Towards Understanding the Polymerization Process in Bitumen Bio-Fluxes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

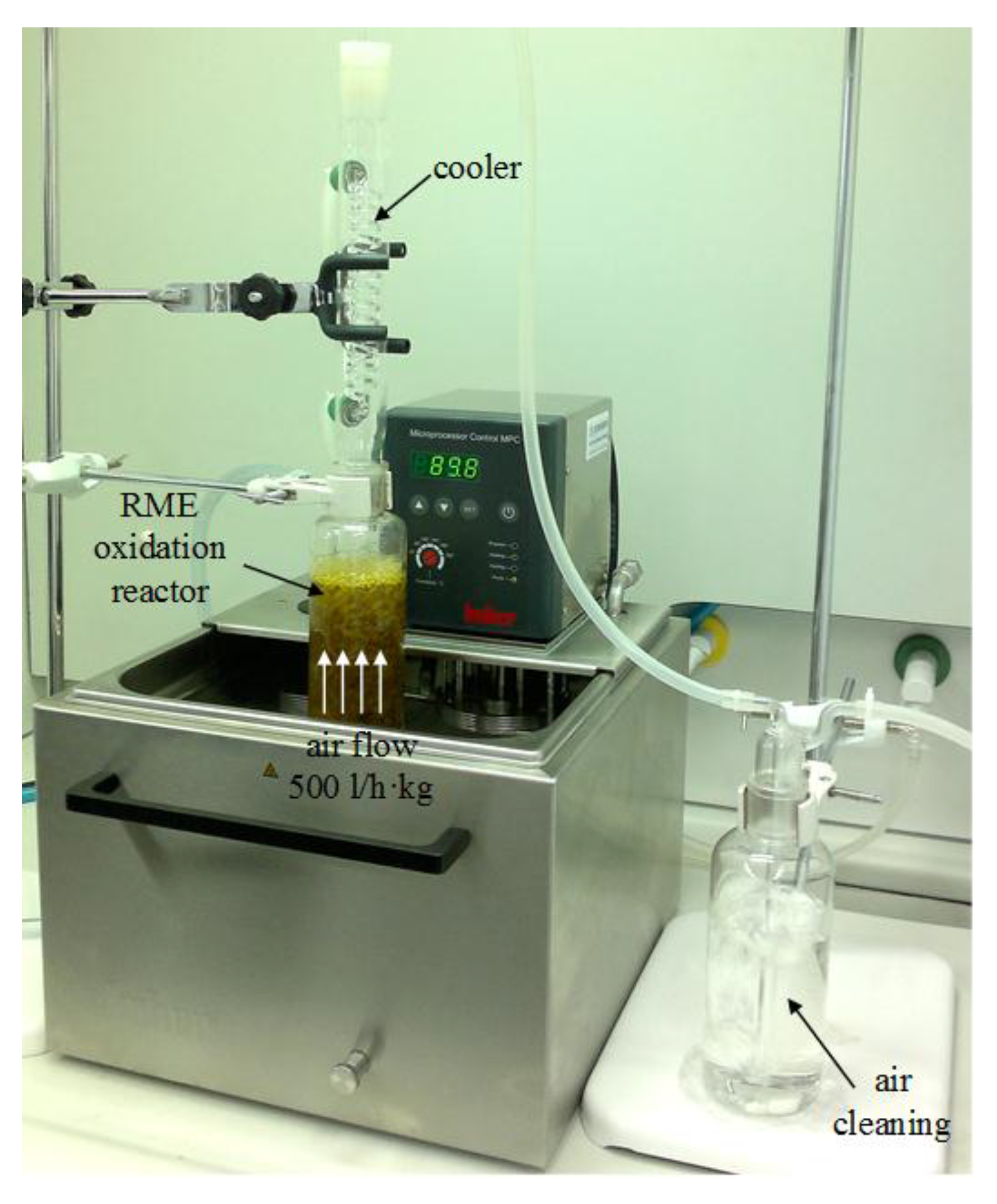

