Preparation of Desirable Porous Cell Structure Polylactide/Wood Flour Composite Foams Assisted by Chain Extender

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PLA/Wood Flour Composite Sheets

2.3. Batch Foaming of PLA/Wood Flour Composites

2.4. Fourier Transform Infrared (FTIR) Spectrometry

2.5. Rheological Properties

2.6. Crystallization Analysis

2.7. Crystal Structure Analysis Using X-ray Diffraction (XRD)

2.8. Foam Characterization

3. Results and Discussion

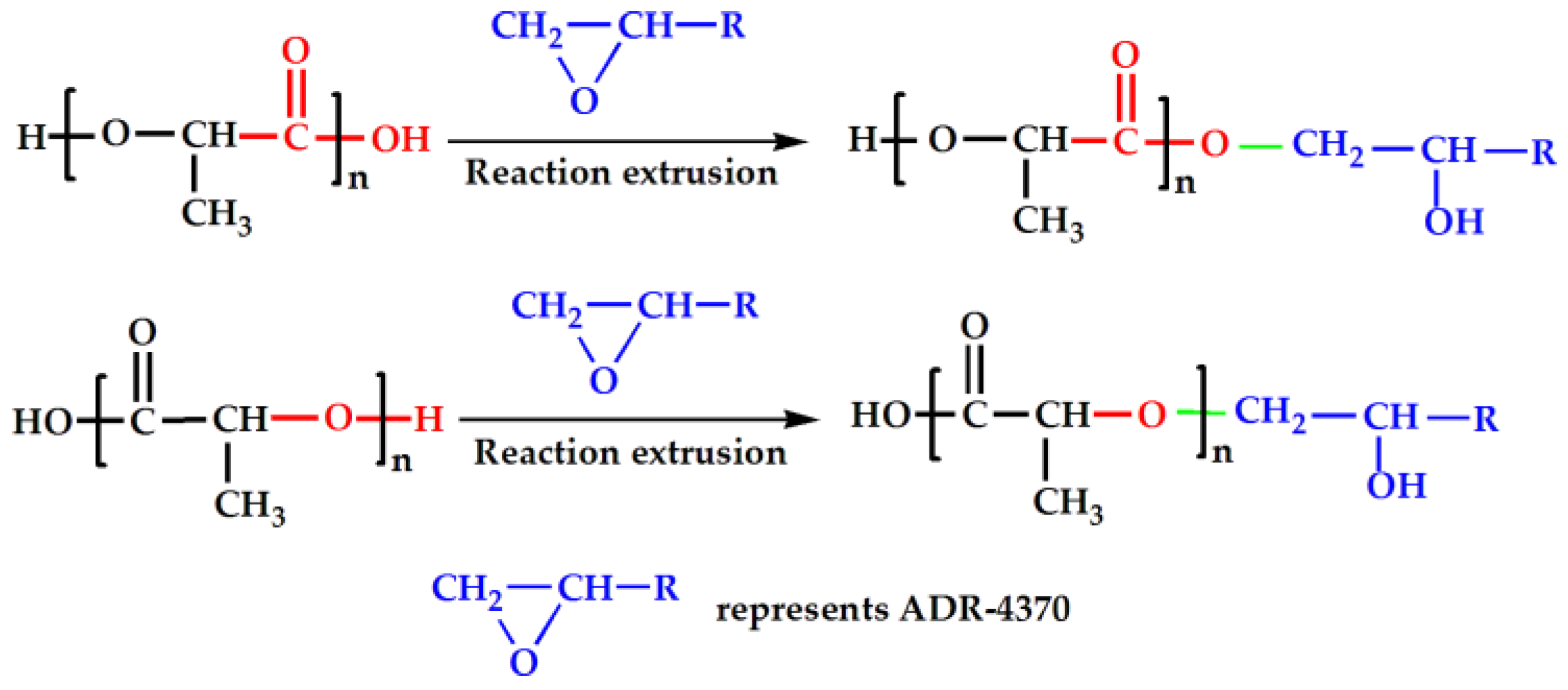

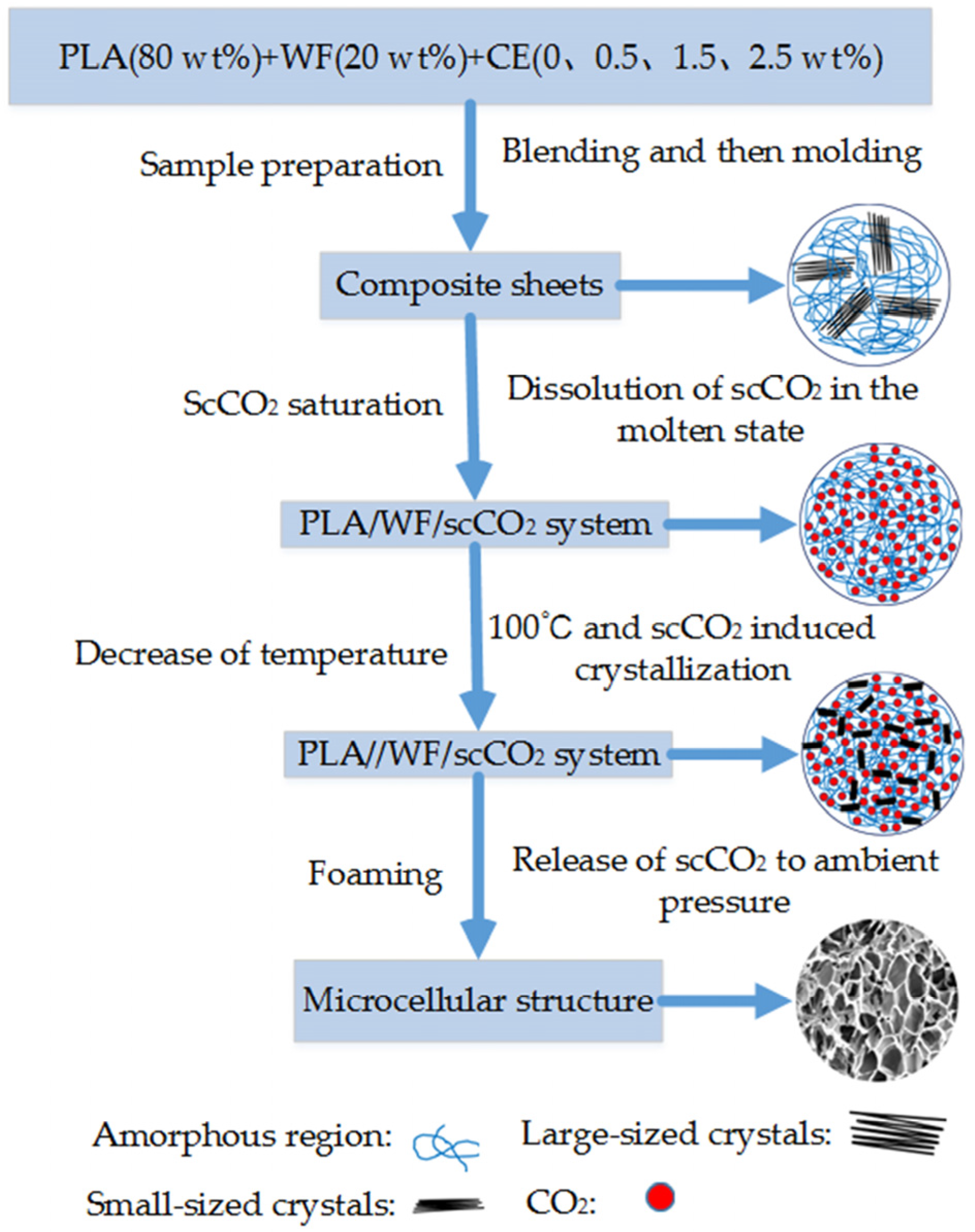

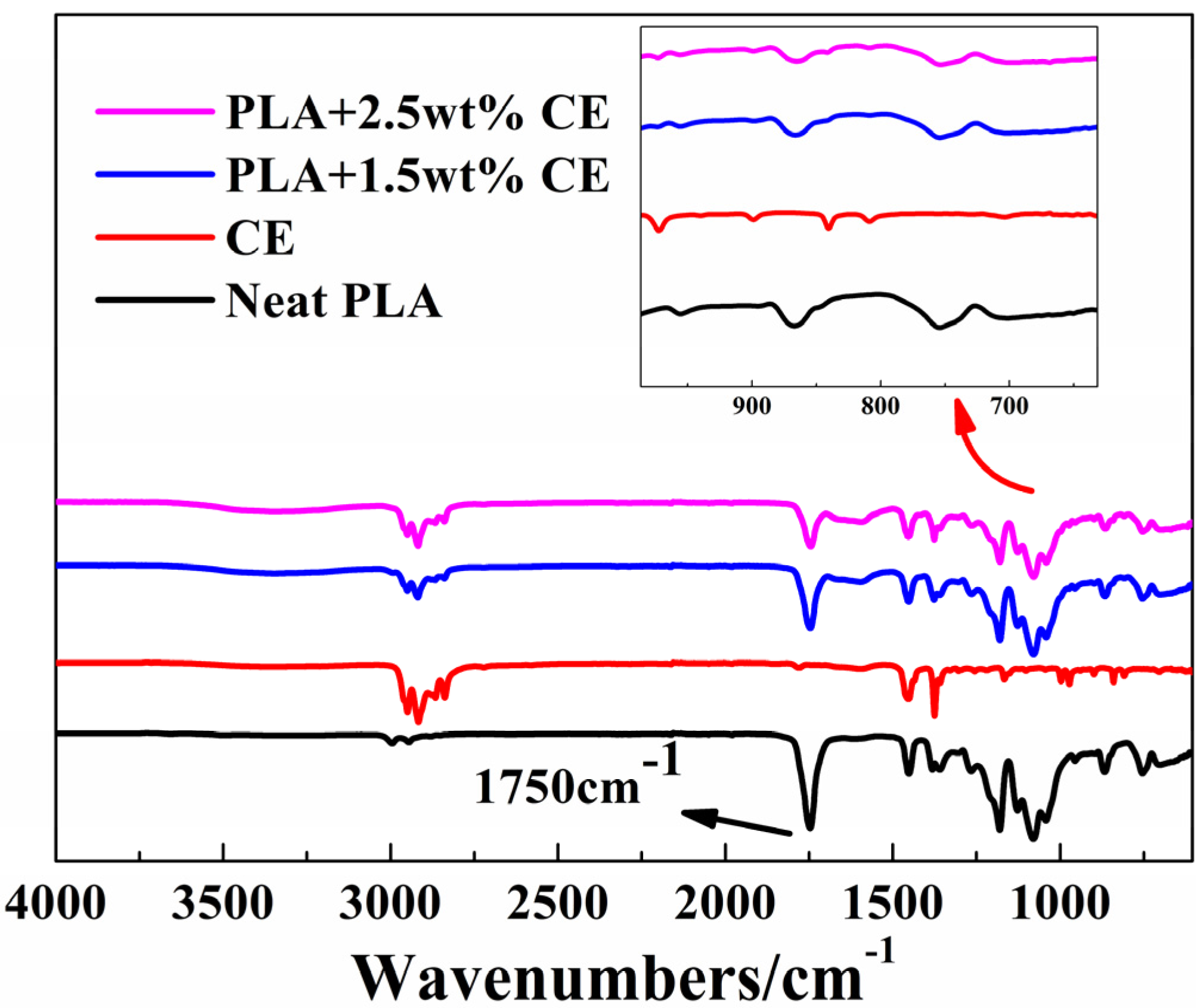

3.1. FTIR Analysis

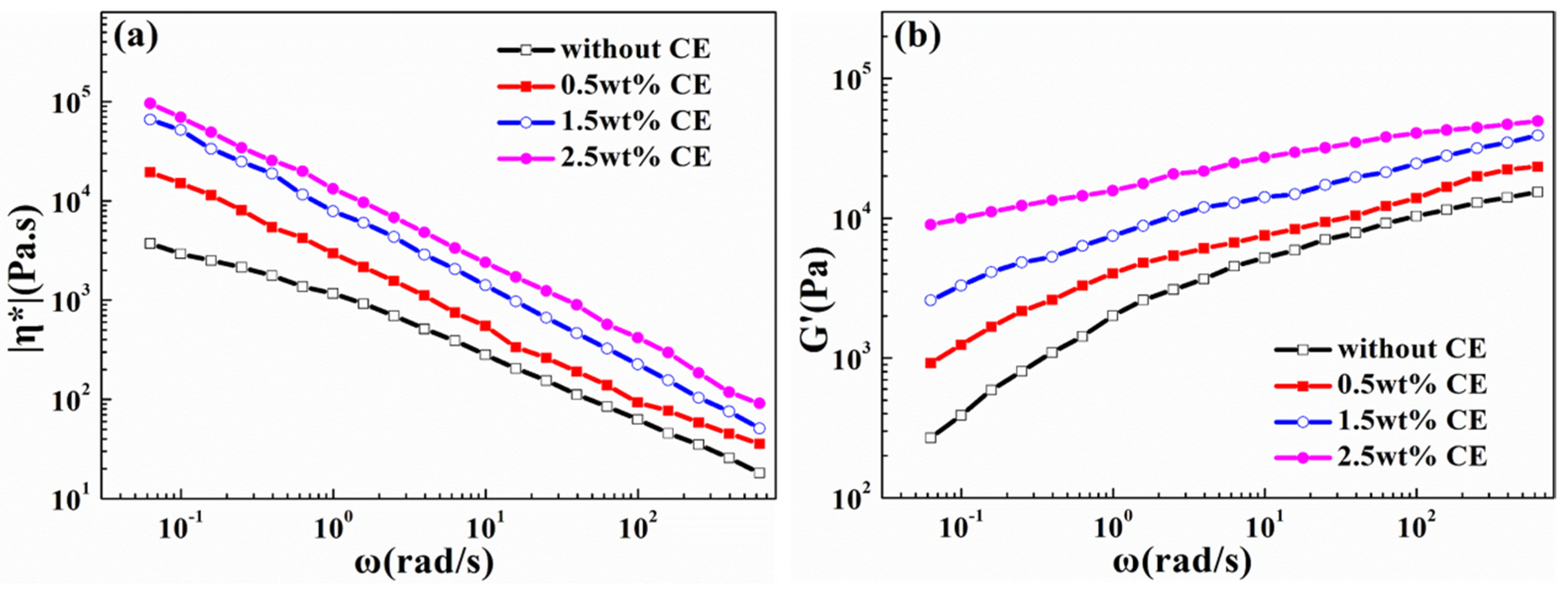

3.2. Rheological Properties

3.3. Crystallization Behavior

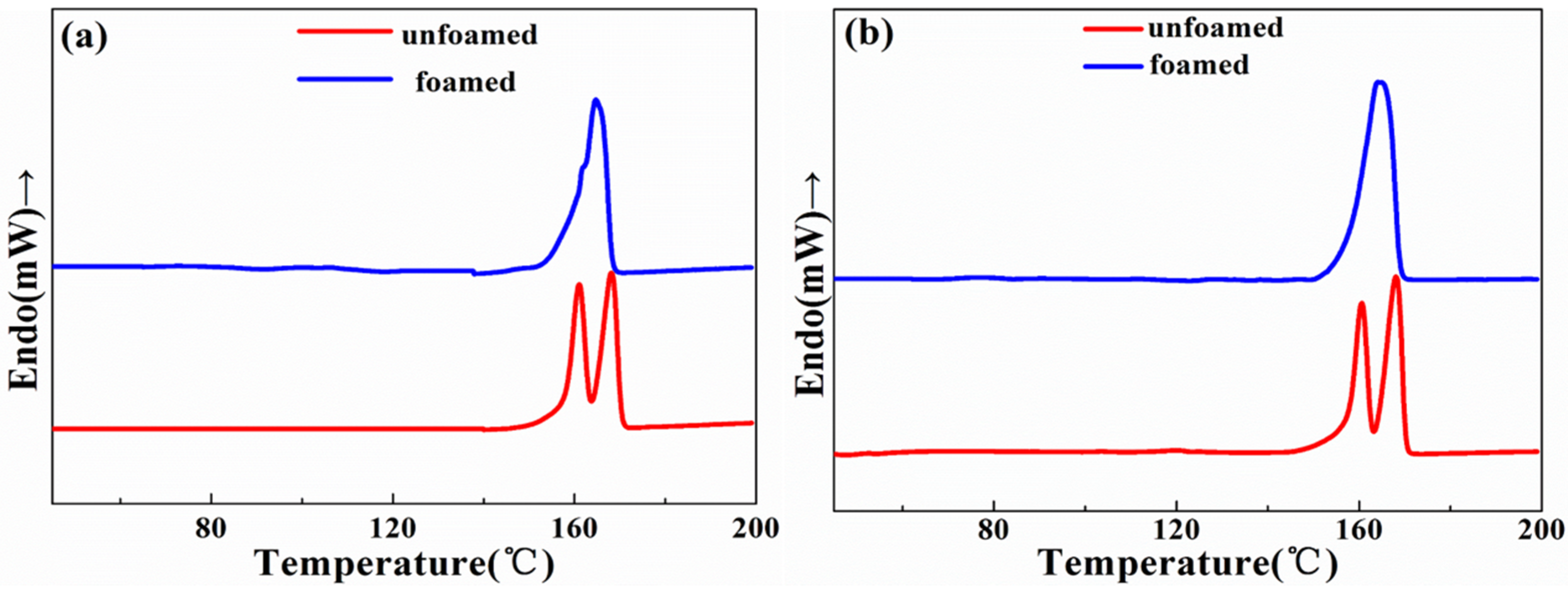

