Effect of Austenitising Temperature on Mechanical Properties of Nanostructured Bainitic Steel

Abstract

:1. Introduction

2. Experimental Procedure

3. Results and Discussion

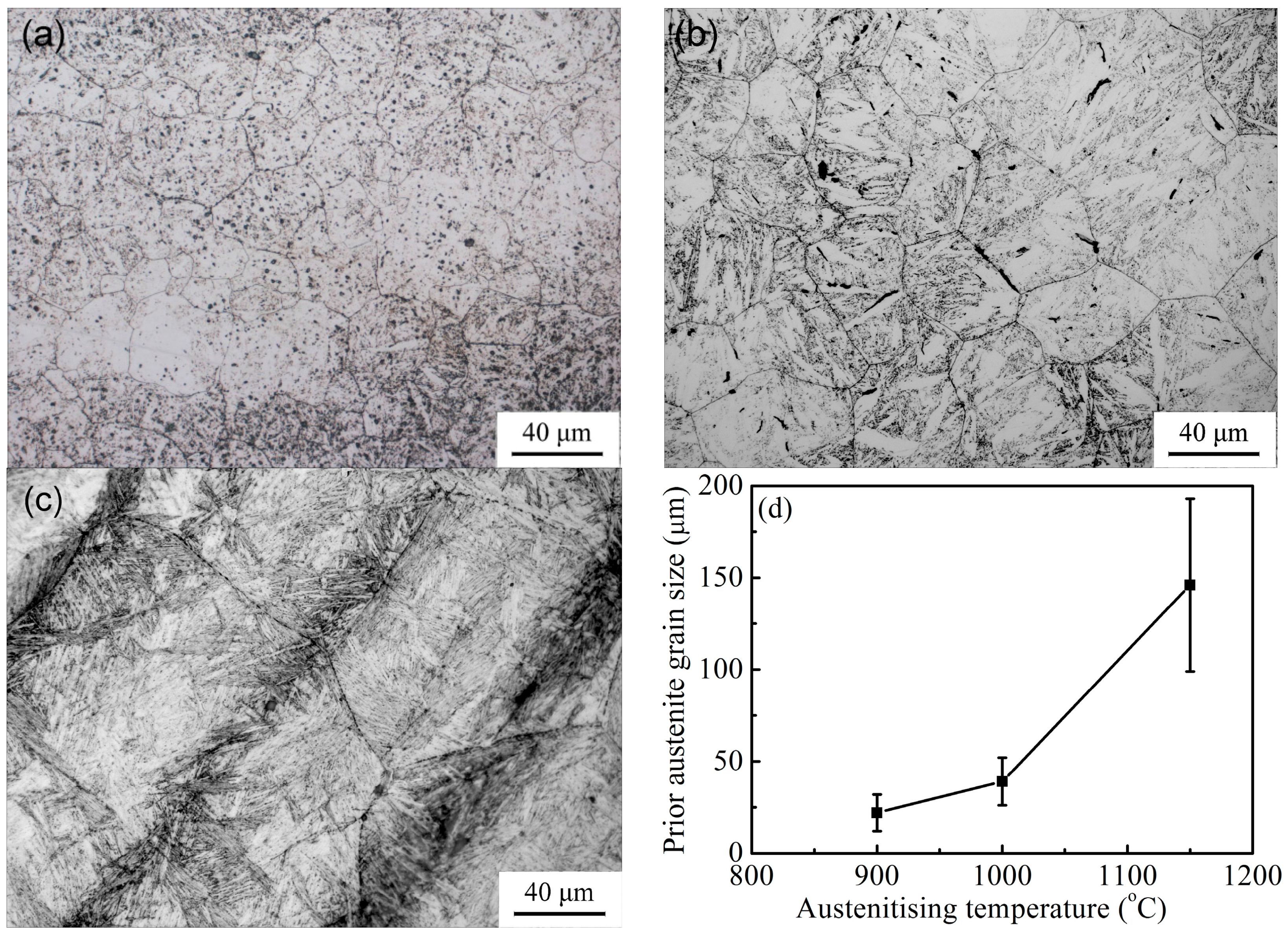

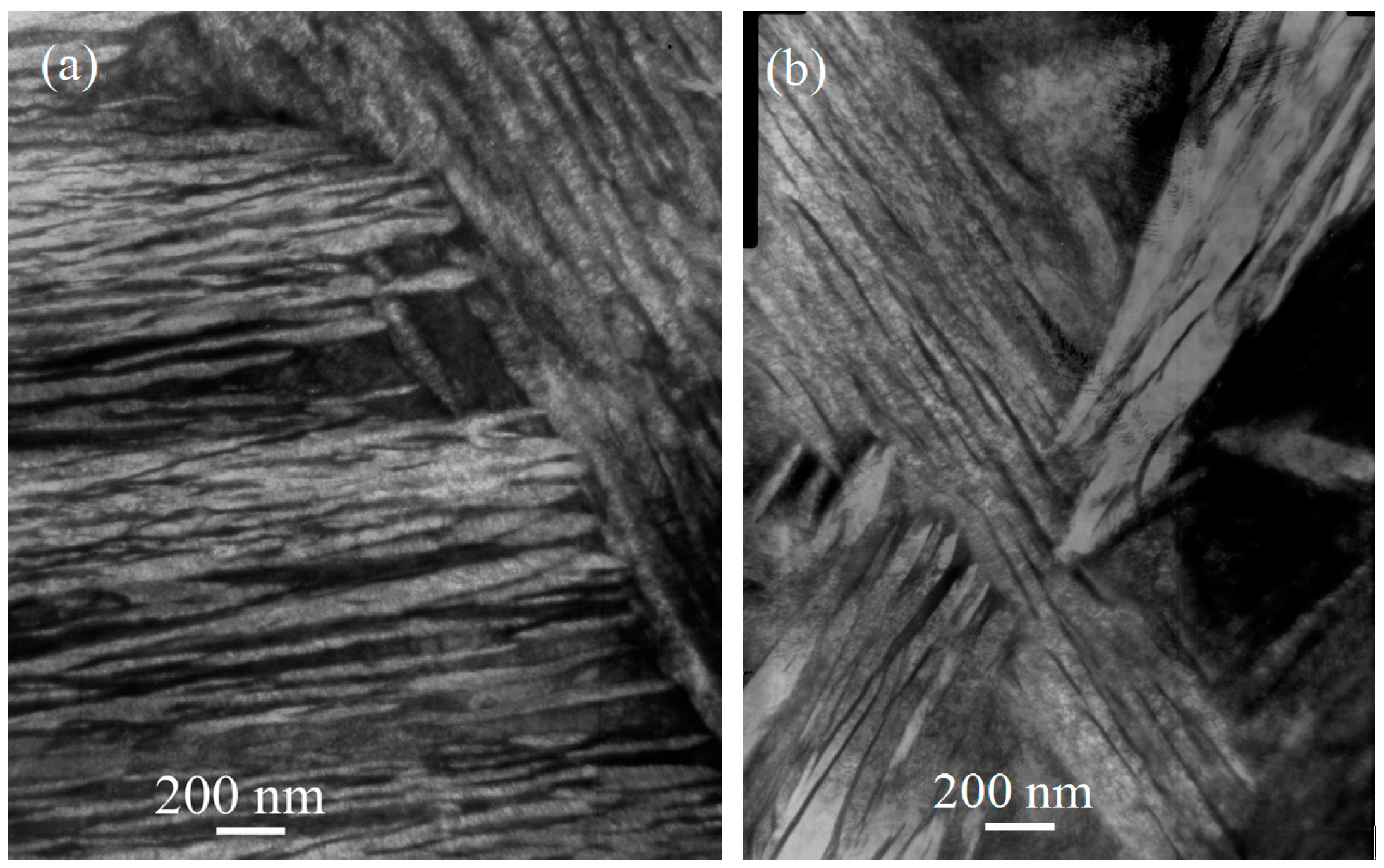

3.1. Microstructure

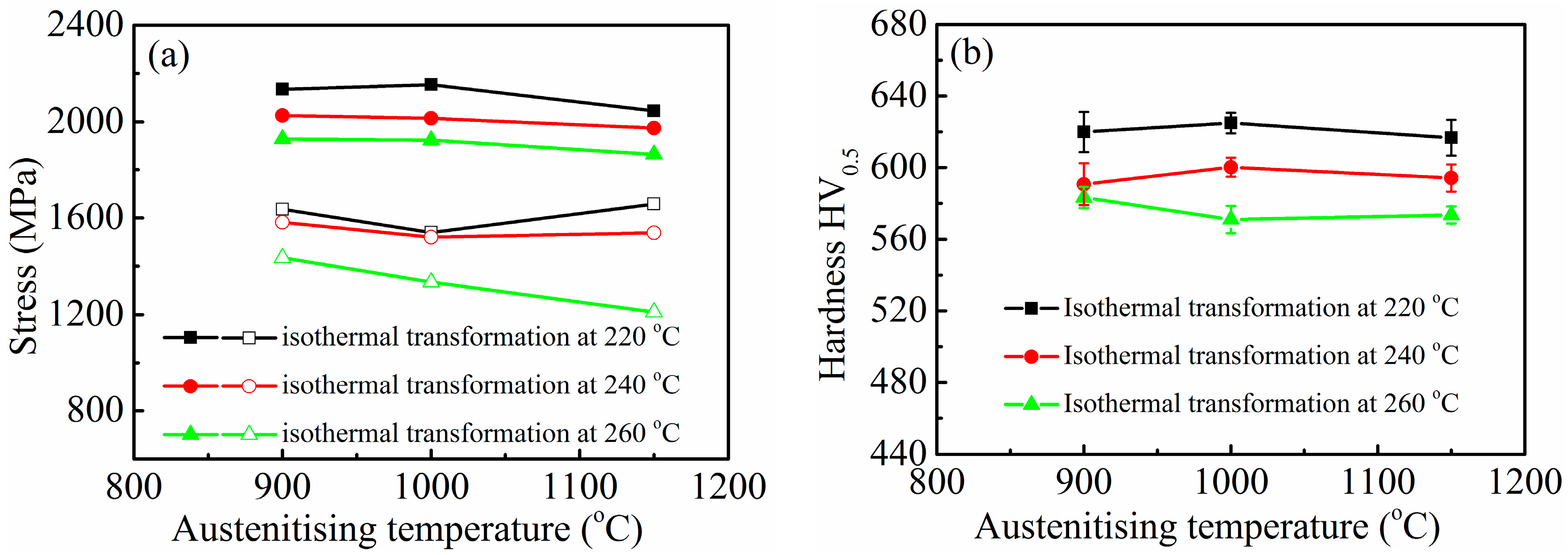

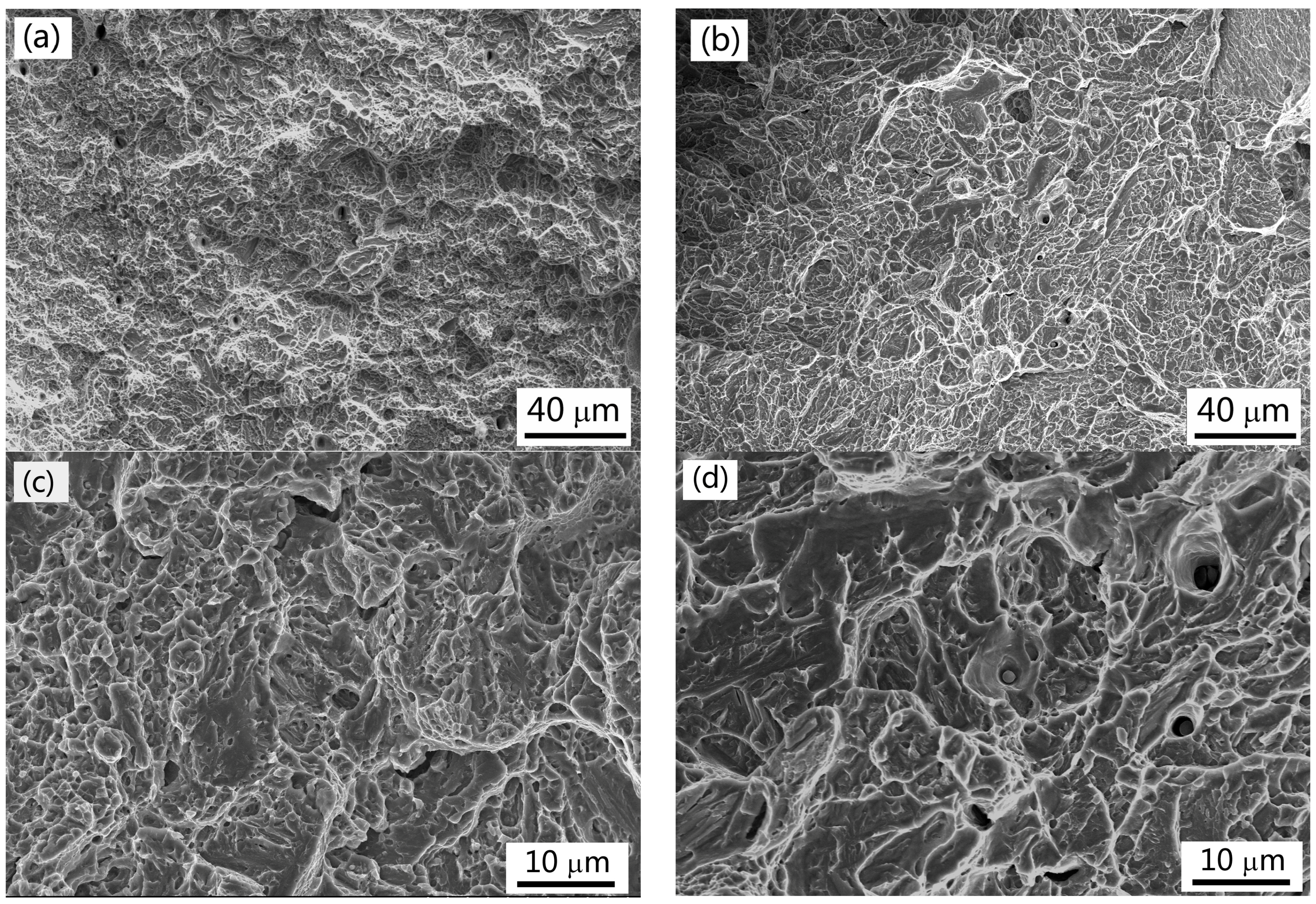

3.2. Mechanical Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Caballero, F.G.; Bhadeshia, H.K.D.H.; Mawella, K.J.A.; Jones, D.G.; Brown, P. Very strong low temperature bainite. Mater. Sci. Technol. 2002, 18, 279–284. