Research on Operation Principle and Control of Novel Hybrid Excitation Bearingless Permanent Magnet Generator

Abstract

:1. Introduction

2. The Operation Principle and Structure of the HEBPMG

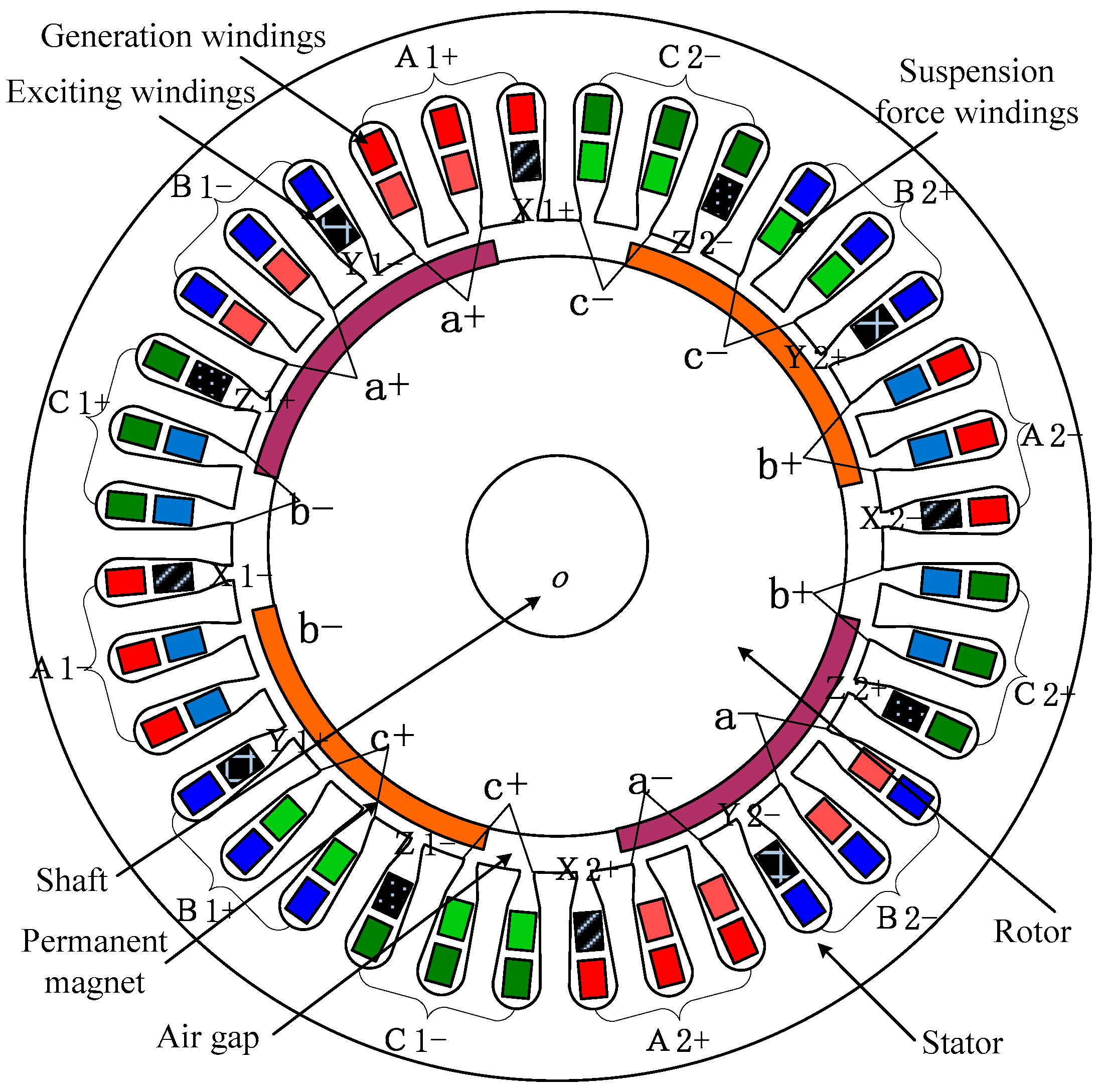

2.1. The Motor Structure and Windings Distributions of the HEBPMG

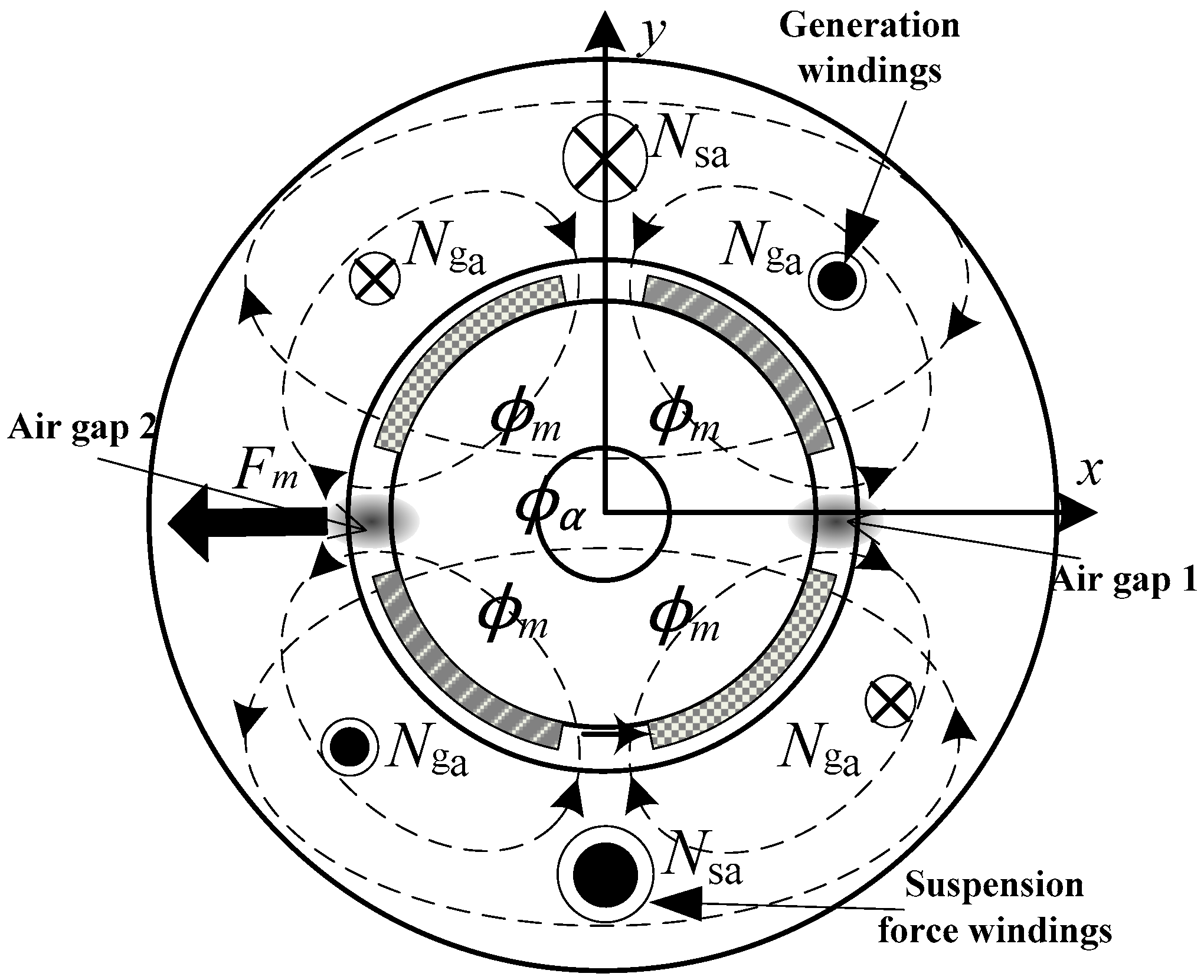

2.2. The Suspension Principle of the HEBPMG

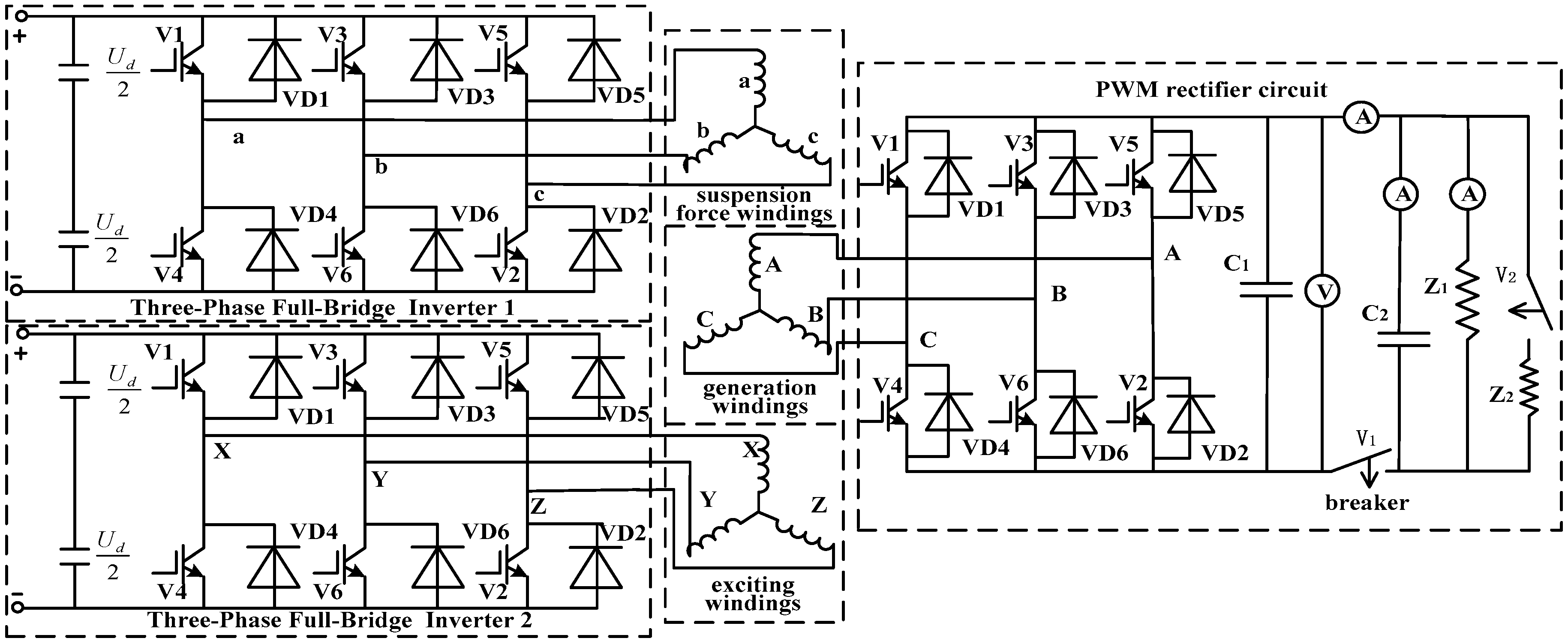

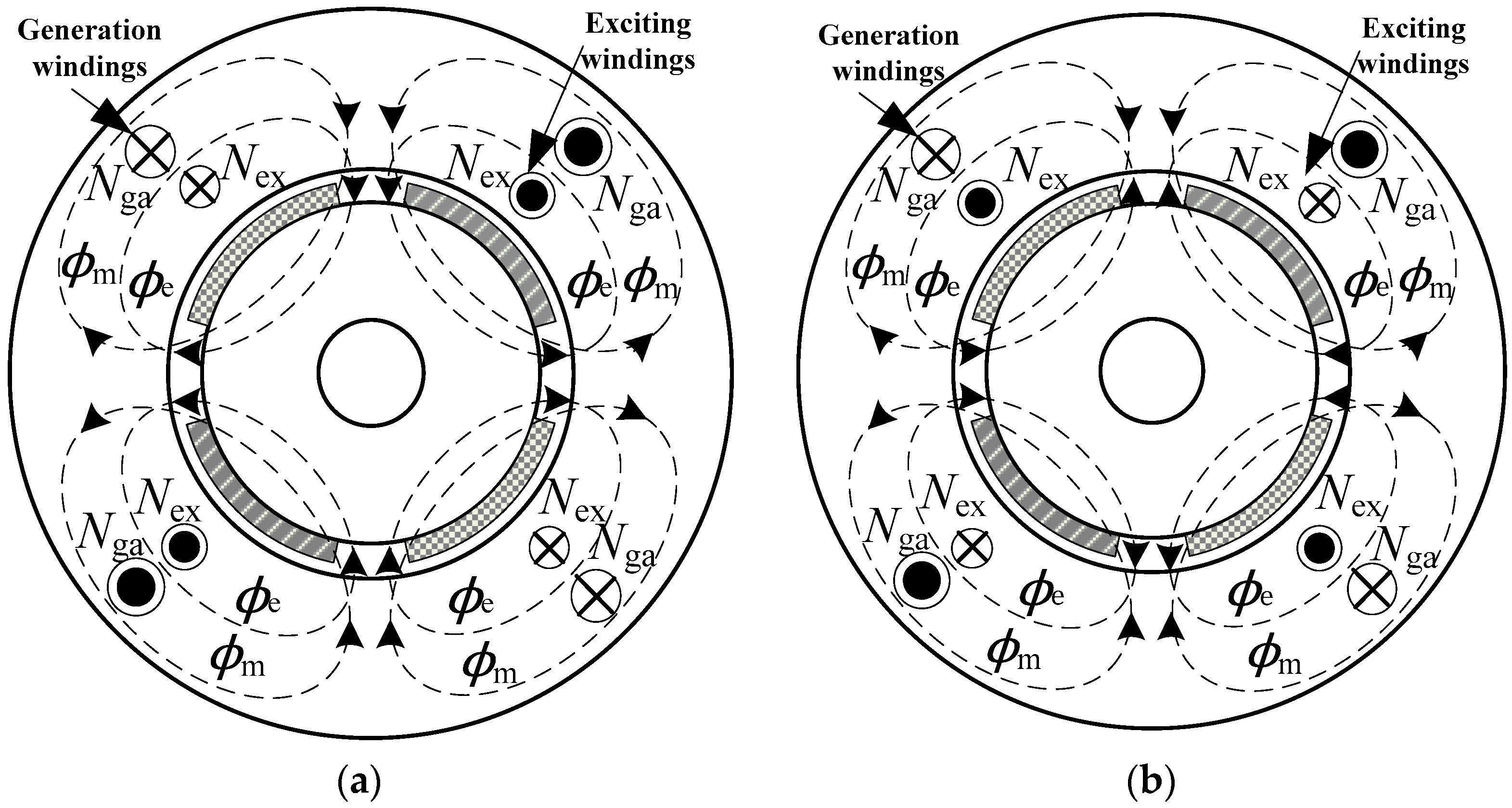

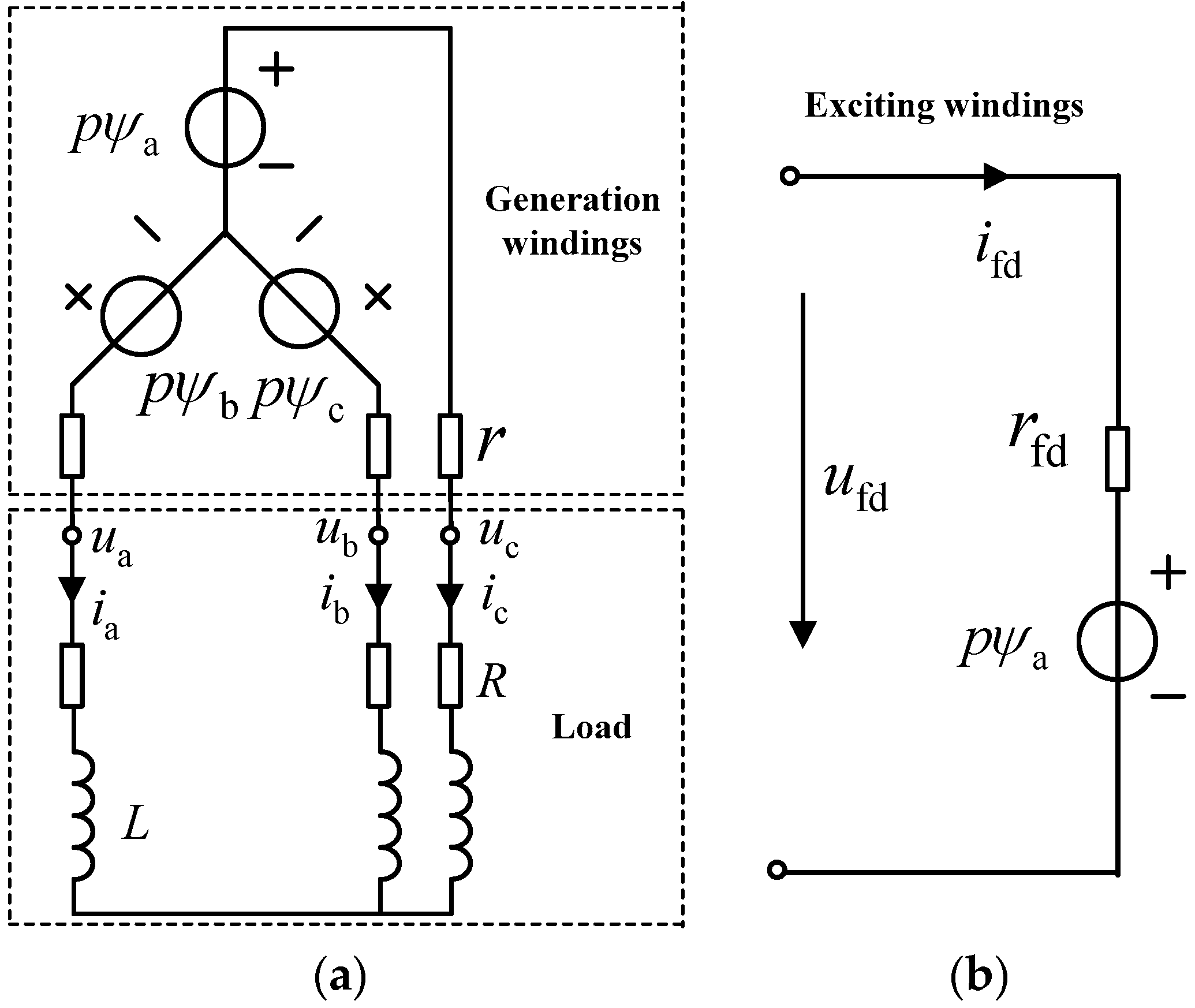

2.3. The Power Generation Principle of the HEBPMG

3. Mathematical Model of HEBPMG

3.1. Mathematical Model of Inducted Voltage

3.2. Mathematical Model of Radial Suspension Force

