Improving Tensile and Compressive Properties of an Extruded AZ91 Rod by the Combined Use of Torsion Deformation and Aging Treatment

Abstract

:1. Introduction

2. Experimental Section

3. Results

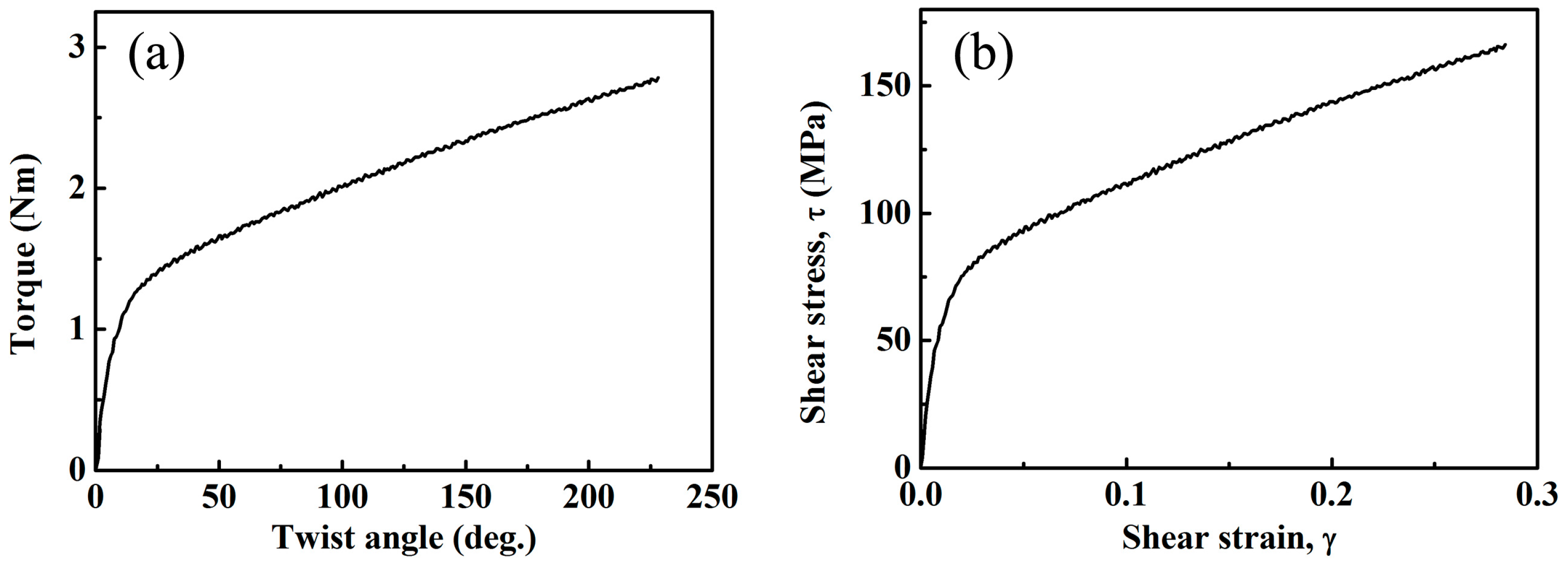

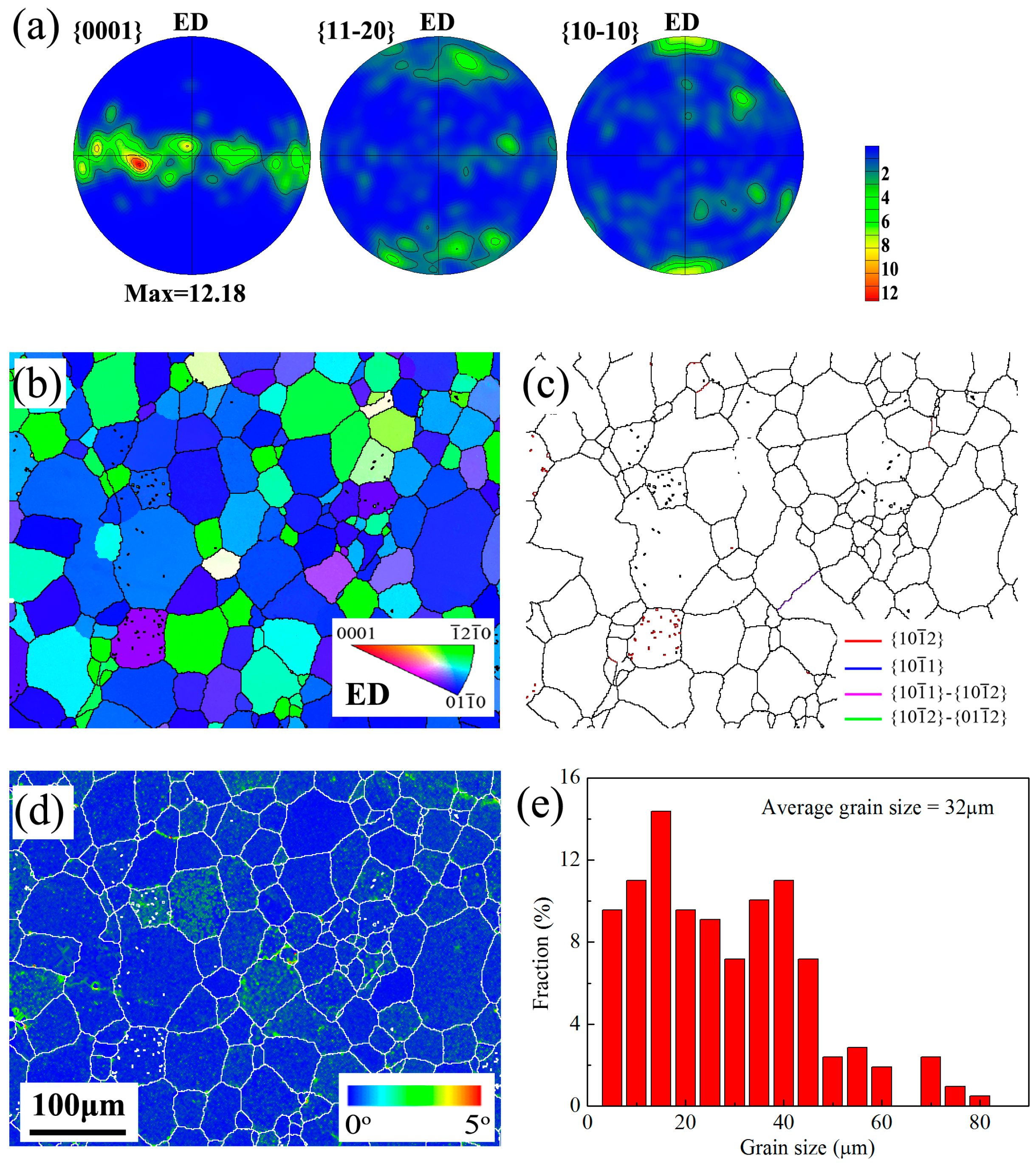

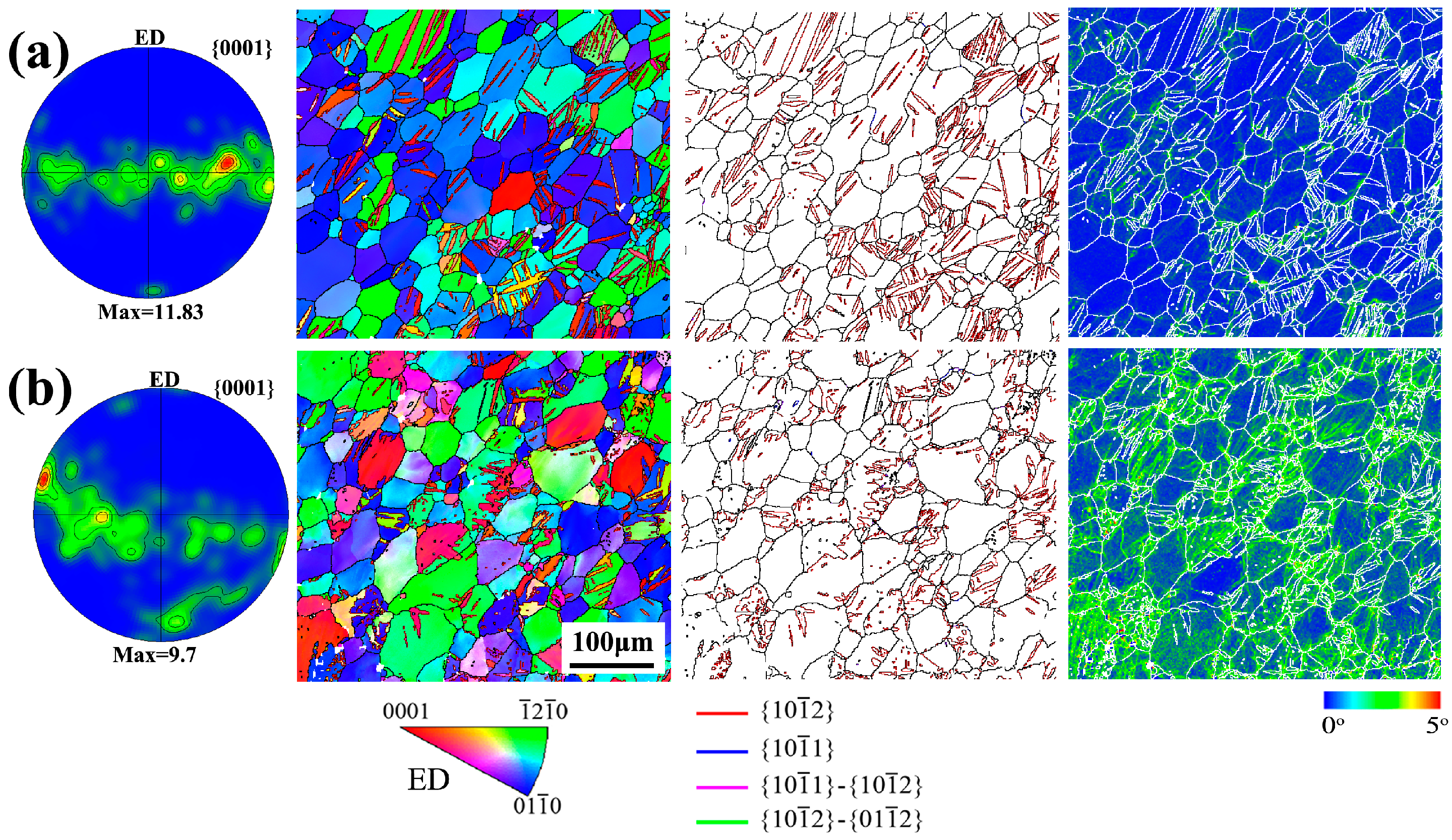

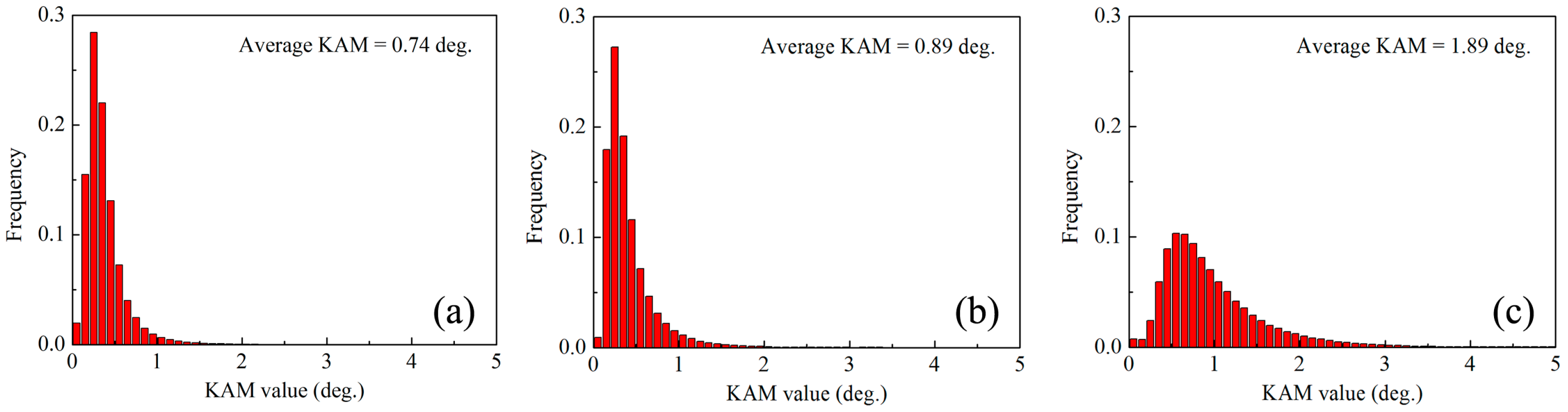

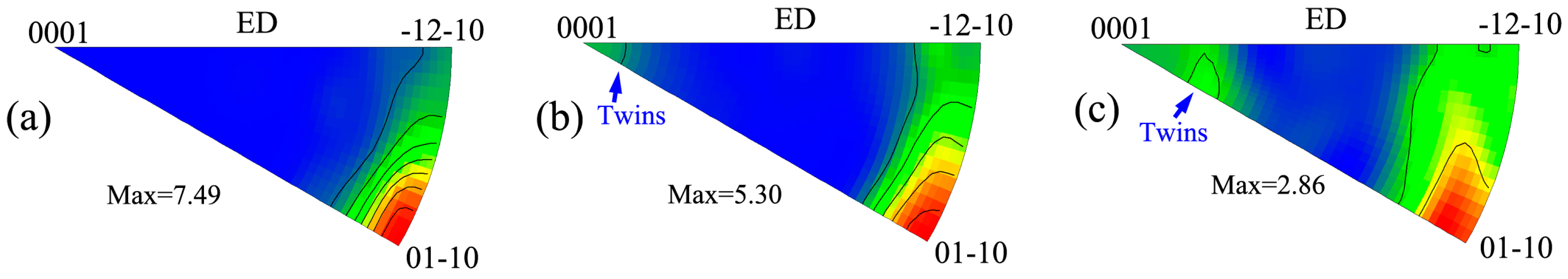

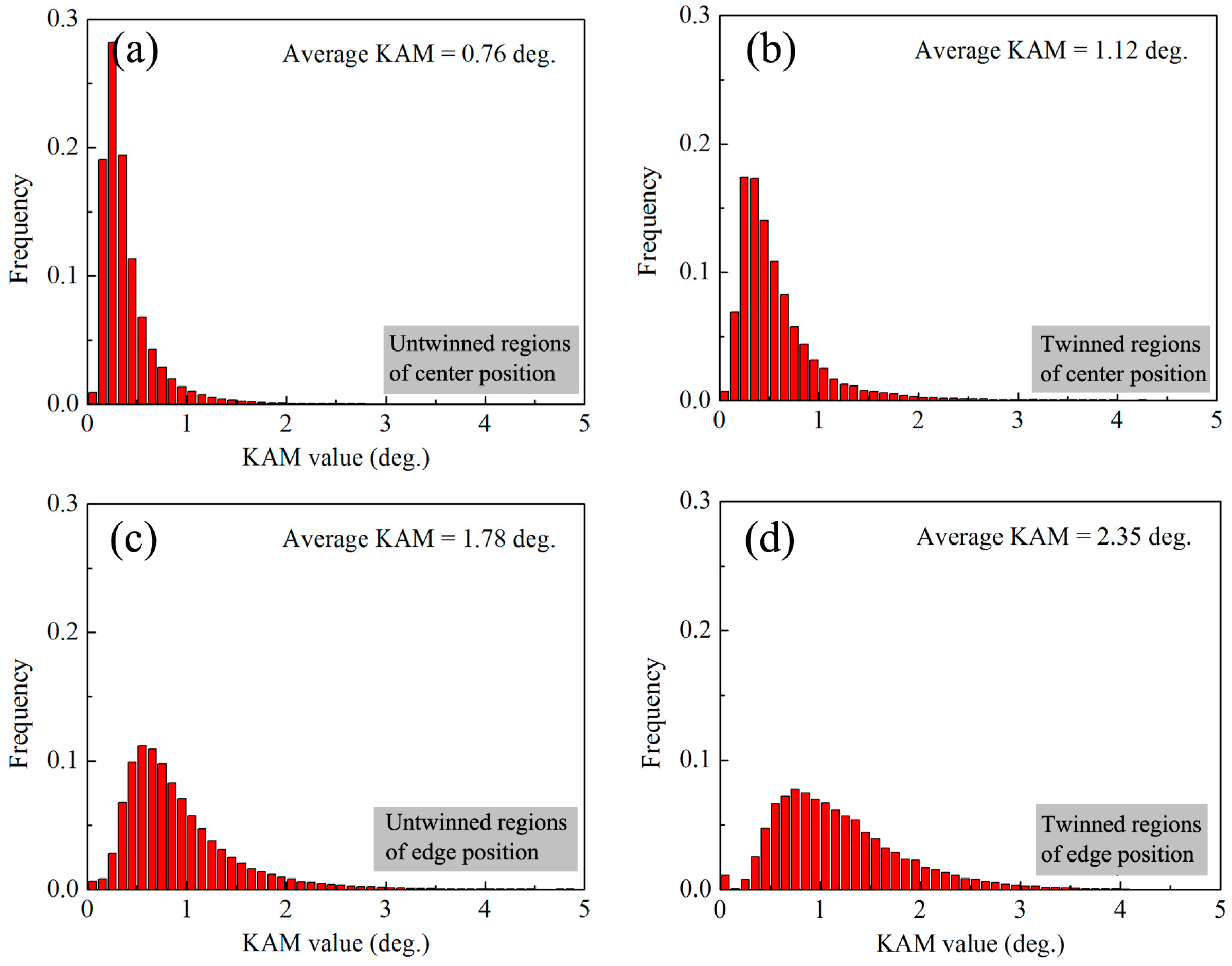

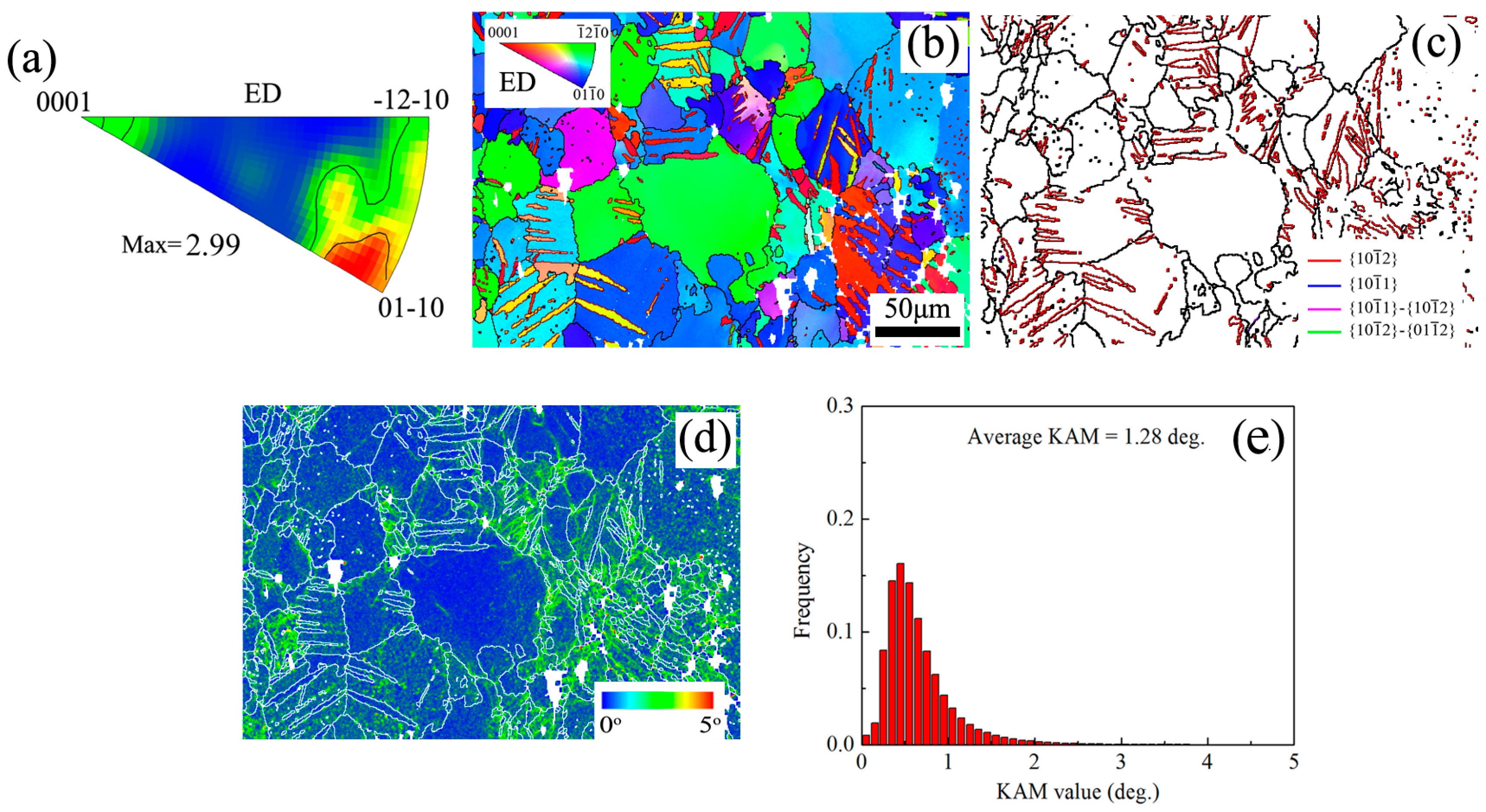

3.1. Microstructure Evolution During Torsion

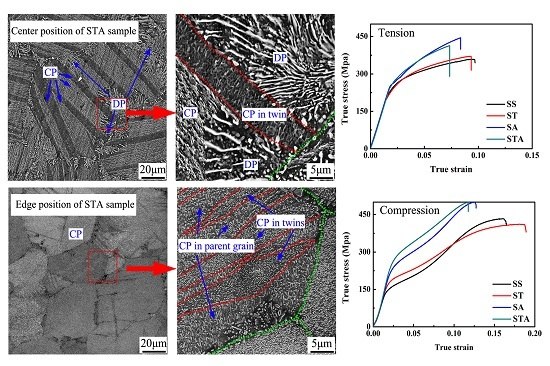

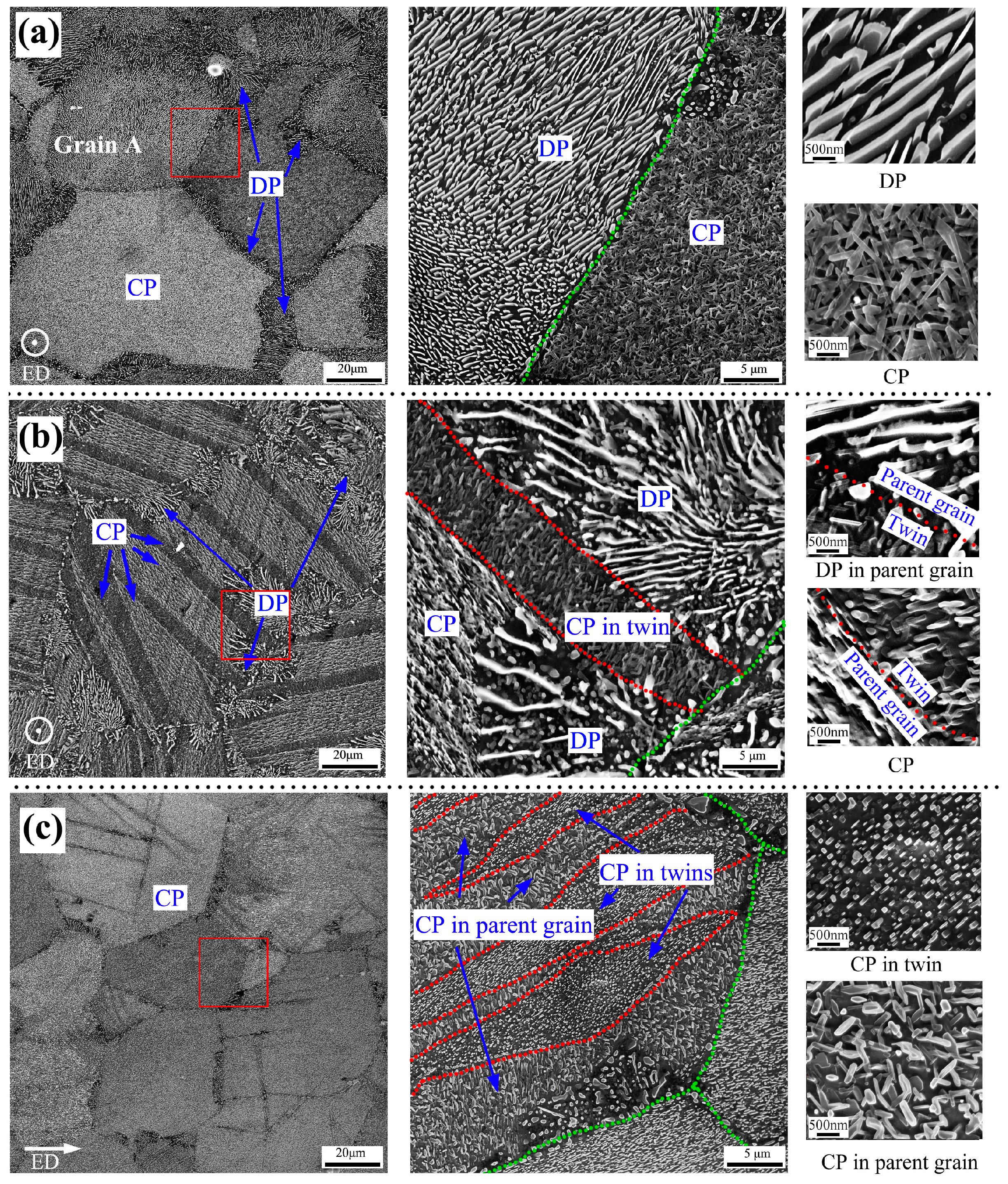

3.2. Precipitation Behavior

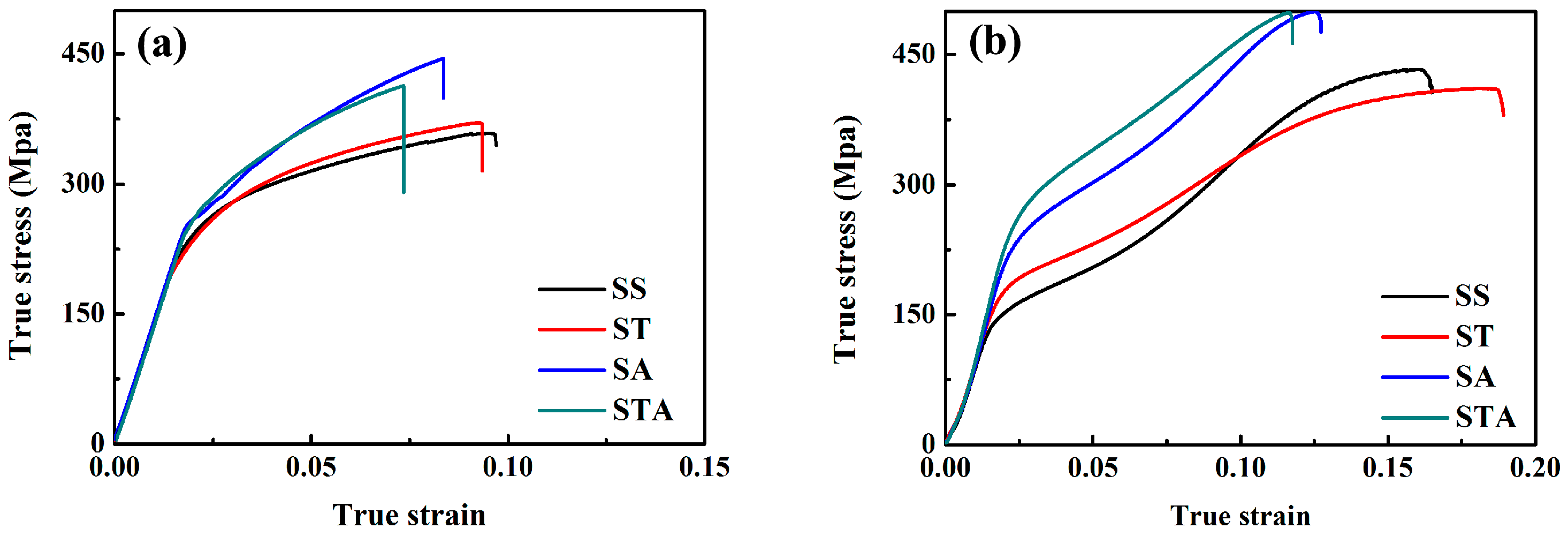

3.3. Tensile and Compressive Properties

4. Discussion

5. Conclusions

