2. Results and Discussion

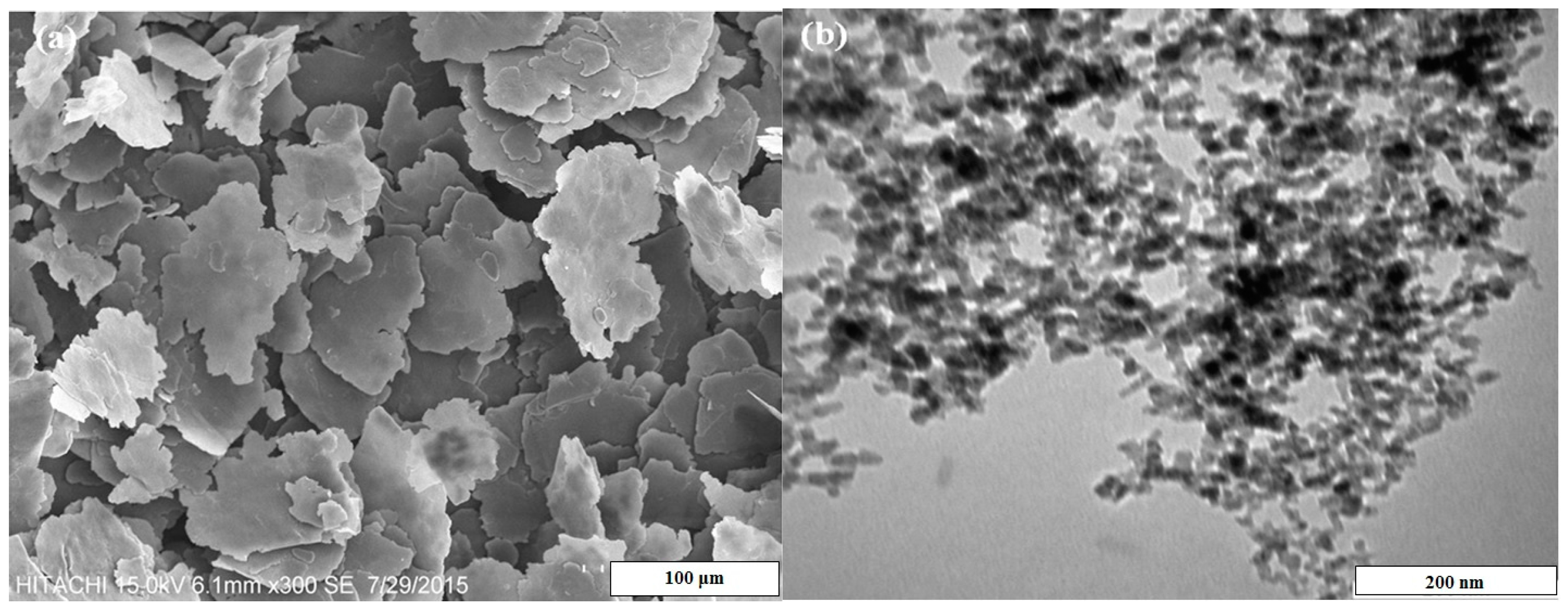

It is well known that milling processes yield a significant change in the morphology of composite powders as a result of severe plastic deformation of the particles within the milling process [

1,

12]. Upon milling of Al-5Al

2O

3 nanocomposite powders, aluminum particles are welded and fractured until reaching a steady state where equiaxed particles are formed in the presence of Al

2O

3 nanoparticles. The morphology of Al-5Al

2O

3 nanocomposite powders at the beginning and the end of milling time is shown in

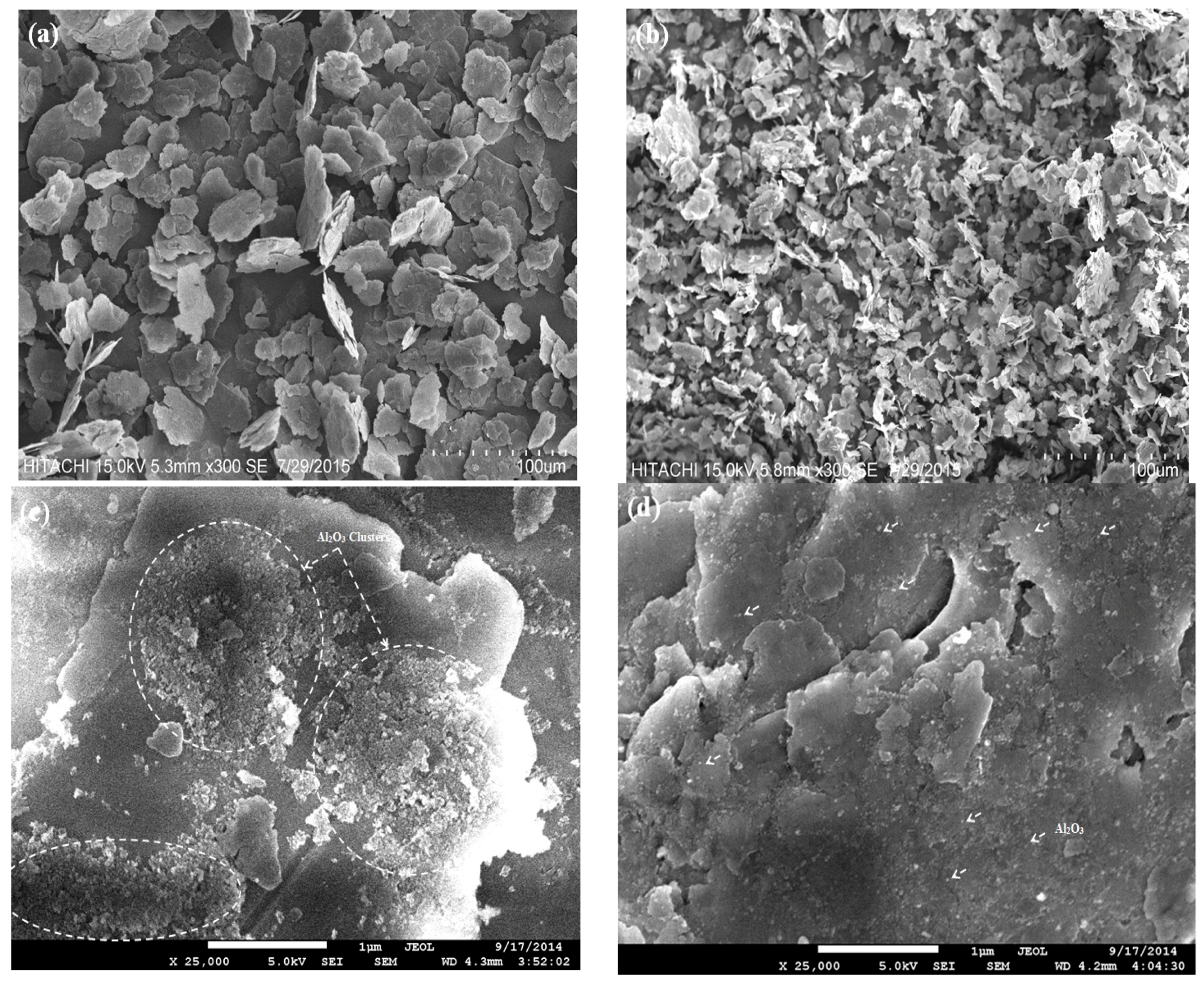

Figure 1.

A short milling time of 0.5 h was found to have no significant effect on the morphology of powders except partial deformation of aluminum particles. At this stage, aluminum particles have kept their initial shape wherein the extreme clustering of Al

2O

3 nanoparticles could be observed.

Figure 1c illustrates the presence of large amounts of Al

2O

3 clusters on the surface of aluminum particles as pointed out inside

Figure 1c. As the milling time increased up to 2 h, cold welding of particles was activated and ductile aluminum particles started to flatten due to the high impact collision of the balls. The lamination of particles of soft aluminum was observed in some areas.

Figure 1a shows that flake-shaped particles having large particle size are formed at this stage under deformation and cold welding of the particles. At the early stage of milling, up to 2, Al

2O

3 nanoparticles can rarely reside within the flattened aluminum particles and Al

2O

3 nanoparticle clusters are observed, but they are smaller and fewer in number than in powders milled for 0.5 h. Certainly, such microstructures have undesirable effects on mechanical properties. Flattening of the Al particles provides more sites for Al

2O

3 dispersion, which facilitates the uniform distribution of Al

2O

3 within the Al matrix.

