Numerical Simulation of the Depressurization Process of a Natural Gas Hydrate Reservoir: An Attempt at Optimization of Field Operational Factors with Multiple Wells in a Real 3D Geological Model

Abstract

:1. Introduction

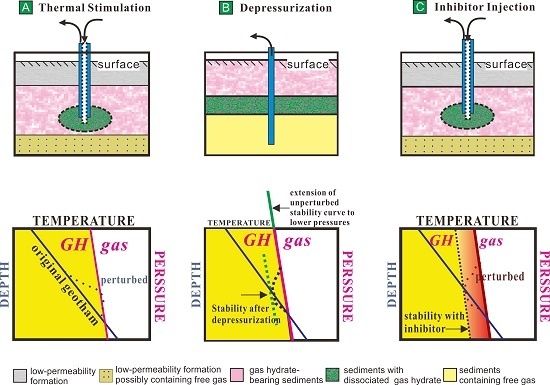

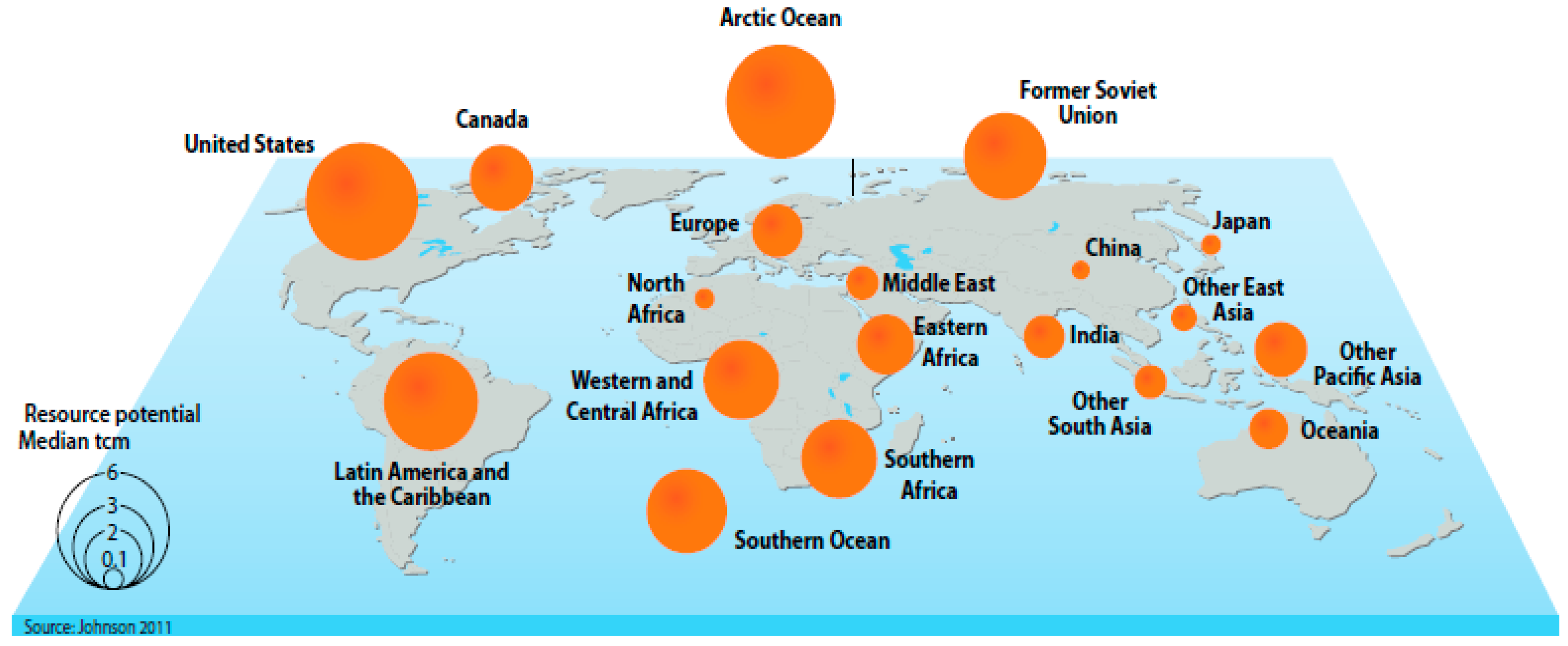

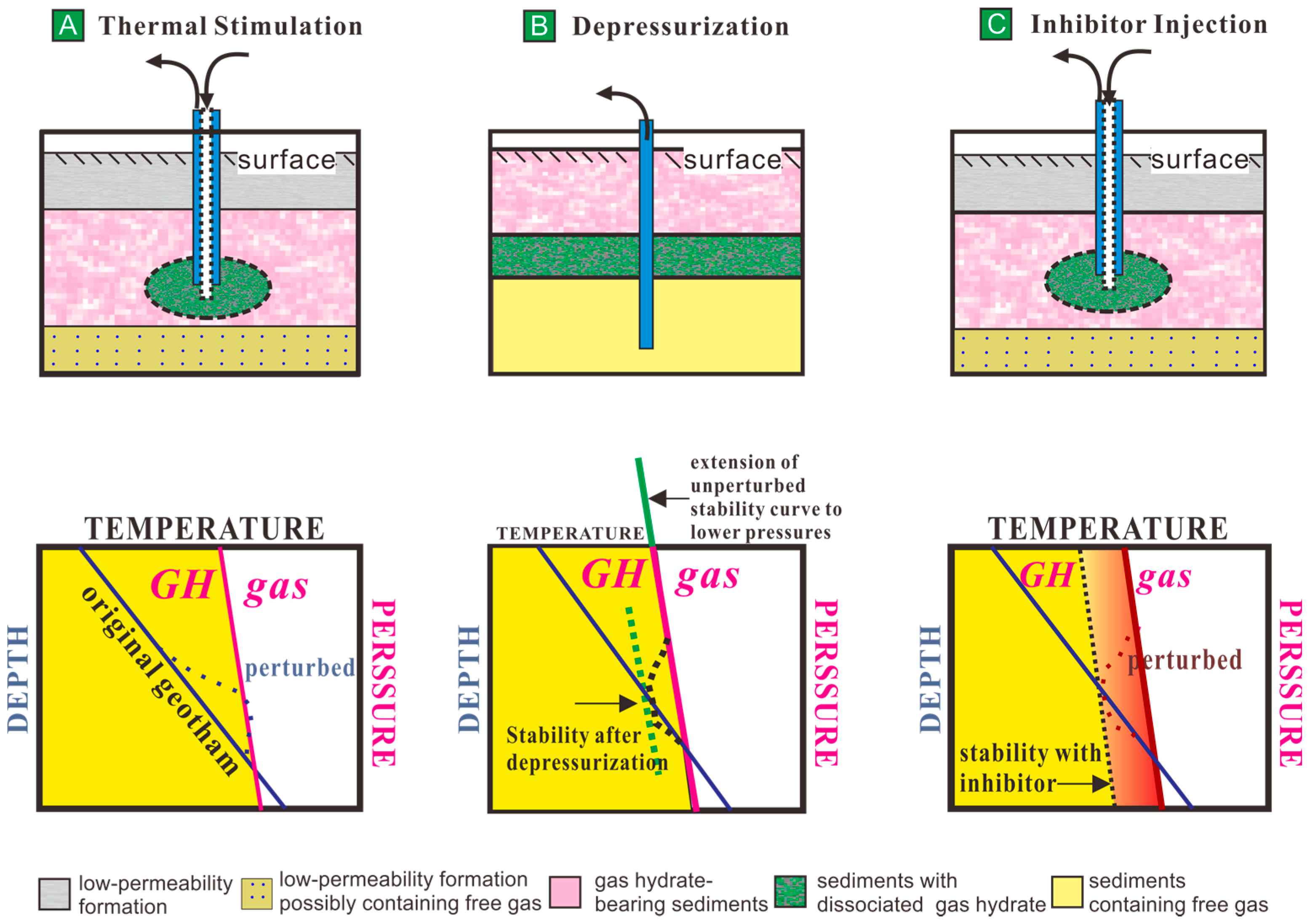

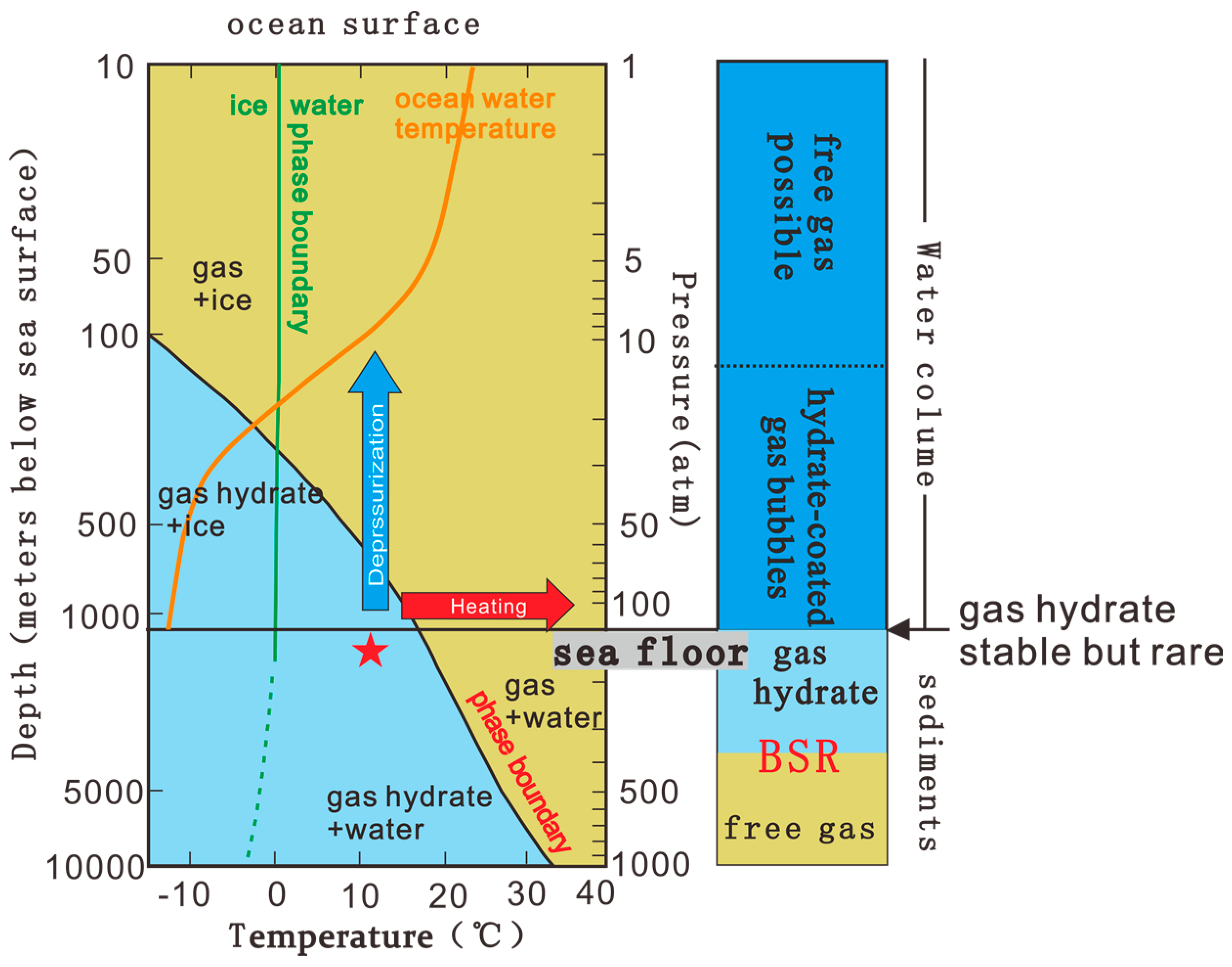

