Damage Evolution in Complex-Phase and Dual-Phase Steels during Edge Stretching

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Material Characterization

2.2. Hole Processing Techniques

2.2.1. Reamed Hole

2.2.2. Sheared Hole

2.3. Hole Tension Test

2.4. Metallographic Specimen Preparation

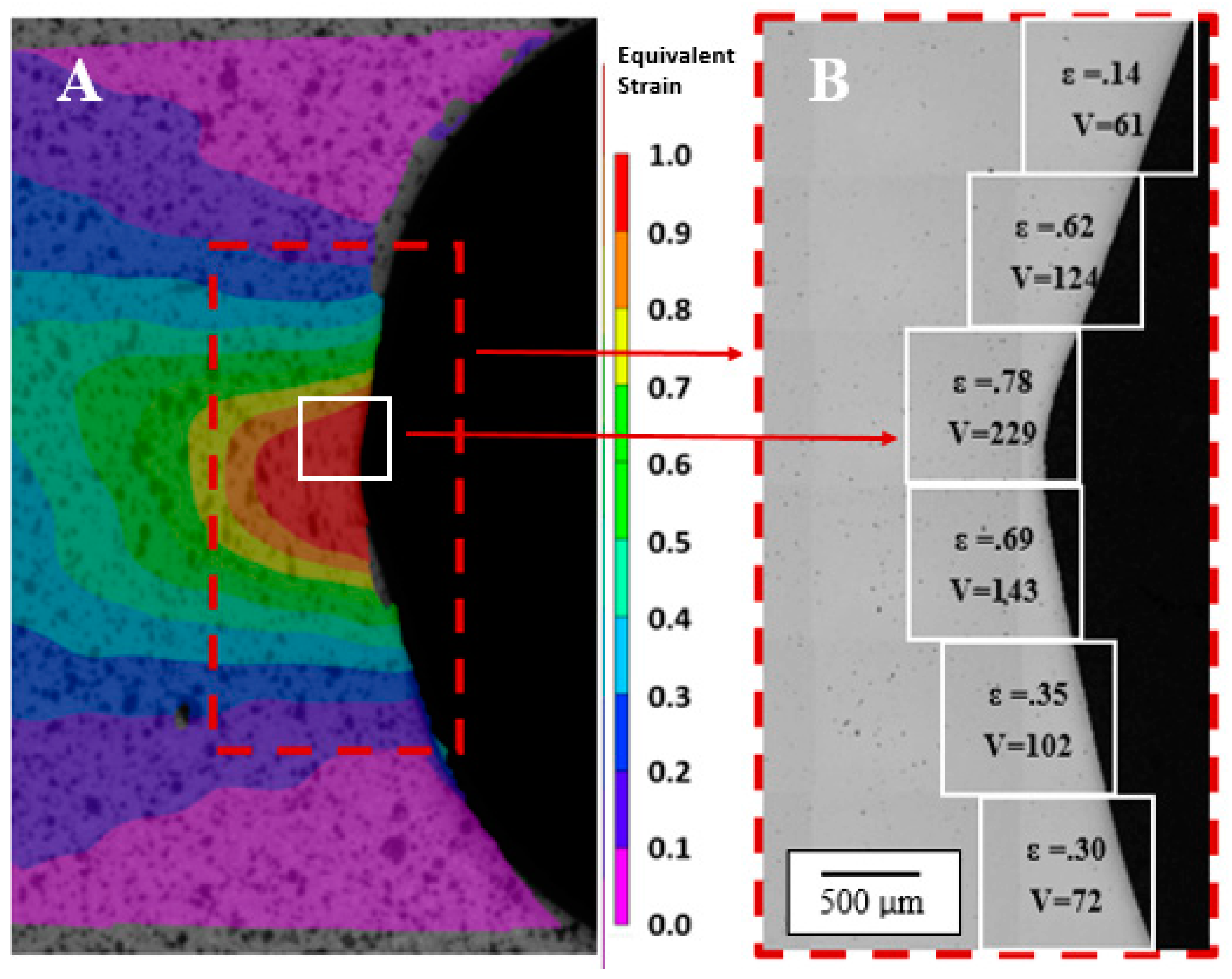

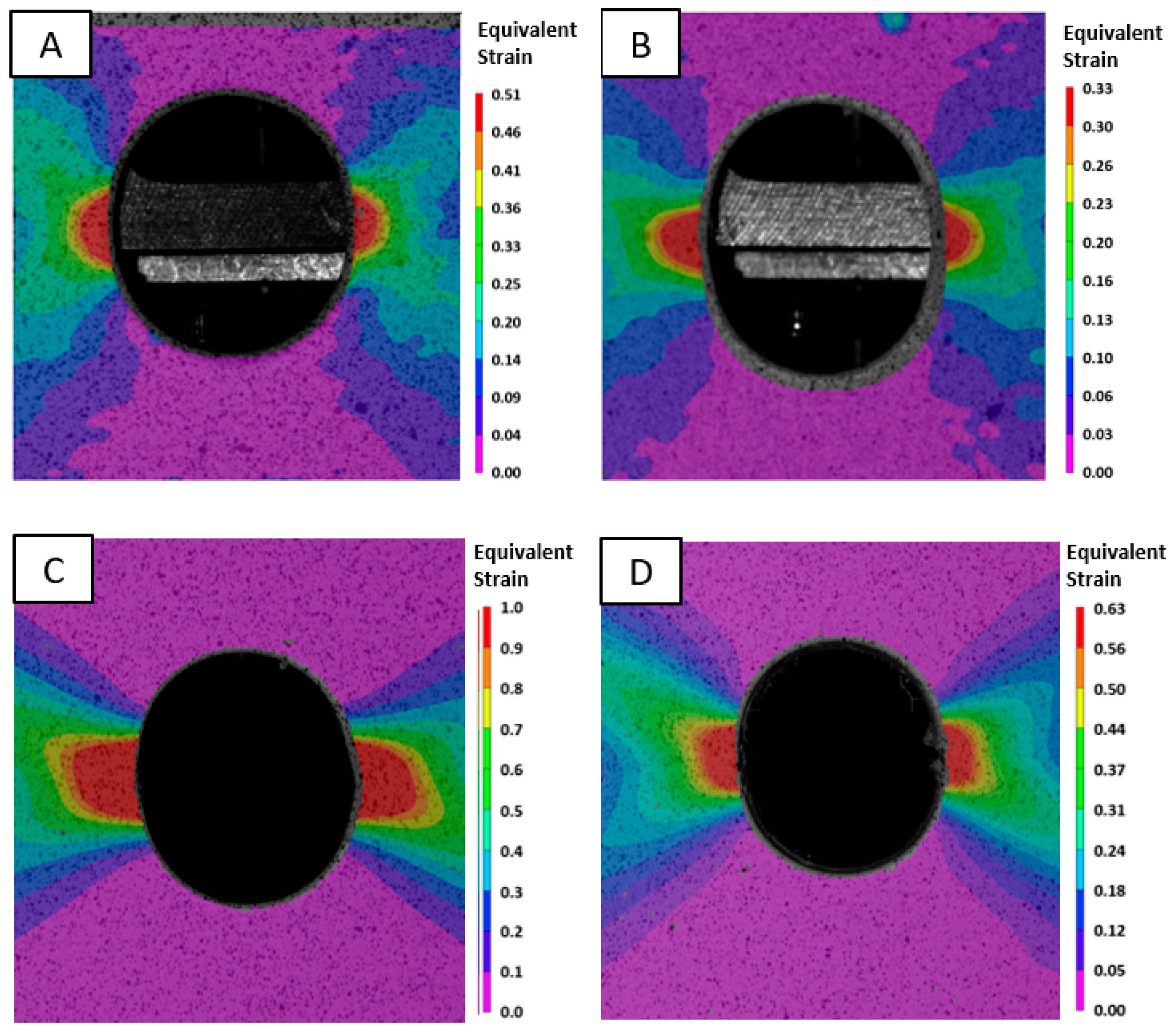

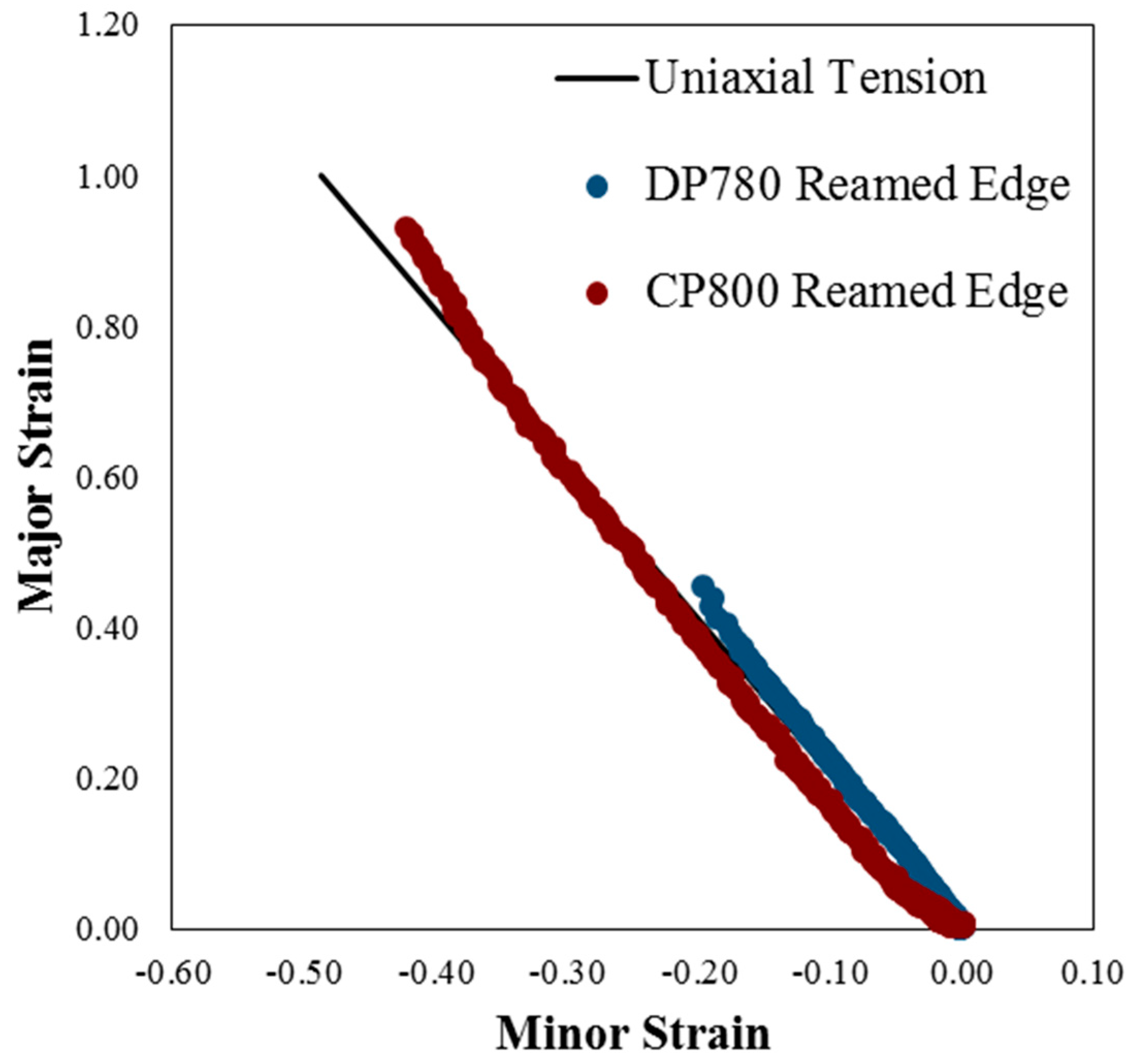

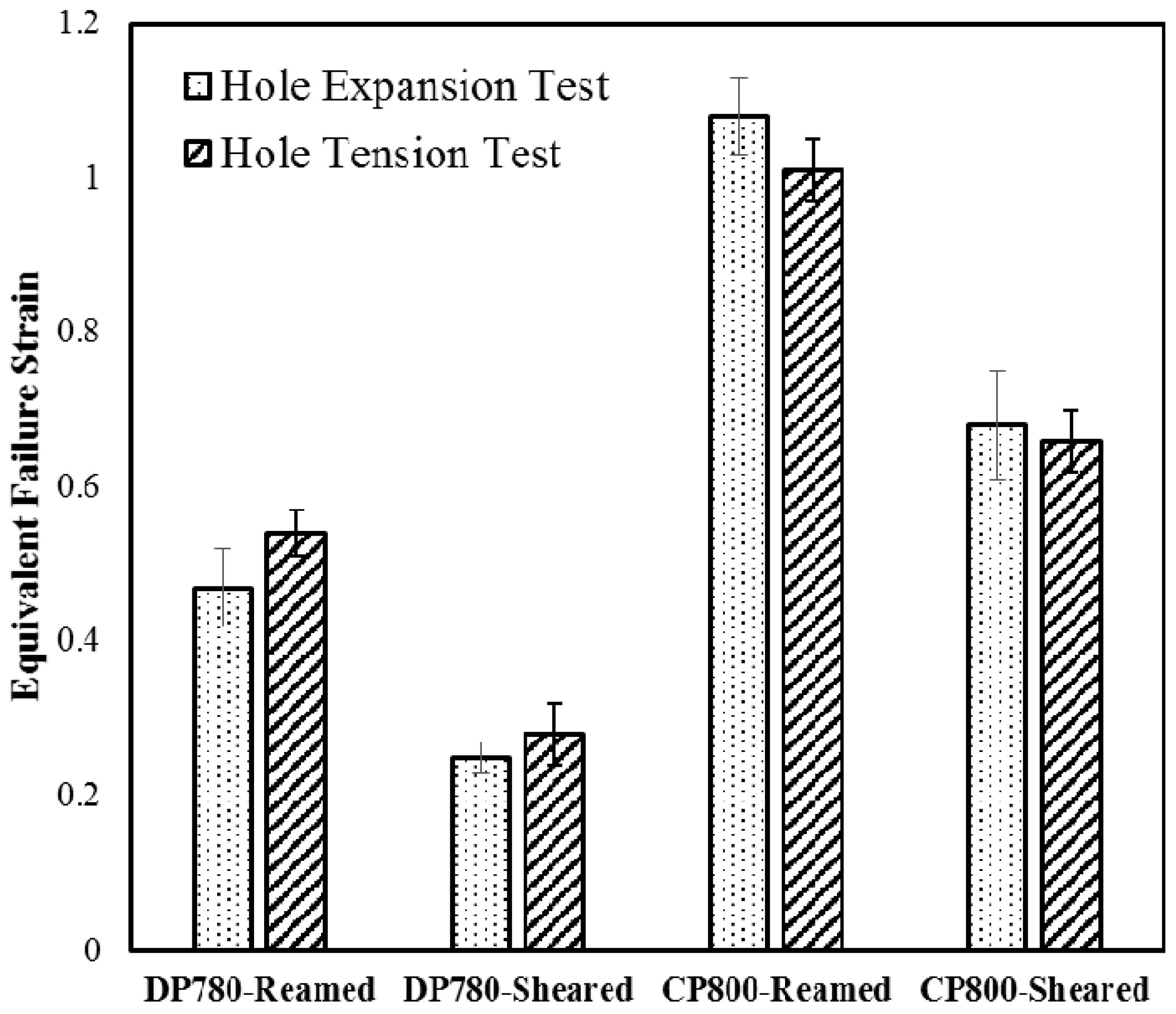

