5.2. Effect of Power Distribution on Rail Potential

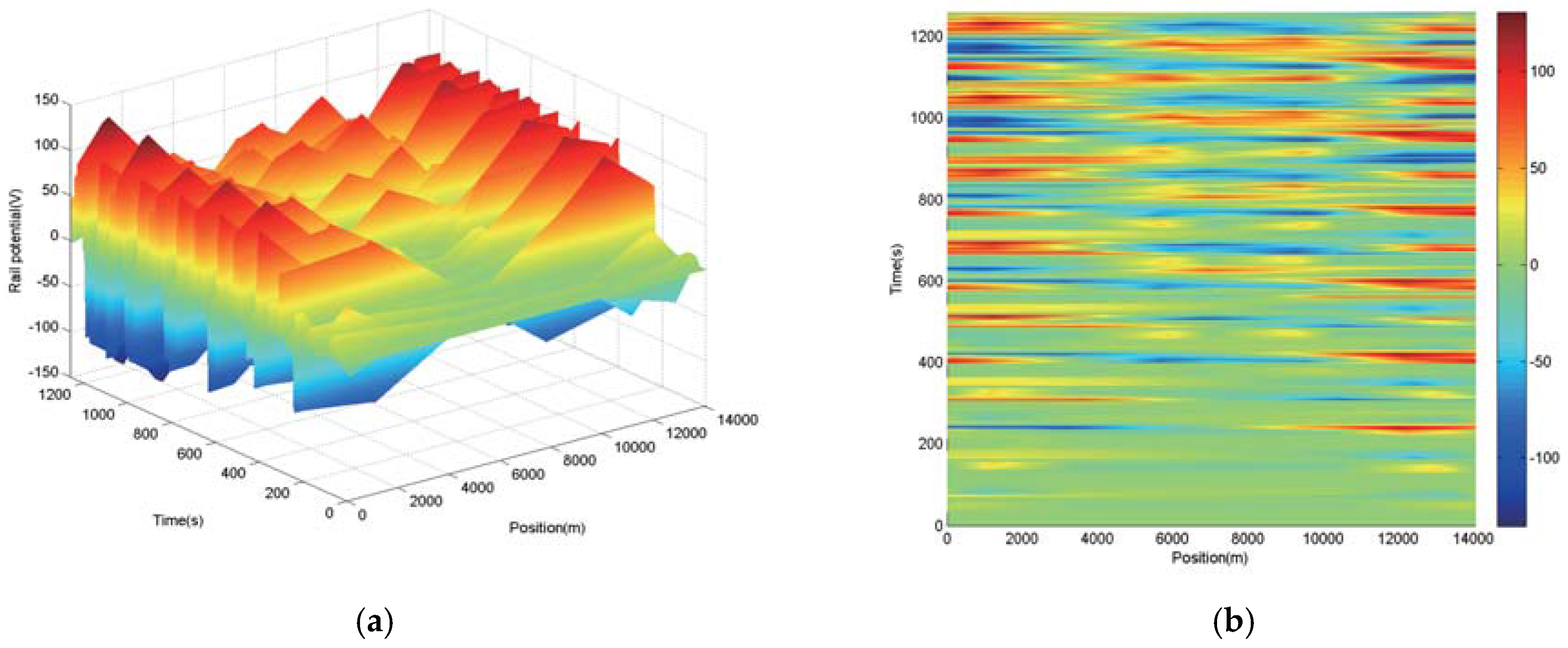

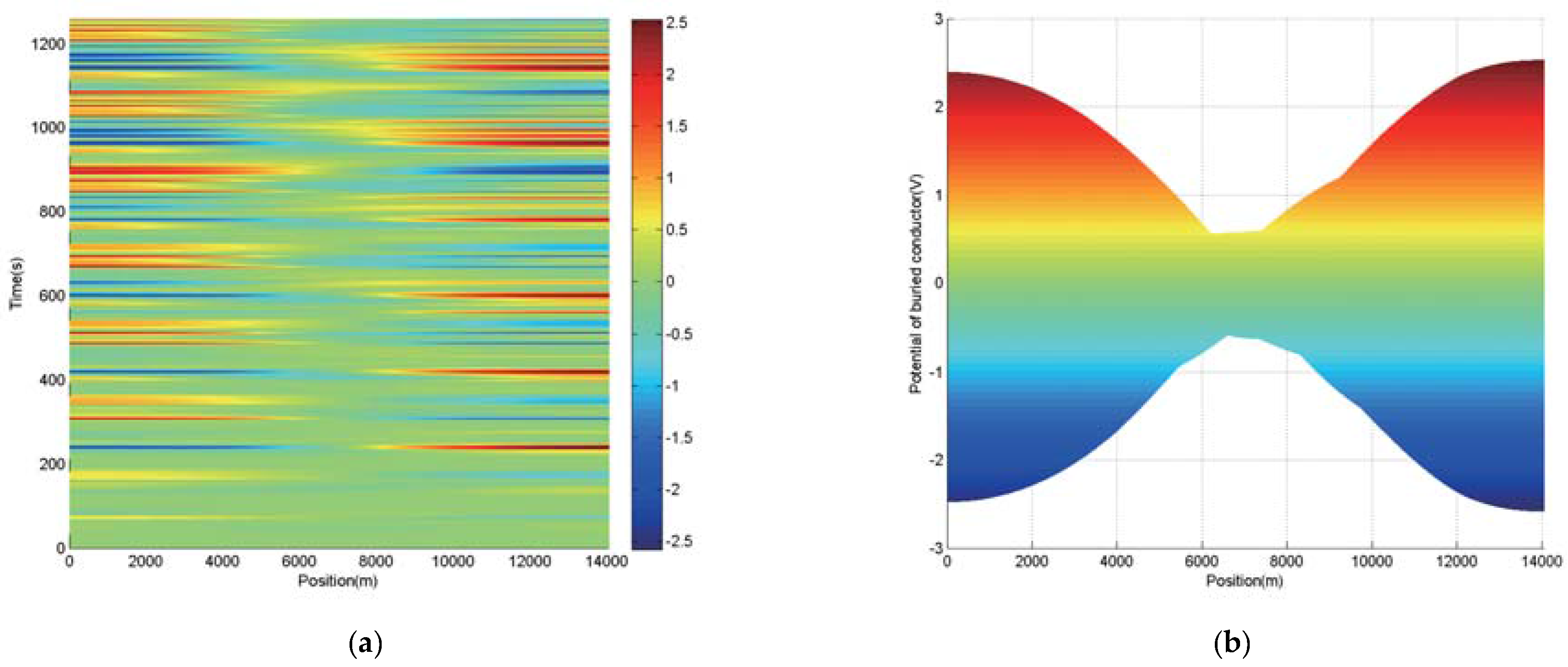

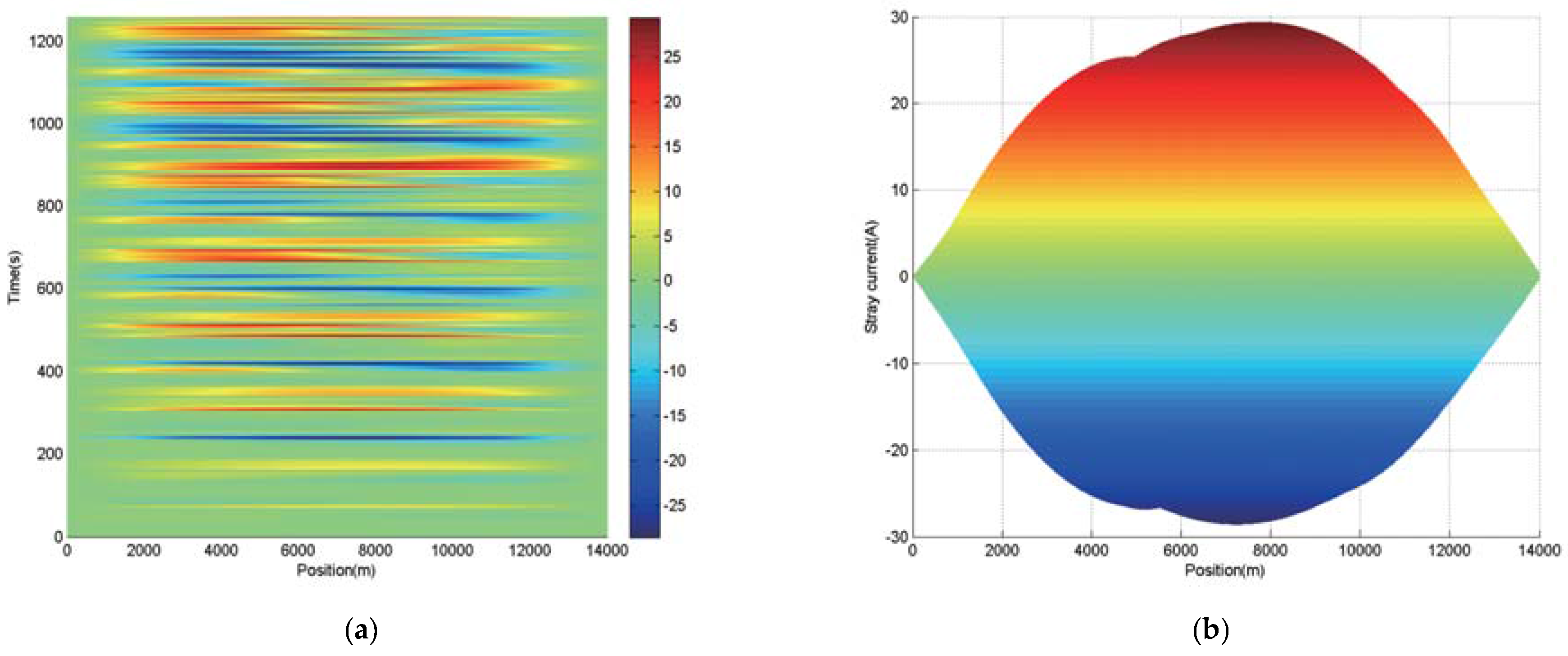

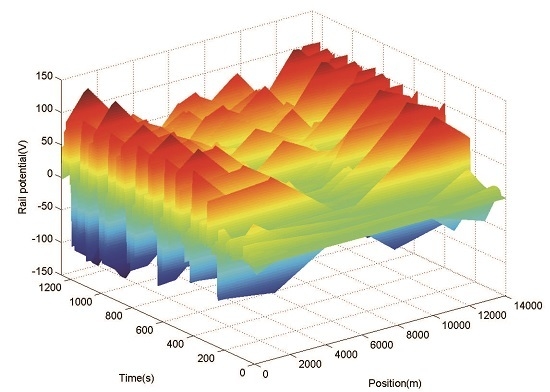

During the simulation time, the dynamic distribution of the rail potential in the line is as shown in

Figure 9.

As shown in

Figure 9, a significant difference between rail potential exists in different times and positions. The maximum rail potential in the line is 130.8 V, occurring in 1230 m at 1231 s. As shown in

Figure 9c, the simulation result of rail potential is consistent with the distribution in the actual line. The rail potential in the first and last sections is much higher than that in the middle sections during the operation of the line. The maximum and minimum values of the rail potential in each section and traction substation are shown in

Table 3.

