 44, L1100–L1102. [Google Scholar] [CrossRef]

- Sakuraba, Y.; Nakata, J.; Oogane, M.; Ando, Y.; Kato, H.; Sakuma, A.; Miyazaki, T. Magnetic tunnel junctions using B2-ordered Co2MnAl Heusler alloy epitaxial electrode. Appl. Phys. Lett. 2006, 88, 022503. [Google Scholar] [CrossRef]

- Kämmerer, S.; Thomas, A.; Hütten, A.; Reiss, G. Co2MnSi Heusler alloy as magnetic electrodes in magnetic tunnel junctions. Appl. Phys. Lett. 2004, 85, 79–81. [Google Scholar] [CrossRef]

- Tsunegi, S.; Sakuraba, Y.; Oogane, M.; Takanashi, K.; Ando, Y. Large tunnel magnetoresistance in magnetic tunnel junctions using a Co2MnSi Heusler alloy electrode and a MgO barrier. Appl. Phys. Lett. 2008, 93, 112506. [Google Scholar] [CrossRef]

- Ishikawa, T.; Liu, H.; Taira, T.; Matsuda, K.; Uemura, T.; Yamamoto, M. Influence of film composition in Co2MnSi electrodes on tunnel magnetoresistance characteristics of Co2MnSi/MgO/Co2MnSi magnetic tunnel junctions. Appl. Phys. Lett. 2009, 95, 232512. [Google Scholar] [CrossRef]

- Liu, H.; Honda, Y.; Taira, T.; Matsuda, K.; Arita, M.; Uemura, T.; Yamamoto, M. Giant tunneling magnetoresistance in epitaxial Co2MnSi/MgO/Co2MnSi magnetic tunnel junctions by half-metallicity of Co2MnSi and coherent tunnelling. Appl. Phys. Lett. 2012, 101, 132418. [Google Scholar] [CrossRef]

- Hu, B.; Moges, K.; Honda, Y.; Liu, H.; Uemura, T.; Yamamoto, M.; Inoue, J.; Shirai, M. Temperature dependence of spin-dependent tunneling conductance of magnetic tunnel junctions with half-metallic Co2MnSi electrodes. Phys. Rev. B 2012, 94, 094428. [Google Scholar] [CrossRef]

- Liu, H.; Kawami, T.; Moges, K.; Uemura, T.; Yamamoto, M.; Shi, F.; Voyles, P.M. Influence of film composition in quaternary Heusler alloy Co2(Mn,Fe)Si thin films on tunnelling magnetoresistance of Co2(Mn,Fe)Si/MgO-based magnetic tunnel junctions. J. Phys. D Appl. Phys. 2015, 48, 164001. [Google Scholar] [CrossRef]

- Yamamoto, M.; Ishikawa, T.; Taira, T.; Li, G.; Matsuda, K.; Uemura, T. Effect of defects in Heusler alloy thin films on spin-dependent tunnelling characteristics of Co2MnSi/MgO/Co2MnSi and Co2MnGe/MgO/Co2MnGe magnetic tunnel junctions. J. Phys. Condens. Matter 2010, 22, 164212. [Google Scholar] [CrossRef] [PubMed]

- Palmstrøm, C. Epitaxial Heusler alloys: New materials for semiconductor spintronics. MRS Bull. 2003, 28, 725–728. [Google Scholar] [CrossRef]

- Dong, X.Y.; Dong, J.W.; Xie, J.Q.; Shih, T.C.; McKernan, S.; Leighton, C.; Palmstrøm, C. Growth temperature controlled magnetism in molecular beam epitaxially grown Ni2MnAl Heusler alloy. J. Cryst. Growth 2003, 254, 384–389. [Google Scholar] [CrossRef]

- Dong, J.W.; Chen, L.C.; Palmstrøm, C.J.; James, R.D.; McKernan, S. Molecular beam epitaxy growth of ferromagnetic single crystal (001) Ni2MnGa on (001) GaAs. Appl. Phys. Lett. 1999, 75, 1443–1445. [Google Scholar] [CrossRef]

- Dong, J.W.; Lu, J.; Xie, J.Q.; Chen, L.C.; James, R.D.; McKernan, S.; Palmstrøm, C.J. MBE growth of ferromagnetic single crystal Heusler alloys on (001)Ga1−xInxAs. Physica E 2001, 10, 428–432. [Google Scholar] [CrossRef]

- Dong, J.W.; Chen, L.C.; Xie, J.Q.; Müller, T.A.R.; Carr, D.M.; Palmstrøm, C.J. Epitaxial growth of ferromagnetic Ni2MnGa on GaAs(001) using NiGa interlayers. J. Appl. Phys. 2000, 88, 7357–7359. [Google Scholar] [CrossRef]