3.3.1. Effect of Foaming on Crystallinity

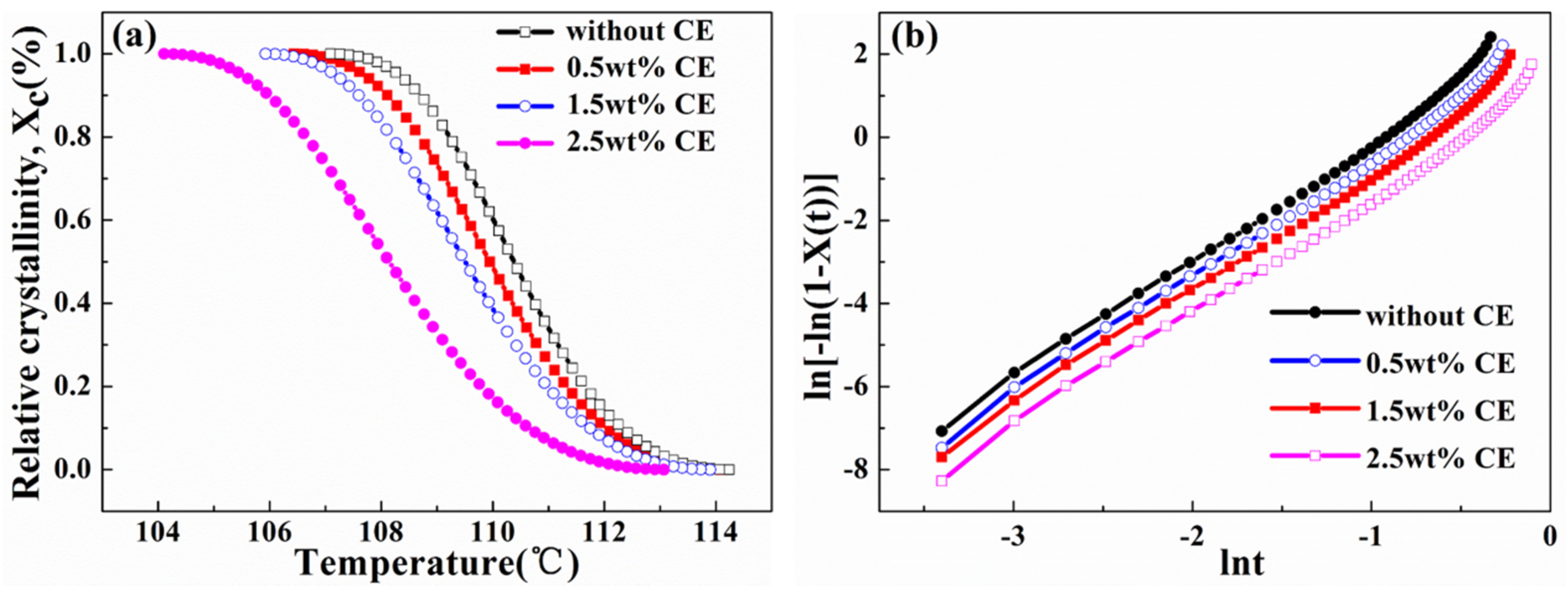

3.3.2. Non-Isothermal DSC Thermograms and Avrami Analysis

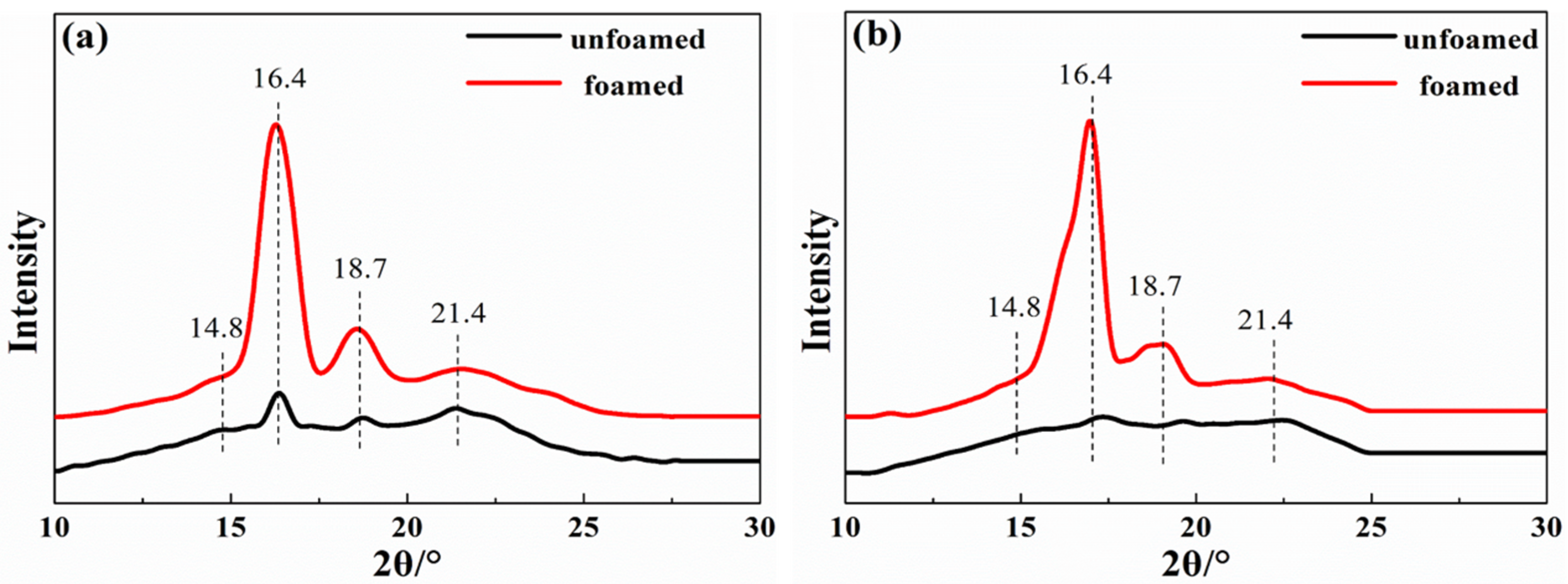

3.4. Crystal Structure Analysis Using XRD

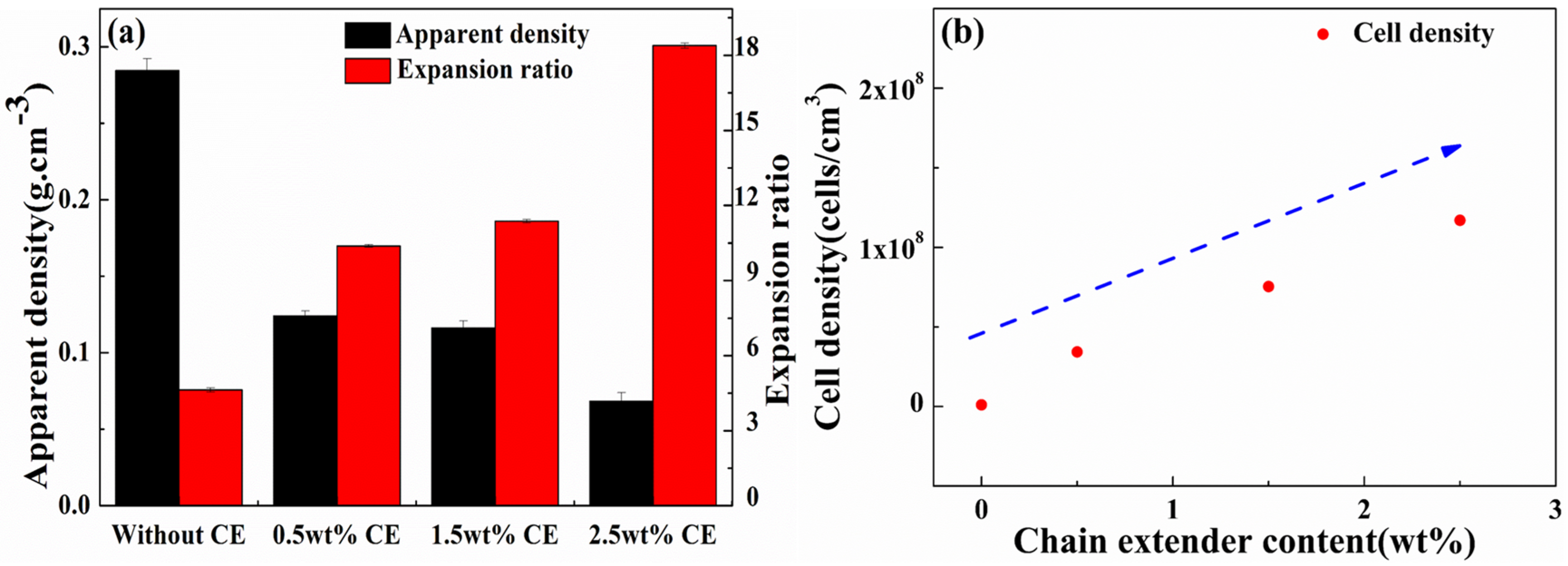

3.5. Apparent Density, Expansion Ratio and Cell Density

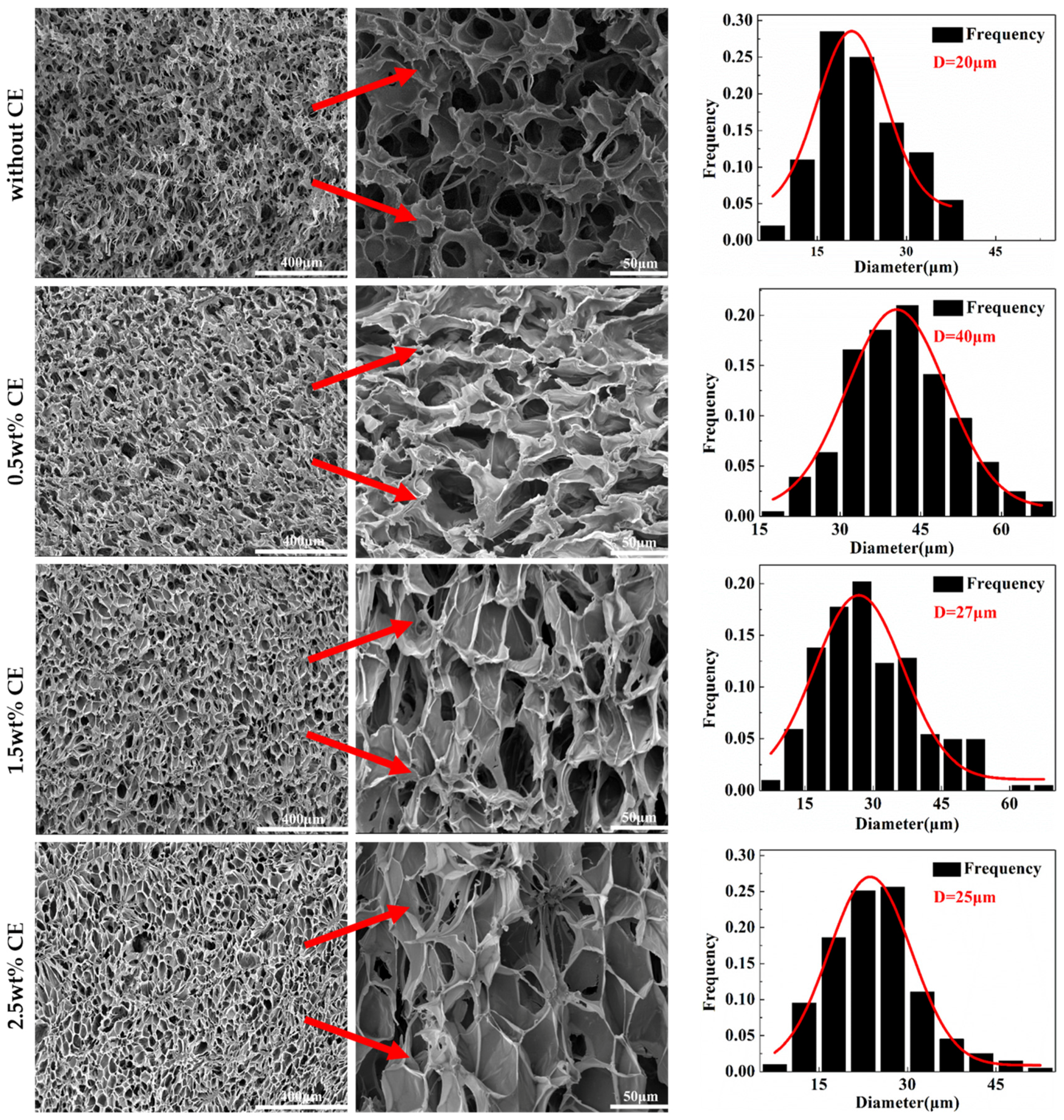

3.6. Cell Micrographs and Cell Size Distribution

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nofar, M.; Park, C.B. Poly (lactic acid) foaming. Prog. Polym. Sci. 2014, 39, 1721–1741. [Google Scholar] [CrossRef]

- Ventura, H.; Laguna-Gutiérrez, E.; Rodriguez-Perez, M.A.; Ardanuy, M. Effect of chain extender and water-quenching on the properties