Grain Refinement and Mechanical Properties of Cu–Cr–Zr Alloys with Different Nano-Sized TiCp Addition

Abstract

:1. Introduction

2. Materials and Methods

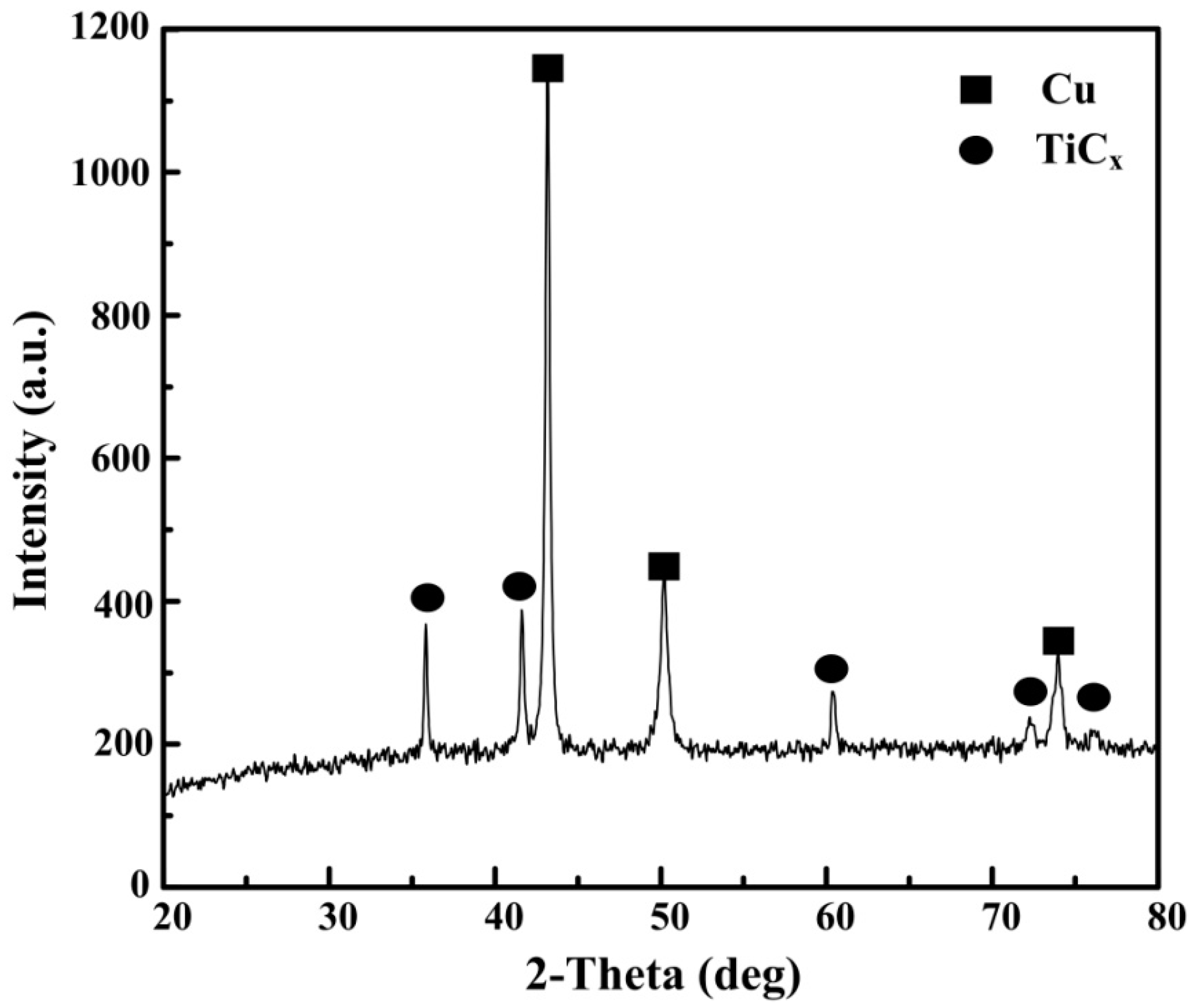

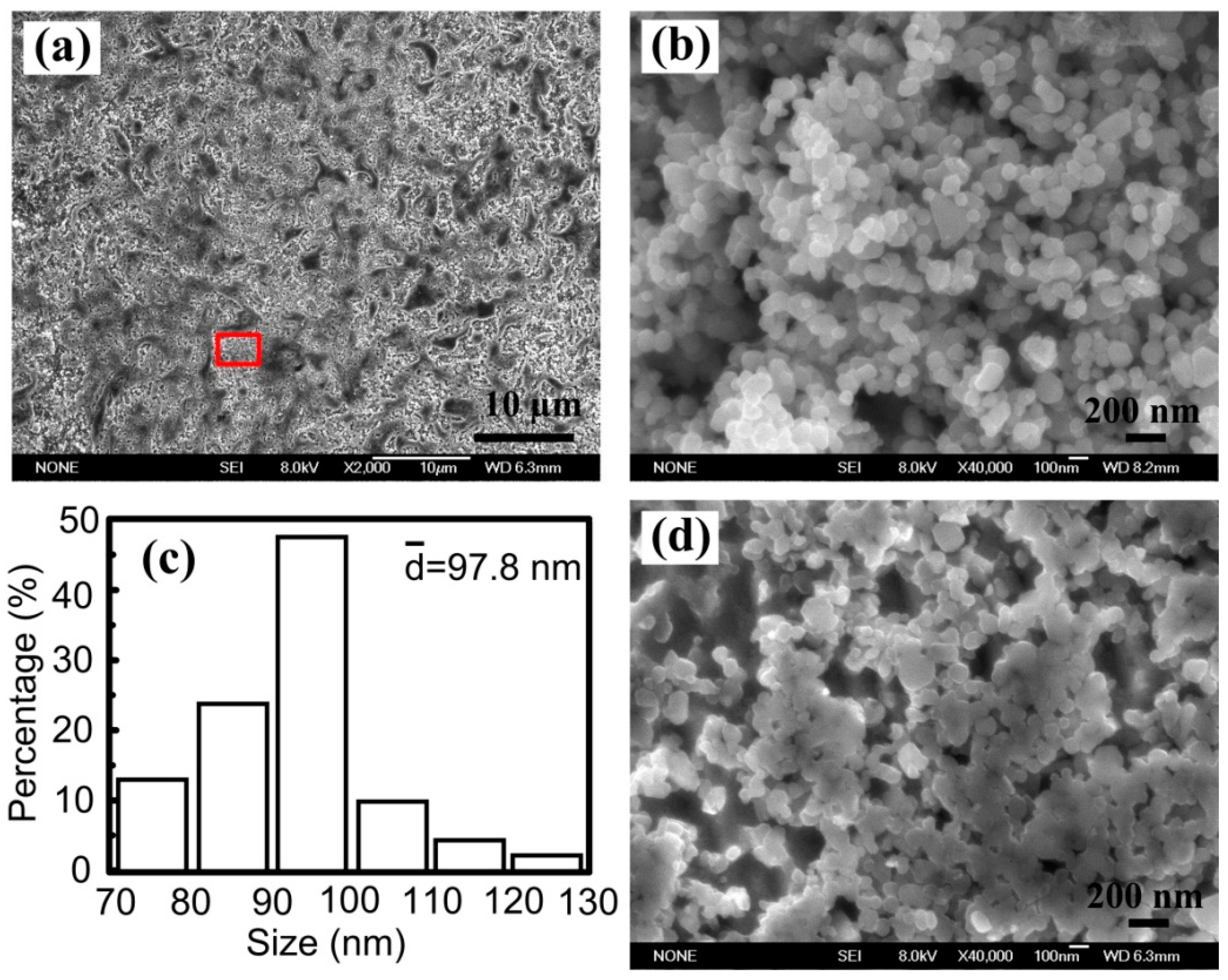

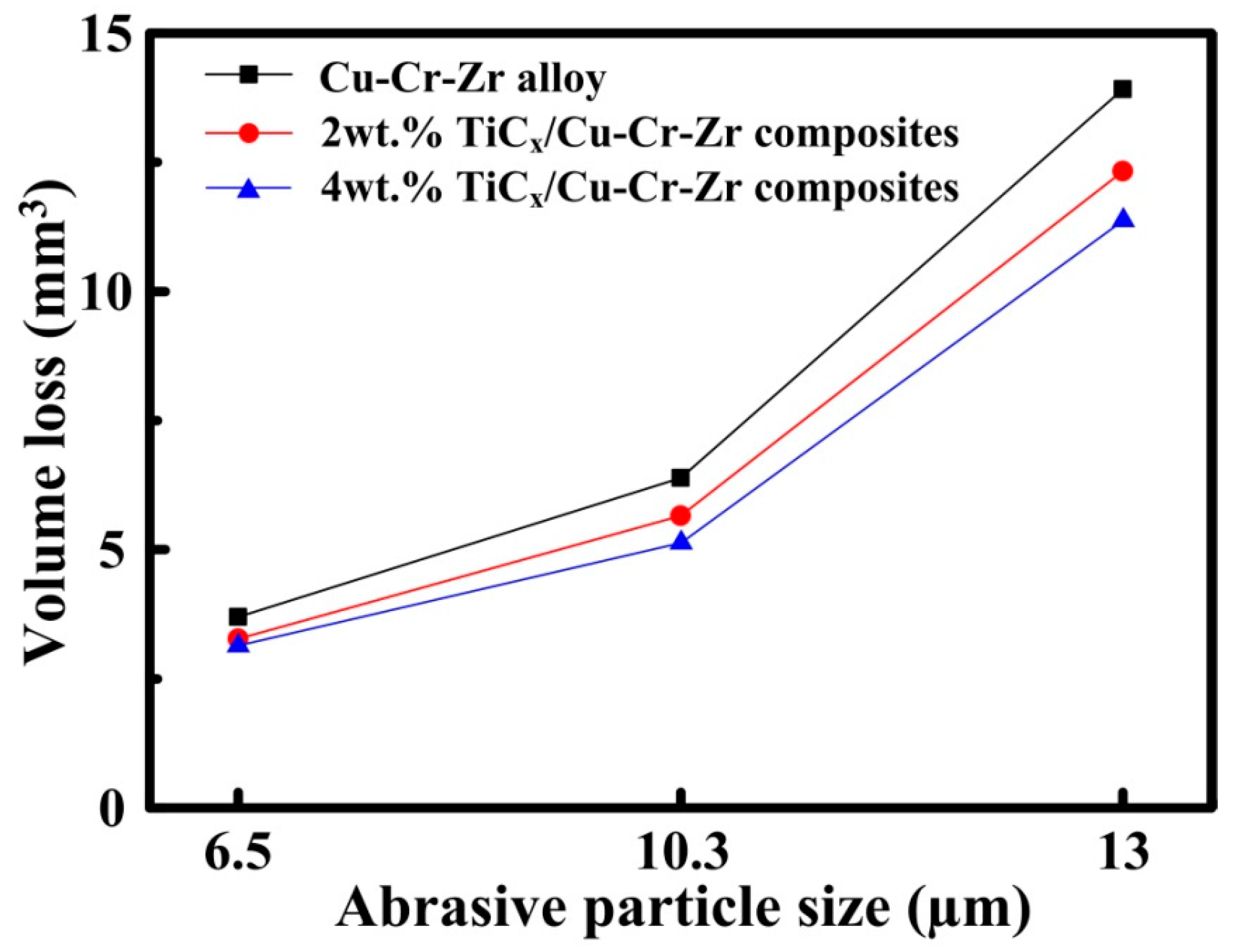

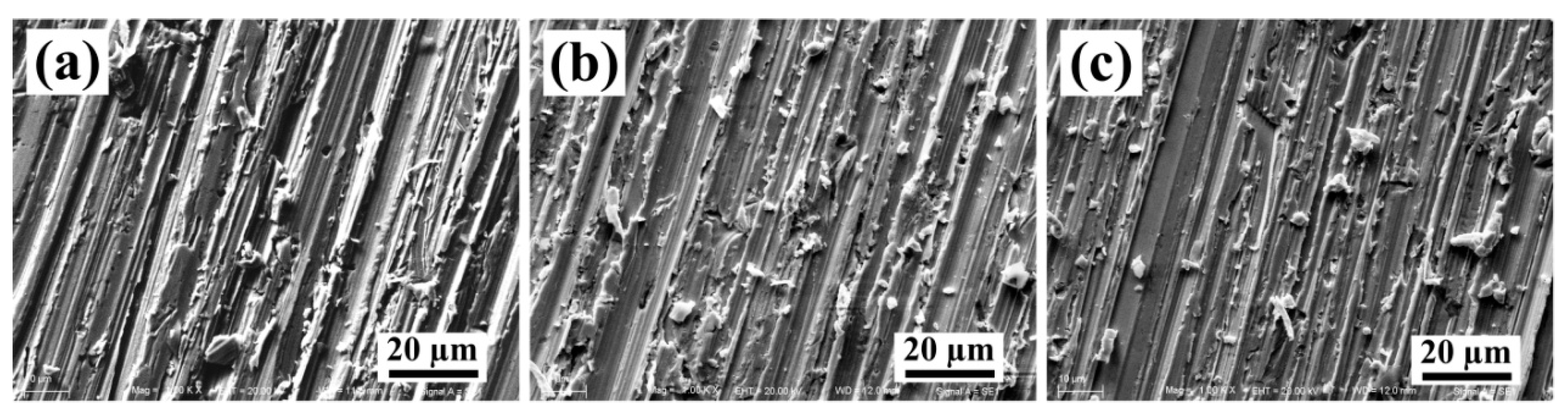

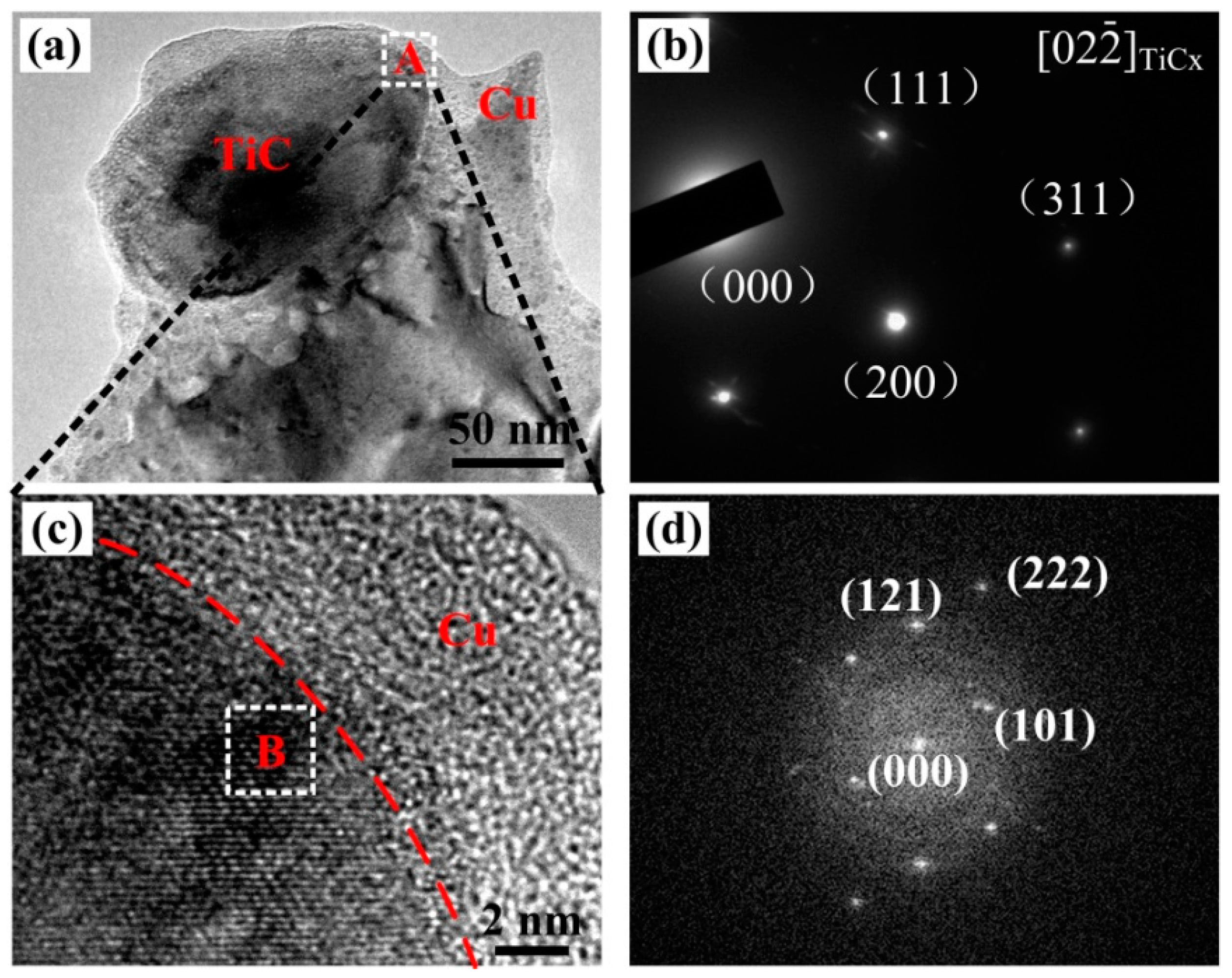

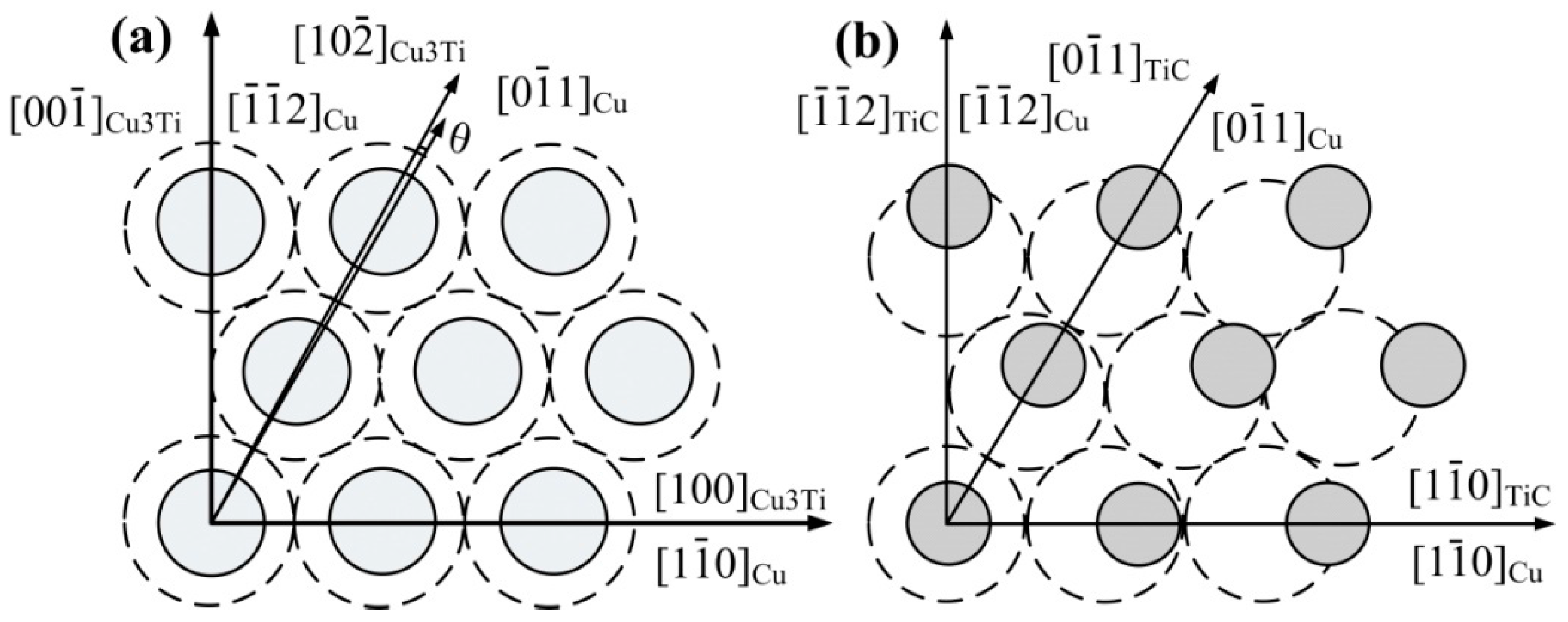

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Purcek, G.; Yanar, H.; Saray, O.; Karaman, I.; Maier, H.J. Effect