- The SS sample has a uniform microstructure and typical fiber texture. Torsion deformation can generate gradient microstructure evolution on the cross-section of as-extruded AZ91 rod. After torsion, from the center to the edge on the cross-section of rod, both stored dislocations and area fraction of {10-12} twins gradually increase, and the basal pole of the texture tends to rotate towards ED direction.

- Direct aging usually generates coarse discontinuous precipitates and fine continuous precipitates simultaneously. Torsion deformation can promote continuous precipitation. Both twin structures and dislocations via torsion deformation can be effective microstructures for the nucleation of continuous precipitates.

- Twin structures are favorable nucleation sites only for the continuous precipitation, while the precipitation behavior of un-twinned regions largely depends on the strain amount. High strain can generate a mass of dislocations to promote continuous precipitation in un-twinned regions. Thus, ST sample exhibits gradient precipitation characteristics due to the gradient distribution of twins and dislocations.

- SS sample exhibits a large tension-compression yield asymmetry. Aging treatment can enhance the tensile and compressive yield strength simultaneously and reduce yield asymmetry. Torsion deformation can also reduce the yield asymmetry owing to the generation of twin lamellae and textural change. Moreover, torsion deformation can enhance the aging hardening effect. Finally, combined use of torsion deformation and aging treatment can effectively enhance the yield strength and almost eliminate the yield asymmetry of the present extruded AZ91 rod.