Preparation and Optical Properties of Infrared Transparent 3Y-TZP Ceramics

Abstract

:1. Introduction

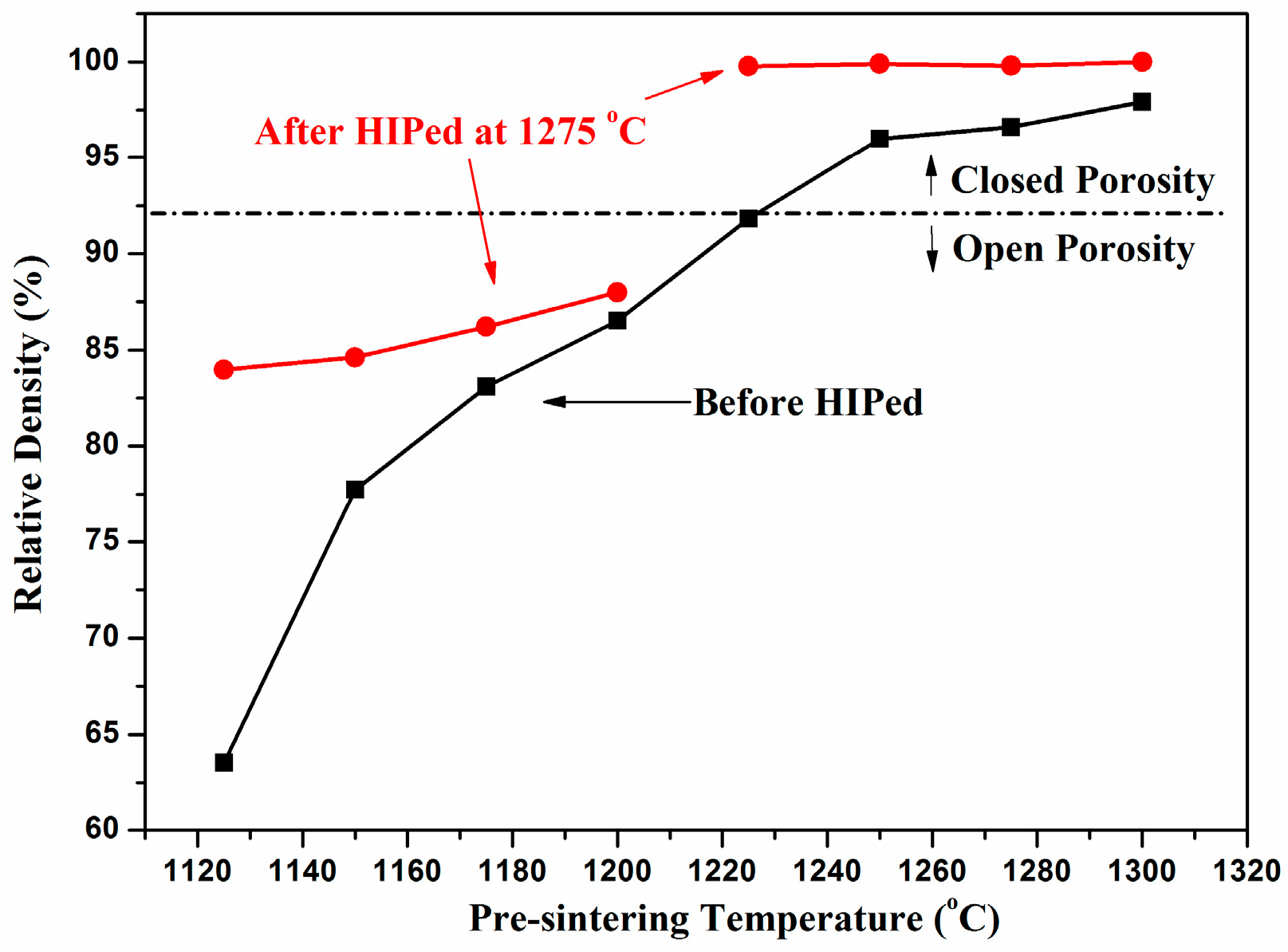

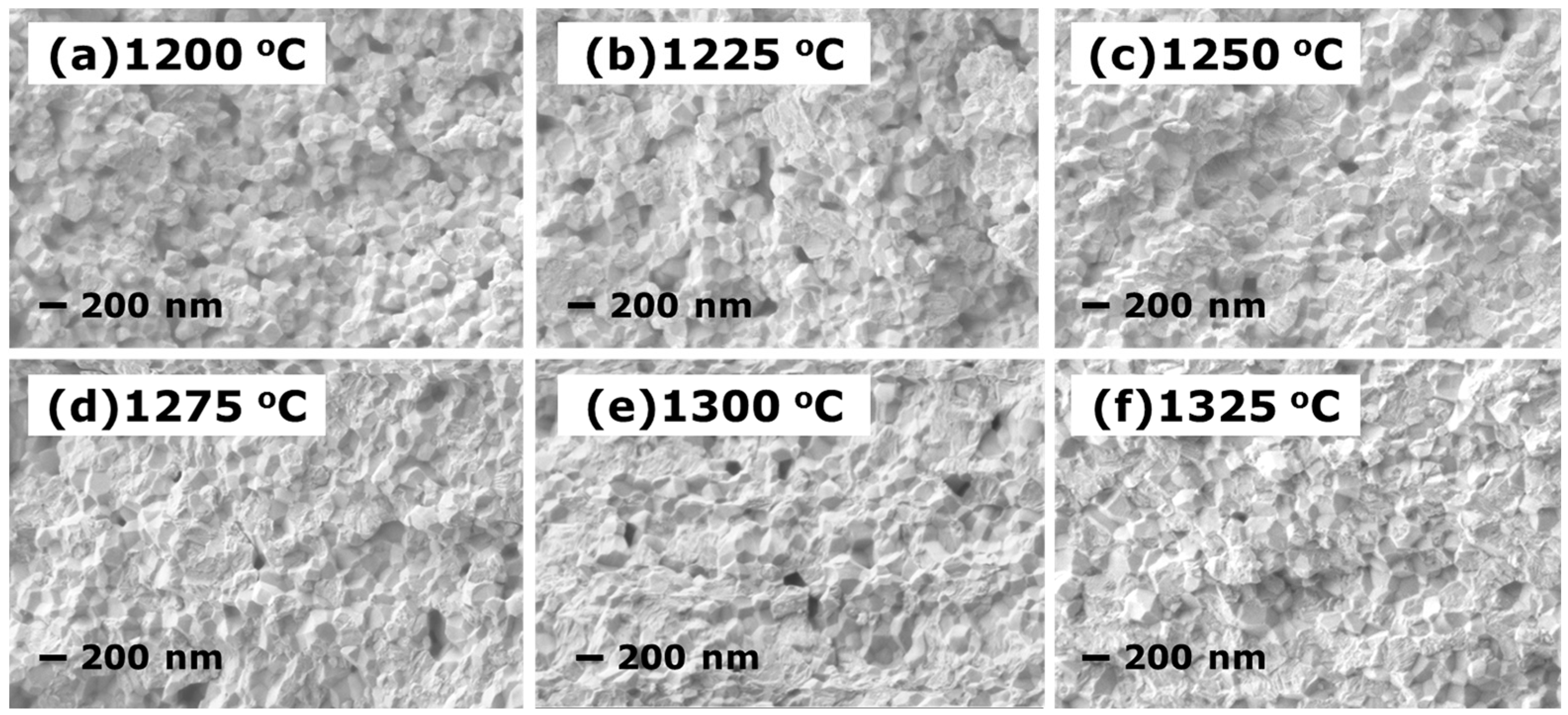

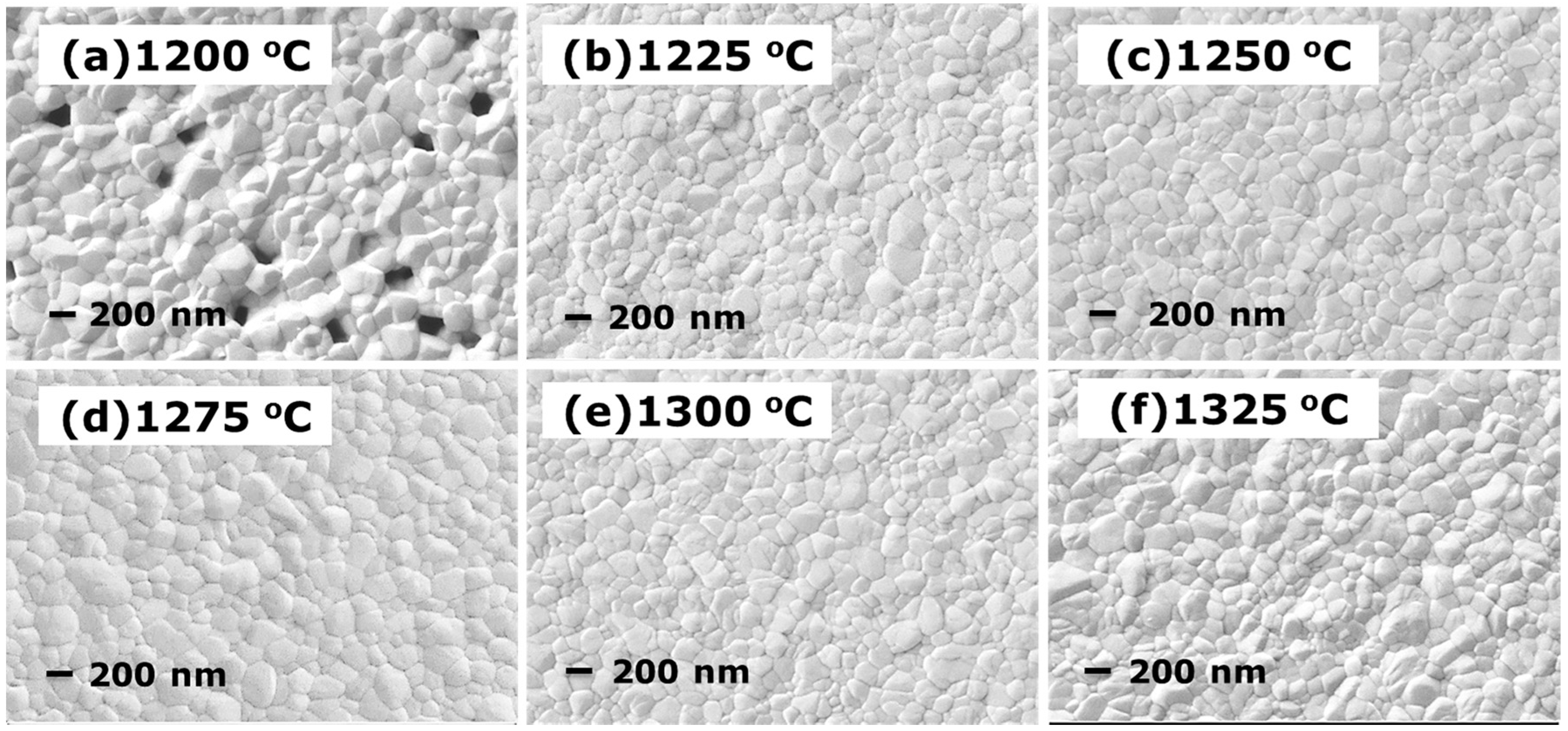

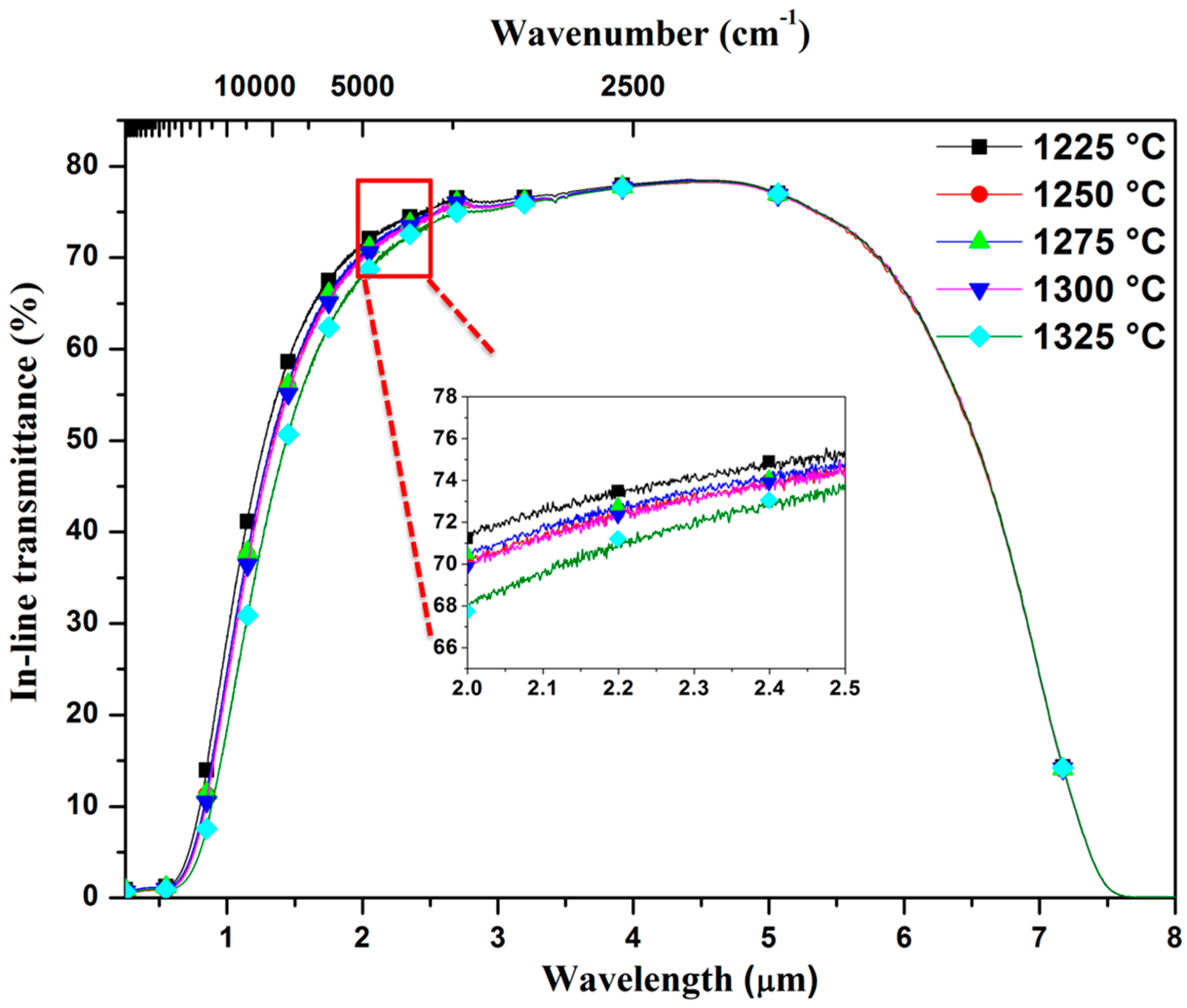

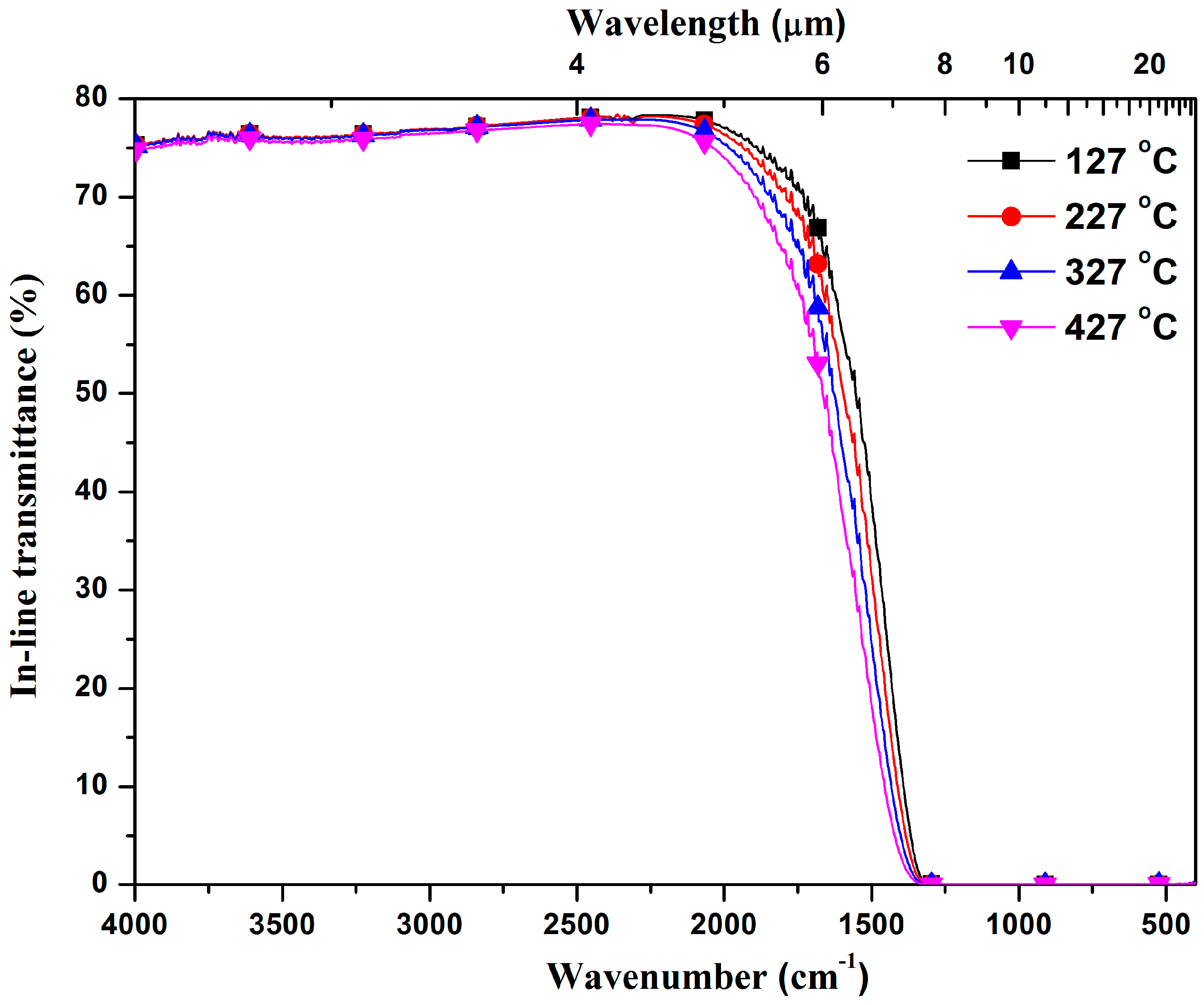

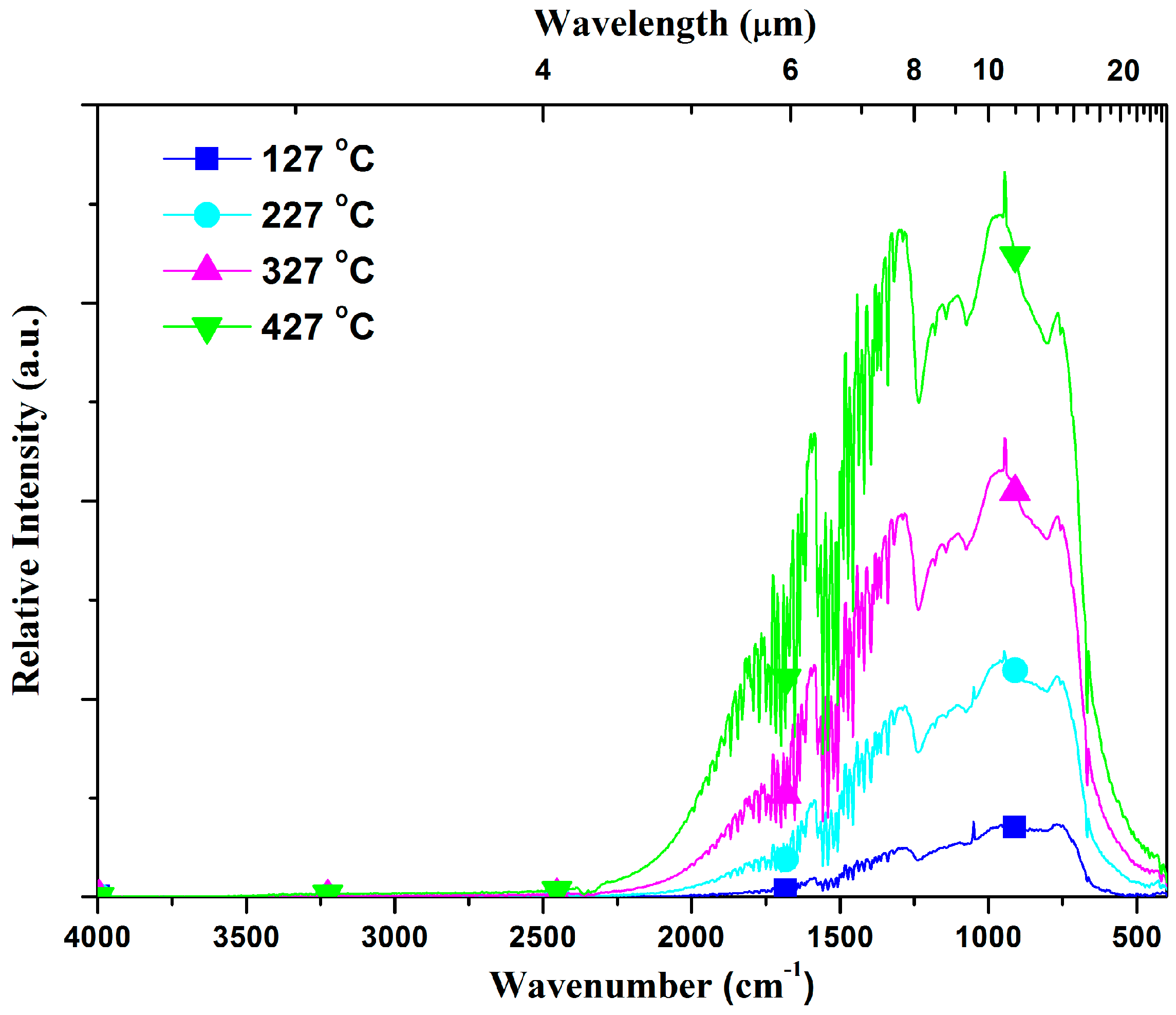

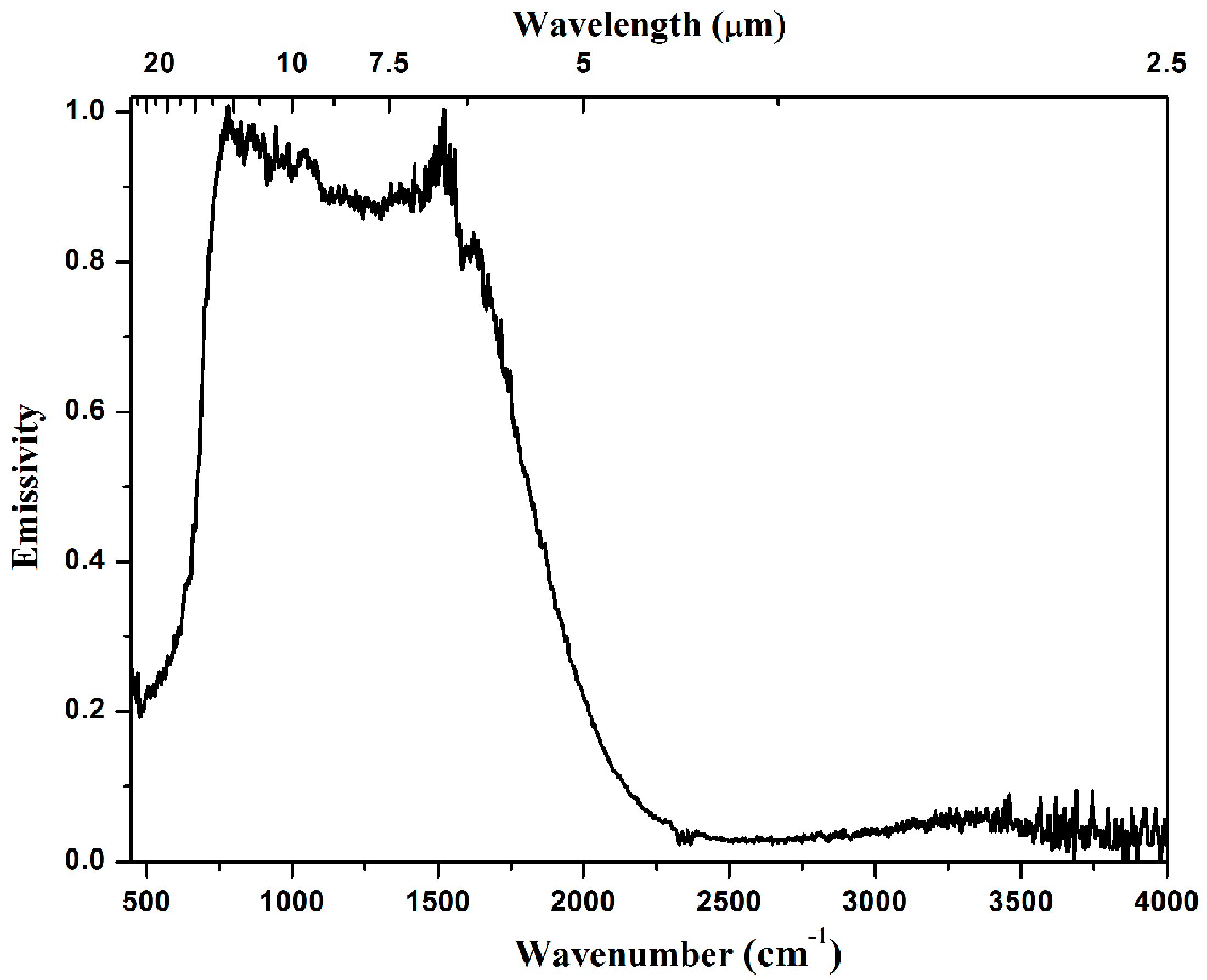

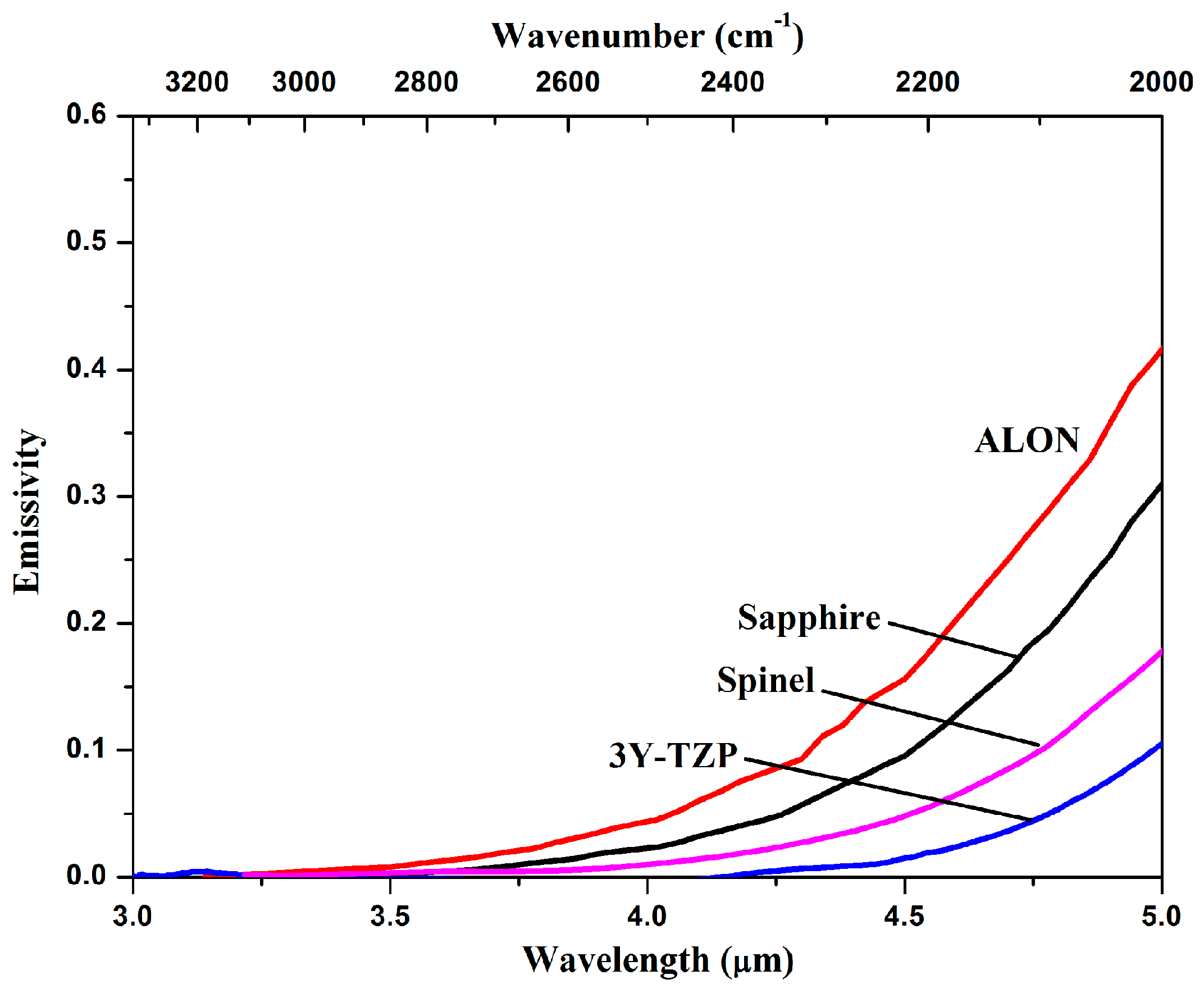

2. Results and Discussion

3. Materials and Methods

