Calcium Phosphate Bioceramics: A Review of Their History, Structure, Properties, Coating Technologies and Biomedical Applications

Abstract

:1. Historical Perspective

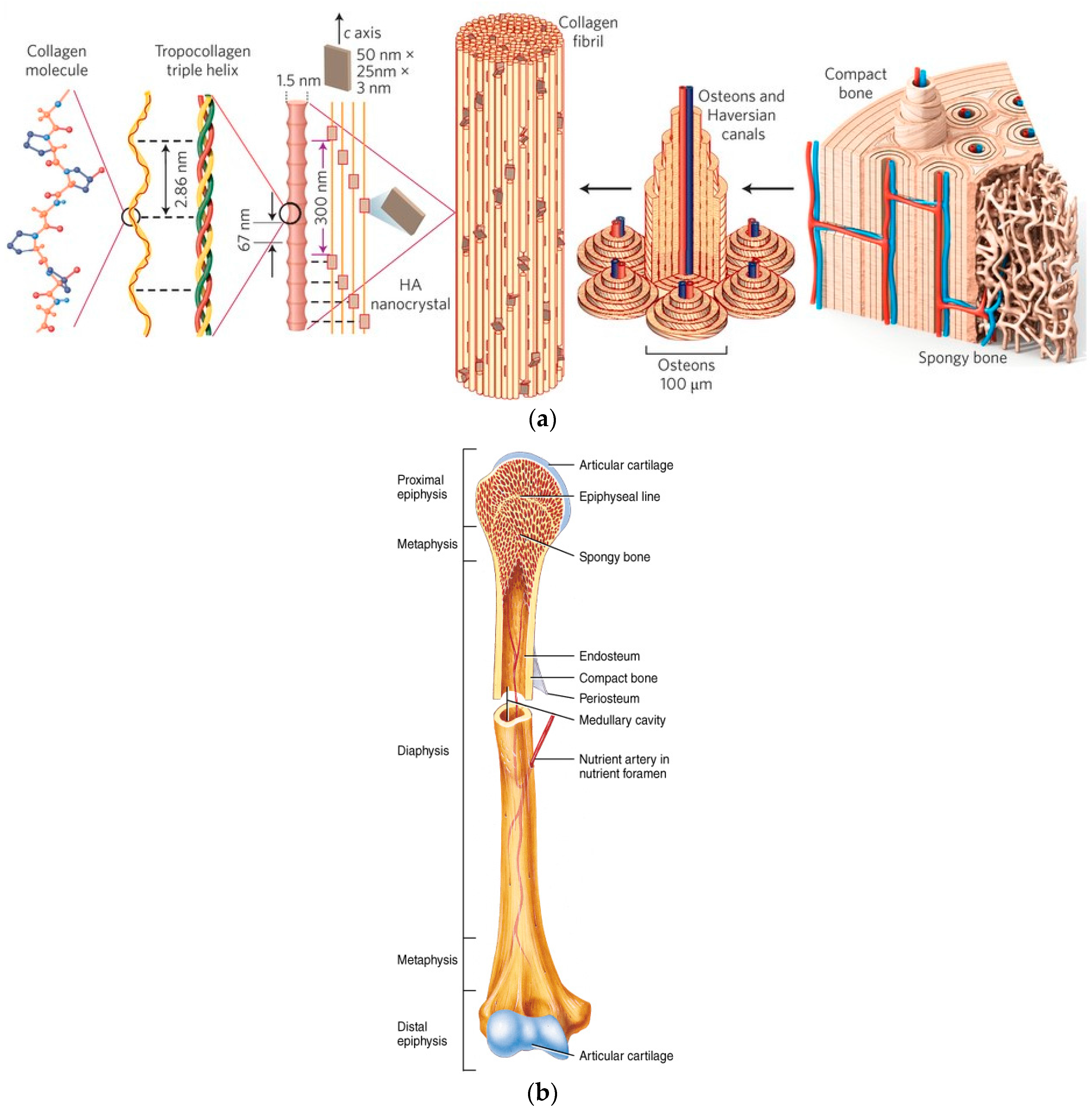

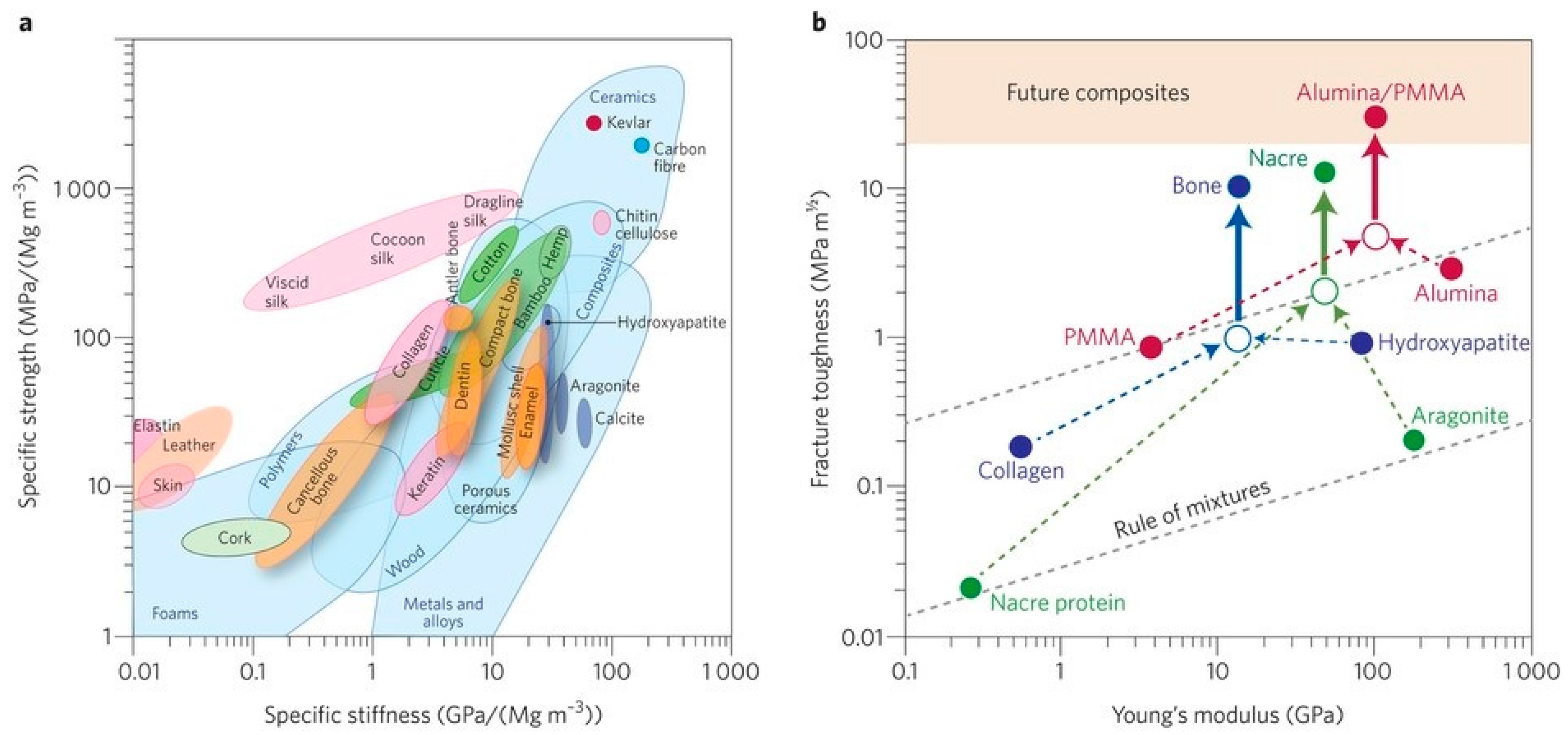

2. The Structure, Chemistry and Mechanical Properties of Bone

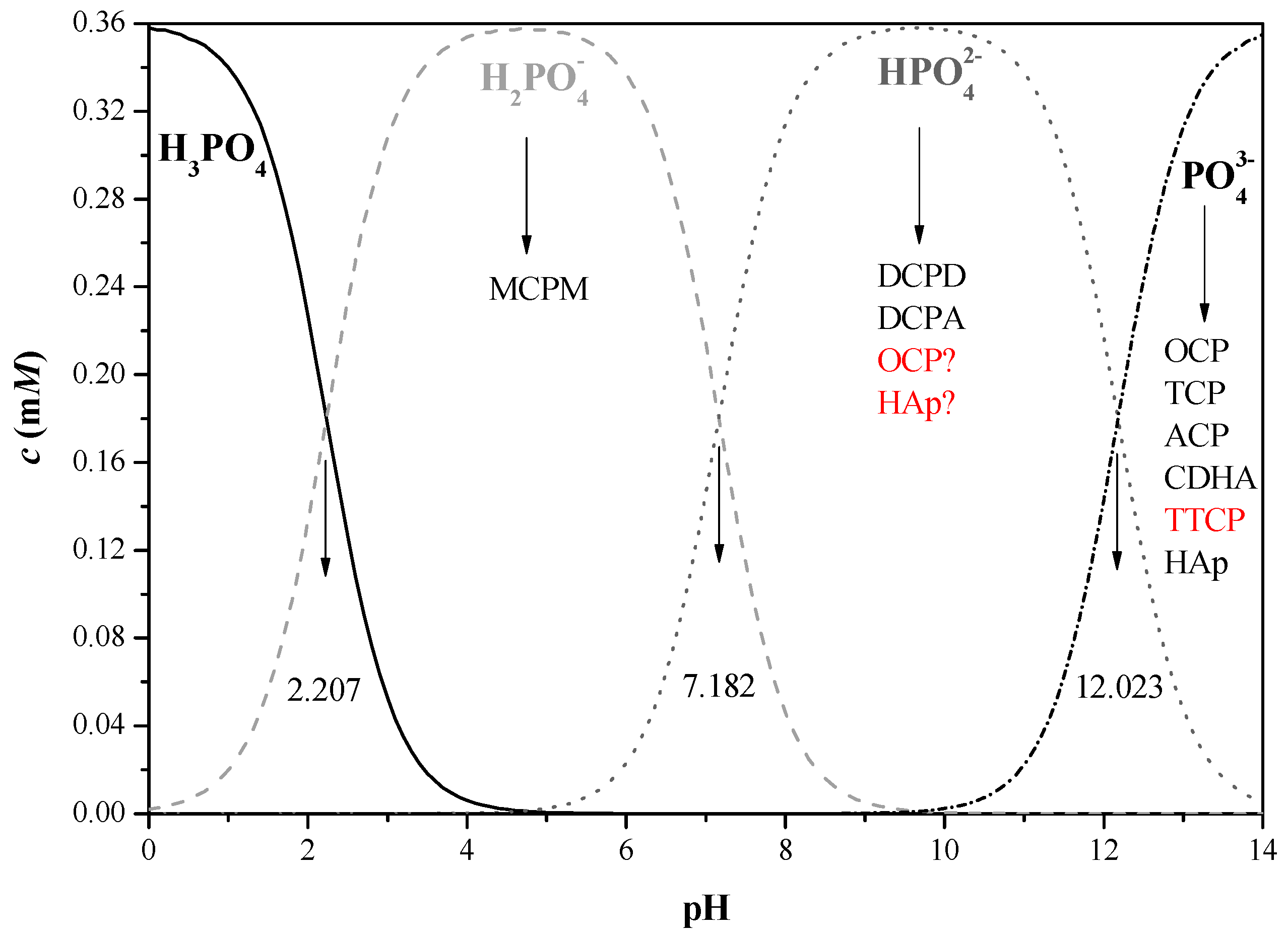

3. Transient Precursor Phases

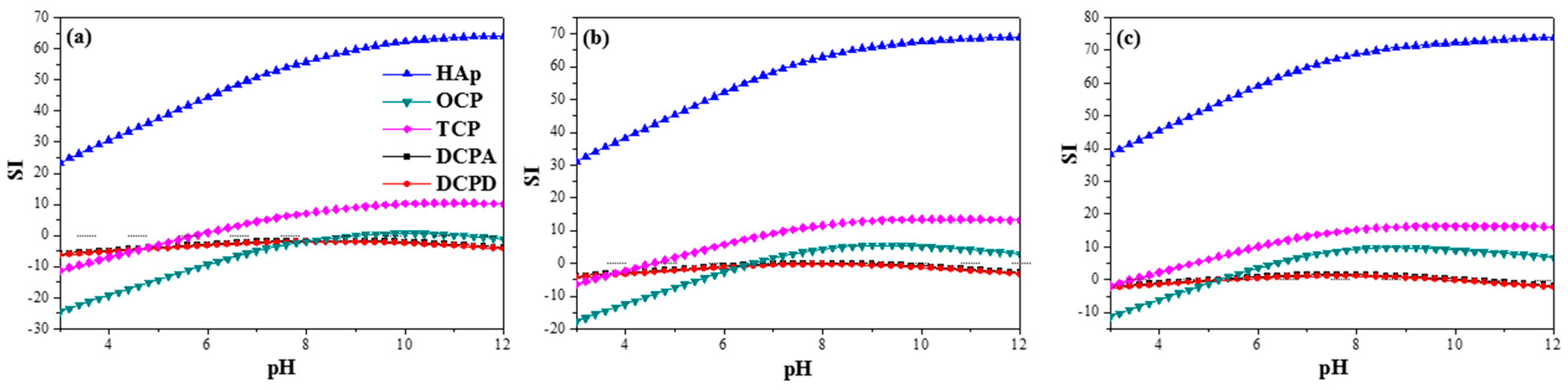

4. Dissolution and Reprecipitation as Bone

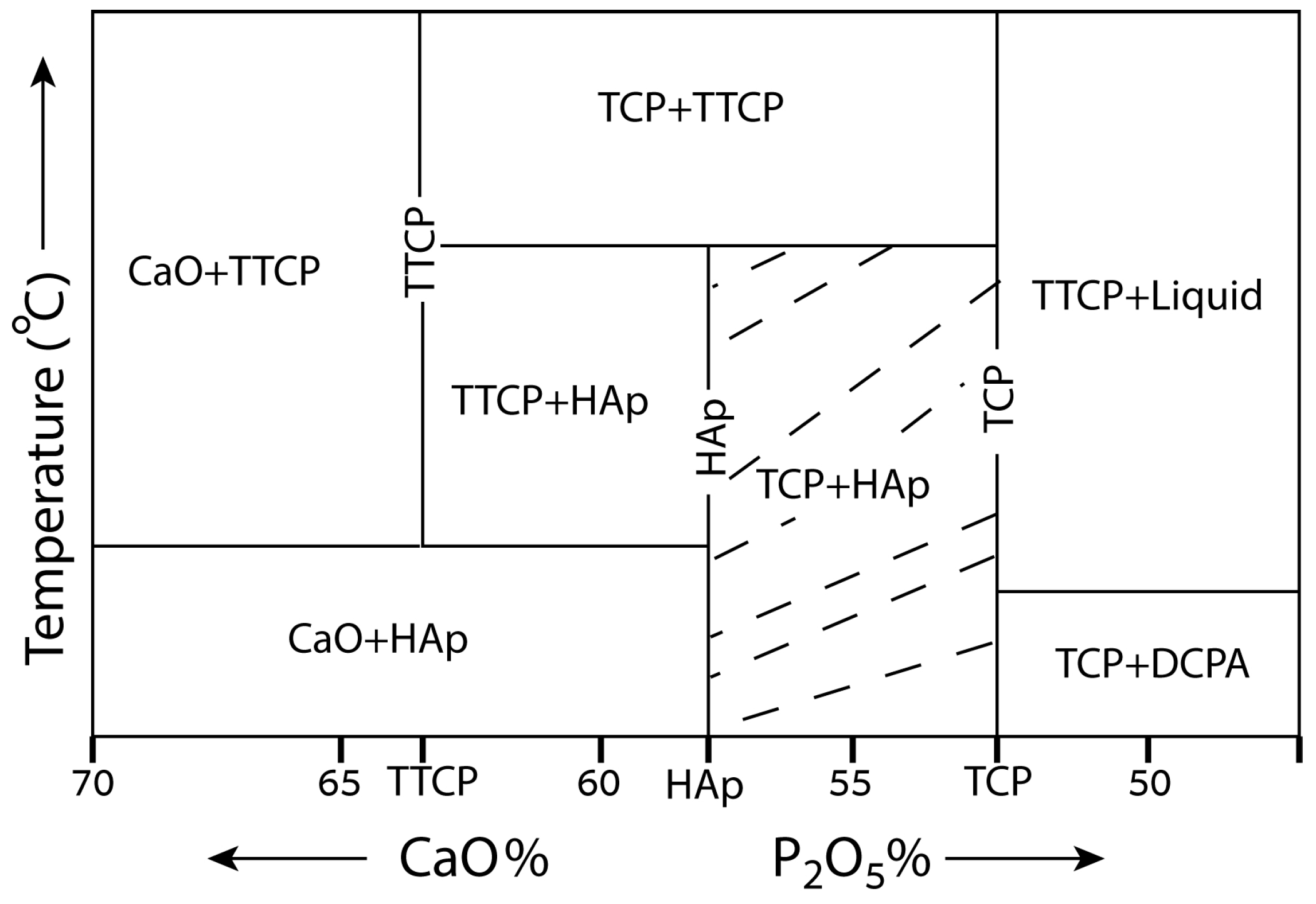

5. Requirements from Calcium Phosphates for Medical Applications

6. Individual Calcium Phosphate Phases and Their Properties

6.1. MCPM

6.2. DCPA

6.3. DCPD

6.4. OCP

6.5. α-TCP

6.6. β-TCP

6.7. ACP

6.8. CDHA

6.9. TTCP

6.10. HAp

7. Nano-CaP

8. Biphasic and Triphasic CaP Formulations

9. Composite Calcium Phosphates

10. Functionally Graded Calcium Phosphates

11. Antibacterial Calcium Phosphates

12. The Effect of Sterilization

13. In Vitro and In Vivo Tests

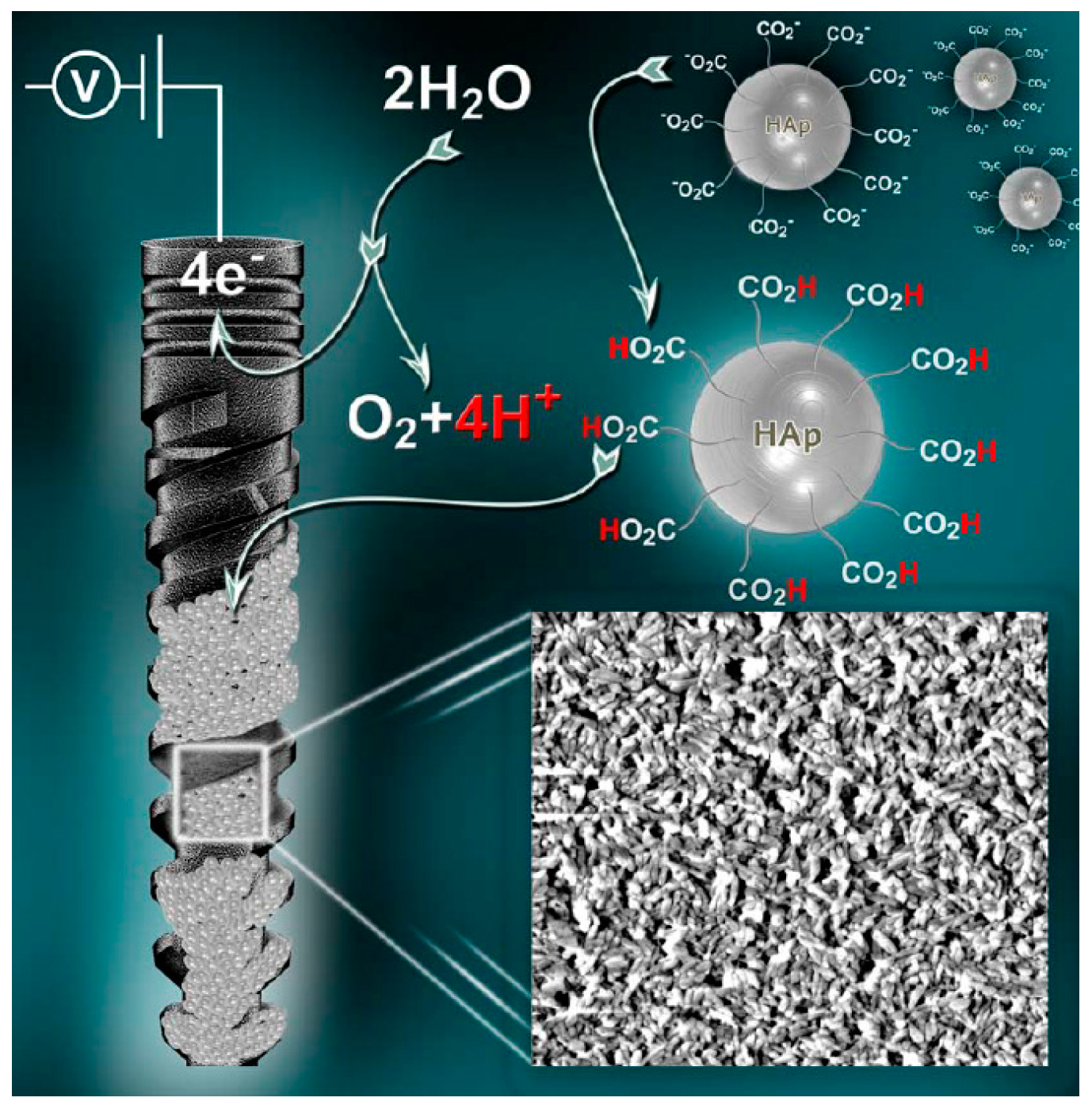

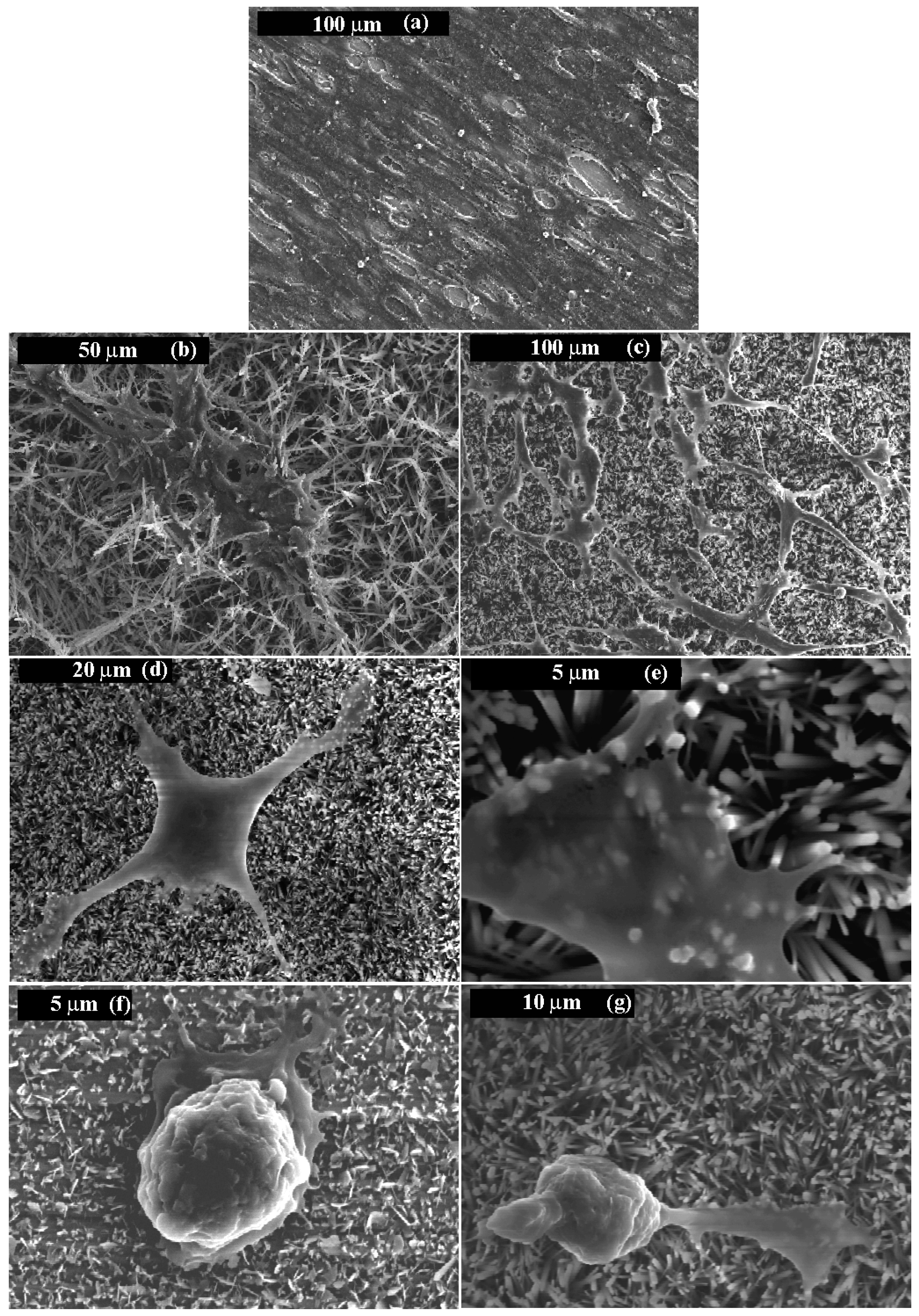

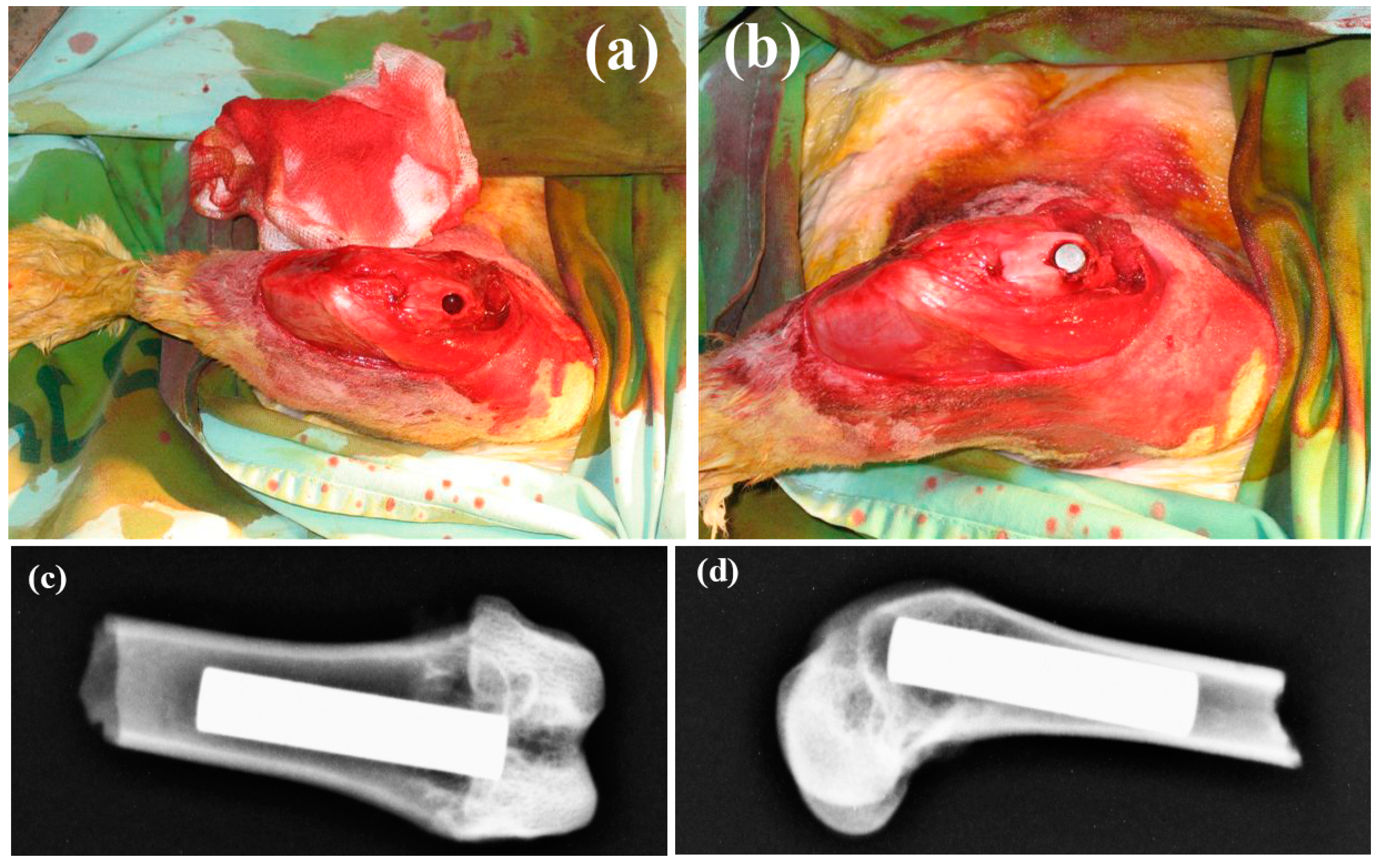

14. CaP Coating Technologies

US FDA and International Standards Requirements

15. Clinical and Industrial Applications

16. The Future of Calcium Phosphates

- (1)

- Dental community mistrust. Interfacial failure of past dental implants coated with PS CaP has left a mark on CaP coatings. When first bursting into the dental industry as coatings, some PS CaP coatings failed within several months or years [850,851]. The cause has been attributed to the extensive dissolution of the coating as well as to its delamination [850,852]. These problems have since been eliminated; yet, many in the dental community have lost their faith in these coatings. A major campaign or sponsored Health Maintenance Organization (HMO) implants may reinstate CaP coatings to dental implants.

- (2)

- Short-term infection. As described earlier, most infections occur due to bacteria adhering to the implant’s surface during implantation, causing a biofilm to form on it prior to implantation [587,853]. In general, infections can be classified based on their time of onset. Most of the infections develop from an early contamination that occurs during the operation or in the first few days after surgery. Events such as these, which become symptomatic or anyway manifest shortly following surgery, within three months of implantation, have been referred to as “early” infections [589]. These infections can be prevented by CaP incorporated with either a drug release system or anti-fouling agents. Anti-fouling or on-demand drug release systems, if designed well, can also be used to prevent long-term infections. This is a goal marked by many companies today.

- (3)