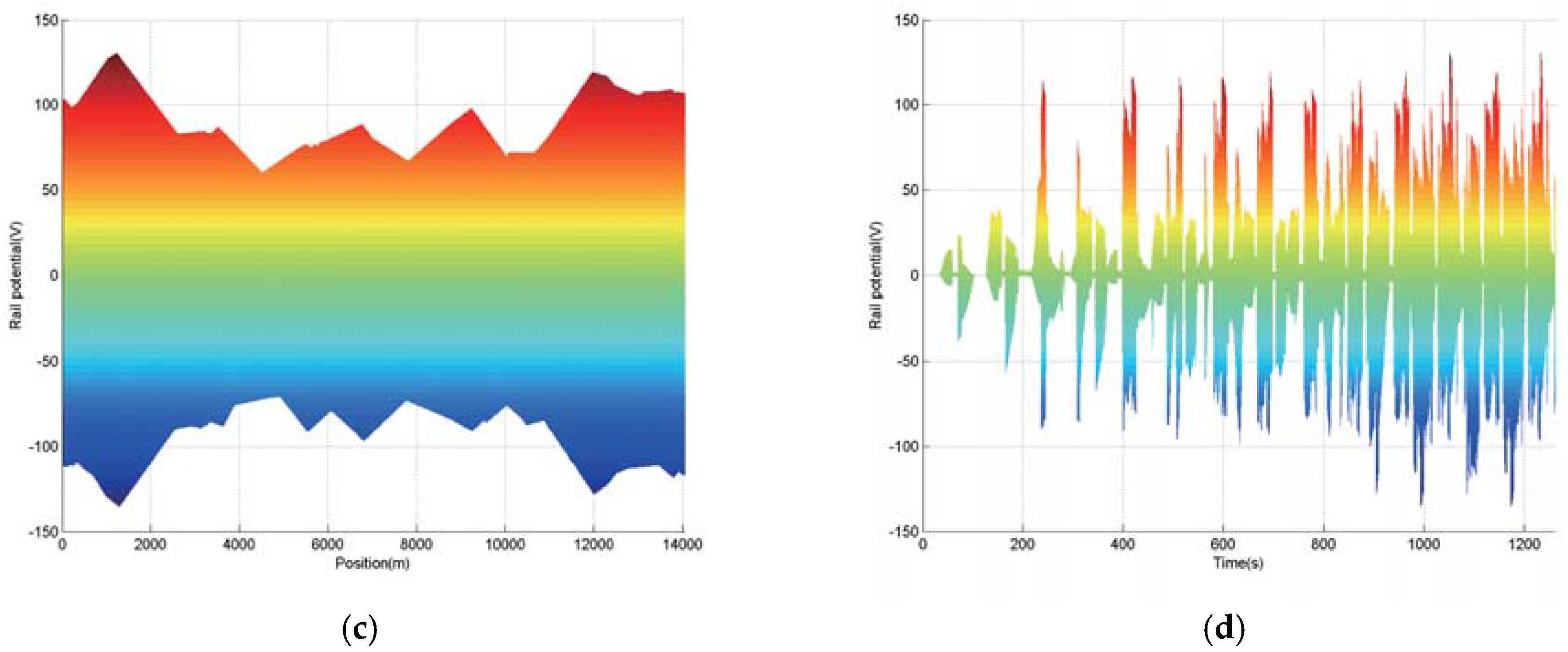

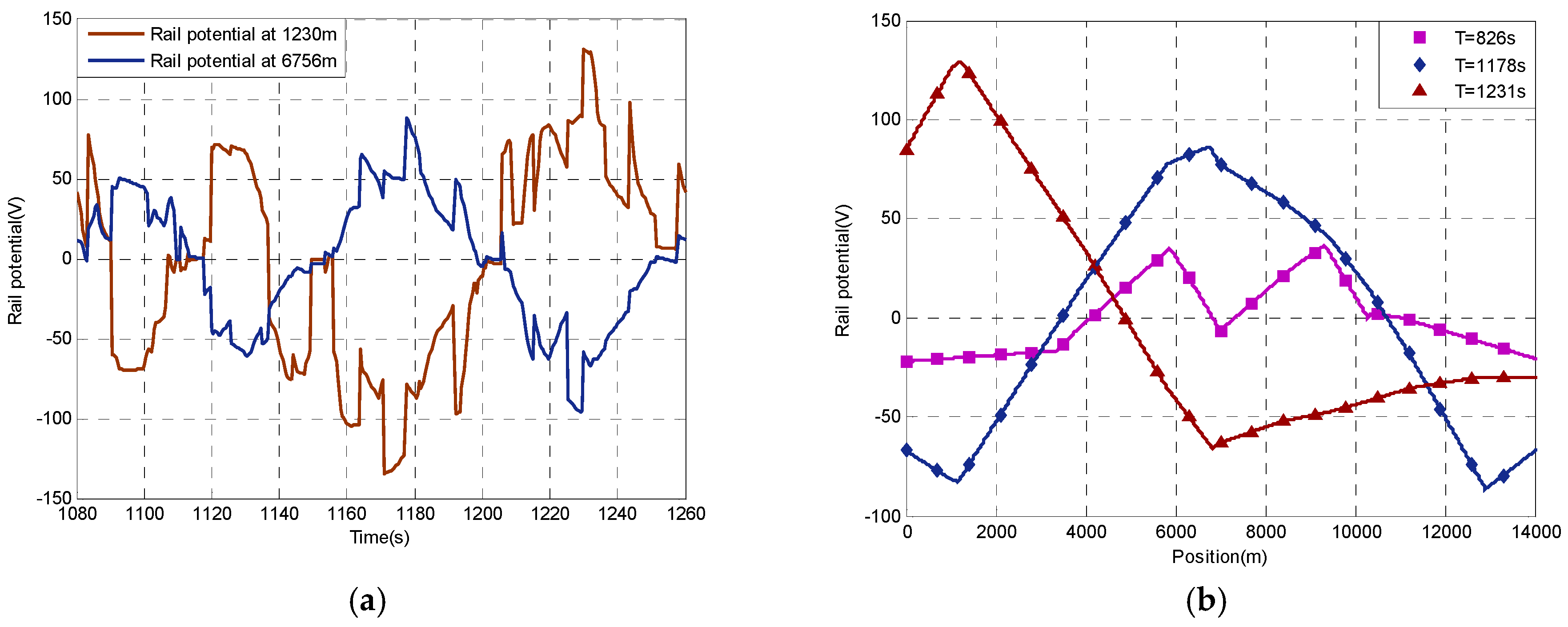

As clearly shown in

Table 3, the rail potential in the first and last sections is higher than that in the middle sections. With the same parameters of the return circuit, the length of section 1 is 3367 m, and the maximum rail potential in section 1 is 130.8 V. By comparison, the length of section 2 is 3627 m, whereas the maximum rail potential is 88.6 V. From 1080 s to 1260 s, the maximum rail potential in section 1 is 130.8 V, occurring in 1230 m at 1231 s, and the maximum rail potential in section 2 is 88.6 V, occurring in 6756 m at 1178 s. Variation of the rail potential at typical moments and positions are shown in

Figure 10.

As shown in

Figure 10a, at 1230s, the rail potential at the position of 1230 m is 89.3 V. When a train in section 2 begins regenerative braking at 1231 s, the rail potential reaches 130.8 V rapidly with the increase of the traction current transferring over the section. At 1177 s, the rail potential at 6756 m is 49.3 V. When a train in section 4 begins regenerative braking at 1178 s, the rail potential rises to 88.6 V with the increase of the traction current transferring over the section. During the period of the train in regenerative braking, the rail potential remains at a high level, and changes with the traction current transfers over the sections. It can be seen that rail potential is highly affected by the power distribution. As shown in

