A Comprehensive Review of the Study and Development of Microcapsule Based Self-Resilience Systems for Concrete Structures at Shenzhen University

Abstract

:1. Introduction

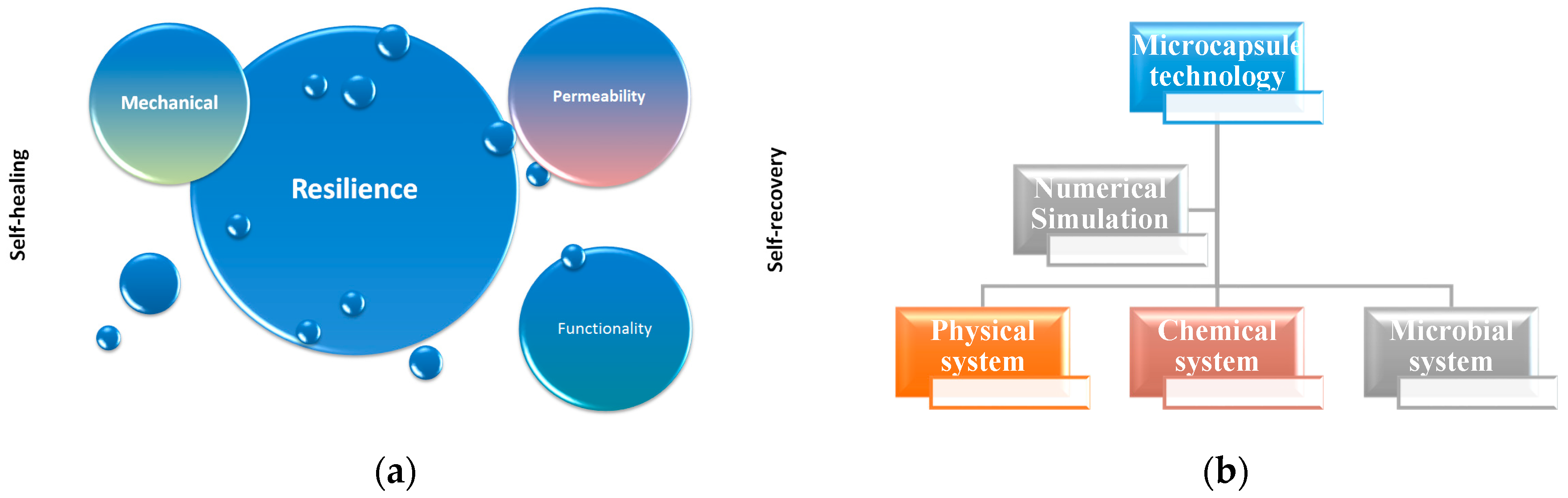

2. Pioneer Work Since 2008

2.1. Microcapsule Technology

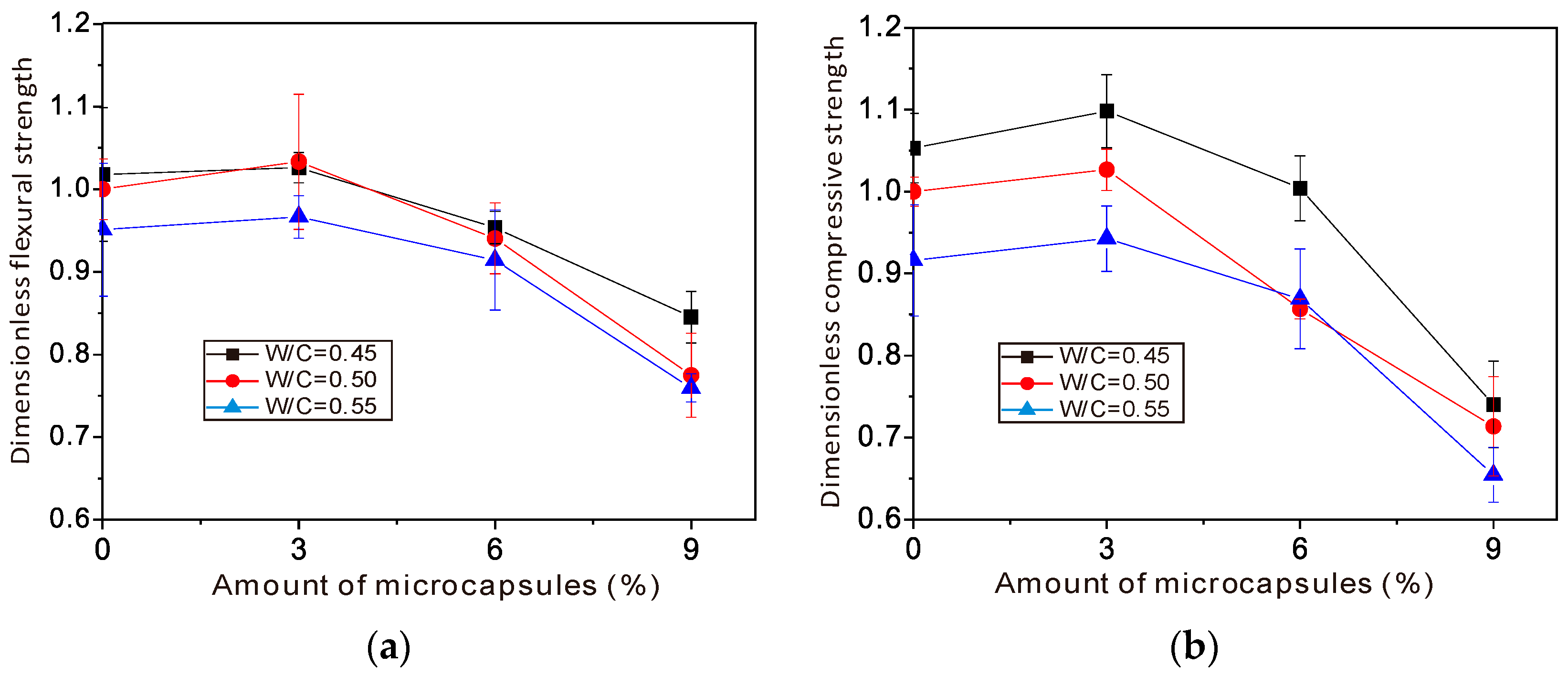

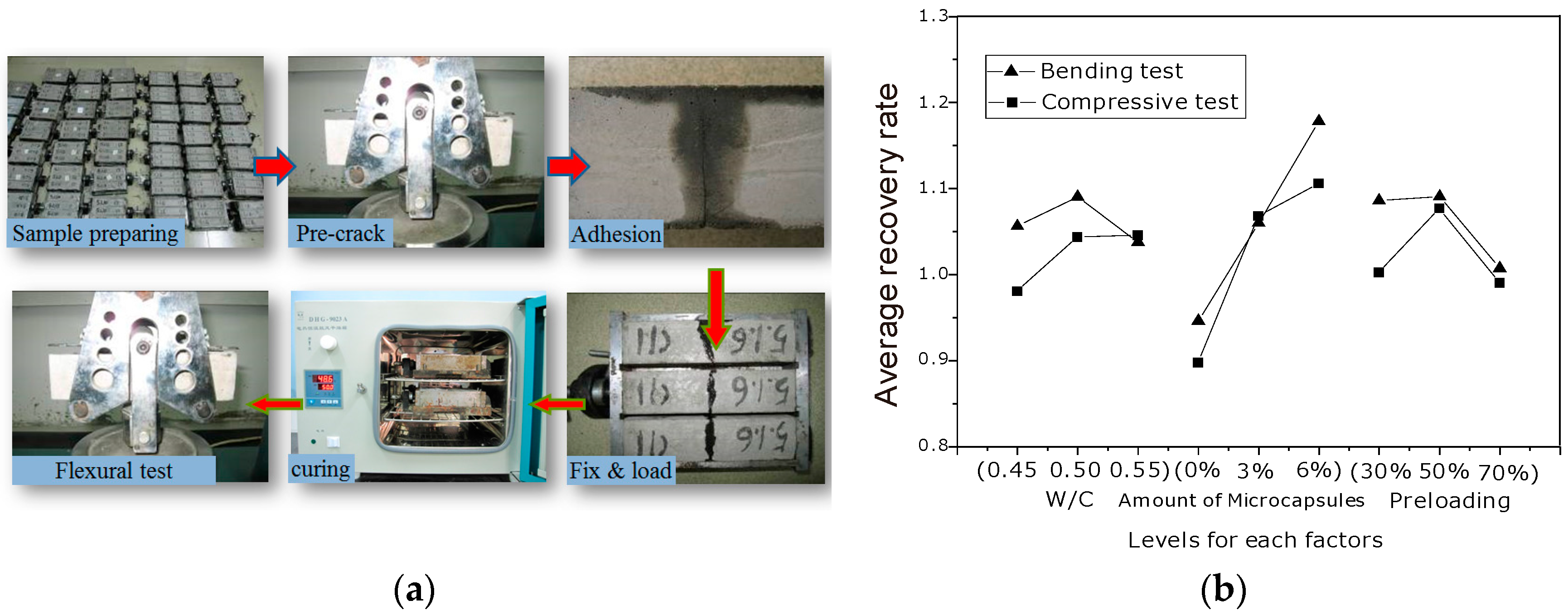

2.2. Feasibility Study and Evaluation

3. Principle and Strategy Development

- Physical system (organic or in-organic healing agent, physical trigger, self-healing at micro or meso level)

- Chemical system (organic or in-organic healing agent, chemical trigger, self-recovery at multi scale)

- Microbial system (bacteria as healing agent supplier, physical trigger, self-recovery at meso or macro level)