of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) foams for its production by extrusion foaming. Eur. Polym. J. 2016, 85, 14–25. [Google Scholar] [CrossRef]

- Feng, Z.; Luo, Y.; Hong, Y.; Wu, J.; Zhu, J.; Li, H. Preparation of Enhanced Poly (butylene succinate) Foams. Polym. Eng. Sci. 2016, 56, 1275–1282. [Google Scholar] [CrossRef]

- Gao, Z.; Zhan, W.; Wang, Y.; Guo, Y.; Wang, L.; Guo, Y. Aldehyde-functionalized mesostructured cellular foams prepared by copolymerization method for immobilization of penicillin G acylase. Microporous Mesoporous Mater. 2015, 202, 90–96. [Google Scholar] [CrossRef]

- Najafi, N.; Heuzey, M.-C.; Carreau, P.J.; Therriault, D.; Park, C.B. Mechanical and morphological properties of injection molded linear and branched-polylactide (PLA) nanocomposite foams. Eur. Polym. J. 2015, 73, 455–465. [Google Scholar] [CrossRef]

- Zhou, C.; Yang, K.; Wang, K.; Pei, X.; Dong, Z.; Hong, Y. Combination of fused deposition modeling and gas foaming technique to fabricated hierarchical macro/microporous polymer scaffolds. Mater. Des. 2016, 109, 415–424. [Google Scholar] [CrossRef]

- Kuang, T.; Chen, F.; Gong, X.; Peng, X. Facile preparation of open-cellular porous poly (l-lactic acid) scaffold by supercritical carbon dioxide foaming for potential tissue engineering applications. Chem. Eng. J. 2017, 307, 1017–1025. [Google Scholar] [CrossRef]

- Zhou, J.; Yao, Z.; Zhou, C.; Wei, D.; Li, S. Mechanical properties of PLA/PBS foamed composites reinforced by organophilic montmorillonite. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Ameli, A.; Nofar, M.; Jahani, D.; Rizvi, G.; Park, C.B. Development of high void fraction polylactide composite foams using injection molding: Crystallization and foaming behaviors. Chem. Eng. J. 2015, 262, 78–87. [Google Scholar] [CrossRef]

- Matuana, L.M.; Faruk, O.; Diaz, C.A. Cell morphology of extrusion foamed poly (lactic acid) using endothermic chemical foaming agent. Bioresour. Technol. 2009, 100, 5947–5954. [Google Scholar] [CrossRef] [PubMed]

- Nofar, M.; Ameli, A.; Park, C.B. A novel technology to manufacture biodegradable polylactide bead foam products. Mater. Des. 2015, 83, 413–421. [Google Scholar] [CrossRef]

- Shi, X.; Zhang, G.; Liu, Y.; Ma, Z.; Jing, Z.; Fan, X. Microcellular foaming of polylactide and poly (butylene adipate-co-terphathalate) blends and their CaCO3 reinforced nanocomposites using supercritical carbon dioxide. Polym. Adv. Technol. 2016, 27, 550–560. [Google Scholar] [CrossRef]

- Matuana, L.M. Solid state microcellular foamed poly (lactic acid): Morphology and property characterization. Bioresour. Technol. 2008, 99, 3643–3650. [Google Scholar] [CrossRef] [PubMed]

- Nofar, M.; Ameli, A.; Park, C.B. Development of polylactide bead foams with double crystal melting peaks. Polymer 2015, 69, 83–94. [Google Scholar] [CrossRef]

- Martini, J.E.; Waldman, F.A.; Suh, N.P. The production and analysis of microcellular thermoplastic foams. SPE ANTEC Tech. Pap. 1982, 43, 674–676. [Google Scholar]

