Nanocomposites for Machining Tools

Abstract

:1. Introduction

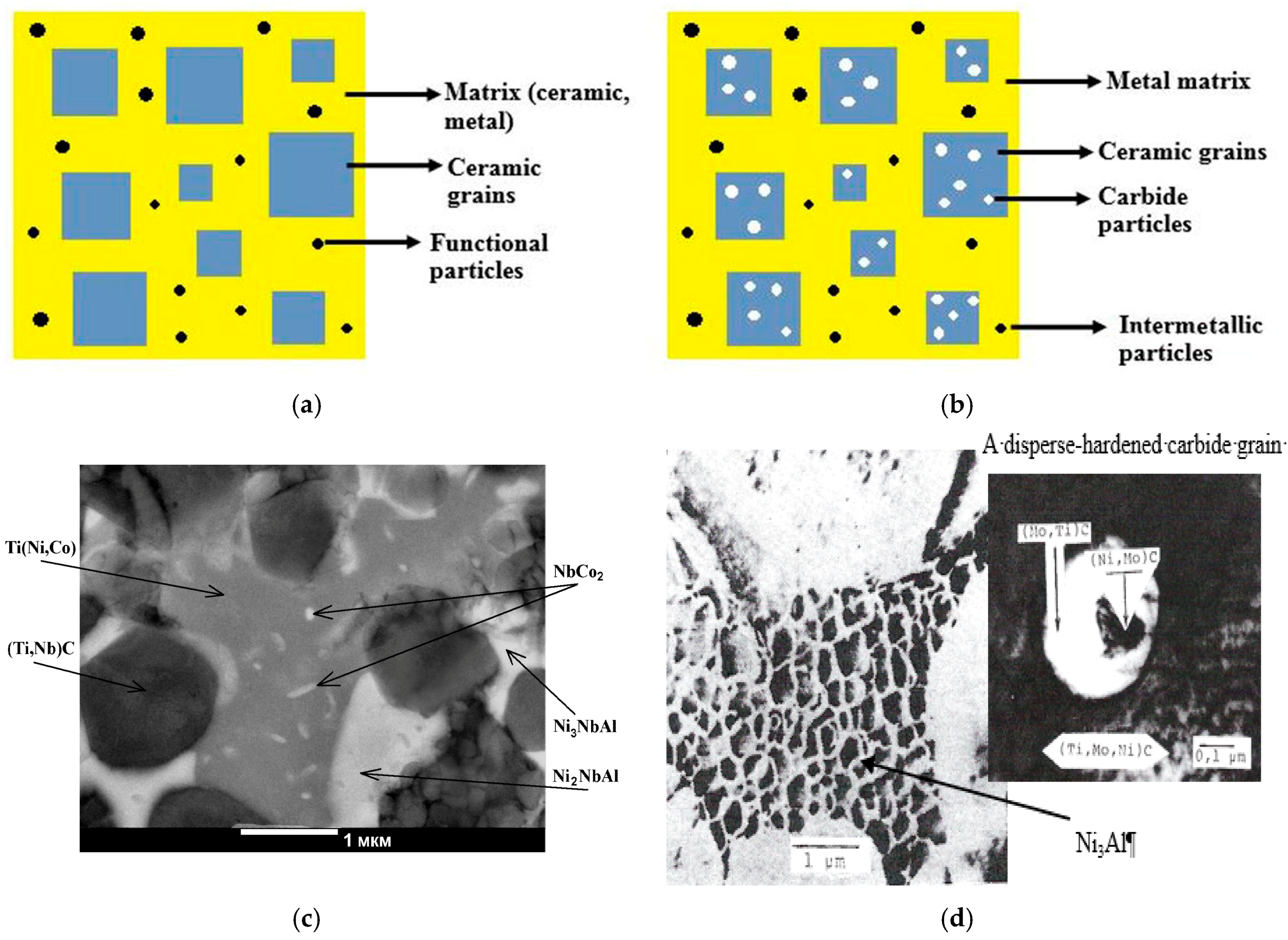

2. Nanocomposites in Machining Tools

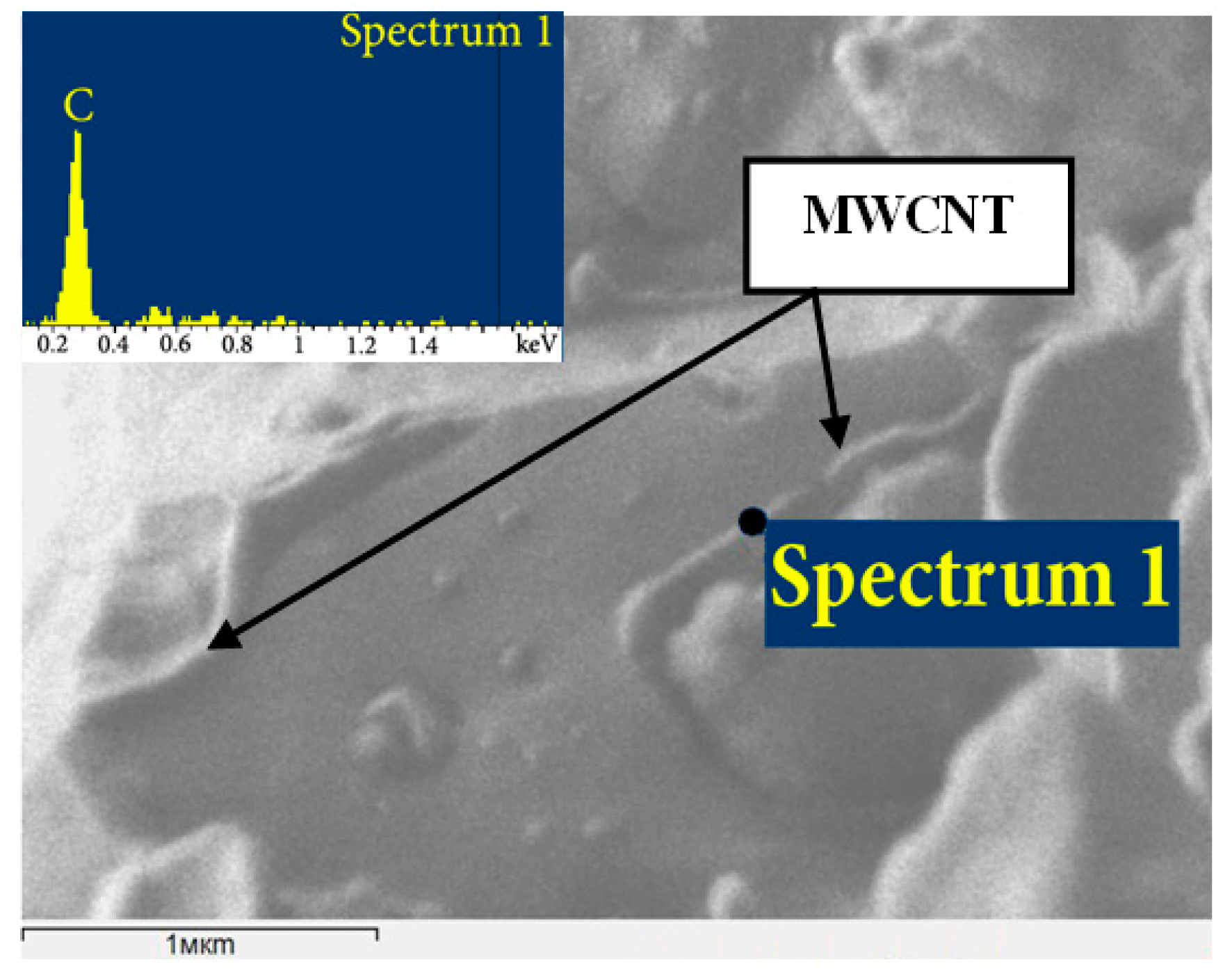

3. Carbon Nanotube-Doped Nanocomposites for Machining

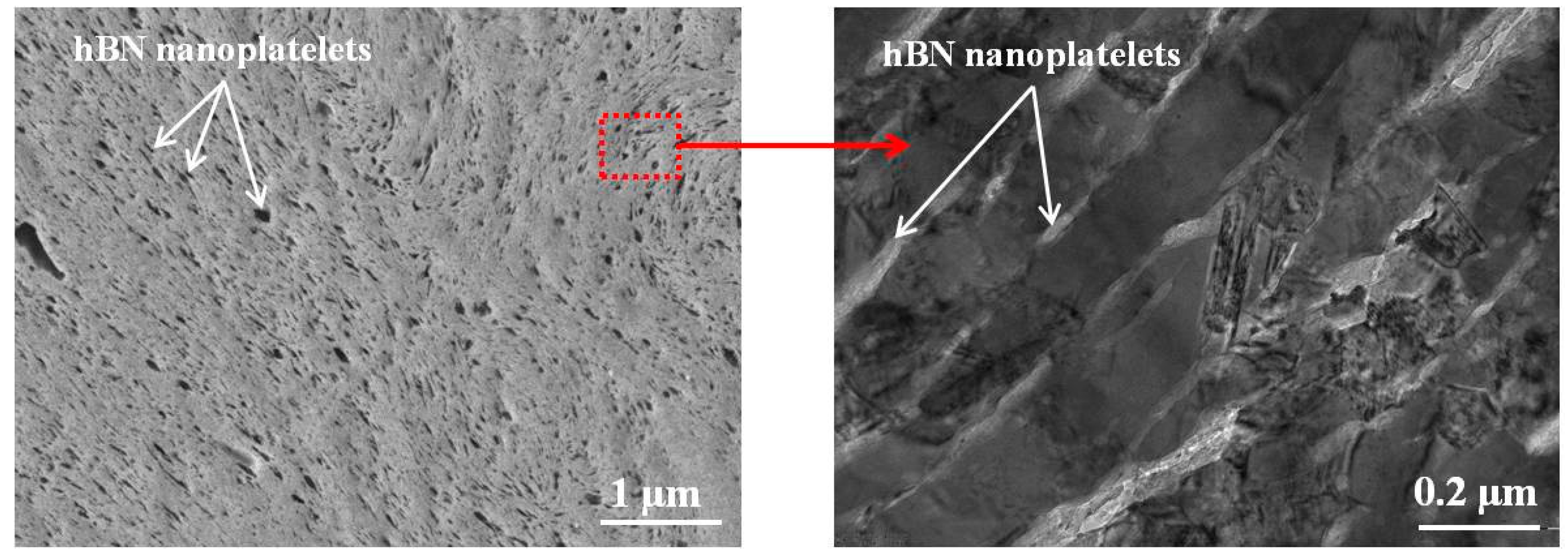

4. hBN-Doped Nanocomposites for Machining