4. Several Major Breakthroughs

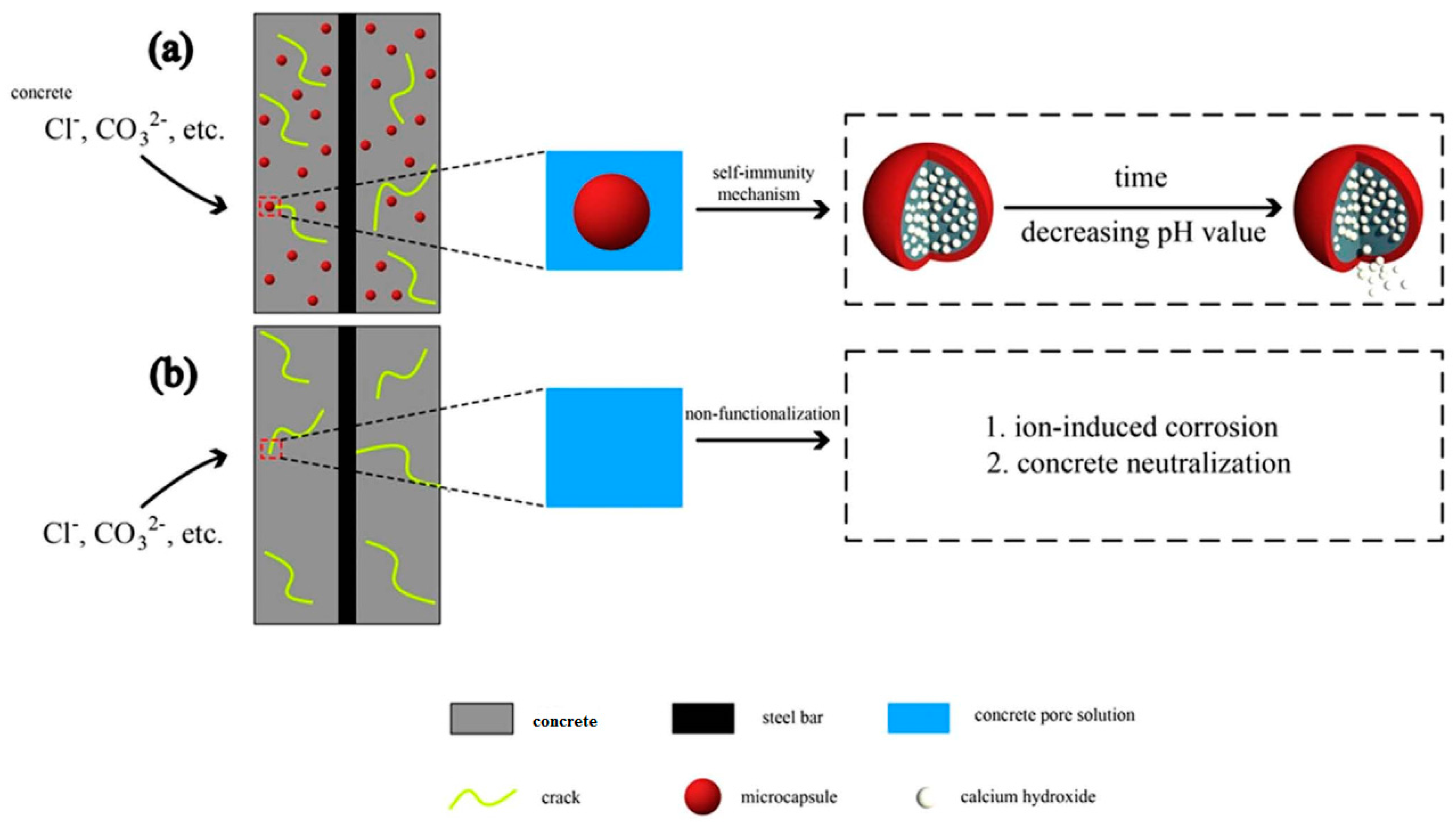

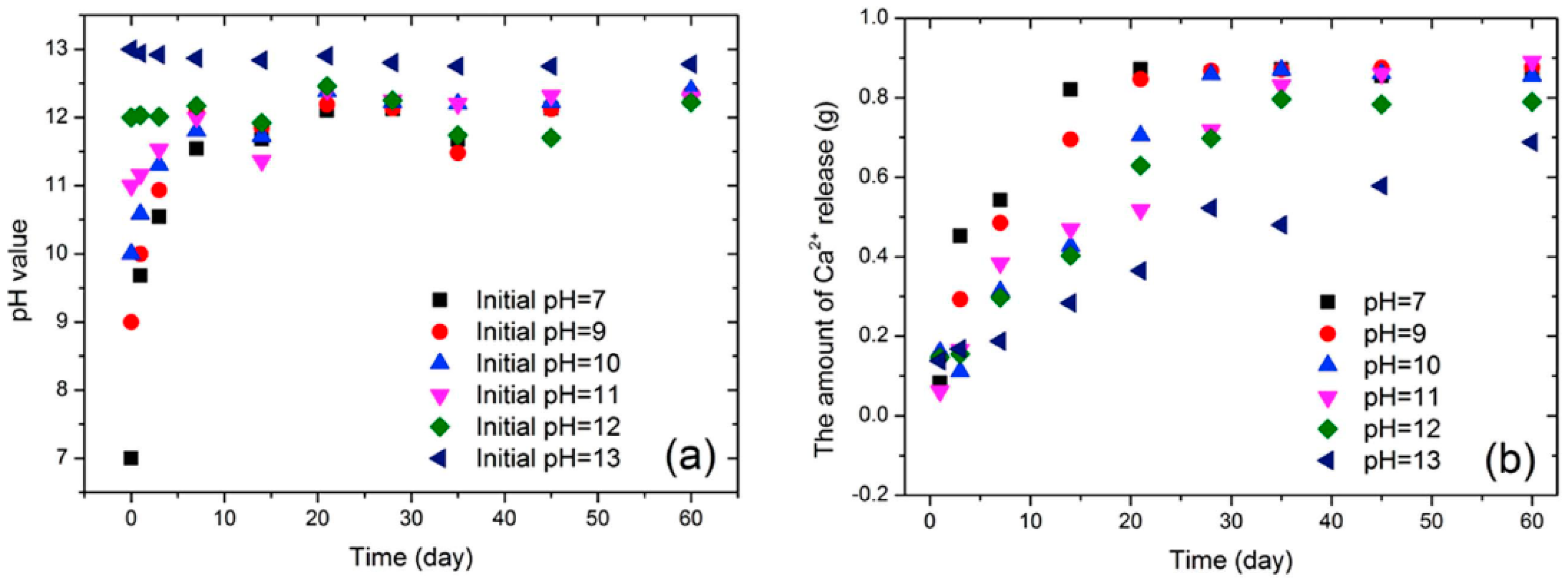

4.1. A Chemical System with a pH Sensitive Trigger

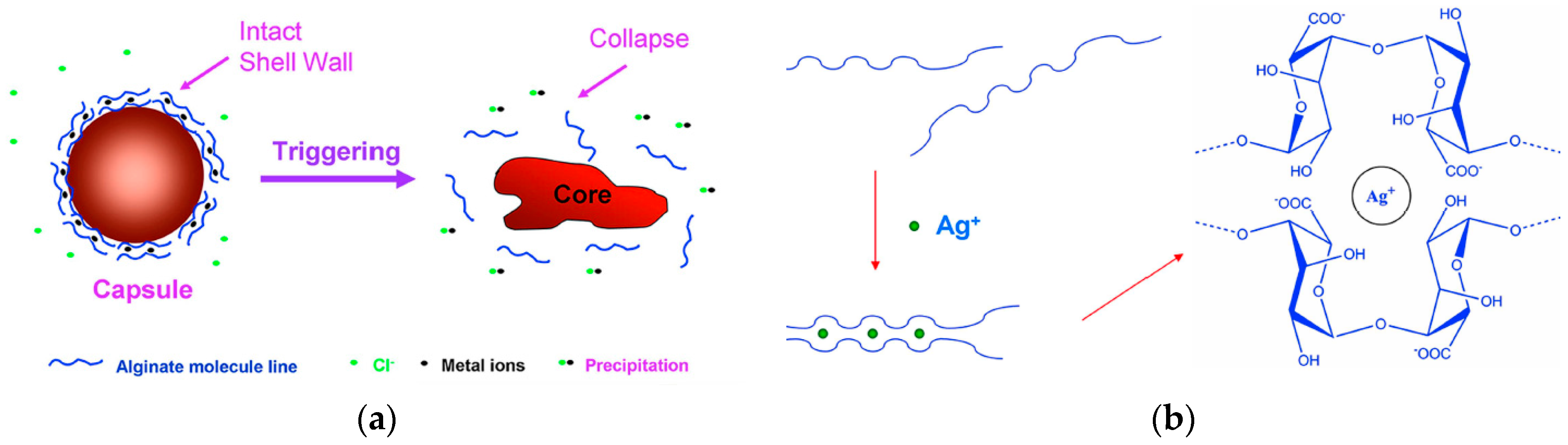

4.2. A Chemical System with a Chloride Sensitive Trigger

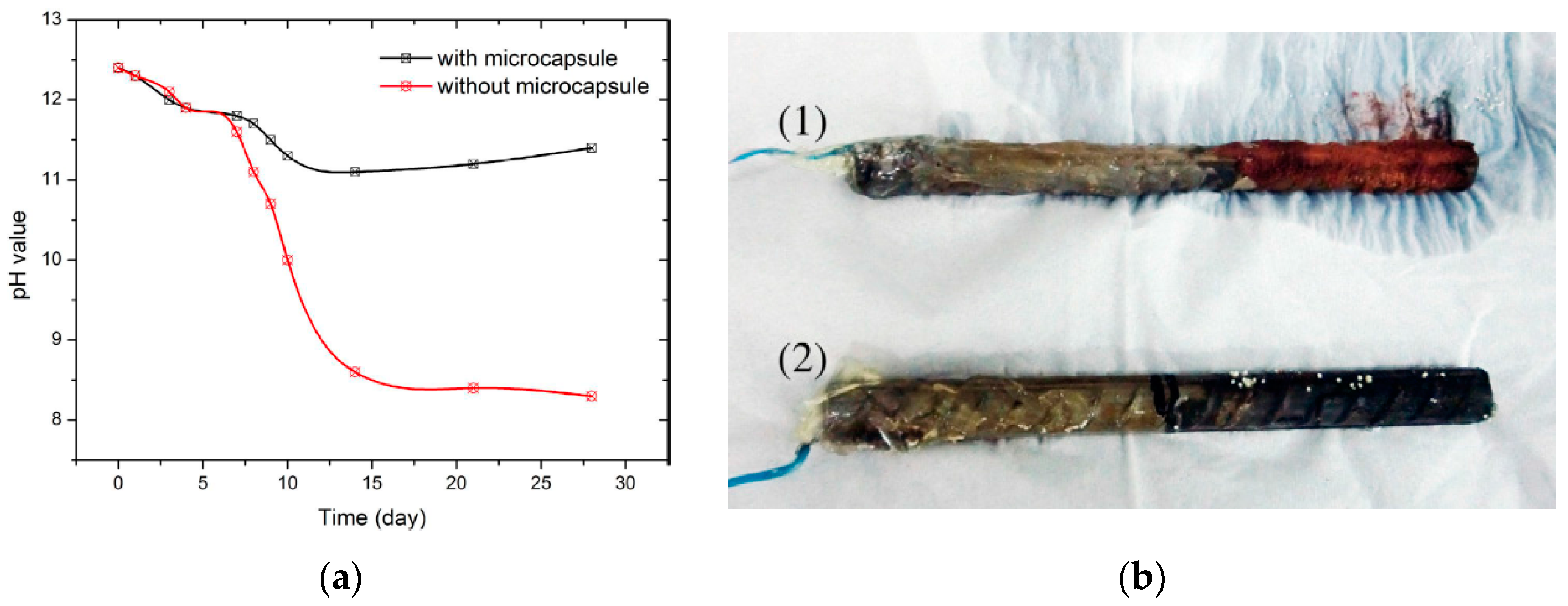

4.3. Microbial Self-Healing System

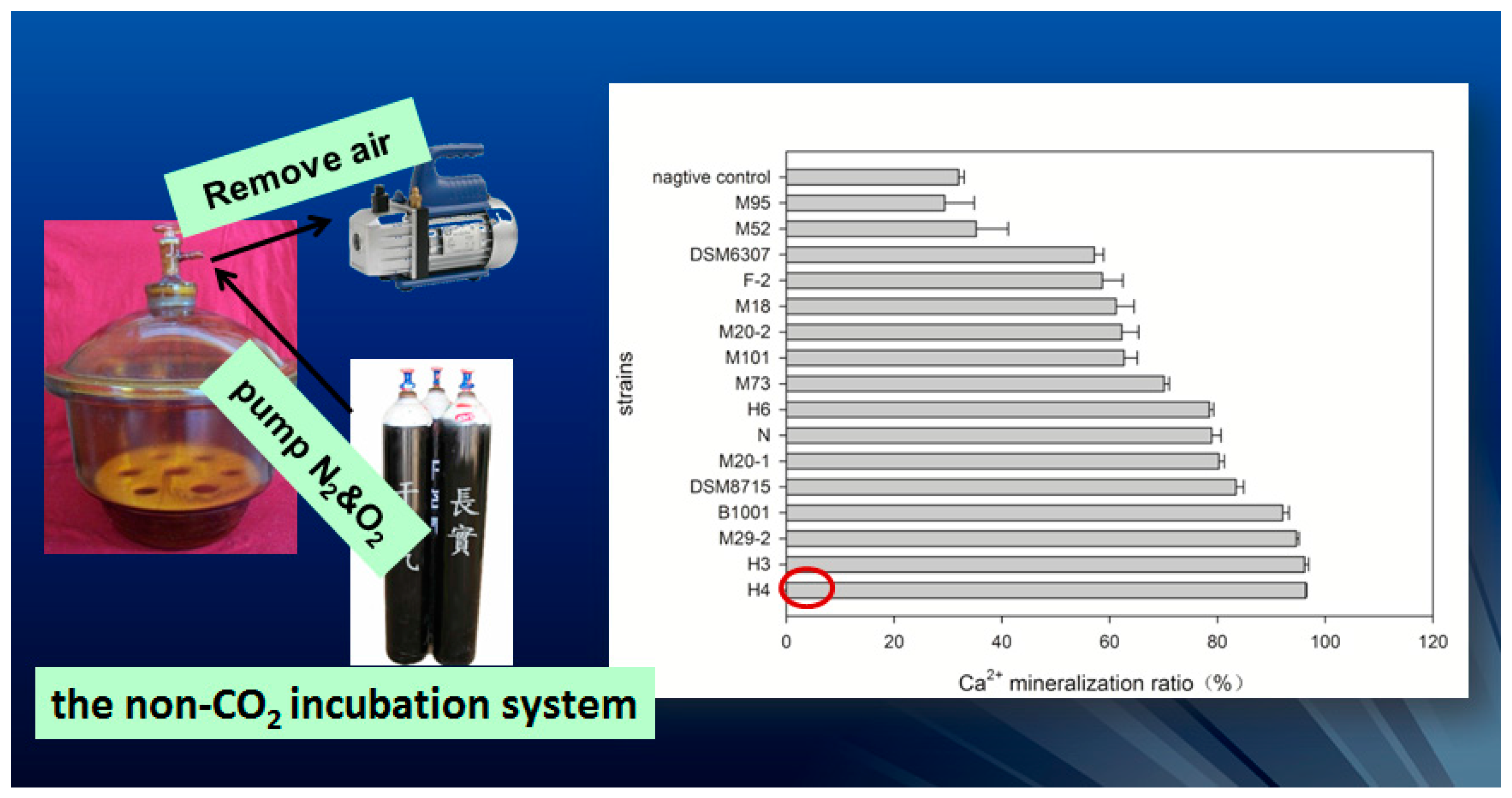

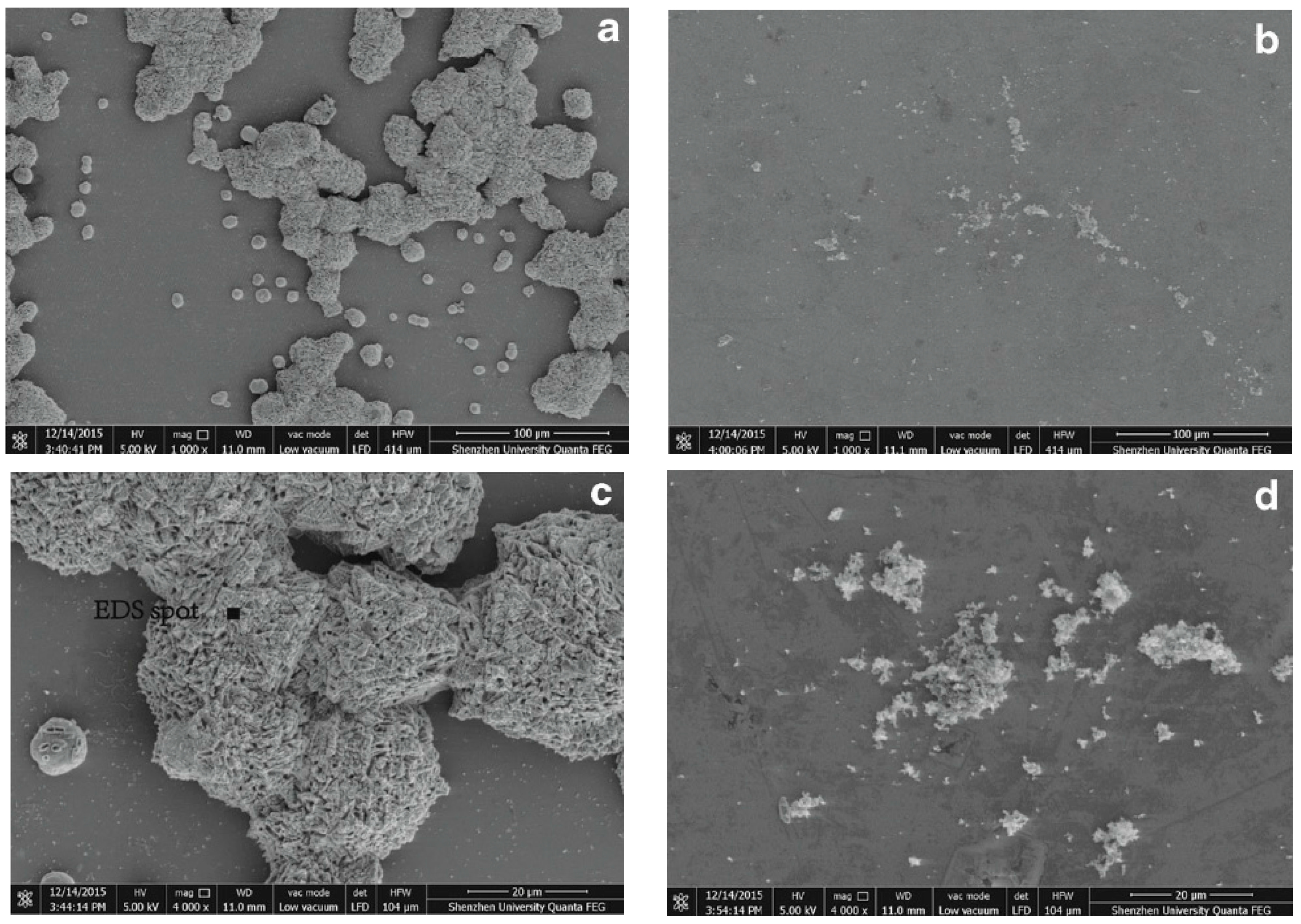

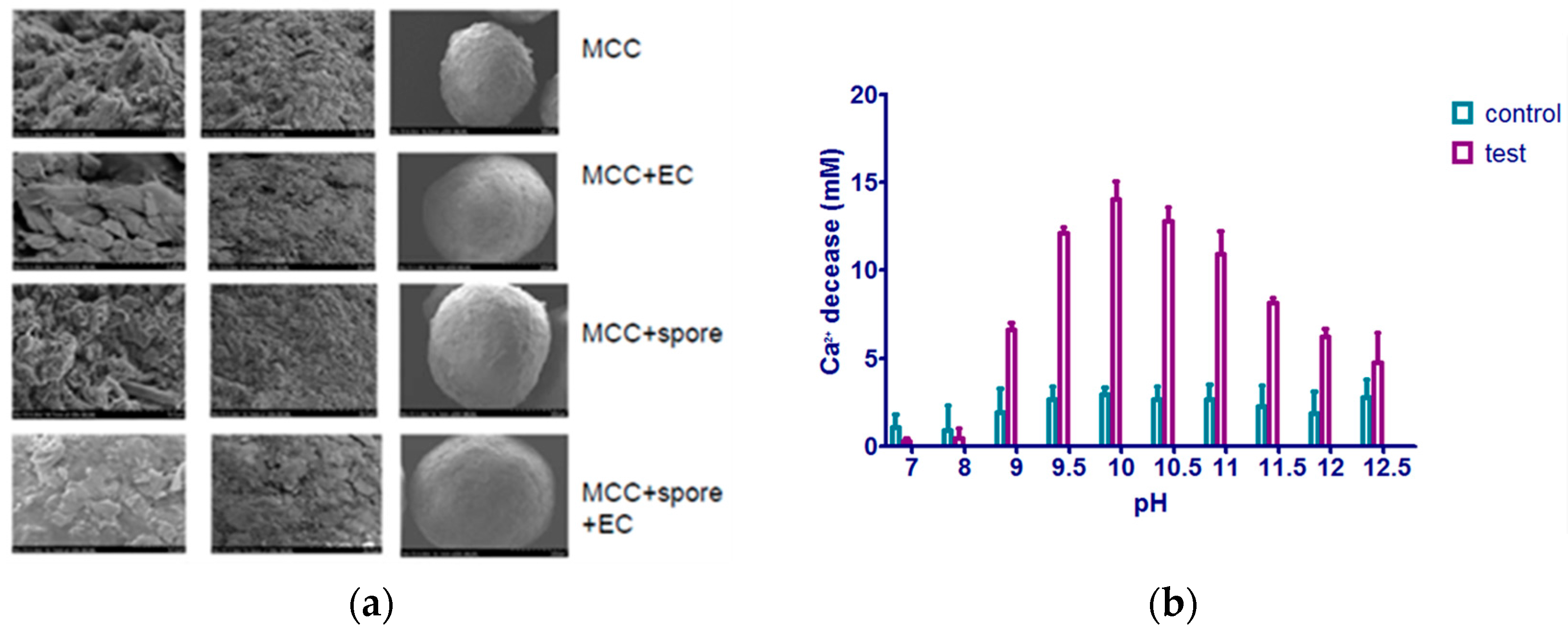

4.3.1. The Calcium Precipitation Activity (CPA) Related Issues

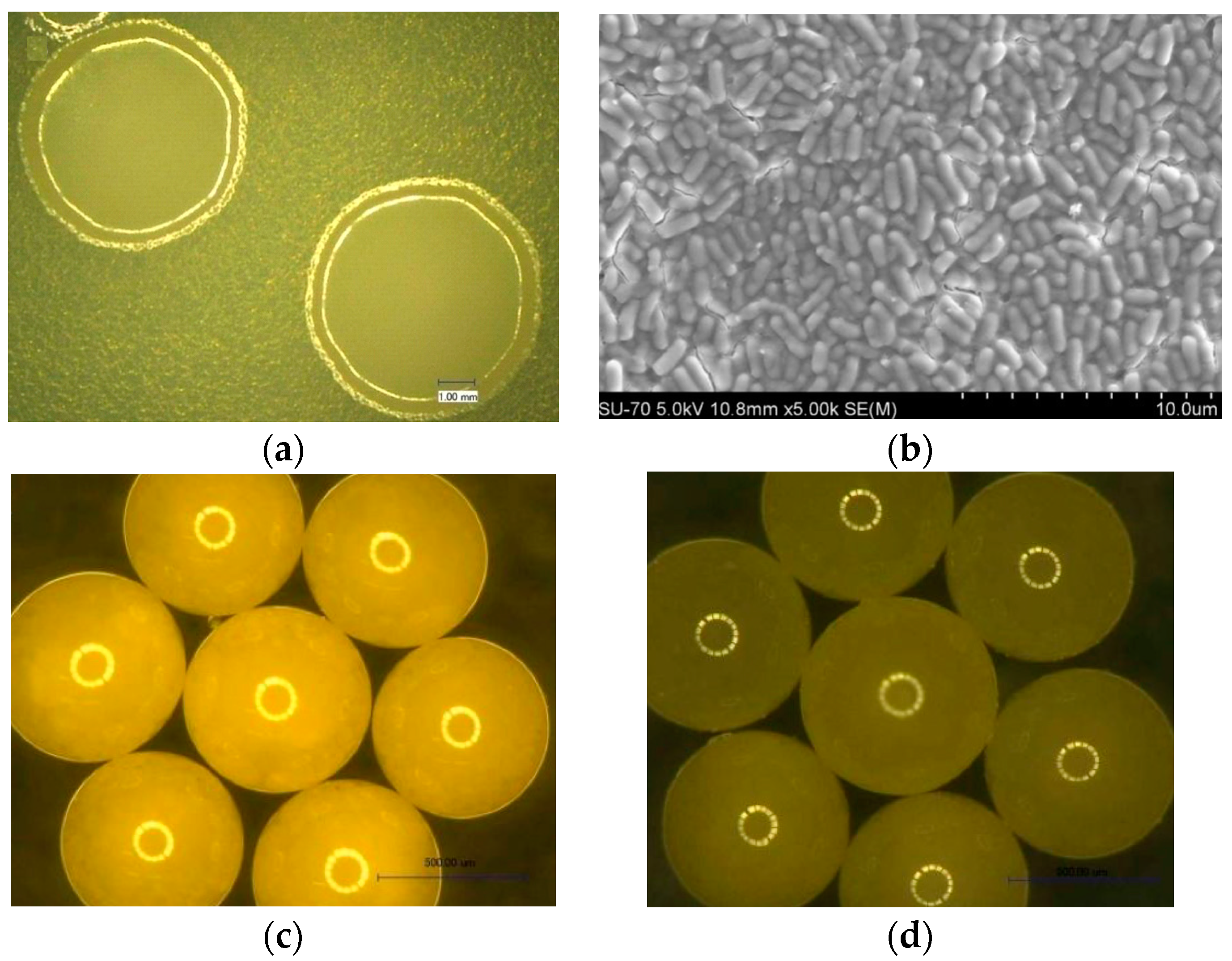

4.3.2. Special Issues Related to the Microcapsule Technology for Microbial Self-Healing System

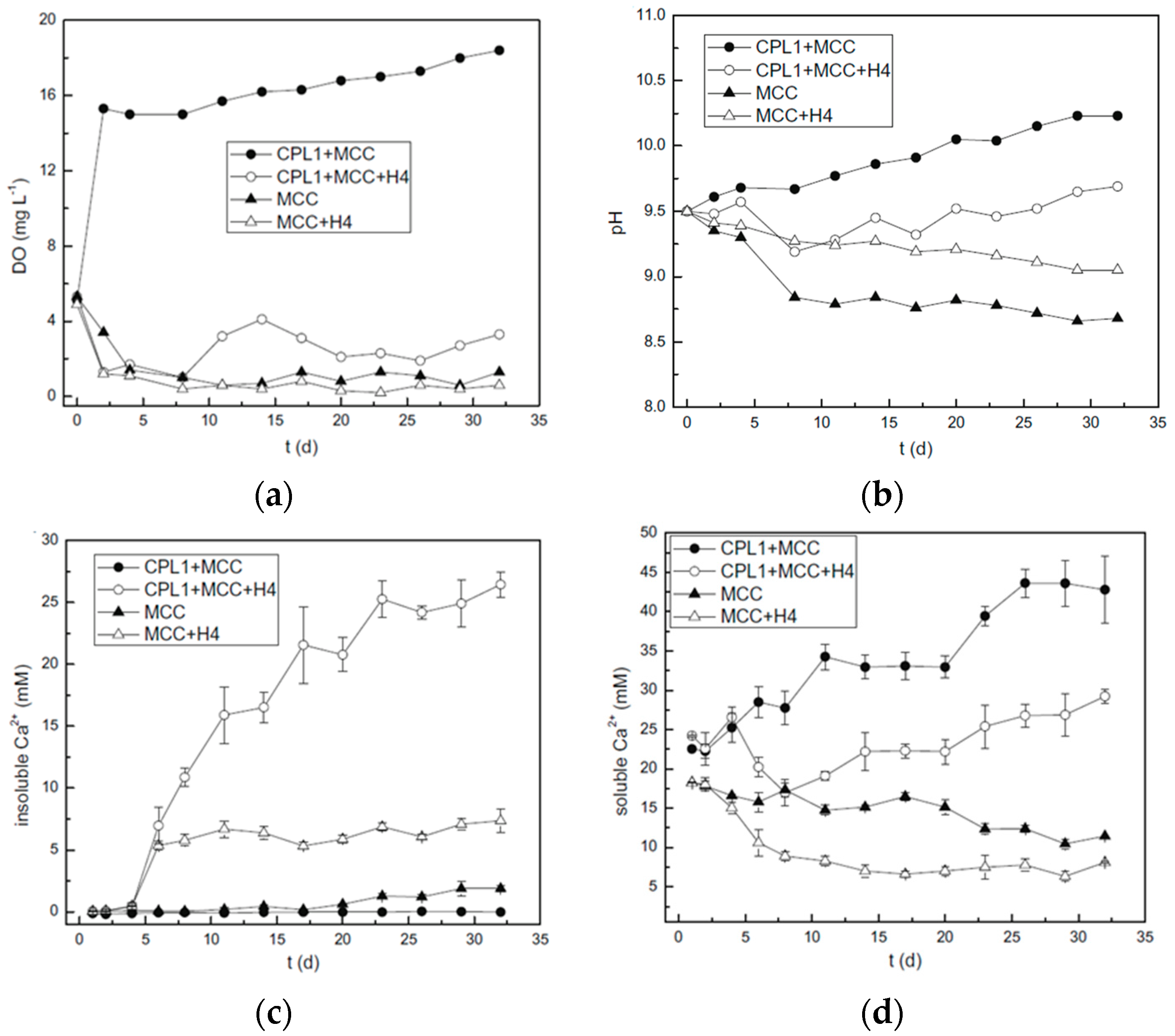

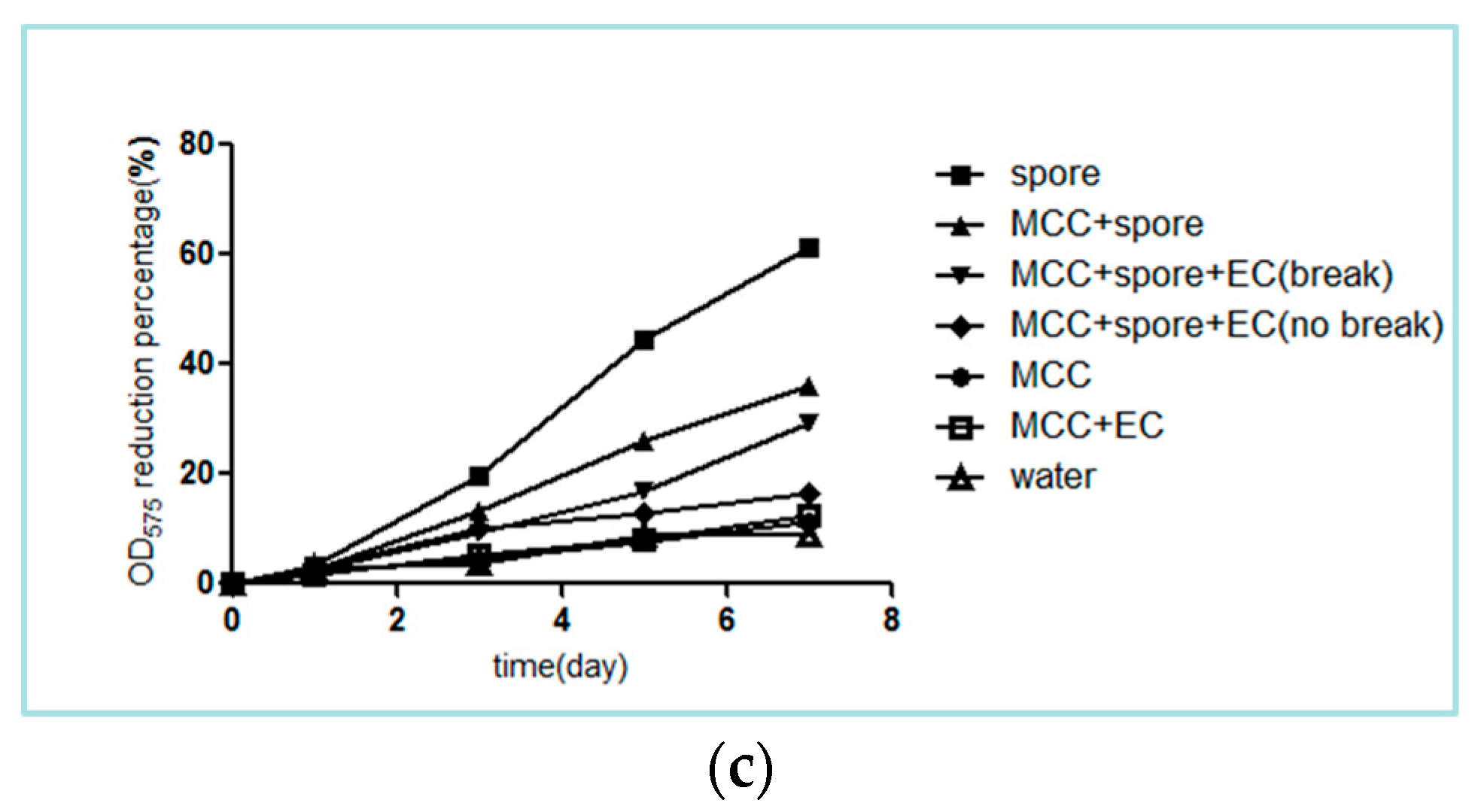

4.3.3. Feasibility Study on the Microcapsule Based Microbial Self-Healing System

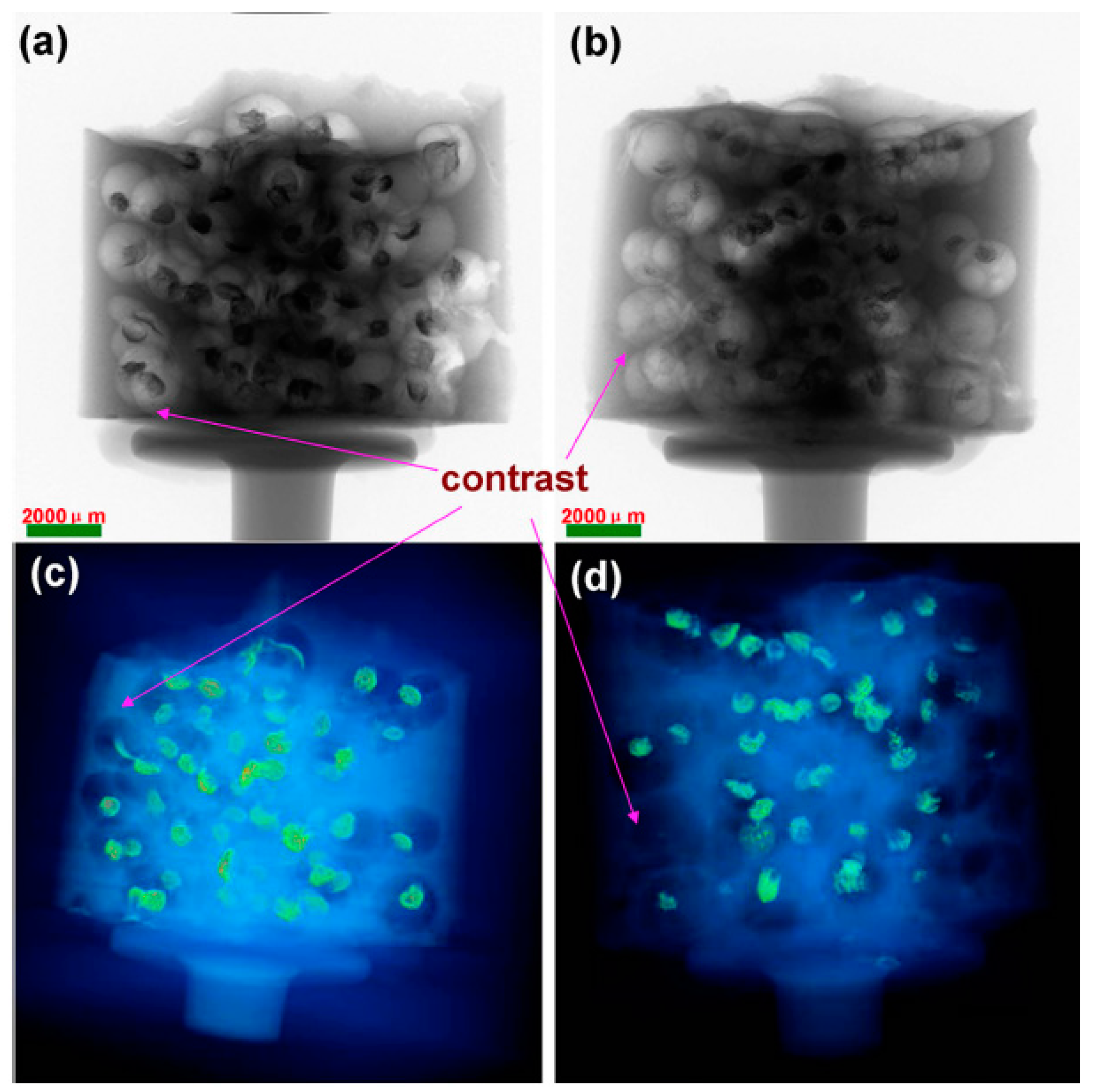

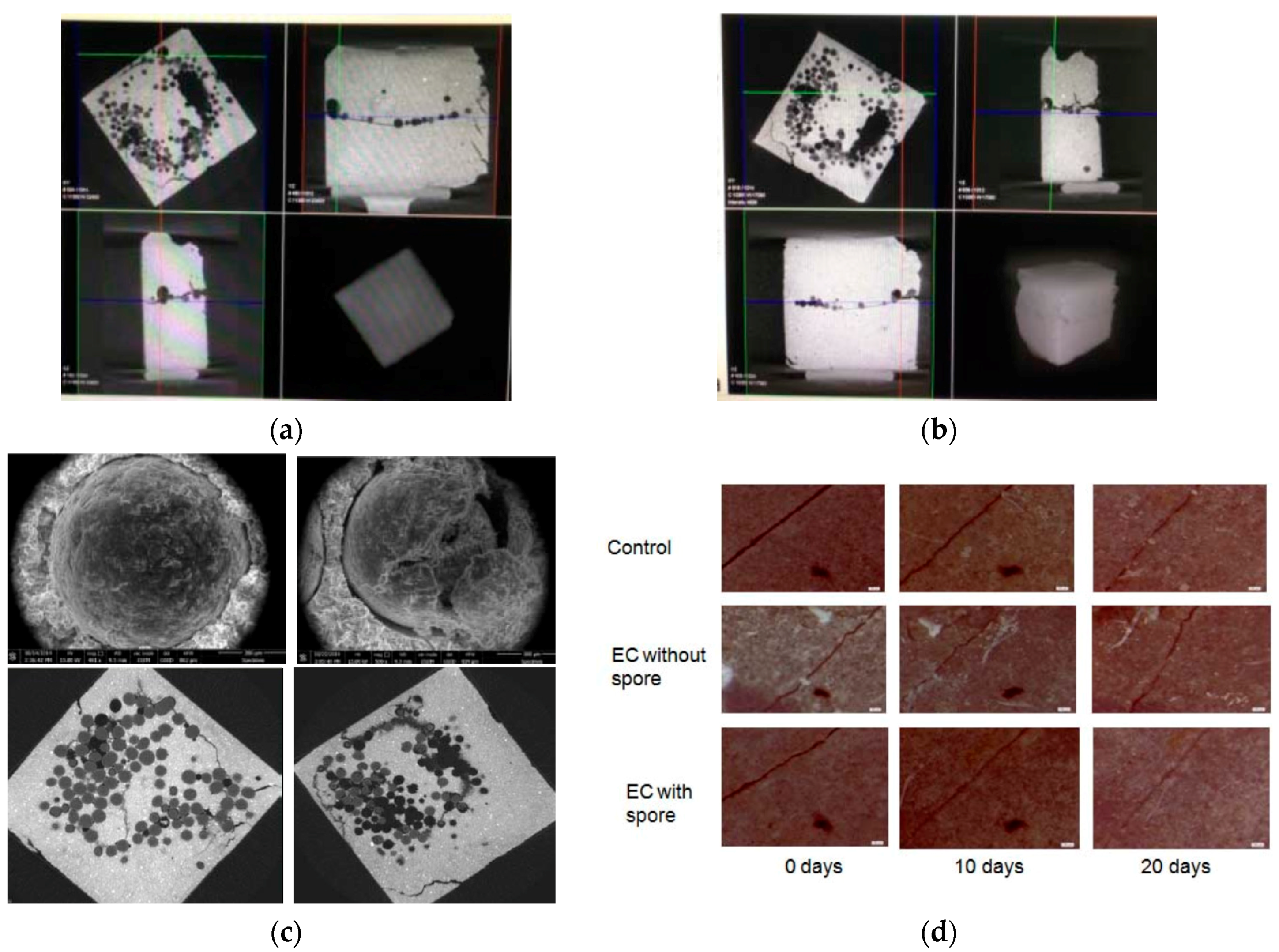

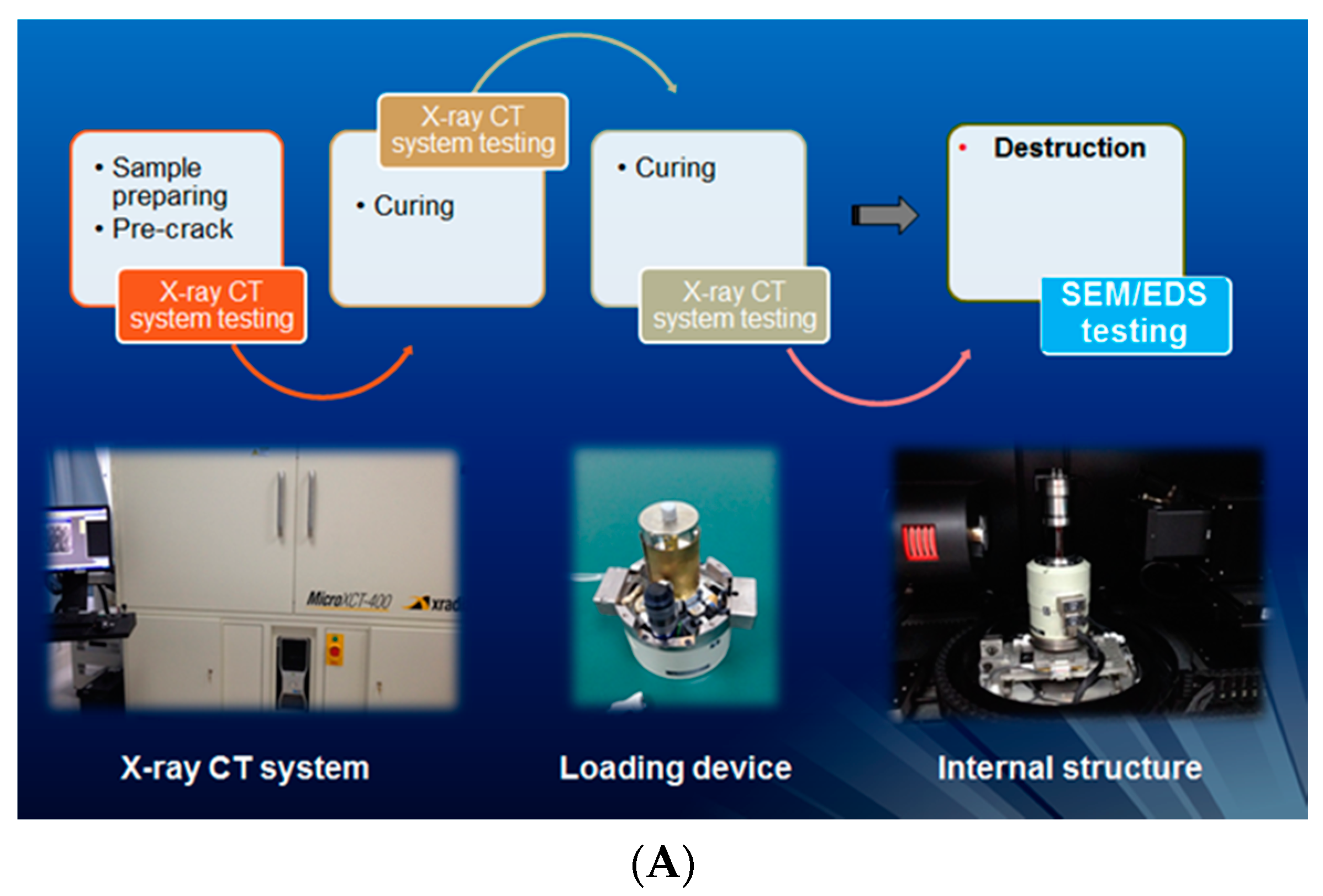

4.4. Evaluation of a Microcapsule Based Self-Resilience System

5. Challenges and Further Development

6. Concluding Remarks

- (i)

- establish the relationship between the multi-actions and the action effect for concrete;

- (ii)

- link resilience requirements with environmental action and the related degradation mechanisms;

- (iii)

