Microstructure and Dielectric Properties of LPCVD/CVI-SiBCN Ceramics Annealed at Different Temperatures

Abstract

:1. Introduction

2. Materials and Methods

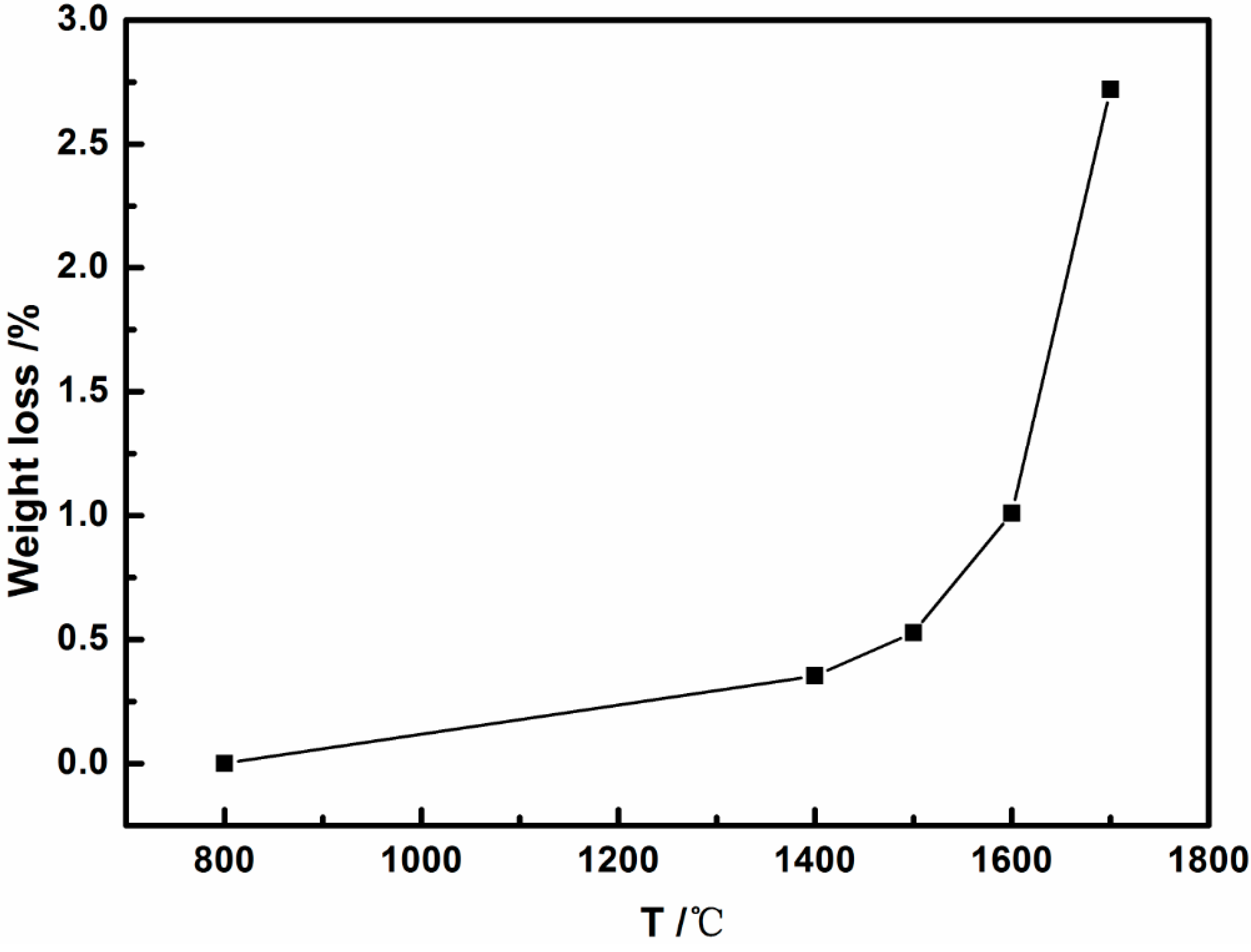

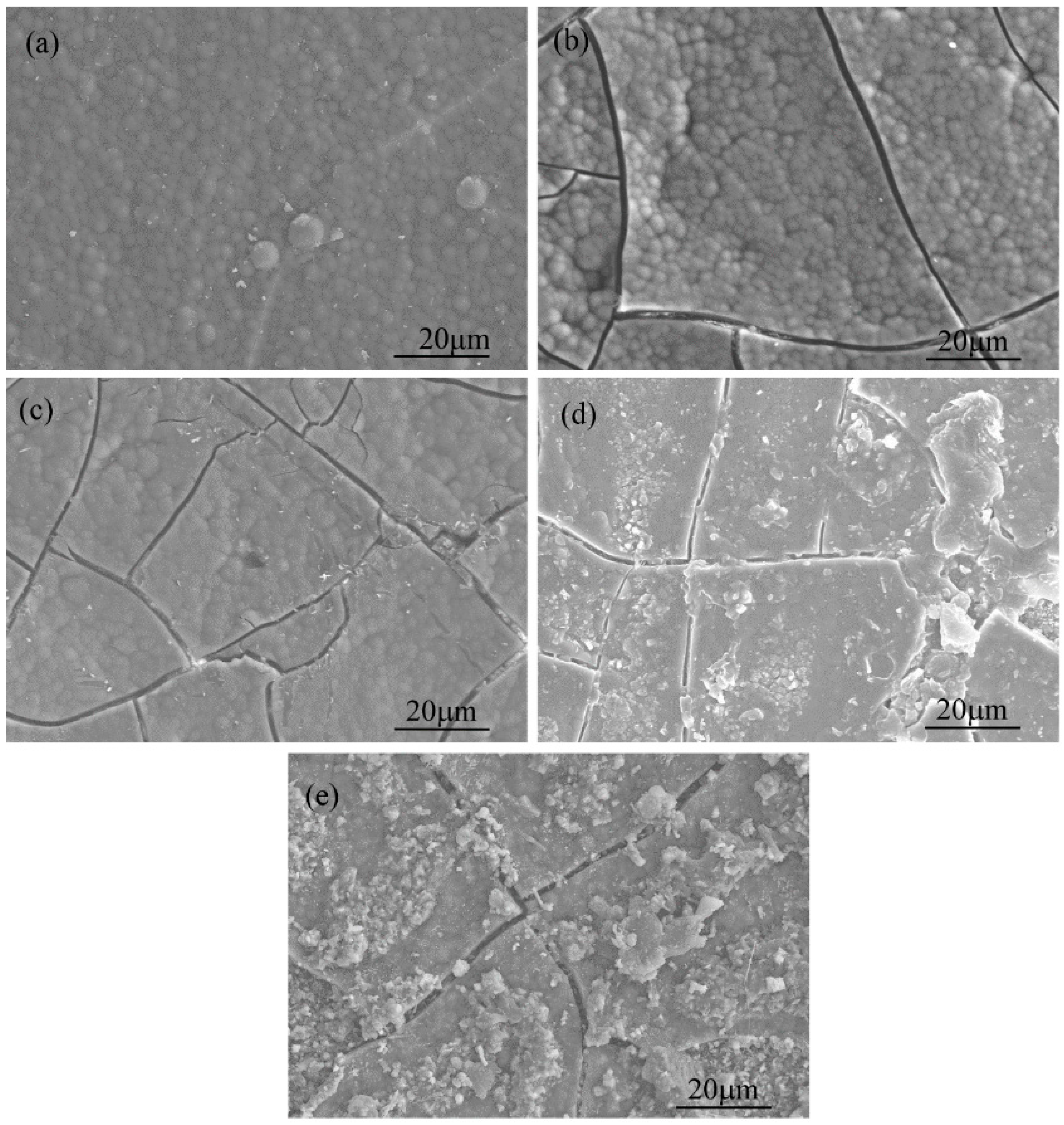