- Godlevsky, V.V.; Rabe, K.M. Soft tetragonal distortions in ferromagnetic Ni2MnGa and related materials from first principles. Phys. Rev. B 2001, 63, 134407. [Google Scholar] [CrossRef]

- Galanakis, I.; Mavropoulos, P.; Dederichs, P.H. Electronic structure and Slater-Pauling behaviour in half-metallic Heusler alloys calculated from first principles. J. Phys. D Appl. Phys. 2006, 39, 765–775. [Google Scholar] [CrossRef]

- Mavropoulos, P.; Galanakis, I.; Popescu, V.; Dederichs, P.H. The influence of spin-orbit coupling on the band gap of Heusler alloys. J. Phys. Condens. Matter 2004, 16, S5759–S5762. [Google Scholar] [CrossRef]

- Van Roy, W.; de Boeck, J.; Brijs, B.; Borghs, G. Epitaxial NiMnSb films on GaAs(001). Appl. Phys. Lett. 2000, 77, 4190–4192. [Google Scholar] [CrossRef]

- Tanaka, C.T.; Nowak, J.; Moodera, J.S. Magnetoresistance in ferromagnet-insulator-ferromagnet tunnel junctions with half-metallic ferromagnet NiMnSb compound. J. Appl. Phys. 1997, 86, 5515–5517. [Google Scholar] [CrossRef]

- Ambrose, T.; Krebs, J.J.; Prinz, G.A. Magnetotransport properties of single crystal Co2MnGe/NM/Co2MnGe trilayers epitaxially grown on GaAs (001). J. Appl. Phys. 2001, 89, 7522–7524. [Google Scholar] [CrossRef]

- Kelekar, R.; Clemens, B.M. Epitaxial growth of the Heusler alloy Co2Cr1−xFexAl. J. Appl. Phys. 2004, 96, 540–543. [Google Scholar] [CrossRef]

- Nakatani, T.M.; Furubayashi, T.; Kasai, S.; Sukegawa, H.; Takahashi, Y.K.; Mitani, S.; Hono, K. Bulk and interfacial scatterings in current-perpendicular-to-plane giant magnetoresistance with Co2FeAl0.5Si0.5 Heusler alloy layers and Ag spacer. Appl. Phys. Lett. 2010, 96, 212501. [Google Scholar] [CrossRef]

- Takahashi, Y.K.; Srinivasan, A.; Varaprasad, B.; Rajanikanth, A.; Hase, N.; Nakatani, T.M.; Kasai, S.; Furubayashi, T.; Hono, K. Large magnetoresistance in current-perpendicular-to-plane pseudospin valve using a Co2Fe(Ge0.5Ga0.5) Heusler alloy. Appl. Phys. Lett. 2011, 98, 152501. [Google Scholar] [CrossRef]

- Li, Y.; Xia, J.; Wang, G.; Yuan, H.; Chen, H. High-performance giant-magnetoresistance junction with B2-disordered Heusler alloy based Co2MnAl/Ag/Co2MnAl trilayer. J. Appl. Phys. 2015, 118, 053902. [Google Scholar] [CrossRef]

- Johnson, P.R.; Kautzky, M.C.; Mancoff, F.B.; Kondo, R.; Clemens, B.M.; White, R.L. Observation of giant magnetoresistance in a Heusler alloy spin valve. IEEE Trans. Magn. 1996, 32, 4615–4617. [Google Scholar] [CrossRef]

- Galanakis, I. Surface properties of the half-and full-Heusler alloys. J. Phys. Condens. Matter 2002, 14, 6329–6340. [Google Scholar] [CrossRef]

- Van Engen, P.G.; Buschow, K.H.J.; Jongebreur, R. PtMnSb, a material with very high magneto-optical Kerr effect. Appl. Phys. Lett. 1983, 42, 202–204. [Google Scholar] [CrossRef]

- Wen, Z.; Kubota, T.; Yamamoto, T.; Takanashi, K. Fully epitaxial C1b-type NiMnSb half-Heusler alloy films for current-perpendicular-to-plane giant magnetoresistance devices with a Ag spacer. Sci. Rep. 2015, 5, 18387. [Google Scholar] [CrossRef] [PubMed]

- Wen, Z.; Kubota, T.; Yamamoto, T.; Takanashi, K. Enhanced current-perpendicular-to-plane giant magnetoresistance effect in half-metallic NiMnSb based nanojunctions with multiple Ag spacers. Appl. Phys. Lett. 2016, 108, 232406. [Google Scholar] [CrossRef]