- incorporate existing self-healing and self-recovery systems to enhance the long-term performance of concrete structures by creating resilience to physical and chemical attack, through the addition of agents within microcapsules, that are able to mitigate the action effects in a range of aggressive environments;

- (iv)

- set up facilities and procedure to evaluate self-healing and self-recovery effects at the micro level;

- (v)

- quantify key parameters related to fundamental material properties in order to supply the basic input for numerical simulations;

- (vi)

- validate the design procedure and numerical model using data from bespoke tests at multi-scales;

- (vii)

- demonstrate the self-resilience system by using experimental and numerical data.

- (viii)

- realize applications in practice.

Acknowledgments

Conflicts of Interest

References

- Han, N.X. Role of NDE in quality control during construction of concrete infrastructures on the basis of service life design. Constr. Build. Mater. 2004, 18, 163–172. [Google Scholar] [CrossRef]

- Han, N.X.; Xing, F. Service life consideration of concrete structures in a broad perspective. In Proceedings of the Eleventh International Symposium on Structural Engineering, Guangzhou, China, 18–20 December 2010; Cui, J., Xing, F., Ru, J.P., Teng, J.G., Eds.; pp. 1206–1217.

- Page, C.L.; Page, M.M. Durability of Concrete and Cement Composites; Woodhead: Cambridge, UK, 2007. [Google Scholar]