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Harris, D.C. Materials for Infrared Windows and Domes: Properties and Performance; SPIE Press: Bellingham, WA, USA, 1999. [Google Scholar]

- Krell, A.; Baur, G.M.; Dahne, C. Transparent sintered sub-μm Al2O3 with infrared transmissivity equal to sapphire. Proc. SPIE Window Dome Technol. VIII 2003, 5078, 199–207. [Google Scholar]

- Krell, A.; Blank, P.; Ma, H.; Hutzler, T.; Bruggen, M.P.; Apetz, R. Transparent Sintered Corundum with High Hardness and Strength. J. Am. Ceram. Soc. 2003, 86, 12–18. [Google Scholar] [CrossRef]

- Jiang, D.; Hulbert, D.M.; Anselmi-Tamburini, U.; Ng, T.; Land, D.; Mukherjee, A.K. Optically Transparent Polycrystalline Al2O3 Produced by Spark Plasma Sintering. J. Am. Ceram. Soc. 2007, 91, 151–154. [Google Scholar] [CrossRef]

- Patterson, M. Fabrication of large thick spinel of transparent spine. Proc. SPIE Inorg. Opt. Mater. III 2001, 4451, 126–132. [Google Scholar]

- Patterson, A.; Fehrenbacher, L.; Roy, D.W. Spinel: Gaining Momentum in Optical Applications. Proc. SPIE Window Dome Technol. VIII 2003, 5078, 71–79. [Google Scholar]

