Ferroelectric Domain Structure and Local Piezoelectric Properties of Lead-Free (Ka0.5Na0.5)NbO3 and BiFeO3-Based Piezoelectric Ceramics

Abstract

:1. Introduction

2. Sintering and Crystal Structure

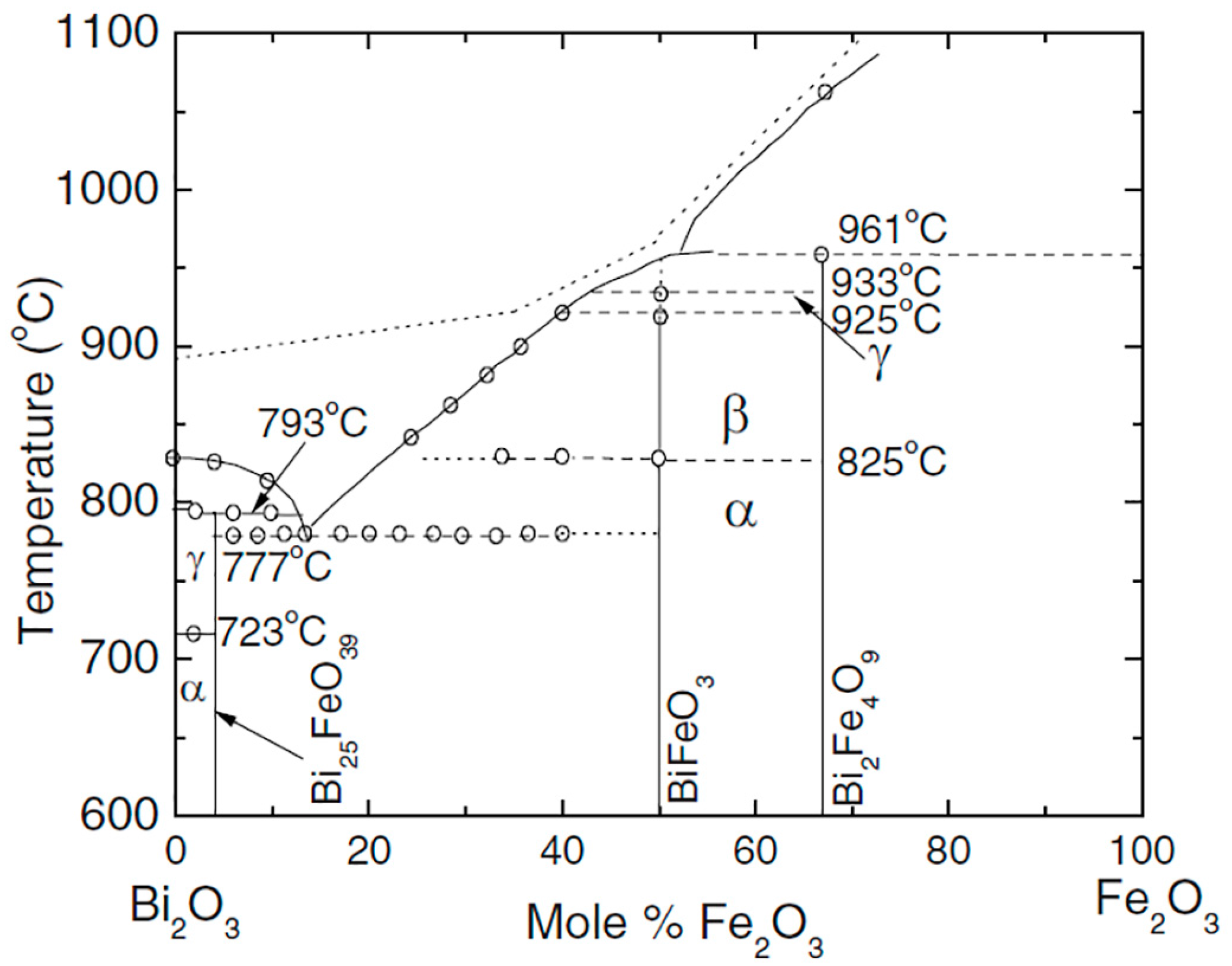

2.1. BiFeO3 System

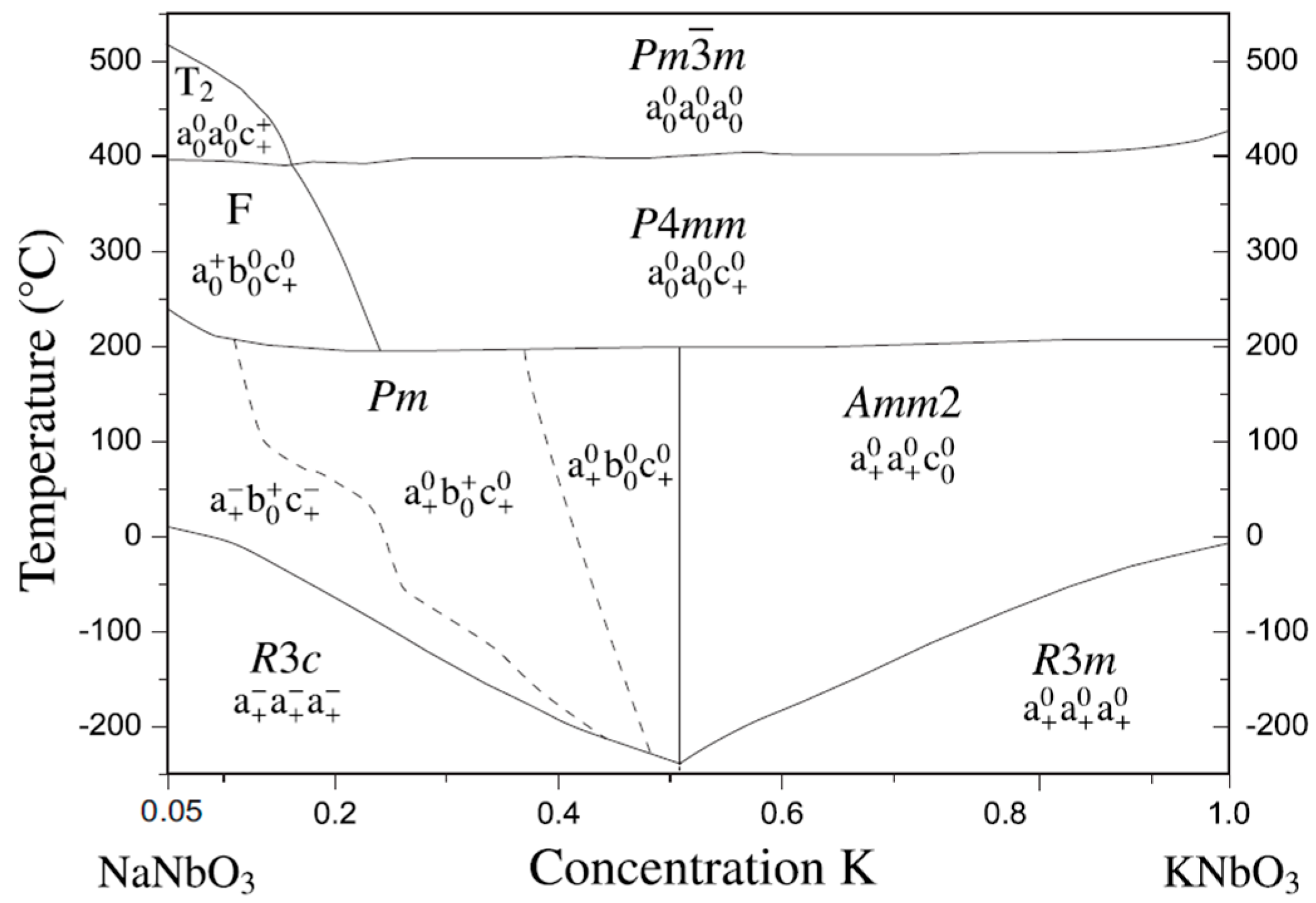

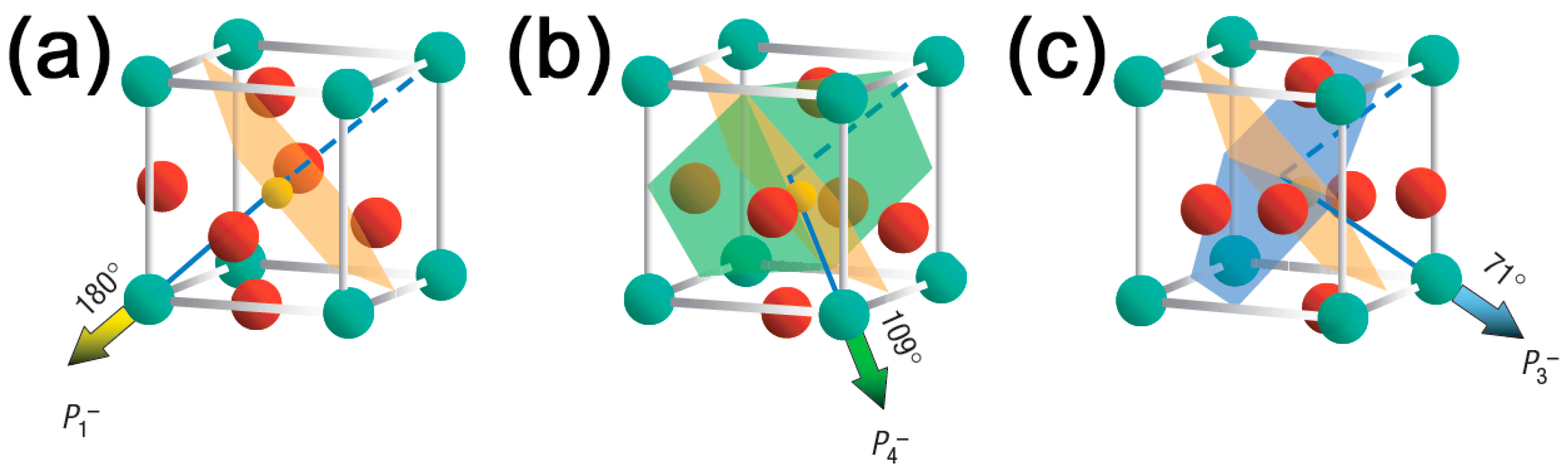

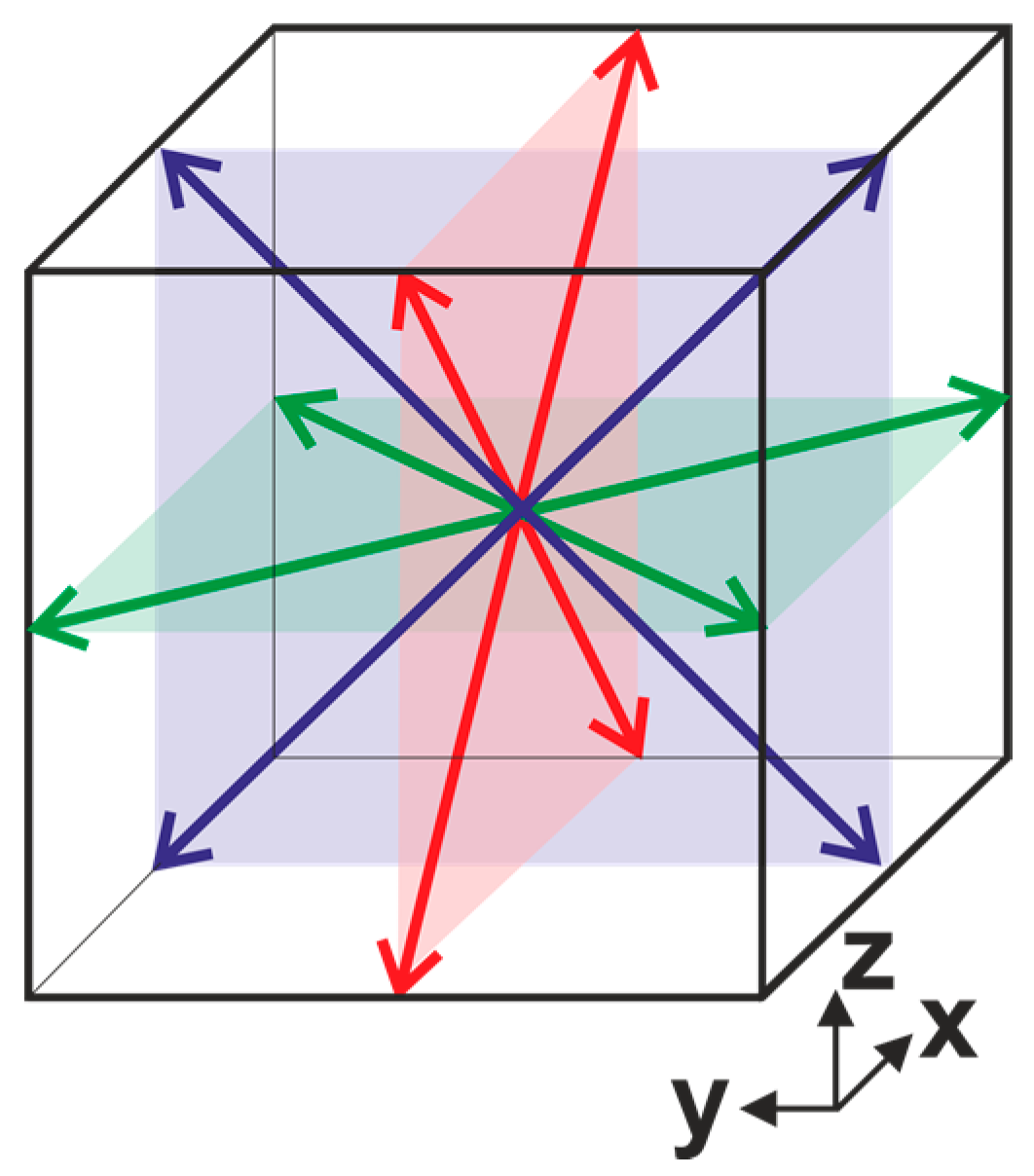

2.2. KNbO3–NaNbO3 System

3. Methods of Domain Structure Visualization

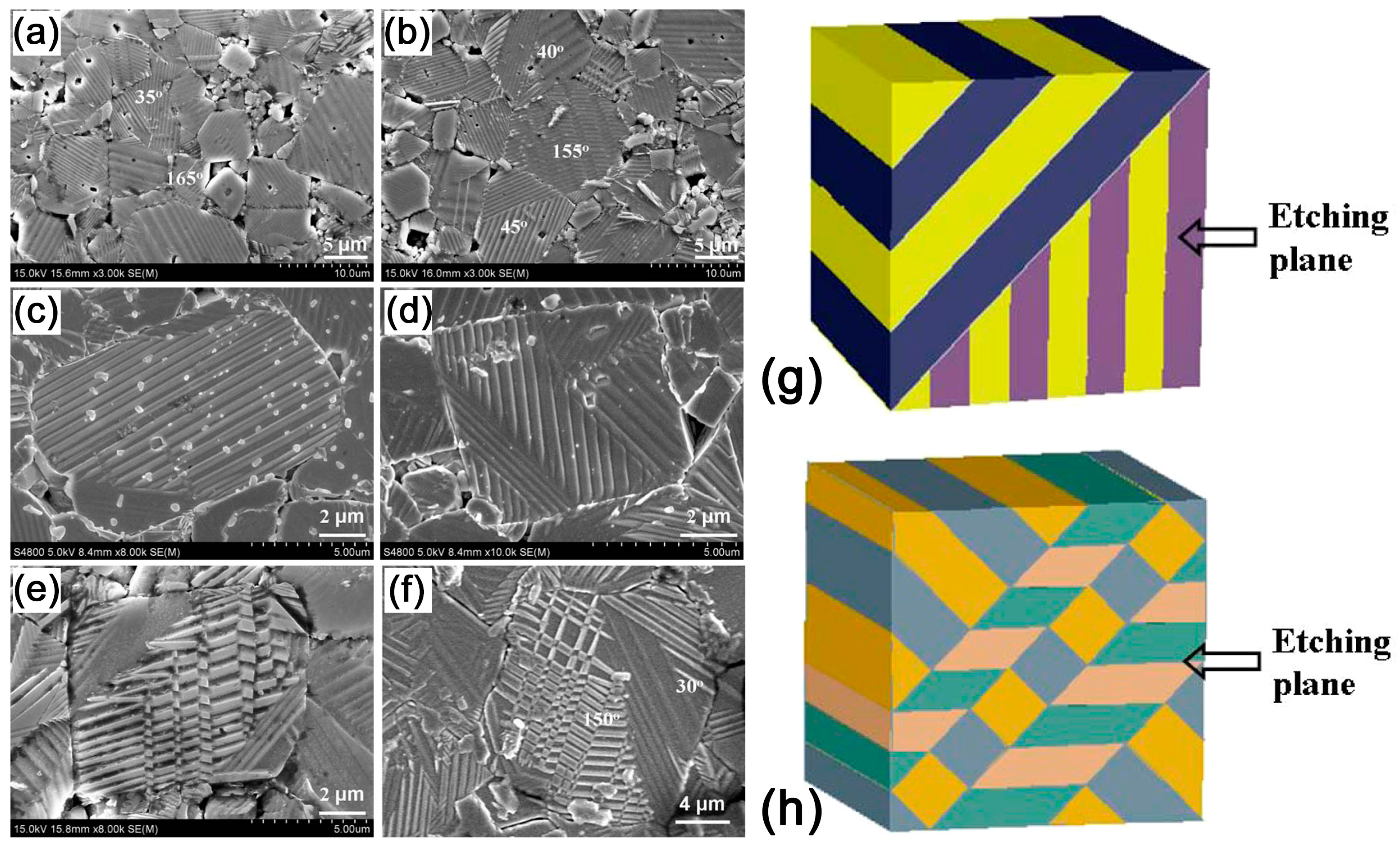

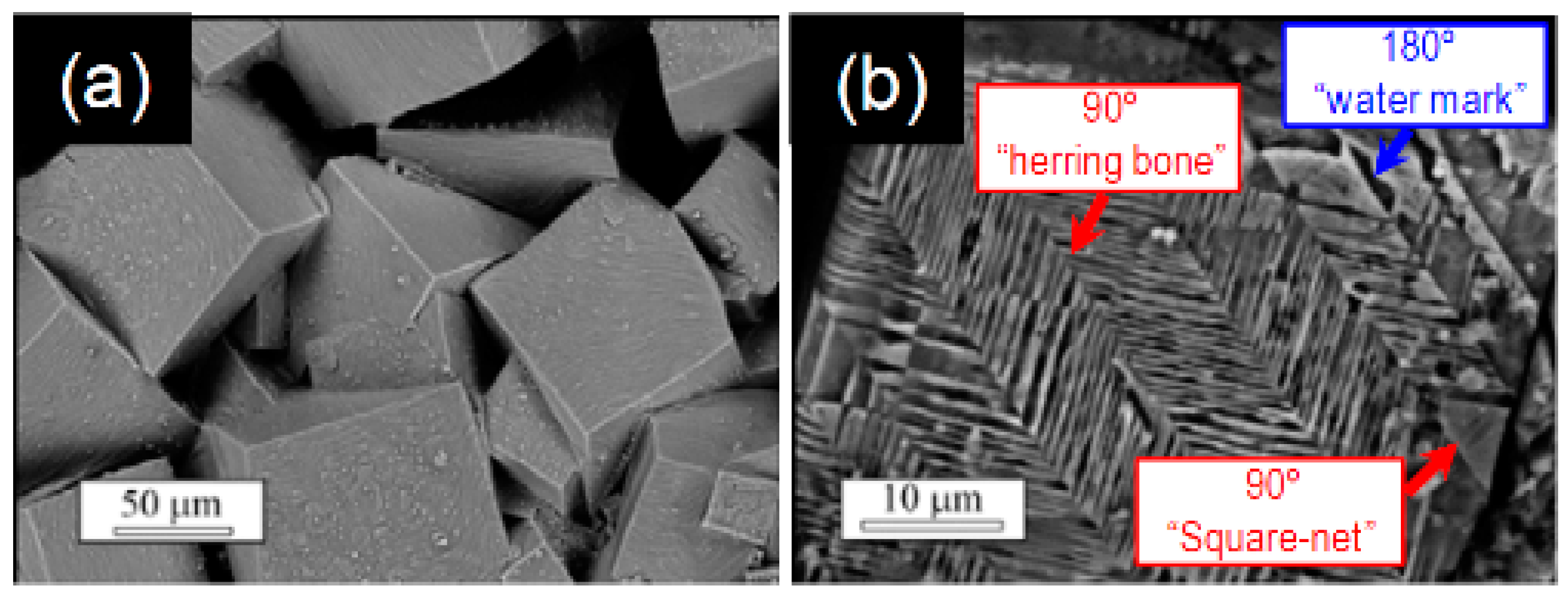