1.1. Background

1.2. Status Quo in Hydrate Reservoir Modeling

1.3. Objectives

2. Geological Model and Simulation Scenarios

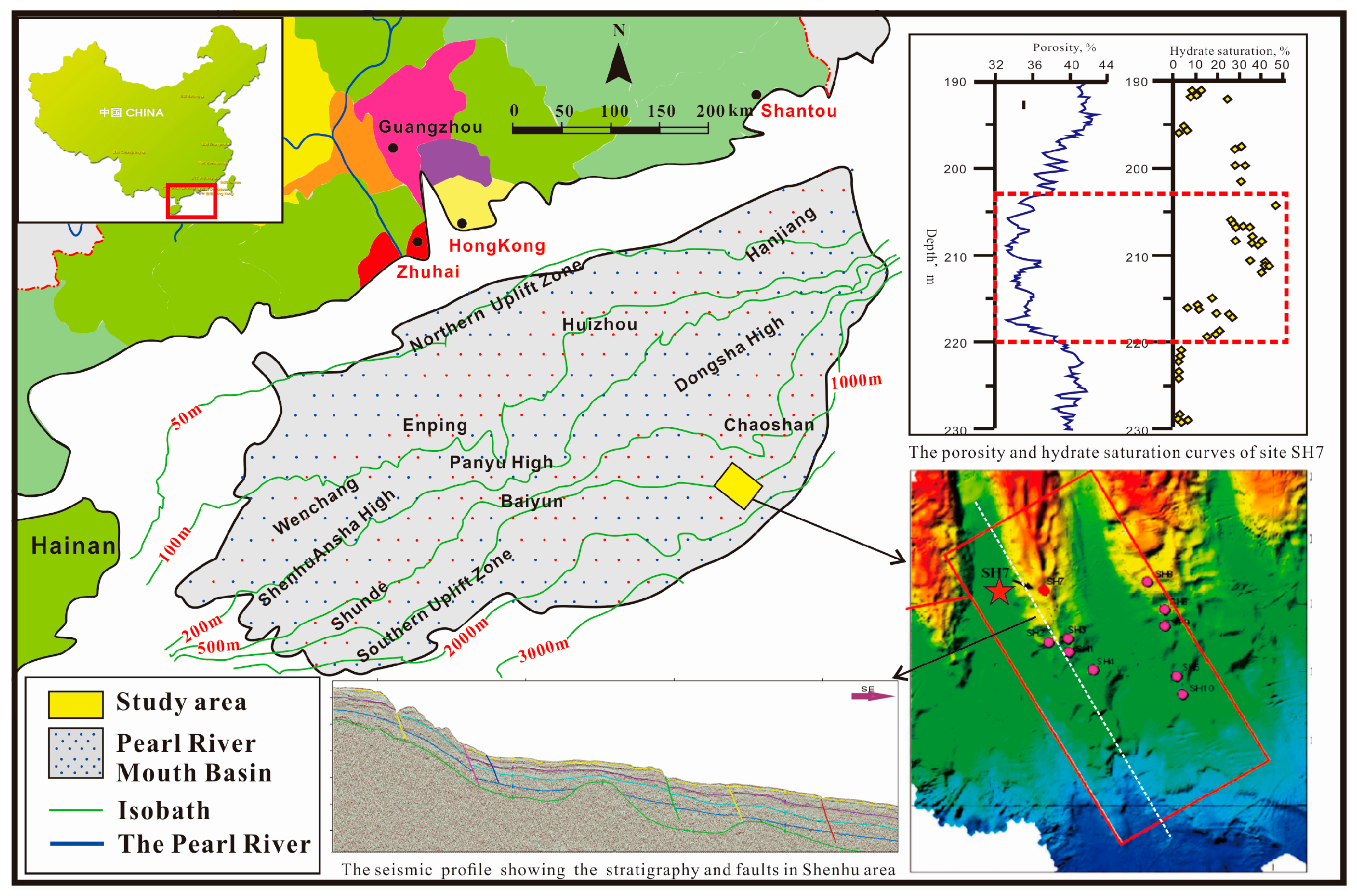

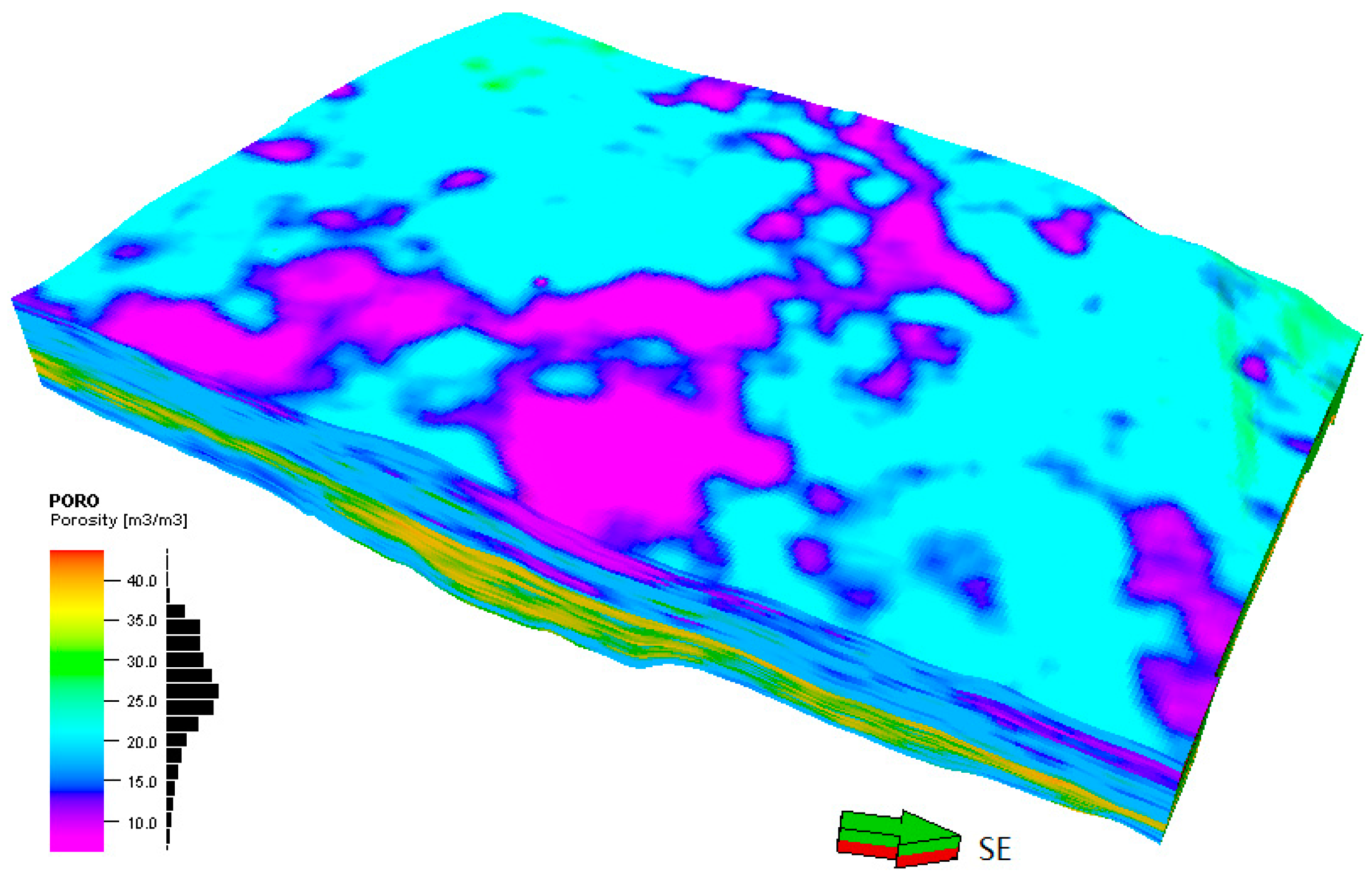

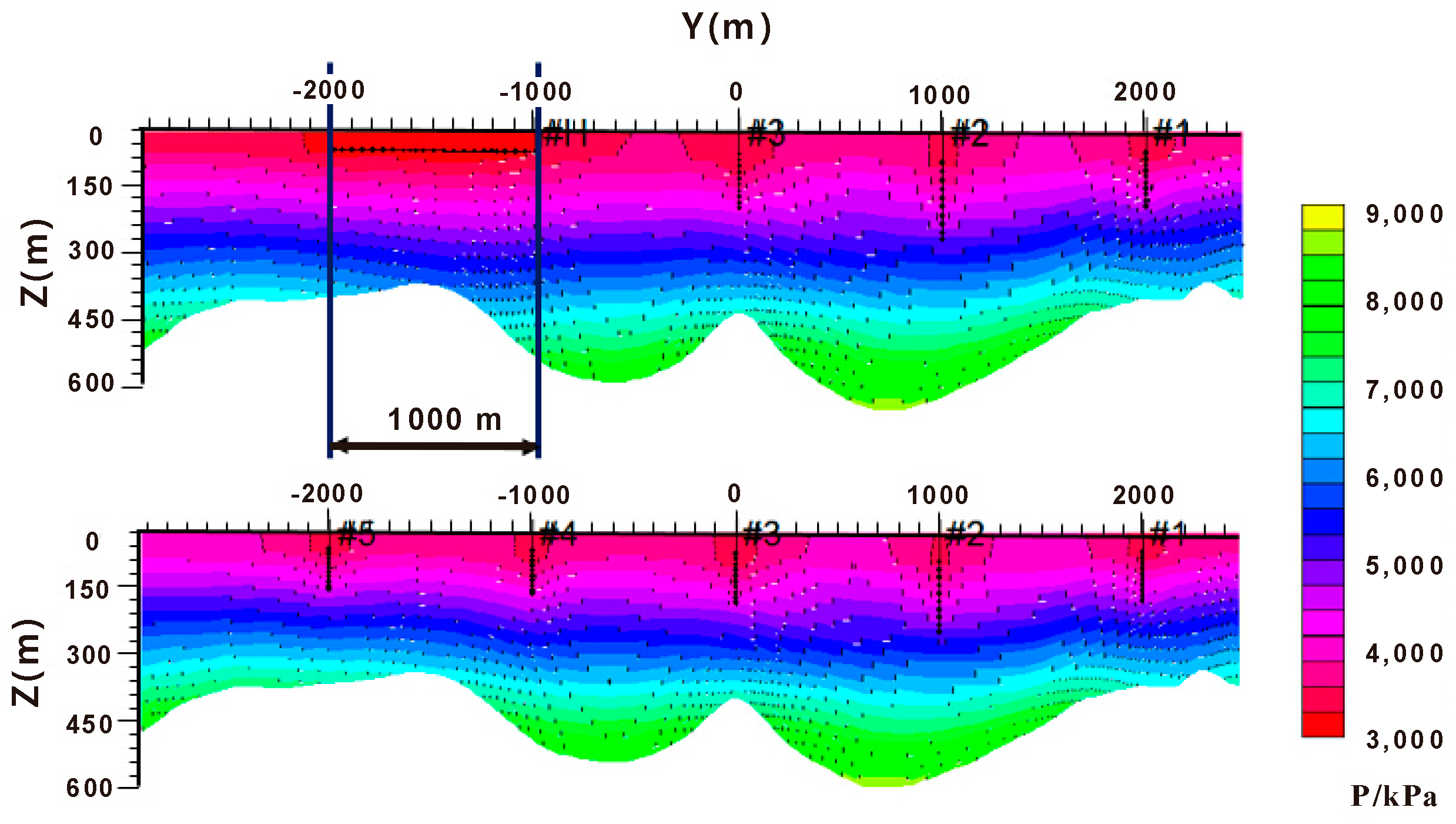

2.1. Geological Settings and Real Model

2.2. Reservoir Parameters and Component Setting

2.3. Scenarios & Simulation

