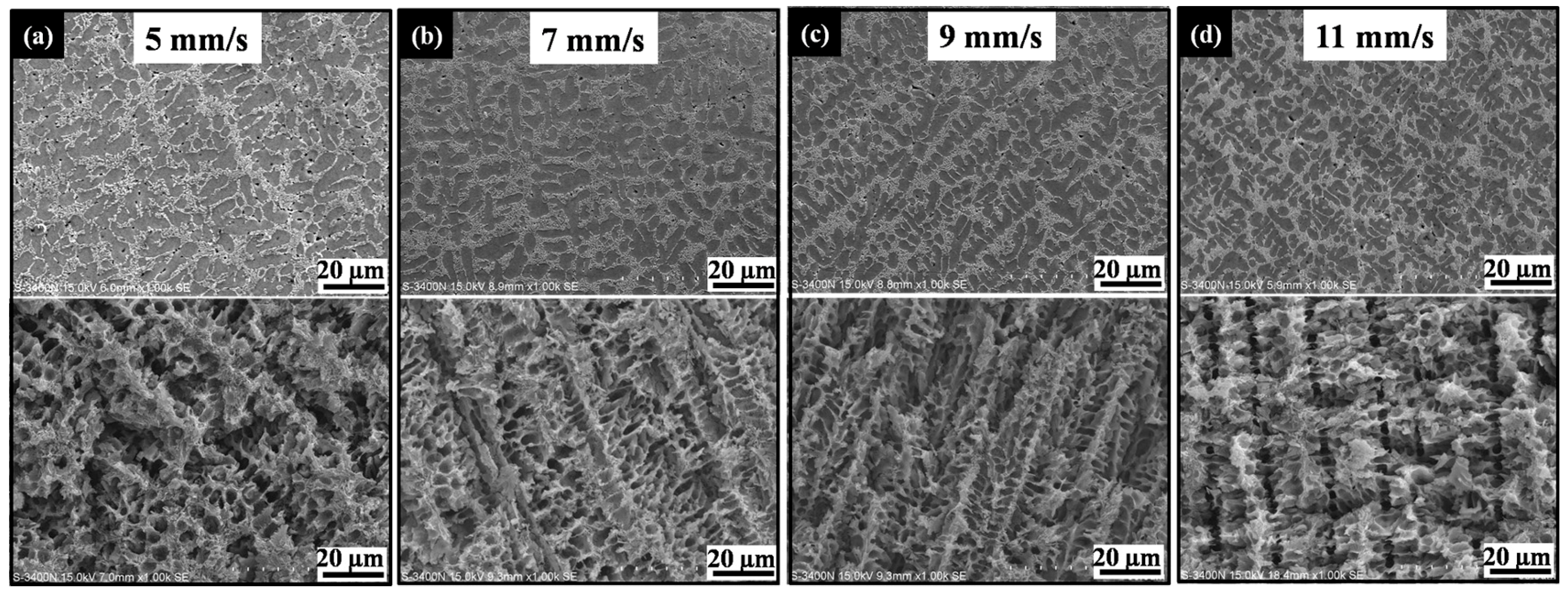

The Fabrication of Porous Si with Interconnected Micro-Sized Dendrites and Tunable Morphology through the Dealloying of a Laser Remelted Al–Si Alloy