- Han, N.X.; Xing, F. Service life, sustainability and resilience—A holistic strategy dealing with marine concrete structures. In Proceedings of the Seventh International Conference on Concrete under Severe Conditions—Environment and Loading, Nanjing, China, 21–23 September 2013; Li, Z.J., Sun, W., Miao, C.W., Sakai, K., Gjorv, O.E., Banthia, N., Eds.; pp. 1460–1475.

- Van de Zwaag, S. Self Healing Materials—An Alternative Approach to 20 Centuries of Materials Science; Springer: Dordrecht, The Netherlands, 2007. [Google Scholar]

- De Rooij, M.; van Tittelboom, K.; de Belie, N.; Schlangen, E. Self-Healing Phenomena in Cement-Based Materials—State-of-the-Art Report of RILEM Technical Committee 221-SHC; Springer: Dordrecht, The Netherlands; Heidelberg, Germany; New York, NY, USA; London, UK, 2013. [Google Scholar]

- Xing, F.; Ni, Z.; Han, N.X.; Dong, B.Q.; Du, X.X.; Huang, Z.; Zhang, M. Self-healing mechanism of a novel cementitious composite using microcapsules. In Proceedings of the First International Conference on the Durability of Concrete Structures, Hangzhou, China, 26–27 November 2008; Jin, W., Ueda, T., Basheer, P.A.M., Eds.; pp. 195–204.

- Dong, B.Q.; Han, N.X.; Zhang, M.; Wang, X.F.; Cui, H.Z.; Xing, F. A microcapsule technology based self-healing system for concrete structures. J. Earthq. Tsunami 2013, 7, 1350014. [Google Scholar] [CrossRef]