2.2. Production Procedure

2.3. Analysis Methods

3. Results

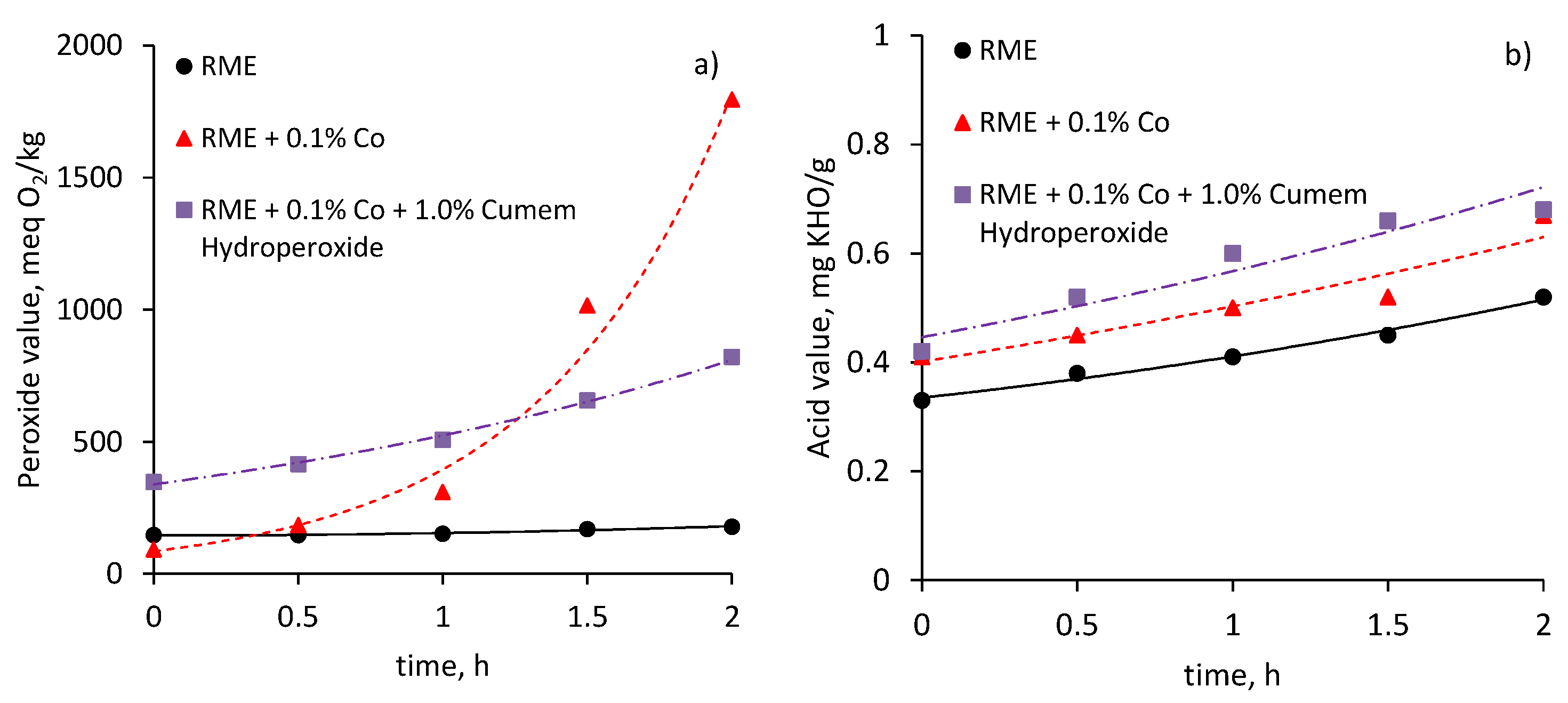

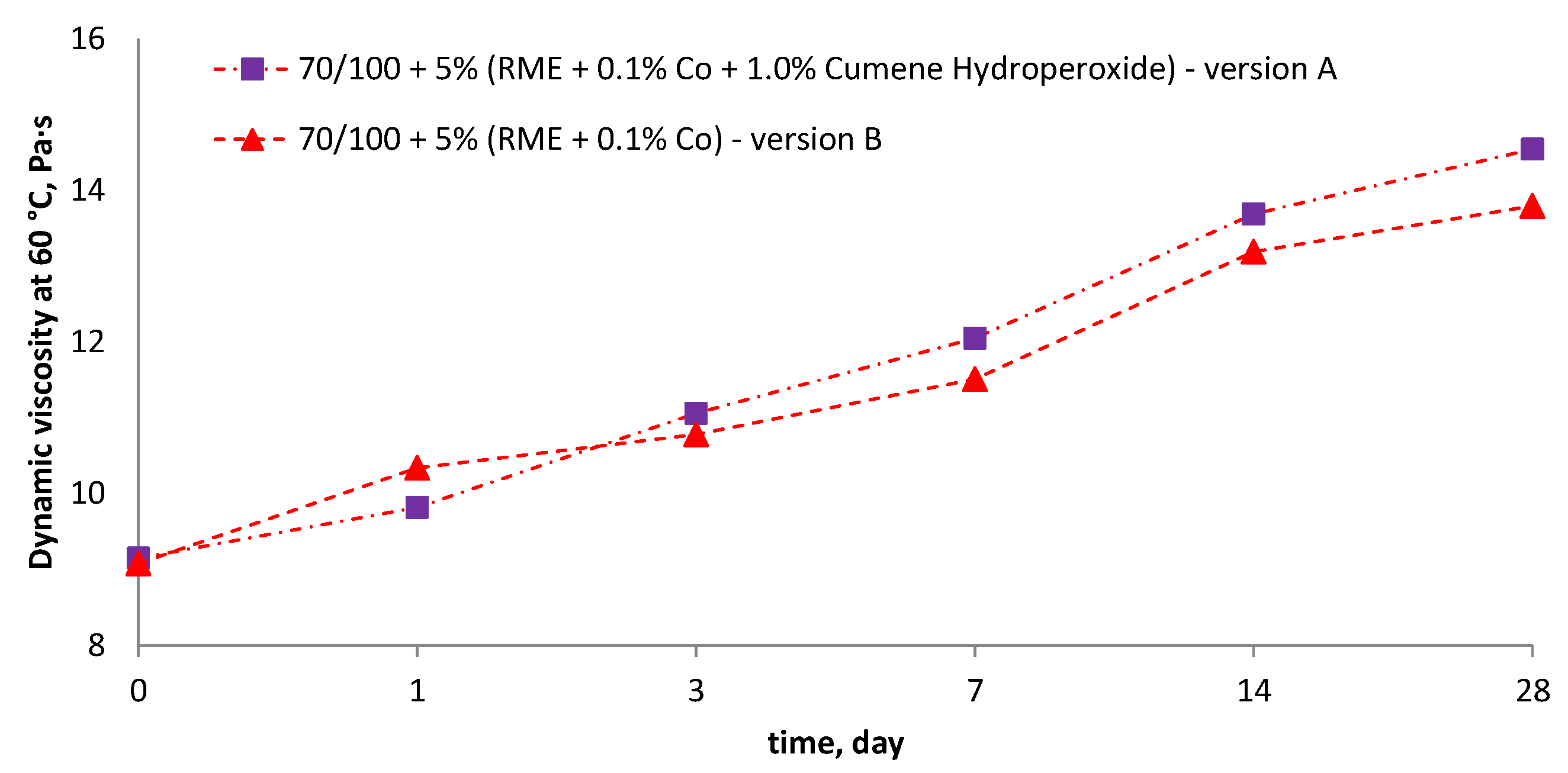

3.1. Physicochemical Changes