- Bang, H.-W.; Yoo, W.; Choi, Y.; You, C.-Y.; Hong, J.-I.; Dolinšek, J.; Jung, M.-H. Perpendicular magnetic anisotropy properties of tetragonal Mn3Ga films under various deposition conditions. Curr. Appl. Phys. 2016, 16, 63–67. [Google Scholar] [CrossRef]

- Winterlik, J.; Balke, B.; Fecher, G.H.; Felser, C.; Alves, M.C.M.; Bernardi, F.; Morais, J. Structural, electronic, and magnetic properties of tetragonal Mn3−xGa: Experiments and first-principles calculations. Phys. Rev. B 2008, 77, 054406. [Google Scholar] [CrossRef]

- Kubota, T.; Miura, Y.; Watanabe, D.; Mizukami, S.; Wu, F.; Naganuma, H.; Zhang, X.; Oogane, M.; Shirai, M.; Ando, Y. Magnetoresistance effect in tunnel junctions with perpendicularly magnetized D022-Mn3−δGa electrode and MgO barrier. Appl. Phys. Exp. 2011, 4, 043002. [Google Scholar] [CrossRef]

- Ma, Q.L.; Kubota, T.; Mizukami, S.; Zhang, X.M.; Naganuma, H.; Oogane, M.; Ando, Y.; Miyazaki, T. Magnetoresistance effect in L10-MnGa/MgO/CoFeB perpendicular magnetic tunnel junctions with Co interlayer. Appl. Phys. Lett. 2012, 101, 032402. [Google Scholar] [CrossRef]

- Suzuki, K.Z.; Ranjbar, R.; Okabayashi, J.; Miura, Y.; Sugihara, A.; Tsuchiura, H.; Mizukami, S. Perpendicular magnetic tunnel junction with a strained Mn-based nanolayer. Sci. Rep. 2016, 6, 30249. [Google Scholar] [CrossRef] [PubMed]

- Kurt, H.; Coey, J.M.D. Magnetic and electronic properties of thin films of Mn-Ga and Mn-Ge compounds with cubic, tetragonal and hexagonal crystal structures. In Heusler Alloys; Felser, C., Hirohata, A., Eds.; Springer: Berlin, Germany, 2016; pp. 3–36. ISBN 978-3-319-21449-8. [Google Scholar]

- Mao, S.; Lu, J.; Zhao, X.; Wang, X.; Wei, D.; Liu, J.; Xia, J.; Zhao, J. MnGa-based fully perpendicular magnetic tunnel junctions with ultrathin Co2MnSi interlayers. Sci. Rep. 2017, 7, 43064. [Google Scholar] [CrossRef] [PubMed]

- Wen, Z.; Sukegawa, H.; Kasai, S.; Hayashi, M.; Mitani, S.; Inomata, K. Magnetic tunnel junctions with perpendicular anisotropy using a Co2FeAl full-Heusler alloy. Appl. Phys. Exp. 2012, 5, 063003. [Google Scholar] [CrossRef]

- Wen, Z.; Sukegawa, H.; Furubayashi, T.; Koo, J.; Inomata, K.; Mitani, S.; Hadorn, J.P.; Ohkubo, T.; Hono, K. A 4-fold-symmetry hexagonal ruthenium for magnetic heterostructures exhibiting enhanced perpendicular magnetic anisotropy and tunnel magnetoresistance. Adv. Mater. 2014, 26, 6483–6490. [Google Scholar] [CrossRef] [PubMed]

- Hiratsuka, T.; Kim, G.; Sakuraba, Y.; Kubota, T.; Kodama, K.; Inami, N.; Naganuma, H.; Oogane, M.; Nakamura, T.; Takanashi, K.; et al. Fabrication of perpendicularly magnetized magnetic tunnel junctions with L10-CoPt/Co2MnSi hybrid electrode. J. Appl. Phys. 2010, 107, 09C714. [Google Scholar] [CrossRef]