5. A Micromechanical Model of the Reinforced Metallic Matrix

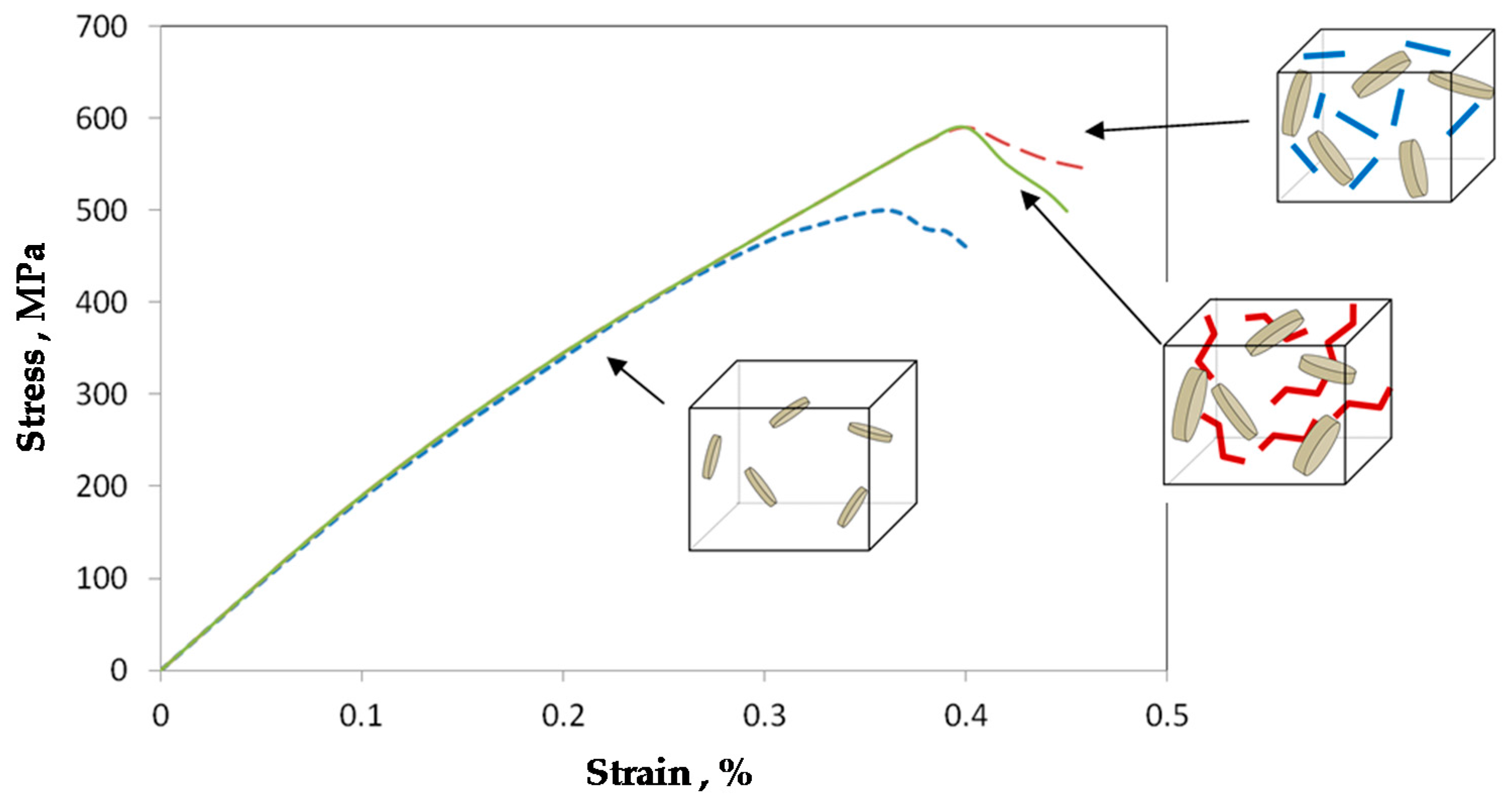

5.1. Metallic Fe–Cu Binder Reinforced with CNT Particles

5.2. Effect of MWCNT Reinforcement on the Mechanical Properties of the Binder and Tool Wear

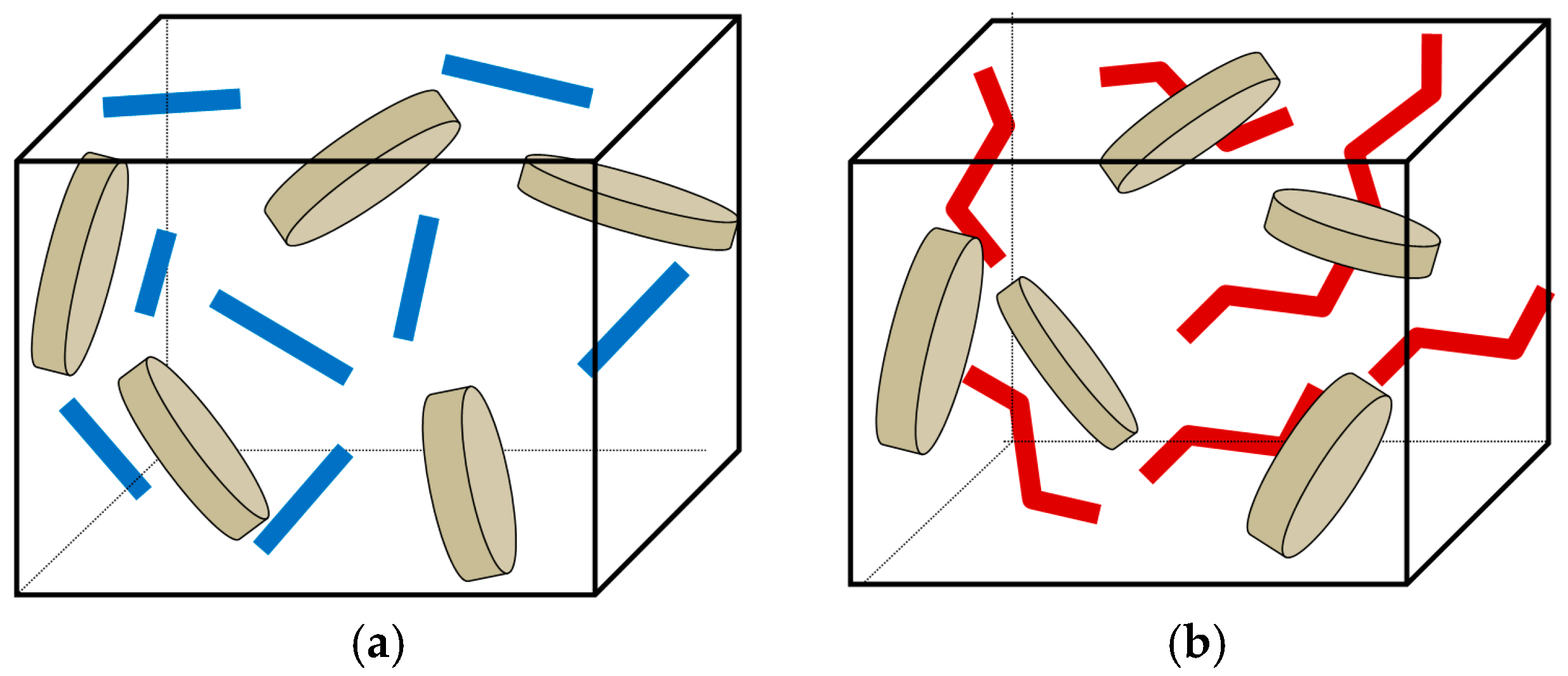