The particles’ deformation was found to be more pronounced at longer milling times and a considerable change in morphology of nanocomposite powders was observable after 2 h of milling. Excessive work hardening and an increment of brittleness of soft aluminum powders activate the fracture mechanism; particles are fractured until reaching a steady state. Fracturing of work-hardened and brittle aluminum powders results in the formation of irregular-shaped powders and particles with smaller particle sizes until 8 h of milling. The progressive decrease in the particle size to Al

2O

3 particles encourage Al

2O

3 particles to be dispersed and embedded into the ductile aluminum particles more homogenously due to intense and repeated collision between the balls and the work-hardened powder. In fact, the finer matrix powder sizes, the more uniform the dispersion [

13].

When the powder mixture reaches a steady state after 8 h, the particles’ morphology stabilizes and particles are in an equiaxed shape and certain size, which are randomly oriented as shown in

Figure 1b. It is anticipated that in the steady state, the milling time is sufficient that no considerable change in the morphology of the powders is observable. At the steady state stage, Al

2O

3 nanoparticles are uniformly dispersed and the distance between Al

2O

3 nanoparticles is reduced; representing a tight bonding of the matrix and reinforcement at the steady state (

Figure 1d). It can be inferred that the steady state can be achieved with the attainment of a full homogeneity of Al

2O

3 nanoparticles throughout the Al matrix [

14]. A low amount of the Al

2O

3 nanoparticles can be observed because the remaining Al

2O

3 nanoparticles are embedded in the Al particles after reaching the steady state. At longer milling times, up to 12 h, the steady state is still predominated and milling has no considerable effect on the morphology of the powders, however, grain refinement is expected. The similar finding was found for Al-1 wt % Al

2O

3 in the authors’ previous study [

1]. However, the deformation of the particles is more prominent in this study revealing the efficiency of the milling process in the presence of a larger content of Al

2O

3 nanoparticles. Alizadeh and Mirzaei Aliabadi [

12] also reported a large Al

2O

3 content, and the contribution of the fracture mechanism increases and leads to a decrease in the particle size of the composite powder even with low milling time.

As can be observed in

Figure 1c,d, Al

2O

3 nanoparticles which appear in large clusters (as highlighted in the

Figure 1c) start to disperse within pure aluminum particles with a better homogeneity and smaller interparticle space by increasing the milling time.

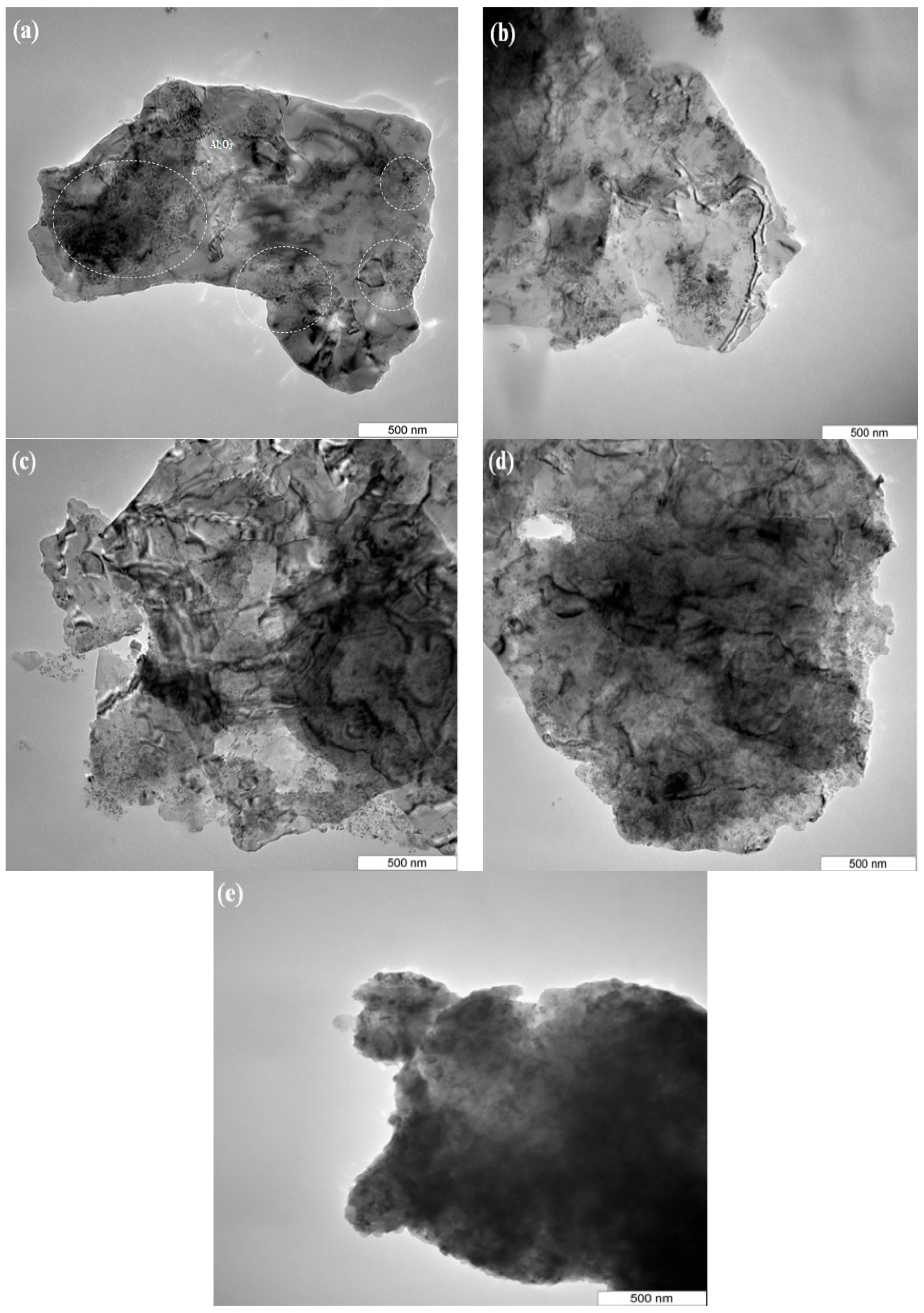

Figure 2 shows the dispersion uniformity of Al

2O

3 nanoparticles within the Al matrix particles more precisely at different milling times.

The dispersion of Al

2O

3 nanoparticles within the aluminum matrix increases by increasing the milling time until a well-homogenous dispersion is obtained at the steady state after 8 h of milling. A short milling time of 0.5 h has no noticeable effect on the dispersion of 5 wt % Al

2O

3 nanoparticles within the Al matrix. It can be seen that Al

2O

3 nanoparticles are heterogeneously dispersed on the surfaces of Al particles. Al

2O

3 nanoparticles appear in a clusters and most of the Al surface areas are not fully covered (

Figure 2a). These independent clusters of Al

2O

3 nanoparticles, as shown by circles, are effectively broken up and start to disperse with better homogeneity throughout the Al matrix by increasing the milling time to 8 h. Although some clusters of Al

2O

3 particles can still be observed in some areas, they are smaller as compared with the short milling time. A homogeneous dispersion of Al

2O

3 nanoparticles throughout microstructure is observed after 8 h of milling (

Figure 2d). It also seems that 8 h of milling is sufficient to disperse 5 wt % of Al

2O

3 nanoparticles within the aluminum matrix (

Figure 2d). Milling times longer than 8 h results in no considerable changes in the dispersion of Al

2O

3 nanoparticles at the steady state.

Figure 2e shows the adhesion of Al

2O

3 nanoparticles to the surface of aluminum particles after 12 h of milling, representing a good bonding between Al

2O

3 nanoparticles and aluminum particles. Ostovan et al. [

8] also reported the homogenous dispersion of Al

2O

3 nanoparticles after 8 h of milling in the case of 1 wt % Al

2O

3. In fact, as milling proceeds, clusters of Al

2O

3 nanoparticle disappear, Al

2O

3 nanoparticles disappear throughout the matrix, and the distances between particles reduces [

3,

7,

8,

12,

13,

14].