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Mateo, C.; Caballero, F.G.; Bhadeshia, H.K.D.H. Development of hard bainite. ISIJ Int. 2003, 43, 1238–1243. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Caballero, F.G.; Bhadeshia, H.K.D.H. Low temperature bainite. J. Phys. IV 2003, 112, 285–288. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Mateo, C.; Caballero, F.G. Ultra-high-strength bainitic steels. ISIJ Int. 2005, 45, 1736–1740. [Google Scholar] [CrossRef]

- Caballero, F.G.; Bhadeshia, H.K.D.H. Very strong bainite. Curr. Opin. Solid State Mater. Sci. 2004, 8, 251–257. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Caballero, F.G.; Bhadeshia, H.K.D.H. Acceleration of low-temperature bainite. ISIJ Int. 2003, 43, 1821–1825. [Google Scholar] [CrossRef]

- Amel-Farzad, H.; Faridi, H.R.; Rajabpour, F.; Abolhasani, A.; Kazemi, S.H.; Khaledzadeh, Y. Developing very hard nanostructured bainitic steel. Mater. Sci. Eng. A 2013, 559, 68–73. [Google Scholar] [CrossRef]

- Sourmail, T.; Caballero, F.G.; Garcia-Mateo, C.; Smanio, V.; Ziegler, C.; Kuntz, M.; Elvira, R.; Leiro, A.; Vuorinen, E.; Teeri, T. Evaluation of potential of high Si high C steel nanostructured bainite for wear and fatigue applications. Mater. Sci. Technol. 2013, 29, 1166–1173. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Sourmail, T.; Caballero, F.G.; Smanio, V.; Kuntz, M.; Ziegler, C.; Leiro, A.; Vuorinen, E.; Elvira, R.; Teeri, T. Nanostructured steel industrialisation: Plausible reality. Mater. Sci. Technol. 2014, 30, 1071–1078. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Caballero, F.G.; Sourmail, T.; Kuntz, M.; Cornide, J.; Smanio, V.; Elvira, R. Tensile behaviour of a nanocrystalline bainitic steel containing 3 wt % silicon. Mater. Sci. Eng. A 2012, 549, 185–192. [Google Scholar] [CrossRef] [Green Version]