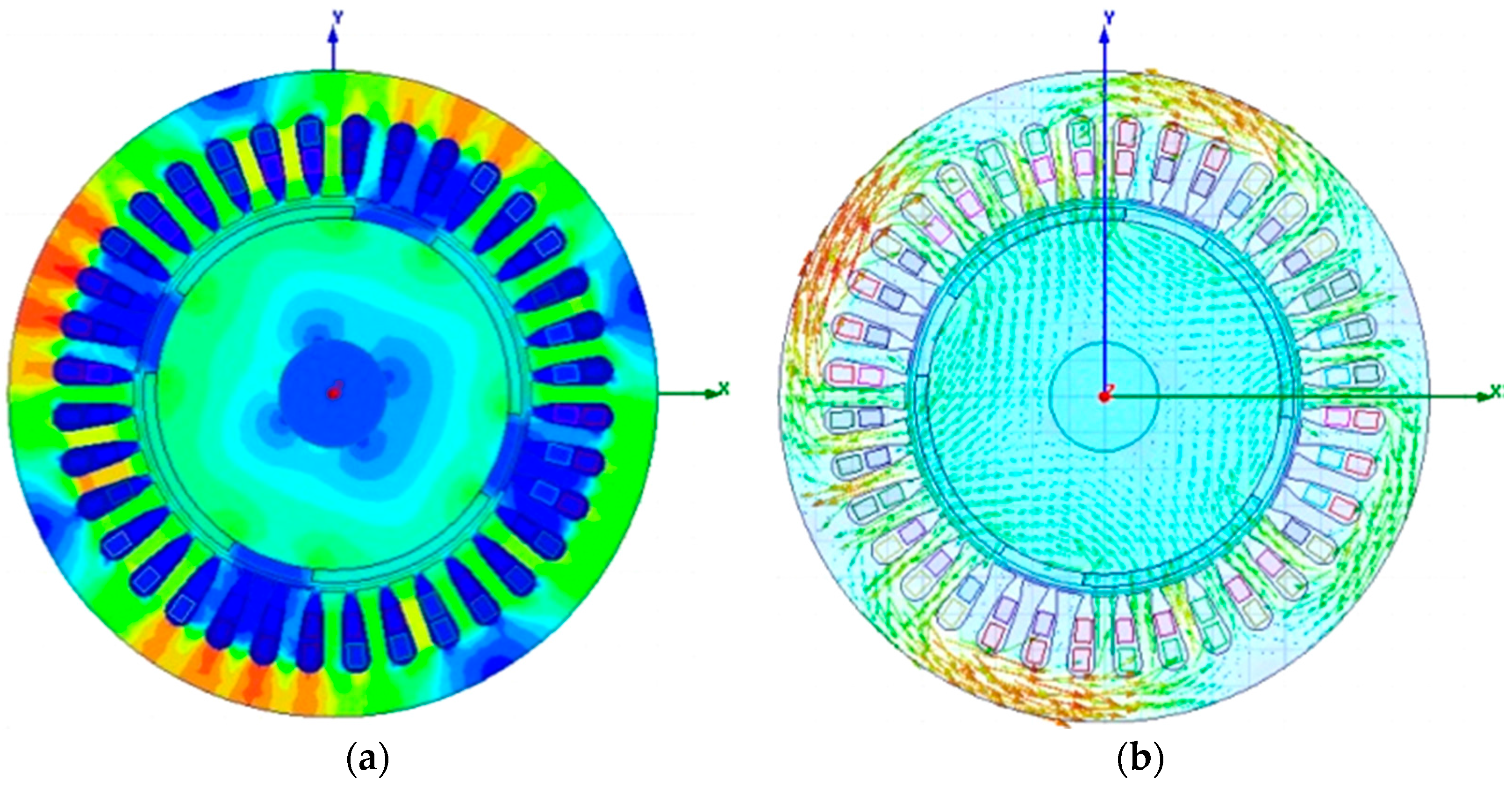

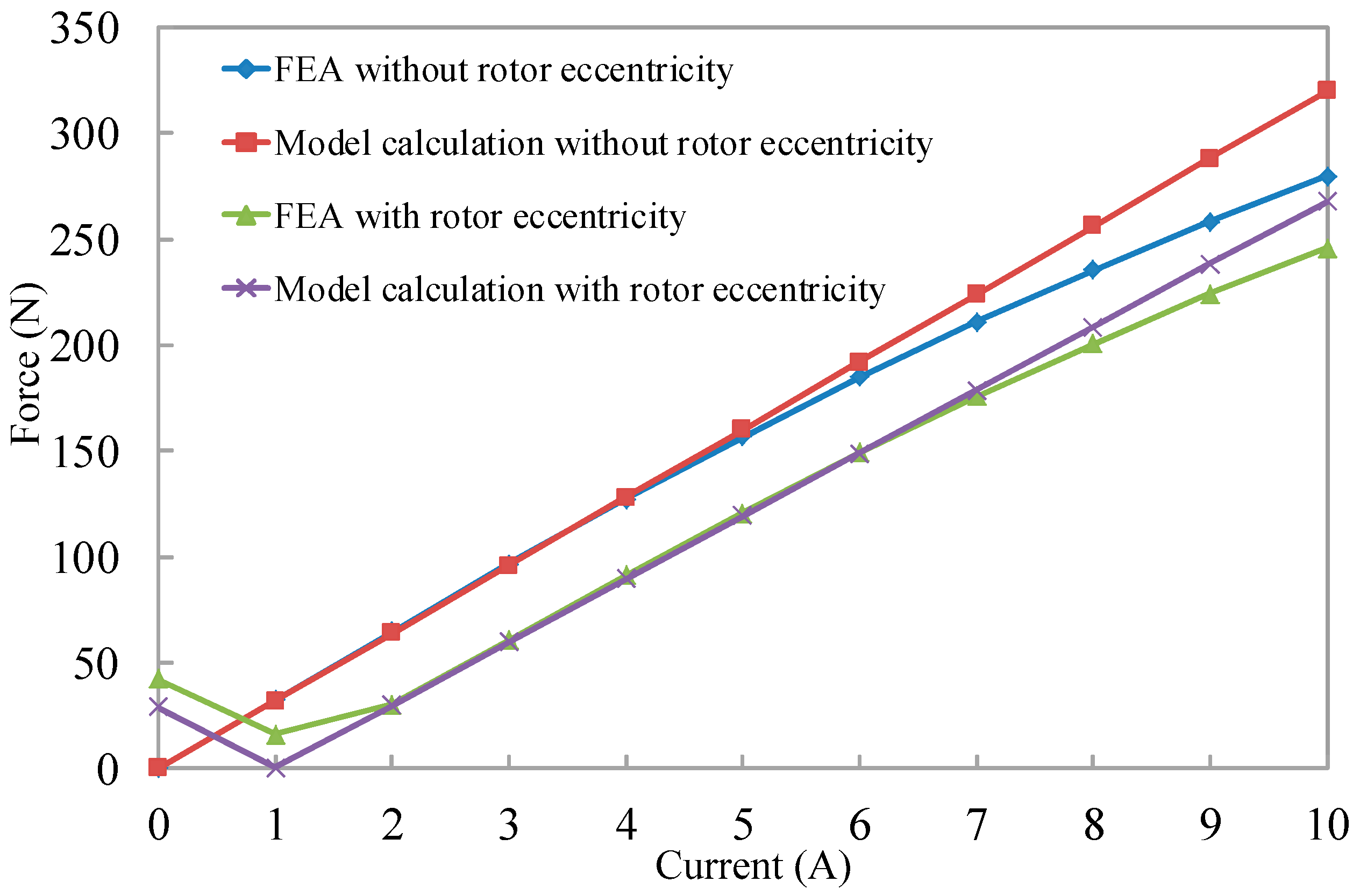

3.3. FEA Analysis of HEBSG

4. Control System of the HEBPMG Based on Flux Observation

5. Simulation and Experiment

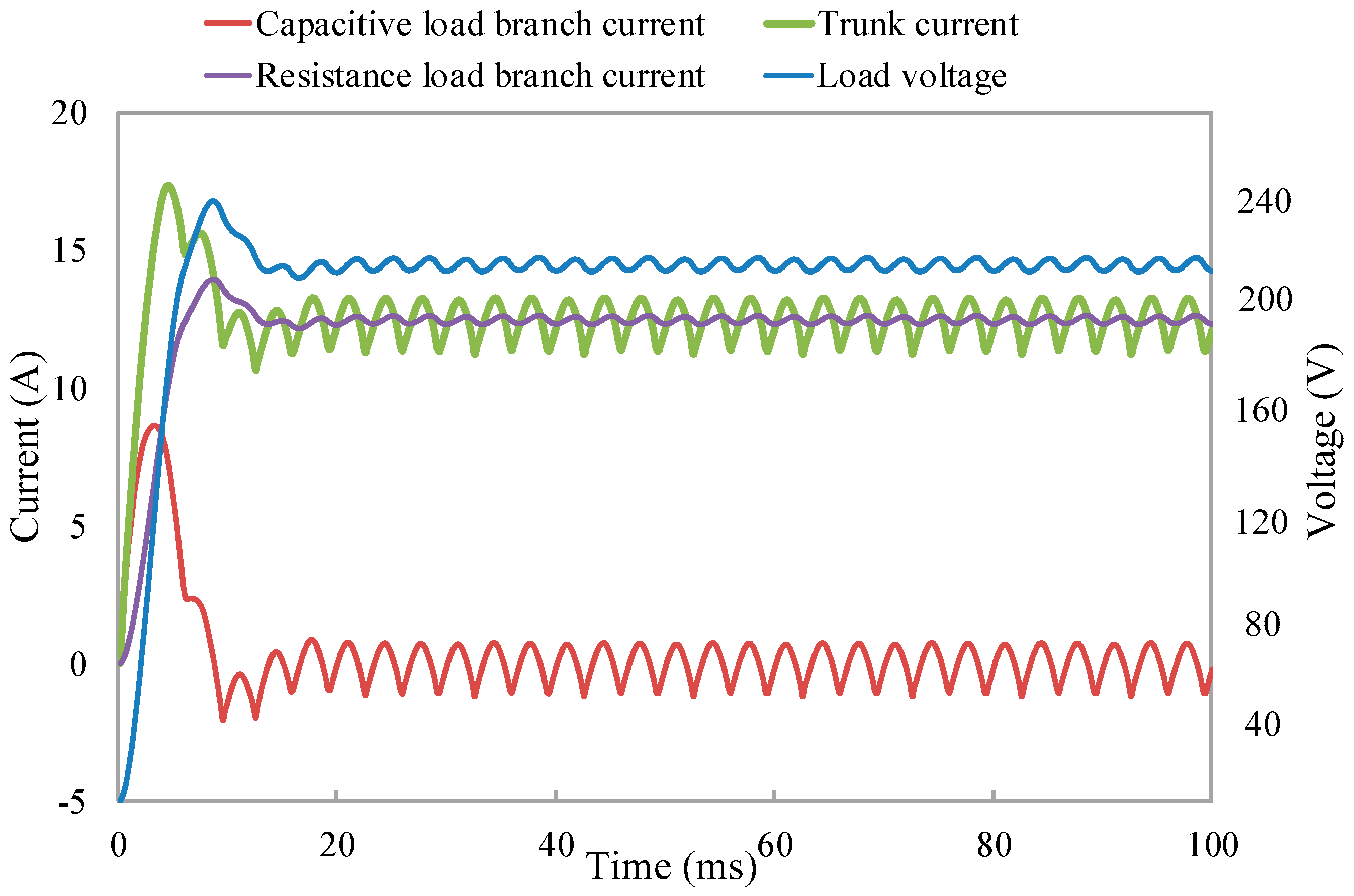

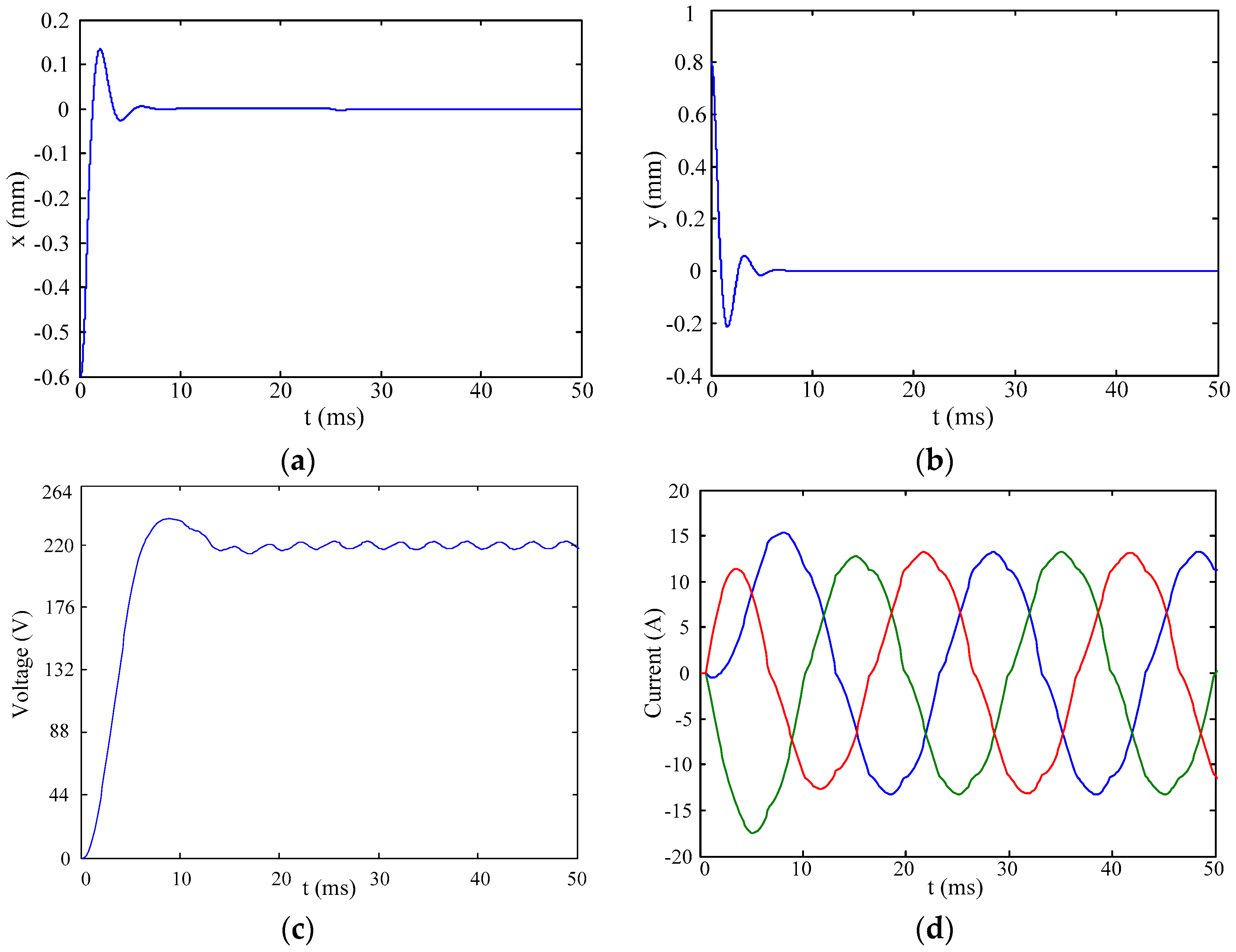

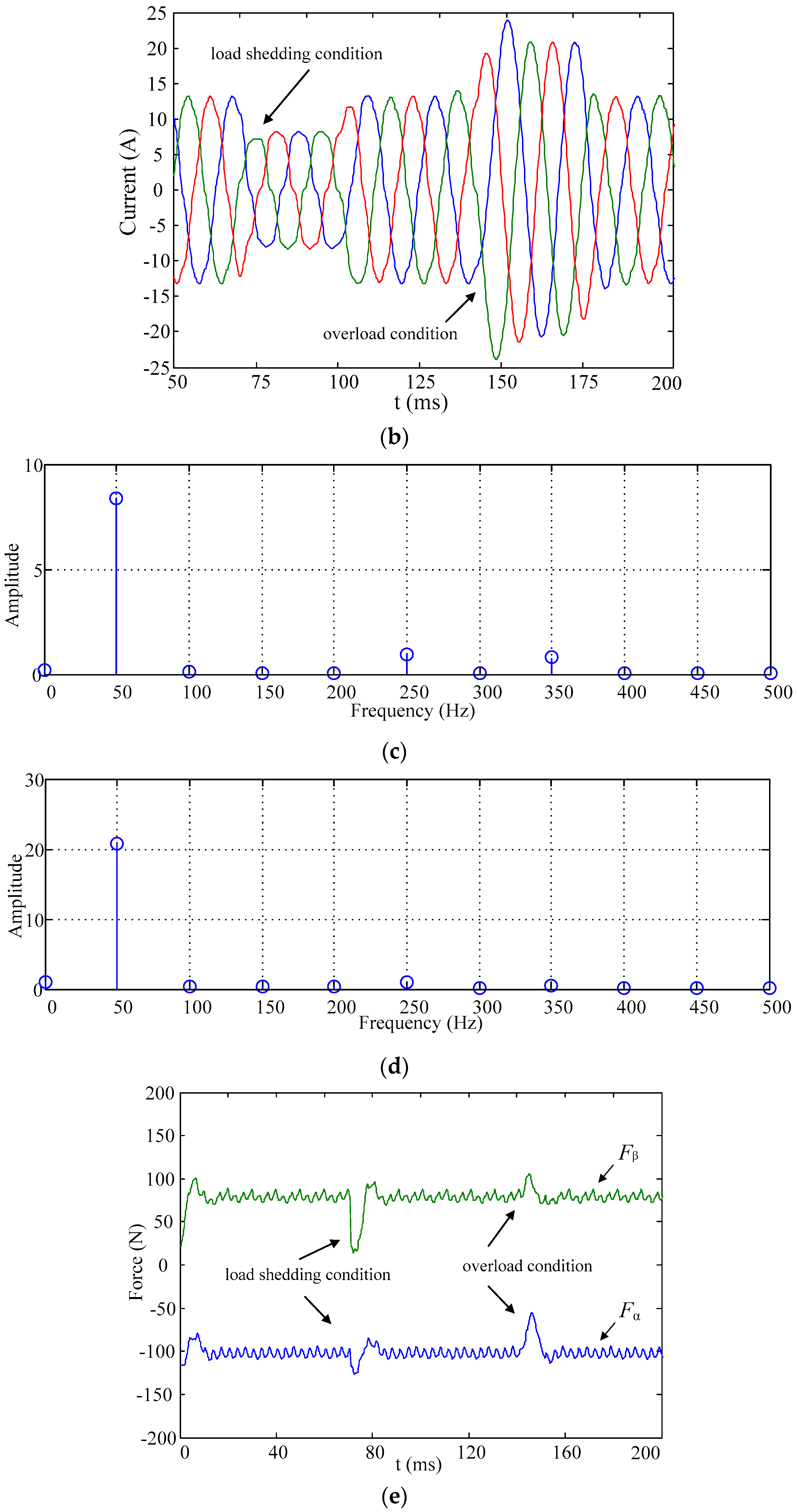

5.1. Simulation and Analysis

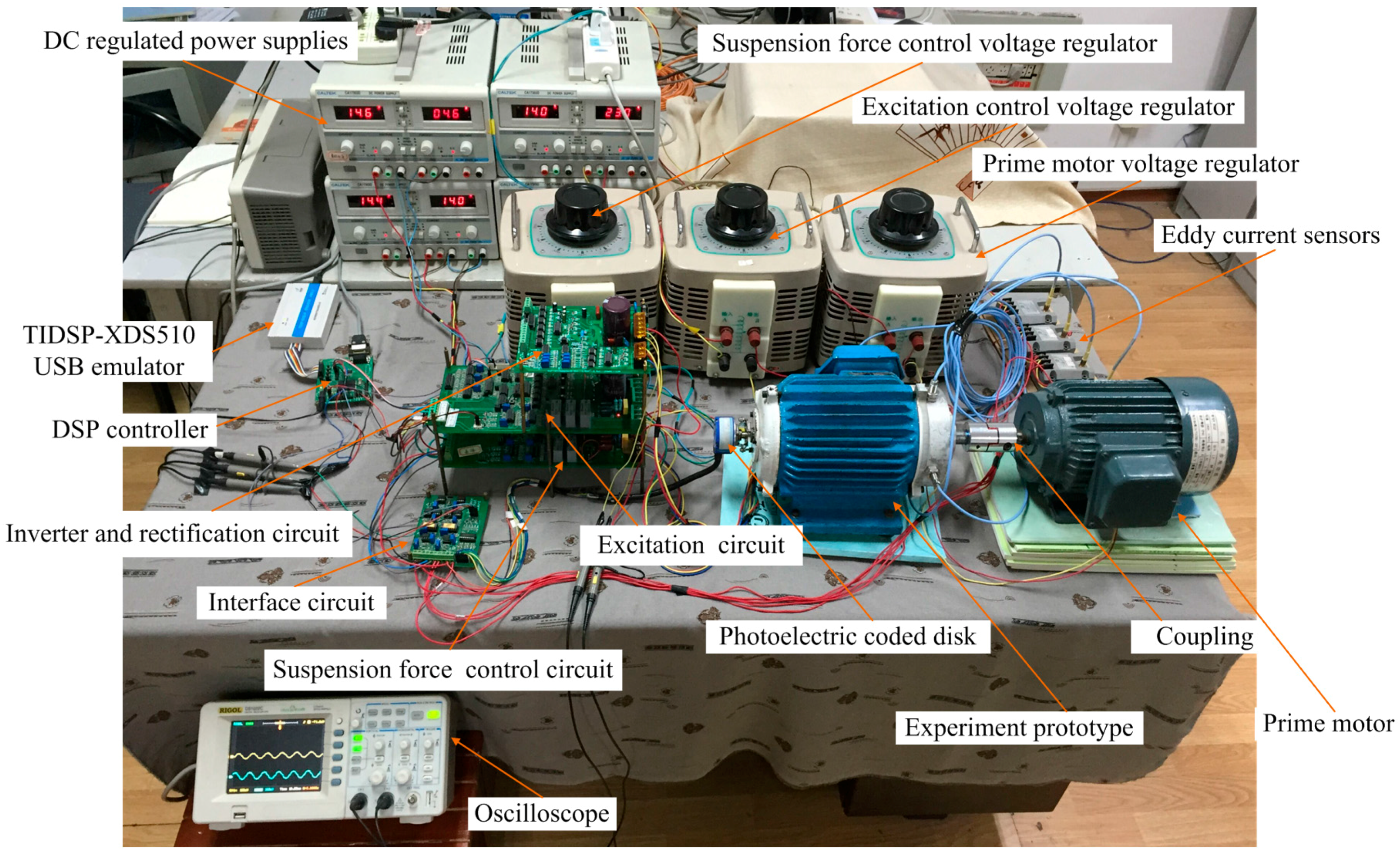

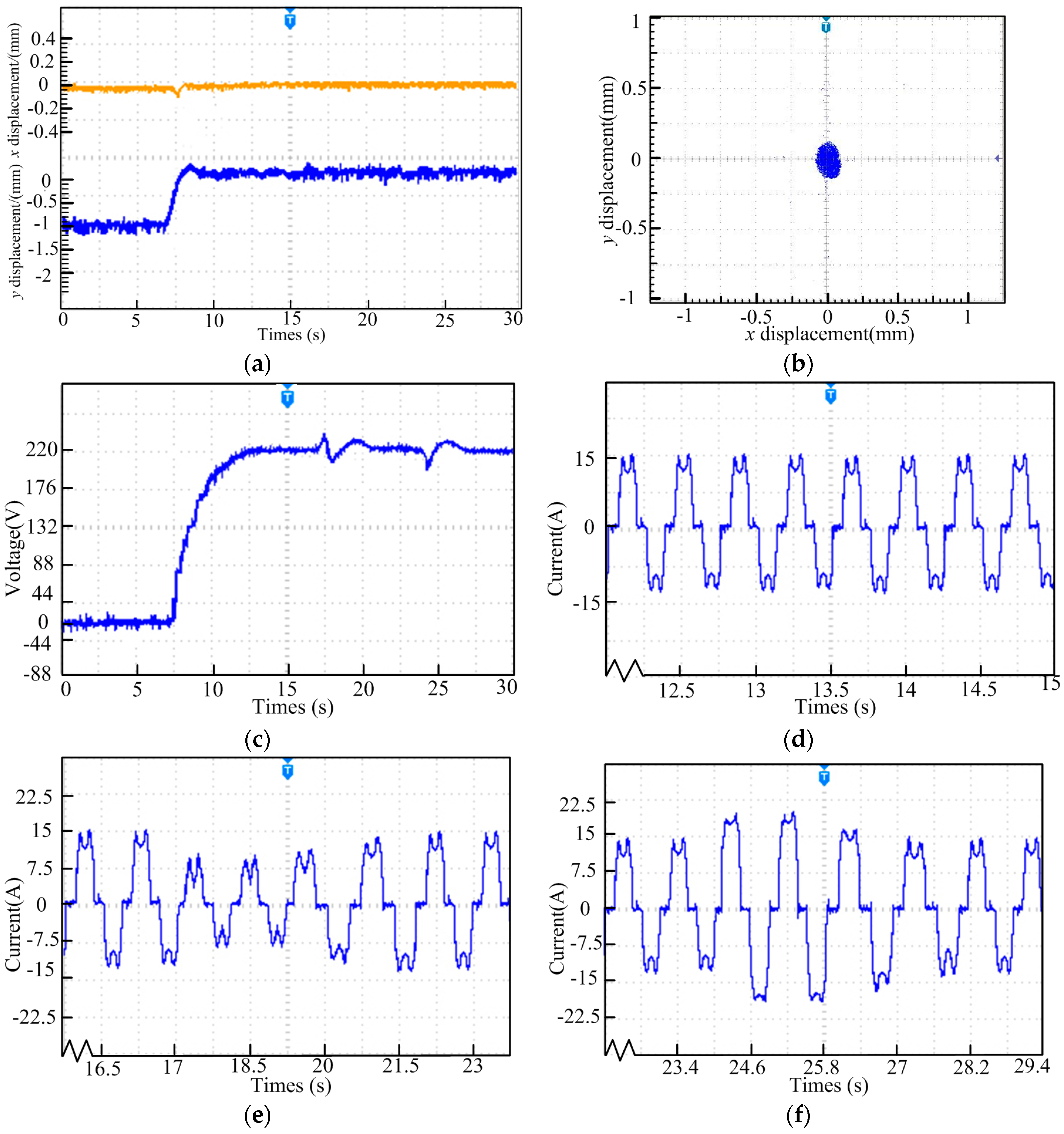

5.2. Experiment Result and Analysis

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ooshima, M.; Kitazawa, S.; Chiba, A.; Fukao, T. Design and analyses of a coreless-stator-type bearingless motor/generator for clean energy generation and storage systems. IEEE Trans. Magn. 2006, 42, 3461–3463. [Google Scholar] [CrossRef]