- Doroudiani, S.; Park, C.B.; Kortschot, M.T. Processing and characterization of microcellular foamed high density polyethylene/isotactic polypropylene blends. Polym. Eng. Sci. 1998, 38, 1205–1215. [Google Scholar] [CrossRef]

- Auras, R.; Harte, B.; Selke, S. An overview of polylactides as packaging materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef] [PubMed]

- Blaker, J.J.; Nazhat, S.N.; Maquet, V.; Boccaccini, A.R. Long-term in vitro degradation of PDLLA/bioglass bone scaffolds in acellular simulated body fluid. Acta Biomater. 2011, 7, 829–840. [Google Scholar] [CrossRef] [PubMed]

- Pandey, A.; Aswath, P. Indentation creep reservoirs for drug-eluting poly (l-lactic acid) scaffolds. J. Biomater. Sci. Polym. Ed. 2011, 22, 1591–1606. [Google Scholar] [CrossRef] [PubMed]

- Sanz-Herrera, J.A.; Boccaccini, A.R. Modelling bioactivity and degradation of bioactive glass based tissue engineering scaffolds. Int. J. Solids Struct. 2011, 48, 257–268. [Google Scholar] [CrossRef]

- Tajbakhsh, S.; Hajiali, F. A comprehensive study on the fabrication and properties of biocomposites of poly (lactic acid)/ceramics for bone tissue engineering. Mater. Sci. Eng. C Mater. Biol. Appl. 2017, 70, 897–912. [Google Scholar] [CrossRef] [PubMed]

- Lee, R.E.; Guo, Y.; Tamber, H.; Planeta, M.; Leung, S.N.S. Thermoforming of Polylactic Acid Foam Sheets: Crystallization Behaviors and Thermal Stability. Ind. Eng. Chem. Res. 2016, 55, 560–567. [Google Scholar] [CrossRef]

- Zhou, M.; Zhou, P.; Xiong, P.; Qian, X.; Zheng, H. Crystallization, rheology and foam morphology of branched PLA prepared by novel type of chain extender. Macromol. Res. 2015, 23, 231–236. [Google Scholar] [CrossRef]

- Pilla, S.; Kramschuster, A.; Yang, L.; Lee, J.; Gong, S.; Turng, L.-S. Microcellular injection-molding of polylactide with chain-extender. Mater. Sci. Eng. C 2009, 29, 1258–1265. [Google Scholar] [CrossRef]

- Khanna, Y.P.; Kuhn, W.P. Measurement of crystalline index in nylons by DSC: Complexities and recommendations. J. Polym. Sci. Part B Polym. Phys. 1997, 35, 2219–2231. [Google Scholar] [CrossRef]

- Mihai, M.; Huneault, M.A.; Favis, B.D. Rheology and extrusion foaming of chain-branched poly (lactic acid). Polym. Eng. Sci. 2010, 50, 629–642. [Google Scholar] [CrossRef]

- Ludwiczak, J.; Kozlowski, M. Foaming of Polylactide in the Presence of Chain Extender. J. Polym. Environ. 2014, 23, 137–142. [Google Scholar] [CrossRef]

- Nofar, M.; Zhu, W.; Park, C.B. Effect of dissolved CO2 on the crystallization behavior of linear and branched PLA. Polymer 2012, 53, 3341–3353. [Google Scholar] [CrossRef]

- Saeidlou, S.; Huneault, M.A.; Li, H.; Park, C.B. Poly (lactic acid) crystallization. Prog. Polym. Sci. 2012, 37, 1657–1677. [Google Scholar] [CrossRef]

- Nofar, M.; Zhu, W.; Park, C.B.; Randall, J. Crystallization Kinetics of Linear and Long-Chain-Branched Polylactide. Ind. Eng. Chem. Res. 2011, 50, 13789–13798. [Google Scholar] [CrossRef]

- Nofar, M.; Tabatabaei, A.; Ameli, A.; Park, C.B. Comparison of melting and crystallization behaviors of polylactide under high-pressure CO2, N2, and He. Polymer 2013, 54, 6471–6478. [Google Scholar] [CrossRef]

- Sarikhani, K.; Nasseri, R.; Lotocki, V.; Thompson, R.B.; Park, C.B.; Chen, P. Effect of well-dispersed surface-modified silica nanoparticles on crystallization behavior of poly (lactic acid) under compressed carbon dioxide. Polymer 2016, 98, 100–109. [Google Scholar] [CrossRef]

- Chen, J.-W.; Liu, J.-L. Batch-foamed biodegradable polylactide acid/organic modified montmorillonite clays and polylactide/sericite powder nanocomposites. J. Polym. Eng. 2012, 32. [Google Scholar] [CrossRef]

- Nofar, M. Effects of nano-/micro-sized additives and the corresponding induced crystallinity on the extrusion foaming behavior of PLA using supercritical CO2. Mater. Des. 2016, 101, 24–34. [Google Scholar] [CrossRef]

- Kuang, T.; Chang, L.; Chen, F.; Sheng, Y.; Fu, D.; Peng, X. Facile preparation of lightweight high-strength biodegradable polymer/multi-walled carbon nanotubes nanocomposite foams for electromagnetic interference shielding. Carbon 2016, 105, 305–313. [Google Scholar] [CrossRef]

- Ding, W.; Jahani, D.; Chang, E.; Alemdar, A.; Park, C.B.; Sain, M. Development of PLA/cellulosic fiber composite foams using injection molding: Crystallization and foaming behaviors. Compos. Part A Appl. Sci. Manuf. 2016, 83, 130–139. [Google Scholar] [CrossRef]

- Matuana, L.M.; Faruk, O. Effect of gas saturation conditions on the expansion ratio of microcellular poly (lactic acid)/wood-flour composites. Express Polym. Lett. 2010, 4, 621–631. [Google Scholar] [CrossRef]