- Huang, H.; Sherif, M.Y.; Rivera-Díaz-del-Castillo, P.E.J. Combinatorial optimization of carbide-free bainitic nanostructures. Acta Mater. 2013, 61, 1639–1647. [Google Scholar] [CrossRef]

- Xu, G.; Liu, F.; Wang, L.; Hu, H.J. A new approach to quantitative analysis of bainitic transformation in a superbainite steel. Scr. Mater. 2013, 68, 833–836. [Google Scholar] [CrossRef]

- Hu, F.; Hodgson, P.D.; Wu, K.M. Acceleration of the super bainite transformation through a coarse austenite grain size. Mater. Lett. 2014, 122, 240–243. [Google Scholar] [CrossRef]

- Kong, D.; Liu, Q.; Yuan, L. Effect of austenitizing temperature on formation of hard bainite. Met. Sci. Heat Treat. 2014, 56, 444–448. [Google Scholar] [CrossRef]

- De, A.K.; Murdock, D.C.; Mataya, M.C.; Speer, J.G.; Matlock, D.K. Quantitative measurement of deformation-induced martensite in 304 stainless steel by X-ray diffraction. Scr. Mater. 2004, 50, 1445–1449. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Bainite in Steels, Transformation, Microstructure and Properties, 2nd ed.; IOM Communications Ltd.: London, UK, 2001. [Google Scholar]

- Chang, L.C.; Bhadeshia, H.K.D.H. Austenite films in bainitic microstructures. Mater. Sci. Technol. 1995, 11, 874–881. [Google Scholar] [CrossRef]

- Avishan, B.; Yazdani, S.; Caballero, F.G.; Wang, T.S.; Garcia-Mateo, C. Characterisation of microstructure and mechanical properties in two different nanostructured bainitic steels. Mater. Sci. Technol. 2015, 31, 1508–1520. [Google Scholar] [CrossRef]

- Garbarz, B.; Niżnik–Harańczyk, B. Modification of microstructure to increase impact toughness of nanostructured bainite-austenite steel. Mater. Sci. Technol. 2015, 31, 773–780. [Google Scholar] [CrossRef]

| Austenitising Temperature (°C) | Isothermal Temperature (°C) | Hardness (HV0.5) | UTS (MPa) | YS (MPa) | TEL (%) | Impact Toughness (J/cm2) |

|---|---|---|---|---|---|---|

| 900 | 220 | 619.9 ± 11.2 | 2135 | 1636 | 10.0 | 10.3 |

| 240 | 590.7 ± 11.7 | 2026 | 1582 | 4.0 | 17.2 | |

| 260 | 583.3 ± 6.0 | 1929 | 1435 | 10.0 | 19.7 | |

| 1000 | 220 | 624.9 ± 5.8 | 2154 | 1540 | 13.0 | 8.7 |

| 240 | 600.2 ± 5.3 | 2015 | 1520 | 8.6 | 16.9 | |

| 260 | 571.0 ± 7.7 | 1924 | 1334 | 12.9 | 18.3 | |

| 1150 | 220 | 616.7 ± 10.0 | 2045 | 1658 | 1.8 | 7.0 |

| 240 | 594.2 ± 7.6 | 1974 | 1538 | 2.1 | 12.0 | |

| 260 | 573.5 ± 4.8 | 1865 | 1210 | 4.0 | 12.9 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Li, J.; Ji, H.; Wang, T. Effect of Austenitising Temperature on Mechanical Properties of Nanostructured Bainitic Steel. Materials 2017, 10, 874. https://doi.org/10.3390/ma10080874

Zhao J, Li J, Ji H, Wang T. Effect of Austenitising Temperature on Mechanical Properties of Nanostructured Bainitic Steel. Materials. 2017; 10(8):874. https://doi.org/10.3390/ma10080874

Chicago/Turabian StyleZhao, Jing, Jiemin Li, Honghong Ji, and Tiansheng Wang. 2017. "Effect of Austenitising Temperature on Mechanical Properties of Nanostructured Bainitic Steel" Materials 10, no. 8: 874. https://doi.org/10.3390/ma10080874