3.1. Scanning Electron Microscopy after Selective Chemical Etching

3.2. Transmission Electron Microscopy

3.3. Piezoresponse Force Microscopy

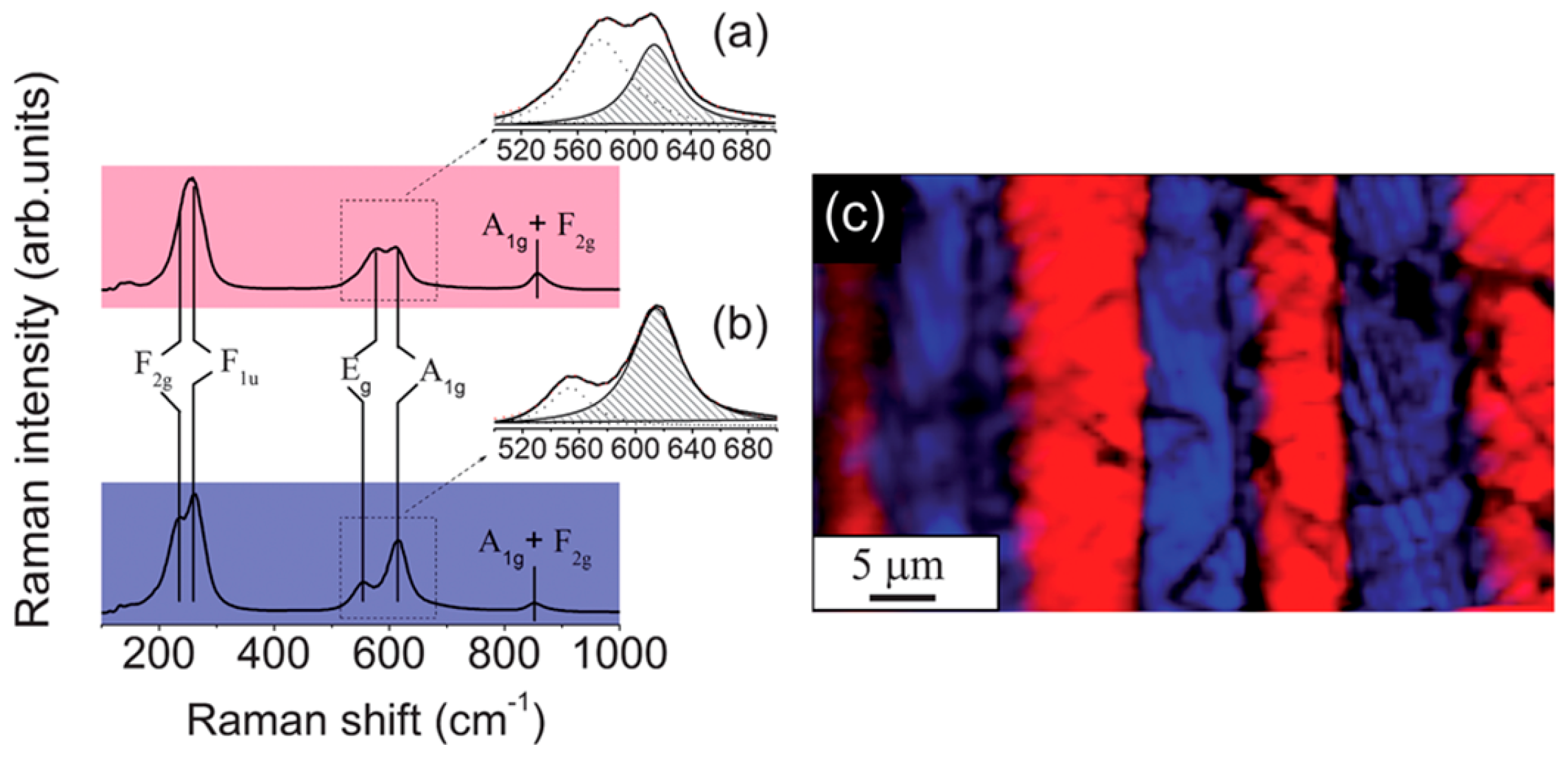

3.4. Confocal Raman Microscopy

4. Domain Structure in BiFeO3

4.1. Undoped BiFeO3

4.2. Doping by Rare Earth Ions

4.3. Doping by Alkaline Earth and Heavy Metal Ions

4.4. BiFeO3-xLaFeO3-0.05La2/3TiO3

4.5. Temperature Dependence of Local Piezoelectric Response

4.6. Grain Size–Domain Size Relation

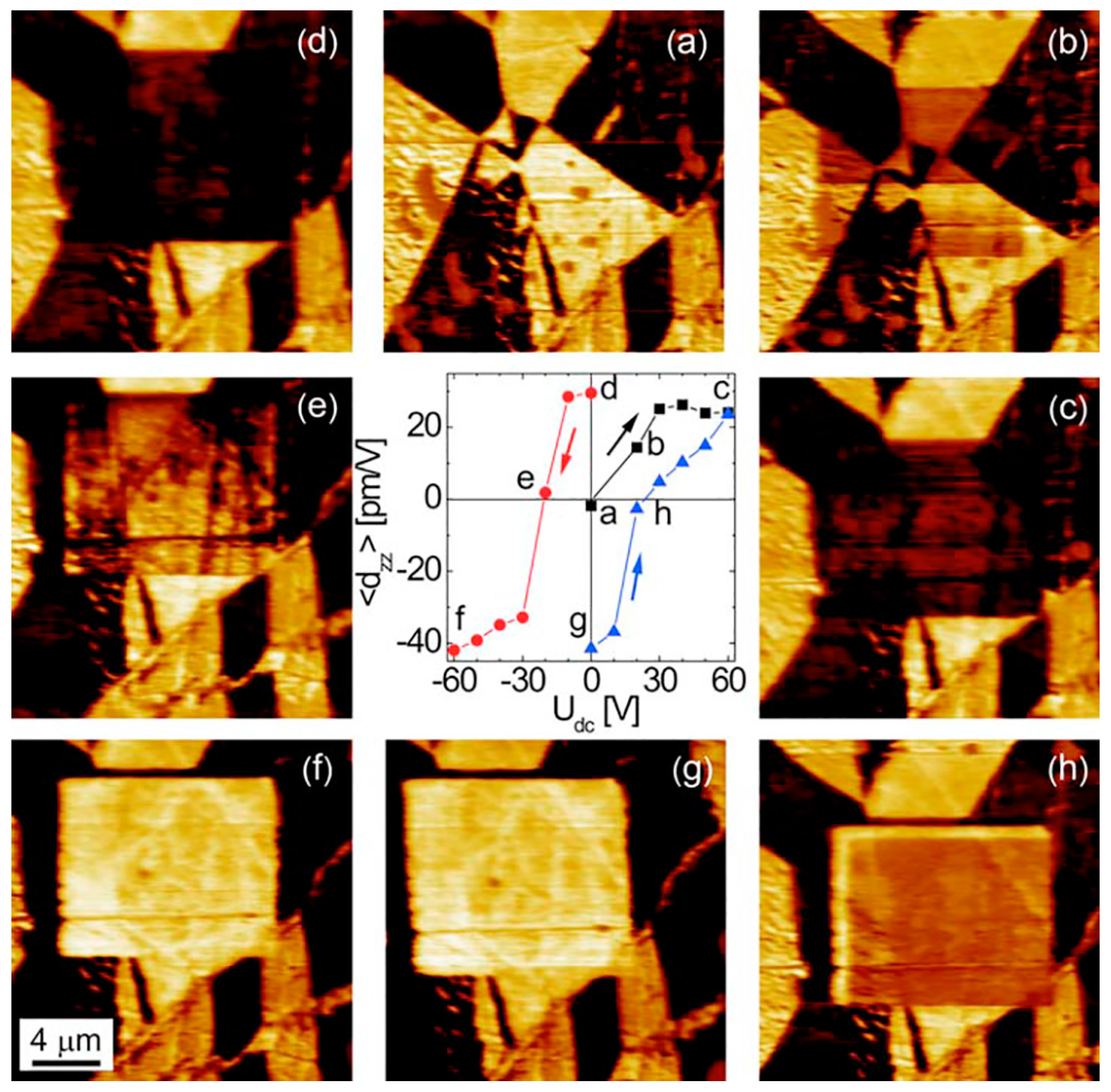