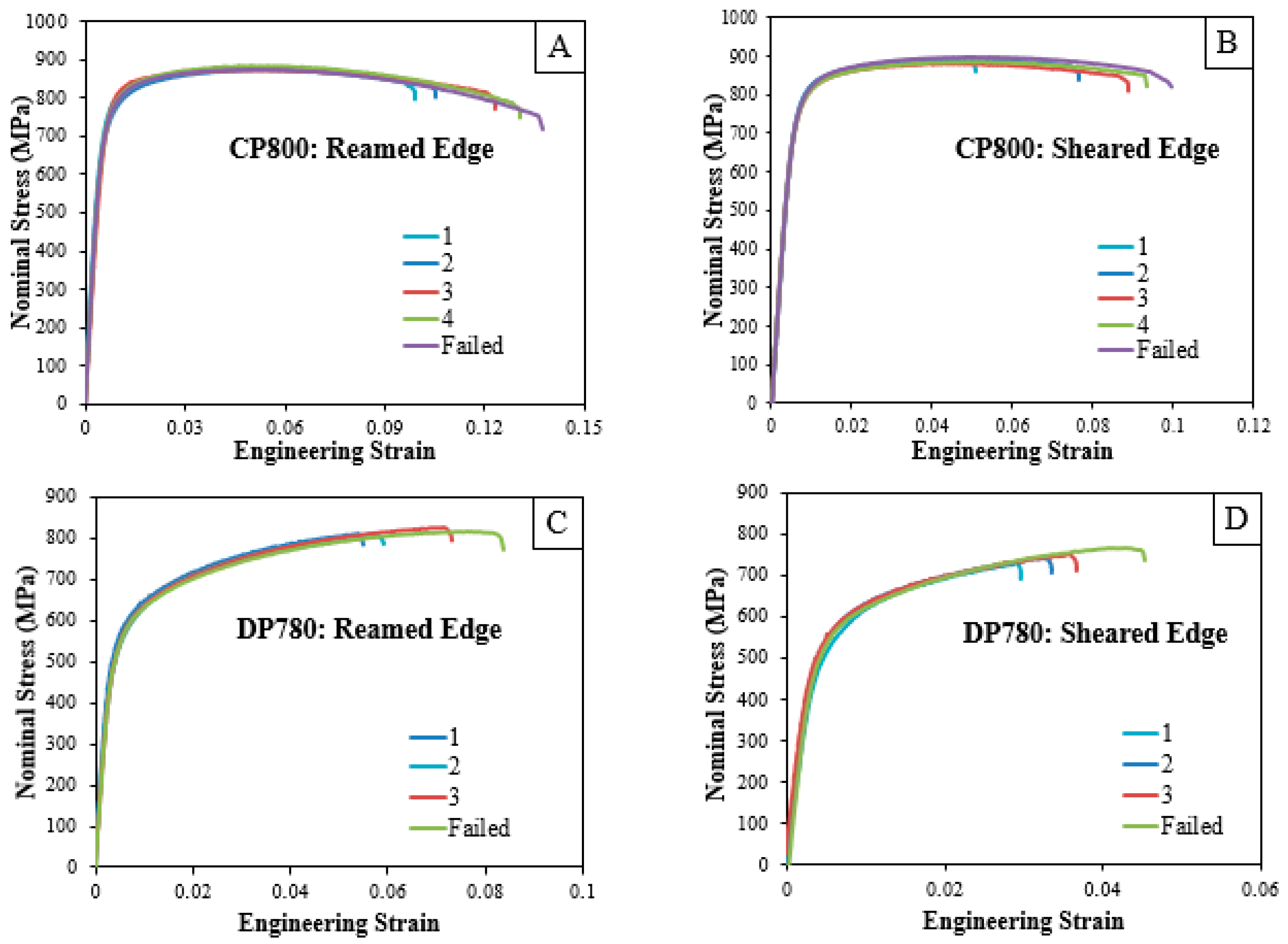

3. Edge Stretchability of the CP and DP steels

4. Damage Development Resulting from Shearing and Hole Tensile Deformation

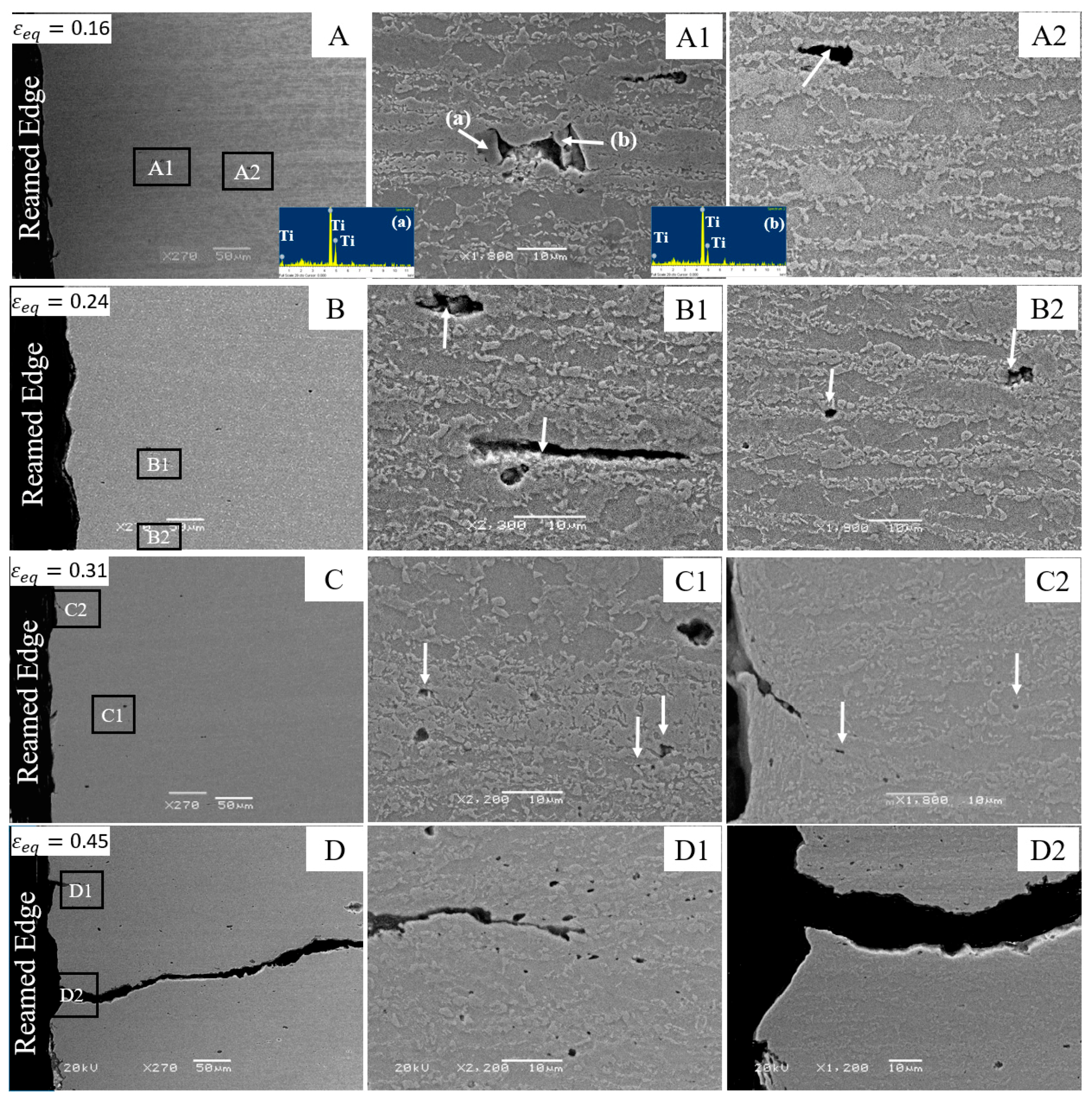

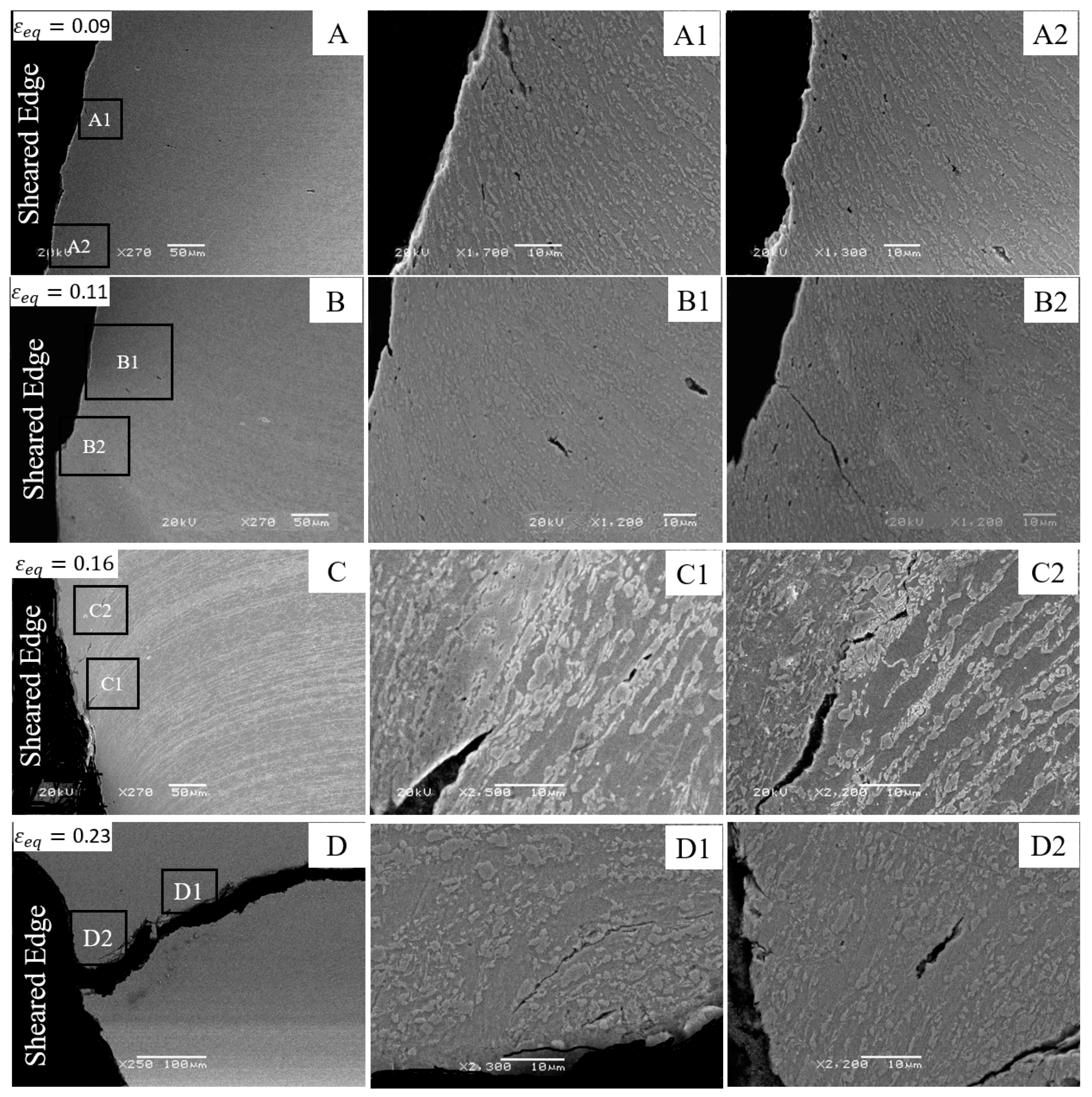

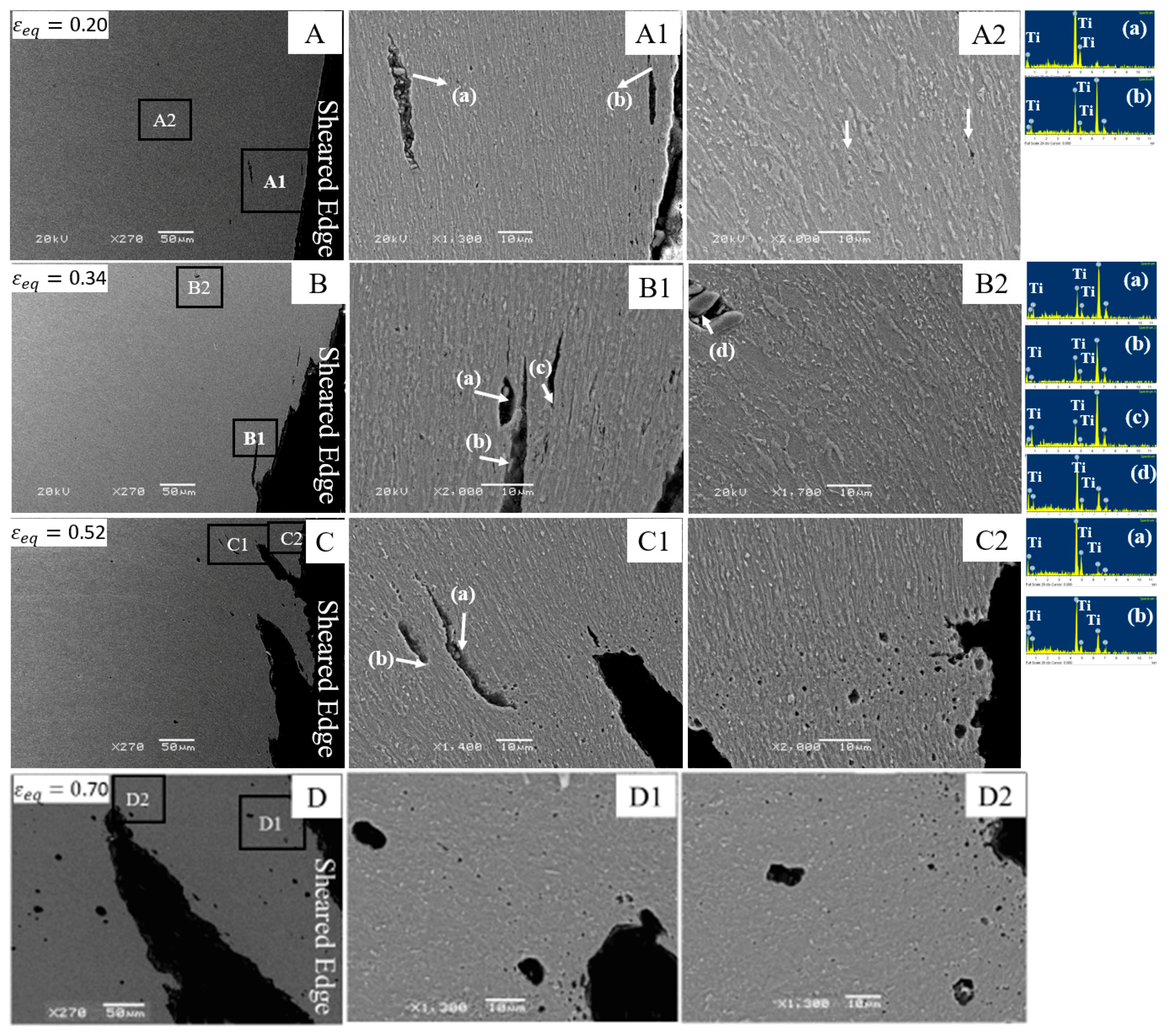

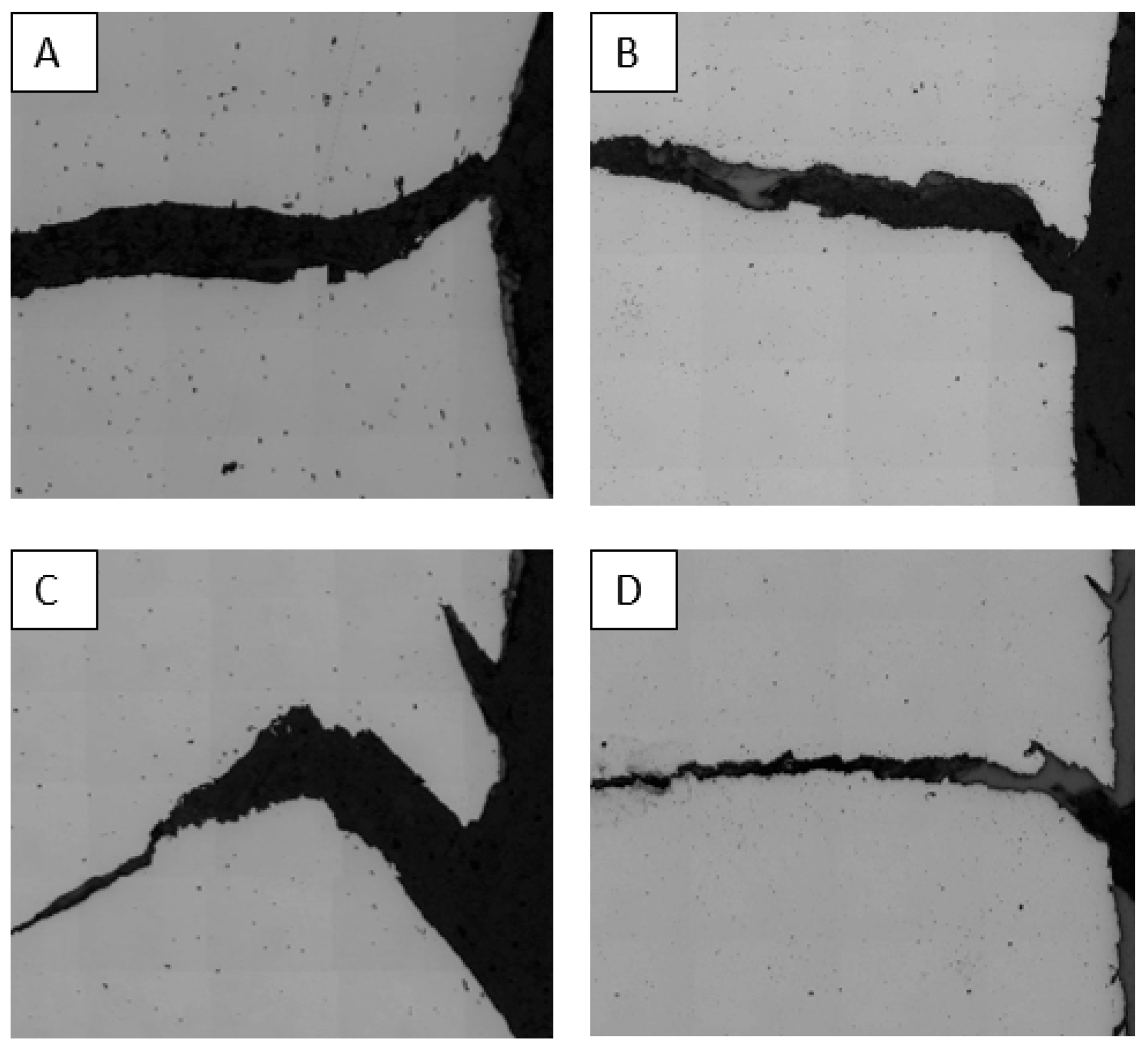

4.1. Fracture Mechanism in DP780

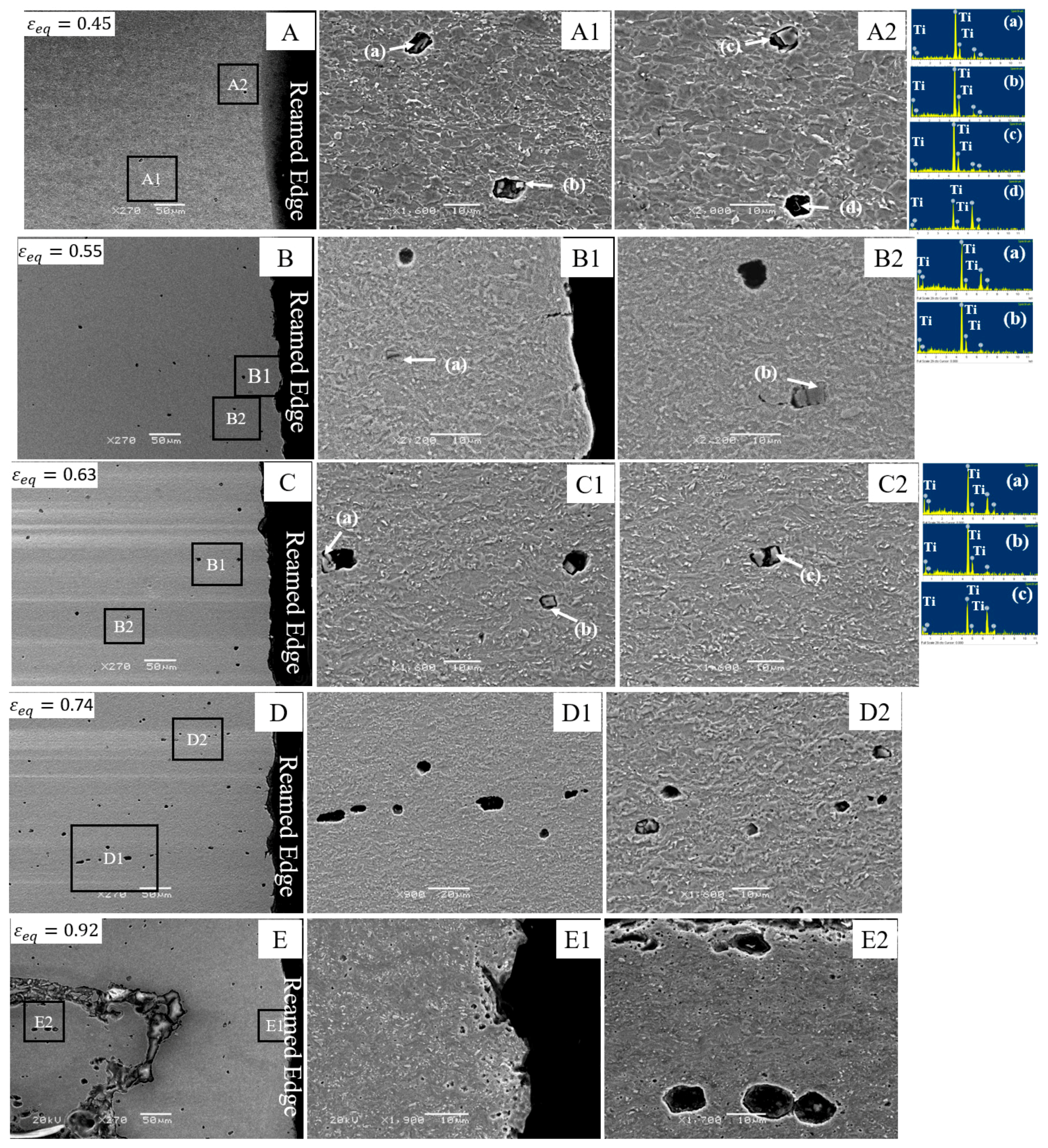

4.2. Fracture Mechanism in CP800

5. Quantitative Examination of Damage Progression