- Long recovery time. CaPs are very good osteoconductive agents. Yet, the recovery period of implants integrated with CaPs is not immediate, unlike other techniques. For example, PMMA fixation of hip implants is immediate, and the patient may apply weight on the implantation site almost immediately after the operation. CaP coatings, and as such so are the scaffolds and cements, need time to allow good osseointegration, and thus extend the recovery period of patients. Encouraging faster integration, or somehow allowing for a bridge to such, may increase the use of CaP products.

- (4)

- Long-term issues with implants. Both long-term infection and resorption of the surrounding bone (e.g., due to stress shielding) introduce serious problems. Sensors allowing the doctor, or even the patient, to monitor the environment of the implant’s surface may allow earlier intervention, especially if such intervention can activate dormant agents within the coating.

- (5)

- Mechanical strength of scaffolds/cements for tissue engineering. Biodegradable scaffolds/cements are very limited in use because of poor mechanical stability, and limited promotion of vascularization. Composites of CaPs with biodegradable metals, e.g., magnesium, and incorporation of GFs could solve this intricate problem and increase the use of CaP products in reconstructive surgery. However, as described in Section 9, the inclusion of GFs is not in favour nowadays due to health safety issues.

- (6)

- Bone/cartilage, bone mineral/collagen and bone/tendon interfaces. While many efforts are focused on the issues described above, not enough attention is focused on bone interfaces. A better understanding of the biological systems is needed. For example, the bonding mechanism between the bone mineral and collagen remains unclear [854]. It is also unclear whether a rapid repair that is elicited by the new generation of bioceramics results from the enhancement of mineralization per se or whether there is a more complex signalling process involving proteins in collagen. If we were able to understand the fundamentals of bone response to specific ions and the signals they activate, then we could design better bioceramics for the future [854]. From application standpoint, CaP-based FGMs may very well address these issues and become the golden standard in CaP implants.

- (7)

- Transient precursor phases. As described in Section 3, ACP, DCPD and OCP have been suggested as transient precursor phases. However, there is yet no consensus in the scientific community regarding the prevalence of these phases and the exact mechanisms of biomineralization relevant to human bone remodelling. High-resolution, in situ structural and chemical studies of human bone formation and remodelling may be possible one day and clarify this old scientific debate. The outcomes of such studies may aid in developing better bone substitutes and CaP-based coatings.