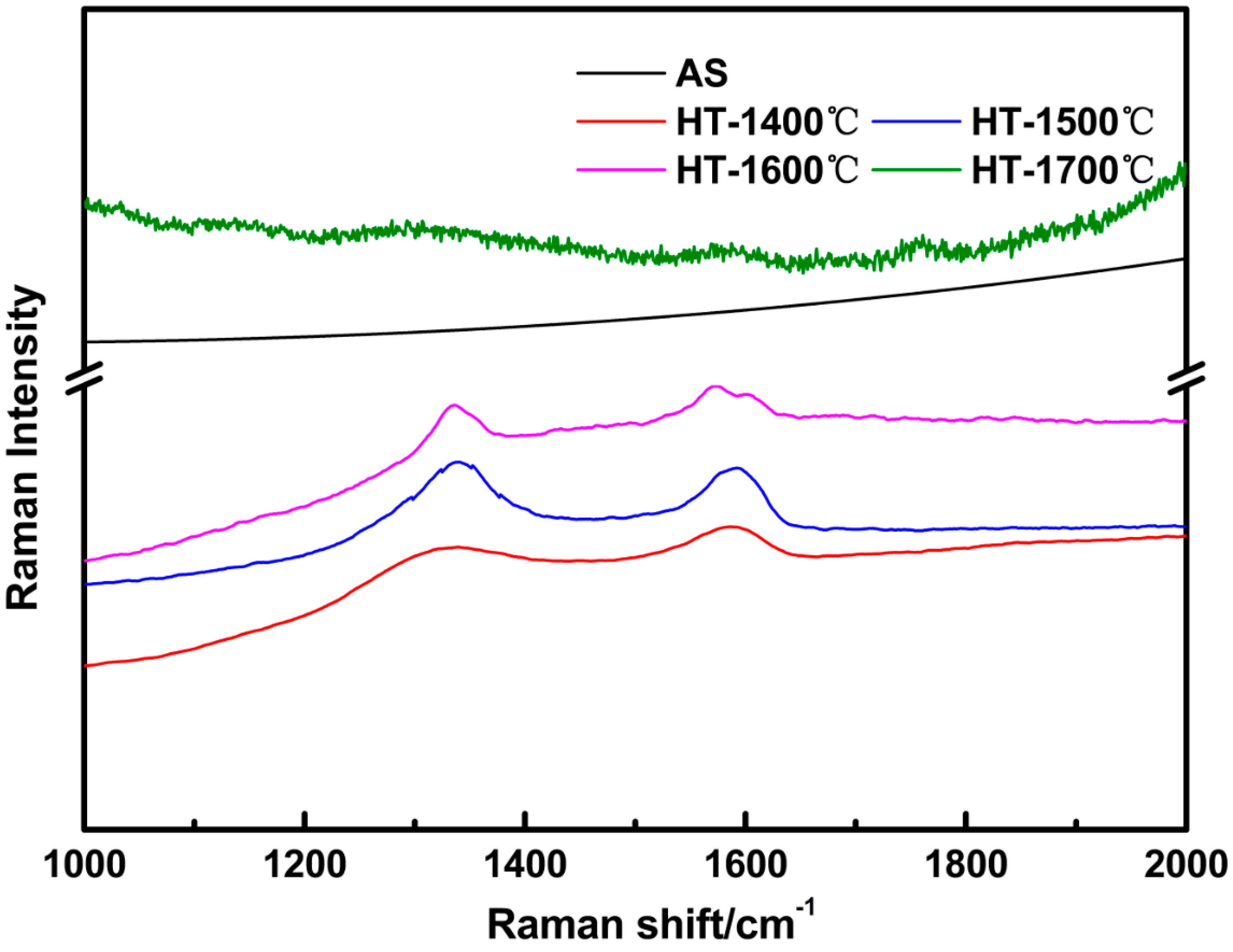

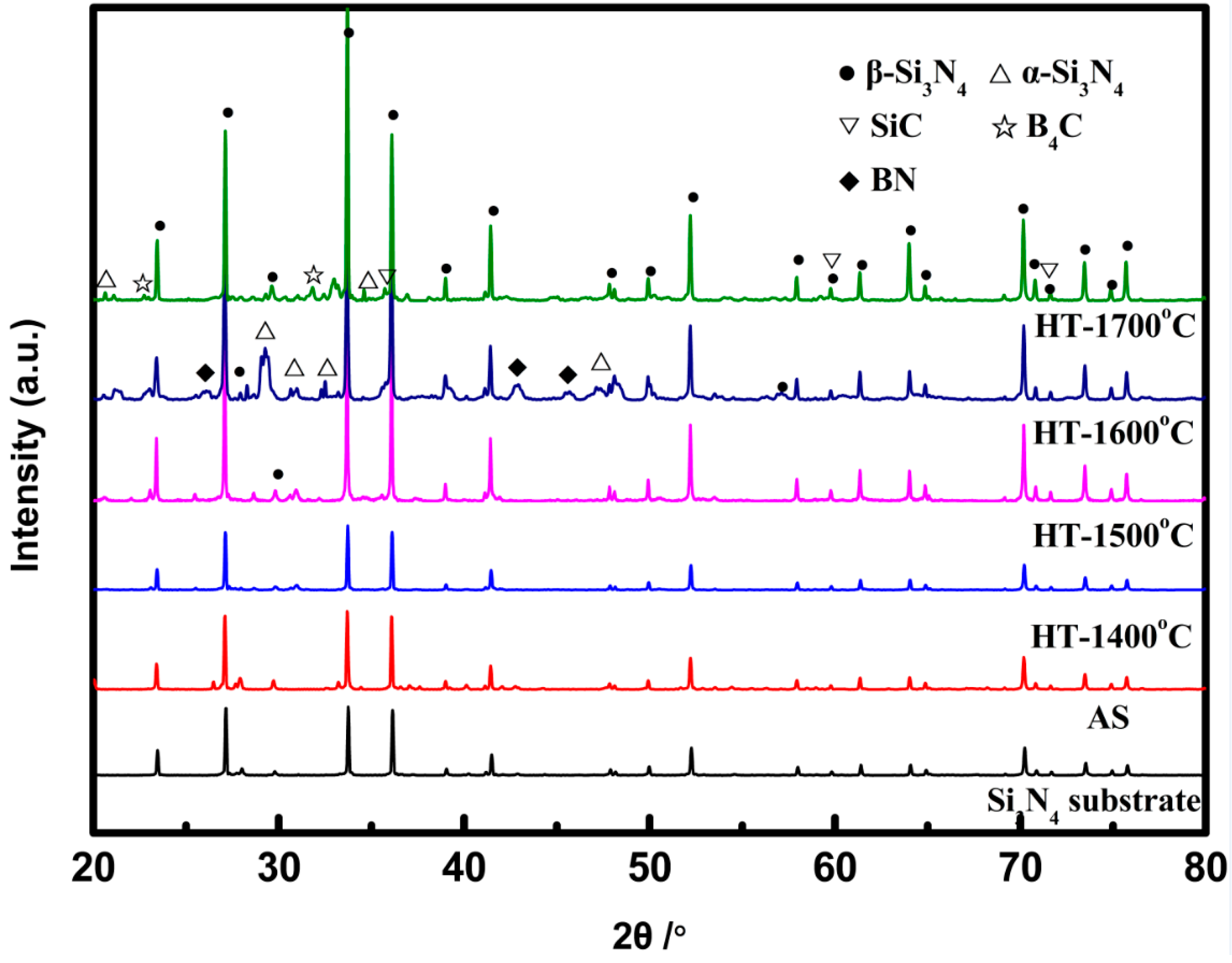

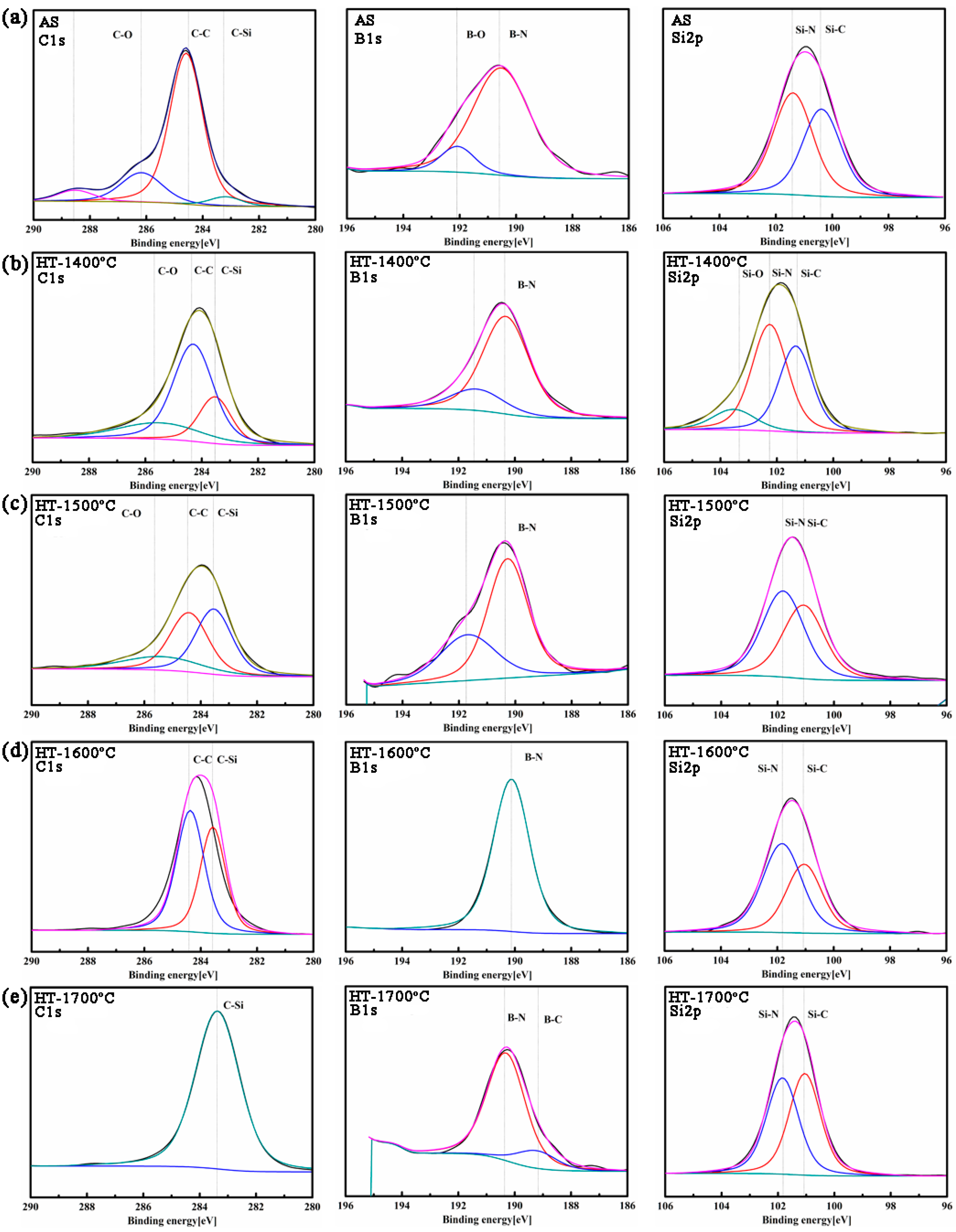

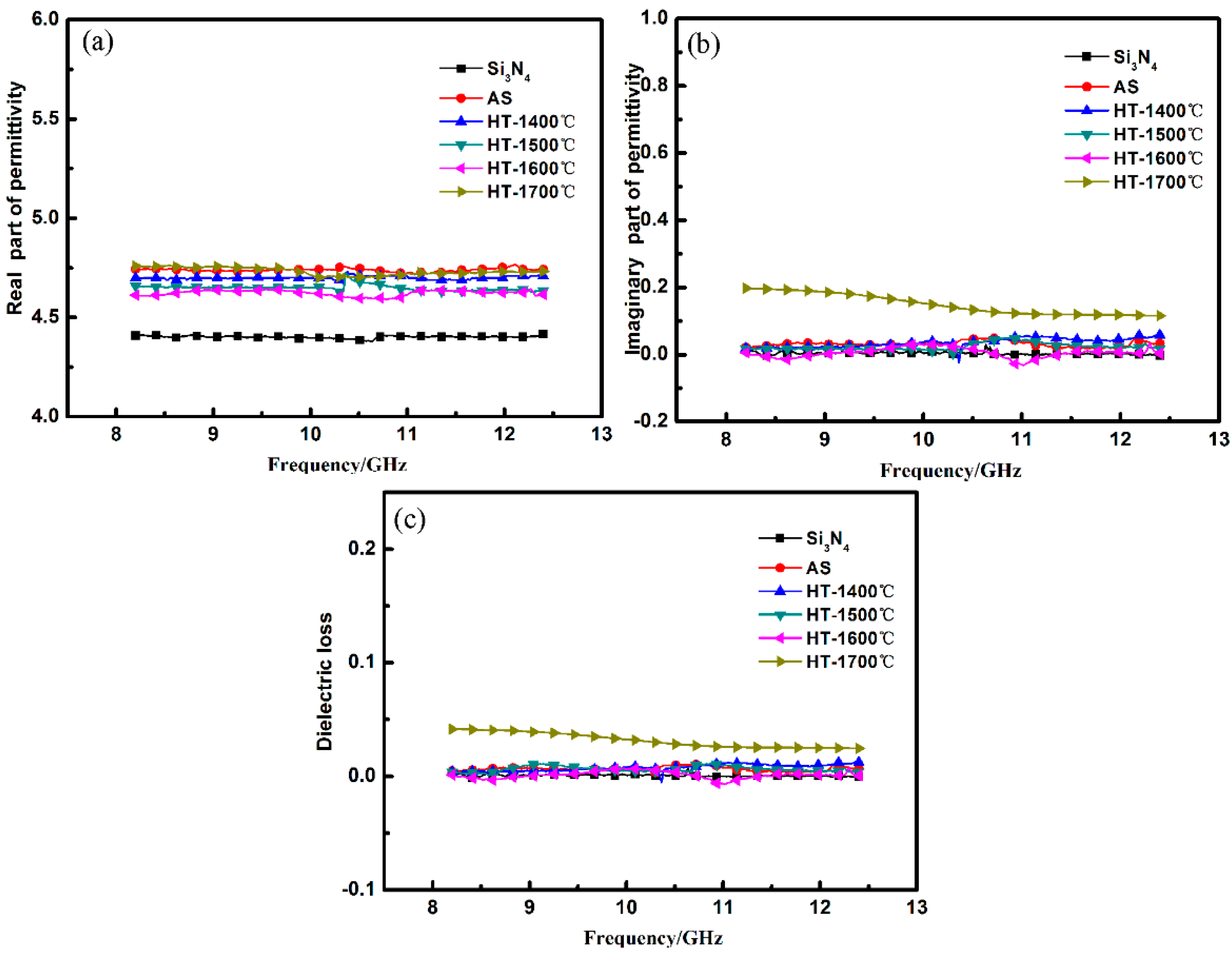

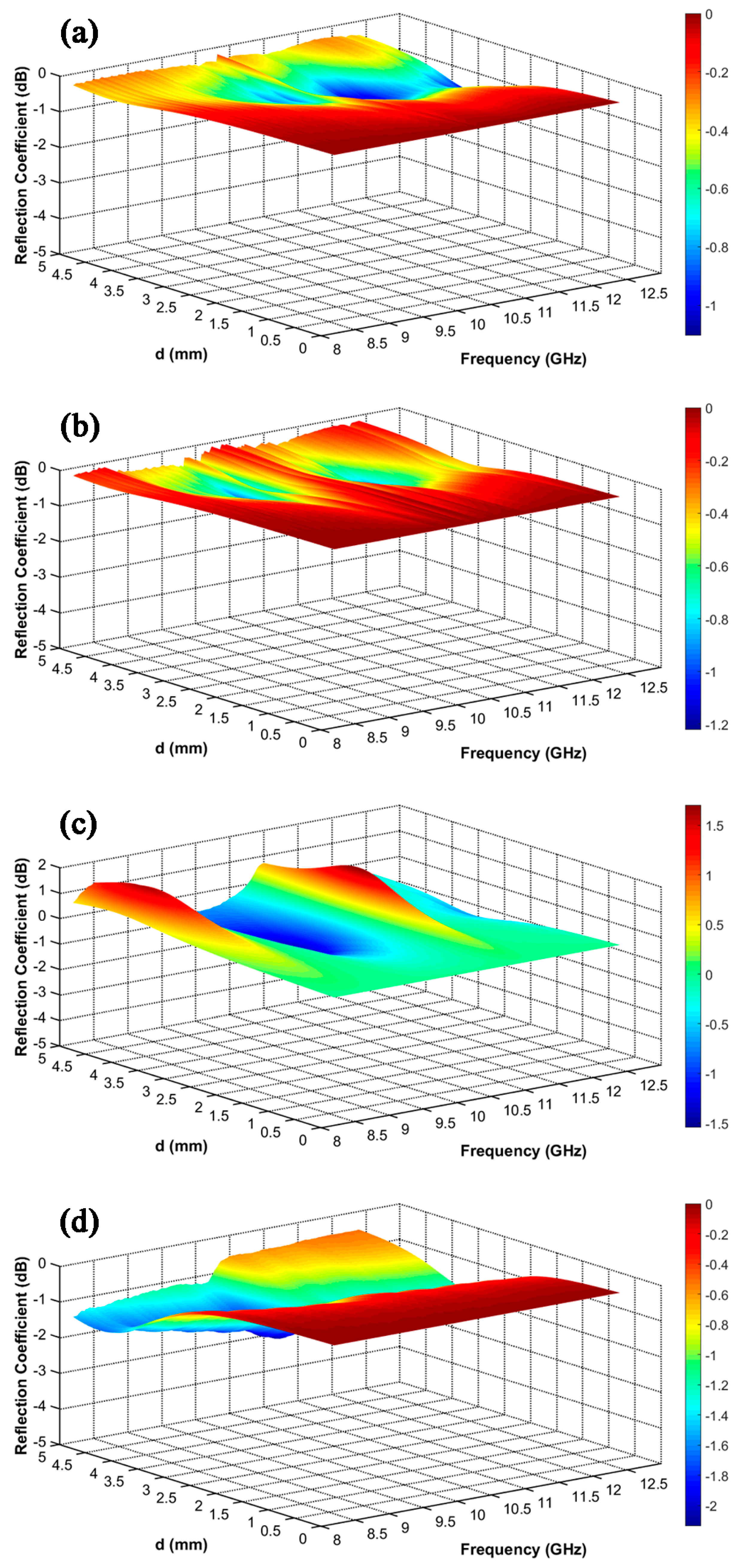

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lee, S.H.