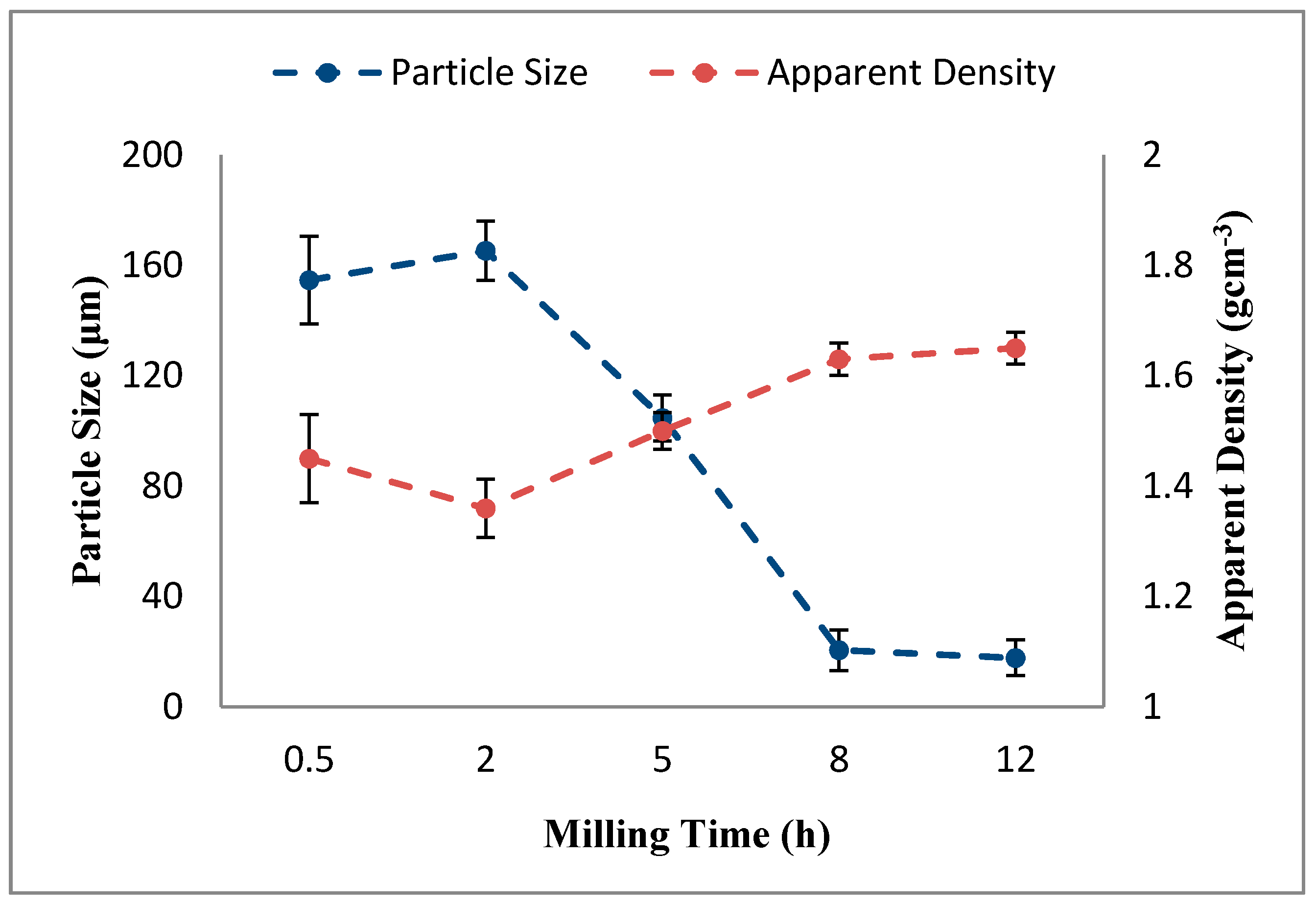

The variation of particle size and apparent density of Al-5Al

2O

3 nanocomposite powders as a function of the milling time is shown in

Figure 3. The average particle size Al-5Al

2O

3 nanocomposite powders increases in the first 2 h of milling and reaches a maximum of 165.3 (

μm due to the predominance of cold welding. Cold welding, along with work-hardening of aluminum particles, leads to the formation of large particles with increased average particle size. This is similar to other composite systems as reported in the literature [

8,

13]. Razavi Tousi et al. [

14] reported a continuous decrease in particle size of Al-Al

2O

3 composites in the presence of the high volume fraction of Al

2O

3 (20 vol %) where 20 vol % Al

2O

3 prevents cold welding from occurring. After 2 h of milling, the average particle size progressively decreases, representing the onset of the fracture mechanism, until 8 h of when steady state is reached. Fracturing of work-hardened and brittle aluminum powders results in the reduction of the average particle size of aluminum particles. At the steady state stage, a balance between cold welding and fracturing is achieved whereby the particle size is kept almost constant. Although the variation of average particle size in the steady state is not significant, it decreases from 20.58 (

μm to the lowest value of 17.82 (

μm at the end of ball milling. The results are in appropriate accordance with the morphology of the mixtures during milling where three different stages of the milling process could be identified.

Dissimilar to the variation of particle size, the apparent density of Al-5Al

2O

3 nanocomposite powders initially decreases at an early stage of milling, up to 2 h, then increases as the milling time increases, as shown in

Figure 3. At early stages of milling, up to 2 h, the apparent density decreases due to the formation of large flake-shaped particles as a result of the cold welding of particles to a minimum of 1.36 (

g·cm

−3. The apparent density of Al-5Al

2O

3 nanocomposite powders start to improve progressively after 2 h of milling, as ascribed by the fracturing of large particles and the formation of small, irregular shapes. The apparent density of Al-5Al

2O

3 nanocomposite powders vary in consistency with the variation in the morphology of Al particles, which varies from large flake-shaped particles at early stages of milling to more or less quasi-spherical particles having small particle sizes. Generally, flake-shaped particles indicate the worst packing properties of the powders, while spherical powders show better packing properties due to the relatively good mobility of particles and a lower tendency to form bridges [

11,

15,

16]. Beyond 8 h of milling, in the steady state, formation of equiaxed particles improves the apparent density slightly to a maximum of 1.65 (

g·cm

−3. The slight variation in apparent density in the steady state is attributed to the slight variation in the particle size of powders.

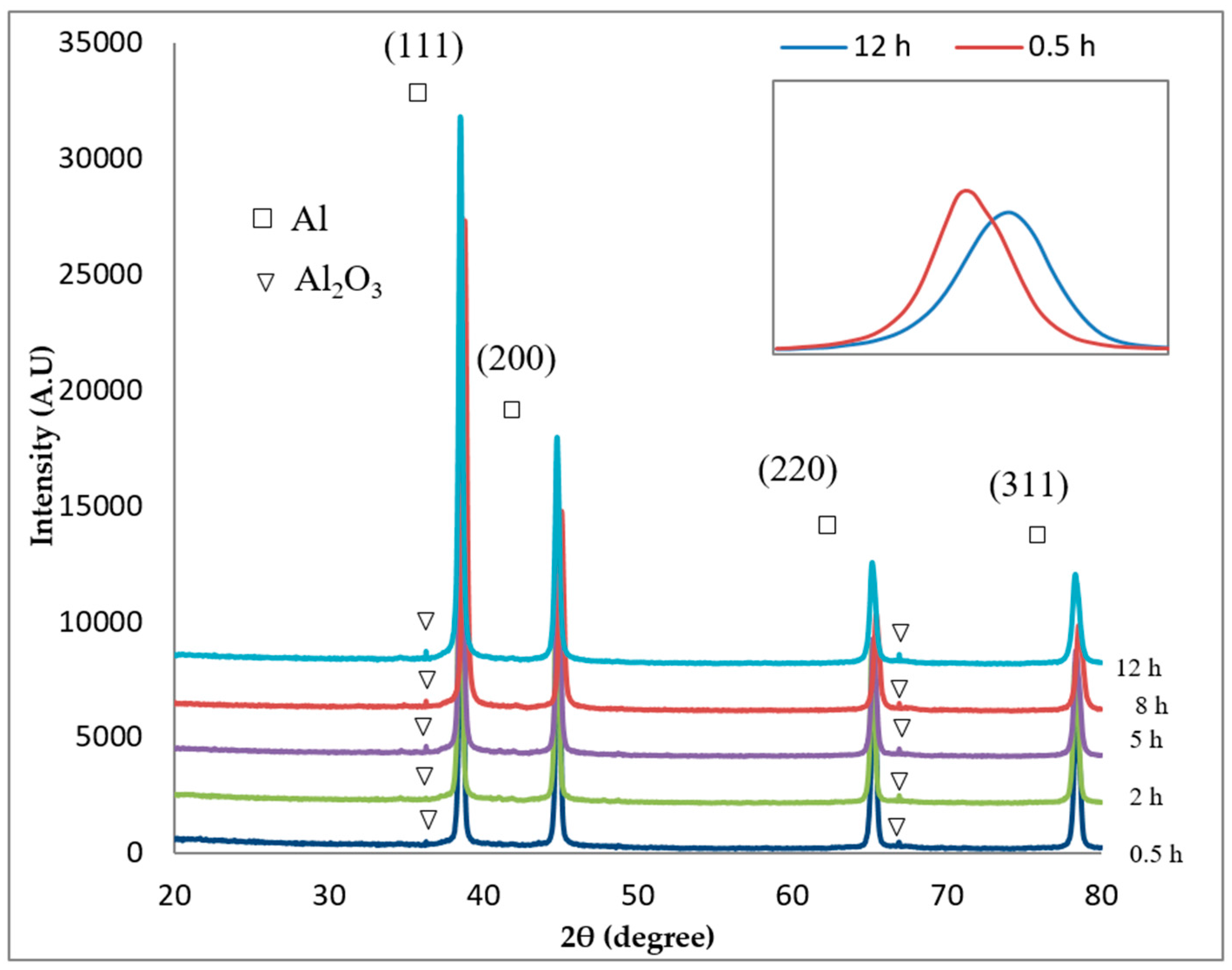

Figure 4 presents the X-ray diffraction patterns of Al-5Al

2O

3 nanocomposite powders ball milled for various times. There are four sharp detected diffraction peaks corresponding to the FCC structure of aluminum along with small Al