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, F.; Bhattacharyya, J.J.; Agnew, S.R. Effect of precipitate shape and orientation on Orowan strengthening of non-basal slip modes in hexagonal crystals, application to magnesium alloys. Mater. Sci. Eng. A 2016, 666, 114–122. [Google Scholar] [CrossRef]

- Nie, J.-F. Precipitation and Hardening in Magnesium Alloys. Metall. Mater. Trans. A 2012, 43, 3891–3939. [Google Scholar] [CrossRef]

- Stanford, N.; Geng, J.; Chun, Y.B.; Davies, C.H.J.; Nie, J.F.; Barnett, M.R. Effect of plate-shaped particle distributions on the deformation behaviour of magnesium alloy AZ91 in tension and compression. Acta Mater. 2012, 60, 218–228. [Google Scholar] [CrossRef]

- Robson, J.D.; Stanford, N.; Barnett, M.R. Effect of precipitate shape on slip and twinning in magnesium alloys. Acta Mater. 2011, 59, 1945–1956. [Google Scholar] [CrossRef]

- Nie, J.F. Effects of precipitate shape and orientation on dispersion strengthening in magnesium alloys. Scr. Mater. 2003, 48, 1009–1015. [Google Scholar] [CrossRef]

- Xin, R.; Song, B.; Zeng, K.; Huang, G.; Liu, Q. Effect of aging precipitation on mechanical anisotropy of an extruded Mg-Y-Nd alloy. Mater. Des. 2012, 34, 384–388. [Google Scholar] [CrossRef]

- Lv, C.; Liu, T.; Liu, D.; Jiang, S.; Zeng, W. Effect of heat treatment on tension-compression yield asymmetry of AZ80 magnesium alloy. Mater. Des. 2012, 33, 529–533. [Google Scholar] [CrossRef]

- Wang, C.; Xin, R.; Li, D.; Song, B.; Wu, M.; Liu, Q. Enhancing the age-hardening response of rolled AZ80 alloy by pre-twinning deformation. Mater. Sci. Eng. A 2017, 680, 152–156. [Google Scholar] [CrossRef]

- Li, R.; Xin, R.; Chapuis, A.; Liu, Q.; Fu, G.; Zong, L.; Yu, Y.; Guo, B.; Guo, S. Effect of cold rolling on microstructure and mechanical property of extruded Mg-4Sm alloy during aging. Mater. Charact. 2016, 112, 81–86. [Google Scholar] [CrossRef]

- Zheng, K.Y.; Dong, J.; Zeng, X.Q.; Ding, W.J. Effect of pre-deformation on aging characteristics and mechanical properties of a Mg-Gd-Nd-Zr alloy. Mater. Sci. Eng. A 2008, 491, 103–109. [Google Scholar] [CrossRef]

- Yang, P.; Wang, L.-N.; Xie, Q.-G.; Li, J.-Z.; Ding, H.; Lu, L.-L. Influence of deformation on precipitation in AZ80 magnesium alloy. Int. J. Miner. Metall. Mater. 2011, 18, 338–343. [Google Scholar] [CrossRef]