17. Conclusions

Conflicts of Interest

References

- Dorozhkin, S.V. A detailed history of calcium orthophosphates from 1770s till 1950. Mater. Sci. Eng. C 2013, 33, 3085–3110. [Google Scholar] [CrossRef] [PubMed]

- Driskell, T.D. Early history of calcium phosphate materials and coatings. In Characterization and Performance of Calcium Phosphate Coatings for Implants; Horowitz, E., Parr, J.E., Eds.; American Society for Testing and Materials (ASTM): Philadelphia, PA, USA, 1994; pp. 1–9. [Google Scholar]

- Shackelford, J.F. Bioceramics—An historical perspective. Mater. Sci. Forum 1999, 293, 1–4. [Google Scholar] [CrossRef]

- Shepperd, J. The early biological history of calcium phosphates. In Fifteen Years of Clinical Experience with Hydroxyapatite Coatings in Joint Arthroplasty; Epinette, J.A., Manley, M.T., Eds.; Springer: Paris, France, 2004; pp. 3–8. [Google Scholar]

- Leeuwenhoek, A. Microscopical observations concerning blood, milk, bone, the brain, spittle, and cuticula, etc. Philos. Trans. 1674, 9, 121–128. [Google Scholar] [CrossRef]

- Leeuwenhoek, A. Part of a letter of Mr. Anthony van Leeuwenhoeck, dated Delst, Sept. 10. 1697. Concerning the eggs of snails, roots of vegetables, teeth, and young Oysters. Philos. Trans. 1695, 19, 790–799. [Google Scholar] [CrossRef]

- Roscoe, H.E.; Schorlemmer, C. A Treatise on Chemistry. Volume I: The Non-Metallic Elements; Macmillan and Co.: London, UK, 1881; p. 751. [Google Scholar]

- Aikin, A.; Aikin, C.R. A Dictionary of Chemistry and Mineralogy, Vol. II; Printed for John and Arthur Arch, Corninll; William Phillips, George Yard, Lombard Street: London, UK, 1807; p. 176. [Google Scholar]

- Nicholson, W. A Dictionary of Practical and Theoretical Chemistry, with Its Application to the Arts and Manufactures, and to the Explanation of the Phenomena of Nature; Printed for Richard Phillips: London, UK, 1808. [Google Scholar]

- Parr, B. The London Medical Dictionary, Vol. I; Wentworth Press: London, UK, 1809; p. 786. [Google Scholar]

- Davy, H. Conversations on Chemistry; Didnep’s Press: London, UK, 1814; p. 383. [Google Scholar]

- Muhlenberg, W.F. Address in hygiene. In Transactions of the Medical Society of the State of Pennsylvania, at Its Thirty-Third Annual Session; Times Printing House: Philadelphia, PA, USA, 1832; Volume 14, p. 90. [Google Scholar]

- Percy, J. Notice of a new hydrated phosphate of lime. Mem. Proc. Chem. Soc. 1843, 2, 222–223. [Google Scholar] [CrossRef]

- Dana, J.D. On the occurrence of fluor spar, apatite and chondtodite in limestone. Philos. Mag. Ser. 3 1846, 29, 245–246. [Google Scholar]

- Lassaigne, M. Solubility of carbonate of lime in water containing carbonic acid. Philos. Mag. Ser. 3 1847, 30, 297–298. [Google Scholar] [CrossRef]

- Jenkins, E.E. Phosphate of Lime. Master’s Thesis, Medical College of the State of South Carolina, Charleston, SC, USA, 1853. [Google Scholar]

- Kramer, B.; Shear, M.J. Composition of bone. IV. Primary calcification. J. Biol. Chem. 1928, 79, 147–160. [Google Scholar] [CrossRef]

- Von Walter, P. Wiedereinheilung der bei der trapanation ausgebohrten knochenscheibe. J. Chir. Augen Heilkd. 1821, 2, 571. [Google Scholar]

- Macewen, W. Observations concerning transplantation of bone. Illustrated by a case of inter-human osseous transplantation, whereby over two-thirds of the shaft of a humerus was restored. Proc. R. Soc. Lond. 1881, 32, 232–247. [Google Scholar] [CrossRef]

- Cravens, J.E. Lacto-phosphate of lime; pathology and treatment of exposed dental pulps and sensitive dentine. Dent. Cosmos. 1876, 18, 463–469. [Google Scholar]

- Wells, H.G. Pathological calcification. J. Med. Res. 1906, 14, 491–525. [Google Scholar] [PubMed]

- Albee, F.H.; Morrison, H.F. Studies in bone growth triple calcium phosphate as a stimulus to osteogenesis. Ann. Surg. 1920, 71, 32–39. [Google Scholar] [PubMed]

- Albee, F.H. Bone-Graft Surgery; W.B. Saunders Company: Philadelphia, PA, USA; London, UK, 1915. [Google Scholar]

- Mehmel, M. On the structure of apatite. Z. Kristallogr. 1930, 75, 323–331. [Google Scholar]

- Náray-Szabó, S. The structure of apatite (CaF)Ca4(PO4)3. Z. Kristallogr. 1930, 75, 387–398. [Google Scholar]

- Hendricks, S.B.; Hill, W.L.; Jacob, K.D.; Jefferson, M.E. Structural characteristics of apatite-like substances and composition of rock and bone as determined from microscopical and X-ray diffraction analysis. Ind. Eng. Chem. 1931, 23, 1413–1418. [Google Scholar] [CrossRef]

- Möller, H.; Trömel, G. Röntgenographische untersuchung über den aufbau der anorganischen zahnsubstanz. Naturwissenschaften 1933, 21, 346–348. [Google Scholar] [CrossRef]

- Möller, H.; Trömel, G. Über die kristallorientierung im zahnschmelz. Naturwissenschaften 1936, 24, 377–378. [Google Scholar] [CrossRef]

- Bale, W.F.; Hodge, H.C.; Warren, S.L. Roentgen-ray diffraction studies of enamel and dentin. Am. J. Roentgenol. Radiat. Ther. 1934, 32, 369–376. [Google Scholar]

- Bredig, M.A.; Franck, H.H.; Fülnder, H. Beiträge zur kenntnis der kalk-phosphorsäure-verbindungen. Z. Elktrochem. 1932, 38, 158–164. [Google Scholar]

- Trömel, G. Beiträge zur kenntnis des systems kalziumoxyd-phosphorpentoxyd. Mitt. Kaiser-Wilhelm-Inst. Eisenforsch. Düsseldorf 1932, 14, 25–34. [Google Scholar]

- Albrektsson, T.; Johansson, C. Osteoinduction, osteoconduction and osseointegration. Eur. Spine J. 2001, 10 (Suppl. 2), S96–S101. [Google Scholar] [PubMed]

- Huggins, C.B. The formation of bone under the influence of epithelium of the urinary tract. Arch. Surg. 1931, 22, 377–408. [Google Scholar] [CrossRef]

- Elmore, K.L.; Farr, T.D. Equilibrium in the system calcium oxide-phosphorous pentoxide-water. Ind. Eng. Chem. 1940, 32, 580–586. [Google Scholar] [CrossRef]

- Schram, W.R.; Fosdick, L.S. Stimulation of healing in long bones by use of artificial material. J. Oral Surg. 1948, 6, 209–217. [Google Scholar] [PubMed]

- Arnold, P.W. The nature of precipitated calcium phosphates. Trans. Faraday Soc. 1950, 46, 1061–1072. [Google Scholar] [CrossRef]

- Kingery, W.D., II. Cold-setting properties. J. Am. Ceram. Soc. 1950, 33, 242–246. [Google Scholar] [CrossRef]

- Köster, K.; Karbe, E.; Kramer, H.; Heide, H.; König, R. Experimental bone replacement with resorbable calcium phosphate ceramic. Langenbecks Arch. Chir. 1976, 341, 77–86. [Google Scholar] [CrossRef] [PubMed]

- Brånemark, P.I. Osseointegration and its experimental background. J. Prosthet. Dent. 1983, 50, 399–410. [Google Scholar] [CrossRef]

- Kay, M.I.; Young, R.A.; Posner, A.S. Crystal structure of hydroxyapatite. Nature 1964, 204, 1050–1052. [Google Scholar] [CrossRef] [PubMed]

- Posner, A.S.; Betts, F. Synthetic amorphous calcium phosphate and its relation to bone mineral structure. Acc. Chem. Res. 1975, 8, 273–281. [Google Scholar] [CrossRef]

- Boskey, A.L. Amorphous calcium phosphate: The contention of bone. J. Dent. Res. 1997, 76, 1433–1436. [Google Scholar] [CrossRef] [PubMed]

- Levitt, S.R.; Crayton, P.H.; Monroe, E.A.; Condrate, R.A. Forming methods for apatite prosthesis. J. Biomed. Mater. Res. 1969, 3, 683–684. [Google Scholar] [CrossRef] [PubMed]

- Bhaskar, S.N.; Brady, J.M.; Getter, L.; Grower, M.F.; Driskell, T. Biodegradable ceramic implants in bone. Electron and light microscopic analysis. Oral Surg. Oral Med. Oral Pathol. 1971, 32, 336–346. [Google Scholar] [CrossRef]

- Driskell, T.D.; Hassler, C.R.; Tennery, V.J.; McCoy, L.R.; Clarke, W.J. Calcium phosphate resorbable ceramics: A potential alternative to bone grafting. J. Dent. Res. 1973, 52, 123. [Google Scholar]

- Nery, E.B.; Lynch, K.L.; Hirthe, W.M.; Mueller, K.H. Bioceramic implants in surgically produced infrabony defects. J. Periodontol. 1975, 46, 328–347. [Google Scholar] [CrossRef] [PubMed]

- Roberts, S.C.; Brilliant, J.D. Tricalcium phosphate as an adjunct to apical closure in pulpless permanent teeth. J. Endod. 1975, 1, 263–269. [Google Scholar] [CrossRef]

- Denissen, H.W.; de Groot, K. Immediate dental root implants from synthetic dense calcium hydroxylapatite. J. Prosthet. Dent. 1979, 42, 551–556. [Google Scholar] [CrossRef]

- León, B.; Jansen, J.A. (Eds.) Thin Calcium Phosphate Coatings for Medical Implants; Springer: New York, NY, USA, 2009. [Google Scholar]

- Sudo, S.Z.; Schotzko, N.K.; Folke, L.E.A. Use of hydroxyapatite coated glass beads for preclinical testing of potential antiplaque agents. Appl. Environ. Microbiol. 1976, 32, 428–437. [Google Scholar] [PubMed]

- Bonfield, W.; Grynpas, M.D.; Tully, A.E.; Bowman, J.; Abram, J. Hydroxyapatite reinforced polyethylene—A mechanically compatible implant material for bone replacement. Biomaterials 1981, 2, 185–186. [Google Scholar] [CrossRef]

- Jarcho, M. Calcium phosphate ceramics as hard tissue prosthetics. Clin. Orthop. Relat. Res. 1981, 157, 259–278. [Google Scholar] [CrossRef]

- De Groot, K. (Ed.) Bioceramics of Calcium Phosphate; CRC Press: Boca Raton, FL, USA, 1983. [Google Scholar]

- Aoki, H.; Kato, K.M.; Ogiso, M.; Tabata, T. Studies on the application of apatite to dental materials. J. Dent. Eng. 1977, 18, 86–89. [Google Scholar]

- Furlong, R.J.; Osborn, J.F. Fixation of hip prostheses by hydroxyapatite ceramic coatings. J. Bone Jt. Surg. Br. 1991, 73, 741–745. [Google Scholar]

- Randzio, J.; Thoma, K.; Alex, R.; Rhomberg, B. Healing and pharmacokinetics of a beta-tricalcium phosphate-gentamycin combination in animal studies (preliminary report). Dtsch. Zahnarztl. Z. 1985, 40, 668–671. [Google Scholar] [PubMed]

- Dorozhkin, S.V. Nanodimensional and nanocrystalline calcium orthophosphates. Am. J. Biomed. Eng. 2012, 2, 48–97. [Google Scholar] [CrossRef]

- Layrolle, P.; Lebugle, A. Characterization and reactivity of nanosized calcium phosphates prepared in anhydrous ethanol. Chem. Mater. 1994, 6, 1996–2004. [Google Scholar] [CrossRef]

- Li, Y.B.; de Wijn, J.; Klein, C.P.A.T.; de Meer, S.V.; de Groot, K. Preparation and characterization of nanograde osteoapatite-like rod crystals. J. Mater. Sci. Mater. Med. 1994, 5, 252–255. [Google Scholar]

- Shirkhanzadeh, M. X-ray diffraction and Fourier transform infrared analysis of nanophase apatite coatings prepared by electrocrystallization. Nanostruct. Mater. 1994, 4, 677–684. [Google Scholar] [CrossRef]

- Norman, M.E.; Elgendy, H.M.; Shors, E.C.; El-Amin, S.F.; Laurencin, C.T. An in-vitro evaluation of coralline porous hydroxyapatite as a scaffold for osteoblast growth. Clin. Mater. 1994, 17, 85–91. [Google Scholar] [CrossRef]

- Dekker, R.J.; de Bruijn, J.D.; van den Brink, I.; Bovell, Y.P.; Layrolle, P.; van Blitterswijk, C.A. Bone tissue engineering on calcium phosphate-coated titanium plates utilizing cultured rat bone marrow cells: A preliminary study. J. Mater. Sci. Mater. Med. 1998, 9, 859–863. [Google Scholar] [CrossRef] [PubMed]

- Friedman, C.D.; Costantino, P.D.; Takagi, S.; Chow, L.C. BoneSource hydroxyapatite cement: A novel biomaterial for craniofacial skeletal tissue engineering and reconstruction. J. Biomed. Mater. Res. 1998, 43, 428–432. [Google Scholar] [CrossRef]

- LeGeros, R.Z. Calcium phosphates in oral biology and medicine. Monogr. Oral Sci. 1991, 15, 1–201. [Google Scholar] [PubMed]

- Aoki, H. Science and Medical Applications of Hydroxyapatite; JAAS: Tokyo, Japan, 1991. [Google Scholar]

- Elliott, J.C. Structure and Chemistry of the Apatites and Other Calcium Orthophosphates; Elsevier: Amsterdam, The Netherlands, 1994. [Google Scholar]

- Brown, P.W.; Constantz, B. (Eds.) Hydroxyapatite and Related Materials; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar]

- Horowitz, E.; Parr, J.E. Characterization and Performance of Calcium Phosphate Coatings for Implants; ASTM STP 1196; American Society for Testing and Materials (ASTM): Philadelphia, PA, USA, 1994. [Google Scholar]

- Epinette, J.A.; Manley, M.T. (Eds.) Fifteen Years of Clinical Experience with Hydroxyapatite Coatings in Joint Arthroplasty; Springer: Paris, France, 2004. [Google Scholar]

- Dorozhkin, S.V. Calcium Orthophosphates: Applications in Nature, Biology, and Medicine; Pan Stanford Publishing Pte.: Singapore, 2012. [Google Scholar]

- Heimann, R.B. (Ed.) Calcium Phosphate: Structure, Synthesis, Properties, and Applications; Nova Science Publishers: Hauppauge, NY, USA, 2014. [Google Scholar]

- Ben-Nissan, B. Advances in Calcium Phosphate Biomaterials; Springer: Berlin, Germany, 2014. [Google Scholar]

- Dey, A.; Mukhopadhyay, A.K. Microplasma Sprayed Hydroxyapatite Coatings; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Weiner, S.; Wagner, H.D. The material bone: Structure-mechanical function relations. Ann. Rev. Mater. Sci. 1998, 28, 271–298. [Google Scholar] [CrossRef]

- Rho, J.Y.; Kuhn-Spearing, L.; Zioupos, P. Mechanical properties and the hierarchical structure of bone. Med. Eng. Phys. 1998, 20, 92–102. [Google Scholar] [CrossRef]

- Currey, J.D. Bones: Structure and Mechanics; Princeton University Press: Princeton, NJ, USA, 2002. [Google Scholar]

- Dorozhkin, S.V.; Epple, M. Biological and medical significance of calcium phosphates. Angew. Chem. Int. Ed. 2002, 41, 3130–3146. [Google Scholar] [CrossRef]

- Fratzl, P.; Gupta, H.S.; Paschalis, E.P.; Roschger, P. Structure and mechanical quality of the collagen-mineral nano-composite in bone. J. Mater. Chem. 2004, 14, 2115–2123. [Google Scholar] [CrossRef]

- Weiner, S. Transient precursor strategy in mineral formation of bone. Bone 2006, 39, 431–433. [Google Scholar] [CrossRef] [PubMed]

- Grynpas, M.D.; Omelon, S. Transient precursor strategy or very small biological apatite crystals? Bone 2007, 41, 162–164. [Google Scholar] [CrossRef] [PubMed]

- Fratzl, P.; Weinkamer, R. Nature’s hierarchical materials. Prog. Mater. Sci. 2007, 52, 1263–1334. [Google Scholar] [CrossRef]

- Olszta, M.J.; Cheng, X.; Jee, S.S.; Kumar, R.; Kim, Y.Y.; Kaufman, M.J.; Douglas, E.P.; Gower, L.B. Bone structure and formation: A new perspective. Mater. Sci. Eng. R 2007, 58, 77–116. [Google Scholar] [CrossRef]

- Dorozhkin, S.V. A hierarchical structure for apatite crystals. J. Mater. Sci. Mater. Med. 2007, 18, 363–366. [Google Scholar] [CrossRef] [PubMed]

- Rey, C.; Combes, C.; Drouet, C.; Glimcher, M.J. Bone mineral—Update on chemical composition and structure. Osteoporos. Int. 2009, 20, 1013–1021. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Zhang, Y.W.; Gao, H. On optimal hierarchy of load-bearing biological materials. Proc. R. Soc. B 2011, 278, 519–525. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Liu, Y.; Sun, W.; Yang, X. First detection, characterization, and application of amorphous calcium phosphate in dentistry. J. Dent. Sci. 2012, 7, 316–323. [Google Scholar] [CrossRef]

- Liu, Q.; Huang, S.; Matinlinna, J.P.; Chen, Z.; Pan, H. Insight into biological apatite: Physiochemical properties and preparation approaches. BioMed Res. Int. 2013, 2013, 929748. [Google Scholar] [CrossRef] [PubMed]