4.7. Local Switching by PFM

5. Domain Structure and Local Piezoelectric Properties of KNN-Based Ceramics

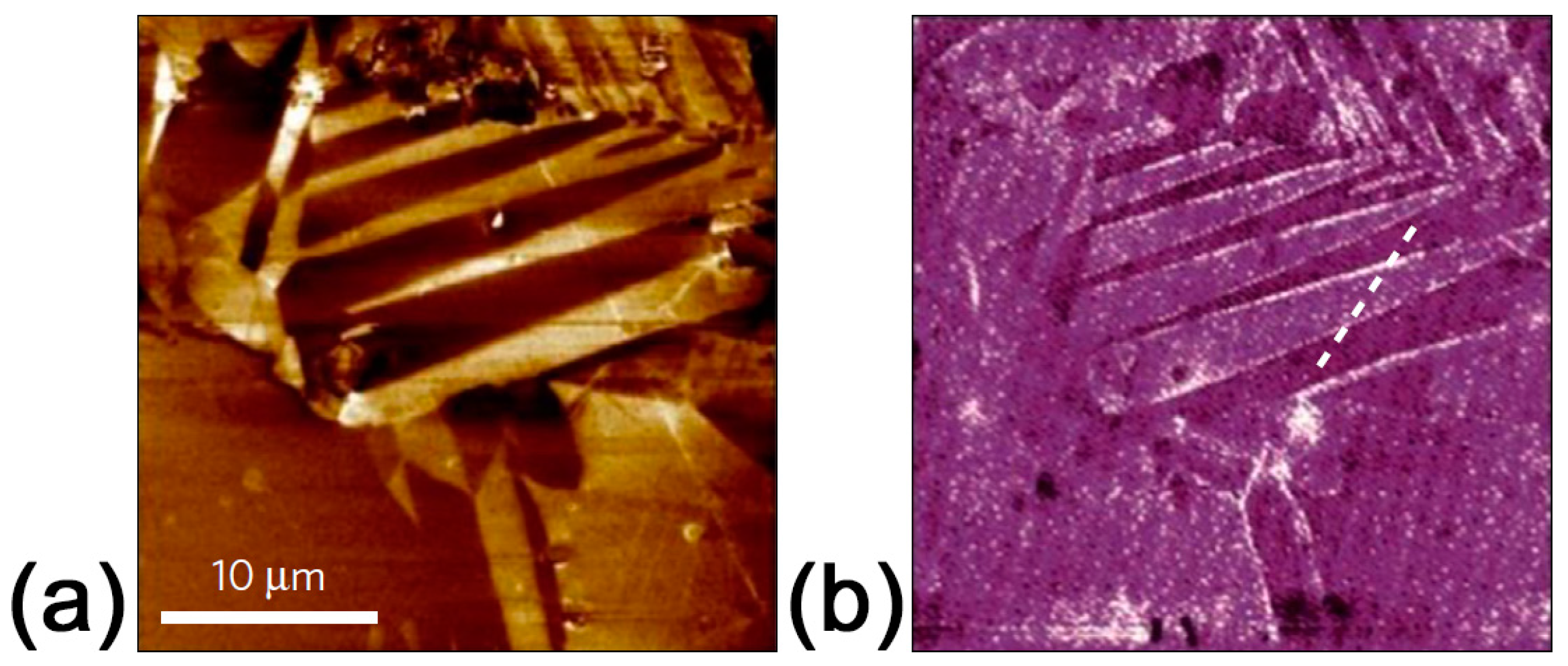

5.1. Domain Structure before Poling

5.2. Domain Structure after Poling

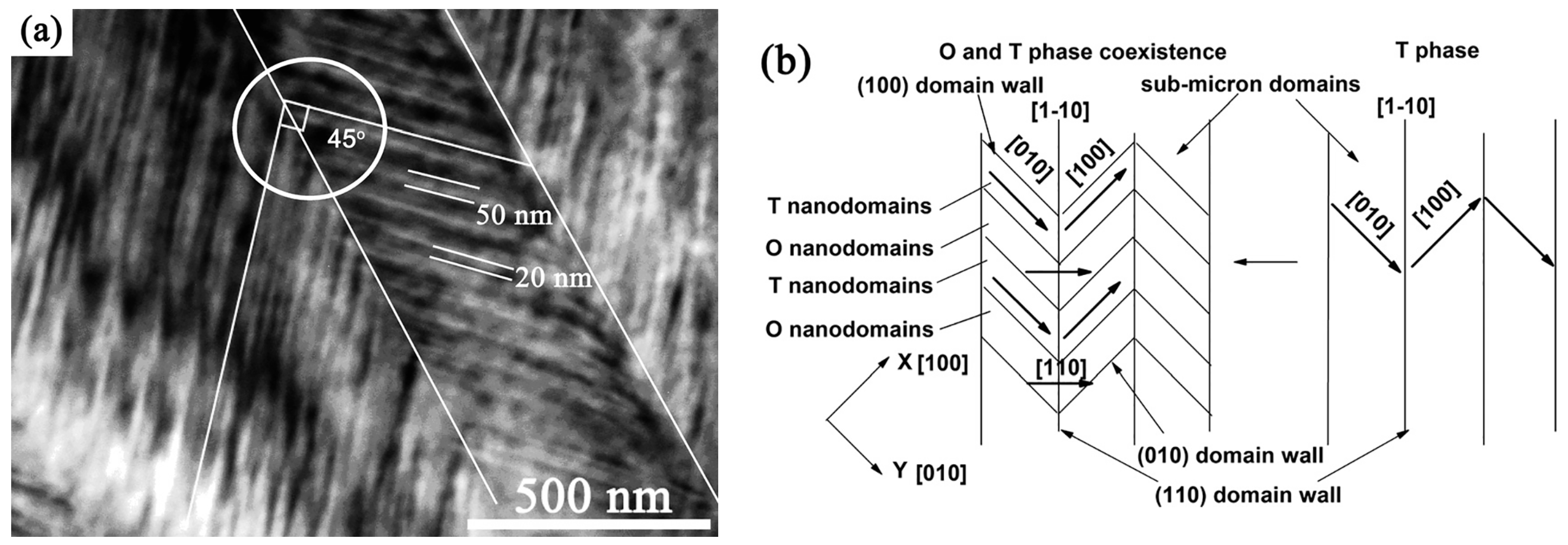

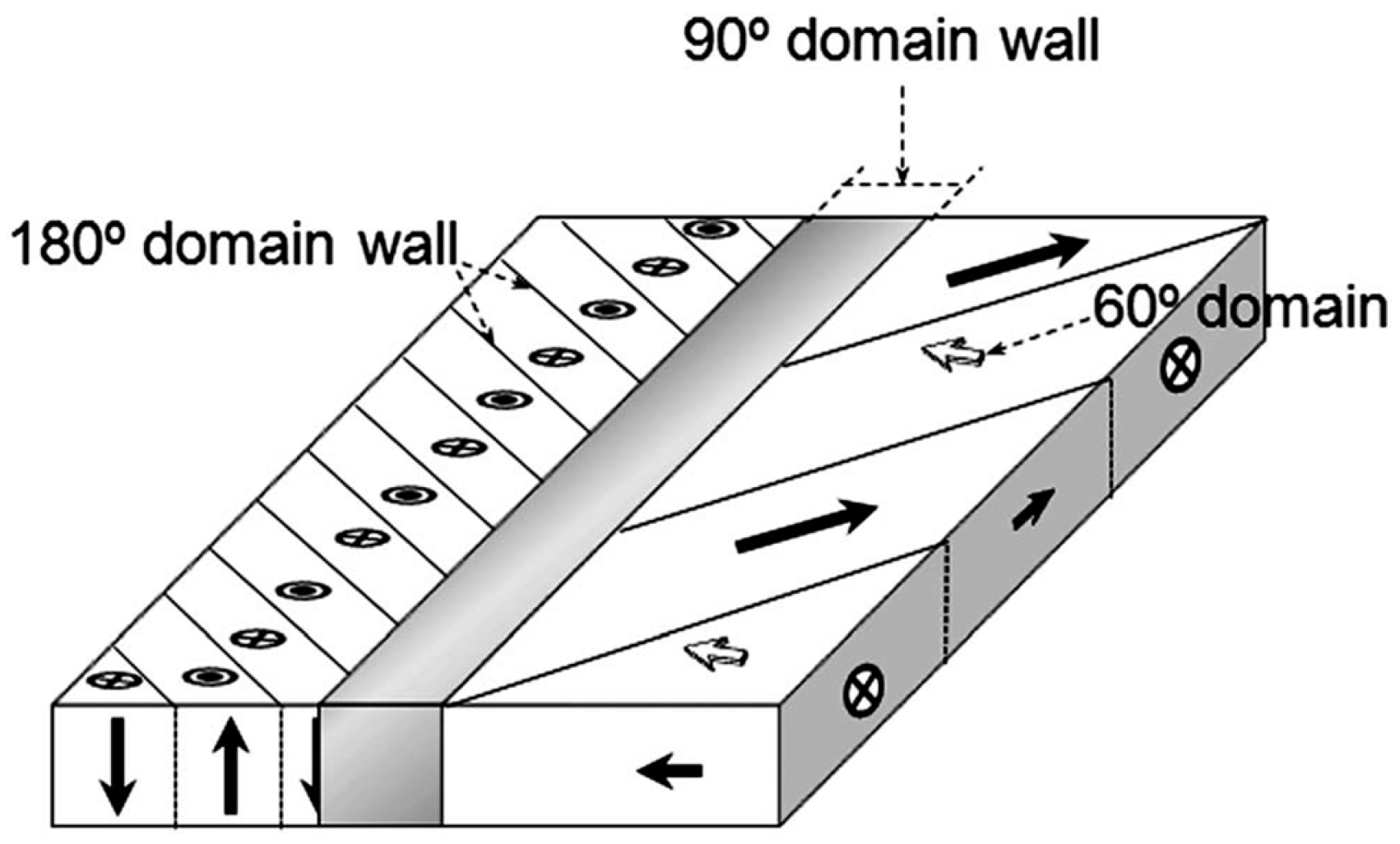

5.3. Coexistence of Tetragonal and Orthorombic Phases

5.4. Temperaute Dependences of Local Piezoelectric Response and Grain Size–Domain Size Relation

5.5. Local Switching by PFM

6. Domain Structure Input to the Dielectric Permittivity and Piezoelectricity

- Emission of elastic shear waves from ferroelastic domain walls [129,131,132,133,134,135]. Ferroelastic domain walls are displaced in an applied electric field, which causes a shift of matter on both sides of the wall in opposite directions parallel to the domain wall. Thus, the domain walls behave like shear wave transducers; the shear waves emitted into the adjacent grains at high frequencies cause considerable dielectric losses, resulting in dielectric relaxation.

- Maxwell–Wagner effect of the conductive domain walls [136].