- Zhang, M.; Han, N.X.; Xing, F.; Wang, X.F.; Schlangen, E. Design of microcapsule system used for self-healing cementitious material. In Proceedings of the Fourth International Conference on Self-Healing Materials, Ghent, Belgium, 16–20 June 2013; de Belie, N., van der Zwaag, S., Gruyaert, E., van Tittelboom, K., Debbaut, B., Eds.; pp. 12–15.

- Zhang, M.; Han, N.X.; Xing, F.; Wang, X.F.; Schlangen, E. Evaluation of a microcapsule based self-healing system for cementitious materials. In Proceedings of the Fourth International Conference on Self-Healing Materials, Ghent, Belgium, 16–20 June 2013; de Belie, N., van der Zwaag, S., Gruyaert, E., van Tittelboom, K., Debbaut, B., Eds.; pp. 216–219.

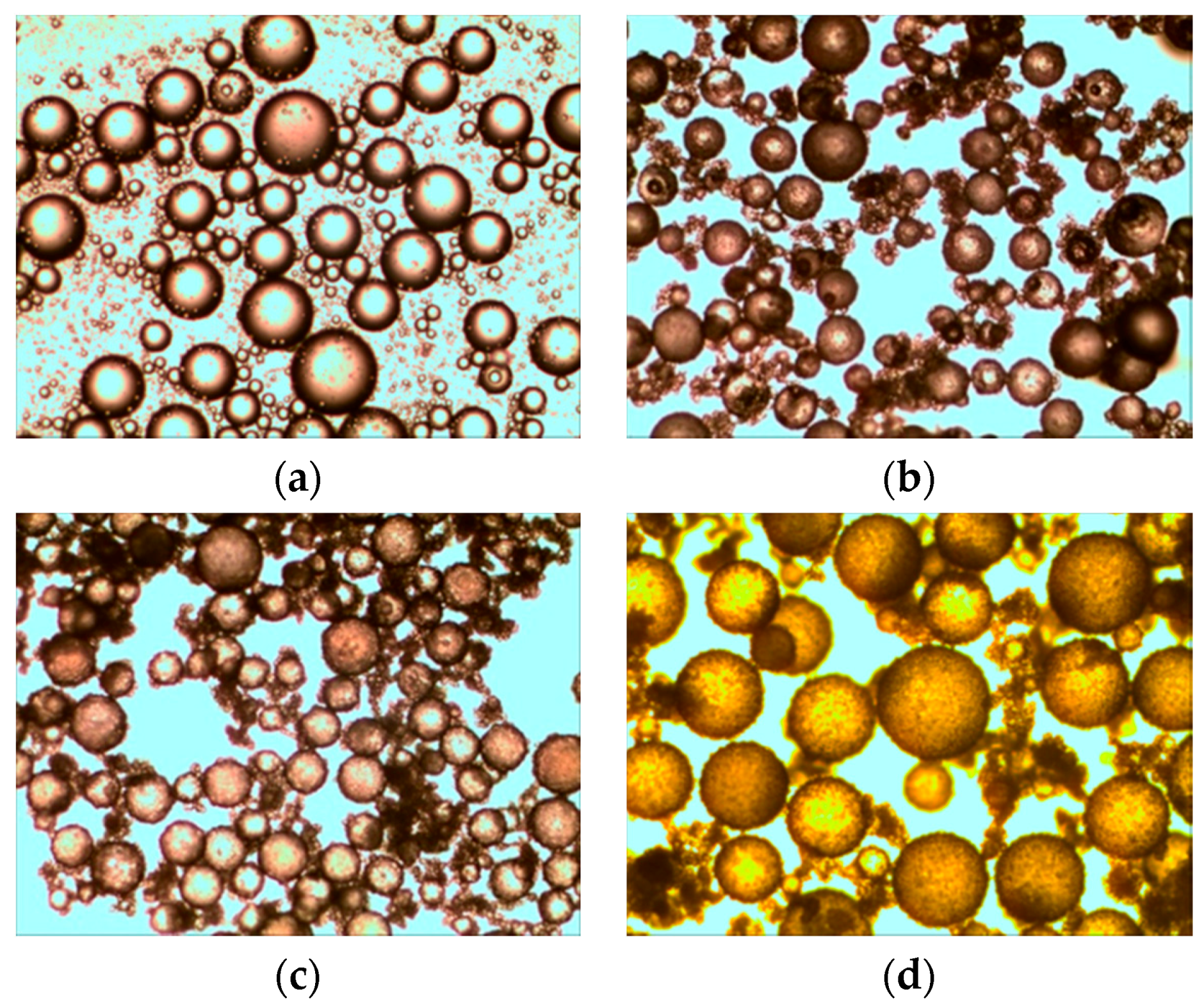

- Wang, X.F.; Xing, F.; Zhang, M.; Han, N.X.; Qian, Z.W. Experimental Study on Cementitious Composites Embedded with Organic Microcapsules. Materials 2013, 6, 4064–4081. [Google Scholar] [CrossRef]

- Dong, B.Q.; Fang, G.H.; Ding, W.J.; Liu, Y.Q.; Zhang, J.C.; Han, N.X.; Xing, F. Self-healing features in cementitious material with urea-formaldehyde/epoxy microcapsules. Constr. Build. Mater. 2016, 106, 608–617. [Google Scholar] [CrossRef]

- Wang, X.F.; Xing, F.; Zhang, M.; Han, N.X.; Qian, Z.W. Interaction between microcapsules and cementitious matrix after cracking in a self-healing system. In Proceedings of the Fourth International Conference on Self-Healing Materials, Ghent, Belgium, 16–20 June 2013; de Belie, N., van der Zwaag, S., Gruyaert, E., van Tittelboom, K., Debbaut, B., Eds.; pp. 66–69.