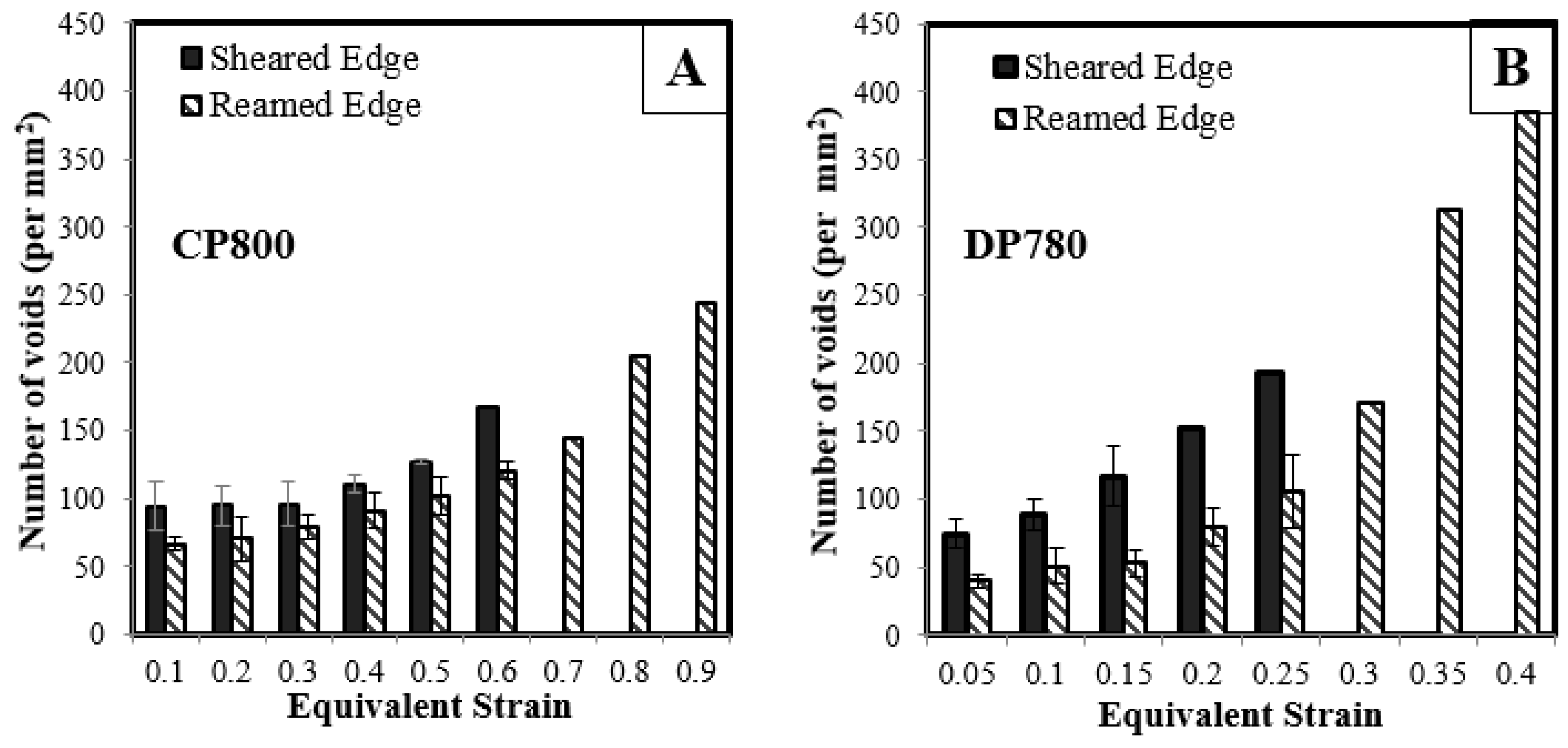

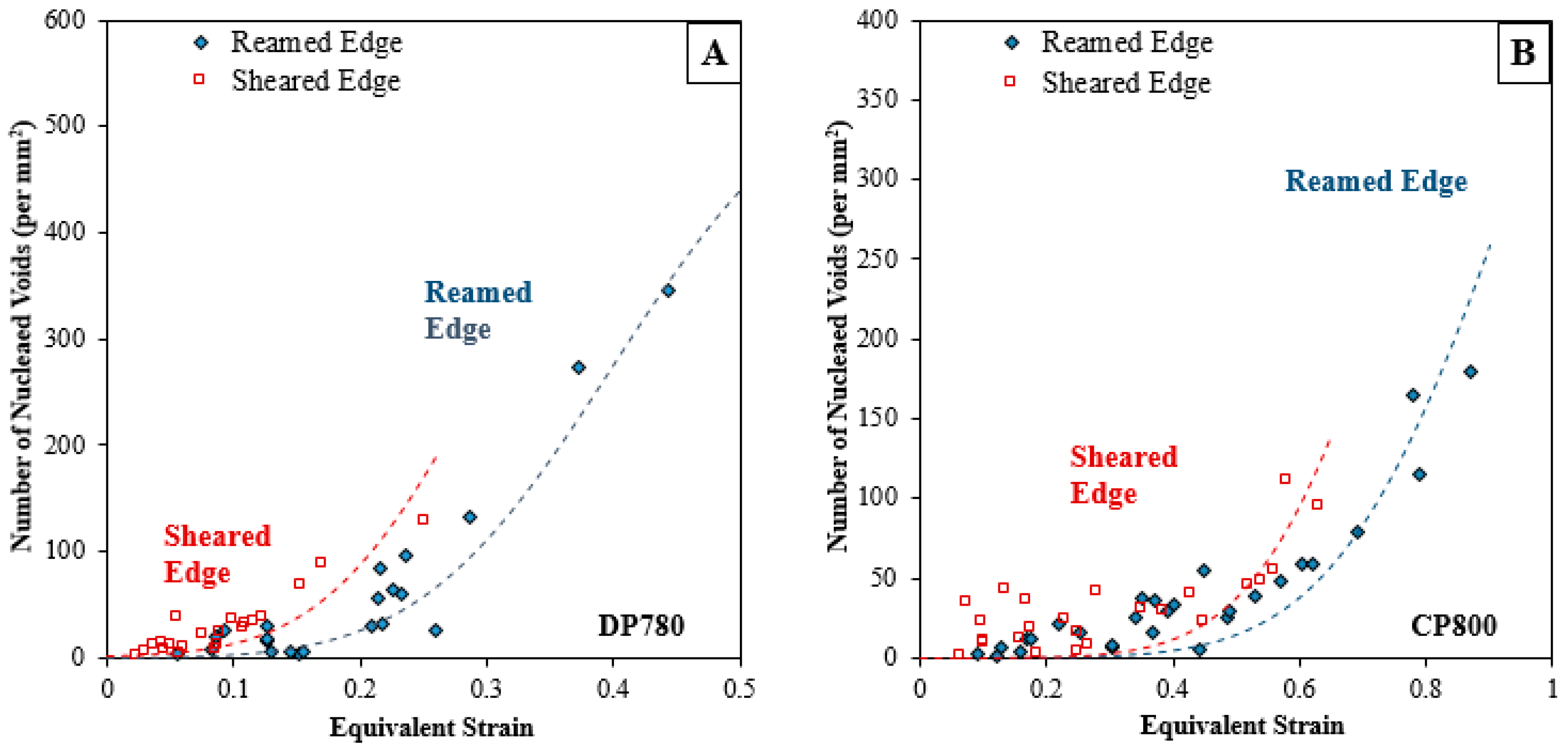

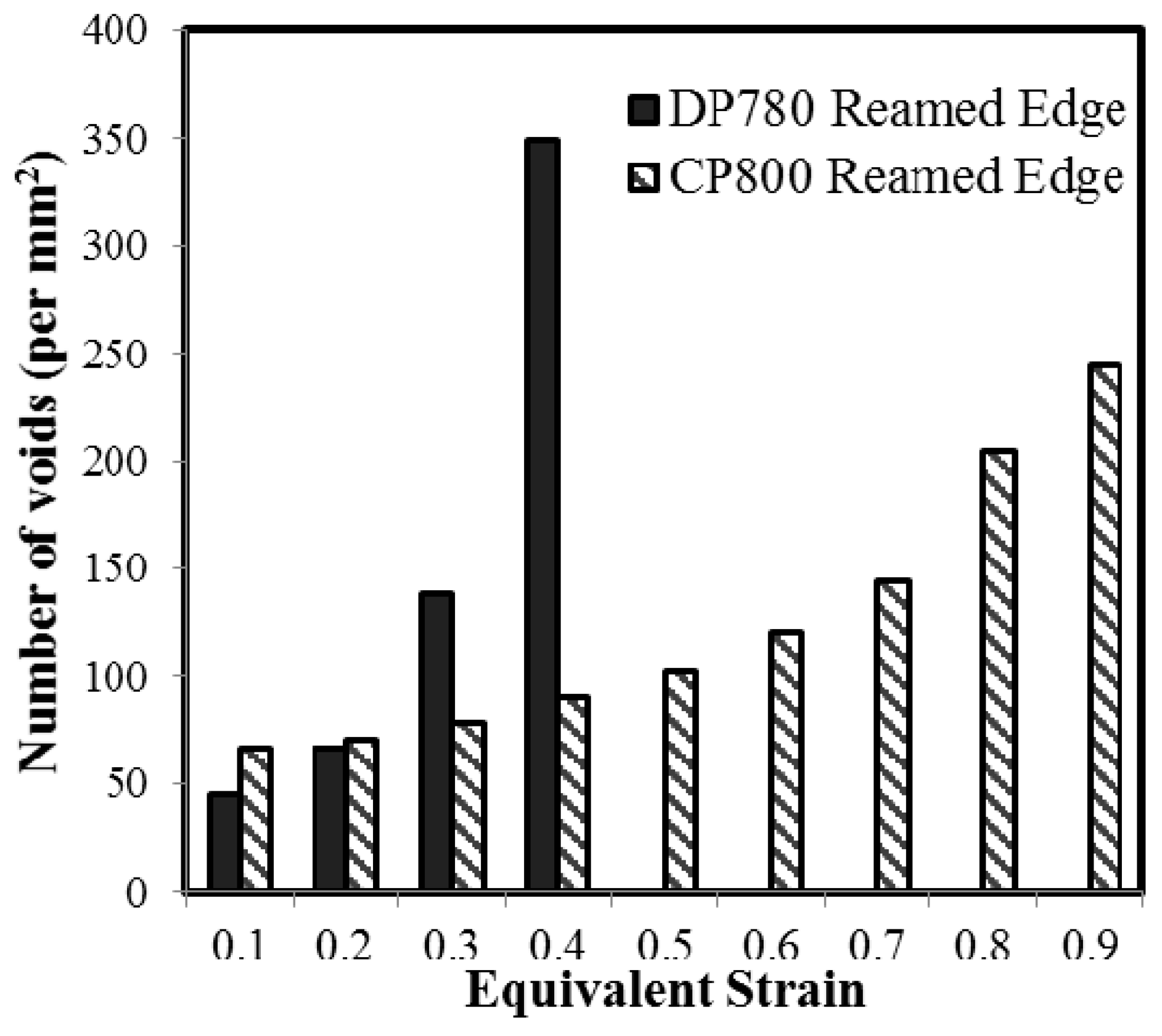

5.1. Void Nucleation

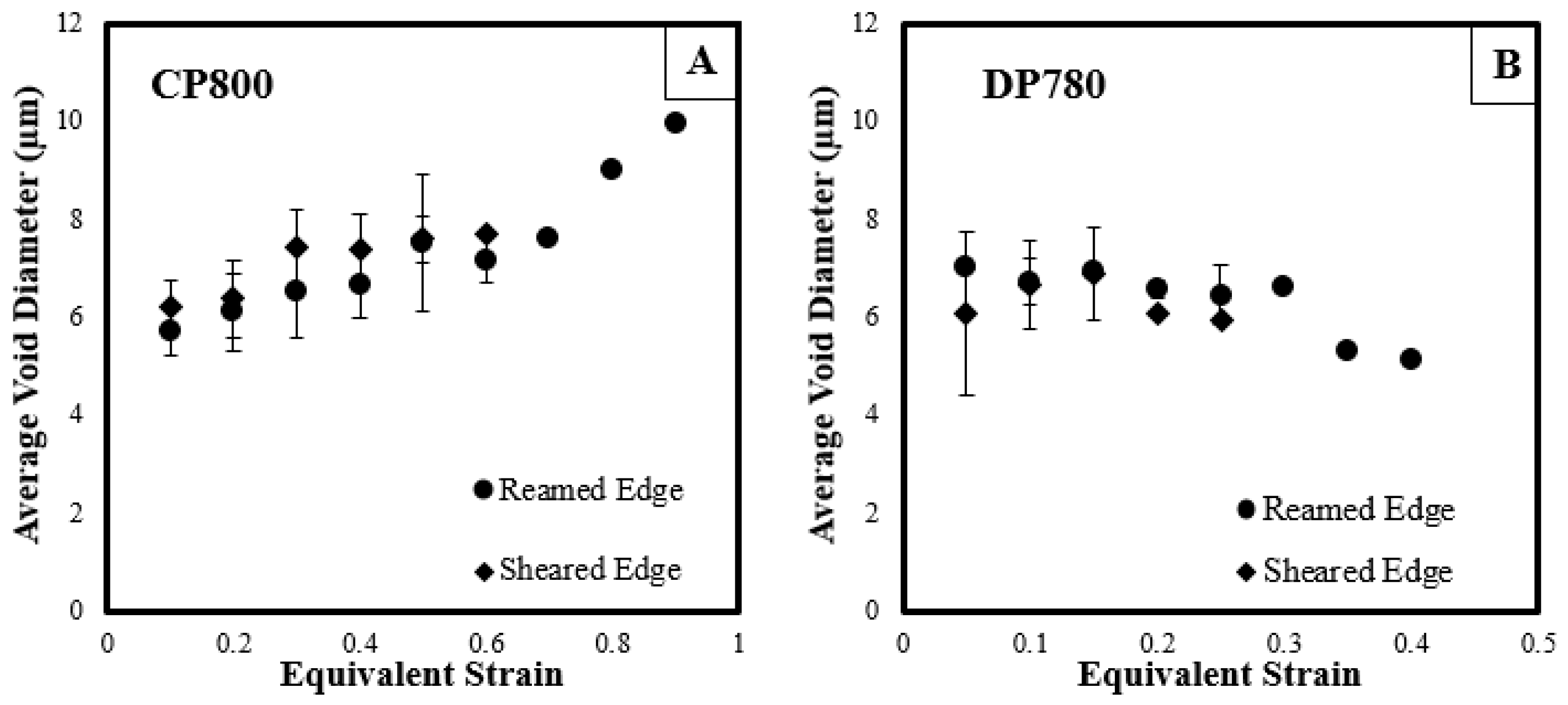

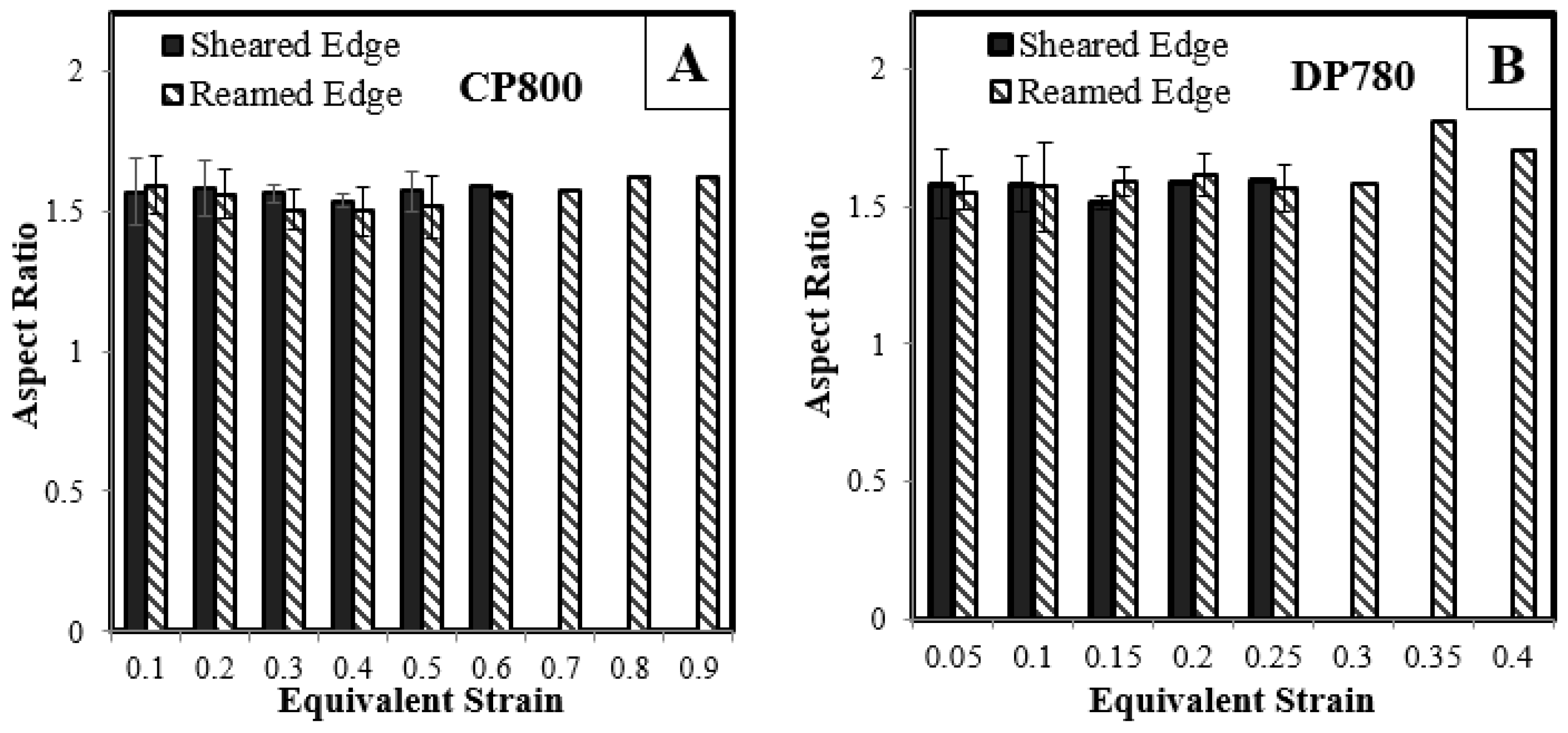

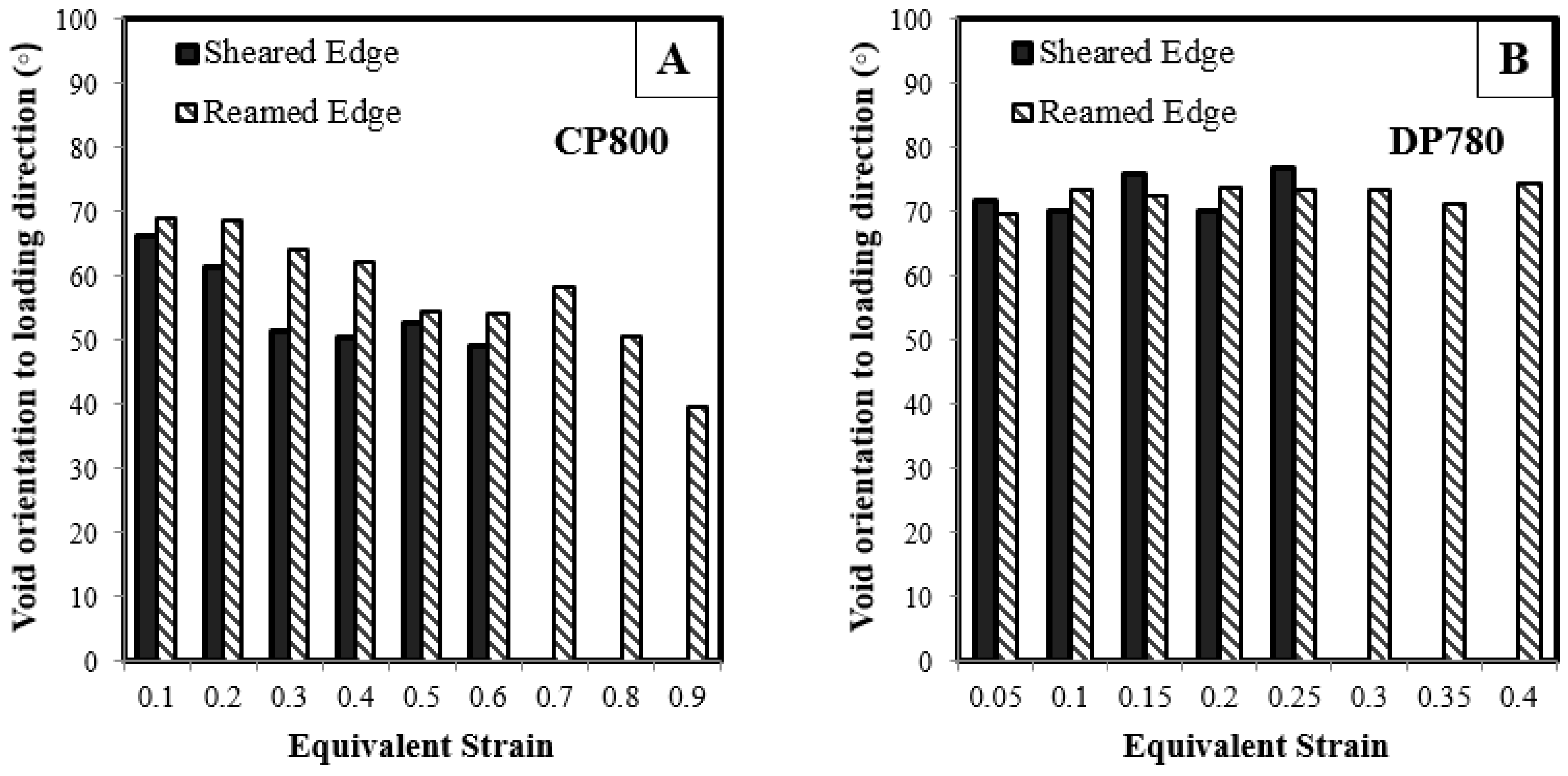

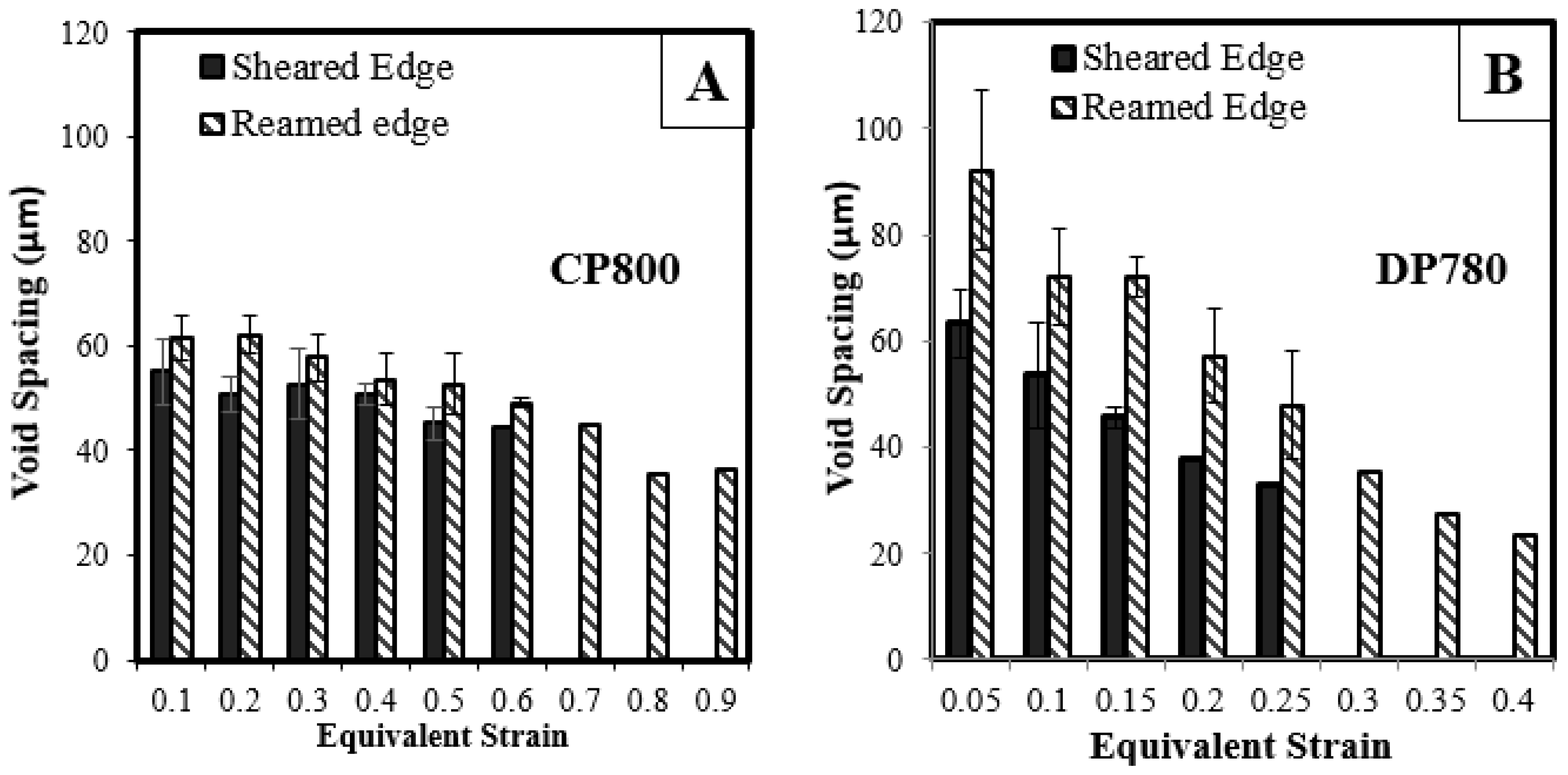

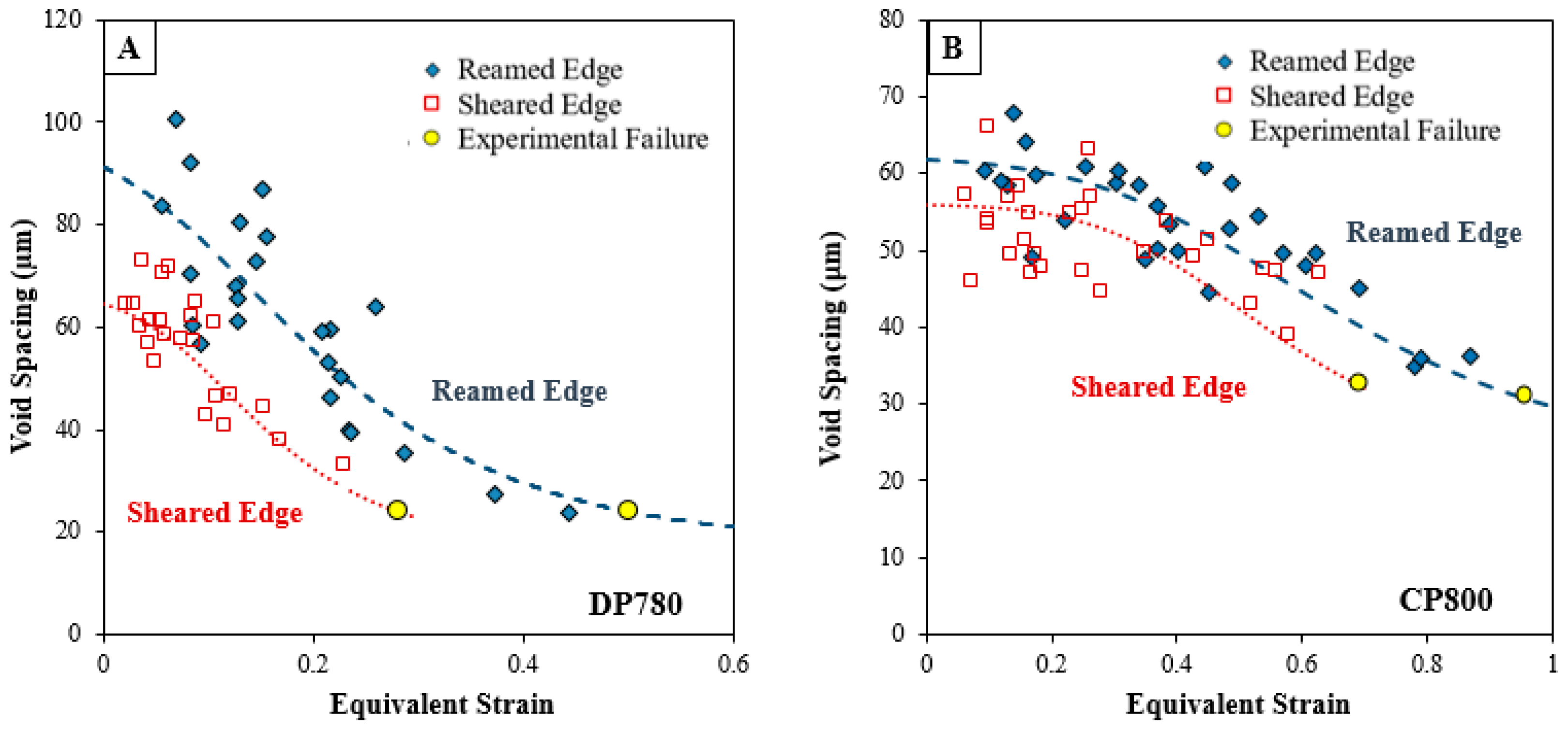

5.2. Void Growth and Evolution

5.3. Damage Accumulation

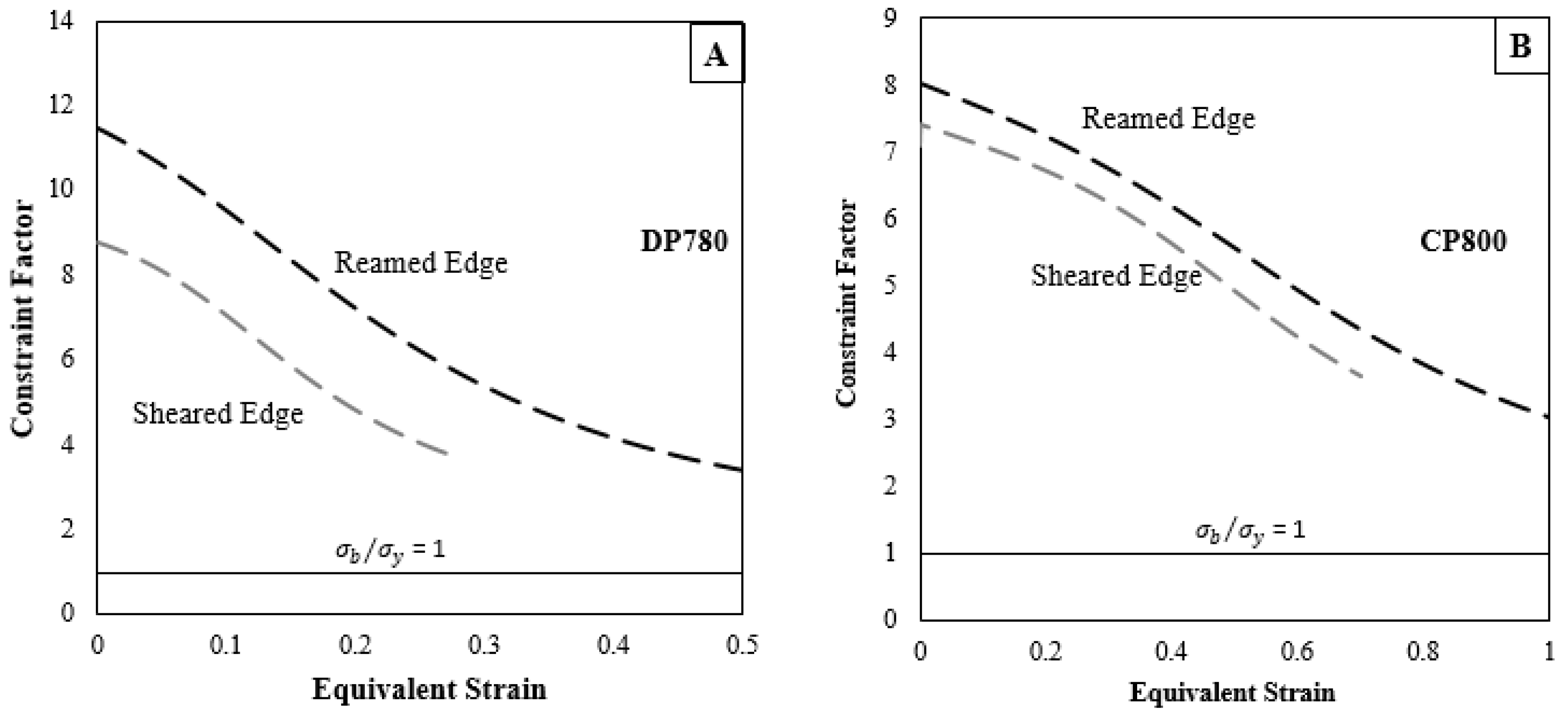

