Effects of HfB2 and HfN Additions on the Microstructures and Mechanical Properties of TiB2-Based Ceramic Tool Materials

Abstract

:1. Introduction

2. Experimental Procedures

3. Results and Discussions

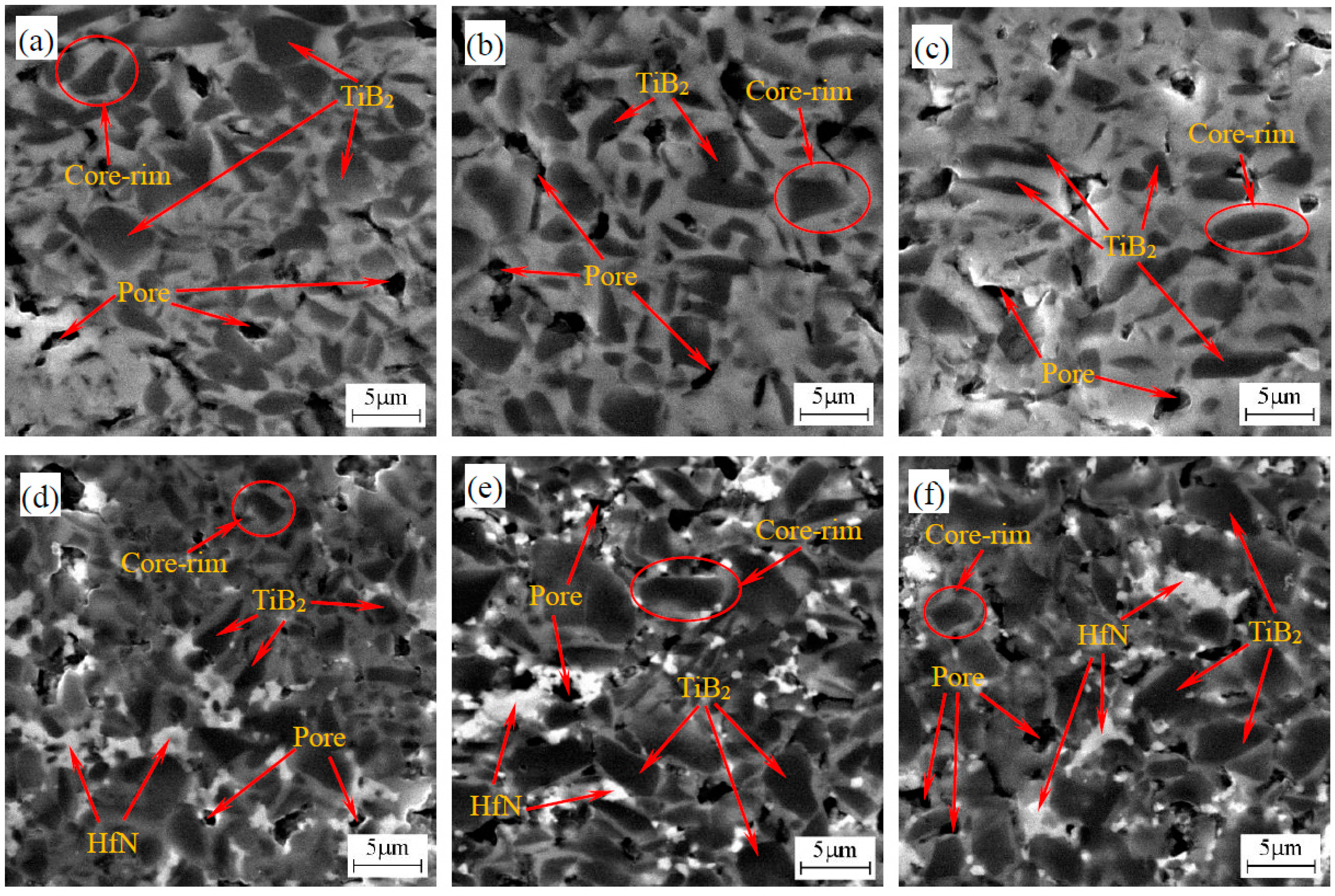

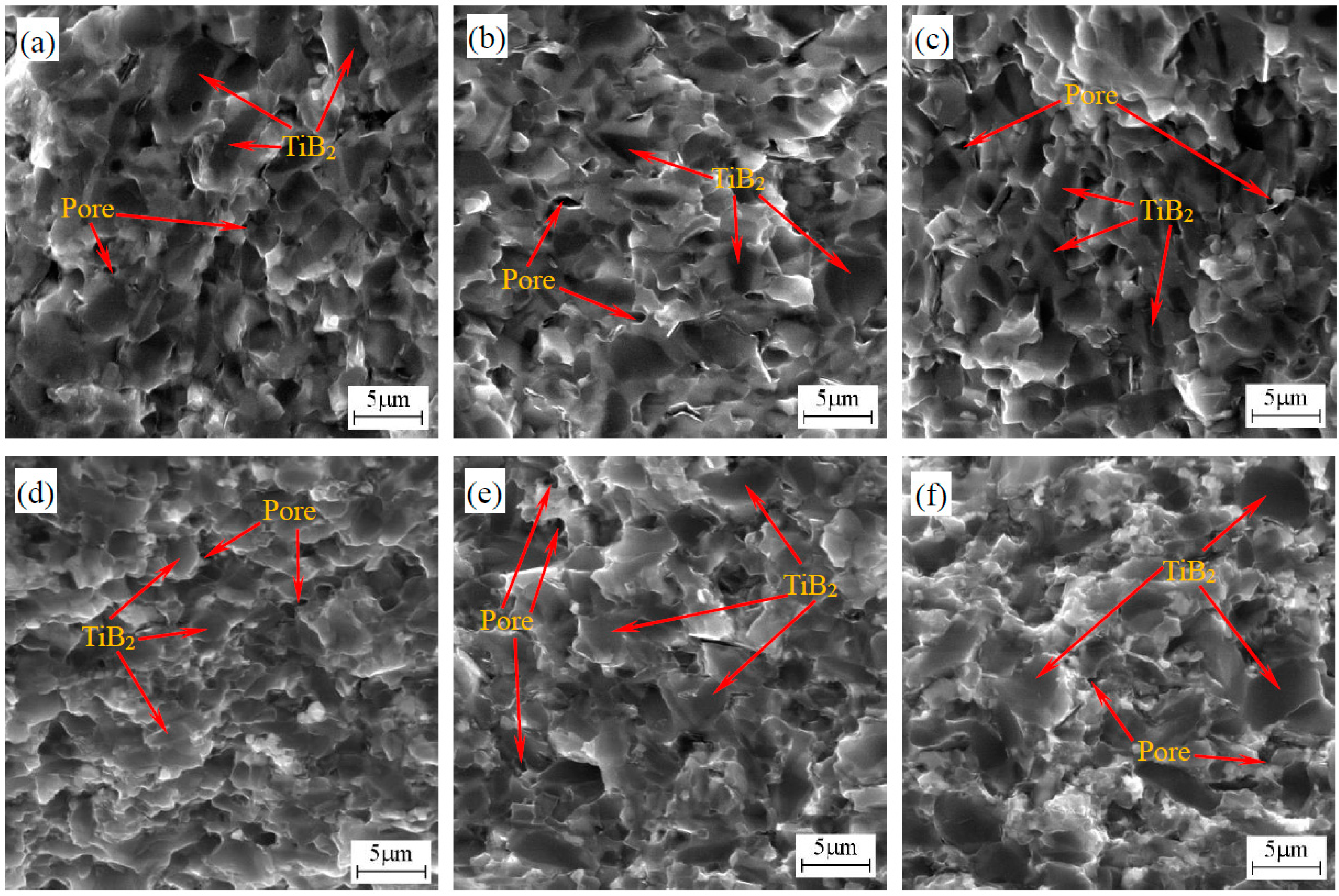

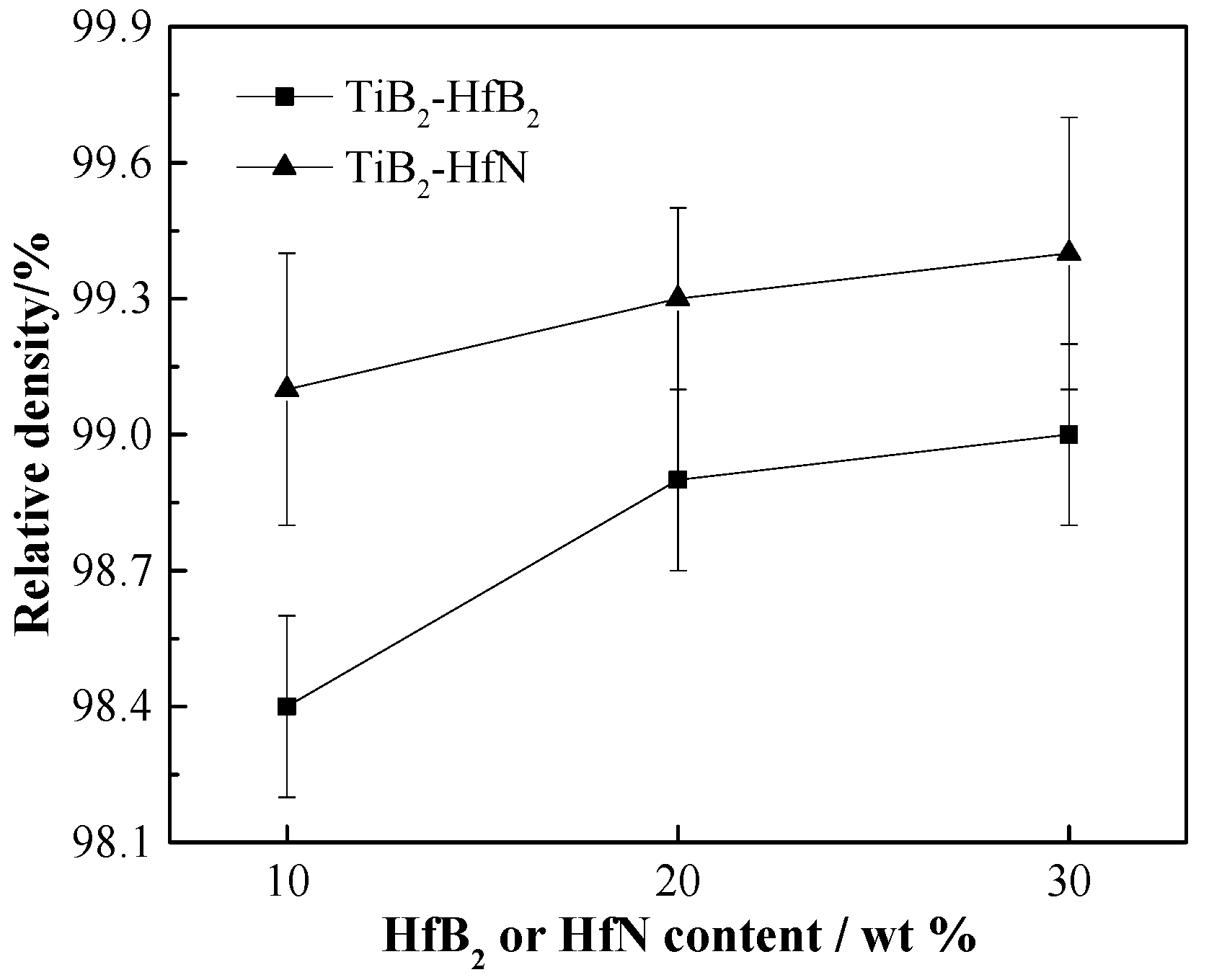

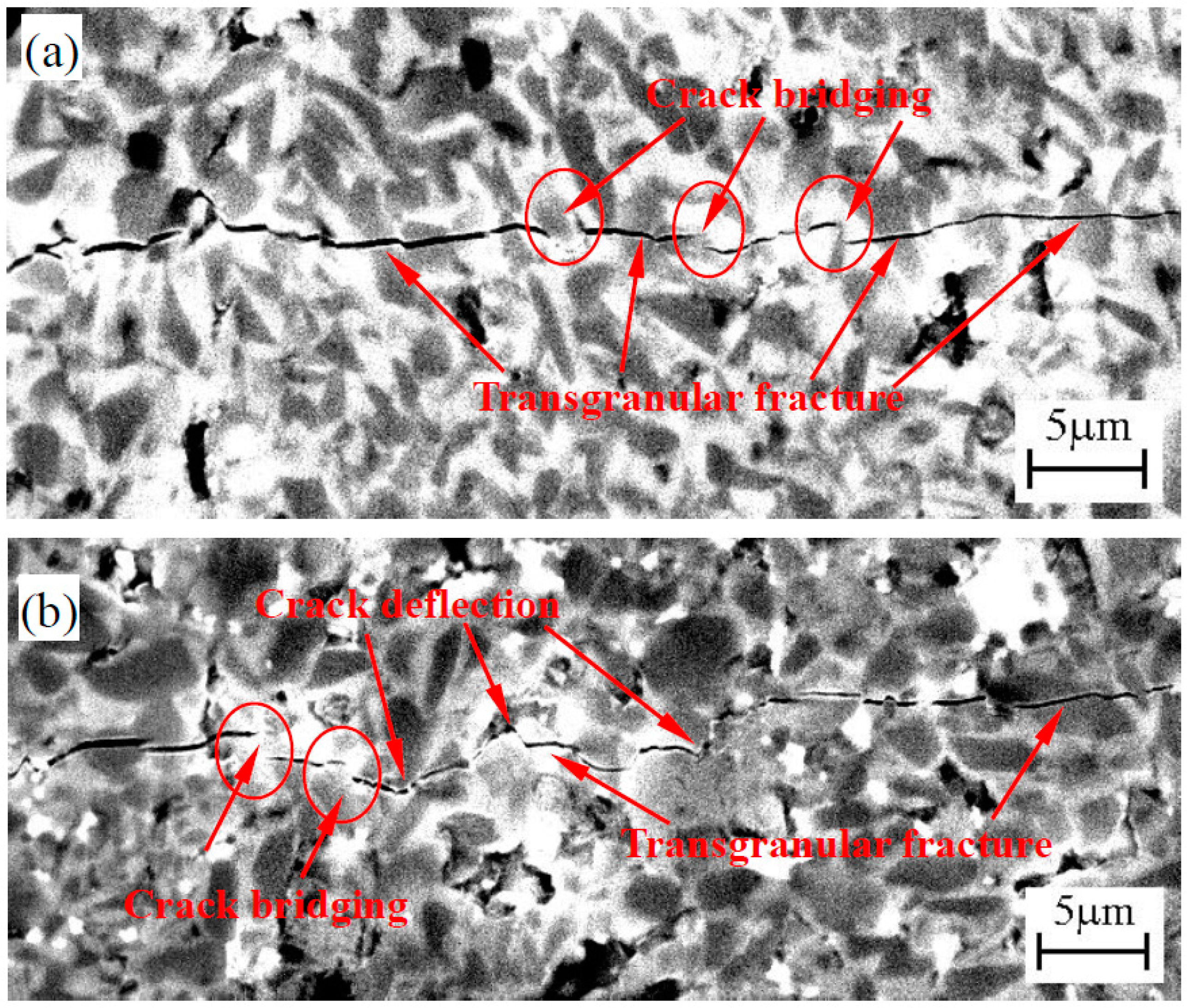

3.1. Microstructure

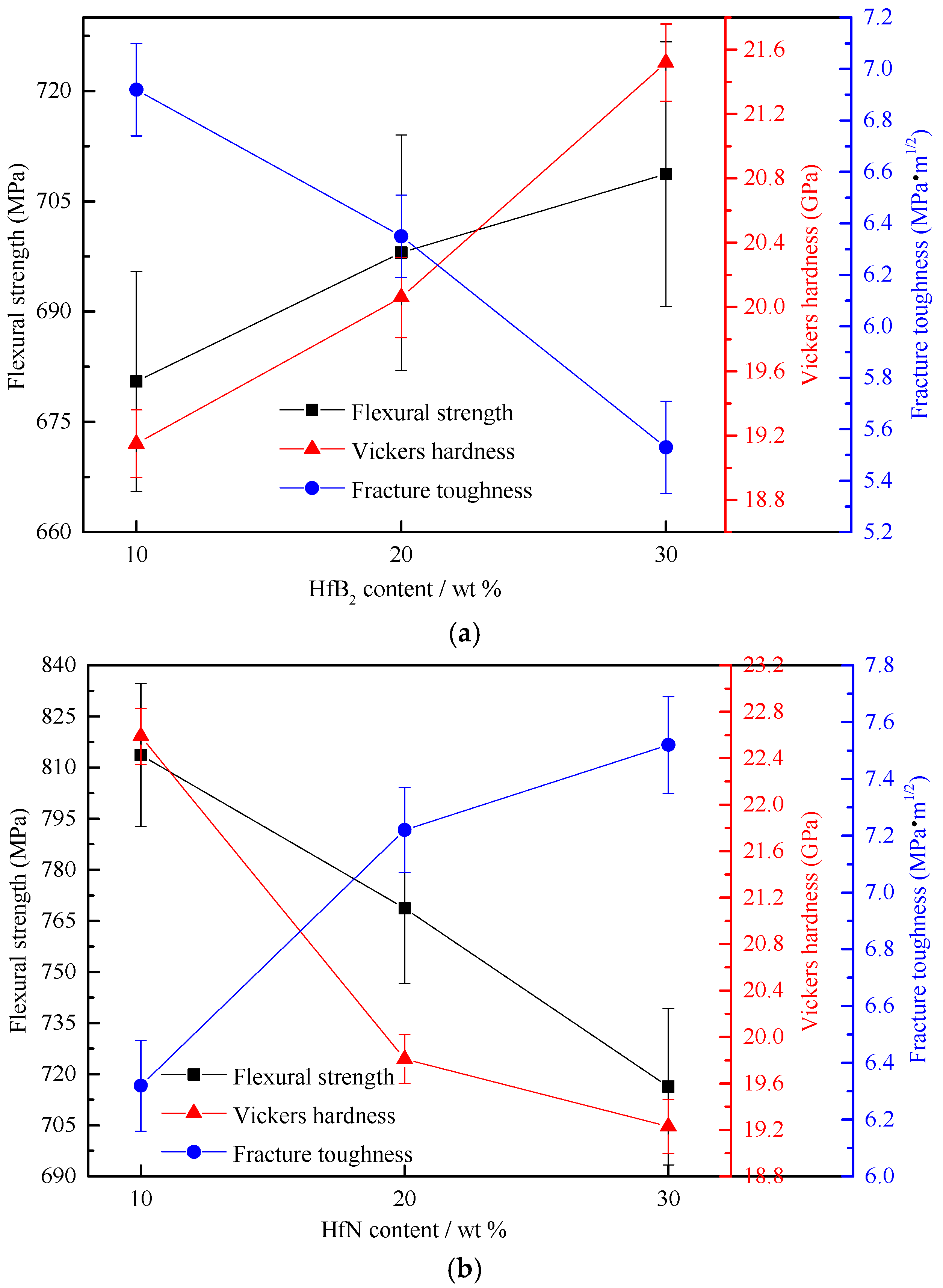