3. Production Performance from Some Sites in the Shenhu Area

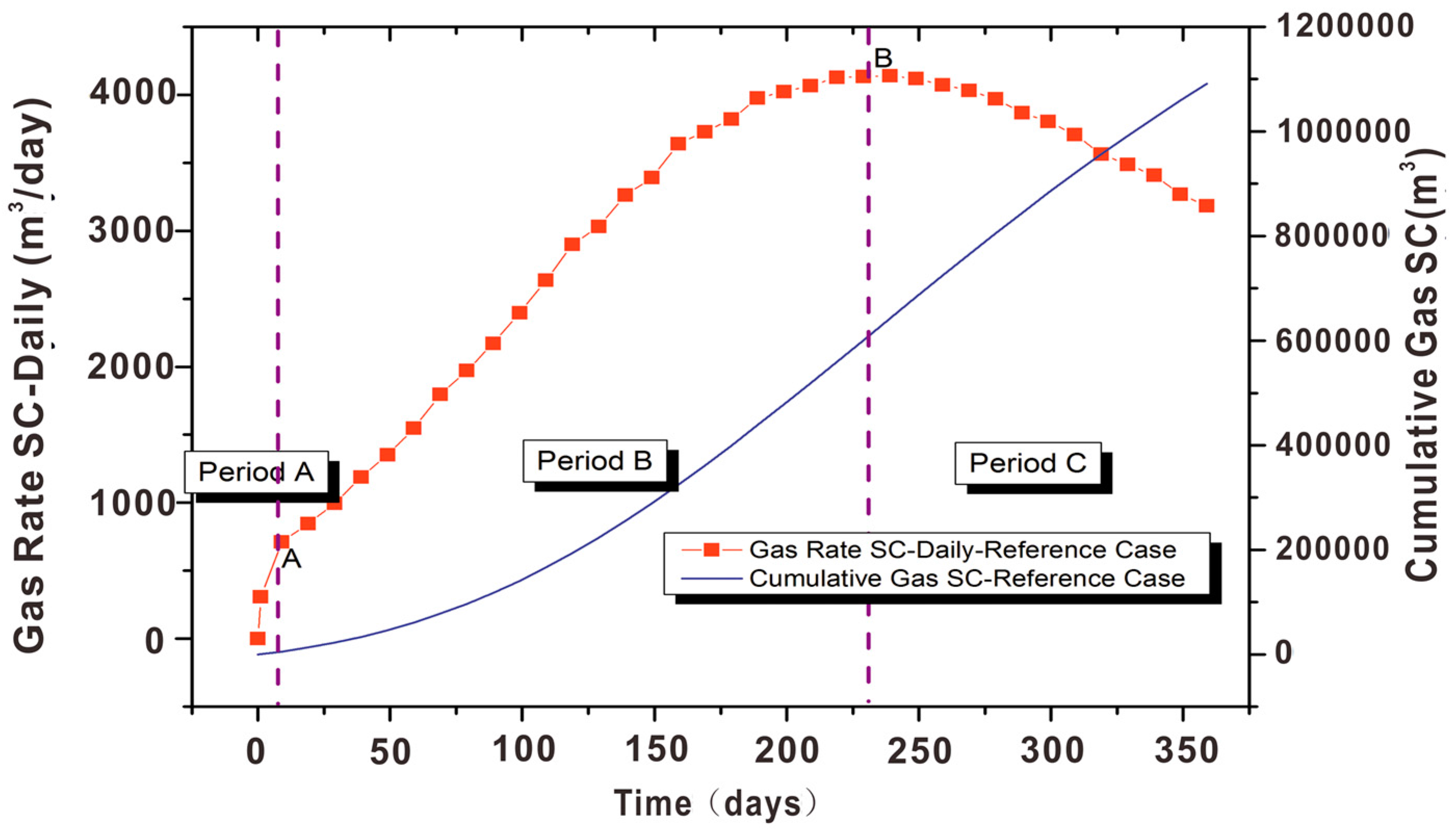

3.1. Reference Case and Gas Production

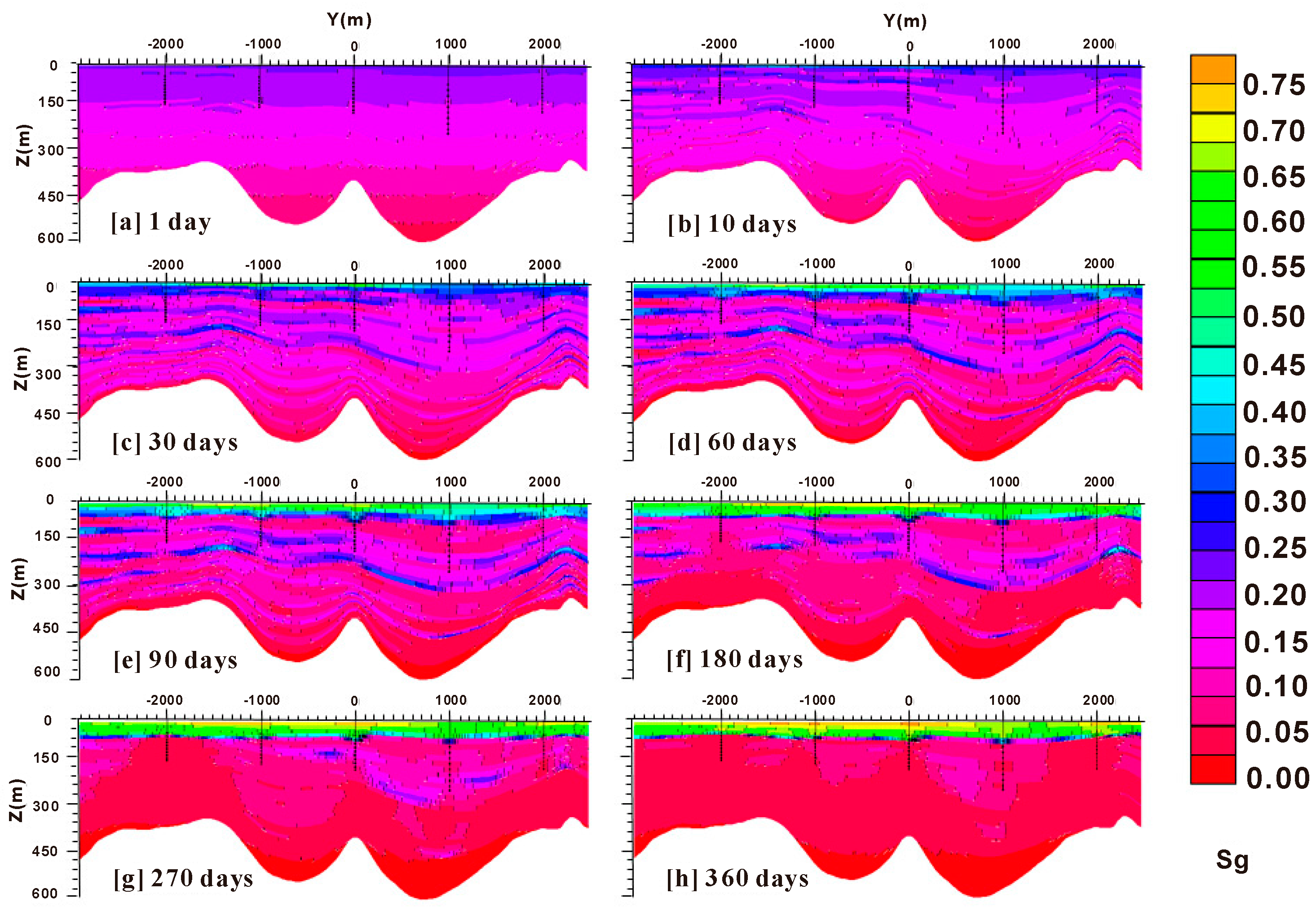

3.2. Spatial Distribution of Sg and Sh

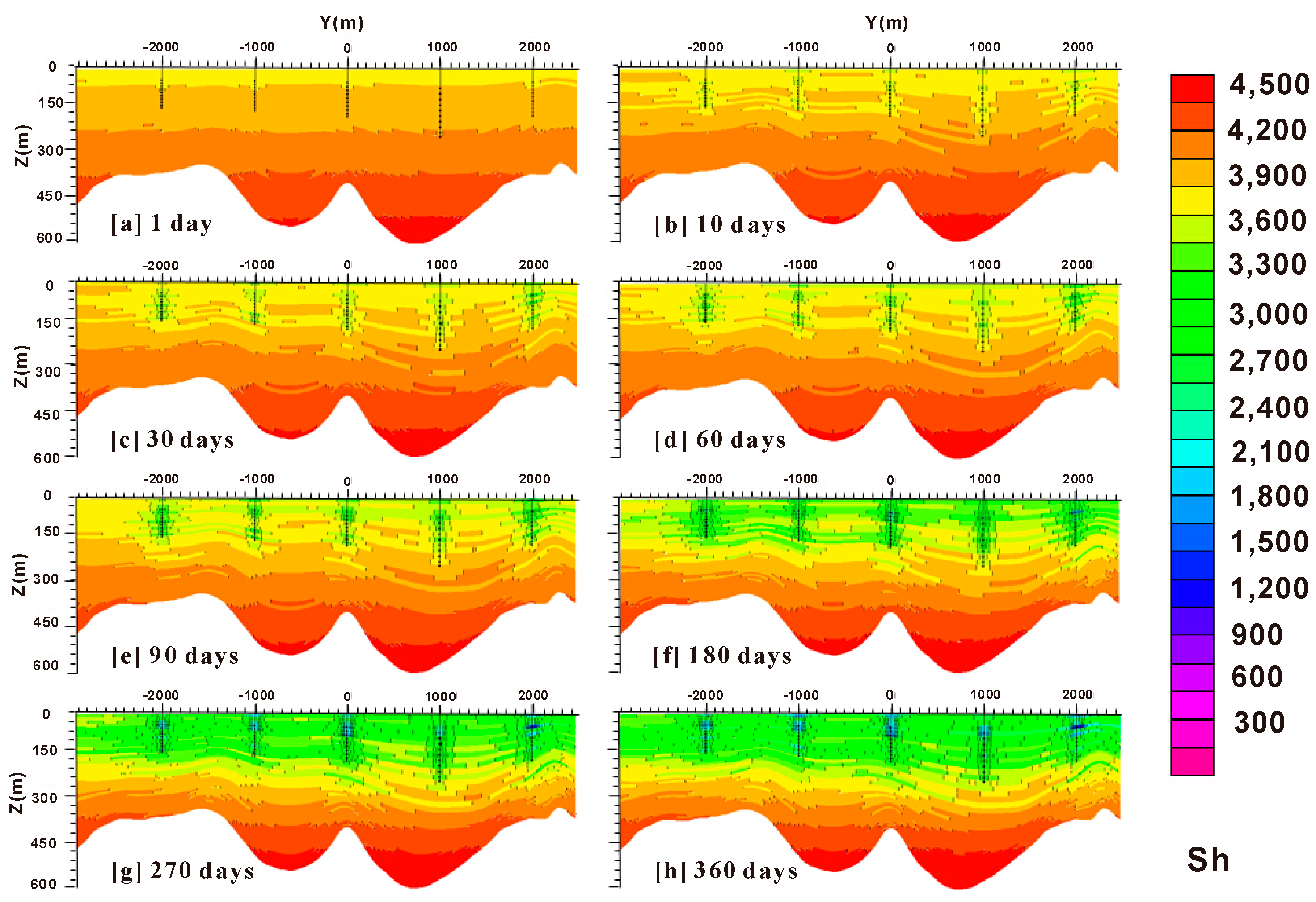

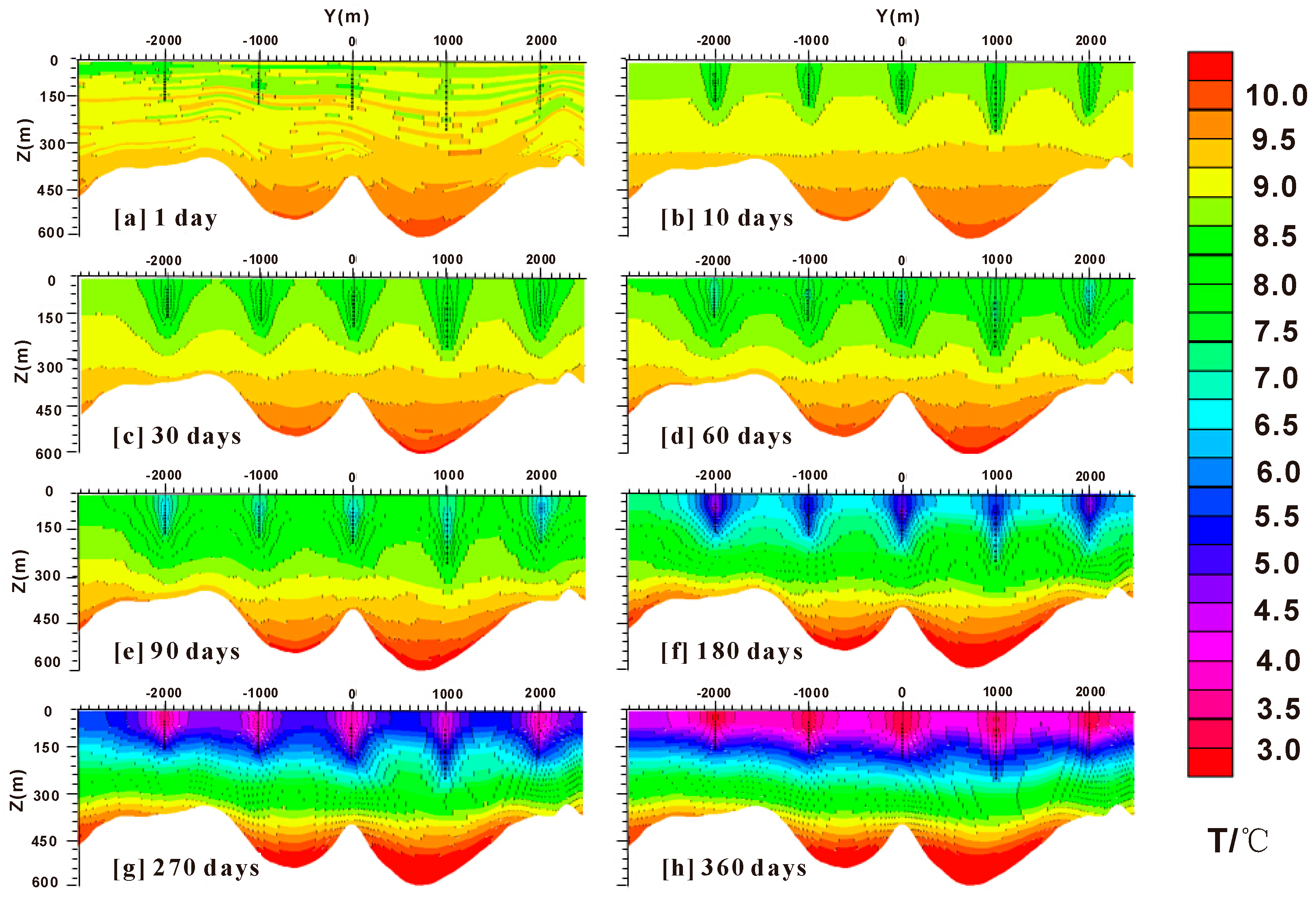

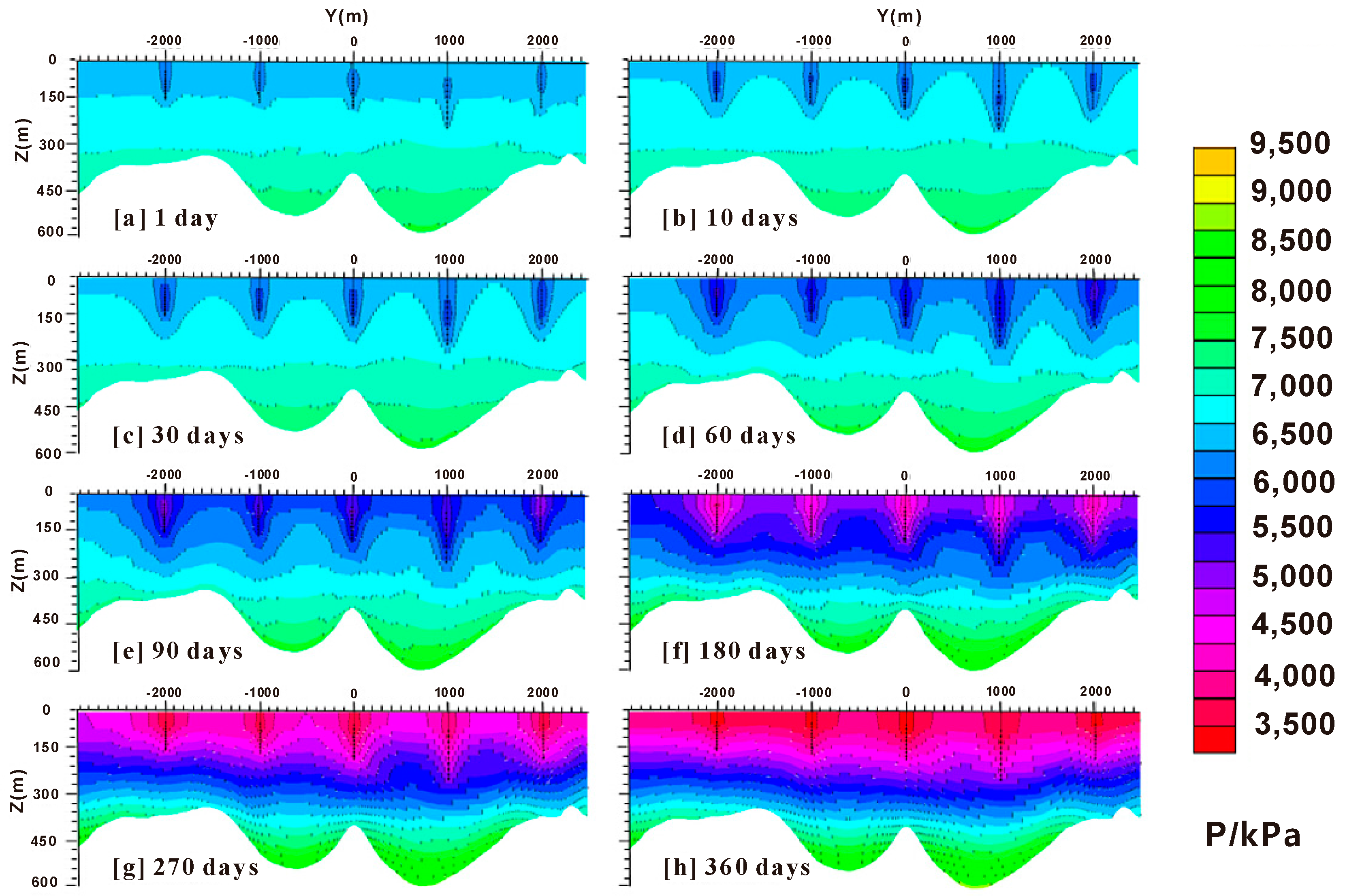

3.3. Spatial Distribution of T and P