of precipitation on mechanical and wear properties of ultrafine-grained Cu-Cr-Zr alloy. Wear 2014, 311, 149–158. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, Z.G.; Li, W. Effects of thermo-mechanical treatment on microstructure and properties of Cu-Cr-Zr alloys. Phys. Procedia 2013, 50, 55–60. [Google Scholar] [CrossRef]

- Batra, I.S.; Dey, G.K.; Kulkarni, U.D.; Banerjee, S. Microstructure and properties of a Cu-Cr-Zr alloy. J. Nucl. Mater. 2001, 299, 91–100. [Google Scholar] [CrossRef]

- Mishnev, R.; Shakhova, I.; Belyakov, A.; Kaibyshev, R. Deformation microstructures, strengthening mechanisms, and electrical conductivity in a Cu-Cr-Zr alloy. Mater. Sci. Eng. A 2015, 629, 29–40. [Google Scholar] [CrossRef]

- Ryu, H.J.; Baik, H.K.; Hong, S.H. Effect of thermomechanical treatments on microstructure and properties of Cu-base leadframe alloy. J. Mater. Sci. 2000, 35, 3641–3646. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Shakhova, I.; Morozova, A.; Belyakov, A.; Kaibyshev, R. Grain refinement kinetics and strengthening mechanisms in Cu-0.3Cr-0.5Zr alloy subjected to intense plastic deformation. Mater. Sci. Eng. A 2016, 654, 131–142. [Google Scholar] [CrossRef]

- Oanh, N.T.H.; Viet, N.H.; Kim, J.S.; Junior, A.M.J. Characterization of In-Situ Cu-TiH2-C and Cu-Ti-C Nanocomposites Produced by Mechanical Millingand Spark Plasma Sintering. Metals 2017, 7, 117. [Google Scholar] [CrossRef]

- Rajkumar, K.; Aravindan, S. Tribological performance of microwave sintered copper-TiC-graphite hybrid composites. Tribol. Int. 2011, 44, 347–358. [Google Scholar] [CrossRef]

- Guo, M.X.; Wang, M.P.; Shen, K. Synthesis of nano TiB2 particles in copper matrix by in situ reaction of double-beam melts. J. Alloys Compd. 2008, 460, 585–589. [Google Scholar] [CrossRef]

- Akhtar, F.; Askari, S.J.; Shah, K.A.; Du, X.L.; Guo, S.J. Microstructure, mechanical properties, electrical conductivity and wear behavior of high volume TiC reinforced Cu-matrix composites. Mater. Charact. 2009, 60, 327–366. [Google Scholar] [CrossRef]