Figure 10b, although the rail potentials at 1231 s and 1178 s are influenced by traction current transferring over sections, the maximum value in section 1 is much higher than that in section 2. Therefore, it is necessary to analyze the power distribution and rail potential at the two typical moments and positions. Meanwhile, the power distribution and rail potential at the time of 826 s is analyzed as a comparison. At 826 s, the total traction current is large, but there are no trains in regenerative braking in the line, and the traction current transferring over sections is low. The maximum rail potential in the line at 826 s is 35.3 V.

Table 4 shows the positions and current of all the trains and traction substations at 1231 s in the line.

As shown in

Table 4, there are six trains,

Tu1~

Tu6, in the up line and there are six trains,

Td1~

Td6, in the down line at 1231 s. At this moment,

Tu2 and

Td1 stop respectively at Huijiang Station and Changgang Station with a traction current of 0 A. Traction substations

S2,

S4 and

S5 are out of operation. The current distribution between the power sources and the loads are shown in

Table 5.

As shown in

Table 5, in the traction current of accelerating train

Td6 at 1230 m, 1414.8 A comes from traction substation

S1 with the distance of 1230 m; 266.3 A comes from the regenerative braking train

Tu3 with the distance of 4571 m; 900.0 A comes from the regenerative braking train

Td4 with the distance of 5598 m.

Table 6 shows the positions and current of all the trains and traction substations at 1178 s in the line.

Table 6 illustrates the current and positions of all trains and traction substations at 1178 s. At this moment, there are six trains,

Tu1~

Tu6, in the up line and there are six trains,

Td1~

Td6, in the down line.