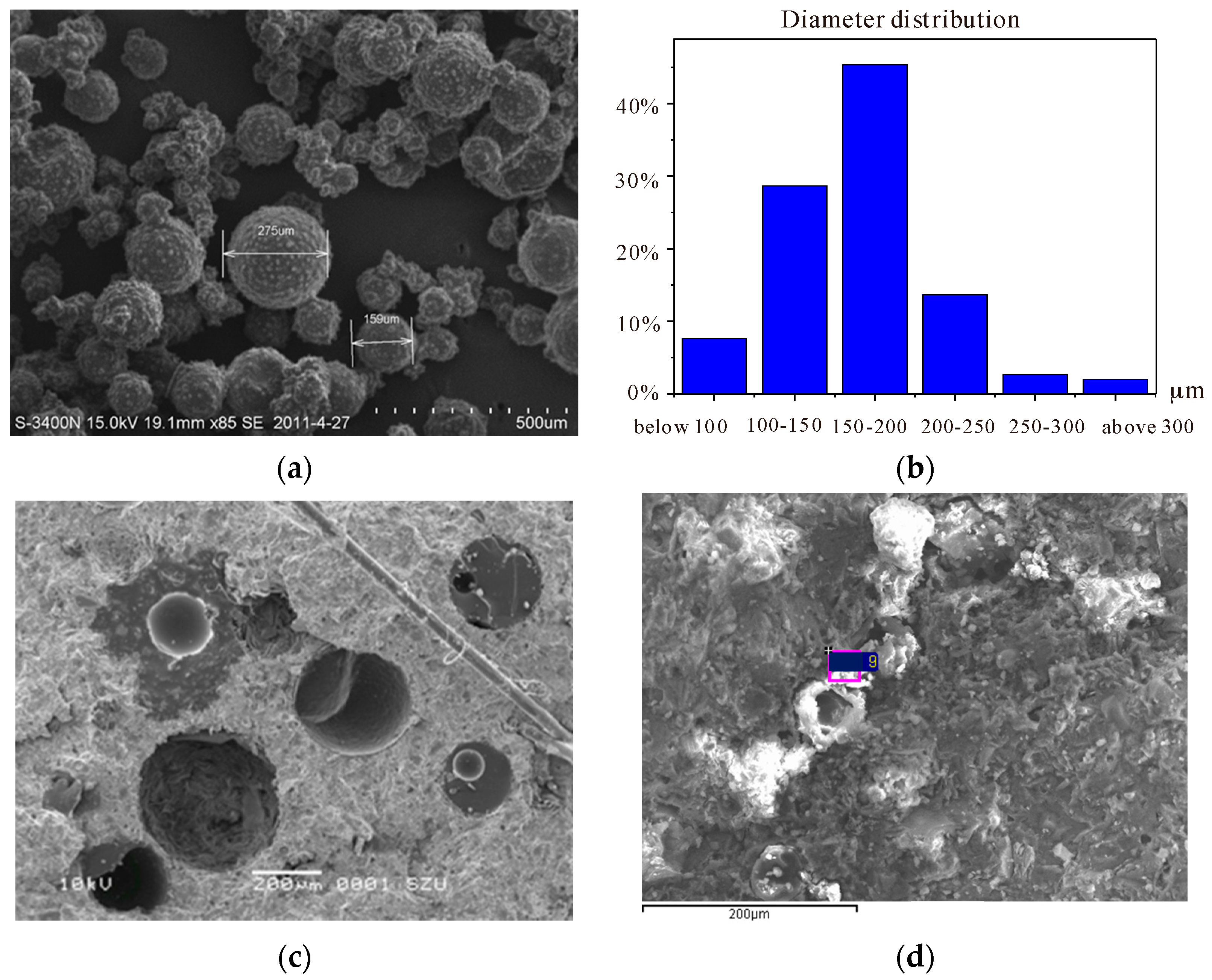

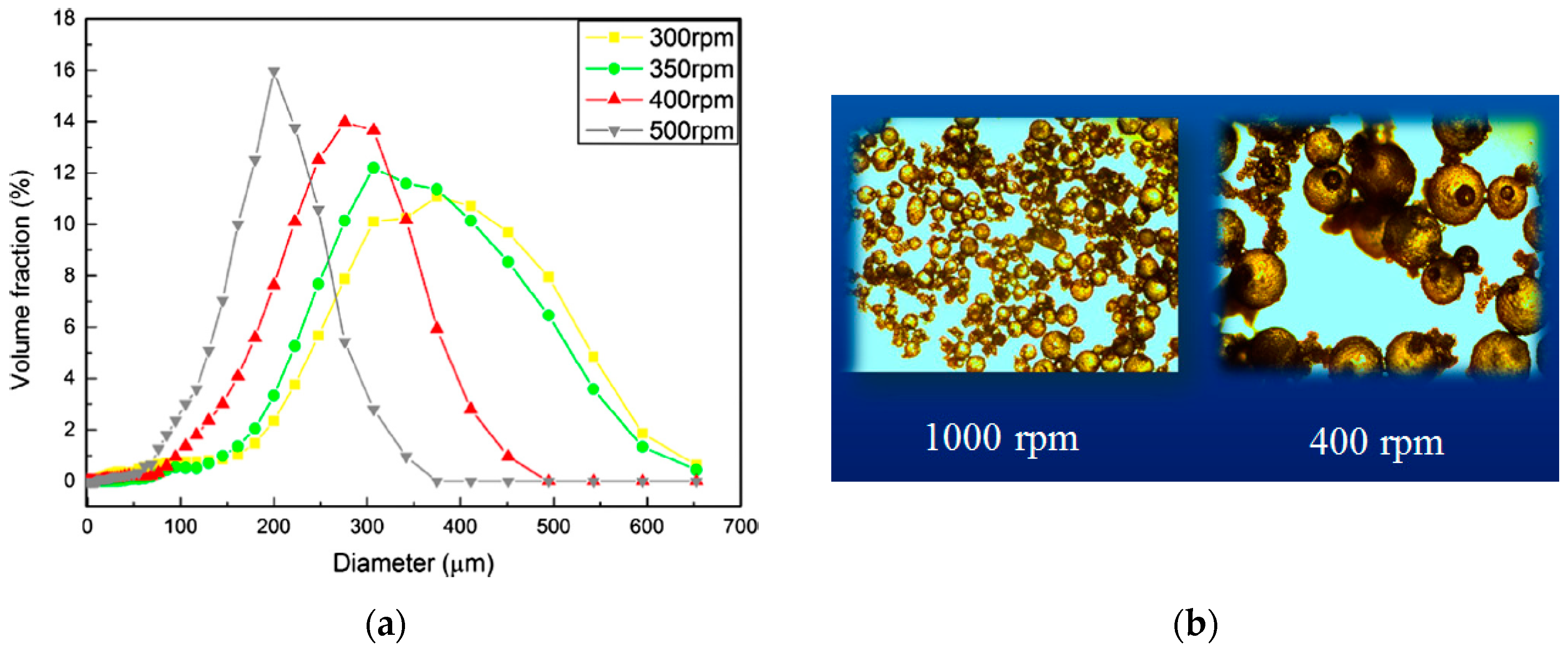

- Zhu, G.M.; Wu, Z.P.; Zhou, Y.M.; Tang, J.N.; Dong, B.Q.; Xing, F.; Han, N.X.; Schlangen, E. The effect of processing parameters on the formation of epoxy/UF resin microcapsules. In Proceedings of the Fourth International Conference on Self-Healing Materials, Ghent, Belgium, 16–20 June 2013; de Belie, N., van der Zwaag, S., Gruyaert, E., van Tittelboom, K., Debbaut, B., Eds.; pp. 235–239.

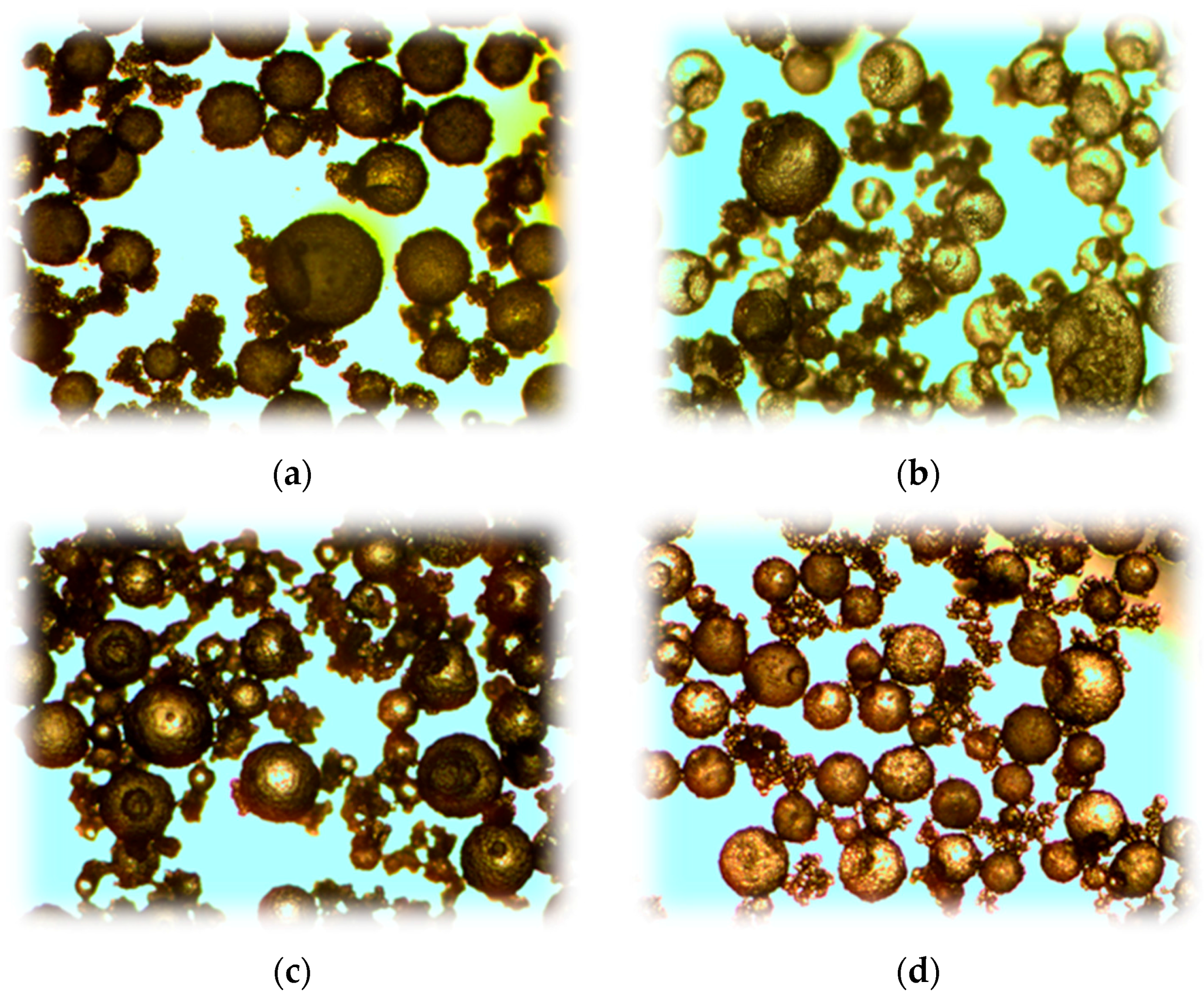

- Lv, L.Y.; Tang, J.N.; Zhu, G.M.; Chen, G.J.; Han, N.X.; Schlangen, E.; Xing, F. Synthesis and characterization of novel mechanical triggered phenol-formaldehyde microcapsules containing a rejuvenator for self-healing cement-based materials. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

- Wang, Y.Y.; Su, J.F.; Schlangen, E.; Han, N.X.; Han, S.; Li, W. Fabrication and characterization of self-healing microcapsules containing bituminous rejuvenator by a nano-inorganic/organic hybrid method. Constr. Build. Mater. 2016, 121, 471–482. [Google Scholar] [CrossRef]

- Lv, L.Y.; Zhang, Z.; Chen, G.; Zhu, G.M.; Han, N.X.; Schlangen, E.; Xing, F. Synthesis and characterization of a new polymeric microcapsule and feasibility investigation in self-healing cementitious materials. Constr. Build. Mater. 2016, 105, 487–495. [Google Scholar] [CrossRef]

- Zhu, G.M.; Zhou, Y.M.; Wu, Z.P.; Tang, J.N.; Dong, B.Q.; Xing, F.; Han, N.X.; Schlangen, E. Self-encapsulation of epoxy resin by a controlled interface curing process in epoxy/water emulsion. In Proceedings of the Fourth International Conference on Self-Healing Materials, Ghent, Belgium, 16–20 June 2013; de Belie, N., van der Zwaag, S., Gruyaert, E., van Tittelboom, K., Debbaut, B., Eds.; pp. 230–234.