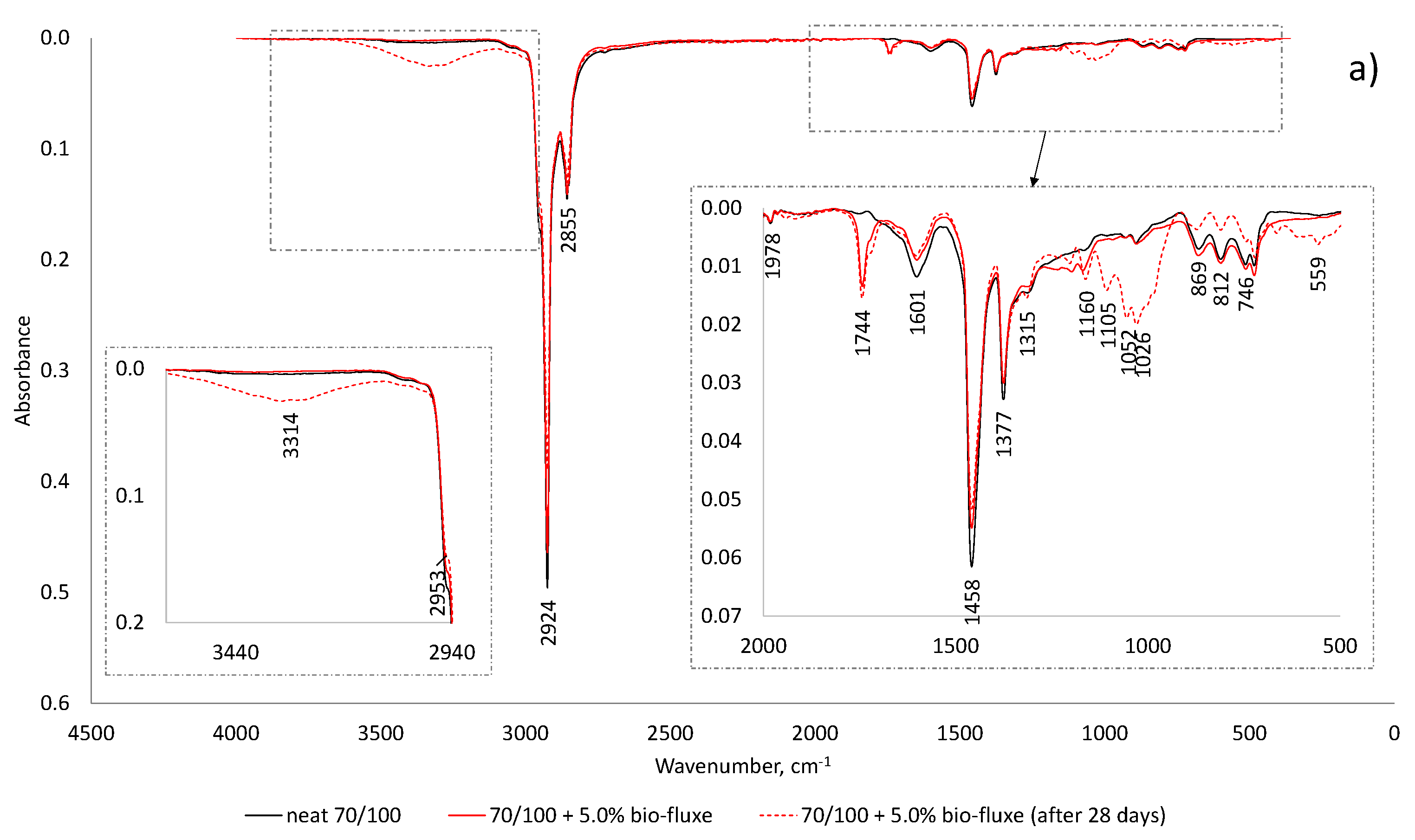

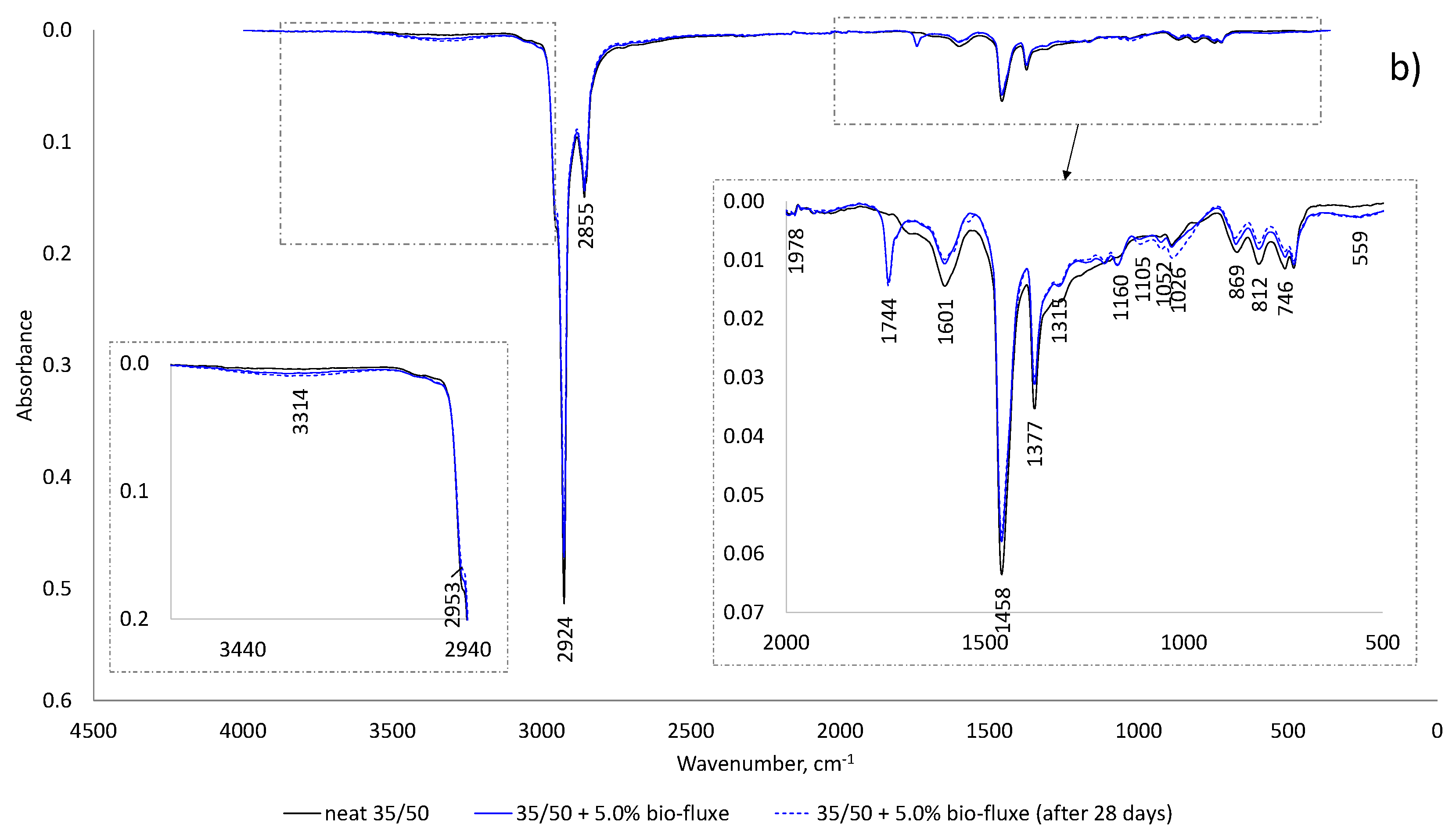

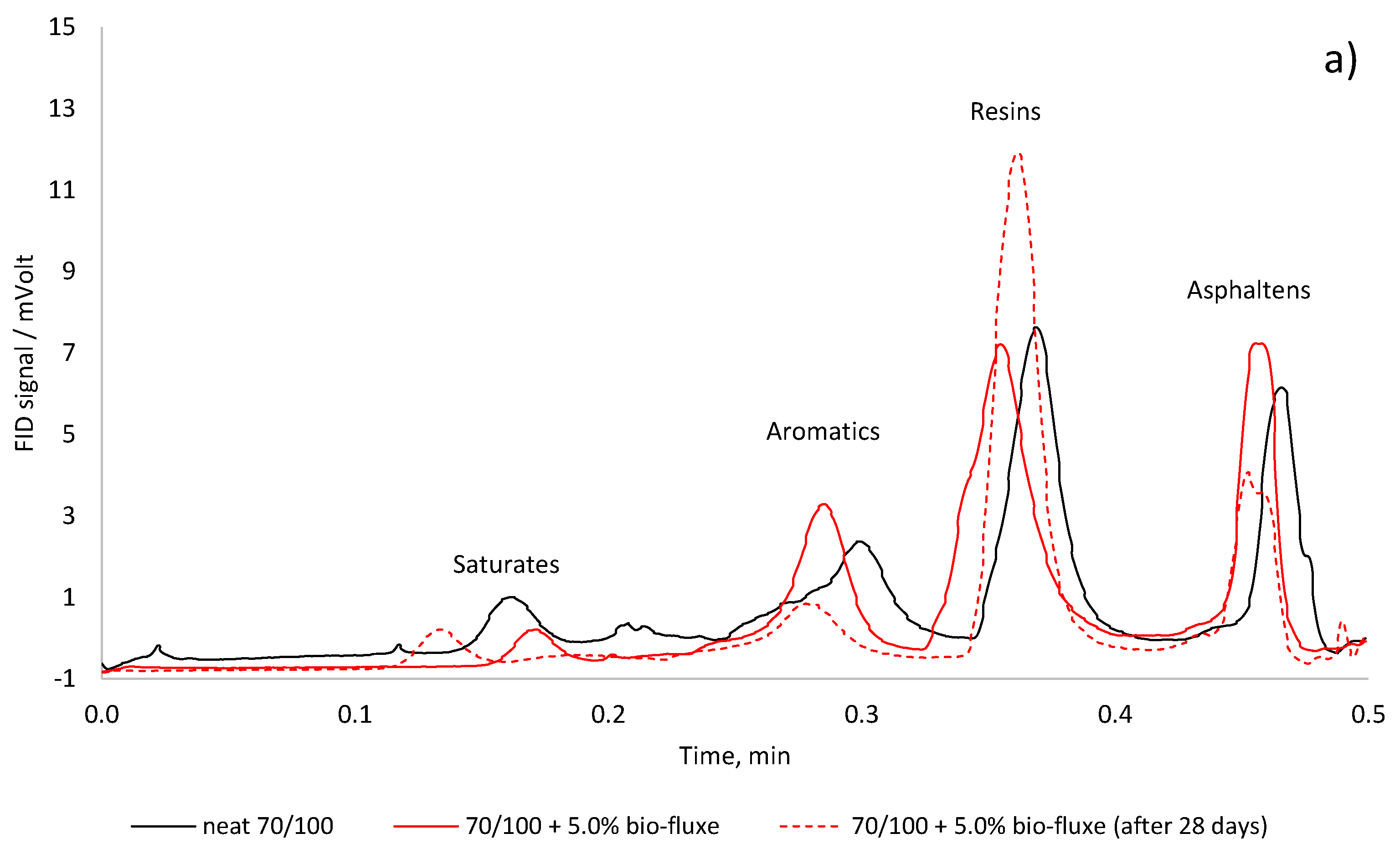

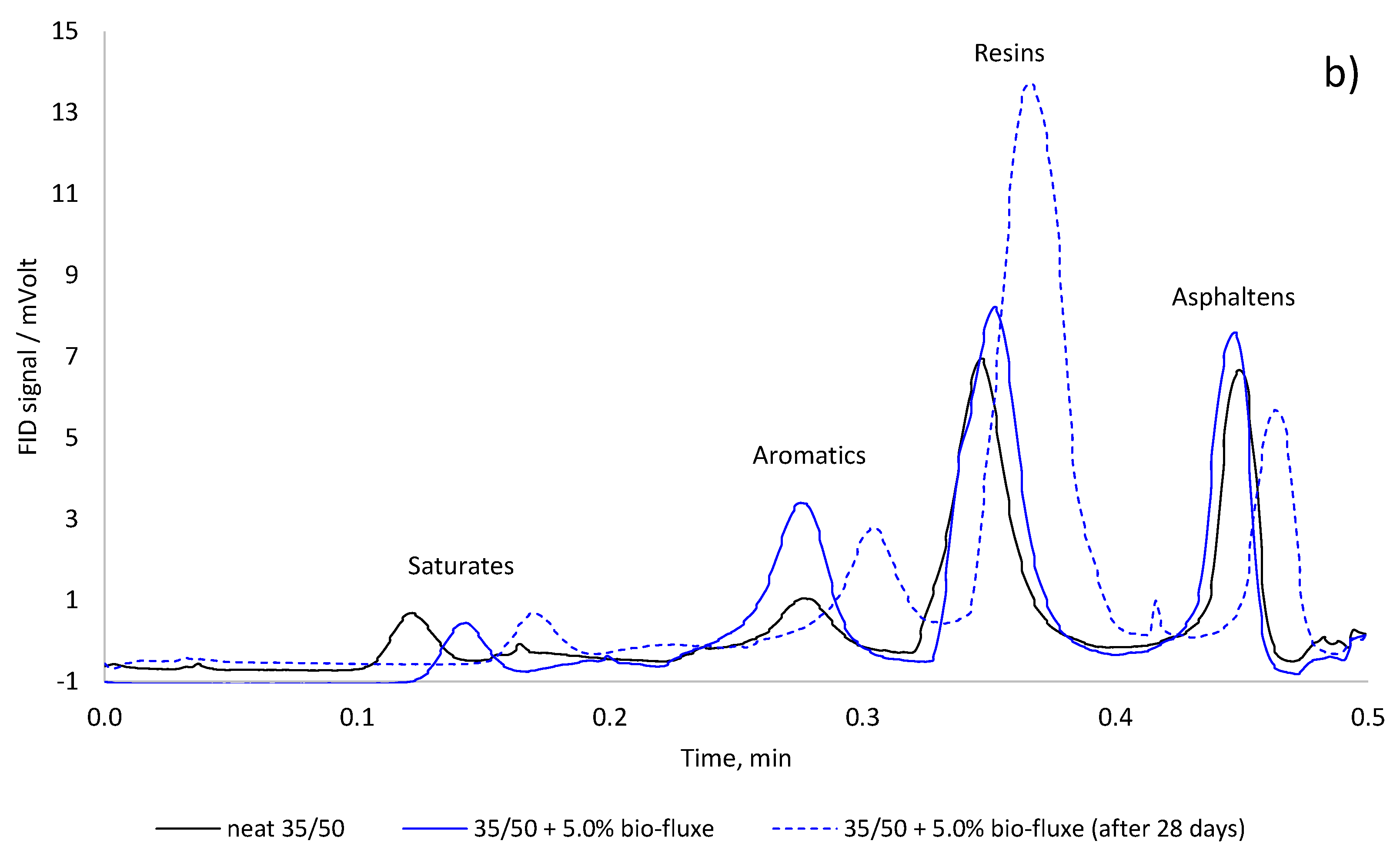