3.2. Mechanical Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, M.; Zhao, J.; Wang, L.L. Wear behaviour of Al2O3/Ti(C,N) ceramic tool during turning process of martensitic stainless steel. Mater. Res. Innov. 2015, 19, 350–354. [Google Scholar] [CrossRef]

- Zheng, G.M.; Zhao, J.; Zhou, Y.H.; Li, A.H.; Cui, X.B.; Tian, X.H. Performance of graded nano-composite ceramic tools in ultra-high-speed milling of Inconel 718. Int. J. Adv. Manuf. Technol. 2013, 67, 2799–2810. [Google Scholar] [CrossRef]

- Wang, D.; Zhao, J.; Cao, Y.; Xue, C.; Bai, Y. Wear behavior of an Al2O3/TiC/TiN micro-nano-composite ceramic cutting tool in high-speed turning of ultra-high-strength steel 300 M. Int. J. Adv. Manuf. Technol. 2016, 87, 3301–3306. [Google Scholar] [CrossRef]

- Kwon, W.T.; Kim, Y.W. Cutting performance of Si3N4 based SiC ceramic cutting tools. J. Mech. Sci. Technol. 2004, 18, 388–394. [Google Scholar] [CrossRef]

- Song, J.P.; Huang, C.Z.; Lv, M.; Zou, B.; Liu, H.L.; Wang, J. Cutting performance and failure mechanisms of TiB2-based ceramic cutting tools in machining hardened Cr12MoV mold steel. Int. J. Adv. Manuf. Technol. 2014, 70, 495–500. [Google Scholar] [CrossRef]

- Zhao, G.L.; Huang, C.Z.; He, N.; Liu, H.L.; Zou, B. Preparation and cutting performance of reactively hot pressed TiB2-SiC ceramic tool when machining Invar36 alloy. Int. J. Adv. Manuf. Technol. 2016, 86, 2679–2688. [Google Scholar] [CrossRef]

- Vlasova1, M.; Bykov, A.; Kakazey, M.; Aguilar, P.A.M.; Melnikov, I.; Rosales, I.; Tapia, R.G. Formation and Properties of TiB2-Ni Composite Ceramics. Sci. Sinter. 2016, 48, 137–146. [Google Scholar] [CrossRef]