Abstract

:1. Introduction

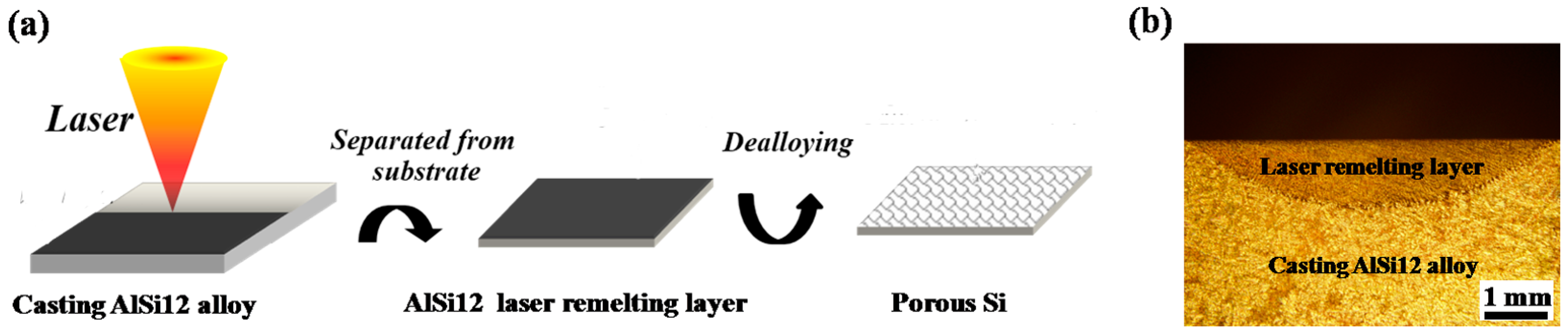

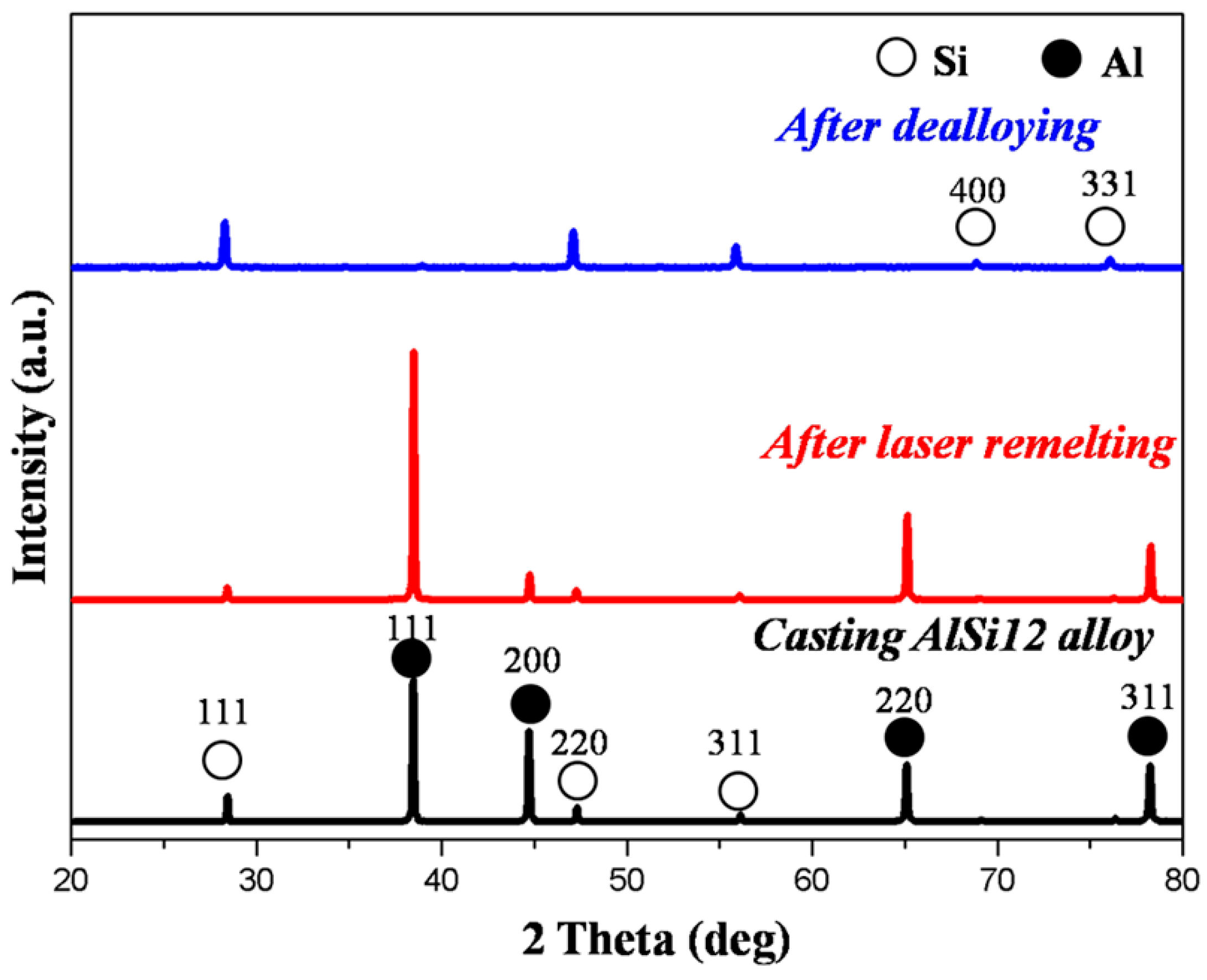

2. Materials and Methods

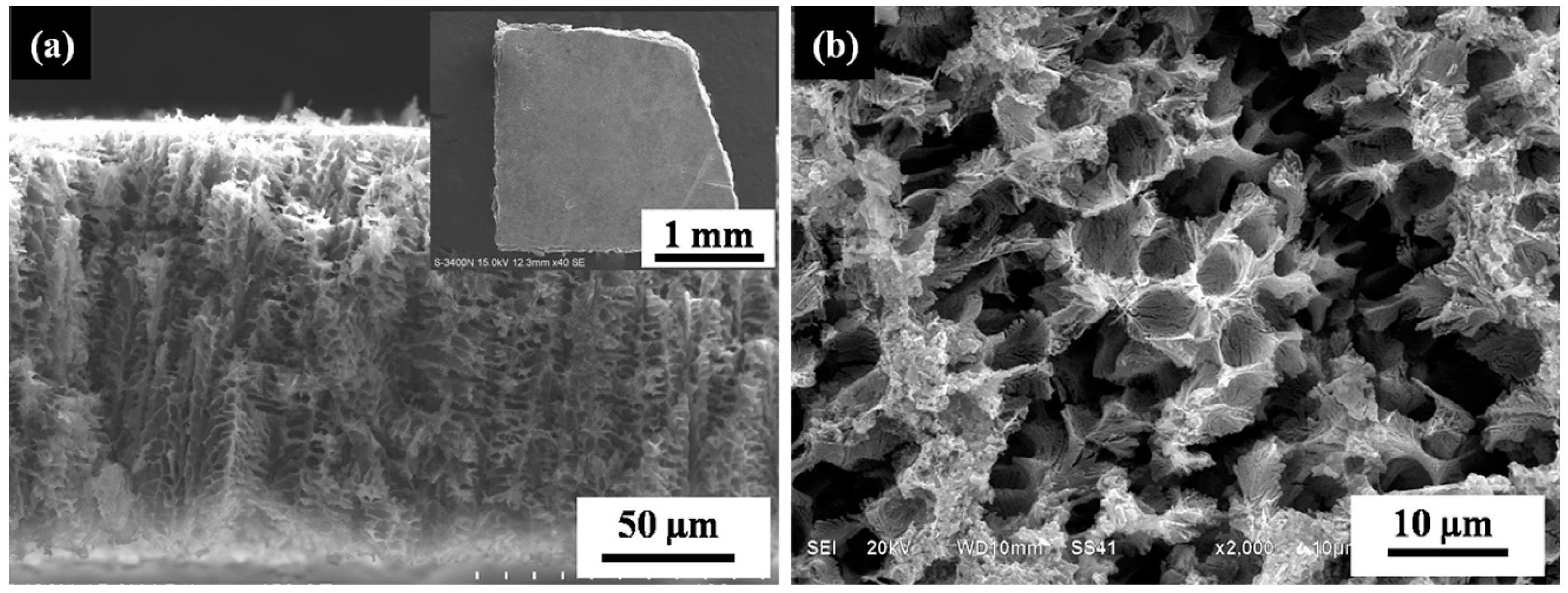

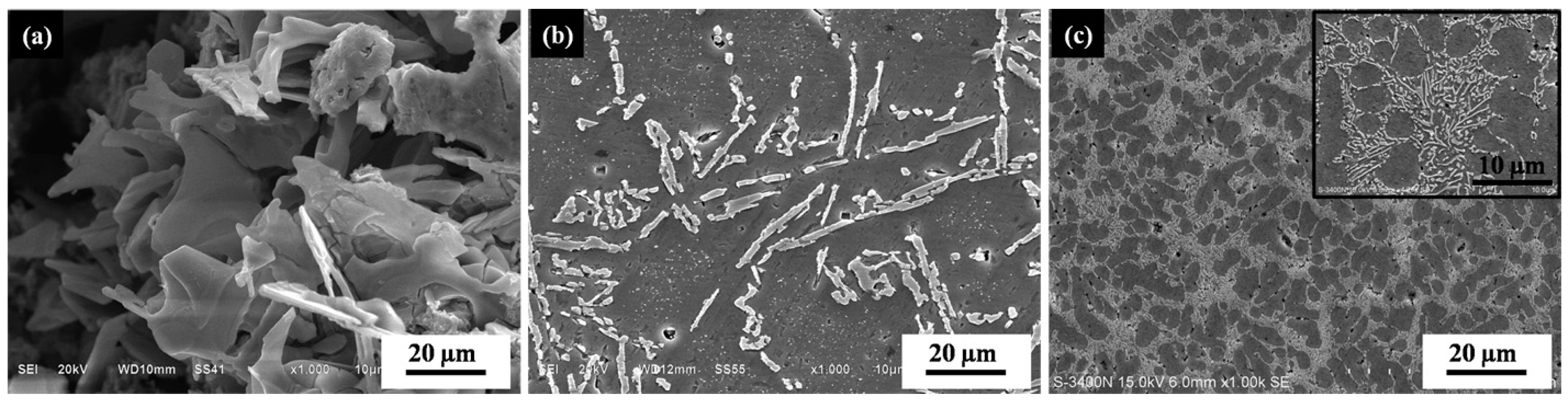

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Arico, A.S.; Bruce, P.; Scrosati, B.; Scrosati, B. Nanostructured materials for advanced energy conversion and storage devices. Nat. Mater. 2005, 4, 367–377. [Google Scholar] [CrossRef] [PubMed]

- Ge, M.; Rong, J.; Fang, X.; Zhang, A.; Lu, Y.; Zhou, C. Scalable production of porous silicon nanoparticles and their application in lithium-ion battery anode. Nano Res. 2013, 6, 174–181. [Google Scholar] [CrossRef]

- Cui, L.F.; Yang, Y.; Hsu, C.M.; Cui, Y. Carbon-Silicon Core-Shell Nanowires as High Capacity Electrode for Lithium Ion Batteries. Nano Lett. 2009, 9, 3371–3374. [Google Scholar] [CrossRef] [PubMed]

- Kasavajjula, U.; Wang, C.; Appleby, A.J. Nano- and bulk-silicon-based insertion anodes for lithium-ion secondary cells. J. Power Sources 2007, 163, 1003–1039. [Google Scholar] [CrossRef]

- Wu, H.; Chan, G.; Choi, J.W.; Ryu, L.; Yao, Y.; McDowell, M.T.; Lee, S.W.; Jackson, A.; Yang, Y.; Hu, L.; et al. Stable cycling of double-walled silicon nanotube battery anodes through solid-electrolyte interphase control. Nat. Nanotechnol. 2012, 7, 309–314. [Google Scholar] [CrossRef] [PubMed]