3.2. Structural Changes and Fractional Composition

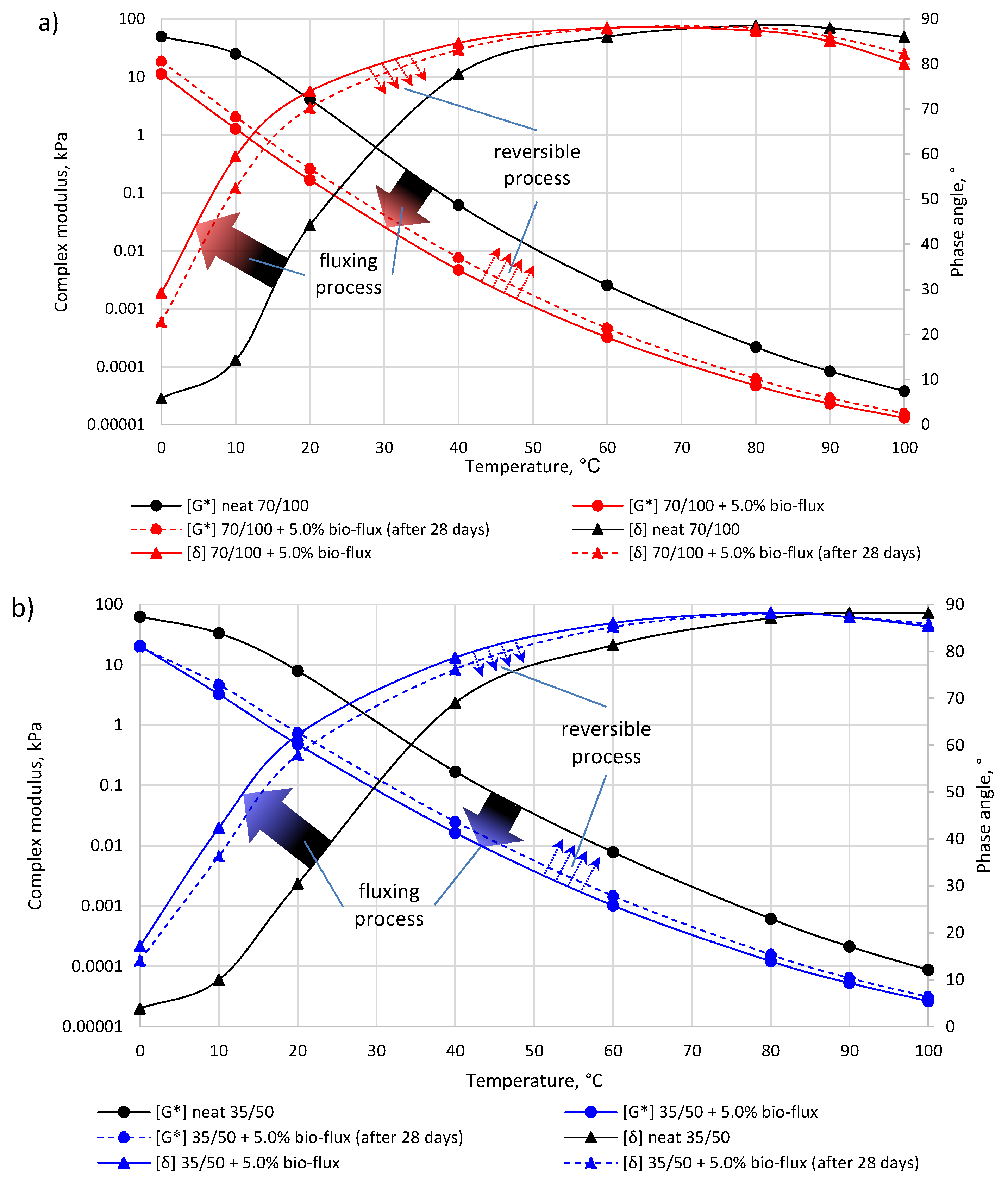

3.3. Physical and Viscoelastic Properties of Fluxed Bitumen