- Lin, J.; Yang, Y.H.; Zhang, H.A.; Chen, W.F.; Huang, Y. Microstructure and mechanical properties of TiB2 ceramics enhanced by SiC particles and carbon nanotubes. Ceram. Int. 2016, 42, 4627–4631. [Google Scholar] [CrossRef]

- Demirskyi, D.; Nishimura, T.; Sakka, Y.; Vasylkiv, O. High-strength TiB2-TaC ceramic composites prepared using reactive spark plasma consolidation. Ceram. Int. 2016, 42, 1298–1306. [Google Scholar] [CrossRef]

- Raju, G.B.; Basu, B.; Tak, N.H.; Cho, S.J. Temperature dependent hardness and strength properties of TiB2 with TiSi2 sinter-aid. J. Eur. Ceram. Soc. 2009, 29, 2119–2128. [Google Scholar] [CrossRef]

- Popov, A.Y.; Sivak, A.A.; Borodianska, H.Y.; Shabalin, I.L. High toughness TiB2-Al2O3 composite ceramics produced by reactive hot pressing with fusible components. Adv. Appl. Ceram. 2015, 114, 178–182. [Google Scholar] [CrossRef]

- Song, J.P.; Huang, C.Z.; Lv, M.; Zou, B.; Wang, S.Y.; Wang, J.; An, J. Effects of TiC content and melt phase on microstructure and mechanical properties of ternary TiB2-based ceramic cutting tool materials. Mater. Sci. Eng. A 2014, 605, 137–143. [Google Scholar] [CrossRef]

- Gao, Y.B.; Tang, T.G.; Yi, C.H.; Zhang, W.; Li, D.C.; Xie, W.B.; Huang, W.; Ye, N. Study of static and dynamic behavior of TiB2-B4C composite. Mater. Des. 2016, 92, 814–822. [Google Scholar] [CrossRef]

- Demirskyi, D.; Sakka, Y.; Vasylkiv, O. High-temperature reactive spark plasma consolidation of TiB2-NbC ceramic composites. Ceram. Int. 2015, 41, 10828–10834. [Google Scholar] [CrossRef]

- Mukhopadhyay, A.; Raju, G.B.; Basu, B.; Suri, A.K. Correlation between phase evolution, mechanical properties and instrumented indentation response of TiB2-based ceramics. J. Eur. Ceram. Soc. 2009, 29, 505–516. [Google Scholar] [CrossRef]

- Li, B. Effect of ZrB2 and SiC addition on TiB2-based ceramic composites prepared by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2014, 46, 84–89. [Google Scholar] [CrossRef]

- Sonber, J.K.; Murthy, T.S.R.C.; Subramanian, C.; Krishnamurthy, N.; Hubli, R.C.; Suri, A.K. Effect of CrSi2 and HfB2 addition on densification and properties of ZrB2. Int. J. Refract. Met. Hard Mater. 2012, 31, 125–131. [Google Scholar] [CrossRef]

- Balak, Z.; Zakeri, M. Effect of HfB2 on microstructure and mechanical properties of ZrB2-SiC-based composites. Int. J. Refract. Met. Hard Mater. 2016, 54, 127–137. [Google Scholar] [CrossRef]

- Tu, R.; Li, N.; Li, Q.Z.; Zhang, S.; Zhang, L.M.; Goto, T. Effect of microstructure on mechanical, electrical and thermal properties of B4C-HfB2 composites prepared by arc melting. J. Eur. Ceram. Soc. 2016, 36, 3929–3937. [Google Scholar] [CrossRef]

- Wang, S.H.; Zhang, Y.C.; Sun, Y.; Xu, Y.; Yang, M. Synthesis and characteristic of SiBCN/HfN ceramics with high temperature oxidation resistance. J. Alloys Compd. 2016, 685, 828–835. [Google Scholar] [CrossRef]

- Li, B.H.; Liu, Y.; Cao, H.; He, L.; Li, J. Rapid synthesis of TiB2/Fe composite in situ by spark plasma sintering. J. Mater. Sci. 2009, 44, 3909–3912. [Google Scholar] [CrossRef]

- Sáez, A.; Arenas, F.; Vidal, E. Microstructure development of WCoB-TiC based hard materials. Int. J. Refract. Met. Hard Mater. 2003, 21, 13–18. [Google Scholar] [CrossRef]

- Zhang, G.; Yang, J.H. In situ synthesis aluminum borate whiskers reinforced TiB2 matrix composites for application in aluminum reduction cells. JOM 2013, 65, 1467–1471. [Google Scholar] [CrossRef]