- Wegst, U.G.K.; Bai, H.; Saiz, E.; Tomsia, A.P.; Ritchie, R.O. Bioinspired structural materials. Nat. Mater. 2015, 14, 23–36. [Google Scholar] [CrossRef] [PubMed]

- Wolff, J. The Law of Bone Remodeling; Springer: Berlin, Germany, 1986. [Google Scholar]

- Frost, H.M. Wolff’s Law and bone’s structural adaptations to mechanical usage: An overview for clinicians. Angle Orthod. 1994, 64, 175–188. [Google Scholar] [PubMed]

- Tortora, G.J.; Derrickson, B. Principles of Anatomy and Physiology, 11th ed.; John Wiley & Sons: Hoboken, NJ, USA, 1993; p. 173. [Google Scholar]

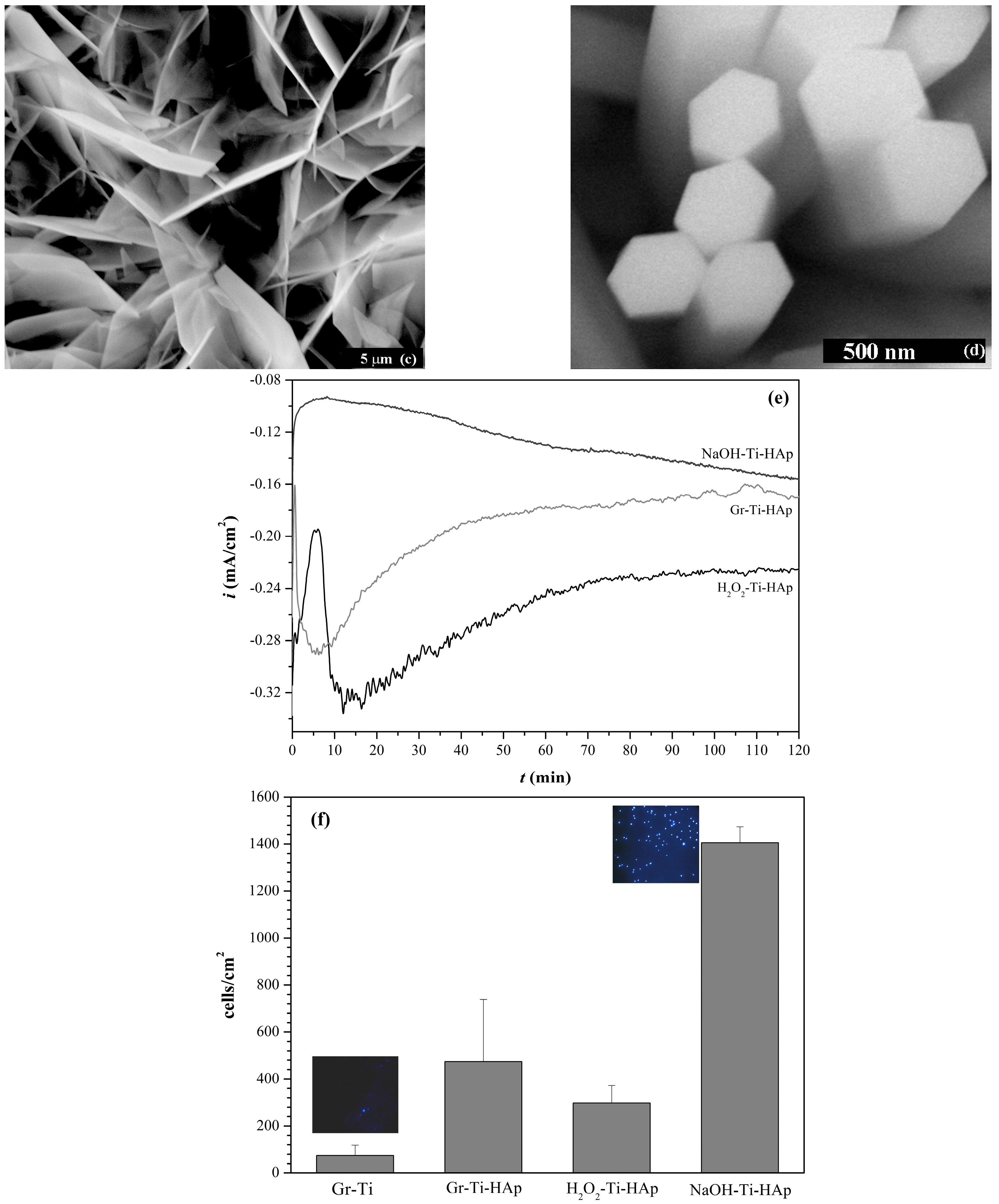

- Lakstein, D.; Kopelovitch, W.; Barkay, Z.; Bahaa, M.; Hendel, D.; Eliaz, N. Enhanced osseointegration of grit-blasted, NaOH-treated and electrochemically hydroxyapatite-coated Ti–6Al–4V implants in rabbits. Acta Biomater. 2009, 5, 2258–2269. [Google Scholar] [CrossRef] [PubMed]

- Hassenkam, T.; Fantner, G.E.; Cutroni, J.A.; Weaver, J.C.; Morse, D.E.; Hansma, P.K. High-resolution AFM imaging of intact and fractured trabecular bone. Bone 2004, 35, 4–10. [Google Scholar] [CrossRef] [PubMed]

- Ke, P.; Jiao, X.N.; Ge, X.H.; Xiao, W.M.; Yu, B. From macro to micro: Structural biomimetic materials by electrospinning. RSC Adv. 2014, 4, 39704–39724. [Google Scholar] [CrossRef]

- Koutsoukos, P.G.; Nancollas, G.H. Crystal growth of calcium phosphates—Epitaxial considerations. J. Cryst. Growth 1981, 53, 10–19. [Google Scholar] [CrossRef]

- Panda, R.N.; Hsieh, M.F.; Chung, R.J.; Chin, T.S. X-ray diffractometry and X-ray photoelectron spectroscopy investigations of nanocrytalline hydroxyapatite synthesized by a hydroxide gel technique: Structure and mechanical and thermal properties of condensed matter. Jpn. J. Appl. Phys. Part 1 2001, 40, 5030–5035. [Google Scholar] [CrossRef]

- Betts, F.; Blumenthal, N.C.; Posner, A.S. Bone mineralization. J. Cryst. Growth 1981, 53, 63–73. [Google Scholar] [CrossRef]

- Benezra, V.; Spector, M.; Hobbs, L.W. Characterization of mineral deposits on plasma-sprayed HA-coated Ti–6Al–4V. Mater. Res. Soc. 1995, 414, 165–170. [Google Scholar] [CrossRef]

- Danilchenko, S.N.; Kukharenko, O.G.; Moseke, C.; Protsenko, I.Y.; Sukhodub, L.F.; Sulkio-Cleff, B. Determination of the bone mineral crystallite size and lattice strain from diffraction line broadening. Cryst. Res. Technol. 2002, 37, 1234–1240. [Google Scholar] [CrossRef]

- Nyman, J.S.; Reyes, M.; Wang, X. Effect of ultrastructural changes on the toughness of bone. Micron 2005, 36, 566–582. [Google Scholar] [CrossRef] [PubMed]

- Kuhn-Spearing, L.; Rey, C.; Kim, H.M.; Glimcher, M.J. Carbonated apatite nanocrystals of bone. In Synthesis and Processing of Nanocrystalline Powder; The Minerals, Metals and Materials Society: Warrendale, PA, USA, 1996. [Google Scholar]

- Moreno, E.C.; Varughese, K. Crystal growth of calcium apatites from dilute solutions. J. Cryst. Growth 1981, 53, 20–30. [Google Scholar] [CrossRef]

- Barakat, N.A.M.; Khalil, K.A.; Sheikh, F.A.; Omran, A.N.; Gaihre, B.; Khil, S.M.; Kim, H.Y. Physiochemical characterizations of hydroxyapatite extracted from bovine bones by three different methods: Extraction of biologically desirable HAp. Mater. Sci. Eng. C 2008, 28, 1381–1387. [Google Scholar] [CrossRef]

- Arsenault, A.L. Crystal-collagen relationships in calcified turkey leg tendons visualized by selected-area dark field electron microscopy. Calcif. Tissue Int. 1988, 43, 202–212. [Google Scholar] [CrossRef] [PubMed]

- Danilchenko, S.N.; Koropov, A.V.; Protsenko, I.Y.; Sulkio-Cleff, B.; Sukhodub, L.F. Thermal behavior of biogenic apatite crystals in bone: An X-ray diffraction study. Cryst. Res. Technol. 2006, 41, 268–275. [Google Scholar] [CrossRef]

- Janus, A.M.; Faryna, M.; Haberko, K.; Rakowska, A.; Panz, T. Chemical and microstructural characterization of natural hydroxyapatite derived from pig bones. Microchim. Acta 2008, 161, 349–353. [Google Scholar] [CrossRef]

- Kim, H.M.; Rey, C.; Glimcher, M.J. Isolation of calcium phosphate crystals of bone by non-aqueous methods at low temperature. J. Bone Miner. Res. 1995, 10, 1589–1601. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.M.; Rey, C.; Glimcher, M.J. X-ray diffraction, electron microscopy, and Fourier transform infrared spectroscopy of apatite crystals isolated from chicken and bovine calcified cartilage. Calcif. Tissue Int. 1996, 59, 58–63. [Google Scholar] [CrossRef] [PubMed]

- Rubin, M.A.; Jasiuk, I.; Taylor, J.; Rubin, J.; Ganey, T.; Apkarian, R.P. TEM analysis of the nanostructure of normal and osteoporotic human trabecular bone. Bone 2003, 33, 270–282. [Google Scholar] [CrossRef]

- Palmer, L.C.; Newcomb, C.J.; Kaltz, S.R.; Spoerke, E.D.; Stupp, S.I. Biomimetic systems for hydroxyapatite mineralization inspired by bone and enamel. Chem. Rev. 2008, 108, 4754–4783. [Google Scholar] [CrossRef] [PubMed]

- Suvorova, E.I.; Buffat, P.A. Electron diffraction from micro- and nanoparticles of hydroxyapatite. J. Microsc. 1999, 196, 46–58. [Google Scholar] [CrossRef] [PubMed]

- Posner, A.S.; Perloff, A.; Diorio, A.F. Refinement of the hydroxyapatite structure. Acta Cryst. 1958, 11, 308–309. [Google Scholar] [CrossRef]

- Elliott, J.C.; Mackie, P.E.; Young, R.A. Monoclinic hydroxyapatite. Science 1973, 180, 1055–1057. [Google Scholar] [CrossRef] [PubMed]

- Ma, G.B.; Liu, X.Y. Hydroxyapatite: Hexagonal or monoclinic? Cryst. Growth Des. 2009, 9, 2991–2994. [Google Scholar] [CrossRef]

- De Leeuw, N.H. Local ordering of hydroxy groups in hydroxyapatite. Chem. Commun. 2001, 17, 1646–1647. [Google Scholar] [CrossRef]

- Vallet-Regi, M. Biomimetic Nanoceramics in Clinical Use: From Materials to Applications; Royal Society of Chemistry: Cambridge, UK, 2008. [Google Scholar]

- Bonar, L.C.; Lees, S.; Mook, H.A. Neutron diffraction studies of collagen in fully mineralized bone. J. Mol. Biol. 1985, 181, 265–270. [Google Scholar] [CrossRef]

- Kuhn, L.T.; Grynpas, M.D.; Rey, C.C.; Wu, Y.; Ackerman, J.L.; Glimcher, M.J. A comparison of the physical and chemical differences between cancellous and cortical bovine bone mineral at two ages. Calcif. Tissue Int. 2008, 83, 146–154. [Google Scholar] [CrossRef] [PubMed]

- Joschek, S.; Nies, B.; Krotz, R.; Göpferich, A. Chemical and physicochemical characterization of porous hydroxyapatite ceramics made of natural bone. Biomaterials 2000, 21, 1645–1658. [Google Scholar] [CrossRef]

- Pasteris, J.D.; Wopenka, B.; Freeman, J.J.; Rogers, K.; Valsami-Jones, E.; van der Houwen, J.A.M.; Silva, M.J. Lack of OH in nanocrystalline apatite as a function of degree of atomic order: Implications for bone and biomaterials. Biomaterials 2004, 25, 229–238. [Google Scholar] [CrossRef]

- Murugan, R.; Ramakrishna, S. Development of nanocomposites for bone grafting. Compos. Sci. Technol. 2005, 65, 2385–2406. [Google Scholar] [CrossRef]

- Gordon, L.M.; Tran, L.; Joester, D. Atom probe tomography of apatites and bone-type mineralized tissues. ACS Nano 2012, 6, 10667–10675. [Google Scholar] [CrossRef] [PubMed]

- Florencio-Silva, R.; da Silva Sasso, G.R.; Sasso-Cerri, E.; Simões, M.J.; Cerri, P.S. Biology of bone tissue: Structure, function, and factors that influence bone cells. Biomed. Res. Int. 2015, 2015, 421746. [Google Scholar] [CrossRef] [PubMed]

- Ashby, M.F.; Gibson, L.J.; Wegst, U.; Olive, R. The mechanical properties of natural materials, I: Material property charts. Proc. R. Soc. Lond. Ser. A 1995, 450, 123–140. [Google Scholar] [CrossRef]

- Wegst, U.G.K.; Ashby, M.F. The mechanical efficiency of natural materials. Philos. Mag. 2004, 84, 2167–2186. [Google Scholar] [CrossRef]

- Knowles, T.P.J.; Buehler, M.J. Nanomechanics of functional and pathological amyloid materials. Nat. Nanotechnol. 2011, 6, 469–479. [Google Scholar] [CrossRef] [PubMed]

- Bonfield, W.; Wang, M.; Tanner, K.E. Interfaces in analogue biomaterials. Acta Mater. 1998, 46, 2509–2518. [Google Scholar] [CrossRef]

- Yamada, H. Strength of Biological Materials; Williams & Wilkins: Baltimore, MD, USA, 1970. [Google Scholar]

- Beniash, E.; Aizenberg, J.; Addadi, L.; Weiner, S. Amorphous calcium carbonate transforms into calcite during sea-urchin larval spicule growth. Proc. R. Soc. Lond. Ser. B 1997, 264, 461–465. [Google Scholar] [CrossRef]

- Beniash, E.; Metzler, R.A.; Lam, R.S.; Gilbert, P.U. Transient amorphous calcium phosphate in forming enamel. J. Struct. Biol. 2009, 166, 133–143. [Google Scholar] [CrossRef] [PubMed]

- Towe, K.M.; Lowenstam, H.A. Ultrastructure and development of iron mineralization in the radular teeth of Cryptochiton stelleri (Mollusca). J. Ultrastruct. Res. 1967, 17, 1–13. [Google Scholar] [CrossRef]

- Politi, Y.; Arad, T.; Klein, E.; Weiner, S.; Addadi, L. Sea urchin spine calcite forms via a transient amorphous calcium carbonate phase. Science 2004, 306, 1161–1164. [Google Scholar] [CrossRef] [PubMed]

- Mahamid, J.; Sharir, A.; Addadi, L.; Weiner, S. Amorphous calcium phosphate is a major component of the forming fin bones of zebrafish: Indications for an amorphous precursor phase. Proc. Natl. Acad. Sci. USA 2008, 105, 12748–12753. [Google Scholar] [CrossRef] [PubMed]

- Mahamid, J.; Aichmayer, B.; Shimoni, E.; Ziblat, R.; Li, C.; Siegel, S.; Paris, O.; Fratzl, P.; Weiner, S.; Addadi, L. Mapping amorphous calcium phosphate transformation into crystalline mineral from the cell to the bone in zebrafish fin rays. Proc. Natl. Acad. Sci. USA 2010, 107, 6316–6321. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Nancollas, G.H. Dynamics of biomineralization and biodemineralization. Met. Ions Life Sci. 2010, 4, 413–456. [Google Scholar] [PubMed]

- Glimcher, M.J. Recent studies of the mineral phase in bone and its possible linkage to the organic matrix by protein-bound phosphate bonds. Philos. Trans. R. Soc. Lond. Ser. B 1984, 304, 479–508. [Google Scholar] [CrossRef]

- Harper, R.; Posner, A. Measurement of non-crystalline calcium phosphate in bone mineral. Exp. Biol. Med. 1966, 122, 137–142. [Google Scholar] [CrossRef]

- Termine, J.D.; Posner, A.S. Infra-red determination of percentage of crystallinity in apatitic calcium phosphates. Nature 1966, 211, 268–270. [Google Scholar] [CrossRef] [PubMed]

- Termine, J.D.; Posner, A.S. Infrared analysis of rat bone: Age dependency of amorphous and crystalline mineral fractions. Science 1966, 153, 1523–1525. [Google Scholar] [CrossRef] [PubMed]

- Termine, J.D.; Posner, A.S. Amorphous/crystalline interrelationships in bone mineral. Calcif. Tissue Res. 1967, 1, 8–23. [Google Scholar] [CrossRef] [PubMed]

- Posner, A.S.; Blumenthal, N.C.; Boskey, A.L.; Betts, F. Synthetic analogue of bone-mineral formation. J. Dent. Res. 1975, 54, B88–B93. [Google Scholar] [CrossRef] [PubMed]