5.3. 3D-Modelling of Real CNT Shapes in Matrix

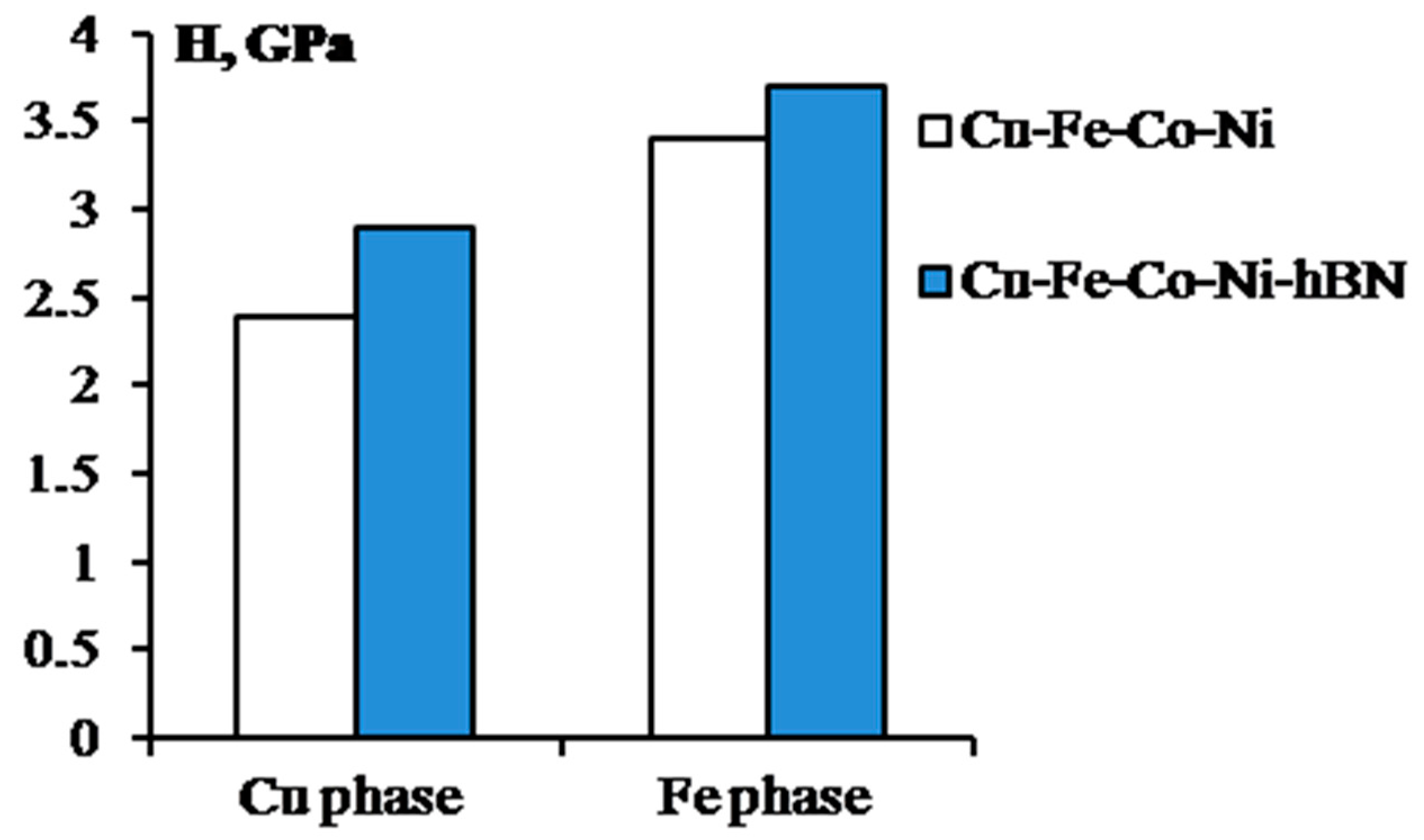

5.4. Metallic Binder Reinforced with hBN Particles

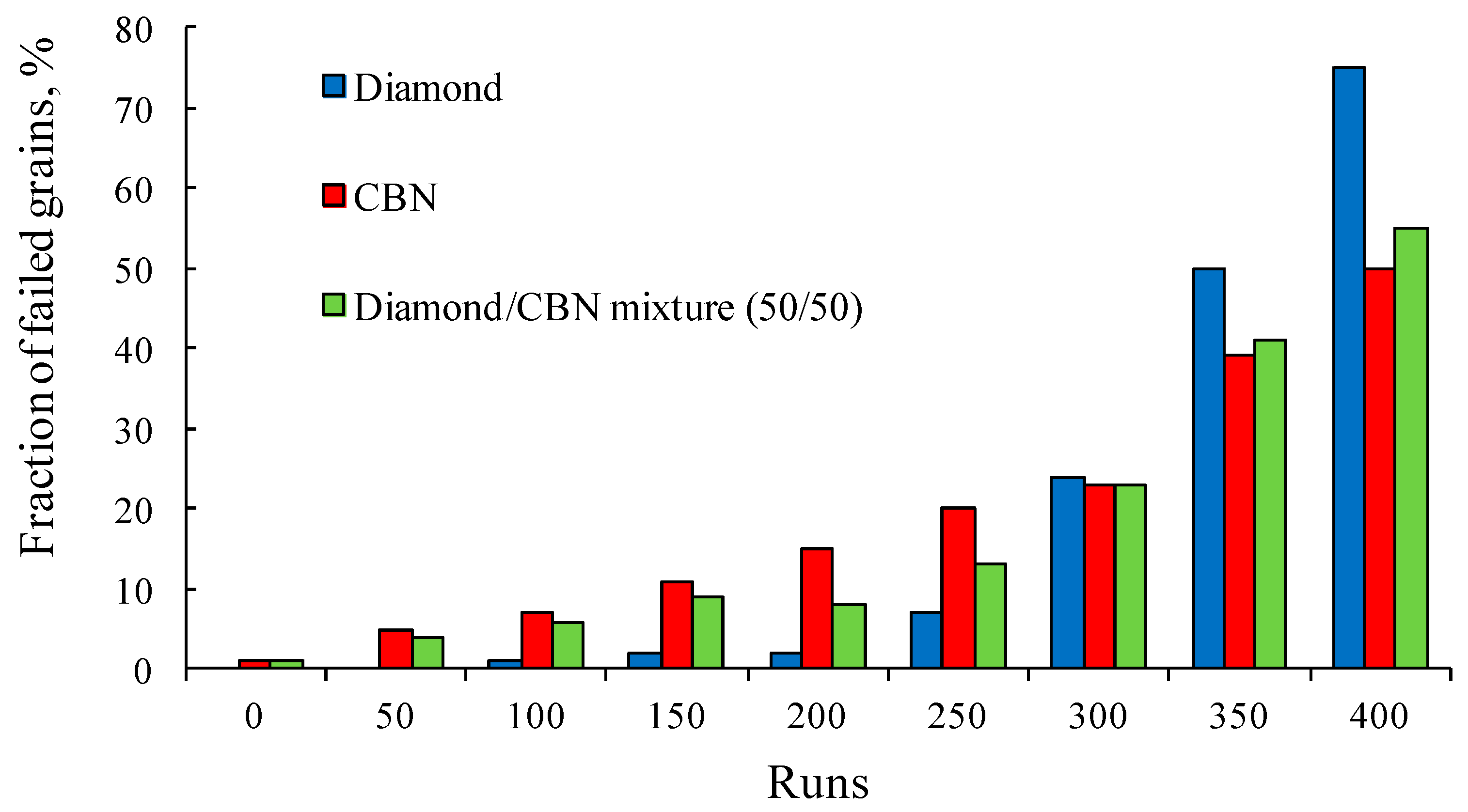

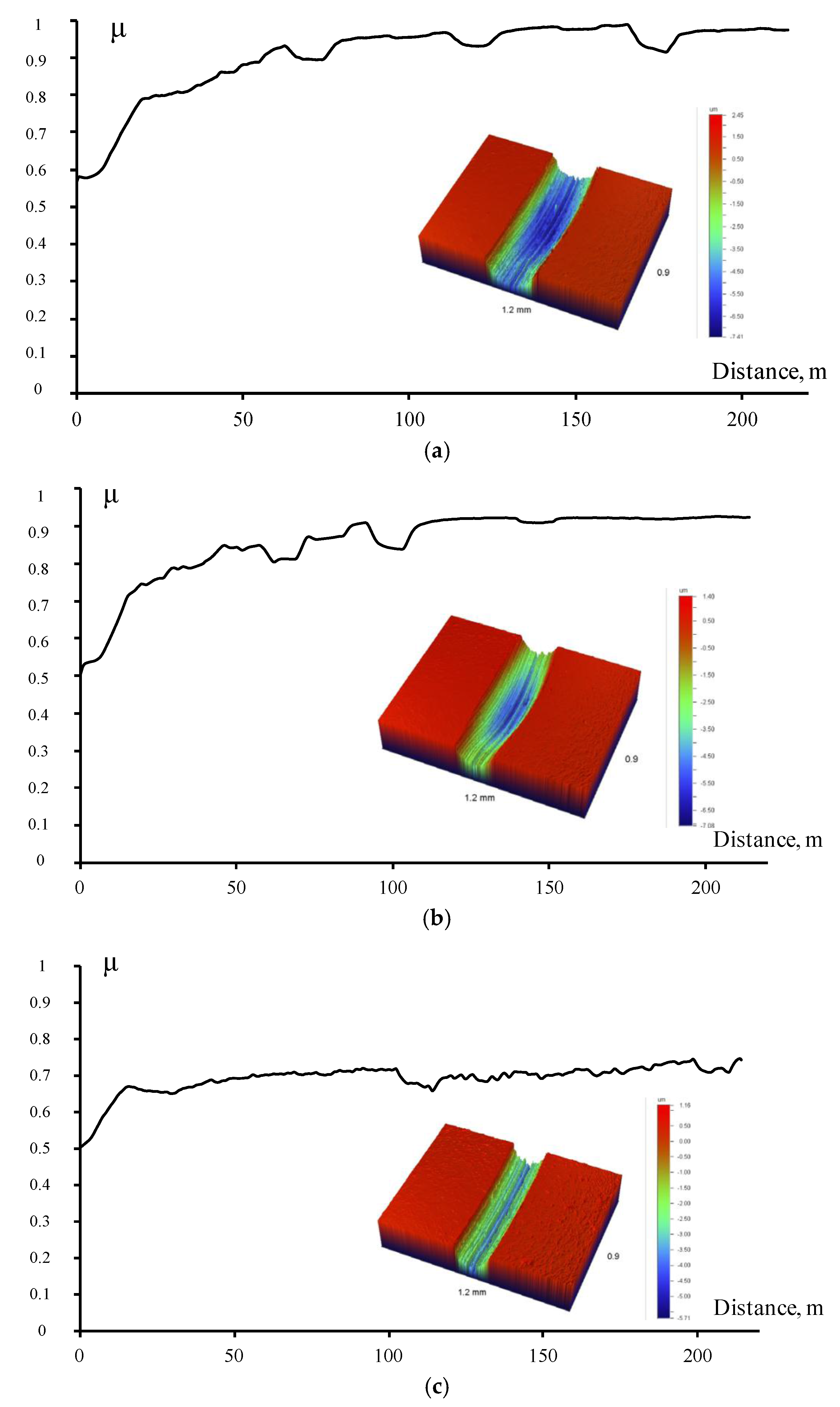

6. Wear-Resistance of CNT- and hBN-Containing Nanocomposites

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Saxena, P.K.; Sharma, A. Role of Machine Tools Industry in Economic Development. Int. J. Enhanc. Res. Sci. Technol. Eng. 2014, 3, 188–193. [Google Scholar]

- 2016 World Machine Tool Survey. 2016. Available online: https://www.gardnerweb.com/articles/2016-world-machine-tool-survey (accessed on 12 October 2017).