4. Discussion

5. Conclusions

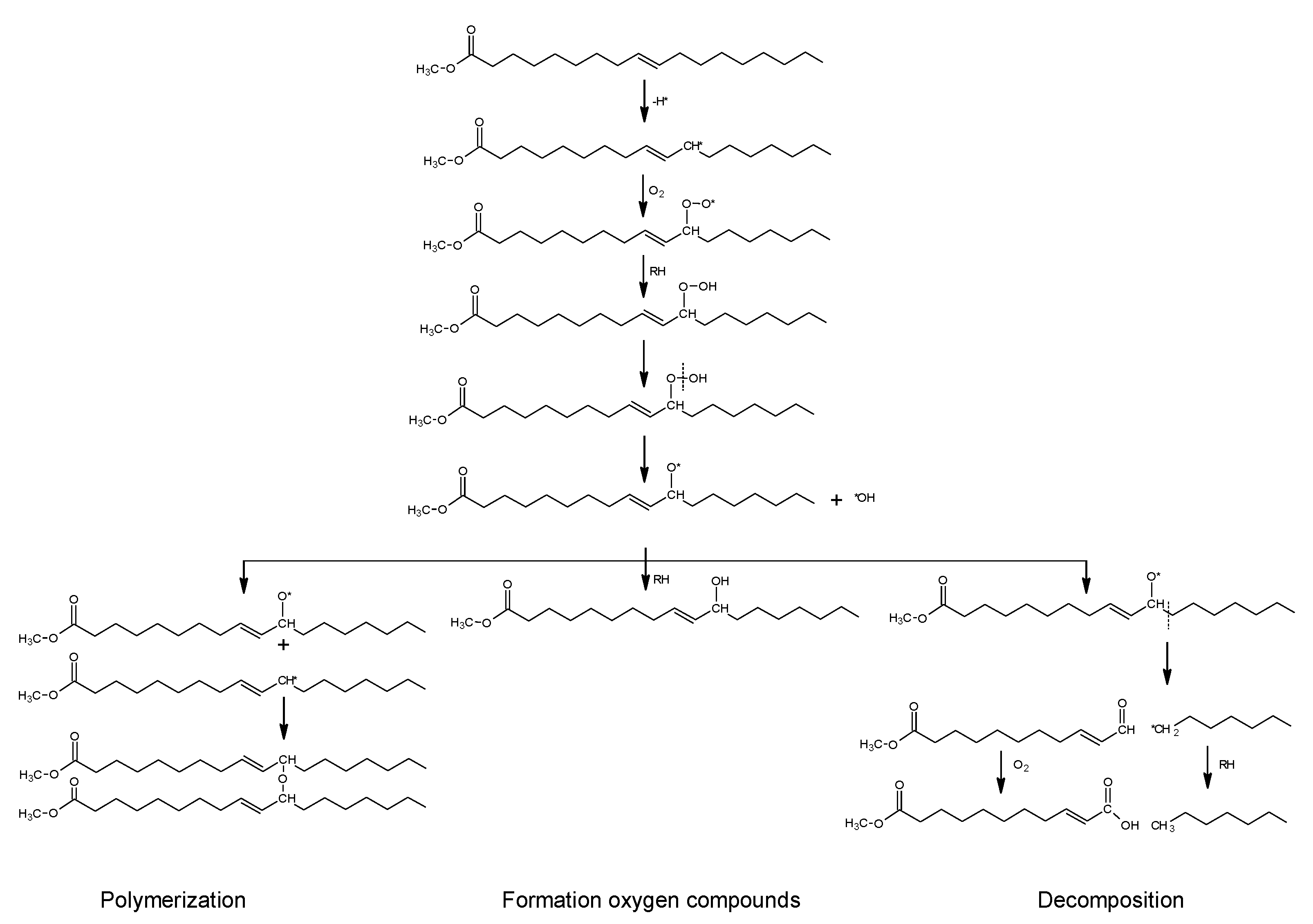

- The most characteristic changes in the rapeseed oil methyl ester structure upon catalytic oxidation are the formation of organic peroxides and hydroperoxides (intermediate products) and the loss of the unsaturated bonds in the fatty acid methyl ester.