4. Results and Discussion

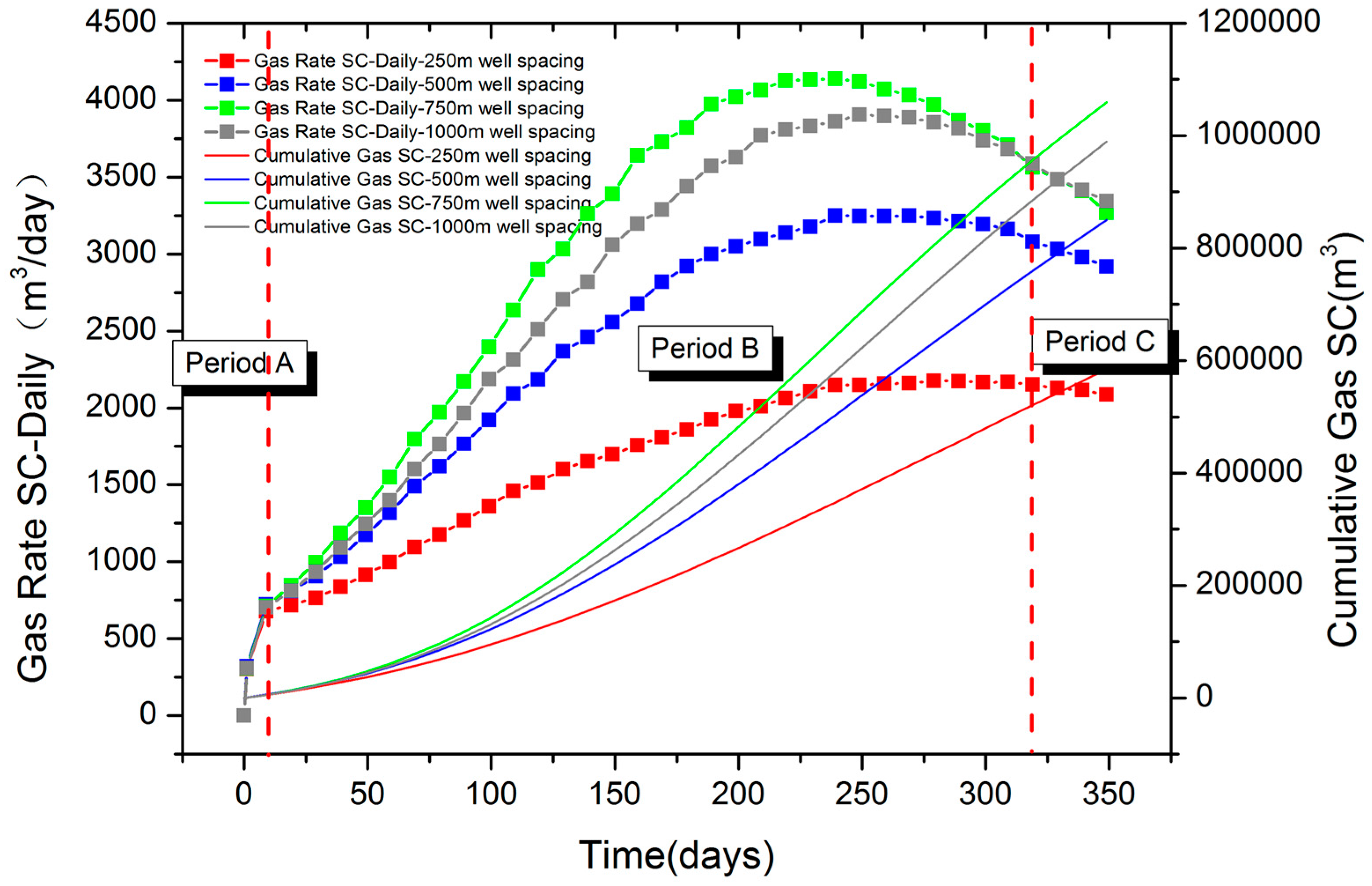

4.1. Sensitivity of Producer Well Spacing

4.2. Sensitivity of BHP

4.3. Sensitivity of Well Types

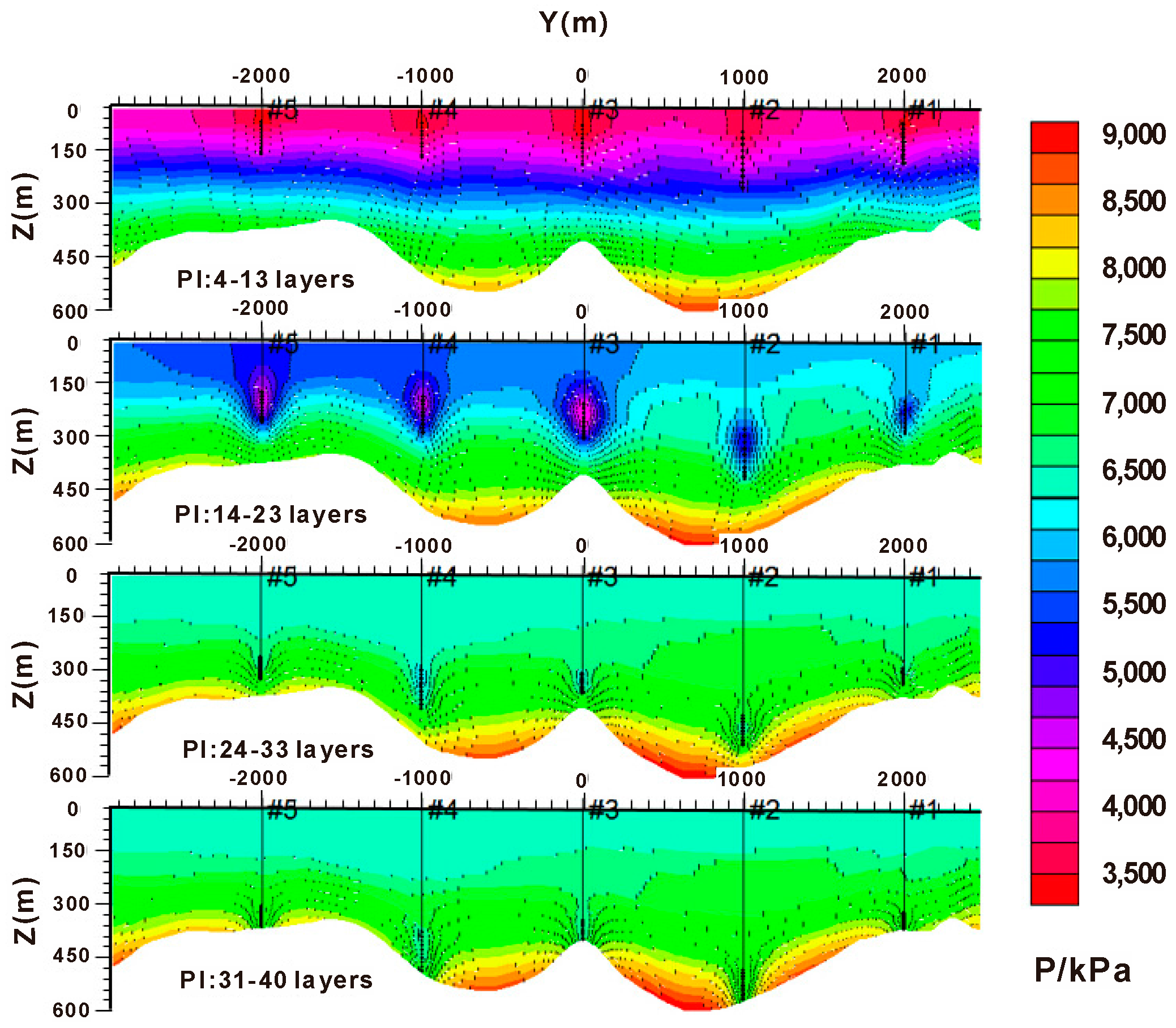

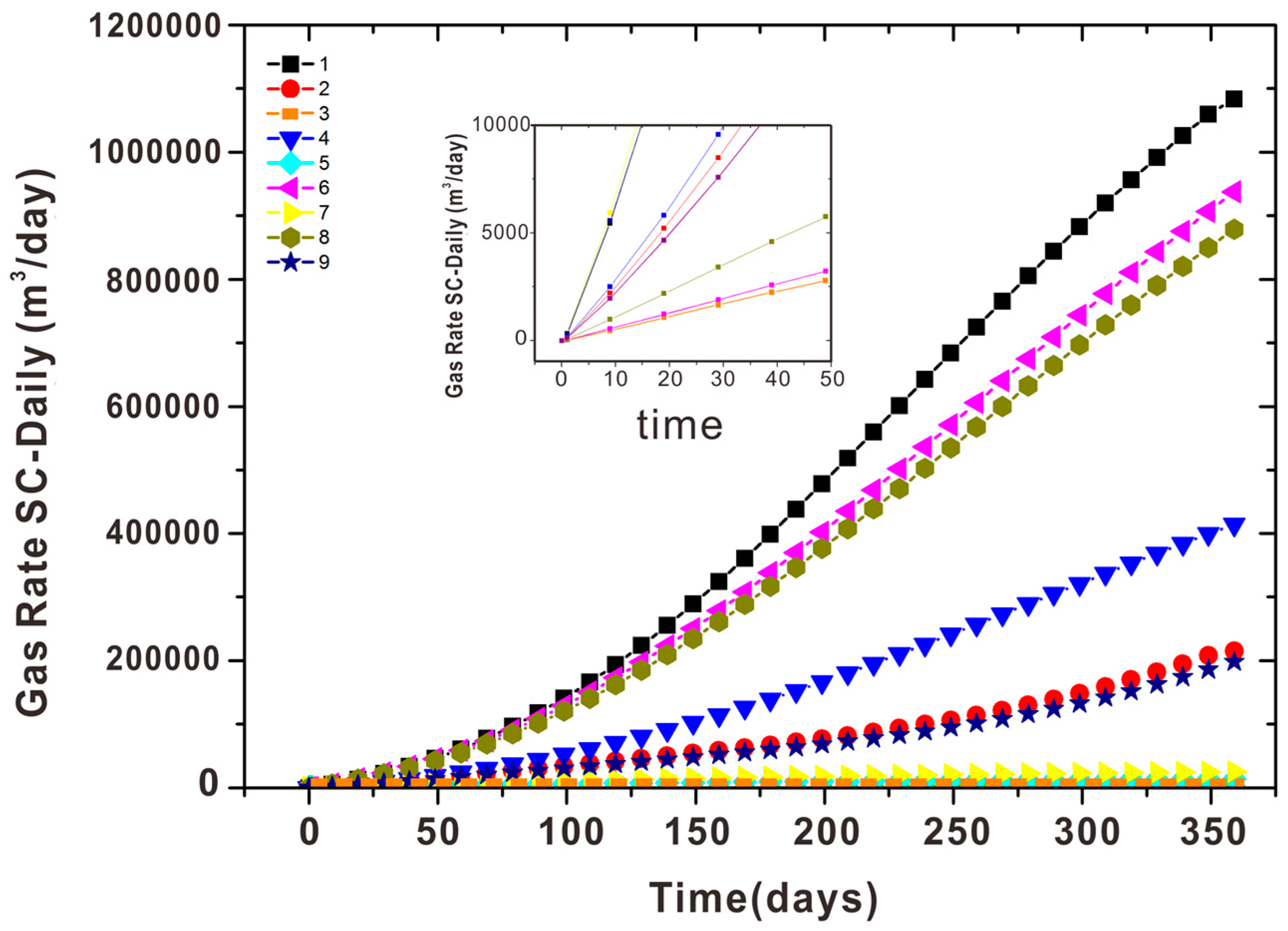

4.4. Sensitivity of Perforation Intervals of Producing Well

4.5. Orthogonal Design

5. Conclusions

- (1)

- As for the actual geological model of the Shenhu area, the gas accumulation of the basis scenario of operational conditions with 1000 m well spacing, 3000 kPa BHP and perforated 4–13 intervals can reach 1.02 × 106 S Tm3 after one years’ production, and the peak daily gas rate can reach approximately 4000 STm3/day. That outcome can be used as reference data when it comes to the real field development.