- Čížek, J.; Procházka, I.; Smola, B.; Stulíková, I.; Očenášek, V. Influence of deformation on precipitation process in Mg-15wt.%Gd alloy. J. Alloys Compd. 2007, 430, 92–96. [Google Scholar] [CrossRef]

- Ye, J.; Lin, X.-P.; Zhao, T.-B.; Liu, N.-N.; Xie, H.-B.; Niu, Y.; Teng, F. Influence of pre-strain on the aging hardening effect of the Mg-9.02Zn-1.68Y alloy. Mater. Sci. Eng. A 2016, 663, 49–55. [Google Scholar] [CrossRef]

- Hong, S.-G.; Park, S.H.; Lee, C.S. Role of {10-12} twinning characteristics in the deformation behavior of a polycrystalline magnesium alloy. Acta Mater. 2010, 58, 5873–5885. [Google Scholar] [CrossRef]

- Song, B.; Xin, R.; Sun, L.; Chen, G.; Liu, Q. Enhancing the strength of rolled ZK60 alloys via the combined use of twinning deformation and aging treatment. Mater. Sci. Eng. A 2013, 582, 68–75. [Google Scholar] [CrossRef]

- Chen, H.; Liu, T.; Zhang, Y.; Song, B.; Hou, D.; Pan, F. The yield asymmetry and precipitation behavior of pre-twinned ZK60 alloy. Mater. Sci. Eng. A 2016, 652, 167–174. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, T.; Ding, X.; Xu, S.; He, J.; Chen, H.; Pan, F.; Lu, L. The precipitation behavior of a pretwinned Mg-6Al-1Zn alloy and the effect on subsequent deformation. J. Mater. Res. 2014, 29, 2141–2146. [Google Scholar] [CrossRef]

- Song, B.; Guo, N.; Liu, T.; Yang, Q. Improvement of formability and mechanical properties of magnesium alloys via pre-twinning: A review. Mater. Des. 2014, 62, 352–360. [Google Scholar] [CrossRef]

- Song, B.; Xin, R.; Zheng, X.; Chen, G.; Liu, Q. Activation of multiple twins by pre-tension and compression to enhance the strength of Mg-3Al-1Zn alloy plates. Mater. Sci. Eng. A 2015, 621, 100–104. [Google Scholar] [CrossRef]

- Park, S.H.; Hong, S.-G.; Lee, J.-H.; Kim, S.-H.; Cho, Y.-R.; Yoon, J.; Lee, C.S. Effects of pre-tension on fatigue behavior of rolled magnesium alloy. Mater. Sci. Eng. A 2017, 680, 351–358. [Google Scholar] [CrossRef]

- Song, B.; Xin, R.; Chen, G.; Zhang, X.; Liu, Q. Improving tensile and compressive properties of magnesium alloy plates by pre-cold rolling. Scr. Mater. 2012, 66, 1061–1064. [Google Scholar] [CrossRef]

- Guo, N.; Song, B.; Guo, C.; Xin, R.; Liu, Q. Improving tensile and compressive properties of magnesium alloy rods via a simple pre-torsion deformation. Mater. Des. 2015, 83, 270–275. [Google Scholar] [CrossRef]

- Song, B.; Zhao, H.; Chai, L.; Guo, N.; Pan, H.; Chen, H.; Xin, R. Preparation and characterization of Mg alloy rods with gradient microstructure by torsion deformation. Met. Mater. Int. 2016, 22, 887–896. [Google Scholar] [CrossRef]

- Song, B.; Guo, N.; Xin, R.; Pan, H.; Guo, C. Strengthening and toughening of extruded magnesium alloy rods by combining pre-torsion deformation with subsequent annealing. Mater. Sci. Eng. A 2016, 650, 300–304. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, D.; Li, Y.; Xiao, Z.; Fouse, J.; Yang, X. Effect of initial orientation on the microstructure and mechanical properties of textured AZ31 Mg alloy during torsion and annealing. Mater. Des. 2015, 86, 526–535. [Google Scholar] [CrossRef]

- Chen, C.; Beygelzimer, Y.; Toth, L.S.; Estrin, Y.; Kulagin, R. Tensile Yield Strength of a Material Preprocessed by Simple Shear. J. Eng. Mater. Technol. 2016, 138, 031010. [Google Scholar] [CrossRef]

- Wei, Y.; Li, Y.; Zhu, L.; Liu, Y.; Lei, X.; Wang, G.; Wu, Y.; Mi, Z.; Liu, J.; Wang, H.; Gao, H. Evading the strength-ductility trade-off dilemma in steel through gradient hierarchical nanotwins. Nat. Commun. 2014, 5, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Guo, N.; Song, B.; Yu, H.; Xin, R.; Wang, B.; Liu, T. Enhancing tensile strength of Cu by introducing gradient microstructures via a simple torsion deformation. Mater. Des. 2016, 90, 545–550. [Google Scholar] [CrossRef]

- Jung, I.C.; Kim, Y.K.; Cho, T.H.; Oh, S.H.; Kim, T.E.; Shon, S.W.; Kim, W.T.; Kim, D.H. Suppression of discontinuous precipitation in AZ91 by addition of Sn. Met. Mater. Int. 2013, 20, 99–103. [Google Scholar] [CrossRef]

- Guo, X.Q.; Wu, W.; Wu, P.D.; Qiao, H.; An, K.; Liaw, P.K. On the Swift effect and twinning in a rolled magnesium alloy under free-end torsion. Scr. Mater. 2013, 69, 319–322. [Google Scholar] [CrossRef]

- Toth, L.S.; Biswas, S.; Gu, C.; Beausir, B. Notes on representing grain size distributions obtained by electron backscatter diffraction. Mater. Charact. 2013, 84, 67–71. [Google Scholar] [CrossRef]