- Kaygorodov, A.S.; Ivanov, V.V.; Khrustov, V.R.; Kotov, Y.A.; Medvedev, A.I.; Osipov, V.V.; Ivanov, M.G.; Orlov, A.N.; Murzakaev, A.M. Fabrication of Nd:Y2O3 transparent ceramics by pulsed compaction and sintering of weakly agglomerated nanopowders. J. Eur. Ceram. Soc. 2007, 27, 1165–1169. [Google Scholar] [CrossRef]

- Hu, X.; Yang, Q.; Dou, C.; Xu, J.; Zhou, H. Fabrication and spectral properties of Nd3+-doped yttrium lanthanum oxide transparent ceramics. Opt. Mater. 2008, 30, 1583–1586. [Google Scholar] [CrossRef]

- Mouzon, J.; Lindbäck, T.; Odén, M. Influence of Agglomeration on the Transparency of Yttria Ceramics. J. Am. Ceram. Soc. 2008, 91, 3380–3387. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, L.; Chen, D.; Jordan, E.H.; Gell, M. Y2O3–MgO–ZrO2 Infrared Transparent Ceramic Nanocomposites. J. Am. Ceram. Soc. 2011, 95, 1033–1037. [Google Scholar] [CrossRef]

- Harris, D.C.; Cambrea, L.R.; Johnson, L.F.; Seaver, R.T.; Baronowski, M.; Gentilman, R.; Scott Nordahl, C.; Gattuso, T.; Silberstein, S.; Rogan, P.; et al. Properties of an Infrared-Transparent MgO:Y2O3 Nanocomposite. J. Am. Ceram. Soc. 2013, 96, 3828–3833. [Google Scholar] [CrossRef]

- Kear, B.H.; Sadangi, R.; Shukla, V.; Stefanik, T.; Gentilman, R. Sub-micron-Grained Transparent Yttria Composites. Proc. SPIE Window Dome Technol. IX 2005, 5786, 227–233. [Google Scholar]

- Wang, J.; Chen, D.; Jordan, E.H.; Gell, M. Infrared-TransparentY2O3-MgO Nanocomposites Using Sol-Gel Combustion Synthesized Powder. J. Am. Ceram. Soc. 2010, 93, 3535–3538. [Google Scholar] [CrossRef]

- Krell, A.; Hutzler, T.; Klimke, J. Transmission physics and consequences for materials selection, manufacturing, and applications. J. Eur. Ceram. Soc. 2009, 29, 207–221. [Google Scholar] [CrossRef]