6. Modeling

7. Discussion

7.1. Effect of Microstructure Constituents on Damage Mechanism

7.2. Effect of Edge Condition on Damage Mechanism

8. Conclusions

- (1)

- Comparison of the limit strains in the current hole tension experiments and the hole expansion results presented by Pathak et al. [7] indicates that the edge limit strains are the same, at least for the current materials and hole processing methods.

- (2)

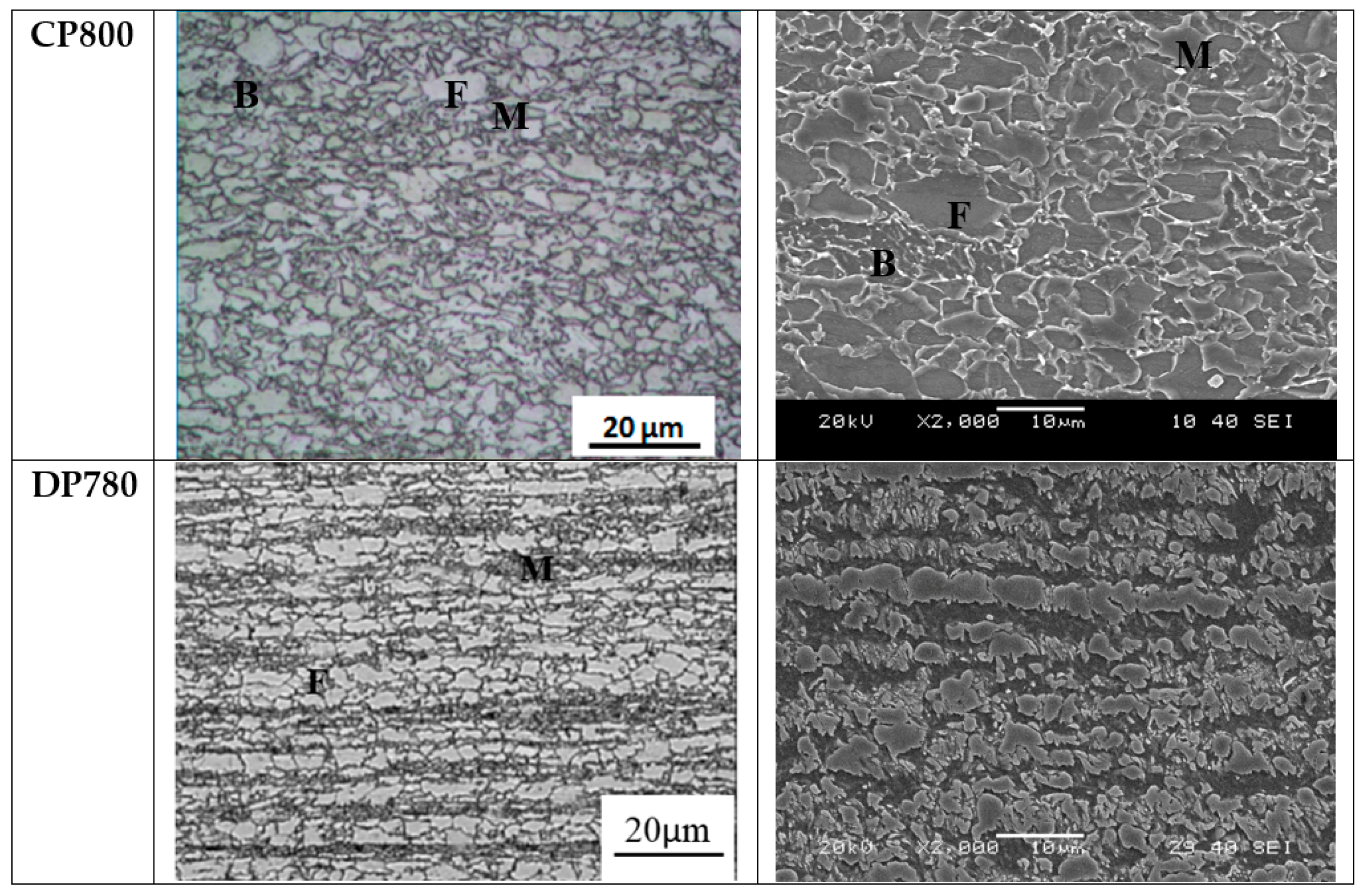

- In the DP780 steel examined herein, martensite cracking and decohesion of ferrite-martensite interfaces are the dominant nucleation mechanisms. A smaller quantity of voids is nucleated due to failure of ferrite grains near the fracture strain. Voids associated with TiN particles were few and formed at a lower strain.

- (3)

- Two nucleation mechanisms related to TiN particles were observed in the CP800 steel: inclusion cracking and decohesion. The primary voids were related to TiN particles, while secondary voids nucleated within the martensite or bainite microstructures at larger strains.

- (4)

- The microstructure of DP780 consists of a higher fraction of martensite that has a larger strength differential with the ferrite matrix, resulting in a lower nucleation strain and accelerated void nucleation in comparison to the ferritic-bainitic CP800 steel that has a lower strength differential between phases.