- Liu, Q.; He, X.B.; Ren, S.B.; Liu, T.T.; Kang, Q.P.; Qu, X.H. Fabrication and thermal conductivity of copper matrix composites reinforced with Mo2C or TiC coated graphite fiber. Mater. Res. Bull. 2013, 48, 4811–4817. [Google Scholar] [CrossRef]

- Qiu, F.; Han, Y.; Cheng, A.; Lu, J.B.; Jiang, Q.C. Effect of Cr Content on the Compression Properties and Abrasive Wear Behavior of the High-Volume Fraction (TiC–TiB2)/Cu Composites. Acta Metall. Sin. 2014, 27, 951–956. [Google Scholar] [CrossRef]

- Qiu, F.; Chu, J.G.; Hu, W.; Lu, J.B.; Li, X.D.; Han, Y.; Jiang, Q.C. Study of effect of Zr addition on the microstructures and mechanical properties of (TiCx–TiB2)/Cu composites by combustion synthesis and hot press consolidation in the Cu-Ti-B4C-Zr system. Mater. Res. Bull. 2015, 70, 167–172. [Google Scholar] [CrossRef]

- Shojaeepour, F.; Abachi, P.; Purazrang, K.; Moghanian, A.H. Production and properties of Cu/Cr2O3 nano-composites. Powder Technol. 2012, 222, 80–84. [Google Scholar] [CrossRef]

- Lu, J.B.; Shu, S.L.; Qiu, F.; Wang, Y.W.; Jiang, Q.C. Compression properties and abrasive wear behavior of high volume fraction TiCx–TiB2/Cu composites fabricated by combustion synthesis and hot press consolidation. Mater. Des. 2012, 40, 157–162. [Google Scholar] [CrossRef]

- Storms, E.K. The Refractory Carbides; Academic Press: New York, NY, USA, 1967. [Google Scholar]

- Rahaei, M.B.; Yazdanirad, R.; Kazemzadeh, A.; Ebadzadeh, T. Mechanochemical synthesis of nano TiC powder by mechanical milling of titanium and graphite powders. Powder Technol. 2012, 217, 369–376. [Google Scholar] [CrossRef]

- Yang, Y.F.; Mu, D.K.; Jiang, Q.C. A simple route to fabricate TiC–TiB2/Ni composite via thermal explosion reaction assisted with external pressure in air. Mater. Chem. Phys. 2014, 143, 480–485. [Google Scholar] [CrossRef]

- Klinger, L.; Gotman, I.; Horvitz, D. In-situ processing of TiB2: TiC ceramic composites by thermal explosion under pressure: Experimental study and modeling. Mater. Sci. Eng. A 2001, 302, 92–99. [Google Scholar] [CrossRef]

- Lin, Q.L.; Shen, P.; Yang, L.L.; Jin, S.B.; Jiang, Q.C. Wetting of TiC by molten Al at 1123–1323 K. Acta Mater. 2011, 59, 1898–1911. [Google Scholar] [CrossRef]

- Yang, Y.F.; Jiang, Q.C. Effect of TiB2/TiC ratio on the microstructure and mechanical properties of high volume fractions of TiB2/TiC reinforced Fe matrix composite. Int. J. Refract. Met. Hard Mater. 2013, 38, 137–139. [Google Scholar] [CrossRef]

- Zhao, Q.; Liang, Y.H.; Zhang, Z.H.; Li, X.J.; Ren, L.Q. Study on the Impact Resistance of Bionic Layered Composite of TiC–TiB2/Al from Al-Ti-B4C System. Materials 2016, 9, 708. [Google Scholar] [CrossRef] [PubMed]

- Zhou, D.S.; Qiu, F.; Wang, H.Y.; Jiang, Q.C. Manufacture of Nano-Sized Particle-Reinforced Metal Matrix Composites: A Review. Acta Metall. Sin. 2014, 27, 798–805. [Google Scholar] [CrossRef]

- Wang, L.; Qiu, F.; Zhao, Q.L.; Wang, H.Y.; Yang, D.L.; Jiang, Q.C. Simultaneously increasing the elevated-temperature tensile strength and plasticity of in-situ nano-sized TiCx/Al-Cu-Mg composites. Mater. Charact. 2017, 125, 7–12. [Google Scholar] [CrossRef]

- Liang, Y.H.; Zhao, Q.; Li, X.J.; Zhang, Z.H.; Ren, L.Q. Effect of Ti and C particle size on reaction behavior of thermal explosion (TE) reaction of Cu-Ti-C system under Ar and air atmosphere. J. Alloys Compd. 2016, 679, 65–73. [Google Scholar] [CrossRef]

- Popov, V.A.; Shelekhov, E.V.; Prosviryakov, A.S.; Presniakov, M.Y.; Senatulin, B.R.; Kotov, A.D.; Khomutov, M.G. Particulate metal matrix composites development on the basis of in-situ synthesis of TiC reinforcing nanoparticles during mechanical alloying. J. Alloys Compd. 2017, 707, 365–370. [Google Scholar] [CrossRef]