- Koji, T.; Isao, Y. Transparent 8 mol % Y2O3–ZrO2 (8Y) Ceramics. J. Am. Ceram. Soc. 2008, 91, 813–818. [Google Scholar]

- Garvie, R.C.; Hannink, R.H.; Pascoe, R.T. Ceramic Steel. Nature 1975, 258, 703–704. [Google Scholar] [CrossRef]

- Piconi, C.; Maccauro, G. Zirconia as a ceramic biomaterial. Biomaterials 1999, 20, 1–25. [Google Scholar] [CrossRef]

- Apetz, R.; Bruggen, M.P.B. Transparent Alumina: A Light-Scattering Model. J. Am. Ceram. Soc. 2003, 86, 480–486. [Google Scholar] [CrossRef]

- Peelen, J.G.J.; Metselaar, R. Light scattering by pores in polycrystalline materials: Transmission properties of alumina. J. Appl. Phys. 1974, 45, 216–220. [Google Scholar] [CrossRef]

- Klimke, J.; Trunec, M.; Krell, A. Transparent Tetragonal Yttria-Stabilized Zirconia Ceramics: Influence of Scattering Caused by Birefringence. J. Am. Ceram. Soc. 2011, 94, 1850–1858. [Google Scholar] [CrossRef]

- Zhang, H.; Li, Z.; Kim, B.N.; Morita, K.; Yoshida, H.; Hiraga, K.; Sakka, Y. Highly Infrared Transparent Nanometric Tetragonal Zirconia Prepared by High-Pressure Spark Plasma Sintering. J. Am. Ceram. Soc. 2011, 94, 2739–2741. [Google Scholar] [CrossRef]

- Casolco, S.R.; Xu, J.; Garay, J.E. Transparent/translucent polycrystalline nanostructured yttria stabilized zirconia with varying colors. Scr. Mater. 2008, 58, 516–519. [Google Scholar] [CrossRef]

- Musikant, S. Development of A New Family of Improved Infrared (IR) Dome Ceramics. Proc. SPIE 1981, 297, 2–12. [Google Scholar]

- Rice, R.W.; Spann, J.R.; McDonough, W.J.; Ingel, R.P.; Lewis, D. Partially Stabilized ZrO2 As A Possible Ir Dome Material. Proc. SPIE 1984, 505, 171–178. [Google Scholar]

- Matsui, K.; Yoshida, H.; Ikuhara, Y. Phase-transformation and grain-growth kinetics in yttria-stabilized tetragonal zirconia polycrystal doped with a small amount of alumina. J. Euro. Ceram. Soc. 2010, 30, 1679–1690. [Google Scholar] [CrossRef]

- Wood, D.L.; Nassau, K. Refractive index of cubic zirconia stabilized with yttria. Appl. Opt. 1982, 21, 2978–2981. [Google Scholar] [CrossRef] [PubMed]

- Xue, T.; Zhang, L.; Wen, L.; Liao, M.; Hu, L. Er3+-doped fluorogallate glass for mid-infrared applications. Chin. Opt. Lett. 2015, 13, 081602–081606. [Google Scholar]

- Ouyang, S.; Zhang, W.; Zhang, Z.; Zhang, Y.; Xia, H. Near-white light-emitting Dy3+-doped transparent glass ceramics containing Ba2LaF7 nanocrystals. Chin. Opt. Lett. 2015, 13, 091601–091604. [Google Scholar] [CrossRef]

- Harris, D.C. Durable 3–5 μm transmitting infrared window materials. Infrared Phys. Technol. 1998, 39, 185–201. [Google Scholar] [CrossRef]