- Nelson, D.G.; Featherstone, J.D.; Duncan, J.F.; Cutress, T.W. Paracrystalline disorder of biological and synthetic carbonate-substituted apatites. J. Dent. Res. 1982, 61, 1274–1281. [Google Scholar] [CrossRef] [PubMed]

- Brecevic, L.J.; Furedi-Milhofer, H. Precipitation of calcium phosphates from electrolyte solutions. II. The formation and transformation of precipitates. Calcif. Tissue Res. 1972, 10, 82–90. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Nancollas, G.H. Pathways to biomineralization and biodemineralization of calcium phosphates: The thermodynamic and kinetic controls. Dalton Trans. 2009, 21, 2665–2672. [Google Scholar] [CrossRef] [PubMed]

- Feenstra, T.P.; de Bruyn, P.L. Formation of calcium phosphates in moderately supersaturated solutions. J. Phys. Chem. 1979, 83, 475–479. [Google Scholar] [CrossRef]

- Eanes, E.D. Amorphous calcium phosphate: Thermodynamic and kinetic considerations. In Calcium Phosphates in Biological and Industrial Systems; Dordrecht, A.Z., Ed.; Kluwer Academic: Dordrecht, The Netherlands, 1998. [Google Scholar]

- Tadic, D.; Peters, F.; Epple, M. Continuous synthesis of amorphous carbonated apatites. Biomaterials 2002, 23, 2553–2559. [Google Scholar] [CrossRef]

- Nagano, M.; Nakamura, T.; Kokubo, T.; Tanahashi, M.; Ogawa, M. Differences of bone bonding ability and degradation behaviour in vivo between amorphous calcium phosphate and highly crystalline hydroxyapatite coating. Biomaterials 1996, 17, 1771–1777. [Google Scholar] [CrossRef]

- Christoffersen, J.; Christoffersen, M.R.; Kibalczyc, W.; Andersen, F.A. A contribution to the understanding of the formation of calcium phosphates. J. Cryst. Growth 1989, 94, 767–777. [Google Scholar] [CrossRef]

- Feenstra, T.P.; de Bruyn, P.L. The Ostwald rule of stages in precipitation from highly supersaturated solutions: A model and its application to the formation of the nonstoichiometric amorphous calcium phosphate precursor phase. J. Colloid Interface Sci. 1981, 84, 66–72. [Google Scholar] [CrossRef]

- Tung, M.S.; Brown, W.E. An intermediate state in hydrolysis of amorphous calcium phosphate. Calcif. Tissue Int. 1983, 3, 783–790. [Google Scholar] [CrossRef]

- Watson, M.L.; Robinson, R.A. Collagen-crystal relationships in bone. II. Electron microscope study of basic calcium phosphate crystals. Am. J. Anat. 1953, 93, 25–59. [Google Scholar] [CrossRef] [PubMed]

- Eanes, E.D.; Termine, J.D.; Nylen, M.U. An electron microscopic study of the formation of amorphous calcium phosphate and its transformation to crystalline apatite. Calcif. Tissue Res. 1973, 12, 143–158. [Google Scholar] [CrossRef] [PubMed]

- Zyman, Z.Z.; Rokhmistrov, D.V.; Glushko, V.I. Structural and compositional features of amorphous calcium phosphate at the early stage of precipitation. J. Mater. Sci. Mater. Med. 2010, 21, 123–130. [Google Scholar] [CrossRef] [PubMed]

- Dorozhkin, S.V. Amorphous calcium (ortho)phosphates. Acta Biomater. 2010, 6, 4457–4475. [Google Scholar] [CrossRef] [PubMed]

- Boskey, A.L.; Posner, A.S. Conversion of amorphous calcium phosphate to microcrystalline hydroxyapatite. A pH-dependent, solution-mediated, solid-solid conversion. J. Phys. Chem. 1973, 77, 2313–2317. [Google Scholar] [CrossRef]

- Bar-Yosef, O.P.; Govrin-Lippman, R.; Garti, N.; Furedi-Milhofer, H. The influence of polyelectrolytes on the formation and phase transformation of amorphous calcium phosphate. Cryst. Growth Des. 2004, 4, 177–183. [Google Scholar] [CrossRef]

- Tao, J.; Pan, H.; Zeng, Y.; Xu, R.; Tang, R. Roles of amorphous calcium phosphate and biological additives in the assembly of hydroxyapatite nanoparticles. J. Phys. Chem. B 2007, 111, 13410–13418. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Liu, Y.; Sun, W.; Zhang, H. Amorphous calcium phosphate and its application in dentistry. Chem. Cent. J. 2011, 5, 40. [Google Scholar] [CrossRef] [PubMed]

- Addadi, L.; Vidavsky, N.; Weiner, S. Transient precursor amorphous phases in biomineralization. In the footsteps of Heinz A. Lowenstam. Z. Kristallogr. 2012, 227, 711–717. [Google Scholar] [CrossRef]

- He, G.; Dahl, T.; Veis, A.; George, A. Nucleation of apatite crystals in vitro by self-assembled dentin matrix protein 1. Nat. Mater. 2003, 2, 552–558. [Google Scholar] [CrossRef] [PubMed]

- Tsuji, T.; Onuma, K.; Yamamoto, A.; Iijima, M.; Shiba, K. Direct transformation from amorphous to crystalline calcium phosphate facilitated by motif programmed artificial proteins. Proc. Natl. Acad. Sci. USA 2008, 105, 16866–16870. [Google Scholar] [CrossRef] [PubMed]

- Combes, C.; Rey, C. Amorphous calcium phosphates: Synthesis, properties and uses in biomaterials. Acta Biomater. 2010, 6, 3362–3378. [Google Scholar] [CrossRef] [PubMed]

- Pan, H.H.; Liu, X.Y.; Tang, R.K.; Xu, H.Y. Mystery of the transformation from amorphous calcium phosphate to hydroxyapatite. Chem. Commun. 2010, 46, 7415–7420. [Google Scholar] [CrossRef] [PubMed]

- Eanes, E.D.; Meyer, J.L. The maturation of crystalline calcium phosphates in aqueous suspensions at physiologic pH. Calcif. Tissue Res. 1977, 23, 259–269. [Google Scholar] [CrossRef] [PubMed]

- Amjad, Z. Influence of polyelectrolytes on the precipitation of amorphous calcium phosphate. Colloids Surf. 1990, 48, 95–106. [Google Scholar] [CrossRef]

- Wuthier, R.E.; Eanes, E.D. Effect of phospholipids on the transformation of amorphous calcium phosphate to hydroxyapatite in vitro. Calcif. Tissue Int. 1975, 19, 197–210. [Google Scholar] [CrossRef]

- Termine, J.D.; Eanes, E.D.; Conn, K.M. Phosphoprotein modulation of apatite crystallization. Calcif. Tissue Int. 1980, 31, 247–251. [Google Scholar] [CrossRef] [PubMed]

- Qiu, S.M.; Wen, G.; Hirakawa, N.; Soloway, R.D.; Hong, N.K.; Crowther, R.S. Glycochenodeoxycholic acid inhibits calcium phosphate precipitation in vitro by preventing the transformation of amorphous calcium phosphate to calcium hydroxyapatite. J. Clin. Investig. 1991, 88, 1265–1271. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Ryu, H.S.; Shin, H.; Jung, H.S.; Hong, K.S. In situ observation of hydroxyapatite nanocrystal formation from amorphous calcium phosphate in calcium-rich solutions. Mater. Chem. Phys. 2005, 91, 500–506. [Google Scholar] [CrossRef]

- Xin, R.; Leng, Y.; Wang, N. In situ TEM examinations of octacalcium phosphate to hydroxyapatite transformation. J. Cryst. Growth 2006, 289, 339–344. [Google Scholar] [CrossRef]

- Brown, W.E.; Smith, J.P.; Lehr, J.R.; Frazier, A.W. Octacalcium phosphate and hydroxyapatite: Crystallographic and chemical relations between octacalcium phosphate and hydroxyapatite. Nature 1962, 196, 1050–1055. [Google Scholar] [CrossRef]

- Mathew, M.; Takagi, S. Structures of biological minerals in dental research. J. Res. Natl. Inst. Stand. Technol. 2001, 106, 1035–1044. [Google Scholar] [CrossRef] [PubMed]

- Tohda, H.; Yamada, M.; Yamaguchi, Y.; Yanagisawa, T. High-resolution electron microscopical observations of initial enamel crystals. J. Electron Microsc. 1997, 46, 97–101. [Google Scholar] [CrossRef]

- Crane, N.J.; Popescu, V.; Morris, M.D.; Steenhuis, P.; Ignelzi, M.A. Raman spectroscopic evidence for octacalcium phosphate and other mineral species deposited during intramembranous mineralization. Bone 2006, 39, 434–442. [Google Scholar] [CrossRef] [PubMed]

- Brown, W.; Chow, L. Chemical properties of bone mineral. Ann. Rev. Mater. Sci. 1976, 6, 213–236. [Google Scholar] [CrossRef]

- Glimcher, M.J.; Bonar, L.C.; Grynpas, M.D.; Landis, W.J.; Roufosse, A.H. Recent studies of bone mineral: Is the amorphous calcium phosphate theory valid? J. Cryst. Growth 1981, 53, 100–119. [Google Scholar] [CrossRef]

- Suvorova, E.I.; Buffat, P.A. Electron diffraction and high resolution transmission electron microscopy in the characterization of calcium phosphate precipitation from aqueous solutions under biomineralization conditions. Eur. Cells Mater. 2001, 1, 27–42. [Google Scholar] [CrossRef]

- Johnsson, M.S.A.; Nancollas, G.H. The role of brushite and octacalcium phosphate in apatite formation. Crit. Rev. Oral Biol. Med. 1992, 3, 61–82. [Google Scholar] [CrossRef] [PubMed]

- Brown, W.E.; Eidelman, N.; Tomazic, B. Octacalcium phosphates as a precursor in biomineral formation. Adv. Dent. Res. 1987, 1, 306–313. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, O.; Kamakura, S.; Katagiri, T. Surface chemistry and biological responses to synthetic octacalcium phosphate. J. Biomed. Mater. Res. B 2006, 77, 201–212. [Google Scholar] [CrossRef] [PubMed]

- Muragalelli, M.J.; Narusawa, H.; Shimada, T.; Iijima, M.; Aoba, T. Effects of fluoride on precipitation and hydrolysis of octacalcium phosphate in an experimental-model simulating enamel mineralization during amelogenesis. Cells Mater. 1992, 2, 221–230. [Google Scholar]

- Eliaz, N. Electrocrystallization of calcium phosphates. Isr. J. Chem. 2008, 48, 159–168. [Google Scholar] [CrossRef]

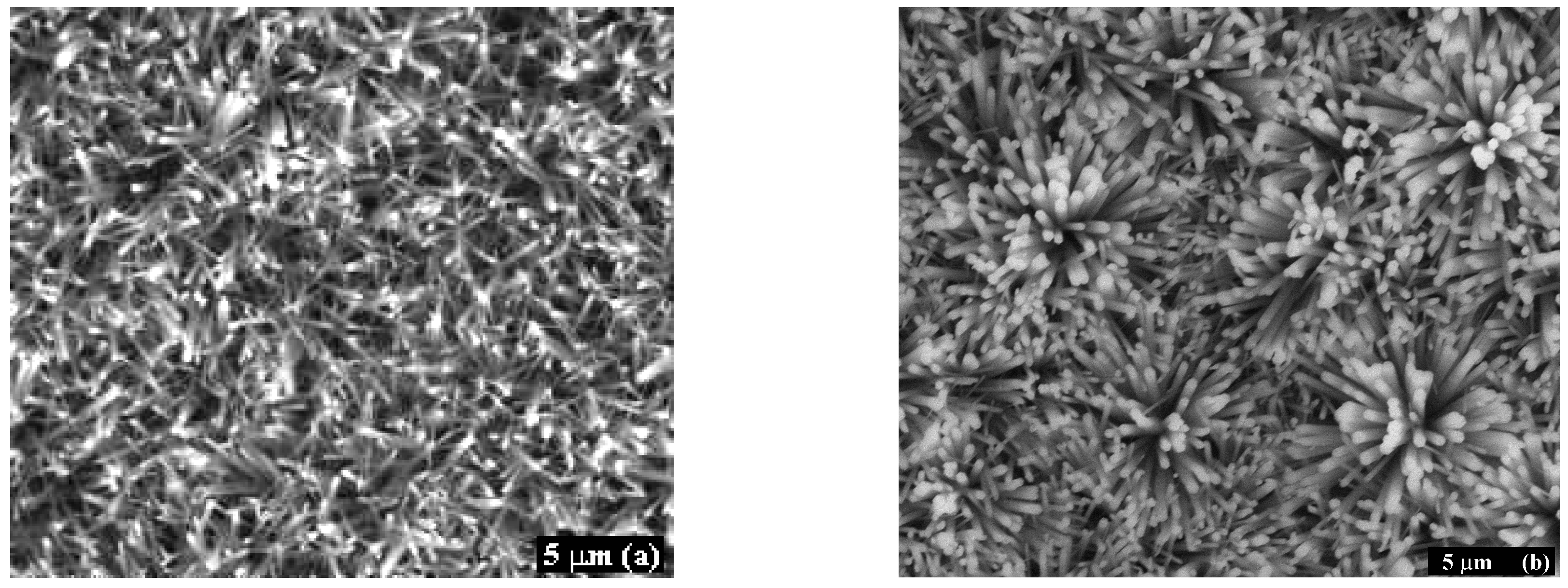

- Eliaz, N.; Sridhar, T.M. Electrocrystallization of hydroxyapatite and its dependence on solution conditions. Cryst. Growth Des. 2008, 8, 3965–3977. [Google Scholar] [CrossRef]

- Eliaz, N.; Kopelovitch, W.; Burstein, L.; Kobayashi, E.; Hanawa, T. Electrochemical processes of nucleation and growth of calcium phosphate on titanium supported by real-time quartz crystal microbalance measurements and X-ray photoelectron spectroscopy analysis. J. Biomed. Mater. Res. A 2009, 89, 270–280. [Google Scholar] [CrossRef] [PubMed]

- Chusuei, C.C.; Goodman, D.W.; Van Stipdonk, M.J.; Justes, D.R.; Schweikert, E.A. Calcium phosphate phase identification using XPS and time-of-flight cluster SIMS. Anal. Chem. 1999, 71, 149–153. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.B.; Campbell, C.T.; Graham, D.J.; Ratner, B.D. Surface characterization of hydroxyapatite and related calcium phosphates by XPS and TOF-SIMS. Anal. Chem. 2000, 72, 2886–2894. [Google Scholar] [CrossRef] [PubMed]

- Ostwald, W. The formation and changes of solids. Z. Phys. Chem. 1897, 22, 289–302. (In German) [Google Scholar]

- Wang, H.; Eliaz, N.; Xiang, Z.; Hsu, H.P.; Spector, M.; Hobbs, L.W. Early bone apposition in vivo on plasma-sprayed and electrochemically deposited hydroxyapatite coatings on titanium alloy. Biomaterials 2006, 27, 4192–4203. [Google Scholar] [CrossRef] [PubMed]

- Lin, D.-Y.; Wang, X.-X. Electrodeposition of hydroxyapatite coating on CoNiCrMo substrate in dilute solution. Surf. Coat. Technol. 2010, 204, 3205–3213. [Google Scholar] [CrossRef]

- Metoki, N.; Leifenberg-Kuznits, L.; Kopelovich, W.; Burstein, L.; Gozin, M.; Eliaz, N. Hydroxyapatite coatings electrodeposited at near-physiological conditions. Mater. Lett. 2014, 119, 24–27. [Google Scholar] [CrossRef]