- Britton, T.B.; Birosca, S.; Preuss, M.; Wilkinson, A.J. Electron backscatter diffraction study of dislocation content of a macrozone in hot-rolled Ti-6Al-4V alloy. Scr. Mater. 2010, 62, 639–642. [Google Scholar] [CrossRef]

- Celotto, S. Tem study of continuous precipitation in Mg-9 Wt%Al-1 Wt%Zn alloy. Acta Mater. 2000, 48, 1775–1787. [Google Scholar] [CrossRef]

- Guo, N.; Luan, B.; Liu, Q. Influence of pre-torsion deformation on microstructures and properties of cold drawing pearlitic steel wires. Mater. Des. 2013, 50, 285–292. [Google Scholar] [CrossRef]

- Kabirian, F.; Khan, A.S.; Gnäupel-Herlod, T. Visco-plastic modeling of mechanical responses and texture evolution in extruded AZ31 magnesium alloy for various loading conditions. Int. J. Plast. 2015, 68, 1–20. [Google Scholar] [CrossRef]

- Beausir, B.; Tóth, L.S.; Neale, K.W. Ideal orientations and persistence characteristics of hexagonal close packed crystals in simple shear. Acta Mater. 2007, 55, 2695–2705. [Google Scholar] [CrossRef]

- Biswas, S.; Beausir, B.; Toth, L.S.; Suwas, S. Evolution of texture and microstructure during hot torsion of a magnesium alloy. Acta Mater. 2013, 61, 5263–5277. [Google Scholar] [CrossRef]

- Braszczyńska-Malik, K.N. Discontinuous and continuous precipitation in magnesium-aluminium type alloys. J. Alloys Compd. 2009, 477, 870–876. [Google Scholar] [CrossRef]

- Pan, H.; Huang, Q.; Qin, G.; Fu, H.; Xu, M.; Ren, Y.; She, J.; Song, B.; Li, B. Activations of stacking faults in the calcium-containing magnesium alloys under compression. J. Alloys Compd. 2017, 692, 898–902. [Google Scholar] [CrossRef]

- Zhang, D.; Zheng, B.; Zhou, Y.; Mahajan, S.; Lavernia, E.J. Prism stacking faults observed contiguous to a {10-12} twin in a Mg-Y alloy. Scr. Mater. 2014, 76, 61–64. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, X.; Shu, Y.; Tan, L.; Liu, Q. Two types of basal stacking faults within {10-12} twin in deformed magnesium alloy. Mater. Lett. 2016, 185, 355–358. [Google Scholar] [CrossRef]

- Park, S.H.; Hong, S.-G.; Lee, C.S. In-plane anisotropic deformation behavior of rolled Mg-3Al-1Zn alloy by initial {10-12} twins. Mater. Sci. Eng. A 2013, 570, 149–163. [Google Scholar] [CrossRef]

- Yin, D.L.; Wang, J.T.; Liu, J.Q.; Zhao, X. On tension-compression yield asymmetry in an extruded Mg-3Al-1Zn alloy. J. Alloys Compds. 2009, 478, 789–795. [Google Scholar] [CrossRef]

- Barnett, M.R.; Keshavarz, Z.; Beer, A.G.; Atwell, D. Influence of grain size on the compressive deformation of wrought Mg-3Al-1Zn. Acta Mater. 2004, 52, 5093–5103. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Lu, K. Making strong nanomaterials ductile with gradients. Science 2014, 345, 1455–1456. [Google Scholar] [CrossRef] [PubMed]

- Lu, K. Gradient nanostructured materials. Acta Metall. Sin. 2015, 51, 1–10. [Google Scholar]

| Samples | Processing History |

|---|---|

| SS | As-solution extruded rod |

| SA | Direct aging |

| ST | Torsion deformation |

| STA | Torsion deformation and then aging |

| Samples | SA | STA-Center | STA-Edge |

|---|---|---|---|

| f-DP | 0.48 | 0.34 | 0.11 |

| f-CP | 0.52 | 0.66 | 0.89 |

| Samples | Loading Conditions | YS (MPa) | PS (MPa) | UE (%) | CYS/TYS |

|---|---|---|---|---|---|

| SS | Ten. | 231 | 358 | 7.9 | 0.63 |

| Comp. | 146 | 433 | 14.1 | ||

| ST | Ten. | 220 | 372 | 7.6 | 0.80 |

| Comp. | 175 | 411 | 16.6 | ||

| SA | Ten. | 264 | 446 | 6.4 | 0.86 |

| Comp. | 226 | 502 | 10.6 | ||

| STA | Ten. | 263 | 427 | 6.0 | 0.99 |

| Comp. | 261 | 500 | 9.7 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, B.; Wang, C.; Guo, N.; Pan, H.; Xin, R. Improving Tensile and Compressive Properties of an Extruded AZ91 Rod by the Combined Use of Torsion Deformation and Aging Treatment. Materials 2017, 10, 280. https://doi.org/10.3390/ma10030280

Song B, Wang C, Guo N, Pan H, Xin R. Improving Tensile and Compressive Properties of an Extruded AZ91 Rod by the Combined Use of Torsion Deformation and Aging Treatment. Materials. 2017; 10(3):280. https://doi.org/10.3390/ma10030280

Chicago/Turabian StyleSong, Bo, Chunpeng Wang, Ning Guo, Hucheng Pan, and Renlong Xin. 2017. "Improving Tensile and Compressive Properties of an Extruded AZ91 Rod by the Combined Use of Torsion Deformation and Aging Treatment" Materials 10, no. 3: 280. https://doi.org/10.3390/ma10030280