- Liang, S.Y.; Shih, A.J. Analysis of Machining and Machine Tools; Springer: New York, NY, USA, 2016; ISBN 978-1-4899-7645-1. [Google Scholar]

- Davim, J.P. Machining (Fundamentals and Recent Advances); Springer: London, UK, 2008; ISBN 978-1-84800-213-5. [Google Scholar]

- Shivakumar, N.; Vasu, V.; Narasaiah, N.; Kumar, S. Synthesis and Characterization of Nano-sized Al2O3 Particle Reinforced ZA-27 Metal Matrix Composites. Procedia Mater. Sci. 2015, 10, 159–167. [Google Scholar] [CrossRef]

- Shabani, M.O.; Mazahery, A. Artificial Intelligence in Numerical Modeling of Nano Sized Ceramic Particulates Reinforced Metal Matrix Composites. Appl. Math. Model. 2012, 36, 5455–5465. [Google Scholar] [CrossRef]

- Pandi, G.; Muthusamy, S. A Review on Machining and Tribological Behaviors of Aluminium Hybrid Composites. Procedia Eng. 2012, 38, 1399–1408. [Google Scholar] [CrossRef]

- Samuel Ratna Kumar, P.S.; Robinson Smart, D.S.; John Alexis, S. Corrosion Behaviour of Aluminium Metal Matrix Reinforced with Multi-wall Carbon Nanotube. J. Asian Ceram. Soc. 2017, 5, 71–75. [Google Scholar] [CrossRef]

- Singh, A.; Ram Prabhu, T.; Sanjay, A.R.; Koti, V. An Overview of Processing and Properties of Cu/CNT Nano Composites. Mater. Today 2017, 4, 3872–3881. [Google Scholar] [CrossRef]

- Ozsoy, I.B.; Li, G.; Choi, H.; Zhao, H. Shape Effects on Nanoparticle Engulfment for Metal Matrix Nanocomposites. J. Cryst. Growth 2015, 422, 62–68. [Google Scholar] [CrossRef]

- Lekka, M.; Koumoulis, D.; Kouloumbi, N.; Bonora, P.L. Mechanical and Anticorrosive Properties of Copper Matrix Micro- and Nano-Composite Coatings. Electrochim. Acta 2009, 54, 2540–2546. [Google Scholar] [CrossRef]

- Gül, H.; Kılıc, F.; Aslan, S.; Alp, A.; Akbulut, H. Characteristics of Electro-co-deposited Ni–Al2O3 Nano-particle Reinforced Metal Matrix Composite (MMC) Coatings. Wear 2009, 267, 976–990. [Google Scholar] [CrossRef]

- Anthony Xavior, M.; Ajith Kumar, J.P. Machinability of Hybrid Metal Matrix Composite—A Review. Procedia Eng. 2017, 174, 1110–1118. [Google Scholar] [CrossRef]

- Bodunrina, M.O.; Alaneme, K.K.; Chown, L.H. Aluminium Matrix Hybrid Composites: A Review of Reinforcement Philosophies; Mechanical, Corrosion and Tribological Characteristics. J. Mater. Res. Technol. 2015, 4, 434–445. [Google Scholar] [CrossRef]

- Zhai, W.; Srikanth, N.; Kong, L.B.; Zhou, K. Carbon Nanomaterials in Tribology. Carbon 2017, 119, 150–171. [Google Scholar] [CrossRef]

- Liu, D.G.; Sun, J.; Gui, Z.X.; Song, K.J.; Luo, L.M.; Wu, Y.C. Super-low Friction Nickel Based Carbon Nanotube Composite Coating Electro-Deposited from Eutectic Solvents. Diam. Relat. Mater. 2017, 74, 229–232. [Google Scholar] [CrossRef]

- Liu, D.; Hu, P.; Min, G. Interfacial Reaction in Cast WC Particulate Reinforced Titanium Metal Matrix Composites Coating Produced by Laser Processing. Opt. Laser Technol. 2015, 69, 180–186. [Google Scholar] [CrossRef]

- Verezub, O.; Kálazi, Z.; Sytcheva, A.; Kuzsella, L.; Buza, G.; Verezub, N.V.; Fedorov, A.; Kaptay, G. Performance of a Cutting Tool Made of Steel Matrix Surface Nano-composite Produced by in situ Laser Melt Injection Technology. J. Mater. Process. Technol. 2011, 211, 750–758. [Google Scholar] [CrossRef]

- Shen, M.J.; Wang, X.J.; Ying, T.; Wu, K.; Song, W.J. Characteristics and Mechanical Properties of Magnesium Matrix Composites Reinforced with micron/submicron/nano SiC Particles. J. Alloys Compd. 2016, 686, 831–840. [Google Scholar] [CrossRef]

- Kim, K.T.; Eckert, J.; Menzel, S.B.; Gemming, T.; Hong, S.H. Grain refinement Assisted Strengthening of Carbon Nanotube Reinforced Copper Matrix Nanocomposites. Appl. Phys. Lett. 2008, 92, 121901:1–121901:4. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, D. Consideration of Orowan Strengthening Effect in Particulate-reinforced Metal Matrix Nanocomposites: A Model for Predicting their Yield Strength. Scr. Mater. 2006, 54, 1321–1326. [Google Scholar] [CrossRef]

- George, R.; Kashyap, K.T.; Rahul, R.; Yamdagni, S. Strengthening in Carbon Nanotube/Aluminium (CNT/Al) Composites. Scr. Mater. 2005, 53, 1159–1163. [Google Scholar] [CrossRef]

- Roberts, G.; Krauss, G.; Kennedy, R. Tool Steels, 5th ed.; ASM International: Novelty, OH, USA, 1998; ISBN 978-0-87170-599-0. [Google Scholar]

- Godec, M.; Večko Pirtovšek, T.; Šetina Batič, B.; McGuiness, P.; Burja, J.; Podgornik, B. Surface and Bulk Carbide Transformations in High-Speed Steel. Sci. Rep. 2015, 5, 16202. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Zhang, D.; Yao, D.; Meng, X. TEM Study on the Vein-like Grain Boundary Structures in Nitrocarburized Cool-work Tool Steels and its Formation Mechanism. Surf. Coat. Technol. 2017, 324, 376–381. [Google Scholar] [CrossRef]

- Wang, S.S.; Chang, L.; Wang, L.; Wang, T.; Wu, Y.D.; Si, J.J.; Zhu, J.; Zhang, M.X.; Hui, X.D. Microstructural Stability and Short-term Creep Properties of 12Cr–W–Mo–Co steel. Mater. Sci. Eng. A 2015, 622, 204–211. [Google Scholar] [CrossRef]

- Kagnaya, T.; Boher, C.; Lambert, L.; Lazard, M. Mechanisms of WC–Co Cutting Tools from High-speed Tribological Tests. Wear 2009, 267, 890–897. [Google Scholar] [CrossRef]

- Fang, Z.Z.; Wang, X.; Ryu, T.; Hwang, K.S.; Sohn, H.Y. Synthesis, Sintering, and Mechanical Properties of Nanocrystalline Cemented Tungsten Carbide—A Review. Int. J. Refract. Met. Hard Mater. 2009, 27, 288–299. [Google Scholar] [CrossRef]

- Fang, Z.Z.; Griffo, A.; White, B.; Lockwood, G.; Belnap, D.; Hilmas, G.; Bitler, J. Fracture Resistant Super Hard Materials and Hardmetals Composite with Functionally Designed Microstructure. Int. J. Refract. Met. Hard Mater. 2001, 19, 453–459. [Google Scholar] [CrossRef]

- Carpinteri, A.; Paggi, M. A Top-down Approach for the Prediction of Hardness and Toughness of Hierarchical Materials. Chaos Solitons Fractals 2009, 42, 2546–2552. [Google Scholar] [CrossRef]

- Konyashin, I.; Schaefer, F.; Cooper, R.; Ries, B.; Mayer, J.; Weirich, T. Novel Ultra-coarse Hardmetal Grades with Reinforced Binder for Mining and Construction. Int. J. Refract. Met. Hard Mater. 2005, 23, 225–232. [Google Scholar] [CrossRef]