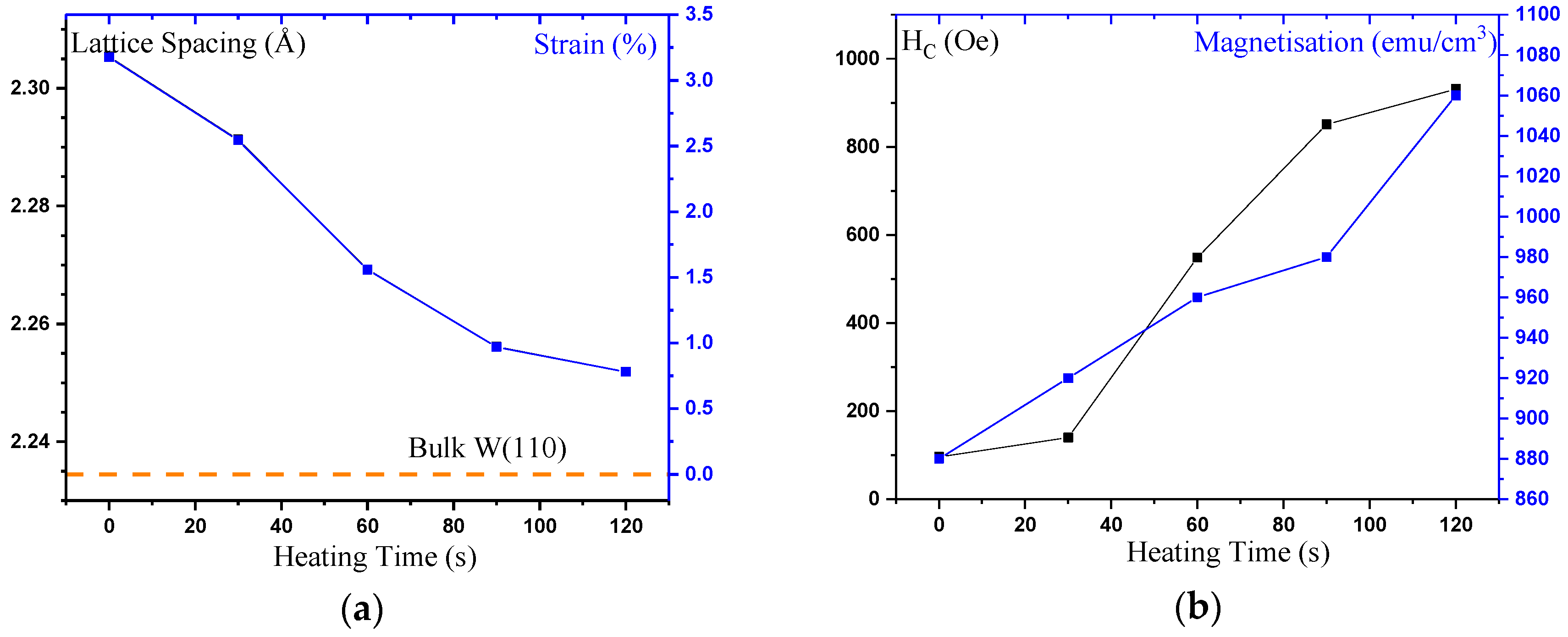

- Frost, W.; Hirohata, A. Perpendicular anisotropy in Heusler alloy layers induced by a V seed layer. IEEE Trans. Magn. 2016, 52, 4400604. [Google Scholar] [CrossRef]

- Serway, R.A. Principles of Physics, 2nd ed.; Broks Cole: Fort Worth, TX, USA, 1997; p. 602. ISBN 978-0030204579. [Google Scholar]

- Jung, W.D.; Schmidt, F.A.; Danielson, G.C. Thermal conductivity of high-purity vanadium. Phys. Rev. B 1977, 15, 659–665. [Google Scholar] [CrossRef]

- Frost, W.; Hirohata, A. Heusler alloys with perpendicular anisotropy induced by bcc tungsten seed layers. J. Magn. Magn. Mater. 2017. under review. [Google Scholar]

- Ono, A.; Suzuki, K.Z.; Ranjbar, R.; Sugihara, A.; Mizukami, S. Ultrathin films of polycrystalline MnGa alloy with perpendicular magnetic anisotropy. Appl. Phys. Exp. 2017, 10, 023005. [Google Scholar] [CrossRef]

- Cui, Y.; Khodadadi, B.; Schäfer, S.; Mewes, T.; Lu, J.; Wolf, S.A. Interfaceial perpendicular magnetic anisotropy and damping parameter in ultra thin Co2FeAl films. Appl. Phys. Lett. 2013, 102, 162403. [Google Scholar] [CrossRef]