- Jin, S.B.; Shen, P.; Zou, B.L.; Jiang, Q.C. Morphology Evolution of TiCx Grains during SHS in an Al-Ti-C System. Cryst. Growth Des. 2009, 9, 646–649. [Google Scholar] [CrossRef]

- Shu, S.L.; Tong, C.Z.; Qiu, F.; Jiang, Q.C. Effect of Ceramic Content on the Compression Properties of TiB2-Ti2AlC/TiAl Composites. Metals 2015, 5, 2200–2209. [Google Scholar] [CrossRef]

- Tian, W.S.; Zhou, D.S.; Qiu, F.; Jiang, Q.C. Superior tensile properties of in situ nano-sized TiCp/Al-Cu composites fabricated by reaction in melt method. Mater. Sci. Eng. A 2016, 658, 409–414. [Google Scholar] [CrossRef]

- Wang, L.; Qiu, F.; Zhao, Q.L.; Zha, M.; Jiang, Q.C. Superior high creep resistance of in situ nano-sized TiCx/Al-Cu-Mg composite. Sci. Rep. 2017, 7, 4540. [Google Scholar] [CrossRef] [PubMed]

- Qiu, F.; Gao, Y.Y.; Liu, J.Y.; Shu, S.L.; Zou, Q.; Zhang, T.Z.; Jiang, Q.C. Effect of reactant C/Ti ratio on the compressive properties and wear properties of the 50 vol % submicron-sized TiCx/2014Al composites fabricated by combustion synthesis and hot press consolidation. Powder Metall. 2016, 59, 256–261. [Google Scholar] [CrossRef]

- Yang, Y.F.; Jiang, Q.C. Reaction behaviour, microstructure and mechanical properties of TiC-TiB2/Ni composite fabricated by pressure assisted self-propagating high-temperature synthesis in air and vacuum. Mater. Des. 2013, 49, 123–129. [Google Scholar] [CrossRef]

- Wang, L.; Qiu, F.; Shu, S.L.; Zhao, Q.L.; Jiang, Q.C. Effects of different carbon sources on the compressive properties of in situ high-volume-fraction TiCx/2009Al composites. Powder Metall. 2016, 59, 370–375. [Google Scholar] [CrossRef]

- Zhang, D.D.; Bai, F.; Sun, L.P.; Wang, Y.; Wang, J.G. Compression properties and electrical conductivity of in-situ 20 vol % nano-sized TiCx/Cu composites with different particle size and morphology. Materials 2017, 10, 499. [Google Scholar] [CrossRef] [PubMed]

- Zhou, D.S.; Qiu, F.; Jiang, Q.C. Simultaneously increasing thestrength and ductility of nano-sized TiN particle reinforced Al-Cu matrix composites. Mater. Sci. Eng. A 2014, 596, 98–102. [Google Scholar] [CrossRef]

- Zhou, D.S.; Qiu, F.; Jiang, Q.C. The nano-sized TiC particle reinforced Al-Cu composite with superior tensile ductility. Mater. Sci. Eng. A 2015, 622, 189–193. [Google Scholar] [CrossRef]

- Qiu, F.; He, Y.; Zhu, L.; Shu, S.L.; Hu, W.; Zhan, C.H.; Jiang, Q.C. Microstructure and compression properties of in-situ dual phase nano-sized (TiB2-Ti5Si3)/TiAl matrix composites fabricated by combustion synthesis and hot press consolidation. Powder Metall. 2015, 58, 235–240. [Google Scholar] [CrossRef]

- Qiu, F.; Zuo, R.; Shu, S.L.; Wang, T.W.; Jiang, Q.C. Effect of Al addition on the microstructures and compression properties of (TiCxNy-TiB2)/Ni composites fabricated by combustion synthesis and hot press. Powder Technol. 2015, 286, 716–721. [Google Scholar] [CrossRef]

- Wang, L.; Qiu, F.; Ouyang, L.C.; Wang, H.Y.; Zha, M.; Shu, S.L.; Zhao, Q.L.; Jiang, Q.C. A Novel Approach of Using Ground CNTs as the Carbon Source to Fabricate Uniformly Distributed Nano-Sized TiCx/2009Al Composites. Materials 2015, 8, 8839–8849. [Google Scholar] [CrossRef]

- Wang, L.; Qiu, F.; Liu, J.Y.; Wang, H.Y.; Wang, J.G.; Zhu, L.; Jiang, Q.C. Microstructure and tensile properties of in situ synthesized nano-sized TiCx/2009Al composites. Mater. Des. 2015, 79, 68–72. [Google Scholar] [CrossRef]