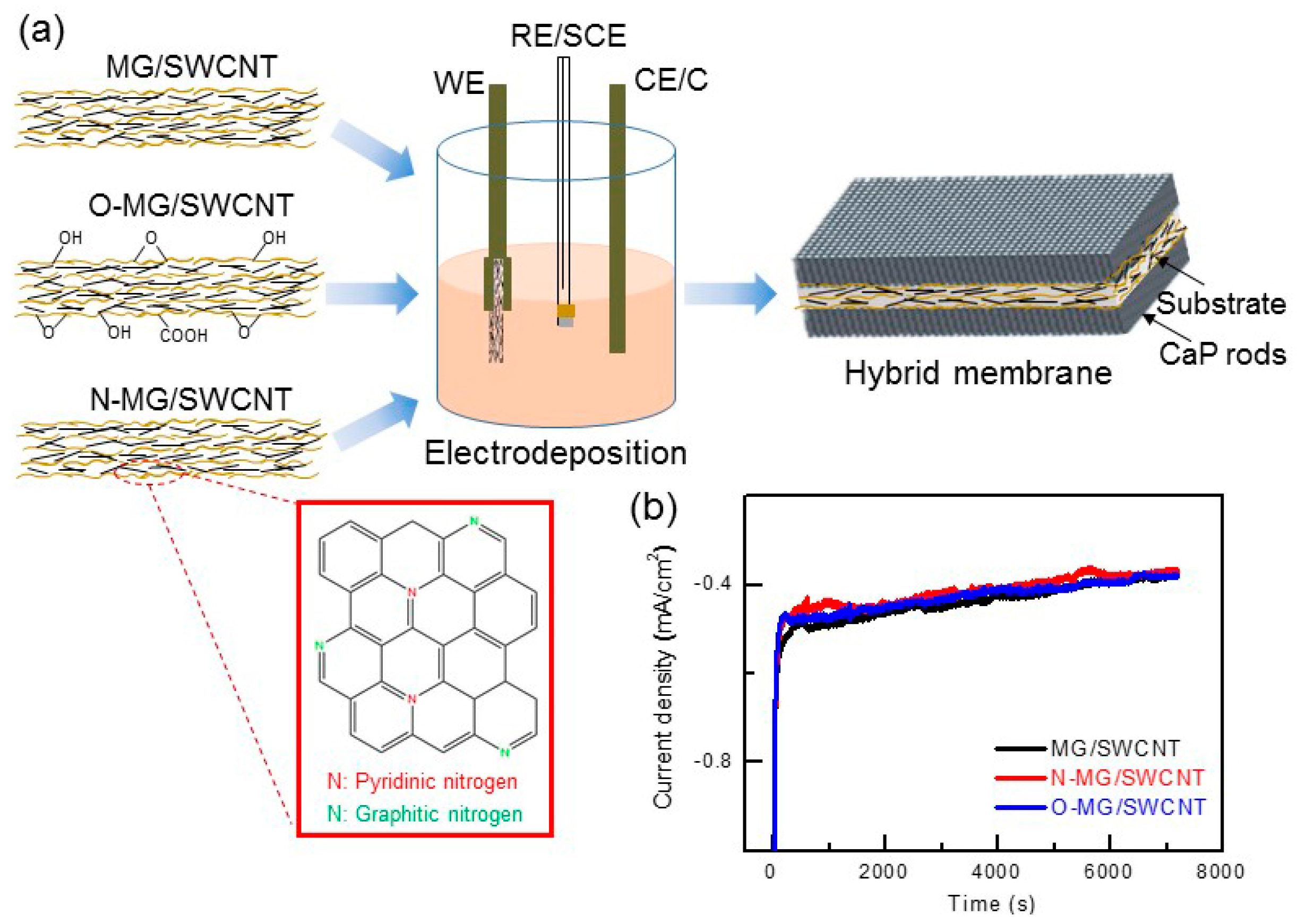

- Metoki, N.; Rosa, C.M.R.; Zanin, H.; Marciano, F.R.; Eliaz, N.; Lobo, A.O. Electrodeposition and biomineralization of nano-β-tricalcium phosphate on graphenated carbon nanotubes. Surf. Coat. Technol. 2016, 297, 51–57. [Google Scholar] [CrossRef]

- Metoki, N.; Sadman, K.; Shull, K.; Mandler, D.; Eliaz, N. Electro-assisted deposition of calcium phosphate on self-assembled monolayers. Electrochim. Acta 2016, 206, 400–408. [Google Scholar] [CrossRef]

- Van der Houwen, J.A.M.; Valsami-Jones, E. The application of calcium phosphate precipitation chemistry to phosphorus recovery: The influence of organic ligands. Environ. Technol. 2001, 22, 1325–1335. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Hahn, H.H.; Hoffmann, E. Effects of solution conditions on the precipitation of phosphate for recovery: A thermodynamic evaluation. Chemosphere 2002, 48, 1029–1034. [Google Scholar] [CrossRef]

- Plant, L.J.; House, W.A. Precipitation of calcite in the presence of inorganic phosphate. Colloids Surf. A Physicochem. Eng. Asp. 2002, 203, 143–153. [Google Scholar] [CrossRef]

- Song, Y.; Weidler, P.G.; Berg, U.; Nüesch, R.; Donnert, D. Calcite-seeded crystallization of calcium phosphate for phosphorus recovery. Chemosphere 2006, 63, 236–243. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Zhang, X.; Chen, Y.; Xie, Q.; Lan, J.; Qian, M.; He, N. A comparative study on the dissolution and solubility of hydroxylapatite and fluorapatite at 25 °C and 45 °C. Chem. Geol. 2009, 268, 89–96. [Google Scholar] [CrossRef]

- Mañas, A.; Pocquet, M.; Biscans, B.; Sperandio, M. Parameters influencing calcium phosphate precipitation in granular sludge sequencing batch reactor. Chem. Eng. Sci. 2012, 77, 165–175. [Google Scholar] [CrossRef]

- Song, Y.; Qian, F.; Gao, Y.; Xiang, L.; He, M. Thermodynamic assessment of effects of solution conditions on precipitation and recovery of phosphorus from wastewater. Environ. Eng. Sci. 2015, 32, 574–581. [Google Scholar] [CrossRef]

- LeGeros, R.Z. Biodegradation and bioresorption of calcium phosphate ceramics. Clin. Mater. 1993, 14, 65–88. [Google Scholar] [CrossRef]

- Habibovic, P.; Li, J.; van der Valk, C.M.; Meijer, G.; Layrolle, P.; van Blitterswijk, C.A.; de Groot, K. Biological performance of uncoated and octacalcium phosphate-coated Ti6Al4V. Biomaterials 2005, 26, 23–36. [Google Scholar] [CrossRef] [PubMed]

- Tfelt-Hansen, J.; Brown, E.M. The calcium-sensing receptor in normal physiology and pathophysiology: A review. Crit. Rev. Clin. Lab. Sci. 2005, 42, 35–70. [Google Scholar] [CrossRef] [PubMed]

- Hofer, A.M. Another dimension to calcium signaling: A look at extracellular calcium. J. Cell Sci. 2005, 118, 855–862. [Google Scholar] [CrossRef] [PubMed]

- Porter, A.E.; Hobbs, L.W.; Rosen, V.B.; Spector, M. The ultrastructure of the plasma-sprayed hydroxyapatite-bone interface predisposing to bone bonding. Biomaterials 2002, 23, 725–733. [Google Scholar] [CrossRef]

- Daculsi, G.; LeGeros, R.Z.; Heughebaert, M.; Barbieux, I. Formation of carbonate-apatite crystals after implantation of calcium-phosphate ceramics. Calcif. Tissue Int. 1990, 46, 20–27. [Google Scholar] [CrossRef] [PubMed]

- Daculsi, G.; LeGeros, R.Z.; Nery, E.; Lynch, K.; Kerebel, B. Transformation of biphasic calcium phosphate ceramics in vivo: Ultrastructural and physicochemical characterization. J. Biomed. Mater. Res. 1989, 23, 883–894. [Google Scholar] [CrossRef] [PubMed]

- Klein, C.; de Groot, K.; Chen, W.; Li, Y.; Zhang, X. Osseous substance formation induced in porous calcium phosphate ceramics in soft tissues. Biomaterials 1994, 15, 31–34. [Google Scholar] [CrossRef]

- Surmenev, R.A.; Surmeneva, M.A.; Ivanova, A.A. Significance of calcium phosphate coatings for the enhancement of new bone osteogenesis—A review. Acta Biomater. 2014, 10, 557–579. [Google Scholar] [CrossRef] [PubMed]

- Ripamonti, U. Osteoinduction in porous hydroxyapatite implanted in heterotopic sites of different animal models. Biomaterials 1996, 17, 31–35. [Google Scholar] [CrossRef]

- Yang, Z.; Yuan, H.; Tong, W.; Zou, P.; Chen, W.; Zhang, X. Osteogenesis in extraskeletally implanted porous calcium phosphate ceramics: Variability among different kinds of animals. Biomaterials 1996, 17, 2131–2137. [Google Scholar] [PubMed]

- Yuan, H.; Yang, Z.; Li, Y.; Zhang, X.; de Bruijn, J.D.; de Groot, K. Osteoinduction by calcium phosphate biomaterials. J. Mater. Sci. Mater. Med. 1998, 9, 723–726. [Google Scholar] [CrossRef] [PubMed]

- Yuan, H.; Yang, Z.; de Bruijn, J.D.; de Groot, K.; Zhang, X. Material-dependent bone induction by calcium phosphate ceramics: A 2.5-year study in dog. Biomaterials 2001, 22, 2617–2623. [Google Scholar] [CrossRef]

- Yuan, H.; van den Doel, M.; Li, S.; van Blitterswijk, C.A.; de Groot, K.; de Bruijn, J.D. A comparison of the osteoinductive potential of two calcium phosphate ceramics implanted intramuscularly in goats. J. Mater. Sci. Mater. Med. 2002, 13, 1271–1275. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; von Euw, S.; Fernandes, F.M.; Cassaignon, S.; Selmane, M.; Laurent, G.; Pehau-Arnaudet, G.; Coelho, C.; Bonhomme-Coury, L.; Giraud-Guille, M.M.; et al. Water-mediated structuring of bone apatite. Nat. Mater. 2013, 12, 1144–1153. [Google Scholar] [CrossRef] [PubMed]

- Dorozhkin, S.V. Dissolution mechanism of calcium apatites in acids: A review of literature. World J. Methodol. 2012, 2, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Ducheyne, P.; Qiu, Q. Bioactive ceramics: The effect of surface reactivity on bone formation and bone cell function. Biomaterials 1999, 20, 2287–2303. [Google Scholar] [CrossRef]

- Schwartz, Z.; Boyan, B.D. Underlying mechanisms at the bone-biomaterial interface. J. Cell. Biochem. 1994, 56, 340–347. [Google Scholar] [CrossRef] [PubMed]

- Puleo, D.A.; Nanci, A. Understanding and controlling the bone-implant interface. Biomaterials 1999, 20, 2311–2321. [Google Scholar] [CrossRef]

- Rahbek, O.; Overgaard, S.; Jensen, T.B.; Bendix, K.; Soballe, K. Sealing effect of hydroxyapatite coating: A 12-month study in canines. Acta Orthop. Scand. 2000, 71, 563–573. [Google Scholar] [CrossRef] [PubMed]

- Cunningham, B.W.; Hu, N.; Zorn, C.M.; McAfee, P.C. Bioactive titanium calcium phosphate coating for disc arthroplasty: Analysis of 58 vertebral end plates after 6- to 12-month implantation. Spine J. 2009, 9, 836–845. [Google Scholar] [CrossRef] [PubMed]

- Surmenev, R.A. A review of plasma-assisted methods for calcium phosphate-based coatings fabrication. Surf. Coat. Technol. 2012, 206, 2035–2056. [Google Scholar] [CrossRef]

- Xu, S.; Long, J.; Sim, L.; Diong, C.H.; Ostrikov, K. RF plasma sputtering deposition of hydroxyapatite bioceramics: Synthesis, performance, and biocompatibility. Plasma Process. Polym. 2005, 2, 373–390. [Google Scholar] [CrossRef]

- Tomsia, A.P.; Launey, M.E.; Lee, J.S.; Mankani, M.H.; Wegst, U.G.K.; Saiz, E. Nanotechnology approaches for better dental implants. Int. J. Oral Maxillofac. Implants 2011, 26, 25–49. [Google Scholar]

- Mouriño, V.; Boccaccini, A.R. Bone tissue engineering therapeutics: Controlled drug delivery in three-dimensional scaffolds. J. R. Soc. Interface 2010, 7, 209–227. [Google Scholar] [CrossRef] [PubMed]

- Ambard, A.J.; Mueninghoff, L. Calcium phosphate cement: Review of mechanical and biological properties. J. Prosthodont. 2006, 15, 321–328. [Google Scholar] [CrossRef] [PubMed]

- Black, J. Biological Performance of Materials: Fundamentals of Biocompatibility; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Samavedi, S.; Whittington, A.R.; Goldstein, A.S. Calcium phosphate ceramics in bone tissue engineering: A review of properties and their influence on cell behavior. Acta Biomater. 2013, 9, 8037–8045. [Google Scholar] [CrossRef] [PubMed]

- Dorozhkin, S.V. Calcium orthophosphates. J. Mater. Sci. 2007, 42, 1061–1095. [Google Scholar] [CrossRef]

- Jimbo, R.; Ivarsson, M.; Koskela, A.; Sul, Y.T.; Johansson, C.B. Protein adsorption to surface chemistry and crystal structure modification of titanium surfaces. J. Oral Maxillofac. Res. 2010, 1, e3. [Google Scholar] [CrossRef] [PubMed]

- Aronov, D.; Rosen, R.; Ron, E.Z.; Rosenman, G. Tunable hydroxyapatite wettability: Effect on adhesion of biological molecules. Proc. Biochem. 2006, 41, 2367–2372. [Google Scholar] [CrossRef]

- Zhao, G.; Schwartz, Z.; Wieland, M.; Rupp, F.; Geis-Gerstorfer, J.; Cochran, D.L.; Boyan, B.D. High surface energy enhances cell response to titanium substrate microstructure. J. Biomed. Mater. Res. A 2005, 74, 49–58. [Google Scholar] [CrossRef] [PubMed]

- Kilpadi, D.V.; Lemons, L.E. Surface energy characterization of unalloyed titanium implants. J. Biomed. Mater. Res. 1994, 28, 1419–1425. [Google Scholar] [CrossRef] [PubMed]

- Eriksson, C.; Nygren, H.; Ohlson, K. Implantation of hydrophilic and hydrophobic titanium discs in rat tibia: Cellular reactions on the surfaces during the first 3 weeks in bone. Biomaterials 2004, 25, 4759–4766. [Google Scholar] [CrossRef] [PubMed]

- Lim, J.Y.; Liu, X.M.; Vogler, E.A.; Donahue, H.J. Systematic variation in osteoblast adhesion and phenotype with substratum surface characteristics. J. Biomed. Mater. Res. A 2004, 68, 504–512. [Google Scholar] [CrossRef] [PubMed]

- Anselme, K. Osteoblast adhesion on biomaterials. Biomaterials 2000, 21, 667–681. [Google Scholar] [CrossRef]

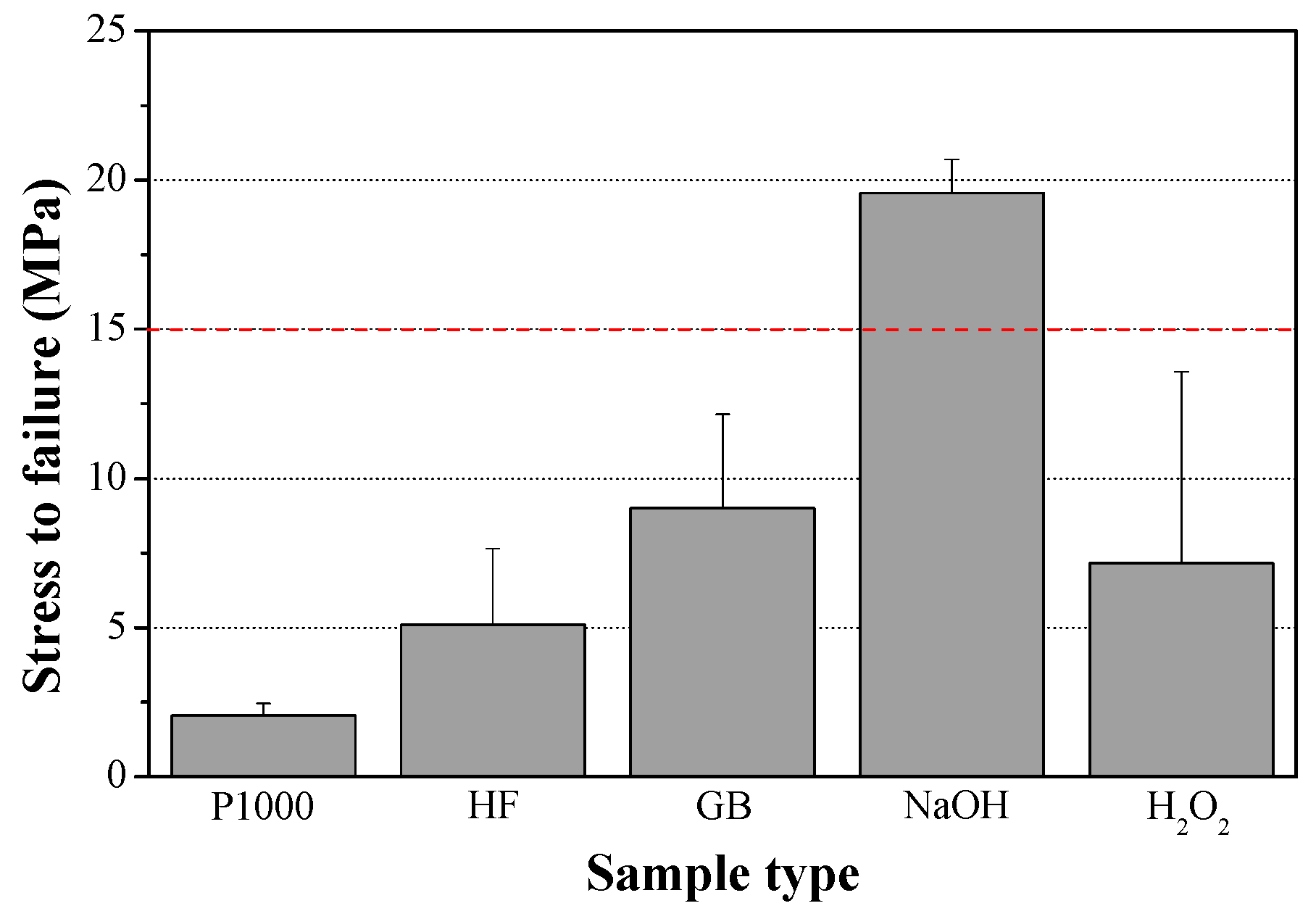

- Eliaz, N.; Ritman-Hertz, O.; Aronov, D.; Weinberg, E.; Shenhar, Y.; Rosenman, G.; Weinreb, M.; Ron, E. The effect of surface treatments on the adhesion of electrochemically deposited hydroxyapatite coating to titanium and on its interaction with cells and bacteria. J. Mater. Sci. Mater. Med. 2011, 22, 1741–1752. [Google Scholar] [CrossRef] [PubMed]

- Eliaz, N.; Shmueli, S.; Shur, I.; Benayahu, D.; Aronov, D.; Rosenman, G. The effect of surface treatment on the surface texture and contact angle of electrochemically deposited hydroxyapatite coating and on its interaction with bone-forming cells. Acta Biomater. 2009, 5, 3178–3191. [Google Scholar] [CrossRef] [PubMed]

- Dorozhkin, S.V. Calcium orthophosphate cements and concretes. Materials 2009, 2, 221–291. [Google Scholar] [CrossRef]

- Standard Test Method for Time of Setting of Hydraulic-Cement Paste by Vicat Needle; ASTM C191-13; ASTM International: West Conshohocken, PA, USA, 2013.