- (5)

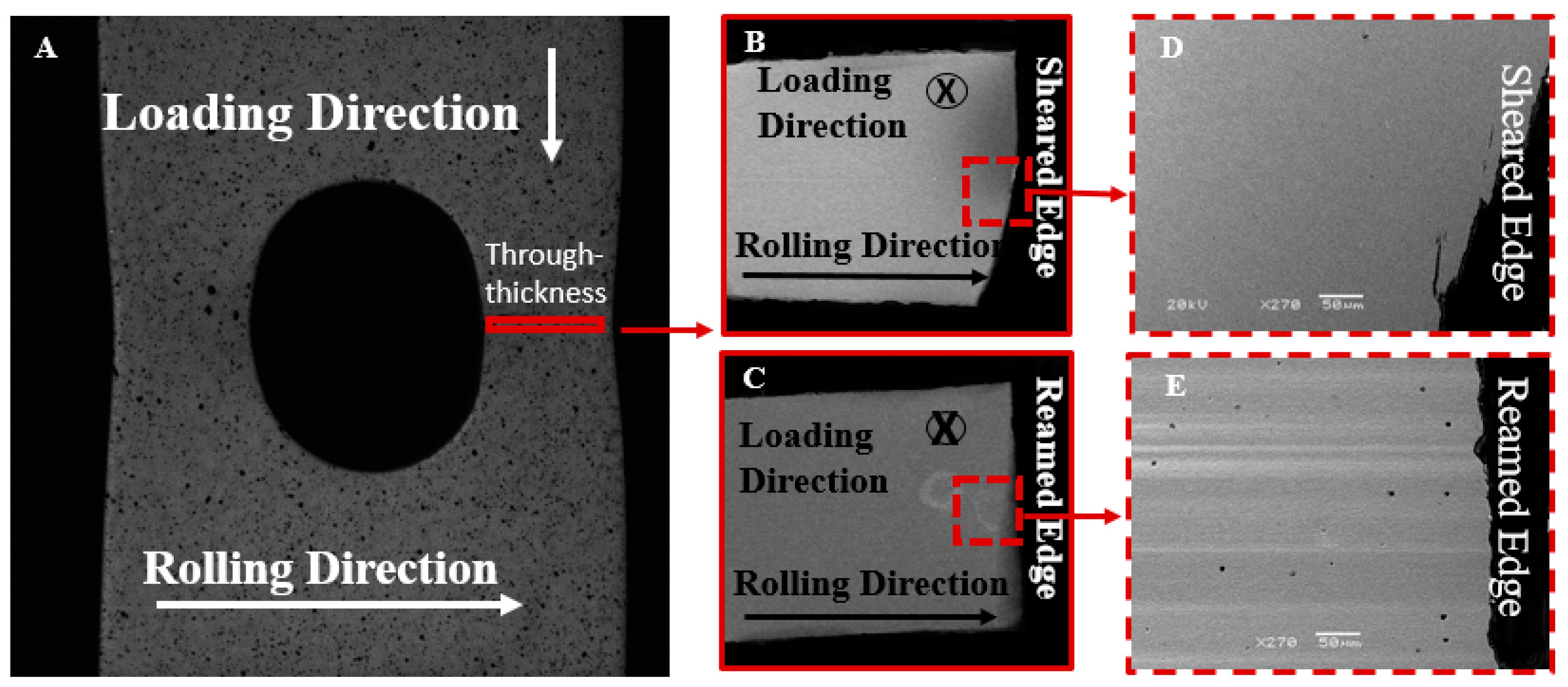

- The nucleation mechanism observed behind the sheared edge is similar to the reamed edge for both materials investigated in this study.

- (6)

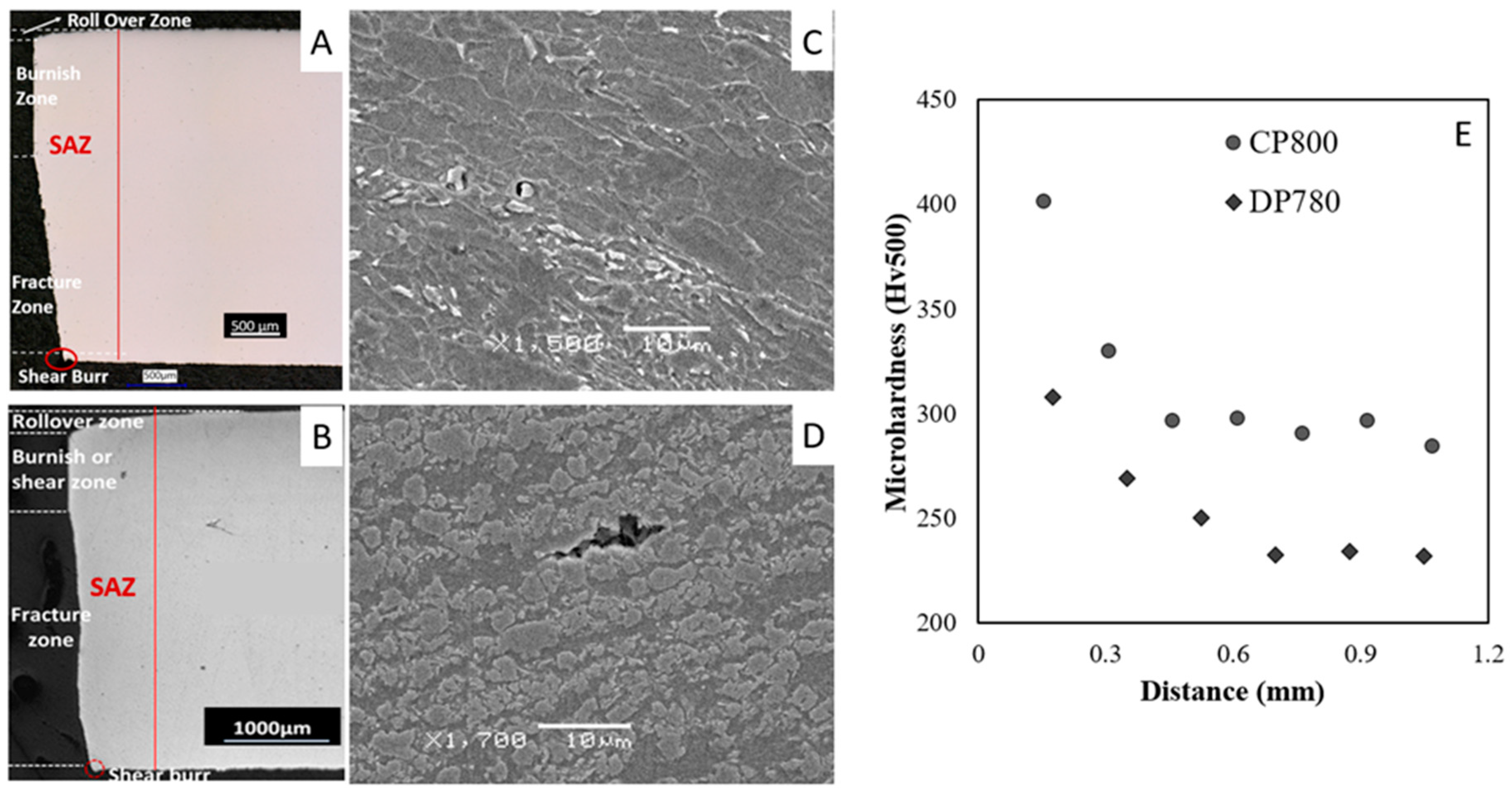

- The rate of damage accumulation is higher behind the sheared edge relative to the reamed edge due to the presence of pre-straining behind the sheared edge that promotes nucleation, growth, and coalescence of voids.

- (7)

- Once a crack initiates at the sheared edge, crack propagation occurs continuously ahead of the crack-tip though accelerated void nucleation, growth, and coalescence and ultimately causes failure.

- (8)

- The Chu and Needleman criterion for nucleation, the Rice and Tracey criterion for void growth and the Benzerga and Leblond criterion for coalescence were adopted in the present work to account for the variation in damage progression between the reamed and sheared edges. The quantitative data from experiments were closely predicted by the analytical models and suggests that a damage-based fracture model can be developed based on the void evolution during the hole tension test to predict edge failure.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Billur, T.; Altan, T. Challenges in forming advanced high strength steels. In Proceedings of the New Developments in Sheet Metal Forming, Stuttgart, Germany, 22–23 May 2012; pp. 285–304. [Google Scholar]

- Takuda, H.; Mori, K.; Fujimoto, H.; Hatta, N. Prediction of forming limit in bore-expanding of sheet metals using ductile fracture criterion. J. Mater. Process. Technol. 1999, 92, 433–438. [Google Scholar] [CrossRef]

- Dykeman, J.; Malcolm, S.; Yan, B.; Chintamani, J.; Huang, G.; Ramisetti, N.; Zhu, H. Characterization of Edge Fracture in Various Types of Advanced High Strength Steel. SAE Tech. Pap. 2011, 1, 1058. Available online: http://papers.sae.org/2011-01-1058/ (accessed on 12 April 2011).

- Rigsbee, J.M.; Abraham, J.K.; Davenport, A.T.; Franklin, J.E.; Pickens, J.W. Proceedings of Structure and Properties of Dual-Phase Steels; The Metallurgical Society of AIME: New York, NY, USA, 1979; pp. 304–329. [Google Scholar]

- Bhadeshia, H.K. Bainite in Steels: Transformations, Microstructure and Properties, 2nd ed.; Institute of Materials, Minerals and Mining: London, UK, 2001. [Google Scholar]

- Fonstein, N. Advanced High Strength Sheet Steels, 1st ed.; Springer International Publishing: New York, NY, USA, 2015. [Google Scholar]

- Pathak, N.; Butcher, C.; Worswick, M. Assessment of the Critical Parameters Influencing the Edge Stretchability of Advanced High Strength Steel. J. Mater. Eng. Perform. 2016, 25, 4919–4932. [Google Scholar] [CrossRef]

- Levy, B.; van Tyne, C. Review of the Shearing Process for Sheet Steels and Its Effect on Sheared-Edge Stretching. J. Mater. Eng. Perform. 2012, 21, 1205–1213. [Google Scholar] [CrossRef]

- Keeler, S. Die design and lubrication. In Understanding Sheet Metal Formability; Sheet Metal Industries: London, UK, 1971; pp. 687–691. [Google Scholar]

- Smith, D. Die Design Handbook, 1st ed.; Society of Manufacturing Engineers: Dearborn, MI, USA, 1990. [Google Scholar]

- Davies, R. Edge cracking in high strength steels. J. Appl. Metalwork. 1983, 2, 293–299. [Google Scholar] [CrossRef]

- Bhattacharya, D.; Patil, R. Edge Formability Properties of a Hot Rolled HSLA Steel Desulfurized by Various Methods. HSLA Steels Technol. Appl. 1983, 10, 429–441. [Google Scholar]

- Adamczyk, R.; Michal, G. Sheared edge extension of high-strength cold-rolled steels. J. Appl. Metalwork. 1986, 4, 157–163. [Google Scholar] [CrossRef]

- Hasegawa, K.; Kawamura, K.; Urabe, T.; Hosaya, Y. Effects of Microstructure on Stretch-flange-formability of 980 MPa Grade Cold-rolled Ultra High Strength Steel Sheets. ISIJ Int. 2004, 44, 603–609. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, S.; Ray, K. Short Fatigue Crack Growth Behaviour in Ferrite–Bainite Dual-phase Steels. ISIJ Int. 2008, 48, 1285–1292. [Google Scholar] [CrossRef]

- Sudo, M.; Hashimoto, S.; Kambe, S. Niobium Bearing Ferrite-Bainite High Strength Hot-rolled Sheet Steel with Improved Formability. Trans. Iron Steel Inst. Jpn. 1983, 23, 303–311. [Google Scholar] [CrossRef]

- Teng, Z.K.; Chen, X.M. Edge Cracking Mechanism in Two Dual-Phase Advanced High Strength Steels. Mater. Sci. Eng. A 2014, 618, 645–653. [Google Scholar] [CrossRef]

- Misra, R.D.K.; Thompson, S.W.; Hylton, T.A.; Boucek, A.J. Microstructures of Hot-Rolled High-Strength Steels with Significant Differences in Edge Formability. Metall. Mater. Trans. A 2001, 32, 745–760. [Google Scholar] [CrossRef]

- Spitzig, W.A.; Smelser, R.E.; Richmond, O. The Evolution of Damage and Fracture in Iron Compacts with Various Initial Porosities. Acta Metall. 1988, 36, 1201–1211. [Google Scholar] [CrossRef]

- Barnby, J.T. The initiation of ductile failure by fractured carbides in an austenitic stainless steel. Acta Metall. 1967, 15, 903–909. [Google Scholar] [CrossRef]

- Tanguy, B.; Besson, J.; Piques, R.; Pineau, A. Ductile to brittle transition of an A508 steel characterized by Charpy impact test: Part I: Experimental results. Eng. Fract. Mech. 2005, 72, 49–72. [Google Scholar] [CrossRef]

- Wallin, K.; Saario, T.; Torronen, K. Statistical model for carbide induced brittle fracture in steel. Met. Sci. 1984, 18, 13–16. [Google Scholar] [CrossRef]

- Krauss, G. Deformation and Fracture in Martensitic Carbon Steels Tempered at Low Temperatures. Metall. Mater. Trans. B 2001, 32, 205–221. [Google Scholar] [CrossRef]

- Morito, S.; Huang, X.; Furuhaar, T.; Maki, T.; Hansen, N. The Morphology and Crystallography of Lath Martensite in Alloy Steels. Acta Mater. 2006, 54, 5323–5331. [Google Scholar] [CrossRef]

- Morito, S.; Kishida, I.; Maki, T. Microstructure of Ausformed Lath Martensite in 18%Ni Maraging Steel. J. Phys. IV Fr. 2003, 112, 453–456. [Google Scholar] [CrossRef]

- Ghadbeigi, H.; Pinna, C.; Celottob, S. Failure mechanisms in DP600 steel: Initiation, evolution and fracture. Mater. Sci. Eng. A 2013, 588, 420–431. [Google Scholar] [CrossRef]

- Ahmad, E.; Manzoor, T.; Ali, K.; Akhter, J. Effect of microvoid formation on the tensile properties of dual-phase steel. J. Mater. Eng. Perform. 2000, 9, 306–310. [Google Scholar] [CrossRef]

- Kadkhodapour, J.; Butz, A.; Rad, S.Z. Mechanisms of Void Formation during Tensile Testing in a Commercial, Dual-Phase Steel. Acta Mater. 2011, 59, 2575–2588. [Google Scholar] [CrossRef]