2O

3 peaks in XRD diffraction patterns of nanocomposite powders. The fewer Al

2O

3 peaks and their lower intensity in the diffraction pattern might be due to the low content of the Al

2O

3 phase and/or the fine size of the powder in the Al-5Al

2O

3 powder mixture [

9,

17]. Additionally, neither the presence of unwanted phases nor the impurity phases, such as Si, Fe, and Al

4C

3, was revealed in the XRD diffraction pattern. The results are inconsistent with previous findings by Zebarjad et al. [

15] and Prabhu et al. [

9]. The absence of impurities or unwanted phases indicates a clean interface between particles and the matrix. According to the literature, Al

2O

3 is so stable that no unwanted solid-state reaction occurs during the milling of aluminum and Al

2O

3 [

18].

An increase in the milling time, up to 12 h, results in a definite shift in the position of the related peaks. An enlarged view of the shift position of the first peak corresponding to the crystalline plane of (111) of aluminum is shown in the right corner of

Figure 4. The shift in the position of peaks may be due to the dissolution of minor alloying elements, impurities, and reinforcement particles in the lattice of the aluminum matrix during milling [

16,

18]. As is also shown in the right corner of

Figure 4, the intensity of the first peak (111) in Al-5Al

2O

3 is decreased and its width broadened. By proceeding the milling time up to 12 h, peak intensities reduce and relative peaks become slightly broadened at the full-width at half-maximum (FWHM). In fact, the higher weight fraction of Al

2O

3 nanoparticles leads to higher peak intensities and the finer particle size results in the broadening of the peaks and lower peak intensities (smaller peak height) [

9].

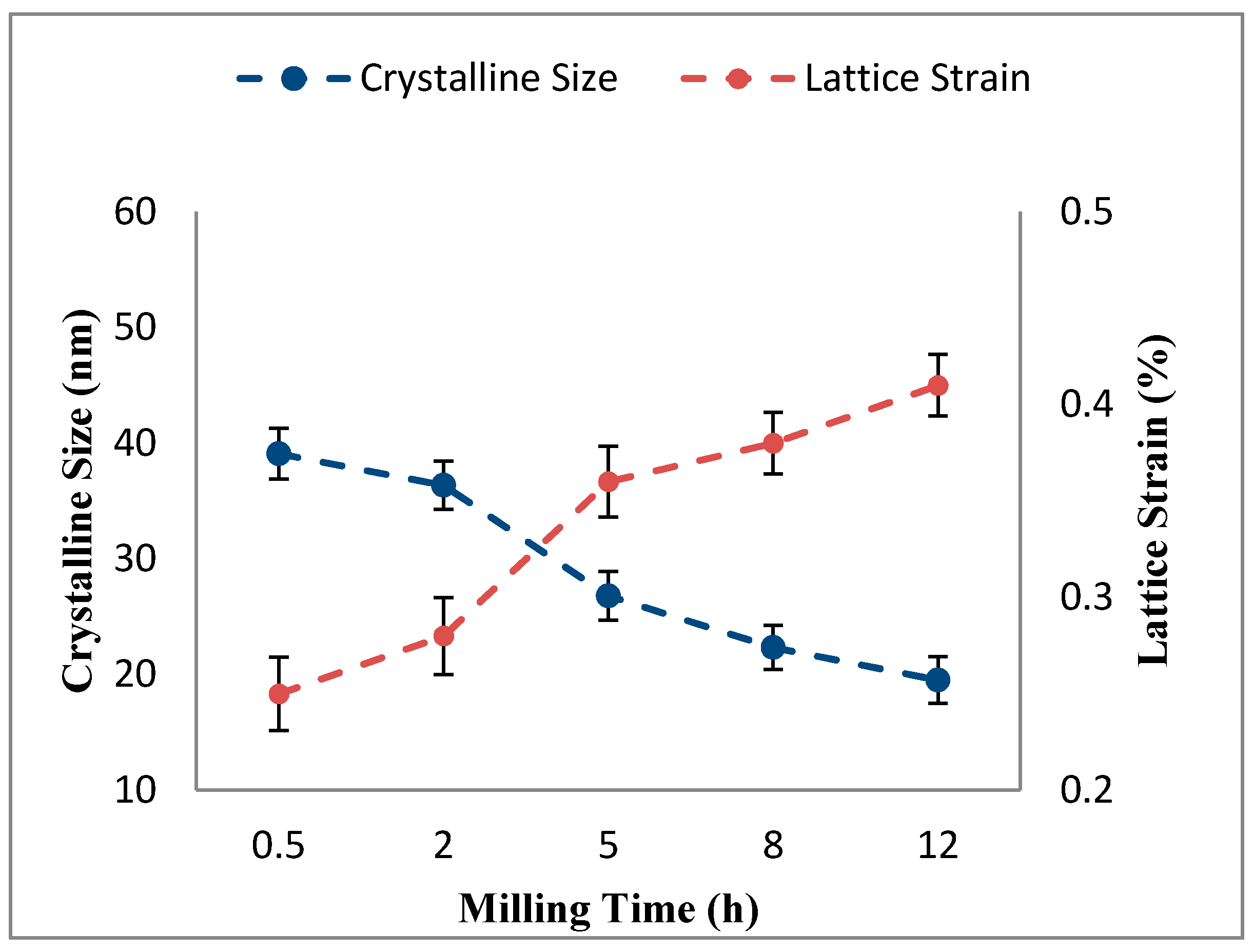

Peak broadening of the ball-milled Al-5Al

2O

3 powders is corresponding to the crystalline size (or grain size) refinement and enhancement of lattice strain [

2]. The Williamson-Hall method was used to analyse the relative peaks in order to relate the broadening in the XRD patterns to the crystalline size (

d) and lattice strain (

of Al-5Al

2O

3 nanocomposite powder mixtures. As shown in

Figure 5, the crystalline size of aluminum particles generally decreases as the milling time increases, while lattice strain increases. The crystalline size of aluminum particles powders decreases from 39.10

nm at 0.5 h to 19.53

nm at 12 h of milling, while the lattice strain increases from 0.0026 (

to 0.0048 (

at the end of the milling process.

The significant variations in the crystalline size (or grain size) and in the lattice strain of aluminum particles is attributed to severe plastic deformation and grain size refinement occuring in the presence of Al

2O

3 nanoparticles within the milling process [

19,

20]. The main contribution to the decrement of crystalline size is the generation of dislocations as a result of local plastic deformation and accelerated work hardening of Al

2O

3 powders [

14,

21,

22]. The interaction between hard and non-deformable Al

2O

3 nanoparticles and dislocations accelerates the grain-refining mechanism [

16]. In the presence of Al

2O

3 nanoparticles, the Orowan bowing mechanism results in dislocation multiplication, as reported by Razavi Hesabi et al. [

16]. By increasing the milling time, the dislocations are rearranged to a lower energy state and the low angle sub-boundaries are formed. The severe plastic deformation and generation of more dislocations at longer milling times leads to the increased misorientations between subgrains at their boundaries. Finally, low angle sub-boundaries turn into high angle boundaries and become grains with nano-scale sizes [

17]. On the other hand, the interaction of Al

2O

3 nanoparticles with dislocations hinders the movement of dislocations resulting in an increase in dislocation density and an accumulation of stresses in the aluminum lattice. In addition, the distortion of the lattice structure and formation of other lattice defects, like vacancies and impurities within the milling process, results in the accumulation of internal stress in the aluminum lattice. Therefore, lattice strain gradually increases by increasing the milling time [

14,

23]. Ahmad et al. [

18] have also reported the increase in the lattice strain as a result of less dissolution of alloying elements and reinforcement in the matrix at longer milling times.