- (2)

- The operation conditions indeed have an important influence on the production performance. The well spacing analysis indicates that the total production period can be divided into three periods according to the degrees of the influencing factors that are initial period, interacting & storage period and storage period. Different well spacing acts similarly in period A because of the pressure interaction has not happened, the pressure dropdown waves and the controlling storage work together in the period B, and the controlling storage plays the main role in the following period when the pressure interaction is slight after the long production time.

- (3)

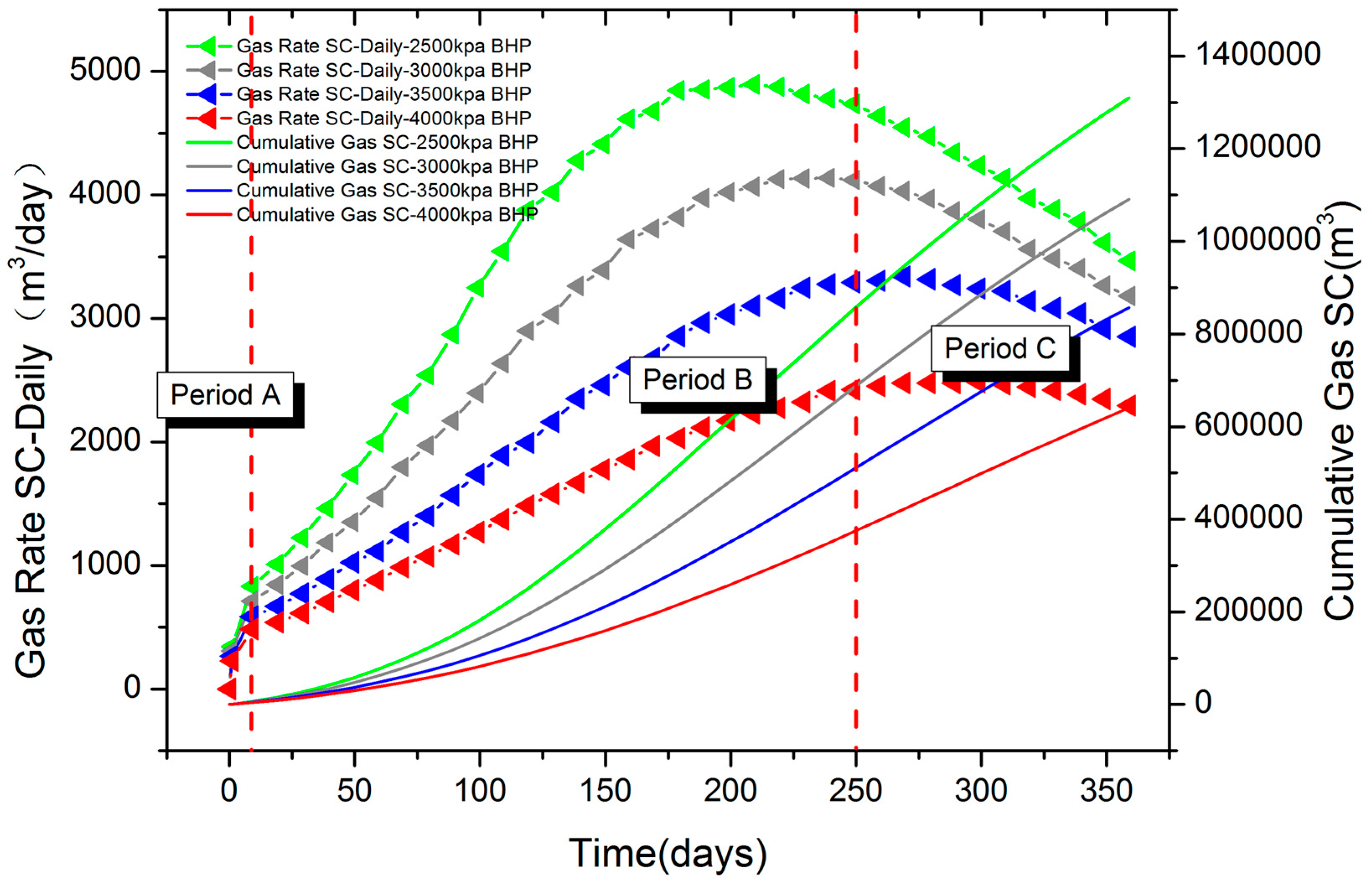

- The BHP analysis indicates that the total production period can also be divided into three periods according to the size of pressure gap that are initial period, speeding period and declining period. Different BHP reflects different pressure gaps between the hydrate reservoir and the BHP, that is the driving force which subsequently results in a higher gas travel velocity in the host formation which subsequently in turn stimulates even more hydrate dissociation. In the following decades, when the gap is gone, the reaction will remain in phase equilibrium and no more extra gas will be produced.

- (4)

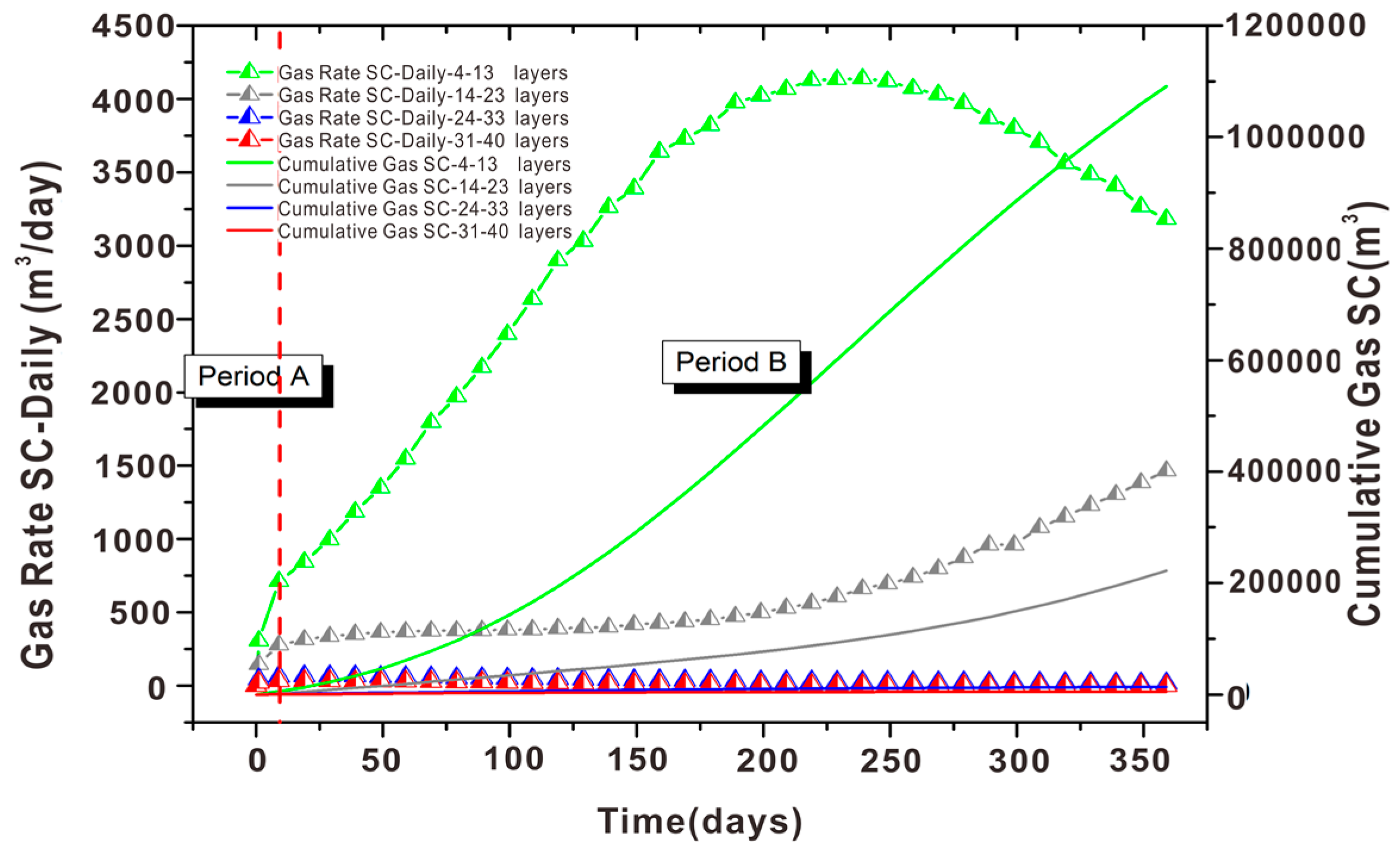

- The perforation intervals analysis indicates that the pressure around the perforated layers is so dominant that lower pressure in the hydrate deposit produced more gas than other scenarios. The perforation intervals have an extremely strong effect on the production. The production well perforation interval should be located in the upper deposit in the development of the Shenhu case.