; Weinmann, M.; Aldinger, F. Processing and properties of C/Si–B–C–N fiber–reinforced ceramic matrix composites prepared by precursor impregnation and pyrolysis. Acta Mater. 2008, 56, 1529–1538. [Google Scholar] [CrossRef]

- Lee, S.-H.; Weinmann, M.; Gerstel, P.; Aldinger, F. Extraordinary thermal stability of sic particulate-reinforced polymer-derived Si–B–C–N composites. Scr. Mater. 2008, 59, 607–610. [Google Scholar] [CrossRef]

- Lee, S.H.; Weinmann, M. C fiber/SiC filler/Si–B–C–N matrix composites with extremely high thermal stability. Acta Mater. 2009, 57, 4374–4381. [Google Scholar] [CrossRef]

- Li, D.X.; Yang, Z.H.; Jia, D.C.; Duan, X.M.; He, P.G.; Zhou, Y. Ablation behavior of graphene reinforced sibcn ceramics in an oxyacetylene combustion flame. Corros. Sci. 2015, 100, 85–100. [Google Scholar] [CrossRef]

- Wang, J.Y.; Yang, Z.H.; Duan, X.M.; Jia, D.C.; Zhou, Y. Microstructure and mechanical properties of sicf/sibcn ceramic matrix composites. J. Adv. Ceram. 2015, 4, 31–38. [Google Scholar] [CrossRef]