- Farhadi, K.; Namini, A.S.; Asl, M.S.; Mohammadzadeh, A.; Kakroudi, M.G. Characterization of hot pressed SiC whisker reinforced TiB2 based composites. Int. J. Refract. Met. Hard Mater. 2016, 61, 84–90. [Google Scholar] [CrossRef]

- Cui, H.Z.; Zhang, Y.F.; Zhang, G.S.; Liu, W.; Song, X.J.; Wei, N. Pore and microstructure change induced by SiC whiskers and particles in porous TiB2-TiC-Ti3SiC2 composites. Ceram. Int. 2016, 42, 8376–8384. [Google Scholar] [CrossRef]

- China State Bureau of Technological Supervision. Chinese National Standards—Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Test Method for Flexural Strength of Monolithic Ceramics at Room Temperature; Chinese Standard Publishing House: Beijing, China, 2006. [Google Scholar]

- Zhao, G.L.; Huang, C.Z.; He, N.; Liu, H.L.; Zou, B. Microstructure and mechanical properties at room and elevated temperatures of reactively hot pressed TiB2-TiC-SiC composite ceramic tool materials. Ceram. Int. 2016, 42, 5353–5361. [Google Scholar] [CrossRef]

- China State Bureau of Technological Supervision. Chinese National Standards—Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Test Method for Flexural Strength of Monolithic Ceramics at Room Temperature; Chinese Standard Publishing House: Beijing, China, 2009. [Google Scholar]

- Khalfallah, I.; Aning, A. Bulk Processing and Mechanical Properties of Ni3Mo. In Proceedings of the 143rd TMS Annual Meeting & Exhibition, San Diego, CA, USA, 16–20 February 2014; pp. 999–1006. [Google Scholar]

- Qi, L.; Jin, Y.C.; Zhao, Y.H.; Yang, X.M.; Zhao, H.; Han, P. The structural, elastic, electronic properties and Debye temperature of Ni3Mo under pressure from first-principles. J. Alloys Compd. 2015, 621, 383–388. [Google Scholar] [CrossRef]

- Chen, H.B.; Wang, Z.; Wu, Z.J. Investigation and characterization of densification, processing and mechanical properties of TiB2-SiC ceramics. Mater. Des. 2014, 64, 9–14. [Google Scholar] [CrossRef]

- Anggraini, L.; Isonishi, K.; Ameyama, K. Toughening and strengthening of ceramics composite through microstructural refinement. Am. Inst. Phys. 2016, 1725, 1–5. [Google Scholar]

- Fu, Z.Z.; Koc, R. Sintering and mechanical properties of TiB2-TiC-Ni using submicron borides and carbides. Mater. Sci. Eng. A 2016, 676, 278–288. [Google Scholar] [CrossRef]

| Sample | TiB2/wt % | HfB2/wt % | HfN/wt % | Ni/wt % | Mo/wt % |

|---|---|---|---|---|---|

| S1 | 82 | 10 | - | 4 | 4 |

| S2 | 72 | 20 | - | 4 | 4 |

| S3 | 62 | 30 | - | 4 | 4 |

| S4 | 82 | - | 10 | 4 | 4 |

| S5 | 72 | - | 20 | 4 | 4 |

| S6 | 62 | - | 30 | 4 | 4 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, J.; Song, J.; Liang, G.; Gao, J.; Xie, J.; Cao, L.; Wang, S.; Lv, M. Effects of HfB2 and HfN Additions on the Microstructures and Mechanical Properties of TiB2-Based Ceramic Tool Materials. Materials 2017, 10, 461. https://doi.org/10.3390/ma10050461

An J, Song J, Liang G, Gao J, Xie J, Cao L, Wang S, Lv M. Effects of HfB2 and HfN Additions on the Microstructures and Mechanical Properties of TiB2-Based Ceramic Tool Materials. Materials. 2017; 10(5):461. https://doi.org/10.3390/ma10050461

Chicago/Turabian StyleAn, Jing, Jinpeng Song, Guoxing Liang, Jiaojiao Gao, Juncai Xie, Lei Cao, Shiying Wang, and Ming Lv. 2017. "Effects of HfB2 and HfN Additions on the Microstructures and Mechanical Properties of TiB2-Based Ceramic Tool Materials" Materials 10, no. 5: 461. https://doi.org/10.3390/ma10050461