- (5)

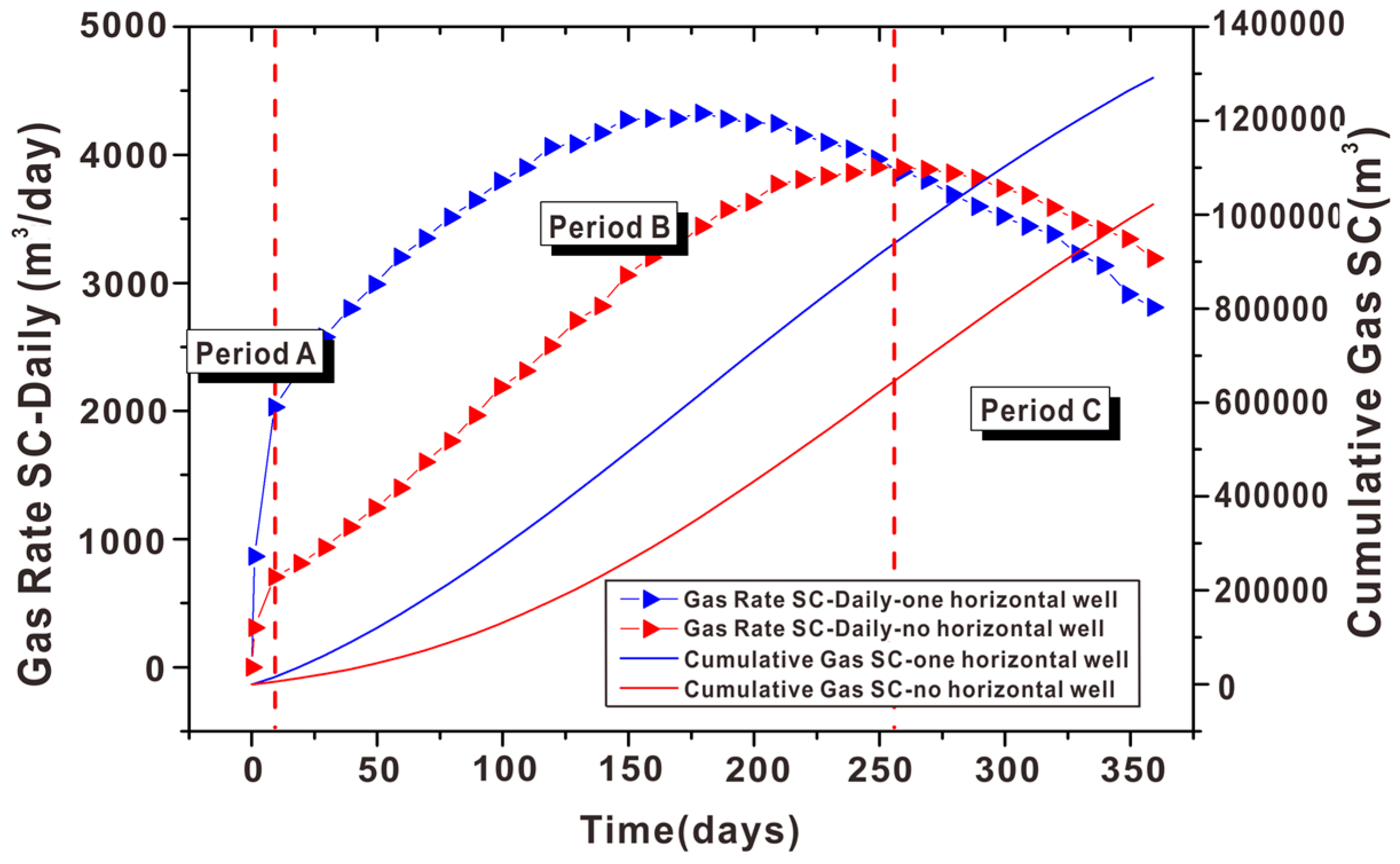

- The well type analysis indicates the use of horizontal wells in such reservoirs may not be attractive in the long run as all layers showed an upward gas migration block which is contrary to gas production from conventional gas reservoirs.

- (6)

- One factor at a time design and orthogonal design indicate that the order of the effects of the factors on gas yield was perforation intervals > bottom hole pressure > well spacing.

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

Governing Equations

Abbreviations

| gas density (g/cm3) | |

| water density (g/cm3) | |

| hydrate density (g/cm3) | |

| gas velocity along the x-axis (m/s) | |

| gas velocity along the y-axis (m/s) | |

| gas velocity along the z-axis (m/s) | |

| gas velocity (m/s) | |

| water velocity (m/s) | |

| hydrate velocity (m/s) | |

| x, y, z | Cartesian coordinates (m) |

| rate of gas production (g/(s·cm3)) | |

| rate of water production (g/(s·cm3)) | |

| rate of hydrate dissociation (g/(s·cm3)) | |

| ϕ | porosity |

| gas saturation | |

| water saturation | |

| hydrate saturation | |

| t | time (days) |

| k | absolute permeability (μm2) |

| kr | relative permeability (μm2) |

| keff | effective permeability (μm2) |

| P | pressure (kPa) |

| Pi | initial pressure (kPa) |

| bottom hole pressure (kPa) | |

| gas viscosity (mPa·s) | |

| water viscosity (mPa·s) | |

| gas gravity (kN·m3) | |

| water gravity (kN·m3) | |

| decomposition rate constant (g/(cm2·Pa·s)) | |

| intrinsic decomposition rate constant (g/(cm2·Pa·s)) | |

| M | molecular mass (kg/mol) |

| hydrate surface area per unit volume (cm2) | |

| f | fugacity (kPa) |

| fugacity of methane (kPa) | |

| fugacity of pure components (kPa) | |

| k | thermal conductivity |

| T | temperature (°C) |

| Ti | initial temperature (°C) |

| h | specific enthalpy |

| QH | heat of hydrate decomposition unit bulk volume (J) |

| Qin | direct heat input bulk volume (J) |

| ΔHR | heat of reaction (J) |

| V | volume (m3) |

| E | activation energy (kJ/mol) |

| R | universal gas constant (8.31 J/(mol·K)) |

| A | reaction frequency factor |

| C | volumetric heat capacity (J/(m3·C)) |

| m | geothermal gradient (K/m) |

| thermal conductivity of the rock (J/(m·day·C)) | |

| d | well spacing (m) |

References

- Montzka, S.A.; Dlugokencky, E.J.; Butler, J.H. Non-CO2 greenhouse gases and climate change. Nature 2011, 476, 43–50. [Google Scholar] [CrossRef] [PubMed]

- Chu, S.; Majumdar, A. Opportunities and challenges for a sustainable energy future. Nature 2012, 488, 294–303. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Seo, Y.; Lee, J.; Moudrakovski, I.; Ripmeester, J.A.; Chapman, N.R.; Coffin, R.B.; Gardner, G.; Pohlman, J. Complex gas hydrate from the Cascadia margin. Nature 2007, 445, 303–306. [Google Scholar] [CrossRef] [PubMed]

- Falenty, A.; Hansen, T.C.; Kuhs, W.F. Formation and properties of ice XVI obtained by emptying a type sII clathrate hydrate. Nature 2014, 516, 231–233. [Google Scholar] [CrossRef] [PubMed]

- Sloan, E.D. Fundamental principles and applications of natural gas hydrates. Nature 2003, 426, 353–363. [Google Scholar] [CrossRef] [PubMed]

- Sloan, E.D., Jr.; Koh, C. Clathrate Hydrates of Natural Gases; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Johnson, A.H. Global Resource Potential of Gas Hydrate—A New Calculation. In Proceedings of the 7th International Conference on Gas Hydrates, Edinburgh, UK, 17–21 July 2011.

- Zhong, D.L.; Daraboina, N.; Englezos, P. Recovery of CH4 from coal mine model gas mixture (CH4N2) by hydrate crystallization in the presence of cyclopentane. Fuel 2013, 106, 425–430. [Google Scholar] [CrossRef]

- Linga, P.; Daraboina, N.; Ripmeester, J.A.; Englezos, P. Enhanced rate of gas hydrate formation in a fixed bed column filled with sand compared to a stirred vessel. Chem. Eng. Sci. 2012, 68, 617–623. [Google Scholar] [CrossRef]

- Zhong, D.; Ye, Y.; Yang, C.; Bian, Y.; Ding, K. Experimental investigation of methane separation from low-concentration coal mine gas (CH4/N2/O2) by tetra-n-butyl ammonium bromide semiclathrate hydrate crystallization. Ind. Eng. Chem. Res. 2012, 51, 14806–14813. [Google Scholar] [CrossRef]

- Zhong, D.; Englezos, P. Methane separation from coal mine methane gas by tetra-n-butyl ammonium bromide semiclathrate hydrate formation. Energy Fuels 2012, 26, 2098–2106. [Google Scholar] [CrossRef]

- Kamath, V.A.; Godbole, S.P. Evaluation of hot-brine stimulation technique for gas production from natural gas hydrates. J. Pet. Technol. 1987, 39, 1379–1388. [Google Scholar] [CrossRef]

- Zhao, J.; Cheng, C.; Song, Y.; Song, Y.; Liu, W.; Liu, Y.; Xue, K.; Zhu, Z.; Yang, Z.; Wang, D.; et al. Heat transfer analysis of methane hydrate sediment dissociation in a closed reactor by a thermal method. Energies 2012, 5, 1292–1308. [Google Scholar] [CrossRef]

- Kawamura, T.; Ohtake, M.; Sakamoto, Y.; Haneda, H.; Komai, T.; Higuchi, S. Experimental Study on Steam Injection Method Using Methane Hydrate Core Samples. In Proceedings of the Seventh ISOPE Ocean Mining Symposium, Lisbon, Portugal, 1–6 July 2007; International Society of Offshore and Polar Engineers: Houston, TX, USA, 2007. [Google Scholar]

- Li, G.; Moridis, G.J.; Zhang, K.; Li, X.-S. Evaluation of gas production potential from marine gas hydrate deposits in Shenhu area of South China Sea. Energy Fuels 2010, 24, 6018–6033. [Google Scholar] [CrossRef]

- Li, X.S.; Li, B.; Li, G. Numerical simulation of gas production potential from permafrost hydrate deposits by huff and puff method in a single horizontal well in Qilian Mountain, Qinghai province. Energy 2012, 40, 59–75. [Google Scholar] [CrossRef]

- Jiang, X.; Li, S.; Zhang, L. Sensitivity analysis of gas production from Class I hydrate reservoir by depressurization. Energy 2012, 39, 281–285. [Google Scholar] [CrossRef]

- Collett, T.S. Gas hydrates as a future energy resource. Geotimes 2004, 49, 24–27. [Google Scholar]

- Li, G.; Li, X.S.; Tang, L.G.; Zhang, Y. Experimental investigation of production behavior of methane hydrate under ethylene glycol injection in unconsolidated sediment. Energy Fuels 2007, 21, 3388–3393. [Google Scholar] [CrossRef]

- Sun, D.; Englezos, P. Storage of CO2 in a partially water saturated porous medium at gas hydrate formation conditions. Int. J. Greenh. Gas Control 2014, 25, 1–8. [Google Scholar] [CrossRef]

- Graue, A.; Ersland, G.; Birkedal, K.A.; Hauge, L. Methane Production from Natural Gas Hydrates by CO2 Replacement-Review of Lab Experiments and Field Trial. In Proceedings of the SPE Bergen One Day Seminar, Bergen, Norway, 2 April 2014; Society of Petroleum Engineers: Houston, TX, USA, 2014. [Google Scholar]

- Kurihara, M.; Funatsu, K.; Ouchi, H.; Masuda, Y.; Narita, H. Investigation on Applicability of Methane Hydrate Production Methods to Reservoirs with Diverse Characteristics. In Proceedings of the 5th International Conference on Gas Hydrates, Trondheim, Norway, 13–16 July 2005.