- Ooshima, M.; Kobayashi, S.; Tanaka, H. Magnetic suspension performance of a bearingless motor/generator for flywheel energy storage systems. In Proceedings of the 2010 IEEE Power Engineering Society General Meeting, Minneapolis, MN, USA, 25–29 July 2010; pp. 1–4.

- Xu, Y.; Patterson, D.; Hudgins, J. Permanent magnet generator design and control for large wind turbines. In Proceedings of the 2012 IEEE Power Electronics and Machines in Wind Applications, Denver, CO, USA, 16–18 July 2012; pp. 1–5.

- Naoe, N.; Fukami, T. Trial Production of a Hybrid Excitation Type Synchronous Machine. In Proceedings of the IEEE International Electric Machines and Drives Conference, Cambridge, MA, USA, 17–20 June 2001; pp. 545–547.

- Luo, X.G.; Lipo, T.A. A synchronous/permanent magnet hybrid AC machine. IEEE Trans. Energy Convers. 2000, 15, 203–210. [Google Scholar]

- Tapia, J.A.; Leonardi, F.; Lipo, T.A. Consequent-pole permanent-magnet machine with extended field-weakening capability. IEEE Trans. Ind. Appl. 2003, 39, 1704–1709. [Google Scholar] [CrossRef]

- Zhang, D.; Zhao, C.; Zhu, L. On hybrid excitation claw-pole synchronous generator with magnetic circuit series connection. In Proceedings of the ICEMS 2008 International Conference, Wuhan, China, 17–20 October 2008; pp. 3509–3513.