- Ye, F.; Zhang, L.T.; Yin, X.W.; Zhang, Y.J.; Kong, L.; Liu, Y.S.; Cheng, L.F. Dielectric and microwave-absorption properties of sic nanoparticle/sibcn composite ceramics. J. Eur. Ceram. Soc. 2014, 34, 205–215. [Google Scholar] [CrossRef]

- Riedel, R.; Kienzle, A.; Dressler, W.; Ruwisch, L.; Bill, J.; Aldinger, F. A silicoboron carbonitride ceramic stable to 2000 c. Nature 1996, 382, 796–798. [Google Scholar] [CrossRef]

- Weinmann, M.; Schuhmacher, J.; Kummer, H.; Prinz, S.; Peng, J.; Seifert, H.J.; Christ, M.; Müller, K.; Bill, J.; Aldinger, F. Synthesis and thermal behavior of novel Si-BCN ceramic precursors. Chem. Mater. 2000, 12, 623–632. [Google Scholar] [CrossRef]

- Zhang, P.F.; Jia, D.C.; Yang, Z.H.; Duan, X.M.; Zhou, Y. Progress of a novel non-oxide Si-B-C-N ceramic and its matrix composites. J. Adv. Ceram. 2012, 1, 157–178. [Google Scholar] [CrossRef]

- Han, M.; Yin, X.; Duan, W.; Ren, S.; Zhang, L.; Cheng, L. Hierarchical graphene/sic nanowire networks in polymer-derived ceramics with enhanced electromagnetic wave absorbing capability. J. Eur. Ceram. Soc. 2016, 36, 2695–2703. [Google Scholar] [CrossRef]

- Duan, W.; Yin, X.; Ye, F.; Li, Q.; Han, M.; Liu, X.; Cai, Y. Synthesis and emw absorbing properties of nano sic modified PDC–SiOC. J. Mater. Chem. C 2016, 4, 5962–5969. [Google Scholar] [CrossRef]

- Melvin, G.J.H.; Ni, Q.-Q.; Wang, Z. Performance of barium titanate@carbon nanotube nanocomposite as an electromagnetic wave absorber. Phys. Status Solidi A 2017, 214. [Google Scholar] [CrossRef]

- Huo, J.; Wang, L.; Yu, H. Polymeric nanocomposites for electromagnetic wave absorption. J. Mater. Sci. 2009, 44, 3917–3927. [Google Scholar] [CrossRef]

- Melvin, G.J.H.; Ni, Q.-Q.; Suzuki, Y.; Natsuki, T. Microwave-absorbing properties of silver nanoparticle/carbon nanotube hybrid nanocomposites. J. Mater. Sci. 2014, 49, 5199–5207. [Google Scholar] [CrossRef]

- Li, Q.; Yin, X.; Duan, W.; Kong, L.; Hao, B.; Ye, F. Electrical, dielectric and microwave-absorption properties of polymer derived sic ceramics in x band. J. Alloys Compd. 2013, 565, 66–72. [Google Scholar] [CrossRef]

- Ye, F.; Zhang, L.T.; Yin, X.W.; Zhang, Y.J.; Kong, L.; Li, Q.; Liu, Y.S.; Cheng, L.F. Dielectric and emw absorbing properties of PDCs- SiBCN annealed at different temperatures. J. Eur. Ceram. Soc. 2013, 33, 1469–1477. [Google Scholar] [CrossRef]

- Sun, X.; Liu, H.T.; Li, J.S.; Cheng, H.F. Effects of CVD SiBCN interphases on mechanical and dielectric properties of Sic F/Sic composites fabricated via a pip process. Ceram. Int. 2016, 42, 82–89. [Google Scholar] [CrossRef]

- Riedel, R.; Mera, G.; Hauser, R.; Klonczynski, A. Silicon-based polymer-derived ceramics: Synthesis properties and applications—A review. J. Ceram. Soc. Jpn. 2006, 114, 425–444. [Google Scholar] [CrossRef]

- Wilden, J.; Wank, A.; Bykava, A. Dc thermal plasma CVD synthesis of coatings from liquid single source sibcn and sicnti precursors. Surf. Coat. Technol. 2005, 200, 612–615. [Google Scholar] [CrossRef]

- Dong, N.; Chai, N.; Liu, Y.; Liu, X.; Qin, H.; Zhang, X.Y.L.; Cheng, L. Thermodynamic analysis on deposition of Si B C N ceramic by low pressure chemical vapor deposition/infiltration from SiCH3Cl3–BCl3–NH3–H2–Ar system. J. Eur. Ceram. Soc. 2016, 36, 3581–3591. [Google Scholar] [CrossRef]

- Vlcek, J.; Potocky, S.; Cizek, J.; Houska, J.; Kormunda, M.; Zeman, P.; Perina, V.; Zemek, J.; Setsuhara, Y.; Konuma, S. Reactive magnetron sputtering of hard Si-B-C-N films with a high-temperature oxidation resistance. J. Vac. Sci. Technol. A 2005, 23, 1513–1522. [Google Scholar] [CrossRef]