- Moridis, G.J. Toward Production from Gas Hydrates: Current Status, Assessment of Resources, and Simulation-Based Evaluation of Technology and Potential; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2008. [Google Scholar]

- Li, G.; Li, B.; Li, X.-S.; Zhang, Y.; Wang, Y. Experimental and numerical studies on gas production from methane hydrate in porous media by depressurization in pilot-scale hydrate simulator. Energy Fuels 2012, 26, 6300–6310. [Google Scholar] [CrossRef]

- Moridis, G.J.; Reagan, M.T. Strategies for Gas Production from Oceanic Class 3 Hydrate Accumulations; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2007. [Google Scholar]

- Sloan, E.D.; Koh, C.A. Clathrate Hydrates of Natural Gases, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2008; p. 119. [Google Scholar]

- Moridis, G.J. The Use of Horizontal Wells in Gas Production from Hydrate Accumulations; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2008. [Google Scholar]

- Wang, Y.; Li, X.-S.; Li, G.; Zhang, Y.; Li, B.; Chen, Z.-Y. Experimental investigation into methane hydrate production during three-dimensional thermal stimulation with five-spot well system. Appl. Energy 2013, 110, 90–97. [Google Scholar] [CrossRef]

- Uddin, M.; Coombe, D.; Wright, F. Modeling of CO2-hydrate formation in geological reservoirs by injection of CO2 gas. J. Energy Resour. Technol. 2008, 130, 032502. [Google Scholar] [CrossRef]

- Howe, S.J. Production Modeling and Economic Evaluation of a Potential Gas Hydrate Pilot Production Program on the North Slope of Alaska; University of Alaska: Fairbanks, AK, USA, 2004. [Google Scholar]

- Uddin, M.; Wright, F.; Coombe, D. Numerical study of gas evolution and transport behaviours in natural gas-hydrate reservoirs. J. Can. Pet. Technol. 2011, 50, 70–88. [Google Scholar] [CrossRef]

- Hong, H.; Pooladi-Darvish, M.; Bishnoi, P.R. Analytical modelling of gas production from hydrates in porous media. J. Can. Pet. Technol. 2003, 42, 45–56. [Google Scholar] [CrossRef]

- Moridis, G.J. TOUGH + HYDRATE v1. 2 User’s Manual: A Code for the Simulation of System Behavior in Hydrate-Bearing Geologic Media; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2014. [Google Scholar]

- White, M.D.; Wurstner, S.K.; McGrail, B.P. Numerical studies of methane production from Class 1 gas hydrate accumulations enhanced with carbon dioxide injection. Mar. Pet. Geol. 2011, 28, 546–560. [Google Scholar] [CrossRef]

- Garapati, N. Reservoir Simulation for Production of CH4 from Gas Hydrate Reservoirs Using CO2/CO2 + N2 by HydrateResSim; West Virginia University: Morgantown, WV, USA, 2013. [Google Scholar]

- Masuda, Y.; Yamamoto, K.; Tadaaki, S.; Ebinuma, T.; Nagakubo, S. Japan’s methane hydrate R&D program progresses to phase 2. Natl. Gas Oil 2012, 304, 285–4541. [Google Scholar]

- Stars, C. Advanced Process and Thermal Reservoir Simulator; Computer Modelling Group Ltd.: Calgary, AB, Canada, 2008. [Google Scholar]

- Su, Z.; Moridis, G.J.; Zhang, K.; Wu, N. A huff-and-puff production of gas hydrate deposits in Shenhu area of South China Sea through a vertical well. J. Pet. Sci. Eng. 2012, 86–87, 54–61. [Google Scholar] [CrossRef]

- Li, G.; Moridis, G.J.; Zhang, K.; Li, X. Evaluation of Gas Production Potential from Marine Gas Hydrate Deposits in Shenhu Area of South China Sea. Energy Fuels 2010, 24, 6018–6033. [Google Scholar] [CrossRef]

- Su, Z.; Cao, Y.; Wu, N.; Chen, D.; Yang, S.; Wang, H. Numerical investigation on methane hydrate accumulation in Shenhu Area, northern continental slope of South China Sea. Mar. Pet. Geol. 2012, 38, 158–165. [Google Scholar] [CrossRef]

- Myshakin, E.; Gamwo, I.; Warzinski, R. Experimental Design Applied to Simulation of Gas Productivity Performance at Reservoir and Laboratory Scales Utilizing Factorial ANOVA Methodology. In Proceedings of the TOUGH Symposium, Berkeley, CA, USA, 14–16 September 2009.

- Saltelli, A.; Ratto, M.; Andres, T.; Campolongo, F.; Cariboni, J.; Gatelli, D.; Saisana, M.; Tarantola, S. Global Sensitivity Analysis: The Primer; John Wiley & Sons: New York, NY, USA, 2008. [Google Scholar]

- Friedmann, F.; Chawathe, A.; Larue, D.K. Assessing Uncertainty in Channelized Reservoirs Using Experimental Designs. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–3 October 2001.

- White, C.D.; Royer, S.A. Experimental Design as a Framework for Reservoir Studies. In Proceedings of the SPE Reservoir Simulation Symposium, The Woodlands, TX, USA, 18–20 February 2013.

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: New York, NY, USA, 2008. [Google Scholar]

- Kim, H.; Bishnoi, P.; Heidemann, R.; Rizvi, S. Kinetics of methane hydrate decomposition. Chem. Eng. Sci. 1987, 42, 1645–1653. [Google Scholar] [CrossRef]

- Liu, Y.; Strumendo, M.; Arastoopour, H. Simulation of methane production from hydrates by depressurization and thermal stimulation. Ind. Eng. Chem. Res. 2008, 48, 2451–2464. [Google Scholar] [CrossRef]

| Basic Properties | Symbols | Value | Units |

|---|---|---|---|

| Intrinsic porosity (all formations) | ϕ | 0.059–0.143 | - |

| Mean porosity | 0.083 | ||

| Intrinsic permeability (all formations) | k | 1.53–31.43 | md |

| Mean permeability | 17.73 | md | |

| Grain density (all formations) | ρ | 2600 | kg/m3 |

| Well spacing | d | 1000 | m |

| Bottom hole pressure | pwf | 3000 | kPa |

| Well type | - | vertical | |

| Perforated intervals | - | 4–13 | layer |

| Thermal conductivity of the rock | λR | 1.5 × 105 | J/(m·day·C) |

| Volumetric heat capacity | C | 8 × 105 | J/(m3·C) |

| Initial Pressure | pi | 1000 | kPa |

| Initial Temperature | Ti | 10 | °C |

| Gas saturation | Sg | 0.02 | - |

| Gas composition | - | 100% CH4 | |

| Geothermal gradient | m | 0.0433 | K/m |

| Water saturation | Sw | 0.98 | - |

| Water salinity (mass fraction) | S‰ | 0.0305 | |

| Hydrate concentration | - | 4616 | gmole/m3 |

| Reaction frequency factor | A | 1.097 × 1013 | - |

| Activation energy | E | 89,660 | J/mole |

| Enthalpy | H | 51,858 | J/mole |

| Operational Factor | Well Spacing (WS)/m | Bottom Hole Pressure (BHP)/kPa | Perforated Intervals (PI)/Layer | Well Type (WP) |

|---|---|---|---|---|

| Value Range | 1000 | 2500 | 4–13 | 5 vertical wells |

| 750 | 3000 | 14–23 | 3 vertical wells + 1 horizontal wells | |

| 500 | 3500 | 24–33 | ||

| 250 | 4000 | 31–40 |

| Case No. | Well Spacing/m | BHP/kPa | Perforated Intervals/Layer | Cumulative Gas/m3 |

|---|---|---|---|---|

| 1 | 1000 | 2500 | 4–13 | 1,083,475 |

| 2 | 1000 | 3000 | 14–23 | 214,946 |

| 3 | 1000 | 3500 | 24–33 | 12,142 |

| 4 | 750 | 2500 | 14–23 | 414,221 |

| 5 | 750 | 3000 | 24–33 | 14,024 |

| 6 | 750 | 3500 | 4–13 | 937,339 |

| 7 | 500 | 2500 | 24–33 | 25,048 |

| 8 | 500 | 3000 | 4–13 | 878,382 |

| 9 | 500 | 3500 | 14–33 | 198,471 |

| Mean A | 436,854.33 | 507,581.33 | 966,398.67 | |

| Mean B | 455,194.67 | 369,117.33 | 275,879.33 | |

| Mean C | 367,300.33 | 382,650.66 | 74,879.00 | |

| Range | 87,894.333 | 124,930.66 | 891,519.67 | |

| Better level | A2 | B1 | C1 | 1,309,742 |

| Order | 3 | 2 | 1 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Z.; Xin, Y.; Sun, Q.; Ma, R.; Zhang, J.; Lv, S.; Cai, M.; Wang, H. Numerical Simulation of the Depressurization Process of a Natural Gas Hydrate Reservoir: An Attempt at Optimization of Field Operational Factors with Multiple Wells in a Real 3D Geological Model. Energies 2016, 9, 714. https://doi.org/10.3390/en9090714

Sun Z, Xin Y, Sun Q, Ma R, Zhang J, Lv S, Cai M, Wang H. Numerical Simulation of the Depressurization Process of a Natural Gas Hydrate Reservoir: An Attempt at Optimization of Field Operational Factors with Multiple Wells in a Real 3D Geological Model. Energies. 2016; 9(9):714. https://doi.org/10.3390/en9090714

Chicago/Turabian StyleSun, Zhixue, Ying Xin, Qiang Sun, Ruolong Ma, Jianguang Zhang, Shuhuan Lv, Mingyu Cai, and Haoxuan Wang. 2016. "Numerical Simulation of the Depressurization Process of a Natural Gas Hydrate Reservoir: An Attempt at Optimization of Field Operational Factors with Multiple Wells in a Real 3D Geological Model" Energies 9, no. 9: 714. https://doi.org/10.3390/en9090714