7. Conclusions

Acknowledgments

Conflicts of Interest

References

- Hong, C.-H.; Kim, H.-P.; Choi, B.-Y.; Han, H.-S.; Son, J.S.; Ahn, C.W.; Jo, W. Lead-free piezoceramics—Where to move on? J. Materiomics 2016, 2, 1–24. [Google Scholar] [CrossRef]

- Irschik, H.; Krommer, M.; Vetyukov, Y. On the use of piezoelectric sensors in structural mechanics: Some novel strategies. Sensors 2010, 10, 5626–5641. [Google Scholar] [CrossRef] [PubMed]

- Safari, A. Novel piezoelectric ceramics and composites for sensor and actuator applications. Mater. Res. Innov. 1999, 52, 263–269. [Google Scholar] [CrossRef]

- Aksel, E.; Jones, J.L. Advances in lead-free piezoelectric materials for sensors and actuators. Sensors 2010, 10, 1935–1954. [Google Scholar] [CrossRef] [PubMed]

- Spanner, K.; Koc, B. Piezoelectric motors, an overview. Actuators 2016, 5, 6. [Google Scholar] [CrossRef]

- Directive 2002/95/EC of the European Parliament and of the Council of 27 January 2003 on the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment; Directive 2002/95/EC; European Union: Brussels, Belgium, 2003.

- Rojac, T.; Bencan, A.; Drazic, G.; Sakamoto, N.; Ursic, H.; Jancar, B.; Tavcar, G.; Makarovic, M.; Walker, J.; Malic, B.; et al. Domain-wall conduction in ferroelectric BiFeO3 controlled by accumulation of charged defects. Nat. Mater. 2016. [Google Scholar] [CrossRef] [PubMed]

- Potnis, P.R.; Tsou, N.T.; Huber, J.E. A review of domain modelling and domain imaging techniques in ferroelectric crystals. Materials 2011, 4, 417–447. [Google Scholar] [CrossRef]

- Shur, V.Y.; Zelenovskiy, P.S. Micro- and nanodomain imaging in uniaxial ferroelectrics: Joint application of optical, confocal Raman, and piezoelectric force microscopy. J. Appl. Phys. 2014, 116, 066802. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X. Large electric polarization in BiFeO3 film prepared via a simple sol-gel process. J. Sol-Gel Sci. Technol. 2008, 47, 154–157. [Google Scholar] [CrossRef]

- Rojac, T.; Bencan, A.; Malic, B.; Tutuncu, G.; Jones, J.L.; Daniels, J.E.; Damjanovic, D. BiFeO3 ceramics: Processing, electrical, and electromechanical properties. J. Am. Ceram. Soc. 2014, 97, 1993–2011. [Google Scholar] [CrossRef]

- Maître, A.; François, M.; Gachon, J.C. Experimental study of the Bi2O3-Fe2O3 pseudo-binary system. J. Phase Equilibria Diffus. 2004, 25, 59–67. [Google Scholar] [CrossRef]

- Achenbach, G.D.; James, W.J. Preparation of single-phase polycrystalline BiFeO3. J. Am. Ceram. Soc. 1967, 50, 437. [Google Scholar] [CrossRef]

- Selbach, S.M.; Einarsrud, M.A.; Grande, T. On the thermodynamic stability of BiFeO3. Chem. Mater. 2009, 21, 169–173. [Google Scholar] [CrossRef]

- Selbach, S.M.; Tybell, T.; Einarsrud, M.; Grande, T. Size-dependent properties of multiferroic BiFeO3 nanoparticles. Chem. Mater. 2007, 19, 6478–6484. [Google Scholar] [CrossRef]

- Valant, M.; Axelsson, A.; Alford, N.; Bifeo, P. Peculiarities of a solid-state synthesis of multiferroic polycrystalline BiFeO3. Chem. Mater. 2007, 19, 5431–5436. [Google Scholar] [CrossRef]

- Khomchenko, V.A.; Kiselev, D.A.; Vieira, J.M.; Jian, L.; Kholkin, A.L.; Lopes, A.M.L.; Pogorelov, Y.G.; Araujo, J.P.; Maglione, M. Effect of diamagnetic Ca, Sr, Pb, and Ba substitution on the crystal structure and multiferroic properties of the BiFeO3 perovskite. J. Appl. Phys. 2008, 103, 024105. [Google Scholar] [CrossRef]

- Nalwa, K.S.; Garg, A.; Upadhyaya, A. Effect of samarium doping on the properties of solid-state synthesized multiferroic bismuth ferrite. Mater. Lett. 2008, 62, 878–881. [Google Scholar] [CrossRef]

- Leist, T.; Granzow, T.; Jo, W.; Rödel, J. Effect of tetragonal distortion on ferroelectric domain switching: A case study on La-doped BiFeO3-PbTiO3 ceramics. J. Appl. Phys. 2010, 108, 014103. [Google Scholar] [CrossRef]

- Ozaki, T.; Matsuo, H.; Noguchi, Y.; Miyayama, M.; Mori, S. Microstructures related to ferroelectric properties in (Bi0.5K0.5)TiO3-BiFeO3. Jpn. J. Appl. Phys. 2010, 49, 09MC05. [Google Scholar] [CrossRef]

- Khomchenko, V.A.; Paixão, J.A.; Kiselev, D.A.; Kholkin, A.L. Intermediate structural phases in rare-earth substituted BiFeO3. Mater. Res. Bull. 2010, 45, 416–419. [Google Scholar] [CrossRef]

- Fujino, S.; Murakami, M.; Anbusathaiah, V.; Lim, S.H.; Nagarajan, V.; Fennie, C.J.; Wuttig, M.; Salamanca-Riba, L.; Takeuchi, I. Combinatorial discovery of a lead-free morphotropic phase boundary in a thin-film piezoelectric perovskite. Appl. Phys. Lett. 2008, 92, 202904. [Google Scholar] [CrossRef]

- Palai, R.; Katiyar, R.S.; Schmid, H.; Tissot, P.; Clark, S.J.; Robertson, J.; Redfern, S.A.T.; Catalan, G.; Scott, J.F. β phase and γ-β metal-insulator transition in multiferroic BiFeO3. Phys. Rev. B 2008, 77, 014110. [Google Scholar] [CrossRef]

- Jaeger, R.E.; Egerton, L. Hot pressing of potassium-sodium niobates. J. Am. Ceram. Soc. 1962, 45, 209–213. [Google Scholar] [CrossRef]

- Ahtee, M.; Hewat, A.W. Structural phase transitions in sodium-potassium niobate solid solutions by neutron powder diffraction. Acta Crystallogr. A 1978, 34, 309–317. [Google Scholar] [CrossRef]

- Ahtee, M.; Glazer, A.M. Lattice parameters and tilted octahedra in sodium-potassium niobate solid solutions. Acta Crystallogr. A 1976, 32, 434–446. [Google Scholar] [CrossRef]

- Jaffe, B.; Cook, W.R.; Jaffe, H.L. Piezoelectric Ceramics; Academic Press: Cambridge, MA, USA, 1971. [Google Scholar]

- Birol, H.; Damjanovic, D.; Setter, N. Preparation and characterization of (K0.5Na0.5)NbO3 ceramics. J. Eur. Ceram. Soc. 2006, 26, 861–866. [Google Scholar] [CrossRef]

- Zhang, B.P.; Li, J.F.; Wang, K.; Zhang, H. Compositional dependence of piezoelectric properties in NaxK1-xNbO3 lead-free ceramics prepared by spark plasma sintering. J. Am. Ceram. Soc. 2006, 89, 1605–1609. [Google Scholar] [CrossRef]

- Li, J.F.; Wang, K.; Zhang, B.P.; Zhang, L.M. Ferroelectric and piezoelectric properties of fine-grained Na0.5K0.5NbO3 lead-free piezoelectric ceramics prepared by spark plasma sintering. J. Am. Ceram. Soc. 2006, 89, 706–709. [Google Scholar] [CrossRef]

- Saito, Y.; Takao, H.; Tani, T.; Nonoyama, T.; Takatori, K.; Homma, T.; Nagaya, T.; Nakamura, M. Lead-free piezoceramics. Nature 2004, 432, 84–87. [Google Scholar] [CrossRef] [PubMed]

- Baker, D.W.; Thomas, P.A.; Zhang, N.; Glazer, A.M. A comprehensive study of the phase diagram of KxNa1-xNbO3. Appl. Phys. Lett. 2009, 95, 91903. [Google Scholar] [CrossRef]

- Malič, B.; Koruza, J.; Hreščak, J.; Bernard, J.; Wang, K.; Fisher, J.; Benčan, A. Sintering of lead-free piezoelectric sodium potassium niobate ceramics. Materials 2015, 8, 8117–8146. [Google Scholar] [CrossRef]

- Fuentes, J.; Portelles, J.; Pérez, A.; Durruthy-Rodríguez, M.D.; Ostos, C.; Raymond, O.; Heiras, J.; Cruz, M.P.; Siqueiros, J.M. Structural and dielectric properties of La- and Ti-modified K0.5Na0.5NbO3 ceramics. Appl. Phys. A 2012, 107, 733–738. [Google Scholar] [CrossRef]

- Zhou, J.J.; Li, J.F.; Wan, K.; Zhang, X.W. Phase structure and electrical properties of (Li,Ta)-doped (K, Na)NbO3 lead-free piezoceramics in the vicinity of Na/K = 50/50. J. Mater. Sci. 2011, 46, 5111–5116. [Google Scholar] [CrossRef]

- Malic, B.; Bernard, J.; Holc, J.; Kosec, M. Strontium doped K0.5Na0.5NbO3 based piezoceramics. Ferroelectrics 2005, 314, 149–156. [Google Scholar] [CrossRef]

- Malic, B.; Bernard, J.; Holc, J.; Jenko, D.; Kosec, M. Alkaline-earth doping in (K, Na)NbO3 based piezoceramics. J. Eur. Ceram. Soc. 2005, 25, 2707–2711. [Google Scholar] [CrossRef]

- Guo, Y.; Kakimoto, K.; Ohsato, H. (Na0.5K0.5)NbO3-LiTaO3 lead-free piezoelectric ceramics. Mater. Lett. 2005, 59, 241–244. [Google Scholar] [CrossRef]

- Fang, B.; Du, Q.; Jiang, N.; Wu, J. Effects of the co-addition of LiSbO3-LiTaO3 on the densification of (Na1/2K1/2)NbO3 lead free ceramics by atmosphere sintering. J. Alloys Compd. 2011, 509, 2420–2424. [Google Scholar]