- Zhu, G.M.; Lv, L.Y.; Tang, J.N.; Dong, B.Q.; Han, N.X.; Xing, F. Preparation of mono-sized epoxy/MF microcapsules in the appearance of polyvinyl alcohol as co-emulsifier. In Proceedings of the Fourth International Conference on Self-Healing Materials, Ghent, Belgium, 16–20 June 2013; de Belie, N., van der Zwaag, S., Gruyaert, E., van Tittelboom, K., Debbaut, B., Eds.; pp. 225–229.

- Xiong, W.; Zhu, G.M.; Tang, J.N.; Xing, F.; Dong, B.Q.; Han, N.X.; Schlangen, E. Preparation and characterization of poly(urea-formaldehyde) microcapsules with dicyclopentadiene as healing material. In Proceedings of the Fourth International Conference on Self-Healing Materials, Ghent, Belgium, 16–20 June 2013; de Belie, N., van der Zwaag, S., Gruyaert, E., van Tittelboom, K., Debbaut, B., Eds.; pp. 220–224.

- Han, N.X.; Xing, F. Intelligent resilience of cementitious materials for marine infrastructures. J. Ceram. Process. Res. 2015, 16, 14–21. [Google Scholar]

- Dong, B.Q.; Wang, Y.S.; Han, N.X.; Xing, F. The smart releasing behavior of a microcapsule based on chemical self-healing system caused by chemical trigger activation. In Proceedings of the Fourth International Conference on Self-Healing Materials, Ghent, Belgium, 16–20 June 2013; de Belie, N., van der Zwaag, S., Gruyaert, E., van Tittelboom, K., Debbaut, B., Eds.; pp. 25–28.

- Dong, B.Q.; Wang, Y.S.; Fang, G.H.; Han, N.X.; Xing, F.; Lu, Y.Y. Smart releasing behavior of a chemical self-healing microcapsule in the stimulated concrete pore solution. Cem. Concr. Compos. 2015, 56, 46–50. [Google Scholar] [CrossRef]

- Wang, Y.S.; Fang, G.H.; Ding, W.J.; Han, N.X.; Xing, F.; Dong, B.Q. Self-immunity microcapsules for corrosion protection of steel bar in reinforced concrete. Sci. Rep. 2015, 5, 18484. [Google Scholar] [CrossRef] [PubMed]

- Dong, B.Q.; Wang, Y.S.; Han, N.X.; Xing, F. A study on the steel corrosion protection of a microcapsule based self-healing cementitious system by means of electrochemical impedance spectroscopy. In Proceedings of the Fourth International Conference on Self-Healing Materials, Ghent, Belgium, 16–20 June 2013; de Belie, N., van der Zwaag, S., Gruyaert, E., van Tittelboom, K., Debbaut, B., Eds.; pp. 211–215.

- Dong, B.Q.; Wang, Y.S.; Ding, W.J.; Li, S.T.; Han, N.X.; Xing, F.; Lu, Y.Y. Electrochemical impedance study on steel corrosion in the simulated concrete system with a novel self-healing microcapsule. Constr. Build. Mater. 2014, 56, 1–6. [Google Scholar] [CrossRef]

- Wang, Y.S.; Ding, W.J.; Fang, G.H.; Liu, Y.Q.; Xing, F.; Dong, B.Q. Feasibility study on corrosion protection of steel bar in a self-immunity system based on increasing OH− content. Constr. Build. Mater. 2016, 125, 742–748. [Google Scholar] [CrossRef]

- Xiong, W.; Tang, J.N.; Zhu, G.M.; Han, N.X.; Schlangen, E.; Dong, B.Q.; Wang, X.F.; Xing, F. A novel capsule-based self-recovery system with a chloride ion trigger. Sci. Rep. 2015, 5, 10866. [Google Scholar] [CrossRef] [PubMed]

- Xiong, W.; Tang, J.N.; Zhu, G.M.; Xing, F.; Han, N.X.; Wang, X.F.; Dong, B.Q.; Schlangen, E. The application of chloride ion triggered capsules in cementitious materials. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

- Zhu, G.M.; He, Y.X.; Tang, J.N.; Han, N.X.; Xing, F. Design and preparation of chloridion—Triggered microcapsule for chemical self-healing application. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

- Xiong, W.; Tang, J.N.; Zhu, G.M.; Xing, F.; Han, N.X.; Wang, X.F.; Dong, B.Q.; Schlangen, E. Fabrication and characterization of chloridion-triggered capsules. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

- Zhu, G.M.; Tang, J.N.; Han, N.X.; Xing, F. The microcapsule responsive to chloride ion. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

- Zhu, G.M.; He, Y.X.; Tang, J.N.; Han, N.X.; Xing, F. Chloridion response of the microcapsule shelled with polystyrenecuprous chloride composite. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

- Zhu, G.M.; Guan, Y.J.; Tang, J.N.; Han, N.X.; Xing, F. Chloridion-triggered microcapsule for self-healing concrete application. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

- Zhang, J.L.; Deng, X.; Xing, F.; Han, N.X.; Jonkers, H.M. Improvement on bacteria-induced calcium mineralization ability of Bacillus pseudofirmus by an integrated high-throughput screening. In Proceedings of the Fourth International Conference on Self-Healing Materials, Ghent, Belgium, 16–20 June 2013; de Belie, N., van der Zwaag, S., Gruyaert, E., van Tittelboom, K., Debbaut, B., Eds.; pp. 597–600.

- Zhang, J.L.; Ke, J.L.; Liu, B.; Deng, X.; Han, N.X.; Xing, F. Isolation and identification of a calcium-precipitating bacterium and optimization of influential factors. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

- Zhang, J.L.; Wu, R.S.; Li, Y.M.; Zhong, J.Y.; Deng, X.; Liu, B.; Han, N.X.; Xing, F. Screening of bacteria for self-healing of concrete cracks and optimization of the microbial calcium precipitation process. Appl. Microbiol. Biotechnol. 2016, 100, 6661–6670. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.L.; Cheng, W.F.; Liu, B.; Deng, X.; Han, N.X.; Xing, F. Rapid quantification of viable spore by a simple spectrophotometric method. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

- Zhang, J.L.; Wang, C.G.; Wang, Q.L.; Feng, J.L.; Pan, W.; Zheng, X.C.; Liu, B.; Han, N.X.; Xing, F.; Deng, X. A binary concrete crack self-healing system containing oxygen-releasing tablet and bacteria and its Ca2+-precipitation performance. Appl. Microbiol. Biotechnol. 2016. [Google Scholar] [CrossRef] [PubMed]

- Zhu, G.M.; Luo, Y.C.; Tang, J.N.; Han, N.X.; Xing, F. Preparation of biocompatible and water-proof microcapsule for self-healing concrete. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

- Liu, B.; Ke, J.L.; Deng, X.; Zhu, G.M.; Luo, Y.C.; Han, N.X.; Xing, F. A waterproof epoxy resin microcapsule for the encapsulation of self-healing bacterium. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

- Zhu, G.M.; Luo, Y.C.; Tang, J.N.; Han, N.X.; Xing, F. Effect of different curing agents on the fracture behavior of epoxy-shelled bio-microcapsule under stress. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

- Zhu, G.M.; Lei, Q.; Tang, J.N.; Han, N.X.; Xing, F. Preparation of Cu2+-P (VIm-MMA) complex shelled microcapsule and its respondent behavior to carbonate ion in water. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

- Liu, B.; Zhang, J.L.; Ke, J.L.; Deng, X.; Dong, B.Q.; Han, N.X.; Xing, F. Trigger of self-healing process induced by EC encapsulated mineralization bacterium and healing efficiency in cement paste specimens. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

- Liu, B.; Zhang, J.L.; Cheng, W.F.; Deng, X.; Zhu, G.M.; Han, N.X.; Xing, F. The feasibility of encapsulation of self-healing bacterium with ethyl cellulose. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

- Fang, G.H.; Dong, B.Q.; Han, N.X.; Xing, F. Investigation of a novel self-immunity system in cementitious materials with calcium oxide microcapsules. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

- Su, J.F.; Yang, P.; Wang, Y.Y.; Han, S.; Han, N.X.; Li, W. Investigation of the Self-Healing Behaviors of Microcapsules/Bitumen Composites by a Repetitive Direct Tension Test. Materials 2016, 9, 600. [Google Scholar] [CrossRef]

- Su, J.F.; Wang, Y.Y.; Han, N.X.; Yang, P.; Han, S. Experimental investigation and mechanism analysis of novel multi-self-healing behaviors of bitumen using microcapsules containing rejuvenator. Constr. Build. Mater. 2016, 106, 317–329. [Google Scholar] [CrossRef]