- Yang, Z.-H.; Jia, D.-C.; Zhou, Y.; Yu, C.-Q. Fabrication and characterization of amorphous SiBCN powders. Ceram. Int. 2007, 33, 1573–1577. [Google Scholar] [CrossRef]

- Wang, Z.-C.; Aldinger, F.; Riedel, R. Novel silicon-boron-carbon nitrogen materials thermally stable up to 2200 °C. J. Am. Ceram. Soc. 2001, 84, 2179–2183. [Google Scholar] [CrossRef]

- Liu, Y.S.; Chai, N.; Liu, X.F.; Qin, H.L.; Yin, X.W.; Zhang, L.T.; Cheng, L.F. The microstructure and dielectric properties of SiBCN ceramics fabricated via LPCVD/CVI. J. Am. Ceram. Soc. 2015, 98, 2703–2706. [Google Scholar] [CrossRef]

- Xue, J.; Yin, X.; Pan, H.; Liu, X.; Zhang, L.; Cheng, L. Crystallization mechanism of CVD Si3N4–SiCN composite ceramics annealed in N2 atmosphere and their excellent emw absorption properties. J. Am. Ceram. Soc. 2016, 99, 2672–2679. [Google Scholar] [CrossRef]

- Yin, X.W.; Li, X.M.; Zhang, L.T.; Cheng, L.F.; Liu, Y.S.; Pan, T.H. Microstructure and mechanical properties of Lu2O3-doped porous silicon nitride ceramics using phenolic resin as pore-forming agent. Int. J. Appl. Ceram. Technol. 2010, 7, 391–398. [Google Scholar] [CrossRef]

- Mera, G.; Riedel, R.; Poli, F.; Müller, K. Carbon-rich SiCN ceramics derived from phenyl-containing poly (silylcarbodiimides). J. Eur. Ceram. Soc. 2009, 29, 2873–2883. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of raman spectra of disordered and amorphous carbon. Phys. Rev. B 2000, 61, 14095–14107. [Google Scholar] [CrossRef]

- Tsutsui, H.; Matsutani, T.; Kawasaki, T. Development of B-C-N-O diaphragm for environmental cell transmission electron microscope by plasma enhanced chemical vapor deposition. AIP Conf. Proc. 2010, 1282, 39–43. [Google Scholar]

- Jedrzejowski, P.; Cizek, J.; Amassian, A.; Klemberg-Sapieha, J.E.; Vlcek, J.; Martinu, L. Mechanical and optical properties of hard SiCN coatings prepared by pecvd. Thin Solid Films 2004, 447–448, 201–207. [Google Scholar] [CrossRef]

- Jeon, J.-H.; Choi, S.R.; Chung, W.S.; Kim, K.H. Synthesis and characterization of quaternary Ti–Si–C–N coatings prepared by a hybrid deposition technique. Surf. Coat. Technol. 2004, 188–189, 415–419. [Google Scholar] [CrossRef]

- Melvin, G.J.H.; Ni, Q.-Q.; Natsuki, T.; Wang, Z.; Morimoto, S.; Fujishige, M.; Takeuchi, K.; Hashimoto, Y.; Endo, M. Ag/CNT nanocomposites and their single- and double-layer electromagnetic wave absorption properties. Synth. Met. 2015, 209, 383–388. [Google Scholar] [CrossRef]

- Ni, Q.-Q.; Melvin, G.J.H.; Natsuki, T. Double-layer electromagnetic wave absorber based on barium titanate/carbon nanotube nanocomposites. Ceram. Int. 2015, 41, 9885–9892. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Zhao, M.; Liu, Y.; Chai, N.; Ye, F.; Qin, H.; Cheng, L.; Zhang, L. Microstructure and Dielectric Properties of LPCVD/CVI-SiBCN Ceramics Annealed at Different Temperatures. Materials 2017, 10, 655. https://doi.org/10.3390/ma10060655

Li J, Zhao M, Liu Y, Chai N, Ye F, Qin H, Cheng L, Zhang L. Microstructure and Dielectric Properties of LPCVD/CVI-SiBCN Ceramics Annealed at Different Temperatures. Materials. 2017; 10(6):655. https://doi.org/10.3390/ma10060655

Chicago/Turabian StyleLi, Jianping, Mingxi Zhao, Yongsheng Liu, Nan Chai, Fang Ye, Hailong Qin, Laifei Cheng, and Litong Zhang. 2017. "Microstructure and Dielectric Properties of LPCVD/CVI-SiBCN Ceramics Annealed at Different Temperatures" Materials 10, no. 6: 655. https://doi.org/10.3390/ma10060655