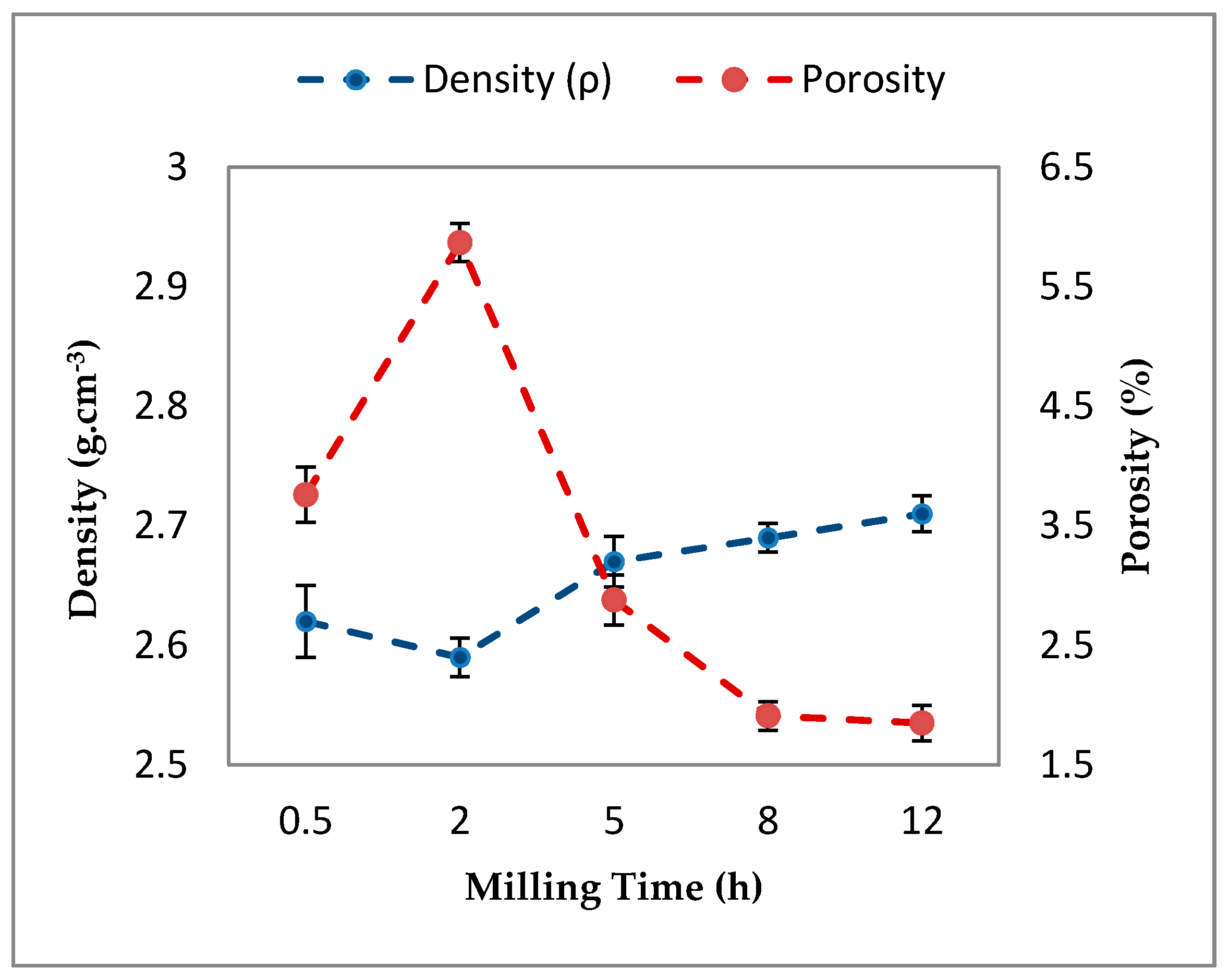

Figure 6 presents experimental density and porosity of sintered Al-5Al

2O

3 nanocomposites with respect to milling time. The theoretical density of Al-5Al

2O

3 was also calculated according to the rule of mixtures and found to be 2.743 g·cm

−3. The small increase of the theoretical density is due to the fact that the density of Al

2O

3 particles (3.95 g·cm

−3) is slightly higher than that of aluminum (2.7 g·cm

−3). It can be seen that the experimental density (

ρ) increases from 2.62 (

to 2.71 (

g·cm

−3 by increasing milling time from 0.5 h to 12 h. Although, there is a slight drop in the density values after 2 h of milling, as shown in

Figure 6.

As a matter of fact, the sintered density is dependent on the morphology of the powders after milling, size, and distribution of the nano-reinforcement within the matrix, as well as compaction and sintering parameters [

24]. Lower density at early stages of milling is due to the presence of aluminum agglomeration and Al

2O

3 clusters in the microstructure. Agglomeration and clustering of Al

2O

3 nanoparticles act as barriers that slow down the diffusion process which is needed for the sintering process. The increment of density is attributed to the better dispersion of Al

2O

3 nanoparticles within the matrix at longer milling times. At longer milling times, Al

2O

3 nanoparticles are dispersed homogeneously (

Figure 2d,e), which accelerates the diffusion rate during sintering, as reported by [

25]. These uniformly-dispersed Al

2O

3 particles are embedded in the grain boundaries and surfaces of aluminum particles and hinder the grain growth by a pinning mechanism, resulting in an increase in the density. On the other hand, more grain refining, which is showed as a reduction of the particle size resulting from longer milling time, further increases the diffusion rate.

It can also be noticed that the values of experimental densities are lower than that of the theoretical densities indicating the presence of some amount of porosity in nanocomposite specimens, as shown in

Figure 7. The amount of porosity in the sintered bulk Al-5Al

2O

3 nanocomposites is found to decrease significantly from 3.76% (

at 0.5 h to 1.85% (

at 12 h. As a well-known fact, porosity is an inevitable part of powder metallurgy (PM) product which is inversely proportional to density. At early stages of milling, nanocomposite specimens contain larger amounts of residual porosity as a result of clustered Al

2O

3 areas, which are the sites where cracks and porosities are formed, as reported by Zebarjad et al. [

26].

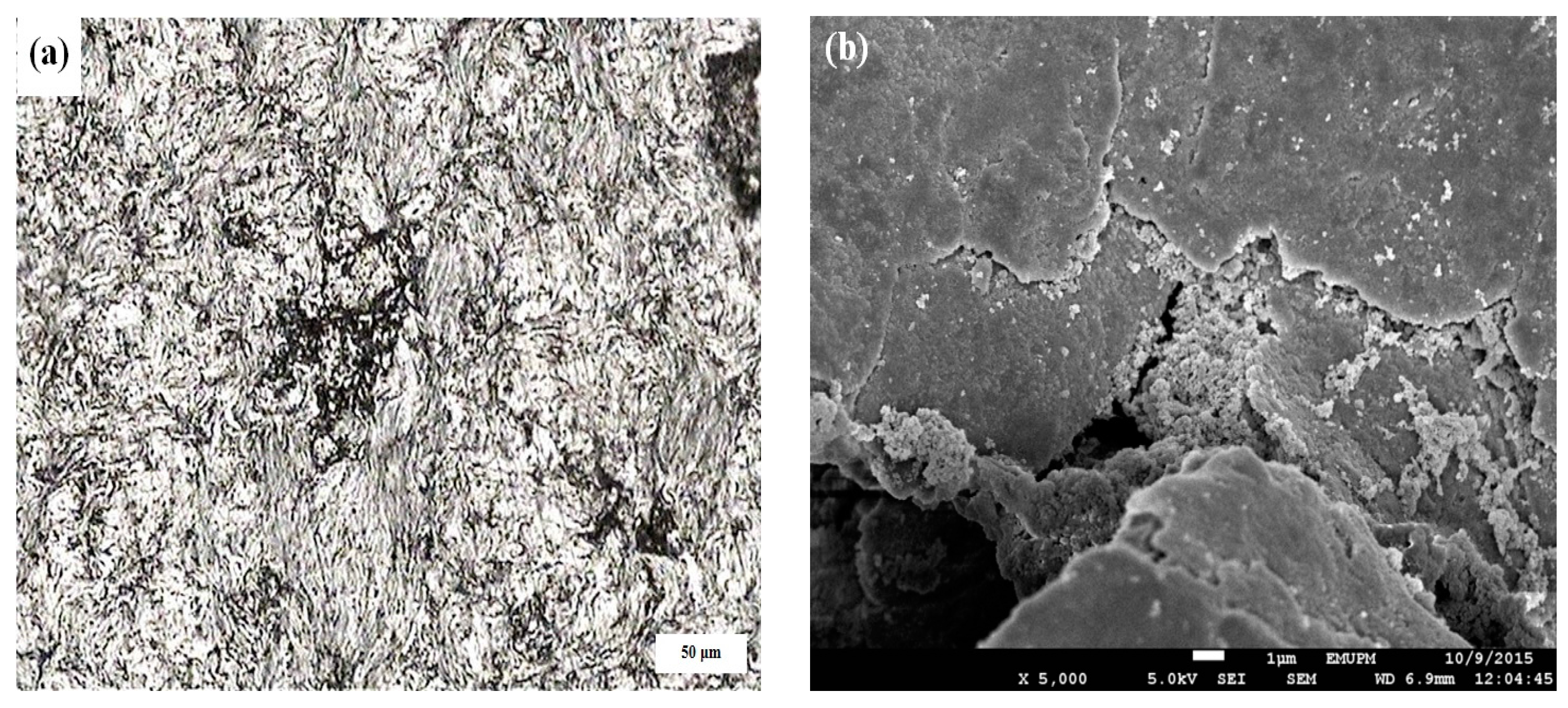

Figure 7 shows the optical and FESEM micrographs of Al-5Al

2O

3 milled for 2 h, indicating the presence of porosities and voids formed on the polished surface of the composite. It can be seen that Al

2O

3 nanoparticles accumulate in the void formed on the surface of the nanocomposite (

Figure 7b).