- Bocz, K.; Tabi, T.; Vadas, D.; Sauceau, M.; Fages, J.; Marosi, G. Characterisation of natural fibre reinforced PLA foams prepared by supercritical CO2 assisted extrusion. Express Polym. Lett. 2016, 10, 771–779. [Google Scholar] [CrossRef]

- Nassiopoulos, E.; Njuguna, J. Thermo-mechanical performance of poly (lactic acid)/flax fibre-reinforced biocomposites. Mater. Des. 2015, 66, 473–485. [Google Scholar] [CrossRef]

- Herrera, N.; Mathew, A.P.; Oksman, K. Plasticized polylactic acid/cellulose nanocomposites prepared using melt-extrusion and liquid feeding: Mechanical, thermal and optical properties. Compos. Sci. Technol. 2015, 106, 149–155. [Google Scholar] [CrossRef]

- Li, S.; He, G.; Liao, X.; Park, C.B.; Yang, Q.; Li, G. Introduction of a long-chain branching structure by ultraviolet-induced reactive extrusion to improve cell morphology and processing properties of polylactide foam. RSC Adv. 2017, 7, 6266–6277. [Google Scholar] [CrossRef]

- Villalobos, M.; Awojulu, A.; Greeley, T.; Turco, G.; Deeter, G. Oligomeric chain extenders for economic reprocessing and recycling of condensation plastics. Energy 2006, 31, 3227–3234. [Google Scholar] [CrossRef]

- Julien, J.M.; Quantin, J.C.; Bénézet, J.C.; Bergeret, A.; Lacrampe, M.F.; Krawczak, P. Chemical foaming extrusion of poly (lactic acid) with chain-extenders: Physical and morphological characterizations. Eur. Polym. J. 2015, 67, 40–49. [Google Scholar] [CrossRef]

- Di, Y.; Iannace, S.; Di Maio, E.; Nicolais, L. Reactively modified poly (lactic acid): Properties and foam processing. Macromol. Mater. Eng. 2005, 290, 1083–1090. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, W.; Zhang, H.; Park, C.B. Continuous processing of low-density, microcellular poly (lactic acid) foams with controlled cell morphology and crystallinity. Chem. Eng. Sci. 2012, 75, 390–399. [Google Scholar] [CrossRef]

- Arruda, L.C.; Magaton, M.; Bretas, R.E.S.; Ueki, M.M. Influence of chain extender on mechanical, thermal and morphological properties of blown films of PLA/PBAT blends. Polym. Test. 2015, 43, 27–37. [Google Scholar] [CrossRef]

- Rizvi, A.; Park, C.B. Dispersed polypropylene fibrils improve the foaming ability of a polyethylene matrix. Polymer 2014, 55, 4199–4205. [Google Scholar] [CrossRef]

- Xu, T.; Tang, Z.; Zhu, J. Synthesis of polylactide-graft-glycidyl methacrylate graft copolymer and its application as a coupling agent in polylactide/bamboo flour biocomposites. J. Appl. Polym. Sci. 2012, 125, E622–E627. [Google Scholar] [CrossRef]

- Rathi, S.; Coughlin, E.; Hsu, S.; Golub, C.; Ling, G.; Tzivanis, M. Maintaining Structural Stability of Poly (lactic acid): Effects of Multifunctional Epoxy based Reactive Oligomers. Polymers 2014, 6, 1232–1250. [Google Scholar] [CrossRef]

- Corre, Y.M.; Maazouz, A.; Duchet, J.; Reignier, J. Batch foaming of chain extended PLA with supercritical CO2: Influence of the rheological properties and the process parameters on the cellular structure. J. Supercrit. Fluids 2011, 58, 177–188. [Google Scholar] [CrossRef]

- Li, D.-C.; Liu, T.; Zhao, L.; Lian, X.-S.; Yuan, W.-K. Foaming of Poly (lactic acid) Based on Its Nonisothermal Crystallization Behavior under Compressed Carbon Dioxide. Ind. Eng. Chem. Res. 2011, 50, 1997–2007. [Google Scholar] [CrossRef]

| Samples | TL/(°C) | TH/(°C) | XC/(%) | |

|---|---|---|---|---|

| Without CE | unfoamed | 160.9 | 168.1 | 40.65 |

| foamed | — | 164.8 | 41.07 | |

| 2.5 wt % CE | unfoamed | 160.6 | 168.1 | 36.20 |

| foamed | — | 164.1 | 46.74 | |

| Samples | t1/2 (min) | G (min−1) | n | lnk | k |

|---|---|---|---|---|---|

| Without CE | 0.38 | 2.63 | 2.93 | 2.44 | 11.45 |

| 0.5 wt % CE | 0.41 | 2.43 | 2.90 | 2.22 | 9.16 |

| 1.5 wt % CE | 0.43 | 2.33 | 2.87 | 2.03 | 7.61 |

| 2.5 wt % CE | 0.48 | 2.08 | 2.84 | 1.70 | 5.45 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Song, Y.; Du, J.; Xi, Z.; Wang, Q. Preparation of Desirable Porous Cell Structure Polylactide/Wood Flour Composite Foams Assisted by Chain Extender. Materials 2017, 10, 999. https://doi.org/10.3390/ma10090999

Wang Y, Song Y, Du J, Xi Z, Wang Q. Preparation of Desirable Porous Cell Structure Polylactide/Wood Flour Composite Foams Assisted by Chain Extender. Materials. 2017; 10(9):999. https://doi.org/10.3390/ma10090999

Chicago/Turabian StyleWang, Youyong, Yongming Song, Jun Du, Zhenhao Xi, and Qingwen Wang. 2017. "Preparation of Desirable Porous Cell Structure Polylactide/Wood Flour Composite Foams Assisted by Chain Extender" Materials 10, no. 9: 999. https://doi.org/10.3390/ma10090999