- Konyashin, I.; Ries, B.; Lachmann, F.; Cooper, R.; Mazilkin, A.; Straumal, B.; Aretz, A.; Babaev, V. Hardmetals with Nanograin Reinforced Binder: Binder Fine Structure and Hardness. Int. J. Refract. Met. Hard Mater. 2008, 26, 583–588. [Google Scholar] [CrossRef]

- Ren, X.; Peng, Z.; Peng, Y.; Fu, Z.; Wang, C.; Qi, L.; Miao, H. Effect of SiC Nano-Whisker Addition on WC–Ni Based Cemented Carbides Fabricated by Hot-press Sintering. Int. J. Refract. Met. Hard Mater. 2013, 36, 294–299. [Google Scholar] [CrossRef]

- Manakova, O.S.; Kurbatkina, V.V.; Levashov, E.A. Structure and Properties of Dispersive Hardening Materials Ti-Nb-C with Binder. Russ. J. Non-Ferr. Met. 2015, 56, 486–491. [Google Scholar] [CrossRef]

- Borovinskaya, I.; Gromov, A.; Levashov, E.; Maksimov, Y.; Mukasyan, A.; Rogachev, A. Concise Encyclopedia of Combustion Synthesis: History, Theory, Technology, and Products, 1st ed.; Elsevier: London, UK, 2017; ISBN 9780128041734. [Google Scholar]

- Levashov, E.A.; Mukasyan, A.S.; Rogachev, A.S.; Shtansky, D.V. Self-Propagating High-Temperature Synthesis of Advanced Materials and Coatings. Int. Mater. Rev. 2017, 62, 203–239. [Google Scholar] [CrossRef]

- Levashov, E.A.; Shtansky, D.V.; Lobov, A.L.; Borovinskaya, I.P. Structure and Properties of a New Disperse-Hardening Alloy Based on Titanium Carbide obtained by the SHS Method. Int. J. SHS 1993, 2, 165–173. [Google Scholar]

- Levashov, E.A.; Shtansky, D.V.; Lobov, A.L.; Bogatov, U.; Merzhanov, A.G. Structure and Properties of a New Disperse-Hardening Alloy Based on TiC, Obtained by the SHS Method. Phys. Met. Metallog. 1994, 77, 118–124. [Google Scholar]

- Zaitsev, A.A.; Kurbatkina, V.V.; Levashov, E.A. Features of the Influence of Nanodispersed Additions on the Process of and Properties of the Fe–Co–Cu–Sn Sintered Alloy. Russ. J. Non-Ferr. Met. 2008, 49, 414–419. [Google Scholar] [CrossRef]

- Tokova, L.V.; Zaitsev, A.A.; Kurbatkina, V.V.; Levashov, E.A.; Sidorenko, D.A.; Andreev, V.A. The Features of Influence of ZrO2 and WC Nanodispersed Additives on the Properties of Metal Matrix Composite. Russ. J. Non-Ferr. Met. 2014, 55, 186–190. [Google Scholar] [CrossRef]

- Zaitsev, A.A.; Sidorenko, D.A.; Levashov, E.A.; Kurbatkina, V.V.; Andreev, V.A.; Rupasov, S.I.; Sevast’yanov, P.V. Diamond Tools in Metal Bonds Dispersion-Strengthened with Nanosized Particles for Cutting Highly Reinforced Concrete. J. Superhard Mater. 2010, 32, 423–431. [Google Scholar] [CrossRef]

- Zaitsev, A.A.; Kurbatkina, V.V.; Levashov, E.A. Features of the Effect of Nanodispersed Additives on the Sintering Process and Properties of Powdered Cobalt Alloys. Russ. J. Non-Ferr. Met. 2008, 49, 120–125. [Google Scholar] [CrossRef]

- Konstanty, J. Powder Metallurgy Diamond Tools; Elsevier: Oxford, UK, 2005; ISBN 9781856174404. [Google Scholar]

- Novikov, N.V. Modern Hardmetals; National Academy of Sciences of Ukraine: Kiev, Ukraine, 2008; ISBN 978-966-02-4718-5.

- Sidorenko, D.A.; Zaitsev, A.A.; Kirichenko, A.N.; Levashov, E.A.; Kurbatkina, V.V.; Loginov, P.A.; Rupasov, S.I.; Andreev, V.A. Interaction of Diamond Grains with Nanosized Alloying Agents in Metal–matrix Composites as Studied by Raman Spectroscopy. Diam. Relat. Mater. 2013, 38, 59–62. [Google Scholar] [CrossRef]

- Sidorenko, D.; Levashov, E.; Loginov, P.; Shvyndina, N.; Skryleva, E.; Yerokhin, A. Self-assembling WC Interfacial Layer on Diamond Grains via Gas-phase Transport Mechanism During Sintering of Metal Matrix Composite. Mater. Des. 2016, 106, 6–13. [Google Scholar] [CrossRef]

- Sidorenko, D.; Loginov, P.; Levashov, E.; Mishnaevsky, L., Jr. Hierarchical Machining Materials and their Performance. MRS Bull. 2016, 41, 678–682. [Google Scholar] [CrossRef]

- Holleck, H. Material Selection for Hard Coatings. J. Vac. Sci. Technol. A 1986, 4, 2661–2669. [Google Scholar] [CrossRef]

- Kustas, F.M.; Fehrehnbacher, L.L.; Kornanduri, R. Nanocoatings on Cutting Tools for Dry Machining. Cirp Ann. Manuf. Technol. 1997, 46, 39–42. [Google Scholar] [CrossRef]

- Veprek, S.; Veprek-Heijman, M.J.G. Industrial Applications of Superhard Nanocomposite Coatings. Surf. Coat. Technol. 2008, 202, 5063–5073. [Google Scholar] [CrossRef]

- Veprek, S. Recent Search for New Superhard Materials: Go Nano! J. Vac. Sci. Technol. A 2013, 31, 050822. [Google Scholar] [CrossRef]

- Pal Dey, S.; Deevi, S.C. Single Layer and Multilayer Wear Resistant Coatings of (Ti,Al)N: A Review. Mater. Sci. Eng. A. 2003, 342, 58–79. [Google Scholar] [CrossRef]

- Bull, S.J.; Jones, A.M. Multilayer Coatings for Improved Performance. Surf. Coat. Technol. 1996, 78, 173–184. [Google Scholar] [CrossRef]

- Idriss, M.; Célarié, F.; Yokoyama, Y.; Tessier, F.; Rouxel, T. Evolution of the elastic modulus of Zr–Cu–Al BMGs during annealing treatment and crystallization: Role of Zr/Cu ratio. J. Non-Cryst. Solids 2015, 421, 35–40. [Google Scholar] [CrossRef]

- Debnath, M.R.; Chang, H.-J.; Fleury, E. Effect of group 5 elements on the formation and corrosion behavior of Ti-based BMG matrix composites reinforced by icosahedral quasicrystalline phase. J. Alloys Compd. 2014, 612, 134–142. [Google Scholar] [CrossRef]

- Shamlaye, K.F.; Laws, K.J.; Löffler, J.F. Exceptionally broad bulk metallic glass formation in the Mg–Cu–Yb system. Acta Mater. 2017, 128, 188–196. [Google Scholar] [CrossRef]

- Liao, P.; Yang, B.J.; Zhang, Y.; Lu, W.Y.; Gu, X.J.; Wang, J.Q. Evaluation of glass formation and critical casting diameter in Al-based metallic glasses. Mater. Des. 2015, 88, 222–226. [Google Scholar] [CrossRef]

- Qin, C.L.; Zhang, W.; Asami, K.; Kimura, H.; Wang, X.M.; Inoue, A. A novel Cu-based BMG composite with high corrosion resistance and excellent mechanical properties. Acta Mater. 2006, 54, 3713–3719. [Google Scholar] [CrossRef]