- The cumene hydroperoxide in the presence of a cobalt catalyst is a more effective promoter of oxidative polymerization.

- The pocess is time-dependent. The hardening of the bio-fluxed binders with time results in oxidative polymerization process of unsaturated fatty acid methyl ester with the formation of oxygen compounds.

- The application of oxidized rapeseed oil methyl esters to bitumen reduces the asphaltene content and stabilizes the colloidal structure of the binder.

- Twenty-eight day oxygen exposure to bio-fluxed bitumen results in approximately 25% recovery of the original binder stiffness.

- The fuxing effect is particularly advantageous in the temperature range of 0 °C to 40 °C, which can potentially increase the fatigue life of the bitumen binder.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Simonen, M.; Pellinen, T.; Valtonen, J.; Blomberg, T. Biofluxed bitumens—Experiences from field tests and further developments. In Proceedings of the 5th Eurasphalt & Eurobitume Congress, Istanbul, Turkey, 13–15 June 2012. Paper No. A5EE-318. [Google Scholar]

- Peralta, J.; Williams, R.C.; Rover, M.; Silva, H.M. Development of a rubber-modified fractionated bio-oil for use as noncrude petroleum binder in flexible pavements. Transp. Res. Circ. 2012, E-C165, 23–36. [Google Scholar]

- Peralta, J.; Silva, H.M.; Williams, R.C.; Rover, M.; Machado, A.V. Development of an innovative bio-binder using asphalt-rubber technology. Int. J. Pavement Res. Technol. 2013, 6, 447–456. [Google Scholar]

- Guarin, A.; Khan, A.; Butt, A.A.; Birgisson, B.; Kringos, N. An extensive laboratory investigation of the use of bio-oil modified bitumen in road construction. Constr. Build. Mater. 2016, 106, 133–139. [Google Scholar] [CrossRef]

- Tanghe, T.; Lemoine, G.; Nösler, I.; Kloet, B. Influence of rejuvenating additives on recycled asphalt (RAP) properties. In Proceedings of the 5th Eurasphalt & Eurobitume Congress, Istanbul, Turkey, 13–15 June 2012. Paper No. P5EE-416. [Google Scholar]

- Kowalski, K.J.; Król, J.B.; Bańkowski, W.; Radziszewski, P.; Sarnowski, M. Thermal and fatigue evaluation of asphalt mixtures containing RAP treated with a bio-agent. Appl. Sci. 2017, 7, 2016. [Google Scholar] [CrossRef]

- Majid, Z.; Esmaeil, A.; Hallizza, A.; Mohamed, R.K. Investigation of the possibility of using waste cooking oil as a rejuvenating agent for aged bitumen. J. Hazard. Mater. 2012, 233, 254–258. [Google Scholar]

- Hugener, M.; Partl, M.N.; Morant, M. Cold asphalt recycling with 100% reclaimed asphalt pavement and vegetable oil-based rejuvenators. Road Mater. Pavement Des. 2014, 15, 239–258. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Poulikakos, L.; Frank, R. Influence of six rejuvenators on the performance properties of Reclaimed Asphalt Pavement (RAP) binder and 100% recycled asphalt mixtures. Constr. Build. Mater. 2014, 71, 538–550. [Google Scholar] [CrossRef]

- Hassan, N.A.; Khan, R.; Raaberg, J.; Presti, D.L. Effect of mixing time on reclaimed asphalt mixtures: An investigation by means of imaging techniques. Constr. Build. Mater. 2015, 99, 54–61. [Google Scholar] [CrossRef]

- Porot, L.; Broere, D.; Wistuba, M.; Grönniger, J. Asphalt and binder evaluation of asphalt mix with 70% reclaimed asphalt. Road Mater. Pavement Des. 2017, 18, 66–75. [Google Scholar] [CrossRef]

- Bocci, E.; Grilli, A.; Bocci, M.; Gomes, V. Recycling of high percentages of reclaimed asphalt using a bio-rejuvenator—A case study. In Proceedings of the 6th Eurasphalt & Eurobitume Congress, Prague, Czech, 1–3 June 2016. Paper No. EE.2016.334. [Google Scholar]

- Chen, M.; Leng, B.; Wu, S.; Sang, Y. Physical, chemical and rheological properties of waste edible vegetable oil rejuvenated asphalt binders. Constr. Build. Mater. 2014, 66, 286–298. [Google Scholar] [CrossRef]

- Lei, Z.; Bahia, H.; Yi-Qiu, T. Effect of bio-based and refined waste oil modifiers on low temperature performance of asphalt binders. Constr. Build. Mater. 2015, 86, 95–100. [Google Scholar] [CrossRef]

- Behnood, A.; Olek, J. Rheological properties of asphalt binders modified with styrene-butadiene-styrene (SBS), ground tire rubber (GTR), or polyphosphoric acid (PPA). Constr. Build. Mater. 2017, 151, 464–478. [Google Scholar] [CrossRef]

- Somé, C.; Pavoine, A.; Chailleux, E.; Andrieux, L.; DeMarco, L.; Da Silva Philippe, B.S. Rheological behavior of vegetable oil-modified asphaltite binders and mixes. In Proceedings of the 6th Eurasphalt & Eurobitume Congress, Prague, Czech, 1–3 June 2016. Paper No. EE.2016.222. [Google Scholar] [CrossRef]