- Ni, Y.; Wang, Q.; Bao, X. Optimal design of a hybrid excitation claw-pole alternator based on a 3-D MEC method. Int. Conf. Electr. Mach. Syst. 2005, 1, 27–29. [Google Scholar]

- Sun, X.D.; Chen, L.; Yang, Z.B. Overview of bearingless permanent-magnet synchronous motors. IEEE Trans. Ind. Electron. 2013, 60, 5528–5538. [Google Scholar] [CrossRef]

- Wang, Y.; Deng, Z.Q. A stator flux estimation method for direct torque linear control of electrical excitation flux-switching generator. In Proceedings of the IEEE Conference and Expo of Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August–3 September 2014; pp. 110–116.

- Wang, Y.; Deng, Z.Q. Improved Stator Flux Estimation Method for Direct Torque Linear Control of Parallel Hybrid Excitation Switched-Flux Generator. IEEE Trans. Energy Convers. 2012, 27, 747–756. [Google Scholar] [CrossRef]

- Chen, H. The Power System Steady State Analysis, China; China Electric Power Press: Beijing, China, 2007; pp. 240–243. [Google Scholar]

| Symbol | Quantity | Value |

|---|---|---|

| Q | Stator slot counts | 36 |

| DS1 | Outer diameter of stator | 180 mm |

| DS2 | Inner diameter of stator | 110 mm |

| Dr1 | Outer diameter of rotor | 98 mm |

| Dr2 | Inner diameter of rotor | 30 mm |

| Lg | Radial length of air-gap | 1 mm |

| l | Axial length of rotor | 50 mm |

| P | Rated power | 2.2 kW |