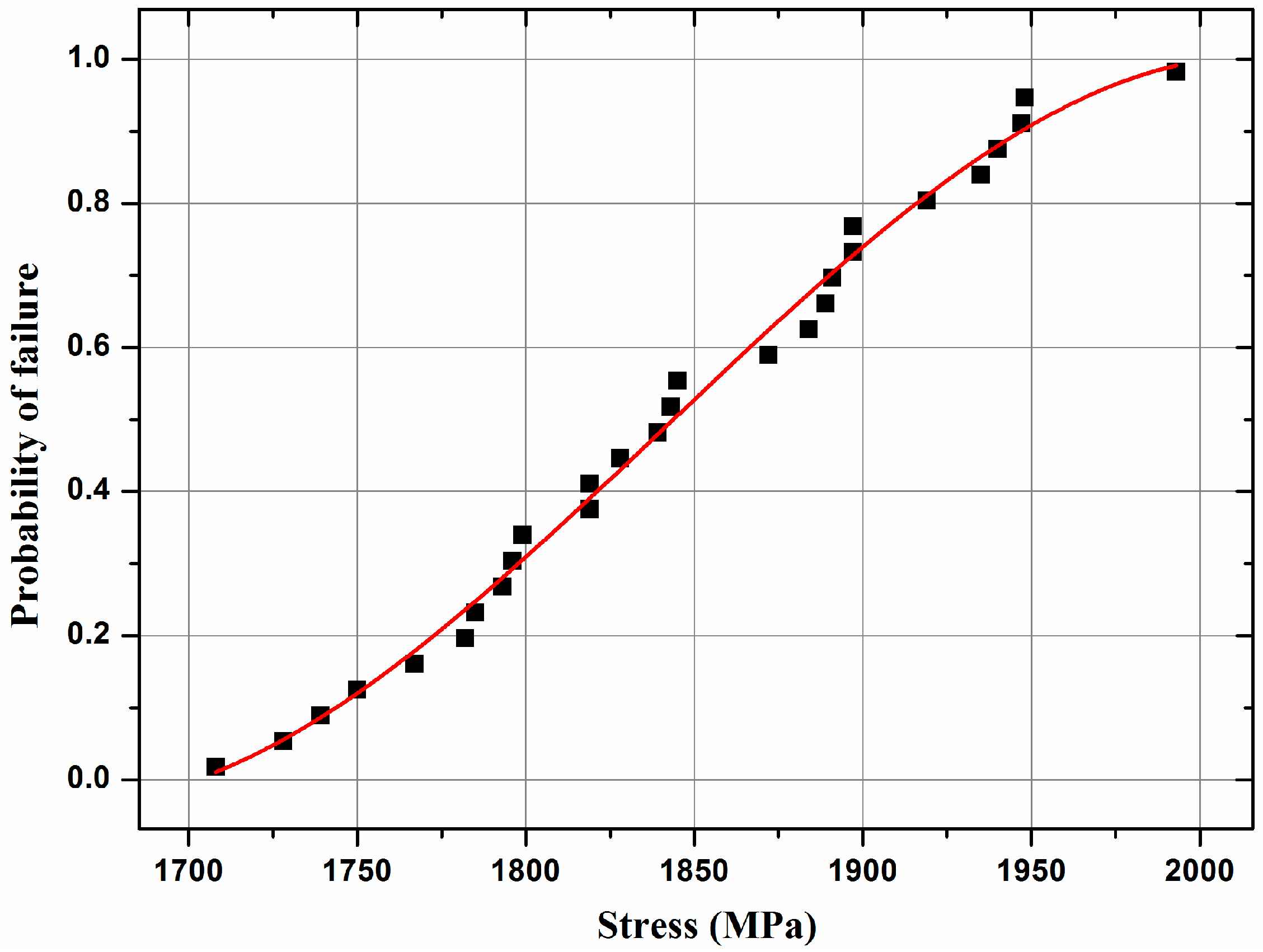

- Klein, C.A.; Miller, R.P. How to do a Weibull Statistical Analysis of Flexural Strength Data. Proc. SPIE 2001, 4375, 241–257. [Google Scholar]

- Wu, D.; Zhou, J.; Li, Y. Unbiased estimation of Weibull parameters with the linear regression method. J. Eur. Ceram. Soc. 2006, 26, 1099–1105. [Google Scholar] [CrossRef]

- Huie, J.C.; Dudding, C.B.; McCloy, J. Polycrystalline yttrium aluminum garnet (YAG) for IR transparent missile domes and windows. Proc. SPIE Window Dome Technol. Mater. X 2007, 6545. [Google Scholar] [CrossRef]

- Harris, D.C. Development of Yttria and Lanthana-Doped Yttria as Infrared-Transmitting Materials; Naval Weapons Center: China Lake, CA, USA, 1991. [Google Scholar]

- Fischer, J.W.; Compton, W.R.; Jaeger, N.A.; Harris, D.C. Strength of sapphire as a function of temperature and crystal orientation. Proc. SPIE 1990, 1326. [Google Scholar] [CrossRef]

- Harris, D.C.; Schmid, F.; Mecholsky, J.J.; Tsai, Y.L. Mechanism of mechanical failure of sapphire at high temperature. Proc. SPIE 1994, 2286. [Google Scholar] [CrossRef]

- Roy, D.W.; Martin, G.G. Advances in spinel optical quality, size/shape capacity, and applications. Proc. SPIE 1992, 1760. [Google Scholar] [CrossRef]

- Masaki, T. Mechanical Properties of Toughened ZrO2-Y2O3 Ceramics. J. Am. Ceram. Soc. 1986, 69, 638–640. [Google Scholar] [CrossRef]

- Belli, R.; Wendler, M.; de Ligny, D.; Cicconi, M.R.; Petschelt, A.; Peterlik, H.; Lohbauer, U. Chairside CAD/CAM materials. Part 1: Measurement of elastic constants and microstructural characterization. Dent. Mater. 2016, 33, 84–98. [Google Scholar] [CrossRef] [PubMed]

- Schubert, H. Anisotropic Thermal Expansion Coefficients of Y2O3-Stabilized Tetragonal Zirconia. J. Am. Ceram. Soc. 1986, 69, 270–271. [Google Scholar] [CrossRef]

- Chujie, W.; Yoshinobu, M.; Taiju, S.; Shinichi, B.; Masahiro, I.; Taiji, H. Thermal Conductivity of Superplastically Deformed 3Y-TZP. Mater. Trans. 2002, 43, 2473–2479. [Google Scholar]

- Klein, C.A. Thermal shock resistance of infrared transmitting windows and domes. Opt. Eng. 1998, 37, 2826–2836. [Google Scholar] [CrossRef]

- Medelson, M.I. Average Grain Size in Polycrystalline Ceramics. J. Am. Ceram. Soc. 1969, 52, 443–446. [Google Scholar] [CrossRef]

| Materials | Characteristic Bending Strength (Mpa) | Vickers Hardness (Gpa) |

|---|---|---|

| 3Y-TZP | 1888 | 13.82 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Mao, X.; Peng, Y.-P.; Jiang, B.; Fan, J.; Xu, Y.; Zhang, L.; Zhao, J. Preparation and Optical Properties of Infrared Transparent 3Y-TZP Ceramics. Materials 2017, 10, 390. https://doi.org/10.3390/ma10040390

Wang C, Mao X, Peng Y-P, Jiang B, Fan J, Xu Y, Zhang L, Zhao J. Preparation and Optical Properties of Infrared Transparent 3Y-TZP Ceramics. Materials. 2017; 10(4):390. https://doi.org/10.3390/ma10040390

Chicago/Turabian StyleWang, Chuanfeng, Xiaojian Mao, Ya-Pei Peng, Benxue Jiang, Jintai Fan, Yangyang Xu, Long Zhang, and Jingtai Zhao. 2017. "Preparation and Optical Properties of Infrared Transparent 3Y-TZP Ceramics" Materials 10, no. 4: 390. https://doi.org/10.3390/ma10040390