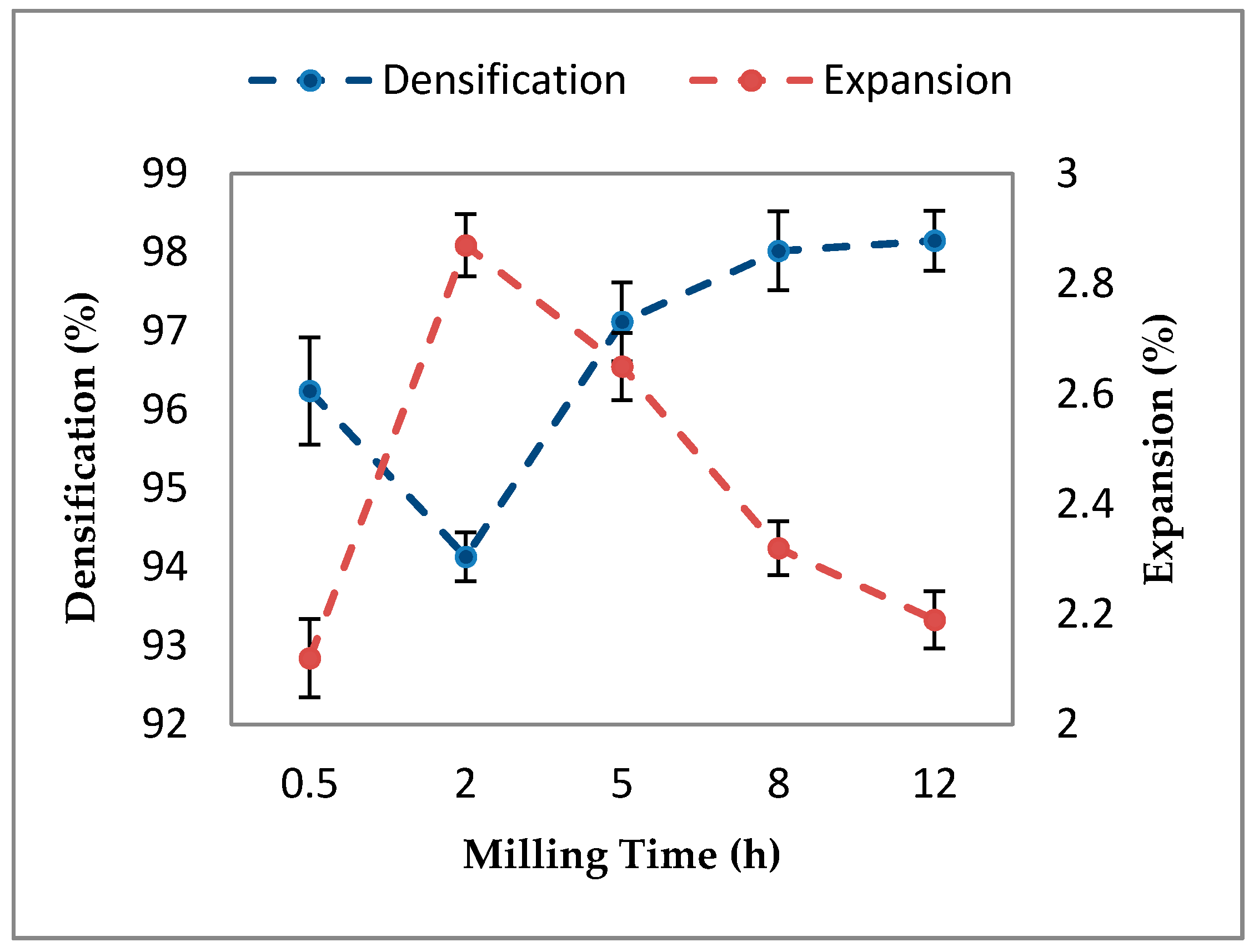

In addition, the densification mechanism shows a similar trend, as observed in the density. Densification decreases in the first 2 h of milling, reaching a minimum of 94.13%, and then increasing to 98.15% at 12 h of milling. The densification curve of the Al-5Al

2O

3 nanocomposite (

Figure 8) is similar to the apparent density curve (

Figure 3) which corresponds to the powder morphology and particle size variations.

As discussed earlier, at early stage of milling up 2 h, nanocomposite powders showing the worst packing properties due to formation of large flake-shape particles as a result of the cold welding of particles. Cold-welded and work-hardened powders decrease the pressing capacity of the specimens. The nanocomposites containing large particles cannot reach the full density. In contrast, particles with small sizes are easily densified rather than large particles under the same compaction conditions. Additionally, heterogeneous dispersion of Al2O3 nanoparticles and the formation of clustered regions at this stage lead to the lack of bonding between Al2O3 clusters and aluminum at the surface of the sintered composites. These microstructural features lead to higher plastic strain in clustered region and favors the formation of voids and cracks, and consequently-reduced mechanical properties. Uniform distribution of Al2O3 nanoparticles within the aluminum matrix at longer milling time and shorter distance between nanoparticles provide tighter bonding between Al2O3 nanoparticles and matrix, which results in the denser sintered composite. Conversely, as the bonding of particles is increased, the amount of porosities is decreased, so that a more dense part is obtained.

The variation of physical dimensional changes (or expansion) of Al-5Al

2O

3 nanocomposite specimens is shown in

Figure 8. It can also be seen that dimensional expansion increases in the early stage of milling, up to 2 h. Nanocomposites milled for 2 h show the maximum expansion due to the cold welding of particles. At early stages of milling, the presence of cold-welded (work-hardened) particles and clustered Al

2O

3 areas hinder the diffusion of aluminum particles to form tighter bonds, resulting in greater expansion (grain growth) of specimens and a poor densification process [

14]. As milling time proceeds, dimensional expansion decreases, indicating less grain growth during the sintering process as milling time increases (

Figure 8). The dispersion homogeneity of Al

2O

3 nanoparticles increases by increasing the milling time and a better bonding of particles can be obtained resulting in less dimensional expansion of nanocomposite specimens during the sintering process. According to Mills [

27], dimensional changes of composites are highly dependent to the compaction pressure, time and temperature of sintering, physical properties of the initial powder and the homogeneity of the reinforcement powder.