- Qiu, F.; Gao, X.; Tang, J.; Gao, Y.Y.; Shu, S.L.; Han, X.; Li, Q.; Jiang, Q.C. Microstructures and Tensile Properties of Al–Cu Matrix Composites Reinforced with Nano-Sized SiCp Fabricated by Semisolid Stirring Process. Metals 2017, 7, 49. [Google Scholar] [CrossRef]

- Liang, Y.H.; Han, Z.W.; Lin, Z.H.; Ren, L.Q. Study on the reaction behavior of self-propagating high-temperature synthesis of TiC ceramic in the Cu-Ti-C system. Int. J. Refract. Met. Hard Mater. 2012, 137, 221–227. [Google Scholar] [CrossRef]

- Zarrinfar, N.; Kennedy, A.R.; Shipway, P.H. Reaction synthesis of Cu-TiCx master-alloys for the production of copper-based composites. Scr. Mater. 2004, 50, 949–952. [Google Scholar] [CrossRef]

- Jha, P.; Gautam, R.K.; Tyagi, R.; Kumar, D. Sliding wear behavior of TiC-reinforced Cu-4 wt % Ni matrix composites. J. Mater. Eng. Perform. 2016, 25, 4210–4218. [Google Scholar] [CrossRef]

- Dudiy, S.V.; Lundqvist, B.I. Wetting of TiC and TiN by metals. Phys. Rev. B 2004, 69, 125421. [Google Scholar] [CrossRef]

- Shu, S.L.; Yang, H.Y.; Tong, C.Z.; Qiu, F. Fabrication of TiCx-TiB2/Al Composites for Application as a Heat Sink. Materials 2016, 9, 642. [Google Scholar] [CrossRef] [PubMed]

- Fan, Z.; Wang, Y.; Qin, T.; Zhou, X.R.; Thompson, G.E.; Pennycook, T.; Hashimoto, T. Grain refining mechanism in the Al/Al-Ti-B system. Acta Mater. 2015, 84, 292–304. [Google Scholar] [CrossRef]

- Yang, D.L.; Qiu, F.; Zhao, Q.L.; Wang, L.; Jiang, Q.C. The abrasive wear behavior of Al2014 composites reinforced with Ti5Si3-coated SiCp. Tribol. Int. 2017, 112, 33–41. [Google Scholar] [CrossRef]

- Xu, Z.M.; Liang, G.F.; Guan, Q.F.; Jiang, Q.C. TiC as heterogeneous nuclei of the (Fe, Mn) 3C and austenite intergrowth eutectic in austenite steel matrix wear resistant composite. Mater. Res. Bull. 2004, 39, 457–463. [Google Scholar]

| Samples | σ0.2/MPa | σUCS/MPa | εf/% | Hardness (HV) |

|---|---|---|---|---|

| Cu–Cr–Zr alloys | 97.1 | |||

| 2-wt % TiCp/Cu–Cr–Zr | 112.3 | |||

| 4-wt % TiCp/Cu–Cr–Zr | 118.5 |

| Matching Plane | [uvw]Cu3Ti | [uvw]Cu | θ (deg) | δ (%) |

|---|---|---|---|---|

| (010)Cu3Ti//(111)Cu | [100]Cu3Ti | [1]Cu | 0 | 1.9 |

| [1]Cu3Ti | [1]Cu | 0.33 | ||

| [00]Cu3Ti | []Cu | 0 | ||

| (111)TiC//(111)Cu | [10]TiC | [1]Cu | 0 | 19.8 |

| [01]TiC | [01]Cu | 0 | ||

| [2]TiC | [2]Cu | 0 | ||

| (100)Cu3Ti//(100)TiC | [010]Cu3Ti | [001]TiC | 0 | 1.2 |

| [01]Cu3Ti | [011]TiC | 0.7884 | ||

| [00]Cu3Ti | [010]TiC | 0 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Bai, F.; Wang, Y.; Wang, J.; Wang, W. Grain Refinement and Mechanical Properties of Cu–Cr–Zr Alloys with Different Nano-Sized TiCp Addition. Materials 2017, 10, 919. https://doi.org/10.3390/ma10080919

Zhang D, Bai F, Wang Y, Wang J, Wang W. Grain Refinement and Mechanical Properties of Cu–Cr–Zr Alloys with Different Nano-Sized TiCp Addition. Materials. 2017; 10(8):919. https://doi.org/10.3390/ma10080919

Chicago/Turabian StyleZhang, Dongdong, Fang Bai, Yong Wang, Jinguo Wang, and Wenquan Wang. 2017. "Grain Refinement and Mechanical Properties of Cu–Cr–Zr Alloys with Different Nano-Sized TiCp Addition" Materials 10, no. 8: 919. https://doi.org/10.3390/ma10080919