- Wu, J.; Xiao, D.; Zhu, J. Potassium-sodium niobate lead-free piezoelectric materials: Past, present, and future of phase boundaries. Chem. Rev. 2015, 115, 2559–2595. [Google Scholar] [CrossRef] [PubMed]

- Li, J.F.; Wang, K.; Zhu, F.Y.; Cheng, L.Q.; Yao, F.Z. (K, Na) NbO3-based lead-free piezoceramics: Fundamental aspects, processing technologies, and remaining challenges. J. Am. Ceram. Soc. 2013, 96, 3677–3696. [Google Scholar] [CrossRef]

- Reichmann, A.; Mitsche, S.; Zankel, A.; Poelt, P.; Reichmann, K. In situ mechanical compression of polycrystalline BaTiO3 in the ESEM. J. Eur. Ceram. Soc. 2014, 34, 2211–2215. [Google Scholar] [CrossRef]

- Bradt, R.C.; Ansell, G.S. Transmission electron microscopy of ferroelectric domain boundaries in barium titanate. IEEE Trans. Electron Devices 1969, 16, 594–597. [Google Scholar] [CrossRef]

- Roshchupkin, D.V.; Irzhak, D.V.; Antipov, V.V. Study of LiNbO3 and LiTaO3 ferroelectric domain structures using high-resolution x-ray diffraction under application of external electric field. J. Appl. Phys. 2009, 105, 024112. [Google Scholar] [CrossRef]

- Antipov, V.V.; Blistanov, A.A.; Roshchupkina, E.D.; Tucoulou, R.; Ortega, L.; Roshchupkin, D.V. High-resolution X-ray topography and diffraction study of bulk regular domain structures in LiNbO3 crystals. Appl. Phys. Lett. 2004, 85, 5325. [Google Scholar] [CrossRef]

- Takashige, M.; Hamazaki, S.-I.; Shimizu, F.; Kojima, S. Observation of 90° domains in BaTiO3 by atomic force microscopy. Ferroelectrics 1997, 196, 211–214. [Google Scholar] [CrossRef]

- Son, J.Y.; Kim, B.Q.; Kim, C.H.; Cho, J.H. Writing polarization bits on the multiferroic BiMnO3 thin film using Kelvin probe force microscope. Appl. Phys. Lett. 2004, 84, 4971–4973. [Google Scholar] [CrossRef]

- Hong, J.W.; Park, S.; Khim, Z.G. Measurement of hardness, surface potential, and charge distribution with dynamic contact mode electrostatic force microscope. Rev. Sci. Instrum. 1999, 70, 1735–1739. [Google Scholar] [CrossRef]

- Zeng, H.; Shimamura, K.; Kannan, C.V.; Villora, E.G.; Takekawa, S.; Kitamura, K.; Yin, Q. Acoustic imaging of ferroelectric domains in BaTiO3 single crystals using atomic force microscope. Jpn. J. Appl. Phys. 2007, 46, 286–288. [Google Scholar] [CrossRef]

- Soergel, E. Piezoresponse force microscopy (PFM). J. Phys. D Appl. Phys. 2011, 44, 464003. [Google Scholar] [CrossRef]

- Shur, V.Y.; Zelenovskiy, P.S.; Nebogatikov, M.S.; Alikin, D.O.; Sarmanova, M.F.; Ievlev, A.V.; Mingaliev, E.A.; Kuznetsov, D.K. Investigation of the nanodomain structure formation by piezoelectric force microscopy and Raman confocal microscopy in LiNbO3 and LiTaO3 crystals. J. Appl. Phys. 2011, 110, 052013. [Google Scholar] [CrossRef]

- Hooton, J.A.; Merz, W.J. Etch patterns and ferroelectric domains in BaTiO3 single crystals. Phys. Rev. 1955, 98, 409–413. [Google Scholar] [CrossRef]

- Cook, W.R. Domain twinning in barium titanate ceramics. J. Am. Ceram. Soc. 1956, 1201, 17–19. [Google Scholar] [CrossRef]

- Nassau, K.; Levinstein, H.J.; Loiacono, G.M. The domain structure and etching of ferroelectric lithium niobate. Appl. Phys. Lett. 1965, 6, 228–229. [Google Scholar] [CrossRef]

- Kubel, F.; Schmid, H. Growth, twinning and etch figures of ferroelectric/ferroelastic dendritic BiFeO3 single domain crystals. J. Cryst. Growth 1993, 129, 515–524. [Google Scholar] [CrossRef]

- Nassau, K.; Levinstein, H.J.; Loiacono, G.M. Ferroelectric lithium niobate. 1. Growth, domain structure, dislocations and etching. J. Phys. Chem. Solids 1966, 27, 983–988. [Google Scholar] [CrossRef]

- Belitz, R.K. Differential etching of BaTiO3 by H3PO4. J. Am. Ceram. Soc. 1962, 45, 617–618. [Google Scholar] [CrossRef]

- Johann, F.; Morelli, A.; Vrejoiu, I. Epitaxial BiFeO3 nanostructures fabricated by differential etching of BiFeO3 films. Appl. Phys. Lett. 2011, 99, 082904. [Google Scholar] [CrossRef]

- Rubio-Marcos, F.; del Campo, A.; López-Juárez, R.; Romero, J.J.; Fernández, J.F. High spatial resolution structure of (K, Na)NbO3 lead-free ferroelectric domains. J. Mater. Chem. 2012, 22, 9714–9720. [Google Scholar] [CrossRef]

- Arlt, G.; Sasko, P. Domain configuration and equilibrium size of domains in BaTiO3 ceramics. J. Appl. Phys. 1980, 51, 4956–4960. [Google Scholar] [CrossRef]

- Ohnishi, N.; Iizuka, T. Etching study of microdomains in LiNbO3 single crystals. J. Appl. Phys. 1975, 46, 1063–1067. [Google Scholar] [CrossRef]

- Iwata, M.; Katsuraya, K.; Suzuki, I.; Maeda, M.; Yasuda, N.; Ishibashi, Y. Domain observation of Pb(Zn1/3Nb2/3)O3-PbTiO3 mixed crystals by scanning probe microscopy. Jpn. J. Appl. Phys. 2003, 42, 6201–6204. [Google Scholar] [CrossRef]

- Shur, V.Y.; Lobov, A.I.; Shur, A.G.; Kurimura, S.; Nomura, Y.; Terabe, K.; Liu, X.Y.; Kitamura, K. Rearrangement of ferroelectric domain structure induced by chemical etching. Appl. Phys. Lett. 2005, 87, 022905. [Google Scholar] [CrossRef]

- Fu, Z.; Yang, J.; Yu, H.; Wang, Y.; Lu, P.; Yang, Q.; Xu, F.; Li, Y. Periodic configuration of δ-boundaries and ferroelectric domains in Li-modified (K, Na)NbO3 lead-free piezoelectric single crystals by solid state crystal growth. J. Eur. Ceram. Soc. 2017, 37, 593–598. [Google Scholar] [CrossRef]

- Faryna, M.; Sztwiertnia, K.; Sikorski, K. Simultaneous WDXS and EBSD investigations of dense PLZT ceramics. J. Eur. Ceram. Soc. 2006, 26, 2967–2971. [Google Scholar] [CrossRef]

- Uetsuji, Y.; Kuramae, H.; Tsuchiya, K.; Kamlah, M. Electron backscatter diffraction crystal morphology analysis and multiscale simulation of piezoelectric materials. Int. J. Comput. Methods Exp. Meas. 2013, 1, 199–211. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, J.; Gao, Y.; Tan, Y.; Wang, C. Study of domain structure of poled (K,Na)NbO3 ceramics. J. Appl. Phys. 2013, 113, 204107. [Google Scholar] [CrossRef]

- Ayache, J.; Beaunier, L.; Boumendil, J.; Ehret, G.; Laub, D. Sample Preparation Handbook for Transmission Electron Microscopy; Springer: Berlin, Germany, 2010. [Google Scholar]

- Walker, J.; Ursic, H.; Bencan, A.; Malic, B.; Simons, H.; Reaney, I.; Viola, G.; Nagarajan, V.; Rojac, T. Temperature dependent piezoelectric response and strain–electric-field hysteresis of rare-earth modified bismuth ferrite ceramics. J. Mater. Chem. C 2016, 4, 7859–7868. [Google Scholar] [CrossRef]

- Guo, H.; Zhang, S.; Beckman, S.P.; Tan, X. Microstructural origin for the piezoelectricity evolution in (K0.5Na0.5)NbO3-based lead-free ceramics. J. Appl. Phys. 2013, 114, 154102. [Google Scholar] [CrossRef]

- Fultz, B.; Howe, J. Transmission Electron Microscopy and Diffractometry of Materials, 4th ed.; Springer: New York, NY, USA, 2013. [Google Scholar]

- Tsai, F.; Khiznichenko, V.; Cowley, J.M. High-resolution electron microscopy of 90° ferroelectric domain boundaries in BaTiO3 and Pb(ZrO0.52Ti0.48)O3. Ultramicroscopy 1992, 45, 55–63. [Google Scholar] [CrossRef]

- Gao, P.; Britson, J.; Nelson, C.T.; Jokisaari, J.R.; Duan, C.; Trassin, M.; Baek, S.-H.; Guo, H.; Li, L.; Wang, Y.; et al. Ferroelastic domain switching dynamics under electrical and mechanical excitations. Nat. Commun. 2014, 5, 3801. [Google Scholar] [CrossRef] [PubMed]

- Winkler, C.R.; Damodaran, A.R.; Karthik, J.; Martin, L.W.; Taheri, M.L. Direct observation of ferroelectric domain switching in varying electric field regimes using in situ TEM. Micron 2012, 43, 1121–1126. [Google Scholar] [CrossRef] [PubMed]

- Kholkin, A.; Kalinin, S.; Roelofs, A.; Gruverman, A. Review of ferroelectric domain imaging by piezoresponse force microscopy. In Scanning Probe Microscopy: Electrical and Electromechanical Phenomena at the Nanoscale; Kalinin, S., Gruverman, A., Eds.; Springer Science & Business Media: New York, NY, USA, 2007; pp. 173–214. [Google Scholar]