- He, M.K.; Chen, S.H.; Yu, P.; Xi, L. Enhanced mechanical properties of Ni62Nb38 bulk metallic glasses by Ta substitution. J. Non-Cryst. Solids 2017, 471, 452–455. [Google Scholar] [CrossRef]

- Gaur, J.; Mishra, R.K. Analysis of thermodynamic properties for Pd-based bulk metallic glasses. J. Alloys Compd. 2016, 658, 465–469. [Google Scholar] [CrossRef]

- Madge, S.V.; Sharma, P.; Louzguine-Luzgin, D.V.; Greer, A.L.; Inoue, A. New La-based glass–crystal ex situ composites with enhanced toughness. Scr. Mater. 2010, 62, 210–213. [Google Scholar] [CrossRef]

- Conner, R.D.; Dandliker, R.B.; Johnson, W.L. Mechanical properties of tungsten and steel fiber reinforced Zr41.25Ti13.75Cu12.5Ni10Be22.5 metallic glass matrix composites. Acta Mater. 1998, 46, 6089–6102. [Google Scholar] [CrossRef]

- Eckert, J.; Das, J. Mechanical properties of bulk metallic glasses and composites. J. Mater. Res. 2007, 22, 285–301. [Google Scholar] [CrossRef]

- Das, J.; Güth, A.; Klauß, H.-J.; Mickel, C.; Löser, W.; Eckert, J.; Roy, S.K.; Schultz, L. Effect of casting conditions on microstructure and mechanical properties of high-strength Zr73.5Nb9Cu7Ni1Al9.5 in situ composites. Scr. Mater. 2003, 49, 1189–1195. [Google Scholar] [CrossRef]

- Hays, C.C.; Kim, C.P.; Johnson, W.L. Microstructure controlled shear band pattern formation and enhanced plasticity of bulk metallic glasses containing in situ formed ductile phase dendrite dispersions. Phys. Rev. Lett. 2000, 84, 2901. [Google Scholar] [CrossRef] [PubMed]

- Szuecs, F.; Kim, C.P.; Johnson, W.L. Mechanical properties of Zr56.2Ti13.8Nb5.0Cu6.9Ni5.6Be12.5 ductile phase reinforced bulk metallic glass composite. Acta Mater. 2001, 49, 1507–1513. [Google Scholar] [CrossRef]

- Lee, M.L.; Li, Y.; Schuh, C.A. Effect of a controlled volume fraction of dendritic phases on tensile and compressive ductility in La-based metallic glass matrix composites. Acta Mater. 2004, 52, 4121–4131. [Google Scholar] [CrossRef]

- Hofmann, D.C.; Suh, J.-Y.; Wiest, A.; Duan, G.; Lind, M.-L.; Demetriou, M.D.; Johnson, W.L. Designing metallic glass matrix composites with high toughness and tensile ductility. Nature 2008, 451, 1085–1089. [Google Scholar] [CrossRef] [PubMed]

- Hajlaoui, K.; Yavari, A.R.; Doisneau, B.; LeMoulec, A.; Botta, W.J.F.; Vaughan, G.; Greer, A.L.; Inoue, A.; Zhang, W.; Kvick, A. Shear delocalization and crack blunting of a metallic glass containing nanoparticles: In situ deformation in TEM analysis. Scr. Mater. 2006, 54, 1829–1834. [Google Scholar] [CrossRef]

- Hajlaoui, K.; Yavari, A.R.; Das, J.; Vaughan, G. Ductilization of BMGs by optimization of nanoparticle dispersion. J. Alloys Compd. 2007, 434, 6–9. [Google Scholar] [CrossRef]

- Dugdale, J.S.; Pavuna, D.; Rhodes, P. Metallic glasses: Properties and applications. Endeavour 1985, 9, 62–66. [Google Scholar] [CrossRef]

- Peker, A.; Wiggins, S. Sharp-Edged Cutting Tools. U.S. Patent 6,887,586 B2, 7 March 2001. [Google Scholar]

- Anderson, M.C. Cutting Tools Made of an In Situ Composite of Bulk-Solidifying Amorphous alloy. U.S. Patent WO 2008,079,333 A2, 21 December 2006. [Google Scholar]

- Komova, E.; Varga, M.; Varga, R.; Vojtanik, P.; Bednarcik, J. Nanocrystalline glass-coated FeNiMoB microwires. Appl. Phys. Lett. 2008, 93, 062502. [Google Scholar] [CrossRef]

- Ghidelli, M.; Gravier, S.; Blandin, J.-J.; Djemia, P.; Mompiou, F.; Abadias, G.; Raskin, J.-P.; Pardoen, T. Extrinsic mechanical size effects in thin ZrNi metallic glass films. Acta Mater. 2015, 90, 232–241. [Google Scholar] [CrossRef]

- Ghidelli, M.; Idrissi, H.; Gravier, S.; Blandin, J.-J.; Raskin, J.-P.; Schryvers, D.; Pardoen, T. Homogeneous flow and size dependent mechanical behavior in highly ductile Zr65Ni35 metallic glass films. Acta Mater. 2017, 131, 246–259. [Google Scholar] [CrossRef]

- Huang, J.C.; Chu, J.P.; Jang, J.S.C. Recent progress in metallic glasses in Taiwan. Intermetallics 2009, 17, 973–987. [Google Scholar] [CrossRef]

- Chu, J.P.; Liu, C.T.; Mahalingam, T.; Wang, S.F.; O’Keefe, M.J.; Johnson, B.; Kuo, C.H. Annealing-induced full amorphization in a multicomponent metallic film. Phys. Rev. B 2004, 69, 113410. [Google Scholar] [CrossRef]

- Chu, J.P.; Jang, J.S.C.; Huang, J.C.; Chou, H.S.; Yang, Y.; Ye, J.C.; Wang, Y.C.; Lee, J.W.; Liu, F.X.; Liaw, P.K.; et al. Thin film metallic glasses: Unique properties and potential applications. Thin Solid Films 2012, 520, 5097–5122. [Google Scholar] [CrossRef]

- Chu, J.P.; Wang, C.-Y.; Chen, L.J.; Chen, Q. Annealing-induced amorphization in a sputtered glass-forming film: In-situ transmission electron microscopy observation. Surf. Coat. Technol. 2011, 205, 2914–2918. [Google Scholar] [CrossRef]

- Chou, H.S.; Huang, J.C.; Chang, L.W.; Nieh, T.G. Structural relaxation and nanoindentation response in Zr–Cu–Ti amorphous thin films. Appl. Phys. Lett. 2008, 93, 191901. [Google Scholar] [CrossRef]

- Popov, V.N. Carbon Nanotubes: Properties and Application. Mater. Sci. Eng. R 2004, 43, 61–102. [Google Scholar] [CrossRef]

- Khandoker, N.; Hawkins, S.C.; Ibrahim, R.; Huynh, C.P.; Deng, F. Tensile Strength of Spinnable Multiwall Carbon Nanotubes. Procedia Eng. 2011, 10, 2572–2578. [Google Scholar] [CrossRef]

- Zhang, F.; Shen, J.; Sun, J. Processing and Properties of Carbon Nanotubes-Nano-WC-Co Composites. Mater. Sci. Eng. A. 2004, 381, 86–91. [Google Scholar] [CrossRef]

- Shi, X.L.; Yang, H.; Wang, S.; Shao, G.; Duan, X. Fabrication and Properties of WC–10Co Cemented Carbide Reinforced by Multi-walled Carbon Nanotubes. Mater. Sci. Eng. A 2008, 486, 489–495. [Google Scholar] [CrossRef]