- Fini, E.H.; Hosseinnezhad, S.; Oldham, D.J.; Chailleux, E.; Gaudefroy, V. Source dependency of rheological and surface characteristics of bio-modified asphalts. Road Mater. Pavement Des. 2017, 18, 408–424. [Google Scholar] [CrossRef]

- Pasquier, M. Bituminous Binder, Composition and Use. U.S. Patent 6,156,113, 5 December 2000. [Google Scholar]

- Wexler, H. Polymerization of drying oils. Chem. Rev. 1964, 64, 591–611. [Google Scholar] [CrossRef]

- Mallégol, J.; Gonon, L.; Lemaire, J.; Gardette, J.L. Long-term behaviour of oil-based varnishes and paints 4. Influence of film thickness on the photooxidation. Polym. Degrad. Stab. 2001, 72, 191–197. [Google Scholar] [CrossRef]

- Stiepanowicz-Orchimienko, I.; Wasiljewicz-Wiercholancew, W. Chemia i Technologia Substancji Błonotwórczych; WNT: Warszawa, Poland, 1982; pp. 298–334. (In polish) [Google Scholar]

- Mallégol, J.; Lemaire, J.; Gardette, J.L. Drier influence on the curing of linseed oil. Prog. Org. Coat. 2000, 39, 107–113. [Google Scholar] [CrossRef]

- Mallégol, J.; Gonon, L.; Commereuc, S.; Verney, V. Thermal (DSC) and chemical (iodometric titration) methods for peroxides measurements in order to monitor drying extent of alkyd resins. Prog. Org. Coat. 2001, 41, 171–176. [Google Scholar] [CrossRef]

- Muizebelt, W.J.; Hubert, J.C.; Nielen, M.W.F.; Klaasen, R.P.; Zabel, K.H. Crosslink mechanisms of high-solids alkyd resins in the presence of reactive diluents. Prog. Org. Coat. 2000, 40, 121–130. [Google Scholar] [CrossRef]

- Gorski, W.; Ostaszewski, W.; Wislicki, B. Chemical composition of vegetable oils as potential biomass for production of fuel and lubricants oils. Paliwa Oleje Smary Eksploat. 2002, 96, 14–18. [Google Scholar]

- Bhat, S.V.; Nagasampagi, B.A.; Sivakumar, M. Chemistry of Natural Products; Narosa: New Delhi, India, 2005; pp. 206–213. [Google Scholar]

- Gaweł, I.; Piłat, J.; Radziszewski, P.; Niczke, Ł.; Krol, J.; Sarnowski, M. Bitumen fluxes of vegetable origin. Polimery 2010, 55, 55–60. [Google Scholar]

- Król, J.B.; Kowalski, K.J.; Niczke, Ł.; Radziszewski, P. Effect of bitumen fluxing using a bio-origin additive. Constr. Build. Mater. 2016, 114, 194–203. [Google Scholar] [CrossRef]

- Kowalski, K.J.; Król, B.; Radziszewski, P.; Piłat, J.; Sarnowski, M. New concept of sustainable road structure with RAP binder course using bio-agent. In Proceedings of the 6th Eurasphalt & Eurobitume Congress, Prague, Czech, 1–3 June 2016. Paper No. EE.2016.260. [Google Scholar] [CrossRef]

- Kowalski, K.J.; Król, J.; Radziszewski, P.; Casado, R.; Blanco, V.; Pérez, D.; Viñas, V.M.; Brijsse, Y.; Frosch, M.; Le, D.M.; et al. Eco-friendly materials for a new concept of asphalt pavement. Transp. Res. Procedia 2016, 14, 3582–3591. [Google Scholar] [CrossRef]

| Properties | Rapeseed Oil Methyl Ester |

|---|---|

| Density at 25 °C, g/cm3 | 0.8787 |

| Flash point, °C | 197 |

| Dynamic viscosity at 25 °C, Pa∙s | 0.006 |

| Iodine number, g I2/100 g | 116 |

| Acid value, mg KOH/g | 0.29 |

| Compounds | Version A | Version B |

|---|---|---|

| Rapeseed methyl esters (RME) | 98.9% | 99.9% |

| Cobalt(II) acetate tetrahydrate catalyst | 0.1% | 0.1% |

| Cumene hydroperoxide | 1.0% | - |

| Process parameters | ||

| Oxidation temperature | 20 °C | 90 °C |

| Process duration | 2 h | 1 h |

| Properties | Liquid Product of Oxidation | |

|---|---|---|

| RME + 0.1% Co + 1% Cumene Hydroperoxide (Version A) | RME + 0.1% Co (Version B) | |

| Dynamic viscosity at 25 °C, Pa∙s | 0.011 | 0.008 |

| Iodine number, g I2/100 g | 82 | 102 |

| Acid value, mg KOH/g | 0.68 | 0.67 |

| Flash point, °C | 136 | 191 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Król, J.B.; Niczke, Ł.; Kowalski, K.J. Towards Understanding the Polymerization Process in Bitumen Bio-Fluxes. Materials 2017, 10, 1058. https://doi.org/10.3390/ma10091058

Król JB, Niczke Ł, Kowalski KJ. Towards Understanding the Polymerization Process in Bitumen Bio-Fluxes. Materials. 2017; 10(9):1058. https://doi.org/10.3390/ma10091058

Chicago/Turabian StyleKról, Jan B., Łukasz Niczke, and Karol J. Kowalski. 2017. "Towards Understanding the Polymerization Process in Bitumen Bio-Fluxes" Materials 10, no. 9: 1058. https://doi.org/10.3390/ma10091058