- Li, J.; Li, J.-F.; Yu, Q.; Chen, Q.N.; Xie, S. Strain-based scanning probe microscopies for functional materials, biological structures, and electrochemical systems. J. Mater. 2015, 1, 3–21. [Google Scholar] [CrossRef]

- Kholkin, A.L.; Bdikin, I.K.; Kiselev, D.A.; Shvartsman, V.V.; Kim, S.H. Nanoscale characterization of polycrystalline ferroelectric materials for piezoelectric applications. J. Electroceram. 2007, 19, 81–94. [Google Scholar] [CrossRef]

- Jungk, T.; Hoffmann, Á.; Soergel, E. Quantitative analysis of ferroelectric domain imaging with piezoresponse force microscopy. Appl. Phys. Lett. 2006, 89, 163507. [Google Scholar] [CrossRef]

- Kalinin, S.; Bonnell, D. Imaging mechanism of piezoresponse force microscopy of ferroelectric surfaces. Phys. Rev. B 2002, 65, 125408. [Google Scholar] [CrossRef]

- Kalinin, S.V.; Rodriguez, B.J.; Jesse, S.; Shin, J.; Baddorf, A.P.; Gupta, P.; Jain, H.; Williams, D.B.; Gruverman, A. Vector piezoresponse force microscopy. Microsc. Microanal. 2006, 12, 206–220. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.L.; Huber, J.E. Mapping of ferroelectric domain structure using angle-resolved piezoresponse force microscopy. Rev. Sci. Instrum. 2015, 86, 013705. [Google Scholar] [CrossRef] [PubMed]

- Cho, Y.; Hashimoto, S.; Odagawa, N.; Tanaka, K.; Hiranaga, Y. Nanodomain manipulation for ultrahigh density ferroelectric data storage. Nanotechnology 2006, 17, 137–141. [Google Scholar]

- Pertsev, N.A.; Kiselev, D.A.; Bdikin, I.K.; Kosec, M.; Kholkin, A.L. Quasi-one-dimensional domain walls in ferroelectric ceramics: Evidence from domain dynamics and wall roughness measurements. J. Appl. Phys. 2011, 110, 052001. [Google Scholar] [CrossRef]

- Shur, V.Y.; Shishkin, E.I.; Nikolaeva, E.V.; Nebogatikov, M.S.; Alikin, D.O.; Zelenovskiy, P.S.; Sarmanova, M.F.; Dolbilov, M.A. Study of nanoscale domain structure formation using Raman confocal microscopy. Ferroelectrics 2010, 398, 91–97. [Google Scholar] [CrossRef]

- DeWolf, I. Micro-Raman spectroscopy to study local mechanical stress in silicon integrated circuits. Semicond. Sci. Technol. 1996, 11, 139–154. [Google Scholar]

- Myers, G.A.; Hazra, S.S.; de Boer, M.P.; Michaels, C.A.; Stranick, S.J.; Koseski, R.P.; Cook, R.F.; Delrio, F.W. Stress mapping of micromachined polycrystalline silicon devices via confocal Raman microscopy. Appl. Phys. Lett. 2014, 104, 191908. [Google Scholar] [CrossRef]

- Borodavka, F.; Pokorny, J.; Hlinka, J. Combined piezoresponse force microscopy and Raman scattering investigation of domain boundaries in BiFeO3 ceramics. Phase Transit. 2016, 89, 746–751. [Google Scholar] [CrossRef]

- Zhao, T.; Scholl, A.; Zavaliche, F.; Lee, K.; Barry, M.; Doran, A.; Cruz, M.P.; Chu, Y.H.; Ederer, C.; Spaldin, N.A.; et al. Electrical control of antiferromagnetic domains in multiferroic BiFeO3 films at room temperature. Nat. Mater. 2006, 5, 823–829. [Google Scholar] [CrossRef] [PubMed]

- Shvartsman, V.V.; Kleemann, W.; Haumont, R.; Kreisel, J. Large bulk polarization and regular domain structure in ceramic BiFeO3. Appl. Phys. Lett. 2007, 90, 172115. [Google Scholar] [CrossRef]

- Tu, C.S.; Chen, C.S.; Chen, P.Y.; Wei, H.H.; Schmidt, V.H.; Lin, C.Y.; Anthoniappen, J.; Lee, J.M. Enhanced photovoltaic effects in A-site samarium doped BiFeO3 ceramics: The roles of domain structure and electronic state. J. Eur. Ceram. Soc. 2016, 36, 1149–1157. [Google Scholar] [CrossRef]

- Alikin, D.O.; Turygin, A.P.; Walker, J.; Bencan, A.; Malic, B.; Rojac, T.; Shur, V.Y.; Kholkin, A.L. The effect of phase assemblages, grain boundaries and domain structure on the local switching behavior of rare-earth modified bismuth ferrite ceramics. Acta Mater. 2017, 125, 265–273. [Google Scholar] [CrossRef]

- Walker, J.; Simons, H.; Alikin, D.O.; Turygin, A.P.; Shur, V.Y.; Kholkin, A.L.; Ursic, H.; Bencan, A.; Malic, B.; Nagarajan, V.; et al. Dual strain mechanisms in a lead-free morphotropic phase boundary ferroelectric. Sci. Rep. 2016, 6, 19630. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alikin, D.O.; Turygin, A.P.; Walker, J.; Rojac, T.; Shvartsman, V.V.; Shur, V.Y.; Kholkin, A.L. Quantitative phase separation in multiferroic Bi0.88Sm0.12FeO3 ceramics via piezoresponse force microscopy. J. Appl. Phys. 2015, 118. [Google Scholar] [CrossRef]

- Karimi, S.; Reaney, I.M.; Levin, I.; Sterianou, I. Nd-doped BiFeO3 ceramics with antipolar order. Appl. Phys. Lett. 2009, 94, 112903. [Google Scholar] [CrossRef]

- Karimi, S.; Reaney, I.M.; Han, Y.; Pokorny, J.; Sterianou, I. Crystal chemistry and domain structure of rare-earth doped BiFeO3 ceramics. J. Mater. Sci. 2009, 44, 5102–5112. [Google Scholar] [CrossRef]

- Khomchenko, V.A.; Karpinsky, D.V.; Kholkin, A.L.; Sobolev, N.A.; Kakazei, G.N.; Araujo, J.P.; Troyanchuk, I.O.; Costa, B.F.O.; Paixão, J.A. Rhombohedral-to-orthorhombic transition and multiferroic properties of Dy-substituted BiFeO3. J. Appl. Phys. 2010, 108, 074109. [Google Scholar] [CrossRef]

- Khomchenko, V.A.; Kiselev, D.A.; Bdikin, I.K.; Shvartsman, V.V.; Borisov, P.; Kleemann, W.; Vieira, J.M.; Kholkin, A.L. Crystal structure and multiferroic properties of Gd-substituted BiFeO3. Appl. Phys. Lett. 2008, 93, 262905. [Google Scholar] [CrossRef]

- Yan, F.; Xing, G.; Wang, R.; Li, L. Tailoring surface phase transition and magnetic behaviors in BiFeO3 via doping engineering. Sci. Rep. 2015, 5, 9128. [Google Scholar] [CrossRef] [PubMed]

- Coondoo, I.; Panwar, N.; Bdikin, I.; Puli, V.S.; Katiyar, R.S.; Kholkim, A.L. Structural, morphological and piezoresponse studies of Pr and Sc co-substituted BiFeO3 ceramics. J. Phys. D Appl. Phys. 2012, 45, 055302. [Google Scholar] [CrossRef]

- Azough, F.; Freer, R.; Thrall, M.; Cernik, R.; Tuna, F.; Collison, D. Microstructure and properties of Co-, Ni-, Zn-, Nb- and W-modified multiferroic BiFeO3 ceramics. J. Eur. Ceram. Soc. 2010, 30, 727–736. [Google Scholar] [CrossRef]

- Khesro, A.; Boston, R.; Sterianou, I.; Sinclair, D.C.; Reaney, I.M. Phase transitions, domain structure, and pseudosymmetry in La- and Ti-doped BiFeO3. J. Appl. Phys. 2016, 119, 054101. [Google Scholar] [CrossRef]

- Chen, J.; Cheng, J.; Dong, S. Review on high temperature piezoelectric ceramics and actuators based on BiScO3–PbTiO3 solid solutions. J. Adv. Dielectr. 2014, 4, 1430002. [Google Scholar] [CrossRef]

- De, U.; Sahu, K.R.; De, A. Ferroelectric materials for high temperature piezoelectric applications. Solid State Phenom. 2015, 232, 235–278. [Google Scholar] [CrossRef]

- Rojac, T.; Makarovic, M.; Walker, J.; Ursic, H.; Damjanovic, D.; Kos, T. Piezoelectric response of BiFeO3 ceramics at elevated temperatures. Appl. Phys. Lett. 2016, 109, 042904. [Google Scholar] [CrossRef]

- Martirena, H.T.; Burfoot, J.C. Grain-size effects on properties of some ferroelectric ceramics. J. Phys. C Solid State Phys. 1974, 7, 3182–3192. [Google Scholar] [CrossRef]

- Pertsev, N.A.; Arlt, G. Theory of the banded domain structure in coarse-grained ferroelectric ceramics. Ferroelectrics 1992, 132, 27–40. [Google Scholar] [CrossRef]

- Arlt, G.; Hennings, D.; de With, G. Dielectric properties of fine-grained barium titanate ceramics. J. Appl. Phys. 1985, 58, 1619–1625. [Google Scholar] [CrossRef]

- Arlt, G.; Dederichs, H. Complex elastic, dielectric and piezoelectric constants by domain wall damping in ferroelectric ceramics. Ferroelectrics 1980, 29, 47–50. [Google Scholar] [CrossRef]

- Escobar Castillo, M.; Shvartsman, V.V.; Gobeljic, D.; Gao, Y.; Landers, J.; Wende, H.; Lupascu, D.C. Effect of particle size on ferroelectric and magnetic properties of BiFeO3 nanopowders. Nanotechnology 2013, 24, 355701. [Google Scholar] [CrossRef] [PubMed]