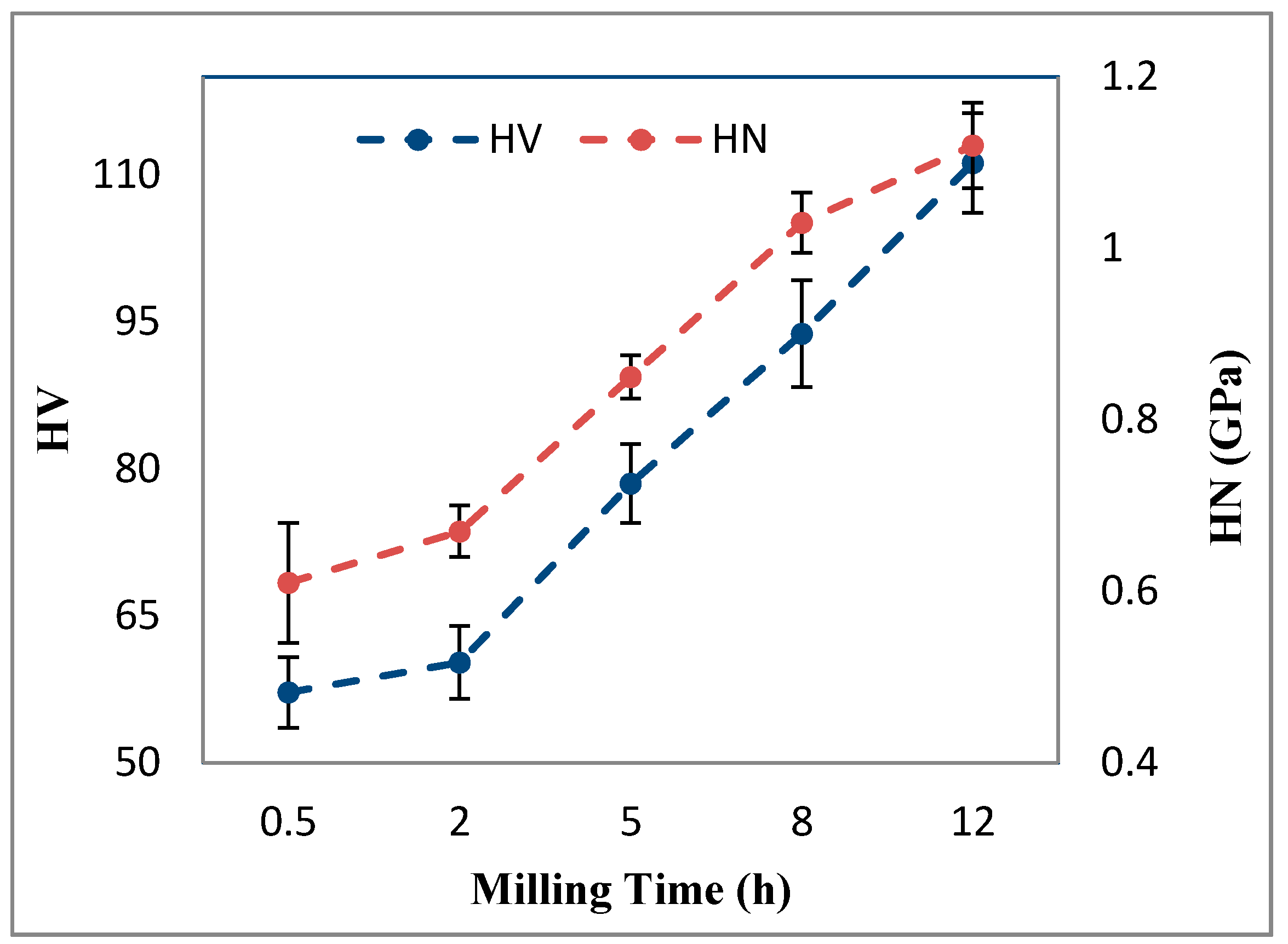

The variation of micro-hardness (

HV) and nano-hardness (

HN) of Al-5Al

2O

3 nanocomposites as a function of milling time is presented in

Figure 9. It is seen that as milling time proceeds,

HV values of Al-5Al

2O

3 nanocomposite specimens increase. However, it can be noticed that the improvement of hardness at early stages of milling, up to 2 h, is not significant, whereas it is more profound at longer milling times.

HV values were found to increase sharply, as it is the expected trend, from 60.25 (

HV after 2 h of milling to a maximum value of 111.20 (

HV at the end of milling, corresponding to an improvement of about 46%. Similarly,

HN values of nanocomposite specimens increases by increasing the milling time. The enhancement of

HN values in the milling time longer than 2 h is also noticeable. Al-5Al

2O

3 nanocomposites milled for 12 h showed

HN of about twice (1.12 GPa) that of the

HN of nanocomposites milled for 0.5 h (0.61 GPa), indicating the profound effect of the milling process in the improvement of the mechanical behaviour. The results are in agreement with previous studies where hardness of Al-5Al

2O

3 nanocomposite increases by increasing milling process [

17,

26,

28,

29].

In both micro- and nano-hardness measurements, the increment f

HV and

HN values of milled Al-5Al

2O

3 nanocomposites is attributed to the presence of Al

2O

3 nanoparticle reinforcements and microstructural variation within milling process of Al-5Al

2O

3 nanocomposite as also reported by Zebarjad et al. [

26] and Mazilkin et al. [

28]. Recall that, at early stages of milling, up to 2 h, cold welding of particles is predominated and hardening is expected because of work-hardening of particles while milling. Within the milling process of Al-5Al

2O

3 nanocomposites, severe local deformation of Al particles in the vicinity of Al

2O

3 nanoparticles result in the cold-working and grain-refining of Al particles which consequently increases the hardness of the powders. In addition, at this stage, Al

2O

3 nanoparticles are heterogeneously dispersed and mostly clustered, wherein the distance between composite particles is large (

Figure 1a and

Figure 2a), resulting in poor sintering. During sintering processes, Al

2O

3 nanoparticle clusters interrupt the diffusion bonding of particles, resulting in large amounts of residual porosity in bulk nanocomposites and, consequently, poor consolidation. Then, this microstructural state contributes to the lower hardness of nanocomposites due to poor sintering in the presence of Al

2O

3 clusters.

After 2 h of milling, both

HV and

HN values increase when dispersion of Al

2O

3 nanoparticles becomes more homogeneous and significant grain size refining occurs. Enhancement of the homogeneous dispersion of Al

2O

3 nanoparticles by increasing the milling time decreases the distance between nanocomposite particles so that further sintering processes will result in better bonding and, consequently, enhanced strength properties. Homogeneity of Al

2O

3 nanoparticles in the sintered composites has been directly related to the homogeneity of nanoparticles before sintering [

1,

26,

29]. These small Al

2O

3 nanoparticlesm which have a short distance from each other, act like a barrier; thus, grain growth will be postponed in milled nanocomposite specimens [

15]. By increasing the milling time, the average particle size of aluminum particles profoundly decreases, which results in a significant increase in the hardness of the matrix particles. The Al

2O

3 nanoparticles, by pinning the grain boundaries, can also hinder the grain growth mechanism and improve the strengthening mechanism. Moreover, the pure Al-5Al

2O

3 nanocomposites are comprehensively strengthened by the generation of high-density dislocations and the formation of fine sub-grains within the milling process, as mentioned earlier. At longer milling times, severe particle deformation, however, yields a homogeneous dispersion of Al

2O

3 nanoparticles within the Al matrix, but introduces strain hardening to the matrix particles through the generation of a large amount of high-density dislocations [

28,

29]. In fact, dispersed Al

2O

3 nanoparticles inhibit dislocation movement resulting in the generation of a large amount of high-density dislocations around the particles. Grain refinement is accelerated when a high dislocation density is present in the microstructure, which contributes to formation of extensive fine sub-grains in the matrix. Then, grain refinement through sub-grain formation strengthens the nanocomposites [

29,

30,

31]. Different orientations of adjacent sub-grains and the high lattice disorder characteristic of the boundary regions hinder dislocation movement in a continuous slip plane and consequently harden the nanocomposites [

32].