- Standard Test Method for Time of Setting of Hydraulic-Cement Paste by Gillmore Needles; ASTM C266-15; ASTM International: West Conshohocken, PA, USA, 2015.

- De Groot, K. Clinical applications of calcium phosphate biomaterials: A review. Ceram. Int. 1993, 19, 363–366. [Google Scholar] [CrossRef]

- Kreidler, E.R.; Hummel, F.A. Phase relations in the system SrO-P2O5 and the influence of water vapor on the formation of Sr4P2O9. Inorg. Chem. 1967, 6, 884–891. [Google Scholar] [CrossRef]

- De Groot, K. Effect of porosity and physicochemical properties on the stability, resorption, and strength of calcium phosphate ceramics, in bioceramics: Material characteristics versus in-vivo behavior. Ann. N. Y. Acad. Sci. 1988, 523, 227–233. [Google Scholar] [CrossRef] [PubMed]

- Manjubala, I.; Sastry, T.P.; Suresh Kumar, R.V. Bone in-growth induced by biphasic calcium phosphate ceramic in femoral defect of dogs. J. Biomater. Appl. 2005, 19, 341–360. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.J.; Tadjiev, T.R.; Kim, J.W.; You, C.K.; Choi, S.K.; Park, K.B.; Ryoo, K.H.; Kim, S.Y. Comparative study of the degradation behavior of mechanically mixed and chemically precipitated biphasic calcium phosphates. Key Eng. Mater. 2006, 309–311, 227–230. [Google Scholar] [CrossRef]

- Yang, X.; Wang, Z. Synthesis of biphasic ceramics of hydroxyapatite and β-tricalcium phosphate with controlled phase content and porosity. J. Mater. Chem. 1998, 8, 2237–2244. [Google Scholar] [CrossRef]

- Lin, F.; Liao, C.; Chen, K.; Sun, J.; Lin, C. Preparation of βTCP/HAP biphasic ceramics with natural bone structure by heating bovine cancellous bone with the addition of (NH4)2HPO4. J. Biomed. Mater. Res. A 2000, 51, 157–163. [Google Scholar] [CrossRef]

- Rey, C.; Combes, C.; Drouet, C.; Grossin, D. Bioactive ceramics: Physical chemistry. In Comprehensive Biomaterials; Ducheyne, P., Healy, K., Hutmacher, D., Grainger, D.E., Kirkpatrick, J., Eds.; Elsevier: Amsterdam, The Netherlands, 2011; pp. 187–221. [Google Scholar]

- Bermúdez, O.; Boltong, M.G.; Driessens, F.C.M.; Planell, J.A. Optimization of a calcium orthophosphate cement formulation occurring in the combination of monocalcium phosphate monohydrate with calcium oxide. J. Mater. Sci. Mater. Med. 1994, 5, 67–71. [Google Scholar] [CrossRef]

- Huan, Z.; Chang, J. Novel bioactive composite bone cements based on the β-tricalcium phosphate-Monocalcium phosphate monohydrate composite cement system. Acta Biomater. 2009, 5, 1253–1264. [Google Scholar] [CrossRef] [PubMed]

- Dorozhkin, S.V. Calcium orthophosphates in dentistry. J. Mater. Sci. Mater. Med. 2013, 24, 1335–1363. [Google Scholar] [CrossRef] [PubMed]

- Van Wazer, J.R. Phosphorus and Its Compounds; Interscience: New York, NY, USA, 1958. [Google Scholar]

- Chow, L.C.; Takagi, S.; Shern, R.J.; Chow, T.H.; Takagi, K.K.; Sieck, B.A. Effects on whole saliva of chewing gums containing calcium phosphates. J. Dent. Res. 1994, 73, 26–32. [Google Scholar] [CrossRef] [PubMed]

- Dorozhkin, S.V. Calcium orthophosphates in nature, biology and medicine. Materials 2009, 2, 399–498. [Google Scholar] [CrossRef]

- Van de Watering, F.C.J.; van den Beucken, J.J.J.P.; Felix Lanao, R.P.; Wolke, J.G.C.; Jansen, J.A. Biodegradation of calcium phosphate cement composites. In Degradation of Implant Materials; Eliaz, N., Ed.; Springer Science + Business Media: New York, NY, USA, 2012; Chapter 7; pp. 139–172. [Google Scholar]

- Constantz, B.; Barr, B.; Ison, I. Histological, chemical, and crystallographic analysis of four calcium phosphate cements in different rabbit osseous sites. J. Biomed. Mater. Res. 1998, 43, 451–461. [Google Scholar] [CrossRef]

- O’Neill, W.C. The fallacy of the calcium-phosphorus product. Kidney Int. 2007, 72, 792–796. [Google Scholar] [CrossRef] [PubMed]

- LeGeros, R.Z. Formation and transformation of calcium phosphates: Relevance to vascular calcification. Z. Kardiol. 2001, 90 (Suppl. 3), III116–III125. [Google Scholar] [CrossRef]

- Bermúdez, O.; Boltong, M.G.; Driessens, F.C.M.; Planell, J.A. Development of some calcium phosphate cements from combinations of α-TCP, MCPM and CaO. J. Mater. Sci. Mater. Med. 1994, 5, 160–163. [Google Scholar] [CrossRef]

- Kurashina, K.; Kurita, H.; Hirano, M.; Kotani, A.; Klein, C.P.; de Groot, K. In vivo study of calcium phosphate cements: Implantation of an α-tricalcium phosphate/dicalcium phosphate dibasic/tetracalcium phosphate monoxide cement paste. Biomaterials 1997, 18, 539–543. [Google Scholar] [CrossRef]

- Driessens, F.C.M.; Planell, J.A.; Boltong, M.G.; Khairoun, I.; Ginebra, M.P. Osteotransductive bone cements. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 1998, 212, 427–435. [Google Scholar] [CrossRef] [PubMed]

- Takagi, S.; Chow, L.C.; Ishikawa, K. Formation of hydroxyapatite in new calcium phosphate cements. Biomaterials 1998, 19, 1593–1599. [Google Scholar] [CrossRef]

- Yamamoto, H.; Niwa, S.; Hori, M.; Hattori, T.; Sawai, K.; Aoki, S.; Hirano, M.; Takeuchi, H. Mechanical strength of calcium phosphate cement in vivo and in vitro. Biomaterials 1998, 19, 1587–1591. [Google Scholar] [CrossRef]

- Crall, J.J.; Bjerga, J.M. Effects of DCPD/APF application and prolonged exposure to fluoride on caries-like lesion formation in vitro. J. Oral Pathol. Med. 1987, 16, 488–491. [Google Scholar] [CrossRef]

- Wefel, J.S.; Harless, J.D. The use of saturated DCPD in remineralization of artificial caries lesions in vitro. J. Dent. Res. 1987, 66, 1640–1643. [Google Scholar] [CrossRef] [PubMed]

- Hoppenbrouwers, P.M.; Groenendijk, E.; Tewarie, N.R.; Driessens, F.C.M. Improvement of the caries resistance of human dental roots by a two-step conversion of the root mineral into fluoridated hydroxylapatite. J. Dent. Res. 1988, 67, 1254–1256. [Google Scholar] [CrossRef] [PubMed]

- Sullivan, R.J.; Charig, A.; Blake-Haskins, J.; Zhang, Y.P.; Miller, S.M.; Strannick, M.; Gaffar, A.; Margolis, H.C. In vivo detection of calcium from dicalcium phosphate dihydrate dentifrices in demineralized human enamel and plaque. Adv. Dent. Res. 1997, 11, 380–387. [Google Scholar] [CrossRef] [PubMed]

- LeGeros, R.Z. Variations in the crystalline components of human dental calculus: I. crystallographic and spectroscopic methods of analysis. J. Dent. Res. 1974, 53, 45–50. [Google Scholar]

- Schroeder, H. Formation and inhibition of dental calculus. J. Periodontol. 1969, 40, 643–646. [Google Scholar] [CrossRef] [PubMed]

- Chow, L.C. Octacalcium Phosphate; Eanes, E.D., Ed.; Karger: Basel, Switzerland, 2001; p. 167. [Google Scholar]

- Brown, W.E. Octacalcium phosphate and hydroxyapatite: Crystal structure of octacalcium phosphate. Nature 1962, 196, 1048–1050. [Google Scholar] [CrossRef]

- Brown, W.E. Crystal growth of bone mineral. Clin. Orthop. Relat. Res. 1966, 44, 205–220. [Google Scholar] [CrossRef] [PubMed]

- Nelson, D.G.A.; Wood, G.J.; Barry, J.C.; Featherstone, J.D.B. The structure of (100) defects in carbonated apatite crystallites: A high-resolution electron microscope study. Ultramicroscopy 1986, 19, 253–265. [Google Scholar] [CrossRef]

- Iijima, M.; Nelson, D.G.A.; Pan, Y.; Kreinbrink, A.T.; Adachi, M.; Goto, T.; Moriwaki, Y. Fluoride analysis of apatite crystals with a central planar OCP inclusion: Concerning the role of F- ions on apatite/OCP/apatite structure formation. Calcif. Tissue Int. 1996, 59, 377–384. [Google Scholar] [CrossRef] [PubMed]

- Bodier-Houllé, P.; Steuer, P.; Voegel, J.C.; Cuisinier, F.J.G. First experimental evidence for human dentine crystal formation involving conversion of octacalcium phosphate to hydroxyapatite. Acta Crystallogr. Sect. D Biol. Crystallogr. 1998, 54, 1377–1381. [Google Scholar] [CrossRef]

- Aoba, T.; Komatsu, H.; Shimazu, Y.; Yagishita, H.; Taya, Y. Enamel mineralization and an initial crystalline phase. Connect. Tissue Res. 1998, 38, 129–137. [Google Scholar] [CrossRef] [PubMed]

- Tomazic, B.B.; Brown, W.E.; Shoen, F.J. Physicochemical properties of calcific deposits isolated from porcine bioprosthetic heart valves removed from patients following 2–13 years function. J. Biomed. Mater. Res. 1994, 28, 35–47. [Google Scholar] [CrossRef] [PubMed]

- Nancollas, G.H.; Wu, W. Biomineralization mechanisms: A kinetics and interfacial energy approach. J. Cryst. Growth 2000, 211, 137–142. [Google Scholar] [CrossRef]

- Kamakura, S.; Sasano, Y.; Homma, H.; Suzuki, O.; Kagayama, M.; Motegi, K. Implantation of octacalcium phosphate (OCP) in rat skull defects enhances bone repair. J. Dent. Res. 1999, 78, 1682–1687. [Google Scholar] [CrossRef] [PubMed]

- Sargolzaei-Aval, F.; Sobhani, A.; Arab, M.R.; Sarani, S.A.; Heydari, M.H. The efficacy of implant of octacalcium phosphate in combination with bone matrix gelatin (BMG) on bone regeneration in skull defects in rat. Iran. J. Med. Sci. 2004, 29, 124–129. [Google Scholar]

- Suzuki, O.; Kamakura, S.; Katagiri, T.; Nakamura, M.; Zhao, B.; Honda, Y.; Kamijo, R. Bone formation enhanced by implanted octacalcium phosphate involving conversion into Ca-deficient hydroxyapatite. Biomaterials 2006, 27, 2671–2681. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, O.; Imaizumi, H.; Kamakura, S.; Katagiri, T. Bone regeneration by synthetic octacalcium phosphate and its role in biological mineralization. Curr. Med. Chem. 2008, 15, 305–313. [Google Scholar] [CrossRef] [PubMed]

- Kikawa, T.; Kashimoto, O.; Imaizumi, H.; Kokubun, S.; Suzuki, O. Intramembranous bone tissue response to biodegradable octacalcium phosphate implant. Acta Biomater. 2009, 5, 1756–1766. [Google Scholar] [CrossRef] [PubMed]

- Stefanic, M.; Krnel, K.; Pribosic, I.; Kosmac, T. Rapid biomimetic deposition of octacalcium phosphate coatings on zirconia ceramics (Y-TZP) for dental implant applications. Appl. Surf. Sci. 2012, 258, 4649–4656. [Google Scholar] [CrossRef]

- Habibovic, P.; van der Valk, C.M.; van Blitterswijk, C.A.; de Groot, K.; Meijer, G. Influence of octacalcium phosphate coating on osteoinductive properties of biomaterials. J. Mater. Sci. Mater. Med. 2004, 15, 373–380. [Google Scholar] [CrossRef] [PubMed]

- Miura, K.; Matsui, K.; Kawai, T.; Kato, Y.; Matsui, A.; Suzuki, O.; Kamakura, S.; Echigo, S. Octacalcium phosphate collagen composites with titanium mesh facilitate alveolar augmentation in canine mandibular bone defects. Int. J. Oral Maxillofac. Surg. 2012, 41, 1161–1169. [Google Scholar] [CrossRef] [PubMed]

- Sena, M.; Yamashita, Y.; Nakano, Y.; Ohgaki, M.; Nakamura, S.; Yamashita, K.; Takagi, Y. Octacalcium phosphate-based cement as a pulp-capping agent in rats. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2004, 97, 749–755. [Google Scholar] [CrossRef] [PubMed]

- Kamakura, S.; Sasano, Y.; Nakamura, M.; Suzuki, O.; Ohki, H.; Kagayama, M.; Motegi, K. Initiation of alveolar ridge augmentation in the rat mandible by subperiosteal implantation of octacalcium phosphate. Arch. Oral Biol. 1996, 41, 1029–1038. [Google Scholar] [CrossRef]

- Kamakura, S.; Sasano, Y.; Homma, H.; Suzuki, O.; Kagayama, M.; Motegi, K. Experimental oral pathology: Implantation of octacalcium phosphate nucleates isolated bone formation in rat skull defects. Oral Dis. 2001, 7, 259–265. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Nancollas, G.H. Calcium orthophosphates: Crystallization and dissolution. Chem. Rev. 2008, 108, 4628–4669. [Google Scholar] [CrossRef] [PubMed]

- Arellano-Jiménez, M.J.; García-García, R.; Reyes-Gasga, J. Synthesis and hydrolysis of octacalcium phosphate and its characterization by electron microscopy and X-ray diffraction. J. Phys. Chem. Solids 2009, 70, 390–395. [Google Scholar] [CrossRef]

- Suzuki, O. Octacalcium phosphate: Osteoconductivity and crystal chemistry. Acta Biomater. 2010, 6, 3379–3387. [Google Scholar] [CrossRef] [PubMed]

- Heughebaert, J.C.; Zawacki, S.; Nancollas, G. The growth of octacalcium phosphate on beta tricalcium phosphate. J. Cryst. Growth 1983, 63, 83–90. [Google Scholar] [CrossRef]

- Yin, X.; Stott, M.J.; Rubio, A. α- and β-tricalcium phosphate: A density functional study. Phys. Rev. B 2003, 68, 205205. [Google Scholar] [CrossRef]

- Ten Huisen, K.S.; Brown, P.W. Formation of calcium-deficient hydroxyapatite from alpha-tricalcium phosphate. Biomaterials 1998, 19, 2209–2217. [Google Scholar] [CrossRef]

- Durucan, C.; Brown, P.W. alpha-Tricalcium phosphate hydrolysis to hydroxyapatite at and near physiological temperature. J. Mater. Sci. Mater. Med. 2000, 11, 365–371. [Google Scholar] [CrossRef] [PubMed]

- Mathew, M.; Schroeder, L.W.; Dickens, B.; Brown, W.E. The crystal structure of α-Ca3(PO4)2. Acta Crystallogr. B 1977, 33, 1325–1333. [Google Scholar] [CrossRef]