- Cho, J.H.; Picraux, S.T. Silicon nanowire degradation and stabilization during lithium cycling by SEI layer formation. Nano Lett. 2014, 14, 3088–3095. [Google Scholar] [CrossRef] [PubMed]

- Li, X.L.; Gu, M.; Hu, S.Y.; Kennard, R.; Yan, P.F.; Chen, X.L.; Wang, C.M.; Sailor, M.J.; Zhang, J.G.; Liu, J. Mesoporous silicon sponge as an anti-pulverization structure for high-performance lithium-ion battery anodes. Nat. Commun. 2014, 5, 4105. [Google Scholar] [CrossRef] [PubMed]

- Tian, H.J.; Tian, X.J.; Xin, F.X. Micro-sized nano-porousSi/Canodesfor lithiumionbatteries. Nano Energy 2015, 11, 490–499. [Google Scholar] [CrossRef]

- Yi, R.; Dai, F.; Gordin, M.L.; Chen, S.R.; Wang, D.H. Micro-sized Si–C Composite with Interconnected Nanoscale Building Blocks as High-Performance Anodes for Practical Application in Lithium-Ion Batteries. Adv. Energy Mater. 2013, 3, 295–300. [Google Scholar] [CrossRef]

- Esmanski, A.; Ozin, G.A. Silicon inverse-opal-based macroporous materials as negative electrodes for lithium ion batteries. Adv. Funct. Mater. 2009, 19, 1999–2010. [Google Scholar] [CrossRef]

- Yao, Y.; McDowell, M.T.; Ryu, I.; Wu, H.; Liu, N.A.; Hu, L.B.; Nix, W.D.; Cui, Y. Interconnected silicon hollow nanospheres for lithium-ion battery anodes with long cycle life. Nano Lett. 2011, 11, 2949–2954. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.Y.; Mei, X.; Ji, G.; Lu, M.H.; Xie, J.P.; Lu, J.M.; Lee, J.Y. Reversible Lithium-Ion Storage in Silver-Treated Nanoscale Hollow Porous Silicon Particles. Angew. Chem. Int. Ed. 2012, 51, 2409–2413. [Google Scholar] [CrossRef] [PubMed]

- Bao, Z.H.; Weatherspoon, M.R.; Shian, S.; Cai, Y.; Graham, P.D.; Allan, S.M.; Ahmad, G.; Dickerson, M.B.; Church, B.C.; Kang, Z.T.; et al. Chemical reduction of three-dimensional silica micro-assemblies into microporous silicon replicas. Nature 2007, 446, 172–175. [Google Scholar] [CrossRef] [PubMed]

- Yamada, T.; Itahara, H.; Yamane, H. Preparation of micro-porous Si particles from Mg2Si powder. Mater. Lett. 2013, 98, 157–160. [Google Scholar] [CrossRef]

- Jiang, Z.Y.; Li, C.L.; Hao, S.J. An easy way for preparing high performance porous silicon powderby acid etching Al–Si alloy powder for lithium ion battery. Electrochim. Acta 2014, 115, 393–398. [Google Scholar] [CrossRef]

- Thakur, M.; Pernites, R.B.; Nitta, N.; Isaacson, M.; Sinsabaugh, S.L.; Wong, M.S.; Biswal, S.L. Freestanding macroporous silicon and pyrolyzedpolyacrylonitrile as a composite anode for lithium ion batteries. Chem. Mater. 2012, 24, 2998–3003. [Google Scholar] [CrossRef]

- Zhou, W.C.; Jiang, T.C.; Zhou, H.; Wang, Y.X.; Fang, J.Y.; Whittingham, M.S. The nanostructure of the Si-Al eutectic and its use in lithium batteries. MRS Commun. 2013, 3, 119–121. [Google Scholar] [CrossRef]