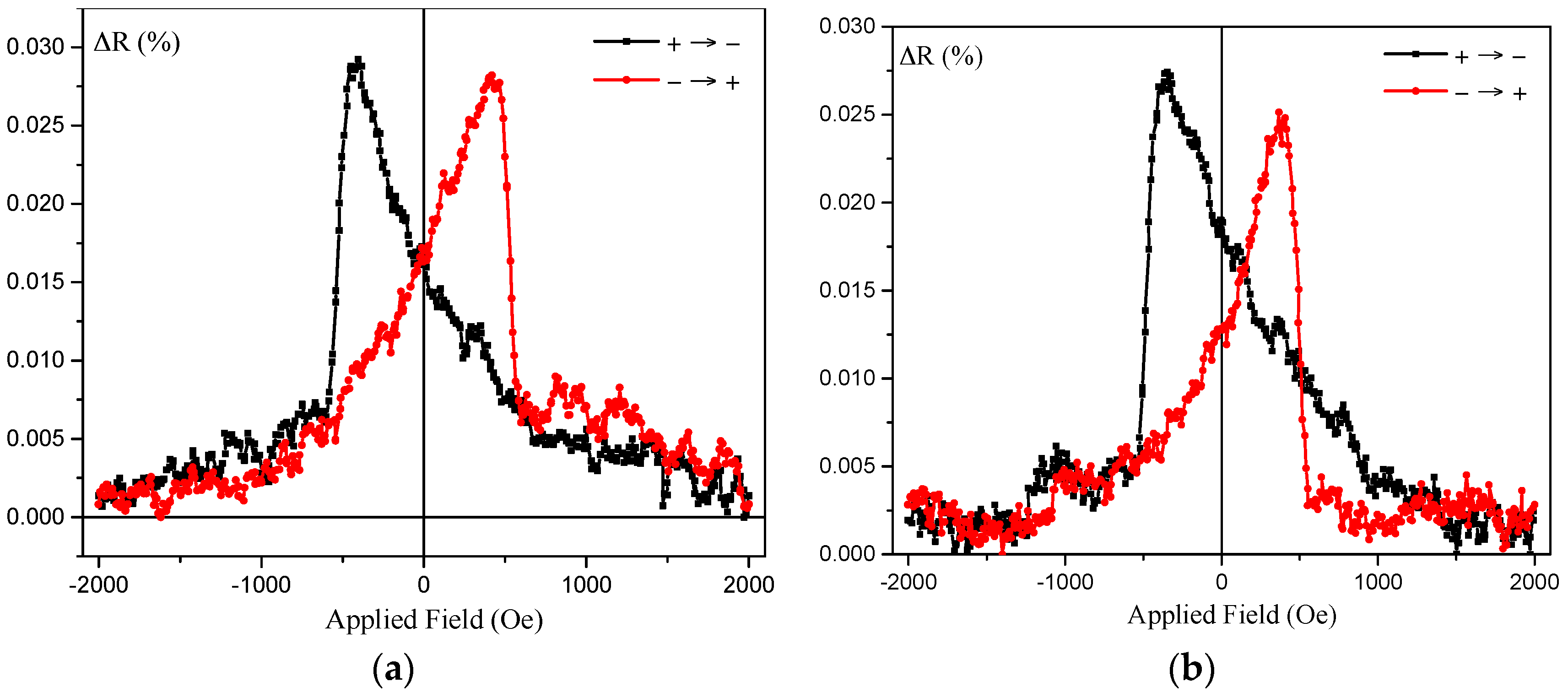

- Frost, W.; Hirohata, A. Heusler Alloys with bcc Tungsten Seed Layers for GMR Junctions. In Proceedings of the Conference on Magnetism and Magnetic Materials, New Orleans, LA, USA, 3 November 2016. [Google Scholar]

- Vopsaroiu, M.; Thwaites, M.J.; Rand, S.; Grundy, P.J.; O’Grady, K. Novel sputtering technology for grain-size control. IEEE Trans. Magn. 2004, 40, 2443–2445. [Google Scholar] [CrossRef]

- Worledge, D.C.; Trouilloud, P.L. Magnetoresistance measurement of unpatterned magnetic tunnel junction wafers by current-in-plane tunneling. Appl. Phys. Lett. 2003, 83, 84–86. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hirohata, A.; Frost, W.; Samiepour, M.; Kim, J.-y. Perpendicular Magnetic Anisotropy in Heusler Alloy Films and Their Magnetoresistive Junctions. Materials 2018, 11, 105. https://doi.org/10.3390/ma11010105

Hirohata A, Frost W, Samiepour M, Kim J-y. Perpendicular Magnetic Anisotropy in Heusler Alloy Films and Their Magnetoresistive Junctions. Materials. 2018; 11(1):105. https://doi.org/10.3390/ma11010105

Chicago/Turabian StyleHirohata, Atsufumi, William Frost, Marjan Samiepour, and Jun-young Kim. 2018. "Perpendicular Magnetic Anisotropy in Heusler Alloy Films and Their Magnetoresistive Junctions" Materials 11, no. 1: 105. https://doi.org/10.3390/ma11010105