- López, R.; González, F.; Cruz, M.P.; Villafuerte-Castrejon, M.E. Piezoelectric and ferroelectric properties of K0.5Na0.5NbO3 ceramics synthesized by spray drying method. Mater. Res. Bull. 2011, 46, 70–74. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, J.; Yao, W.; Wang, C.; Zhang, S. Domain structure of potassium-sodium niobate ceramics before and after poling. J. Am. Ceram. Soc. 2015, 98, 1027–1033. [Google Scholar] [CrossRef]

- Fousek, J.; Janovec, V. The orientation of domain walls in twinned ferroelectric crystals. J. Appl. Phys. 1969, 40, 135–142. [Google Scholar] [CrossRef]

- Hirohashi, J.; Yamada, K.; Kamio, H.; Uchida, M.; Shichijyo, S. Control of specific domain structure in KNbO3 single crystals by differential vector poling method. J. Appl. Phys. 2005, 98, 034107. [Google Scholar] [CrossRef]

- Zhang, J.; Tian, X.; Gao, Y.; Yao, W.; Qin, Y.; Su, W. Domain structure of poled (K0.50Na0.50)1-xLixNbO3 ceramics with different stabilities. J. Am. Ceram. Soc. 2015, 98, 990–995. [Google Scholar] [CrossRef]

- Cho, J.; Lee, Y.; Han, K.; Chun, M.; Nam, J.; Kim, B. Effect of domain size on the coercive field of orthorhombic (Li, K, Na)NbO3 ceramics. J. Korean Phys. Soc. 2010, 57, 971–974. [Google Scholar]

- Arlt, G. Twinning in ferroelectric and ferroelastic ceramics: Stress relief. J. Mater. Sci. 1990, 25, 2655–2666. [Google Scholar] [CrossRef]

- Rossetti, G.A.; Khachaturyan, A.G.; Akcay, G.; Ni, Y. Ferroelectric solid solutions with morphotropic boundaries: Vanishing polarization anisotropy, adaptive, polar glass, and two-phase states. J. Appl. Phys. 2008, 103, 114113. [Google Scholar] [CrossRef]

- Cho, J.; Lee, Y.; Kim, B. Domain structure of orthorhombic (Li,K,Na)NbO3 ceramics. J. Ceram. Process. Res. 2010, 11, 237–240. [Google Scholar]

- Rai, R.; Coondoo, I.; Rani, R.; Bdikin, I.; Sharma, S.; Kholkin, A.L. Impedance spectroscopy and piezoresponse force microscopy analysis of lead-free (1 − x) K0.5Na0.5NbO3 − xLiNbO3 ceramics. Curr. Appl. Phys. 2013, 13, 430–440. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, J.; Tan, Y.; Yao, W.; Wang, C.; Zhang, S. Domain configuration and piezoelectric properties of (K0.50Na0.50)1−xLix(Nb0.80Ta0.20)O3 ceramics. J. Eur. Ceram. Soc. 2014, 34, 4177–4184. [Google Scholar] [CrossRef]

- Fu, J.; Zuo, R.; Xu, Z.; Fu, J.; Zuo, R.; Xu, Z. High piezoelectric activity in (Na,K)NbO3 based lead-free piezoelectric ceramics: Contribution of nanodomains. Appl. Phys. Lett. 2011, 99, 21–24. [Google Scholar] [CrossRef]

- Gobeljic, D.; Shvartsman, V.V.; Wang, K.; Yao, F.; Li, J.F.; Jo, W.; Rödel, J.; Lupascu, D.C. Temperature dependence of the local piezoresponse in (K,Na)NbO3-based ceramics with large electromechanical strain. J. Appl. Phys. 2014, 116, 066811. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, K.; Yao, F.; Zheng, T.; Wu, J. Lead-free piezoceramics with large piezoelectricity. J. Mater. Chem. C 2015, 3, 8780–8787. [Google Scholar] [CrossRef]

- Hunpratub, S.; Yamwong, T.; Srilomsak, S.; Maensiri, S.; Chindaprasirt, P. Effect of particle size on the dielectric and piezoelectric properties of 0–3BCTZO/cement composites. Ceram. Int. 2015, 40, 1209–1213. [Google Scholar] [CrossRef]

- Taylor, D.V.; Damjanovic, D. Evidence of domain wall contribution to the dielectric permittivity in PZT thin films at sub-switching fields. J. Appl. Phys. 1997, 82, 1973–1975. [Google Scholar] [CrossRef]

- Rayleigh, L. XXV. Notes on electricity and magnetism.—III. On the behaviour of iron and steel under the operation of feeble magnetic forces. Philos. Mag. Ser. 5 1887, 23, 225–245. [Google Scholar] [CrossRef]

- Pertsev, N.A.; Arlt, G. Forced translational vibrations of 90-degrees domain-walls and the dielectric-dispersion in ferroelectric ceramics. J. Appl. Phys. 1993, 74, 4105–4112. [Google Scholar] [CrossRef]

- Buixaderas, E.; Bovtun, V.; Kempa, M.; Savinov, M.; Nuzhnyy, D.; Kadlec, F.; Vaněk, P.; Petzelt, J.; Eriksson, M.; Shen, Z. Broadband dielectric response and grain-size effect in K0.5Na0.5NbO3 ceramics. J. Appl. Phys. 2010, 107, 014111. [Google Scholar] [CrossRef]

- Zhang, J.; Hao, W.; Gao, Y.; Qin, Y.; Tan, Y.; Wang, C. Large decrease of characteristic frequency of dielectric relaxation associated with domain-wall motion in Sb5+-modified (K, Na)NbO3-based ceramics. Appl. Phys. Lett. 2012, 101, 252905. [Google Scholar] [CrossRef]

- Huan, Y.; Wang, X.; Li, L.; Koruza, J. Strong domain configuration dependence of the nonlinear dielectric response in (K, Na)NbO3-based ceramics. Appl. Phys. Lett. 2015, 107, 202903. [Google Scholar] [CrossRef]

- Arlt, G.; Böttger, U.; Witte, S. Dielectric dispersion of ferroelectric ceramics and single crystals at microwave frequencies. Ann. Phys. 1994, 506, 578–588. [Google Scholar] [CrossRef]

- Arlt, G.; Böttger, U.; Witte, S. Emission of GHz shear waves by ferroelastic domain walls in ferroelectrics. Appl. Phys. Lett. 1993, 63, 602–604. [Google Scholar] [CrossRef]

- Arlt, G.; Böttger, U.; Witte, S. Dielectric dispersion of ferroelectric ceramics and single crystals by sound generation in piezoelectric domains. J. Am. Ceram. Soc. 1995, 78, 1097–1100. [Google Scholar] [CrossRef]

- Arlt, G. Strong ultrasonic microwaves in ferroelectric ceramics. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1998, 45, 4–10. [Google Scholar] [CrossRef] [PubMed]

- Arlt, G. Ferroelastic domain walls as powerful shear wave emitters at microwaves. Ferroelectrics 1995, 172, 95–104. [Google Scholar] [CrossRef]

- Rojac, T.; Ursic, H.; Bencan, A.; Malic, B.; Damjanovic, D. Mobile domain walls as a bridge between nanoscale conductivity and macroscopic electromechanical response. Adv. Funct. Mater. 2015, 25, 2099–2108. [Google Scholar] [CrossRef]

- Peng, B.; Yue, Z.; Li, L.; Peng, B.; Yue, Z.; Li, L. Evaluation of domain wall motion during polymorphic phase transition in (K, Na)NbO3—Based piezoelectric ceramics by nonlinear response measurements. J. Appl. Phys. 2016, 109, 54107. [Google Scholar] [CrossRef]

- Morozov, M.I.; Hoffmann, M.J.; Benkert, K.; Schuh, C. Influence of the A/B nonstoichiometry, composition modifiers, and preparation methods on properties of Li- and Ta-modified (K, Na)NbO3 ceramics. J. Appl. Phys. 2012, 112, 114107. [Google Scholar] [CrossRef]

- Ge, J.; Qi, Y.; Wan, Y.; Tang, Y.; Wang, F.; Pan, Y.; Jiang, B.; Sun, D. Relationship between dielectric property and shrinkage in ferroelectric KNN-based ceramics. Ferroelectrics 2014, 458, 37–41. [Google Scholar] [CrossRef]

- Huan, Y.; Wang, X.; Koruza, J.; Wang, K.; Webber, K.G.; Hao, Y.; Li, L. Inverted electro-mechanical behaviour induced by the irreversible domain configuration transformation in (K, Na)NbO3—Based ceramics. Sci. Rep. 2016, 6, 22053. [Google Scholar] [CrossRef] [PubMed]

- Huan, Y.; Wang, X.; Shen, Z.; Kim, J.; Zhou, H.; Li, L. Nanodomains in KNN-based lead-free piezoelectric ceramics: Origin of strong piezoelectric properties. J. Am. Ceram. Soc. 2014, 97, 701–703. [Google Scholar] [CrossRef]

- Hayati, R.; Barzegar, A. Microstructure and electrical properties of lead free potassium sodium niobate piezoceramics with nano ZnO additive. Mater. Sci. Eng. B 2010, 172, 121–126. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alikin, D.; Turygin, A.; Kholkin, A.; Shur, V. Ferroelectric Domain Structure and Local Piezoelectric Properties of Lead-Free (Ka0.5Na0.5)NbO3 and BiFeO3-Based Piezoelectric Ceramics. Materials 2017, 10, 47. https://doi.org/10.3390/ma10010047

Alikin D, Turygin A, Kholkin A, Shur V. Ferroelectric Domain Structure and Local Piezoelectric Properties of Lead-Free (Ka0.5Na0.5)NbO3 and BiFeO3-Based Piezoelectric Ceramics. Materials. 2017; 10(1):47. https://doi.org/10.3390/ma10010047

Chicago/Turabian StyleAlikin, Denis, Anton Turygin, Andrei Kholkin, and Vladimir Shur. 2017. "Ferroelectric Domain Structure and Local Piezoelectric Properties of Lead-Free (Ka0.5Na0.5)NbO3 and BiFeO3-Based Piezoelectric Ceramics" Materials 10, no. 1: 47. https://doi.org/10.3390/ma10010047