- Erdogan, M. The effect of new ferrite content on the tensile fracture behaviour of dual phase steels. J. Mater. Sci. 2002, 37, 3623–3630. [Google Scholar] [CrossRef]

- Zhang, L.C.; Zhou, T.; Aindow, M.; Alpay, S.P.; Blackburn, M.J.; Wu, M.H. Nucleation of stress-induced martensites in a Ti/Mo-based alloy. J. Mater. Sci. 2005, 40, 2833–2836. [Google Scholar] [CrossRef]

- Kahziz, M.; Morgeneyer, T.; Maziere, M.; Maire, E.; Bouaziz, O. 3D Synchrotron Laminography Assessment of Damage Evolution in Blanked Dual Phase Steels. Proceedings of 13th International Conference on Fracture, Beijing, China, 16 June 2013. [Google Scholar]

- Chu, C.; Needleman, A. Void nucleation effects in biaxially stretched sheets. J. Eng. Mater. Technol. 1980, 102, 249–256. [Google Scholar] [CrossRef]

- Rice, J.; Tracey, D. On the ductile enlargement of voids in triaxial stress fields. J. Mech. Phys. Solids 1969, 17, 201–217. [Google Scholar] [CrossRef]

- Benzerga, A.; Leblond, J. Effective Yield Criterion Accounting for Microvoid Coalescence. J. Appl. Mech. 2014, 81, 031009. [Google Scholar] [CrossRef]

- Bell, G. The Relationshio between Microstructure and Damage Evolution in Hot-Rolled Complex-Phase Steel; Queen’s University: Kingston, ON, Canada, 2013. [Google Scholar]

- Winkler, S.; Thompson, A.; Salisbury, C.; Worswick, M.J.; van Riemsdijk, I.; Mayer, R. Strain Rate and Temperature Effects on the Formability and Damage of Advanced High Strength Steels. Metall. Mater. Trans. A 2008, 39, 1350–1358. [Google Scholar] [CrossRef]

- Bardelcik, A.; Worswick, M.J.; Wells, M.A. The influence of martensite, bainite and ferrite on the as-quenched constitutive response of simultaneously quenched and deformed boron steel—Experiments and model. Mater. Des. 2014, 55, 509–525. [Google Scholar] [CrossRef]

- Sutton, M.A.; Orteu, J.; Schreier, H.W. Image Correlation Forshape, Motion and Deformation Measurements; Springer: New York, NY, USA, 2009. [Google Scholar]

- Wang, K.; Meng, L.; Wierzbicki, T. Experiments and Modeling of Edge Fracture for an AHSS Sheet. Int. J. Fract. 2014, 187, 245–268. [Google Scholar] [CrossRef]

- Butcher, C.; Anderson, D.; Worswick, M. Predicting failure during sheared edge stretching using a damage-based model for the shear-affected zone. SAE Int. J. Mater. Manuf. 2013, 6, 304–312. [Google Scholar] [CrossRef]

- Han, S.K.; Margolin, H. Void formation, void growth and tensile fracture of plain carbon steel and a dual-phase steel. Mater. Sci. Eng. A 1989, 112, 133–141. [Google Scholar] [CrossRef]

- Garrison, W.M.; Moody, N.R. Ductile fracture. J. Phys. Chem. Solids 1987, 48, 1035–1047. [Google Scholar] [CrossRef]

- Avramovic-Cingara, G.; Ososkov, Y.; Jain, M.; Wilkinson, D. Effect of Martensite Distribution on Damage Behaviour in DP600 Dual Phase Steels. Mater. Sci. Eng. A 2009, 516, 7–12. [Google Scholar] [CrossRef]

- Landron, C.; Maire, E.; Bouaziz, O.; Adrien, J.; Lecarme, L.; Bareggi, A. Validation of void growth models using X-ray microtomography characterization of damage in dual phase steels. Acta Mater. 2011, 59, 7564–7573. [Google Scholar] [CrossRef]

- Thomason, C.; Worswick, M.; Pilkey, A.; Lloyd, D.; Burger, G. Modeling void nucleation and growth within periodic clusters of particles. J. Mech. Phys. Solids 1998, 47, 1–26. [Google Scholar] [CrossRef]

- Pardoen, T.; Hutchinson, J. Micromechanics-based model for trends in toughness of ductile metals. Acta Mater. 2000, 51, 133–148. [Google Scholar] [CrossRef]

- Thomason, P. Ductile spallation fracture and the mechanics of void growth and coalescence under shock-loading conditions. Acta Mater. 1999, 47, 3633–3646. [Google Scholar] [CrossRef]

- Huang, Y. Accurate Dilatation Rates for Spherical Voids in Triaxial Stress Fields. J. Appl. Mech. 1991, 58, 1084–1086. [Google Scholar] [CrossRef]

- Tvergaard, V.; Needleman, A. A continuum model for void nucleation by inclusion debonding. Acta Metall. 1984, 32, 157–169. [Google Scholar] [CrossRef]

- Pardoen, T.; Hutchinson, J. An extended model for void growth and coalescence. J. Mech. Phys. Solids 2000, 48, 2467–2512. [Google Scholar] [CrossRef]

- Benzerga, A. Micromechanics of coalescence in ductile fracture. J. Mech. Phys. Solids 2002, 50, 1331–1362. [Google Scholar] [CrossRef]

- Zengtao, C.; Butcher, C. Micromechanics Modelling of Ductile Fracture, 1st ed.; Springer: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Landron, C.; Bouaziz, O.; Maire, E.; Adrien, J. Experimental investigation of void coalescence in a dual phase steel using X-ray tomography. Acta Mater. 2013, 61, 6821–6829. [Google Scholar] [CrossRef]

- Balliger, N.K.; Gladman, T. Work Hardening of Dual-Phase Steels. Met. Sci. 1981, 15, 95–108. [Google Scholar] [CrossRef]

- Podder, A.S.; Bhattacharjee, D.; Ray, R.K. Effect of Martensite on the Mechanical Behavior of Ferrite–Bainite Dual Phase Steels. ISIJ Int. 2007, 40, 1058–1064. [Google Scholar] [CrossRef]

| Material | C | Mn | Si | Cr | Ti |

|---|---|---|---|---|---|

| CP800 | 0.05 | 1.5 | 0.55 | 0.6 | 0.14 |

| DP780 | 0.14 | 2.0 | 0.26 | 0.26 | 0.023 |

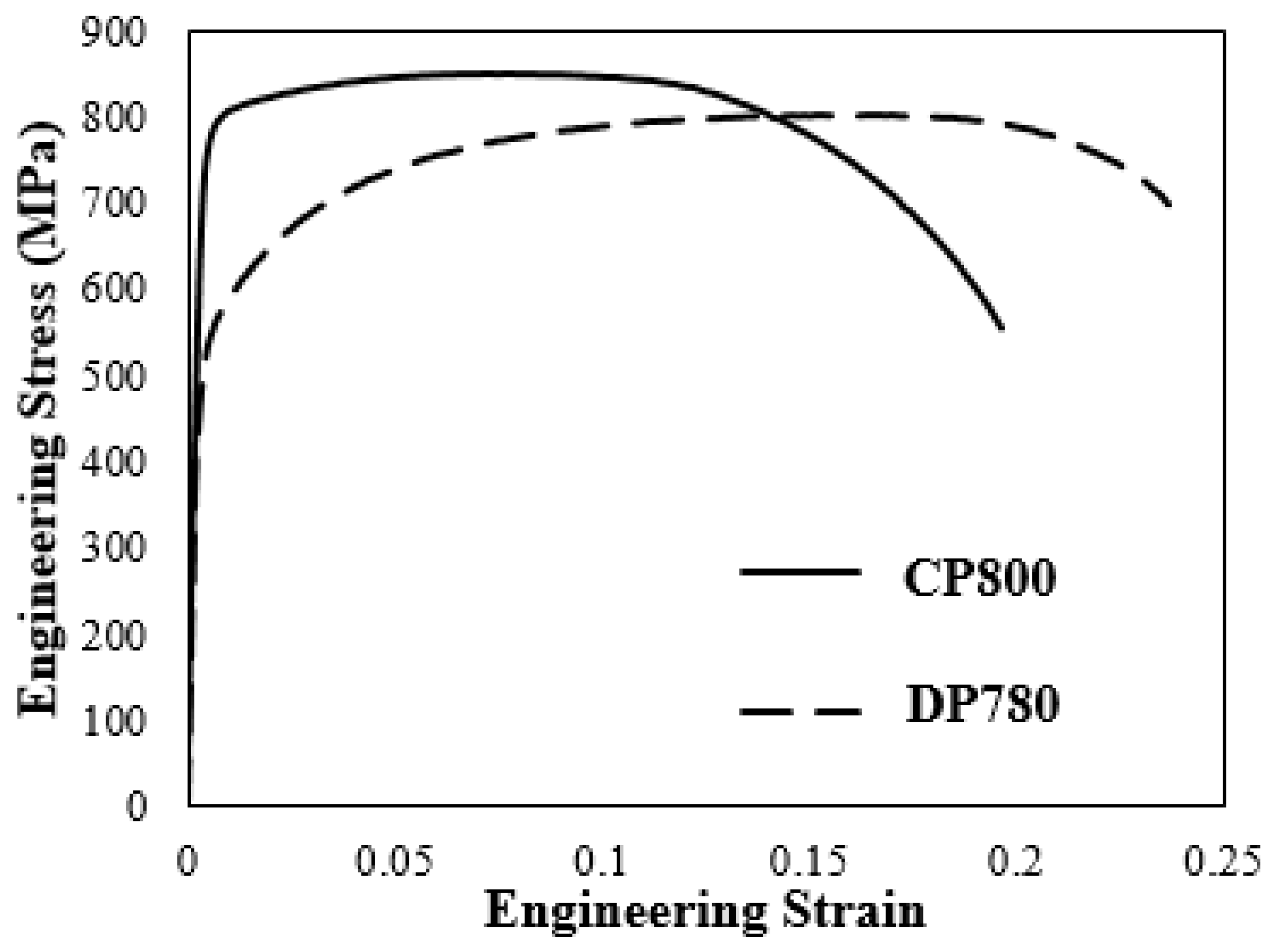

| Material | Thickness (mm) | Direction | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Total Elongation (%) | n (5-UE%) | r | rn | ra | Reduction of Area (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| CP800 | 2.90 | RD | 710 | 810 | 19.6 | 0.08 | 0.70 | 1.08 | −0.51 | 69 (6) |

| (6) | (3) | (1.7) | (0.00) | (0.04) | ||||||

| TD | 788 | 850 | 18.8 | 0.06 | 0.95 | |||||

| (5) | (5) | (1.0) | (0.00) | (0.04) | ||||||

| DD | 726 | 800 | 20.5 | 0.07 | 1.33 | |||||

| (8) | (5) | (2.0) | (0.00) | (0.03) | ||||||

| DP780 | 1.56 | RD | 509 | 800 | 22.8 | 0.16 | 0.72 | 0.90 | −0.16 | 41 (4) |

| (8) | (6) | (2.2) | (0.00) | (0.02) | ||||||

| TD | 522 | 806 | 21.6 | 0.15 | 0.92 | |||||

| (4) | (5) | (1.8) | (0.00) | (0.03) | ||||||

| DD | 533 | 815 | 25.5 | 0.15 | 0.98 | |||||

| (6) | (8) | (1.8) | (0.00) | (0.01) |

| Materials | Edge Condition | Equivalent Failure Strain | Displacement to Failure (mm) | ||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | Failure | |||

| CP800 | Reamed | 1.01 ± 0.04 | 1.78 | 1.89 | 1.97 | 2.31 | 2.42 |

| Sheared | 0.66 ± 0.04 | 0.91 | 1.37 | 1.59 | 1.75 | 1.81 | |

| DP780 | Reamed | 0.54 ± 0.03 | 1.06 | 1.15 | 1.31 | - | 1.51 |

| Sheared | 0.28 ± 0.04 | 0.53 | 0.60 | 0.66 | - | 0.82 | |

| Material | Edge Condition | Nn (per mm2) | ||

|---|---|---|---|---|

| CP800 | Reamed | 350 | 0.85 | 0.23 |

| Sheared | 350 | 0.70 | 0.19 | |

| DP780 | Reamed | 700 | 0.42 | 0.12 |

| Sheared | 700 | 0.30 | 0.10 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pathak, N.; Butcher, C.; Worswick, M.J.; Bellhouse, E.; Gao, J. Damage Evolution in Complex-Phase and Dual-Phase Steels during Edge Stretching. Materials 2017, 10, 346. https://doi.org/10.3390/ma10040346

Pathak N, Butcher C, Worswick MJ, Bellhouse E, Gao J. Damage Evolution in Complex-Phase and Dual-Phase Steels during Edge Stretching. Materials. 2017; 10(4):346. https://doi.org/10.3390/ma10040346

Chicago/Turabian StylePathak, Nikky, Cliff Butcher, Michael James Worswick, Erika Bellhouse, and Jeff Gao. 2017. "Damage Evolution in Complex-Phase and Dual-Phase Steels during Edge Stretching" Materials 10, no. 4: 346. https://doi.org/10.3390/ma10040346