- Feng, J.K.; Zhang, Z.; Ci, L.Y.; Zhai, W.; Ai, Q.; Xiong, S.L. Chemical dealloying synthesis of porous silicon anchored by in situ generated graphene sheets as anode material for lithium-ion batteries. J. Power Sources 2015, 287, 177–183. [Google Scholar] [CrossRef]

- Bang, B.M.; Lee, J.I.; Kim, H.; Cho, J.; Park, S. High-performance macroporous bulk silicon anodes synthesized by template-free chemical etching. Adv. Energy Mater. 2012, 2, 878–883. [Google Scholar] [CrossRef]

- Kim, H.; Han, B.; Choo, J.; Cho, J. Three-dimensional porous silicon particles for use in high-performance lithium secondary batteries. Angew. Chem. Int. Ed. 2008, 47, 10151–10154. [Google Scholar] [CrossRef] [PubMed]

- Chan, C.K.; Peng, H.; Liu, G.; Mcllwrath, K.; Zhang, X.F.; Huggins, R.A.; Cui, Y. High-performance lithium battery anodes using silicon nanowires. Nat. Nanotechnol. 2008, 3, 31–35. [Google Scholar] [CrossRef] [PubMed]

- Gremaud, M.; Allen, D.R.; Rappaz, M.; Perepezko, J.H. The development of nucleation controlled microstructures during laser treatment of AlSi alloys. Acta Mater. 1996, 44, 2669–2681. [Google Scholar] [CrossRef]

- Osorio, W.R.; Cheung, N.; Spinelli, J.E.; Cruz, K.S.; Garcia, A. Microstructural modification by laser surface remelting and its effect on the corrosion resistance of an Al-9 wt % Si casting alloy. Appl. Surf. Sci. 2008, 254, 2763–2770. [Google Scholar] [CrossRef]

- Liu, J.; Bolot, R.; Costil, S.; Planche, M.P. Transient thermal and mechanical analysis of NiCrBSi coatings manufactured by hybrid spray process with in-situ laser remelting. Surf. Coat. Technol. 2016, 292, 132–143. [Google Scholar] [CrossRef]

- Erlebacher, J.; Azia, M.J.; Karma, A.; Dimitrov, N.; Sieradzki, K. Evolution of nanoporosity in dealloying. Nature 2001, 410, 450–453. [Google Scholar] [CrossRef] [PubMed]

- Huang, T.; Gu, Y.; Dong, C.S.; Zhong, M.L.; Li, L.; Ma, M.X. Evolution of three-dimensional manganese-based nanoporous structure under thermal processing. Mater. Lett. 2012, 75, 149–151. [Google Scholar] [CrossRef]

- Huang, T.; Dong, C.; Gu, Y.; Zhong, M.; Li, L. The mechanism of three-dimensional manganese-based nanoporous structure formation by laser deposition coupled with dealloying. Mater. Lett. 2013, 95, 30–32. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, T.; Sun, D.; Yang, W.; Wu, Q.; Xiao, R. The Fabrication of Porous Si with Interconnected Micro-Sized Dendrites and Tunable Morphology through the Dealloying of a Laser Remelted Al–Si Alloy. Materials 2017, 10, 357. https://doi.org/10.3390/ma10040357

Huang T, Sun D, Yang W, Wu Q, Xiao R. The Fabrication of Porous Si with Interconnected Micro-Sized Dendrites and Tunable Morphology through the Dealloying of a Laser Remelted Al–Si Alloy. Materials. 2017; 10(4):357. https://doi.org/10.3390/ma10040357

Chicago/Turabian StyleHuang, Ting, Dingyue Sun, Wuxiong Yang, Qiang Wu, and Rongshi Xiao. 2017. "The Fabrication of Porous Si with Interconnected Micro-Sized Dendrites and Tunable Morphology through the Dealloying of a Laser Remelted Al–Si Alloy" Materials 10, no. 4: 357. https://doi.org/10.3390/ma10040357