- Yin, X.; Stott, M.J. Surface and adsorption properties of alpha-tricalcium phosphate. J. Chem. Phys. 2006, 124, 124701. [Google Scholar] [CrossRef] [PubMed]

- Dickens, B.; Schroeder, L.W.; Brown, W.E. Crystallographic studies of the role of Mg as a stabilizing impurity in β-Ca3(PO4)2, The crystal structure of pure β-Ca3(PO4)2. J. Solid State Chem. 1974, 10, 232–248. [Google Scholar] [CrossRef]

- De Aza, P.N.; Guitian, F.; Santos, C.; de Aza, S.; Cusco, R.; Artus, L. Vibrational properties of calcium phosphate compounds. 2. Comparison between hydroxyapatite and β-tricalcium phosphate. Chem. Mater. 1997, 9, 916–922. [Google Scholar] [CrossRef]

- Cheng, P.T.; Grabher, J.; LeGeros, R.Z. Effects of magnesium on calcium phosphate formation. Magnesium 1988, 7, 123–132. [Google Scholar] [PubMed]

- Tao, J.; Pan, H.; Zhai, H.; Wang, J.; Li, L.; Wu, J.; Jiang, W.; Xu, X.; Tang, R. Controls of tricalcium phosphate single-crystal formation from its amorphous precursor by interfacial energy. Cryst. Growth Des. 2009, 9, 3154–3160. [Google Scholar] [CrossRef]

- Hou, X.J.; Mao, K.Y.; Chen, D.F. Bone formation performance of beta-tricalcium phosphate sintered bone. J. Clin. Rehabil. Tissue. Eng. Res. 2008, 12, 9627–9630. [Google Scholar]

- Ohura, K.; Bohner, M.; Hardouin, P.; Lemaître, J.; Pasquier, G.; Flautre, B. Resorption of, and bone formation from, new beta-tricalcium phosphate-monocalcium phosphate cements: An in vivo study. J. Biomed. Mater. Res. 1996, 30, 193–200. [Google Scholar] [CrossRef]

- Mirtchi, A.A.; Lemaître, J.; Munting, E. Calcium phosphate cements: Study of the beta-tricalcium phosphate–dicalcium phosphate–calcite cements. Biomaterials 1990, 11, 83–88. [Google Scholar] [CrossRef]

- Metsger, D.S.; Driskell, T.D.; Paulsrud, J.R. Tricalcium phosphate ceramic—A resorbable bone implant: Review and current status. J. Am. Dent. Assoc. 1982, 105, 1035–1038. [Google Scholar] [CrossRef] [PubMed]

- Epstein, N.E. Beta tricalcium phosphate: Observation of use in 100 posterolateral lumbar instrumented fusions. Spine J. 2009, 9, 630–638. [Google Scholar] [CrossRef] [PubMed]

- Shayegan, A.; Petein, M.; Vanden Abbeele, A. The use of beta-tricalcium phosphate, white MTA, white Portland cement and calcium hydroxide for direct pulp capping of primary pig teeth. Dent. Traumatol. 2009, 25, 413–419. [Google Scholar] [CrossRef] [PubMed]

- Weiner, M.L.; Salminen, W.F.; Larson, P.R.; Barter, R.A.; Kranetz, J.L.; Simon, G.S. Toxicological review of inorganic phosphates. Food Chem. Toxicol. 2001, 39, 759–786. [Google Scholar] [CrossRef]

- Jungbauer, A.; Hahn, R.; Deinhofer, K.; Luo, P. Performance and characterization of a nanophased porous hydroxyapatite for protein chromatography. Biotechnol. Bioeng. 2004, 87, 364–375. [Google Scholar] [CrossRef] [PubMed]

- Van Velthuizen, J. Giant fluorapatite crystals: A question of locality. Miner. Rec. 1992, 23, 459–463. [Google Scholar]

- Skrtic, D.; Antonucci, J.M.; Eanes, E.D. Improved properties of amorphous calcium phosphate fillers in remineralizing resin composites. Dent. Mater. 1996, 12, 295–301. [Google Scholar] [CrossRef]

- Skrtic, D.; Hailer, A.W.; Takagi, S.; Antonucci, J.M.; Eanes, E.D. Quantitative assessment of the efficacy of amorphous calcium phosphate/methacrylate composites in remineralizing caries-like lesions artificially produced in bovine enamel. J. Dent. Res. 1996, 75, 1679–1686. [Google Scholar] [CrossRef] [PubMed]

- Skrtic, D.; Antonucci, J.M.; Eanes, E.D. Effect of the monomer and filler system on the remineralizing potential of bioactive dental composites based on amorphous calcium phosphate. Polym. Adv. Technol. 2001, 12, 369–379. [Google Scholar] [CrossRef]

- Skrtic, D.; Antonucci, J.M.; Eanes, E.D. Amorphous calcium phosphate-based bioactive polymeric composites for mineralized tissue regeneration. J. Res. Natl. Inst. Stand. Technol. 2003, 108, 167–182. [Google Scholar] [CrossRef] [PubMed]

- Skrtic, D.; Antonucci, J.M.; Eanes, E.D.; Eidelman, N. Dental composites based on hybrid and surface-modified amorphous calcium phosphates. Biomaterials 2004, 25, 1141–1150. [Google Scholar] [CrossRef] [PubMed]

- Skrtic, D.; Antonucci, J.M. Matrix resin effects on selected physicochemical properties of amorphous calcium phosphate composites. J. Bioact. Compat. Polym. 2005, 20, 29–49. [Google Scholar]

- Skrtic, D.; Antonucci, J.M. Dental composites based on amorphous calcium phosphate—Resin composition/physicochemical properties study. J. Biomater. Appl. 2007, 21, 375–393. [Google Scholar] [CrossRef] [PubMed]

- O’Donnell, J.N.R.; Schumacher, G.E.; Antonucci, J.M.; Skrtic, D. Adhesion of amorphous calcium phosphate composites bonded to dentin: A study in failure modality. J. Biomed. Mater. Res. B Appl. Biomater. 2009, 90, 238–249. [Google Scholar] [CrossRef] [PubMed]

- Antonucci, J.M.; O’Donnell, J.N.R.; Schumacher, G.E.; Skrtic, D. Amorphous calcium phosphate composites and their effect on composite–adhesive–dentin bonding. J. Adhes. Sci. Technol. 2009, 23, 1133–1147. [Google Scholar] [CrossRef] [PubMed]

- Tadic, D.; Epple, M. Amorphous calcium phosphates as bone substitution materials. Eur. J. Trauma 2002, 28, 136–137. [Google Scholar]

- Yates, R.; Owens, J.; Jackson, R.; Newcombe, R.G.; Addy, M. A splitmouth placebo-controlled study to determine the effect of amorphous calcium phosphate in the treatment of dentine hypersensitivity. J. Clin. Periodontol. 1998, 25, 687–692. [Google Scholar] [CrossRef] [PubMed]

- Tung, M.S.; Eichmiller, F.C. Dental applications of amorphous calcium phosphates. J. Clin. Dent. 1999, 10, 1–6. [Google Scholar] [PubMed]

- Ambrosio, A.M.A.; Sahota, J.S.; Khan, Y.; Laurencin, CT. A novel amorphous calcium phosphate polymer ceramic for bone repair: I. Synthesis and characterization. J. Biomed. Mater. Res. 2001, 58, 295–301. [Google Scholar] [CrossRef]

- Dunn, W.J. Shear bond strength of an amorphous calcium-phosphate-containing orthodontic resin cement. Am. J. Orthod. Dentofac. Orthop. 2007, 131, 243–247. [Google Scholar] [CrossRef] [PubMed]

- Foster, J.A.; Berzins, D.W.; Bradley, T.G. Bond strength of an amorphous calcium phosphate-containing orthodontic adhesive. Angle Orthod. 2008, 78, 339–344. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.; Zhang, F.; Guo, J.; Wu, J.; Wu, W. Effects of amorphous calcium phosphate on periodontal ligament cell adhesion and proliferation in vitro. J. Med. Biol. Eng. 2008, 28, 107–112. [Google Scholar]

- Uysal, T.; Amasyali, M.; Koyuturk, A.E.; Sagdic, D. Efficiency of amorphous calcium phosphate-containing orthodontic composite and resin modified glass ionomer on demineralization evaluated by a new laser fluorescence device. Eur. J. Dent. 2009, 3, 127–134. [Google Scholar] [PubMed]

- Uysal, T.; Ulker, M.; Baysal, A.; Usumez, S. Microleakage between composite-wire and composite-enamel interfaces of flexible spiral wire retainers. Part 2: Comparison of amorphous calcium phosphate-containing adhesive with conventional lingual retainer composite. Eur. J. Orthod. 2009, 31, 652–657. [Google Scholar] [CrossRef] [PubMed]

- Uysal, T.; Ulker, M.; Akdogan, G.; Ramoglu, S.I.; Yilmaz, E. Bond strength of amorphous calcium phosphate-containing orthodontic composite used as a lingual retainer adhesive. Angle Orthod. 2009, 79, 117–121. [Google Scholar] [CrossRef] [PubMed]

- Uysal, T.; Ustdal, A.; Nur, M.; Catalbas, B. Bond strength of ceramic brackets bonded to enamel with amorphous calcium phosphate containing orthodontic composite. Eur. J. Orthod. 2010, 32, 281–284. [Google Scholar] [CrossRef] [PubMed]

- Uysal, T.; Amasyali, M.; Ozcan, S.; Koyuturk, A.E.; Akyol, M.; Sagdic, D. In vivo effects of amorphous calcium phosphate-containing orthodontic composite on enamel demineralization around orthodontic brackets. Aust. Dent. J. 2010, 55, 285–291. [Google Scholar] [CrossRef] [PubMed]

- Uysal, T.; Amasyali, M.; Koyuturk, A.E.; Ozcan, S.; Sagdic, D. Amorphous calcium phosphate-containing orthodontic composites. Do they prevent demineralisation around orthodontic brackets? Aust. Orthod. J. 2010, 26, 10–15. [Google Scholar] [PubMed]

- Xu, H.H.K.; Moreau, J.L.; Sun, L.; Chow, L.C. Nanocomposite containing amorphous calcium phosphate nanoparticles for caries inhibition. Dent. Mater. 2011, 27, 762–769. [Google Scholar] [CrossRef] [PubMed]

- Fletcher, J.; Walsh, D.; Fowler, C.E.; Mann, S. Electrospun mats of PVP/ACP nanofibres for remineralization of enamel tooth surfaces. CrystEngComm 2011, 13, 3692–3697. [Google Scholar] [CrossRef]

- Hamba, H.; Nikaido, T.; Inoue, G.; Sadr, A.; Tagami, J. Effects of CPP–ACP with sodium fluoride on inhibition of bovine enamel demineralization: A quantitative assessment using micro-computed tomography. J. Dent. 2011, 39, 405–413. [Google Scholar] [CrossRef] [PubMed]

- Bar-Hillel, R.; Feuerstein, O.; Tickotsky, N.; Shapira, J.; Moskovitz, M. Effects of amorphous calcium phosphate stabilized by casein phosphopeptides on enamel de- and remineralization in primary teeth: An in vitro study. J. Dent. Child. 2012, 79, 9–14. [Google Scholar]

- Weir, M.D.; Chow, L.C.; Xu, H.H.K. Remineralization of demineralized enamel via calcium phosphate nanocomposite. J. Dent. Res. 2012, 91, 979–984. [Google Scholar] [CrossRef] [PubMed]

- Llena, C.; Forner, L.; Baca, P. Anticariogenicity of casein phosphopeptide–amorphous calcium phosphate: A review of the literature. J. Contemp. Dent. Pract. 2009, 10, 1–9. [Google Scholar] [PubMed]

- Giniger, M.; MacDonald, J.; Spaid, M.; Felix, H. A 180-day clinical investigation of the tooth whitening efficacy of a bleaching gel with added amorphous calcium phosphate. J. Clin. Dent. 2005, 16, 11–16. [Google Scholar] [PubMed]

- Reynolds, E.C.; Cai, F.; Cochrane, N.J.; Shen, P.; Walker, G.D.; Morgan, M.V.; Reynolds, C. Fluoride and casein phosphopeptide-amorphous calcium phosphate. J. Dent. Res. 2008, 87, 344–348. [Google Scholar] [CrossRef] [PubMed]

- Yengopal, V.; Mickenautsch, S. Caries preventive effect of casein phosphopeptide-amorphous calcium phosphate (CPP-ACP): A meta-analysis. Acta Odontol. Scand. 2009, 67, 321–332. [Google Scholar] [CrossRef] [PubMed]

- Mei, H.L.; Chen, L.Y.; Zhang, D.; Zhang, P.L.; Liu, B.; Zhao, W.; Qi, H.Y. Effects of casein phosphopeptide-stabilized amorphous calcium phosphate solution on enamel remineralization. J. Clin. Rehabil. Tissue Eng. Res. 2009, 13, 4825–4828. [Google Scholar]

- Oreffo, R.O.C.; Driessens, F.C.M.; Planell, J.A.; Triffitt, J.T. Effects of novel calcium phosphate cements on human bone marrow fibroblastic cells. Tissue Eng. 1998, 4, 293–303. [Google Scholar] [CrossRef] [PubMed]

- Okamoto, Y.; Hidaka, S. Studies on calcium-phosphate precipitation—Effects of metal-ions used in dental materials. J. Biomed. Mater. Res. 1994, 28, 1403–1410. [Google Scholar] [CrossRef] [PubMed]

- Daculsi, G. Biphasic calcium phosphate concept applied to artificial bone, implant coating and injectable bone substitute. Biomaterials 1998, 19, 1473–1478. [Google Scholar] [CrossRef]

- LeGeros, R.Z.; Lin, S.; Rohanizadeh, R.; Mijares, D.; LeGeros, J.P. Biphasic calcium phosphate bioceramics: Preparation, properties and applications. J. Mater. Sci. Mater. Med. 2003, 14, 201–209. [Google Scholar] [CrossRef] [PubMed]

- Daculsi, G.; Laboux, O.; Malard, O.; Weiss, P. Current state of the art of biphasic calcium phosphate bioceramics. J. Mater. Sci. Mater. Med. 2003, 14, 195–200. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Lorenzo, L. Studies on calcium deficient apatites structure by means of MAS-NMR spectroscopy. J. Mater. Sci. Mater. Med. 2005, 16, 393–398. [Google Scholar] [CrossRef] [PubMed]

- Rey, C.; Combes, C.; Drouet, C.; Sfihi, H. Chemical diversity of apatites. Adv. Sci. Technol. 2006, 49, 27–36. [Google Scholar] [CrossRef]

- Young, R.A.; Holcomb, D.W. Variability of hydroxyapatite preparations. Calcif. Tissue Int. 1981, 34, S17–S32. [Google Scholar]

- Blumenthal, N.C.; Betts, F.; Posner, A.S. Formation and structure of Ca-deficient hydroxyapatite. Calcif. Tissue Int. 1981, 33, 111–117. [Google Scholar] [CrossRef] [PubMed]

- Ishikawa, K.; Ducheyne, P.; Radin, S. Determination of the Ca/P ratio in calcium-deficient hydroxyapatite using X-ray diffraction analysis. J. Mater. Sci. Mater. Med. 1993, 4, 105–168. [Google Scholar] [CrossRef]

- Ivanova, T.I.; Frank-Kamenetskaya, O.V.; Kol’tsov, A.B.; Ugolkov, V.L. Crystal structure of calcium-deficient carbonated hydroxyapatite. Thermal Decomposition. J. Solid State Chem. 2001, 160, 340–349. [Google Scholar] [CrossRef]

- Zhou, H.H.; Li, H.; Guo, L.H. Molecular and crystal structure characterization of calcium-deficient apatite. Key Eng. Mater. 2007, 330–332, 119–122. [Google Scholar] [CrossRef]

- Domashevskaya, E.P.; Al-Zubadi, A.A.; Goloshchapov, D.L.; Rumyantseva, N.A.; Seredin, P.V. Structure and composition of metal substituted calcium deficient hydroxyapatite. World Appl. Sci. J. 2014, 31, 2093–2100. [Google Scholar] [CrossRef]

- Bhat, S.S.; Waghmare, U.V.; Ramamurty, U. First-principles study of structure, vibrational, and elastic properties of stoichiometric and calcium-deficient hydroxyapatite. Cryst. Growth Des. 2014, 14, 3131–3141. [Google Scholar] [CrossRef]

- Brown, P.W.; Martin, R.I. An analysis of hydroxyapatite surface layer formation. J. Phys. Chem. B 1999, 103, 1671–1675. [Google Scholar] [CrossRef]

- Honghui, Z.; Hui, L.; Linghong, G. Molecular and crystal structure characterization of calcium deficient apatite. Key Eng. Mater. 2007, 330–332, 119–122. [Google Scholar]

- Moseke, C.; Gbureck, U. Tetracalcium phosphate: Synthesis, properties and biomedical applications. Acta Biomater. 2010, 6, 3815–3823. [Google Scholar] [CrossRef] [PubMed]