- Morisada, Y.; Miyamoto, Y. SiC-coated Carbon Nanotubes and their Application as Reinforcements for Cemented Carbides. Mater. Sci. Eng. A. 2004, 381, 57–61. [Google Scholar] [CrossRef]

- Wang, Y.; Iqbal, Z.; Mitra, S. Rapid, Low Temperature Microwave Synthesis of Novel Carbon Nanotube–silicon Carbide Composite. Carbon 2006, 44, 2804–2808. [Google Scholar] [CrossRef]

- Morisada, Y.; Miyamoto, Y.; Takaura, Y.; Hirota, K.; Tamari, N. Mechanical Properties of SiC Composites Incorporating SiC-coated Multi-walled Carbon Nanotubes. Int. J. Refract. Met. Hard Mater. 2007, 25, 322–327. [Google Scholar] [CrossRef]

- Suzuki, T.; Konno, T. Improvement in Tool Life of Electroplated Diamond Tools by Ni-Based Carbon Nanotube Composite Coatings. Precis. Eng. 2014, 38, 659–665. [Google Scholar] [CrossRef]

- Sidorenko, D.A.; Zaitsev, A.A.; Kirichenko, A.N.; Kurbatkina, V.V.; Levashov, E.A.; Sevast’yanov, P.I.; Rupasov, S.I. Modification of the Fe–Cu–Co–Sn–P Metal Matrix with Various Forms of Carbon Nanomaterials. Russ. J. Non-Ferr. Met. 2014, 55, 639–644. [Google Scholar] [CrossRef]

- Sidorenko, D.A.; Zaitsev, A.A.; Kurbatkina, V.V.; Levashov, E.A.; Andreev, V.A.; Rupasov, S.I.; Sevast’yanov, P.I. Influence of Additives of Carbon Nanotubes on the Structure and Properties of Metal Binders for a Diamond Tool. Russ. J. Non-Ferr. Met. 2013, 54, 527–531. [Google Scholar] [CrossRef]

- Sidorenko, D.; Mishnaevsky, L., Jr.; Levashov, E.; Loginov, P.; Petrzhik, M. Carbon Nanotube Reinforced Metal Binder for Diamond Cutting Tools. Mater. Des. 2015, 83, 536–544. [Google Scholar] [CrossRef]

- Kimura, Y.; Wakabayashi, T.; Okada, K.; Wada, T.; Nishikawa, H. Boron Nitride as a Lubricant Additive. Wear 1999, 232, 199–206. [Google Scholar] [CrossRef]

- Nguyen, T.K.; Do, I.; Kwon, P. A Tribological Study of Vegetable Oil Enhanced By Nano-platelets and Implication in MQL Machining. Int. J. Precis. Eng. Manuf. 2012, 13, 1077–1083. [Google Scholar] [CrossRef]

- Talib, N.; Rahim, E.A.; Nasir, R.M. The Performance of Hexagonal Boron Nitride as an Additive in the Bio-based Machining Lubricant. J. Eng. Appl. Sci. 2016, 11, 7835–7840. [Google Scholar]

- Ohji, T.; Sekino, T.; Niihara, K. Strengthening Effect of In-Situ Dispersed Hexagonal Boron Nitride in Ceramic Composites. Key Eng. Mater. 2006, 317–318, 163–167. [Google Scholar]

- Loginov, P.A.; Levashov, E.A.; Kurbatkina, V.V.; Zaitsev, A.A.; Sidorenko, D.A. Evolution of the Microstructure of Cu–Fe–Co–Ni Powder Mixtures upon Mechanical Alloying. Powder Technol. 2015, 276, 166–174. [Google Scholar] [CrossRef]

- Loginov, P.; Mishnaevsky, L., Jr.; Levashov, E.; Petrzhik, M. Diamond and cBN hybrid and nanomodified cutting tools with enhanced performance: Development, testing and modeling. Mater. Des. 2015, 88, 310–319. [Google Scholar] [CrossRef] [Green Version]

- Oliver, W.C.; Pharr, G.M. An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments. J. Mater. Res. 1992, 7, 1564–1580. [Google Scholar] [CrossRef]

- Borowiecka-Jamrozek, J.; Lachowski, J. The Effect of the Properties of the Metal Matrix on the Retention of a Diamond Particle. Metallurgy 2017, 56, 83–86. [Google Scholar]

- Loginov, P.A.; Sidorenko, D.A.; Levashov, E.A.; Andreev, V.A. Razrabotka Novogo Pokoleniya Instrumenta Iz Sverkhtverdykh Materialov S Nanomodifitsirovannoy Svyazkoi Dlya Obrabotki Stali I Chuguna [Design of Novel Superhard Material Based Cutting Tool with Nano modified Binder for Steel and Cast Iron Machining]. Poroshkovaya Metall. Funktsionalnye Pokrytiya 2017, 1, 64–75. [Google Scholar]

- Pontenfisso, A.; Mishnaevsky, L., Jr. Nanomorphology of Graphene and CNT Reinforced Polymer and its Effect on Damage: Micromechanical Numerical Study. Comp. Part B Eng. 2016, 96, 338–349. [Google Scholar] [CrossRef]

- Dai, G.M.; Mishnaevsky, L., Jr. Carbone Nanotube Reinforced Hybrid Composites: Computational Modelling of Environmental Fatigue and Usability for Wind Blades. Comp. Part B Eng. 2015, 78, 349–360. [Google Scholar] [CrossRef] [Green Version]

- Dai, G.M.; Mishnaevsky, L., Jr. Damage Evolution in Nanoclay-Reinforced Polymers: A Three-Dimensional Computational Study. Compos. Sci. Technol. 2013, 74, 67–77. [Google Scholar] [CrossRef]

- Mishnaevsky, L., Jr.; Dai, G. Hybrid and Hierarchical Nanoreinforced Polymer Composites: Computational Modelling of Structure-Properties Relationships. Compos. Struct. 2014, 117, 156–168. [Google Scholar] [CrossRef]

- Halpin, J.C.; Kardos, J.L. The Halpin-Tsai Equations: A Review. Polym. Eng. Sci. 1976, 16, 344–352. [Google Scholar]

- Nielsen, L.E. Generalized equation for the elastic moduli of composite materials. J. Appl. Phys. 1970, 41, 4626–4627. [Google Scholar] [CrossRef]

| Binder Composition | Tool Life, m | Vdrill, cm/min | ||

|---|---|---|---|---|

| a * | b | a | b | |

| V21 | 12.0 ± 1.0 | 3.4 ± 0.3 | 4.0 | 1.51 |

| 11–13 | 3.1–3.7 | |||

| V21 + 0.1%MWCNT | 13.2 ± 1.0 | 3.2 ± 0.3 | 6.4 | 1.72 |

| 12.2–14.2 | 2.9–3.5 | |||

| Binder Composition | Productivity, cm2 | Cutting Speed, cm2/h |

|---|---|---|

| Cu-Fe-Co-Ni | 950 | 220 |

| Cu-Fe-Co-Ni-hBN | 1600 | 320 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sidorenko, D.; Loginov, P.; Mishnaevsky, L.; Levashov, E. Nanocomposites for Machining Tools. Materials 2017, 10, 1171. https://doi.org/10.3390/ma10101171

Sidorenko D, Loginov P, Mishnaevsky L, Levashov E. Nanocomposites for Machining Tools. Materials. 2017; 10(10):1171. https://doi.org/10.3390/ma10101171

Chicago/Turabian StyleSidorenko, Daria, Pavel Loginov, Leon Mishnaevsky, and Evgeny Levashov. 2017. "Nanocomposites for Machining Tools" Materials 10, no. 10: 1171. https://doi.org/10.3390/ma10101171