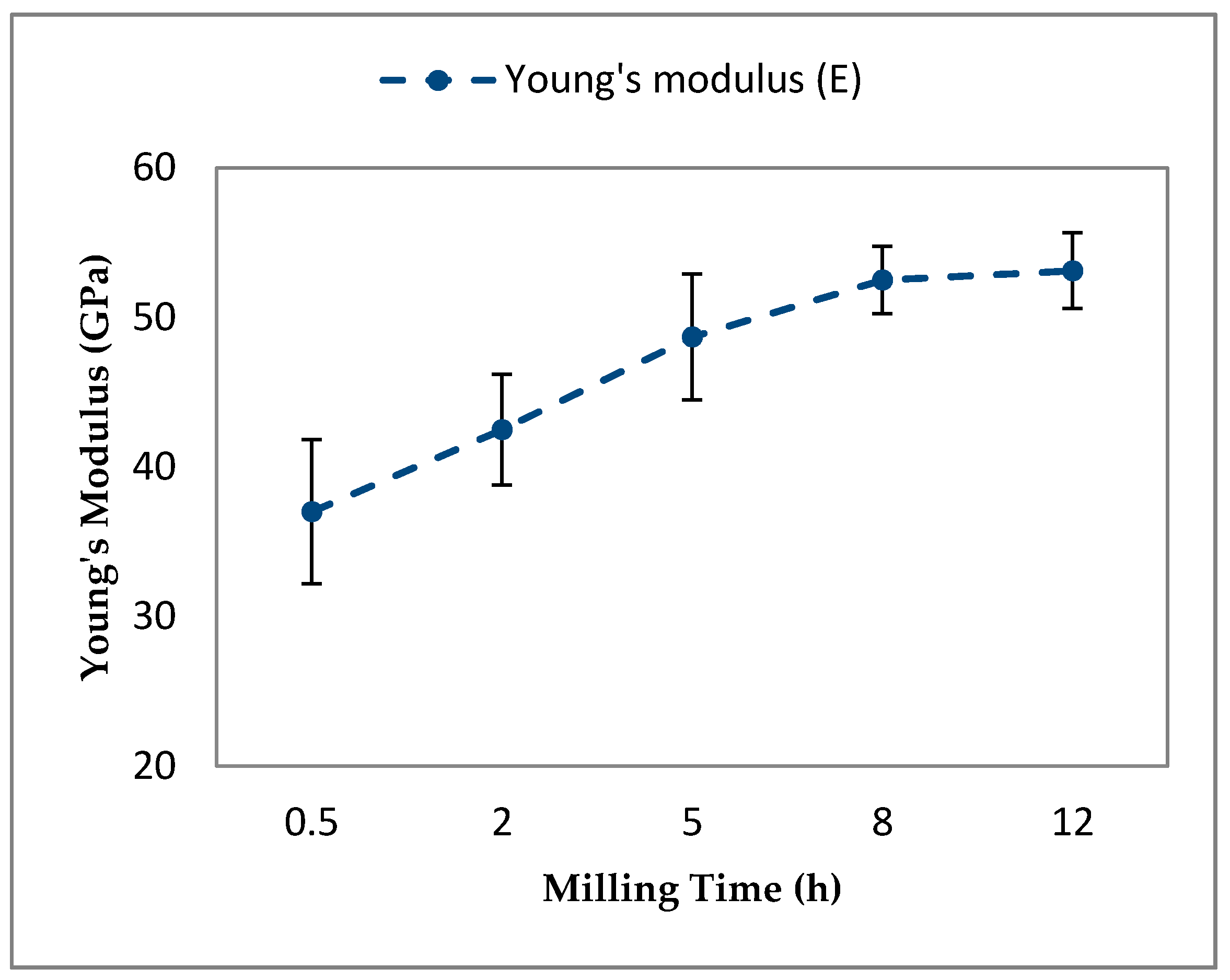

An upward trend in the variation of

E values of Al-5Al

2O

3 nanocomposites was also obtained by increasing the milling time up to 12 h (

Figure 10). Nanocomposites milled for a short milling time of 0.5 h have the lowest E values of 37.1 (

GPa. The

E values of nanocomposites increase linearly to 52.50 (

GPa after 8 h of milling at a steady state. The upward increasing trend of the Young’s modulus extends to the longer milling time of 12 h in the steady state stage where the maximum value of the Young’s modulus value of 53.12 (

GPa, representing an increase in

E values of about 28%.

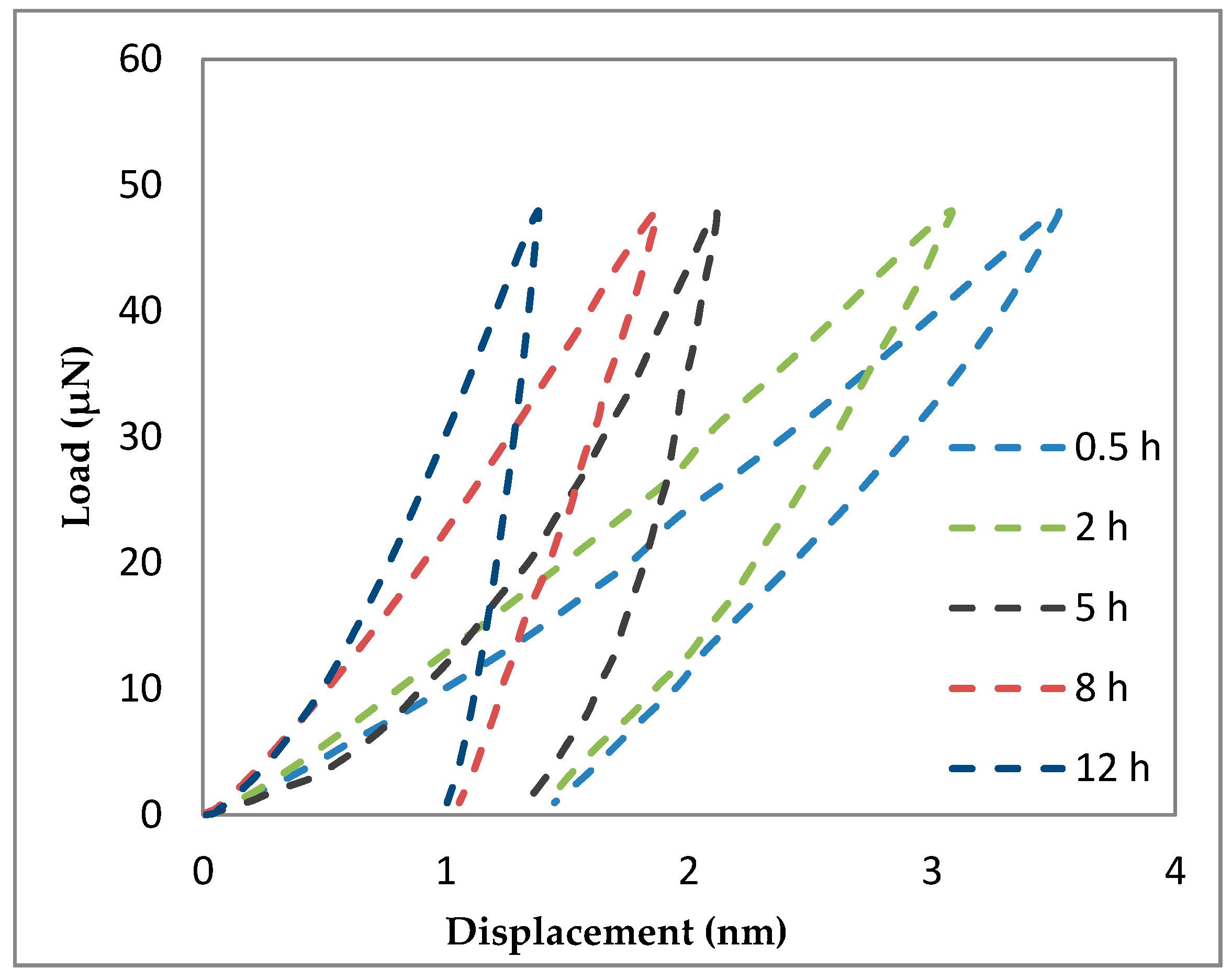

A representative load-displacement curve of Al-5Al

2O

3 with respect to milling time at a peak load of 100 μN is shown in

Figure 11. In nanoindentation measurement, elastic modulus is a function of the slope of the unloading curve. It can be seen that nanocomposites milled for the shortest time of 0.5 h shows the highest displacement, attributed to the lowest Young’s modulus. Conversely, nanocomposites milled for the longest milling time of 12 h shows the lowest displacement, indicating the maximum Young’s modulus under the same indentation conditions. The lower displacement or lower indention depth in nanoindentation measurements represents the strengthening of the matrix in the presence of Al

2O

3 nanoparticles [

33]. Then, the load-displacement curve of Al-5Al

2O

3 shifts toward the left and lower displacements by increasing the milling time due to strengthening of the matrix.

Similar to HV and HN, the variation of the Young’s modulus is attributed to the state of dispersion of Al2O3 nanoparticles and the grain refinement of particles within the milling process. At shorter milling times, heterogeneous dispersion and clustering of Al2O3 nanoparticles and larger particle sizes of particles contributes to the lower Young’s modulus of Al-5Al2O3 nanocomposites. By increasing the milling time, the Young’s modulus of Al-5Al2O3 nanocomposites increases, owing to a more homogenous dispersion of Al2O3 nanoparticles and along with the grain refining of aluminum particles.

As a matter of fact, the Young’s modulus, or resistivity of material to being elastically deformed, of powder metallurgy is significantly affected by the amount of porosity and cracks present in the sintered compacts. The presence of porosities and cracks in the sintered compacts noticeably lowers the Young’s modulus of MMCs [

9,

34]. Heterogeneous dispersion and clustering of Al

2O

3 nanoparticles result in the formation of more porosity and cracks after the sintering process. Resultant residual porosities cause stress concentrations and unexpected fractures, thus, lowering the strength. In contrast, homogeneous dispersion Al

2O

3 nanoparticles provide a better bonding of particles during the sintering process. The homogeneously-dispersed Al

2O

3 nanoparticles and very short distances between Al

2O

3 nanoparticles prevent crack extension and their interconnection and reduce stress concentration, therefore, enhancing the strength properties of the nanocomposites.

Finally, it should be mentioned that there are some mechanisms which may simultaneously be activated that enhance the strength properties of the Al-5Al2O3 nanocomposites like other MMCs. These mechanisms are include Orowon strengthening as a result of the uniform dispersion of Al2O3 particles, solid solution hardening, work hardening as a result of the strain misfit between the reinforcement and matrix particles, grain and substructure strengthening following the classical Hall-Petch relationship, quench hardening due to the dislocations generated to accommodate the differential thermal contraction between reinforcement and matrix particles, and thermal mismatch.