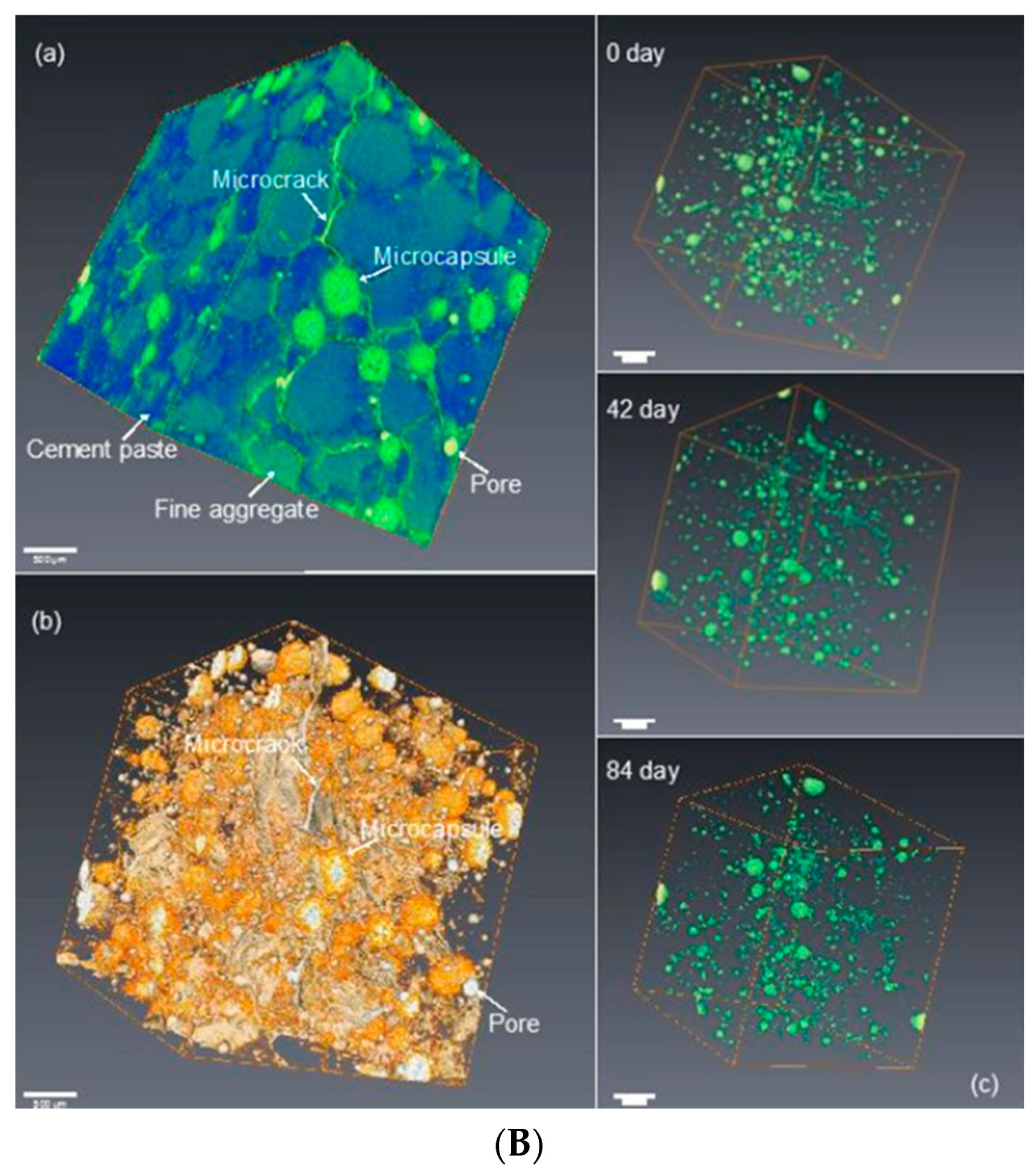

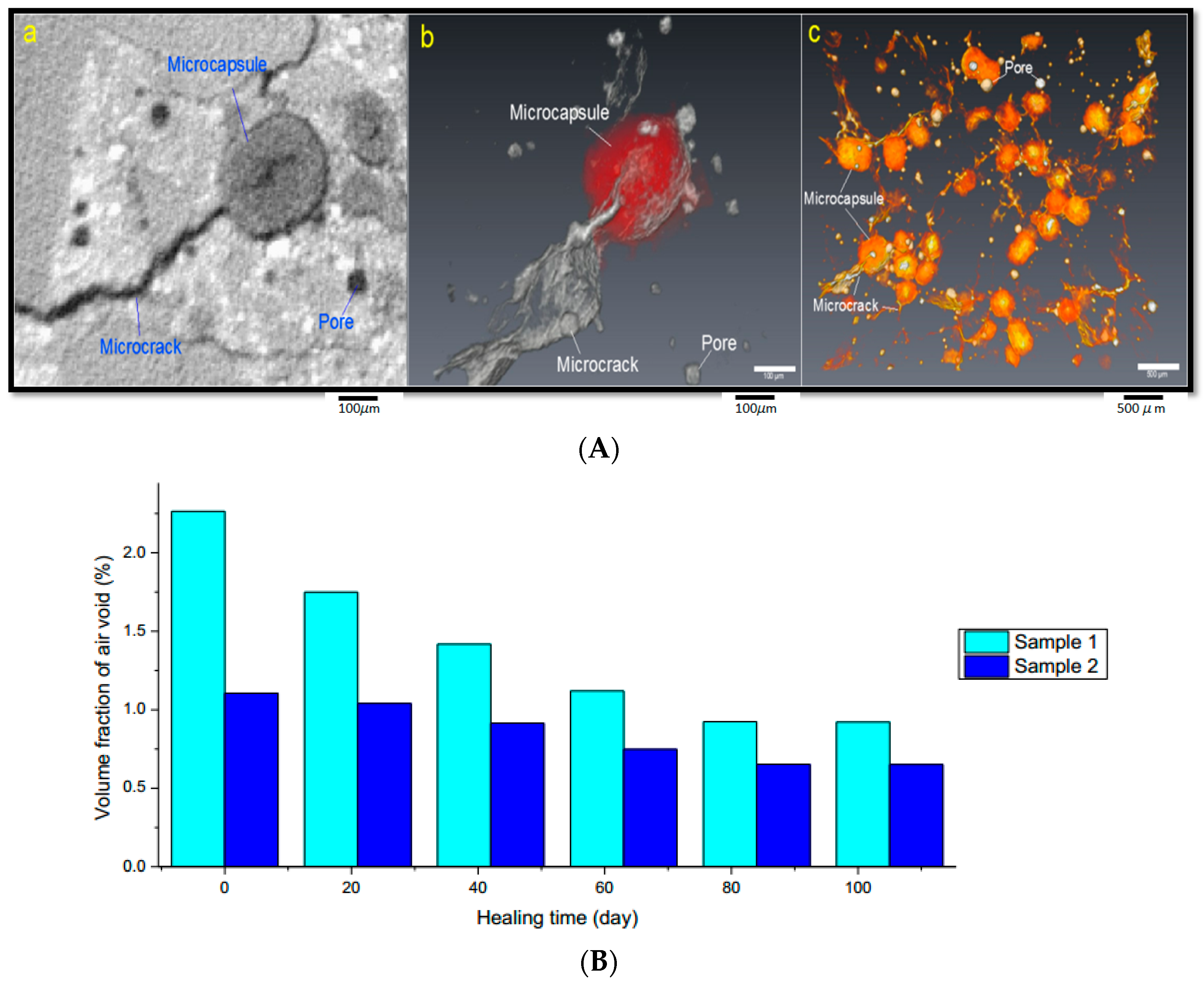

- Fang, G.H.; Dong, B.Q.; Han, N.X.; Xing, F. Investigation of self-healing in cementitious materials with sulfoaluminate cement microcapsules using X-ray computed tomography. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

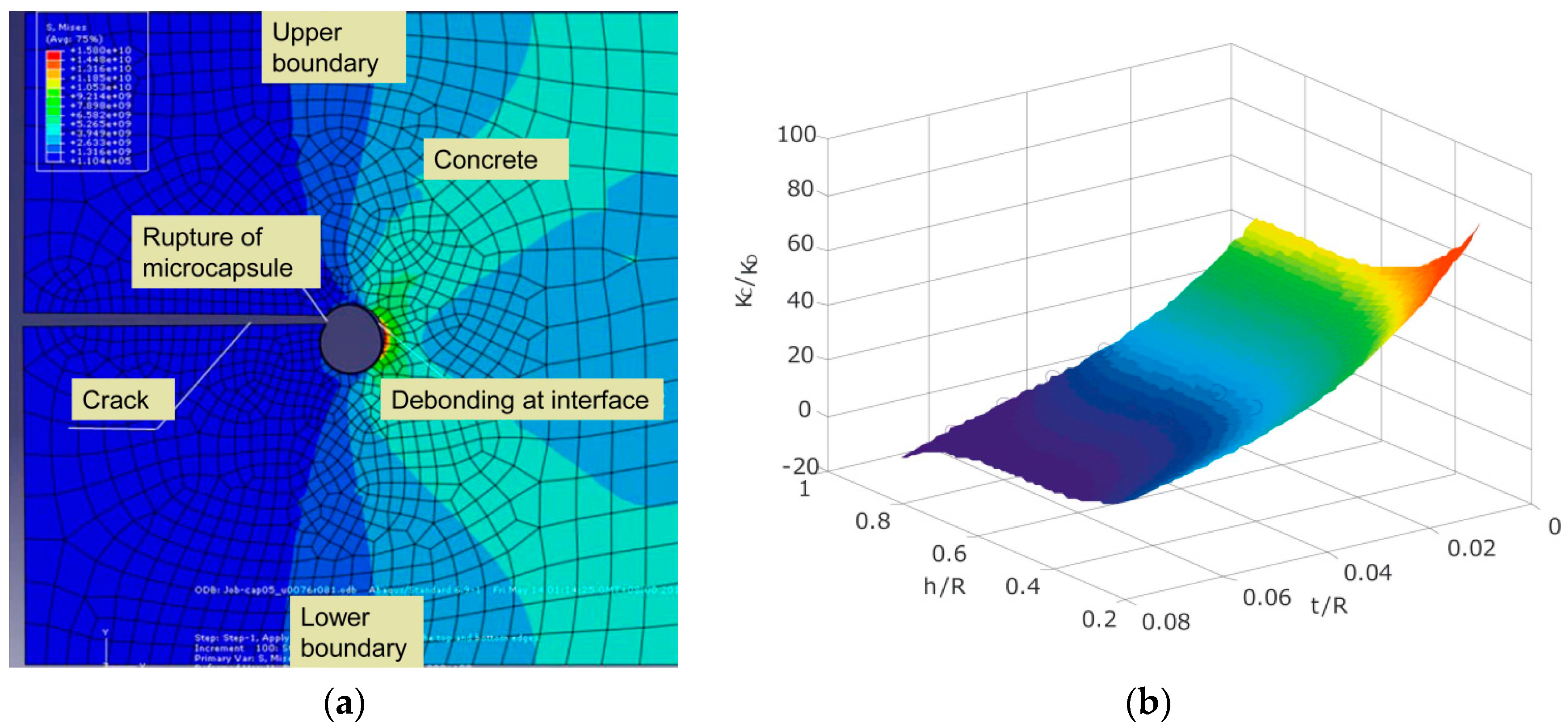

- Wang, X.F.; Xing, F.; Xie, Q.; Han, N.X.; Kishi, T.; Ahn, T.H. Mechanical behavior of a capsule embedded in cementitious matrix-macro model and numerical simulation. J. Ceram. Process. Res. 2015, 16, 74–82. [Google Scholar]

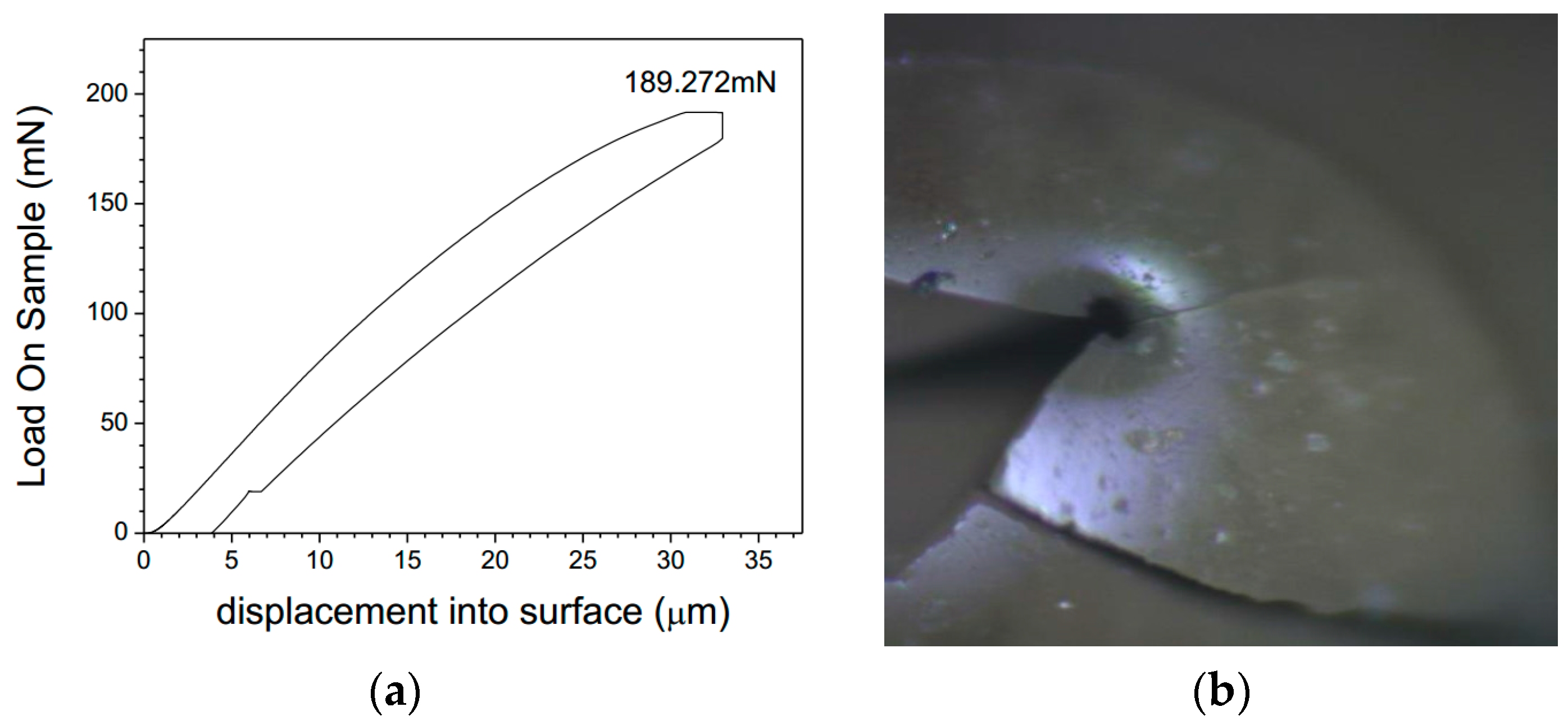

- Lv, L.Y.; Tang, J.N.; Xiao, F.S.; Schlangen, E.; Zhu, G.M.; Han, N.X.; Xing, F. Applying nano-indentation to measure micromechanical properties of phenol–formaldehyde microcapsules for self-healing cement based materials. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

- Zhu, G.M.; Xiao, F.S.; Tang, J.N.; Han, N.X.; Xing, F. Determination of the rupture stress of microcapsule and the Young’s modulus of its shell materials by nanoindenter. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

- Zhu, G.M.; Xiao, F.S.; Tang, J.N.; Han, N.X.; Xing, F. Mechanical-performance Investigation of a single DCPD/PF microcapsule with nanoindenter. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015.

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, N.-X.; Xing, F. A Comprehensive Review of the Study and Development of Microcapsule Based Self-Resilience Systems for Concrete Structures at Shenzhen University. Materials 2017, 10, 2. https://doi.org/10.3390/ma10010002

Han N-X, Xing F. A Comprehensive Review of the Study and Development of Microcapsule Based Self-Resilience Systems for Concrete Structures at Shenzhen University. Materials. 2017; 10(1):2. https://doi.org/10.3390/ma10010002

Chicago/Turabian StyleHan, Ning-Xu, and Feng Xing. 2017. "A Comprehensive Review of the Study and Development of Microcapsule Based Self-Resilience Systems for Concrete Structures at Shenzhen University" Materials 10, no. 1: 2. https://doi.org/10.3390/ma10010002