| Stator slot full rate | 0.75 | |

| I | Suspension force winding current | 5A |

| Ф | Windings wire diameter | 0.71 mm |

| Material of stator and rotor | D32_50 | |

| Material of permanent magnet rotor | NFeB35 | |

| Magnetization of permanent magnet rotor | parallel magnetization | |

| ha | Auxiliary bearing thickness | 0.7 mm |

| PM | Pole-pair of generation windings | 2 |

| PB | Pole-pair of suspension windings | 1 |

| PE | Pole-pair of excitation windings | 2 |

| N1 | Turns in series of each phase of generation windings | 40 |

| N2 | Turns in series of each phase of suspension windings | 60 |

| N3 | Turns in series of each phase of excitation windings | 40 |

| J | The rotational inertia | 0.00059 kg·m2 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, H.; Hu, Y. Research on Operation Principle and Control of Novel Hybrid Excitation Bearingless Permanent Magnet Generator. Energies 2016, 9, 673. https://doi.org/10.3390/en9090673

Zhu H, Hu Y. Research on Operation Principle and Control of Novel Hybrid Excitation Bearingless Permanent Magnet Generator. Energies. 2016; 9(9):673. https://doi.org/10.3390/en9090673

Chicago/Turabian StyleZhu, Huangqiu, and Yamin Hu. 2016. "Research on Operation Principle and Control of Novel Hybrid Excitation Bearingless Permanent Magnet Generator" Energies 9, no. 9: 673. https://doi.org/10.3390/en9090673