Td5 and

Tu6 stop respectively at Huijiang Station and Changgang Station; traction substations

S2 and

S4 are out of operation. The RBEAD at substations

S1 and

S5 are activated to absorb the remaining braking energy. The traction current distribution between the power sources and the loads are shown in

Table 7.

As shown in

Table 7, in the traction current of accelerating train

Tu3 at 6756 m, 147.7 A comes from the regenerative braking train

Td6 with the distance of 5740 m, 538.9A comes from the regenerative braking train

Tu1 with the distance of 5592 m, 1073.2 A comes from the traction substation

S3 with the distance of 238 m, 609.3 A comes from the regenerative braking train

Td1 with the distance of 6149 m.

Table 8 shows the positions and current of all the trains and traction substations at 826 s in the line.

Table 8 illustrates the current and positions of all trains and traction substations at 826 s. At this moment, the maximum rail potential in the line is 35.3 V. There are five trains

Tu1~

Tu5 in the up line and five trains,

Td1~

Td5, exist in the down line.

Td5,

Td4 and

Tu5 stop respectively in Shibi Station, Huijiang Station, and Changgang Station. The current distribution between the power sources and the loads are shown in

Table 9.

As shown in

Table 9, the total traction current of all the accelerating trains in line is 8727.2 A, whereas the total traction current is respectively 4456.3 A at 1231 s and 5027 A at 1178 s. However, the maximum rail potential at 826s is much lower than that at 1231 s and 1178 s. Although the total traction current is high at 826 s, there are no regenerative braking trains in the line at this moment. The traction current of accelerating trains comes from the traction substations with a short distance. In the traction current of the accelerating train

Td3 at 5886 m, 1882.8 A comes from the traction substation

S3 with the distance of 1108 m; 863.8 A comes from the traction substation

S2 with the distance of 2519 m; and 64.2 A comes from

S1 with the distance of 5886 m. In the traction current of the accelerating train

Tu3 at 5933 m, 834.7 A comes from the traction substation

S3 with the distance of 2336 m; and 1862.1 A comes from the traction substation

S4 with the distance of 961 m. In the traction current of the accelerating train

Td1 at 10,345 m, 2279 A comes from the traction substation

S4 with the distance of 54 m, and 172.3 A comes from the traction substation

S5 with the distance of 3697 m.

Comparing the distribution of traction current and rail potential at 826 s, 1178 s and 1231 s, we know that rail potential will increase abnormally when regenerative braking trains feed current back to the catenary and the current is absorbed by the accelerating trains at long distance.

Based on the distribution of traction current and rail potential, the mechanism that rail potential in the first and last sections is much higher than that in the middle sections is analyzed. Maximum rail potential in section 1 is 130.8 V, occurring at 1231 s at the position of Td6, 42.2 V higher than that in section 2, occurring in 1178 s at the position of Tu3. In this paper, transmission distance of traction current (TDTC) is proposed to describe the transmission distance of the load’s traction current at node j. . The TDTC of Td6 is 7996.6 A·km at 1231 s, and the TDTC of Tu3 is 7863.3 A·km at 1178 s. There is little difference between the TDTC of the two trains, but rail potential in the position of Td6 is much higher than that in the position of Tu3. Comparing the TDTCs, we find that unilateral nature of the Td6 is more obvious: 1740.2 A·km of the TDTC comes from the power sources in the section of 0 m to Td6, whereas 6256.4 A·km of the TDTC comes from the power sources in the section of Td6 to L. The TDTC of Tu3 is relatively bilateral at 1178 s; 3861.3 A·km of the TDTC comes from the power sources in the section of 0 m to Tu3; 4002 A·km) of the TDTC comes from the power sources in the section of Tu3 to L. Therefore, the rail potential with multiple trains running in multiple sections is influenced by the TDTC and the unilateral nature or bilateral nature of the train’s traction current.

When the system is in dynamic operation, there are multiple trains in the line. If the current that the regenerative braking train feed backs to the catenary is absorbed by the accelerating trains at long distance, then the rail potential may rise abnormally. The traditional methods such as shortening the distance between traction substations or ensuring the longitudinal resistance within the standard values cannot control the rail potential effectively.